Method for preventing formation of urea-based deposits and exhaust passage having coating

A technology for exhaust channels and deposits, which is applied in exhaust treatment, exhaust devices, machines/engines, etc., can solve problems such as shortcomings that have not been eliminated, and achieve the effects of saving materials, increasing service life, and improving effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

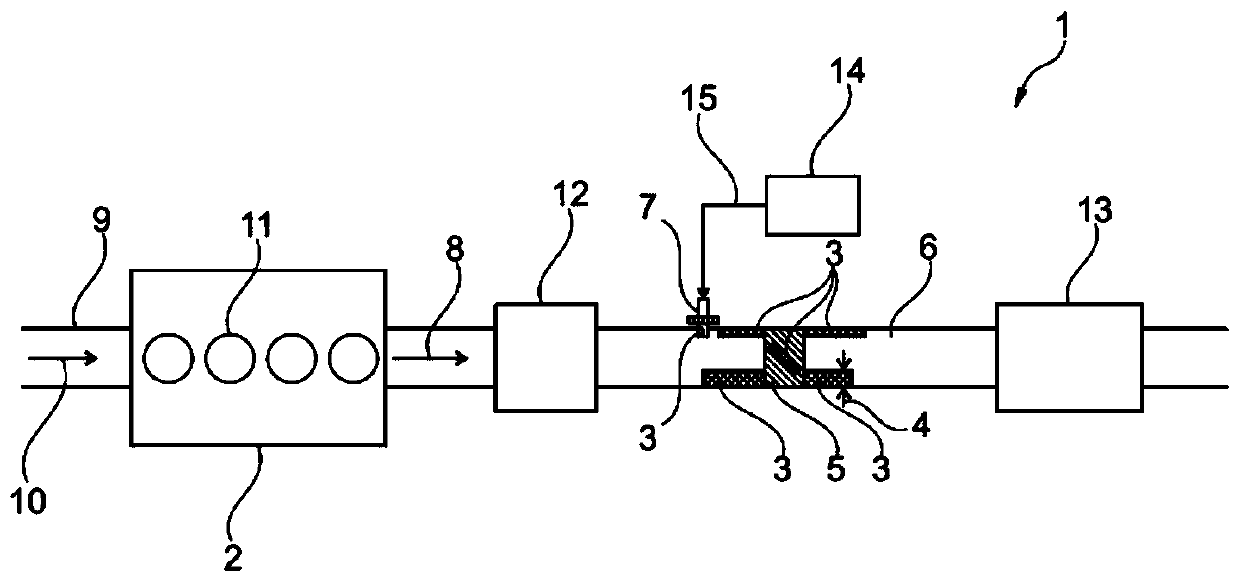

[0059] figure 1 The sequence of the method for preventing the formation of urea-based deposits in the exhaust tract 1 of an internal combustion engine 2 is shown. In a first process step S1 , those regions of the exhaust duct 1 where there is a risk of forming urea-based deposits are identified. For example, this can be the area between the spraying device 7 and the SCR or SDPF catalytic converter 13 arranged downstream of the spraying device 7 . Since the spraying device 7 is used to introduce an aqueous urea solution into the exhaust gas 8, there is a risk that urea-based deposits will form in the region of the spraying device 7 and downstream of the spraying device 7, for example, water evaporates from the aqueous urea solution and Urea precipitates prior to urea deposition. The formation of urea-based deposits depends, inter alia, on the temperature of the exhaust gas 8 , the temperature of the exhaust duct 1 (eg the temperature of the pipes belonging to the exhaust duct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com