Patents

Literature

77results about How to "Determine the size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Road barrier identification method and device

InactiveCN105957145AImprove recognition accuracyDetermine the sizeImage enhancementDetails involving processing stepsPoint cloudAlgorithm

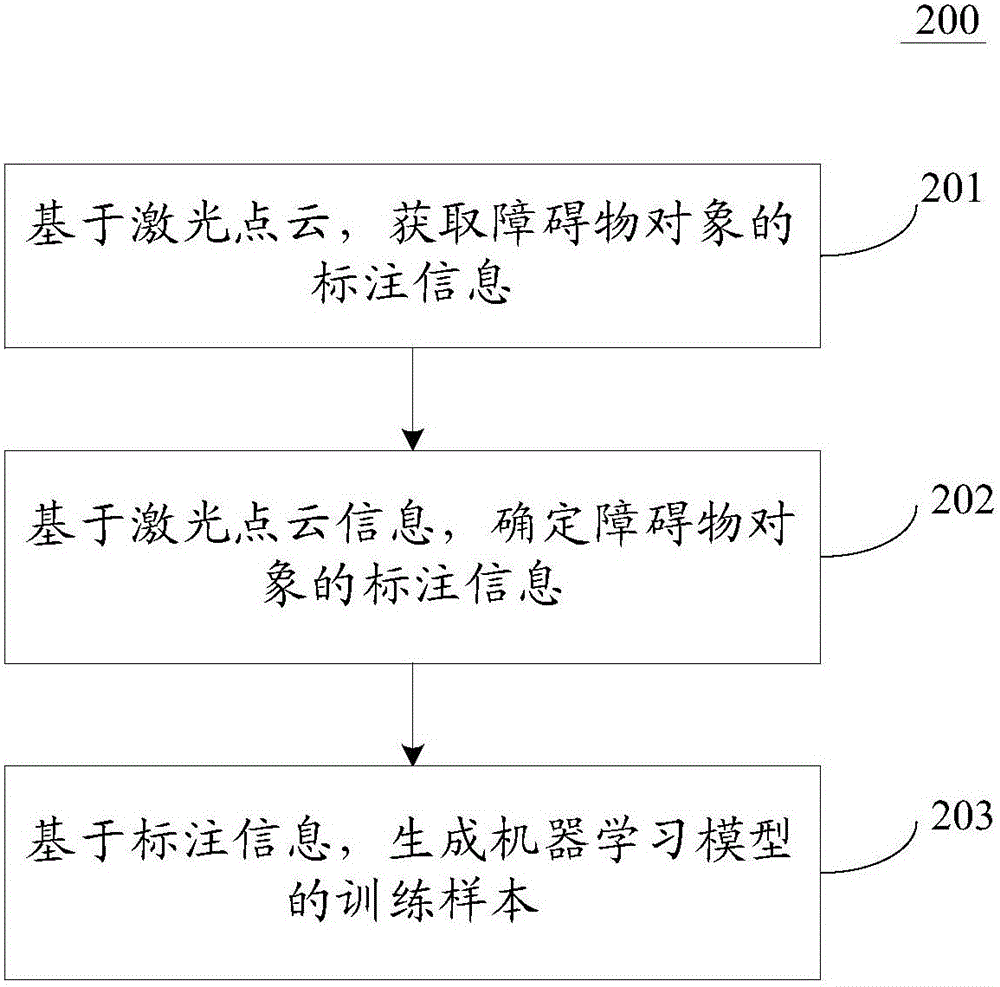

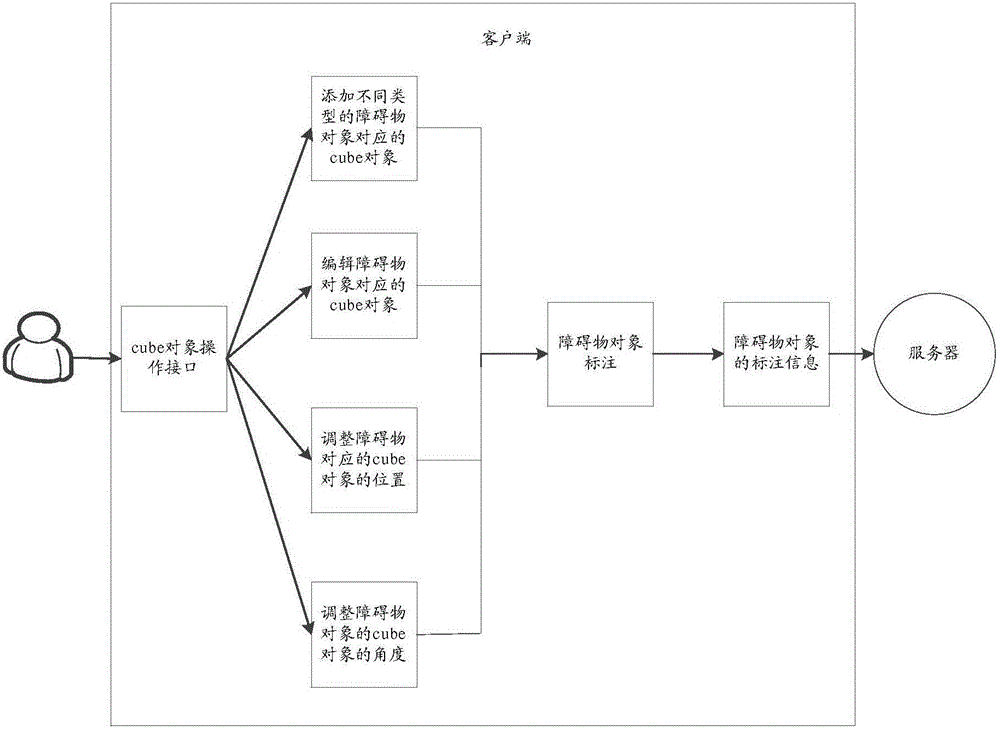

The invention discloses a road barrier identification method and device. One specific embodiment of the invention comprises the steps of: obtaining laser point cloud of a barrier object on a road; based on the laser point cloud, obtaining mark information of the barrier object; and based on the mark information, generating training samples of a machine learning model. According to the invention, different type of mark information of the barrier objects are obtained based on the laser point cloud of the barrier objects, so that the sizes, positions and angles of the different kinds of barrier objects are accurately determined; and furthermore, based on the mark information of the barrier object, the training samples of the machine learning model for identifying the sizes, positions and angles of the different kinds of barriers using the laser point cloud of the barriers as input are generated, and the identification accuracy of the machine learning model is continuously improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

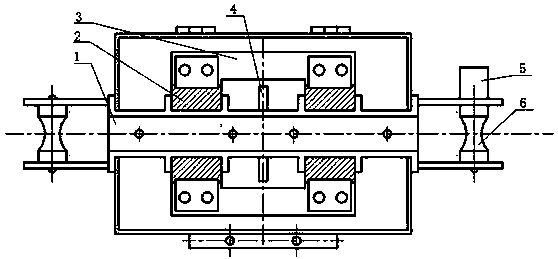

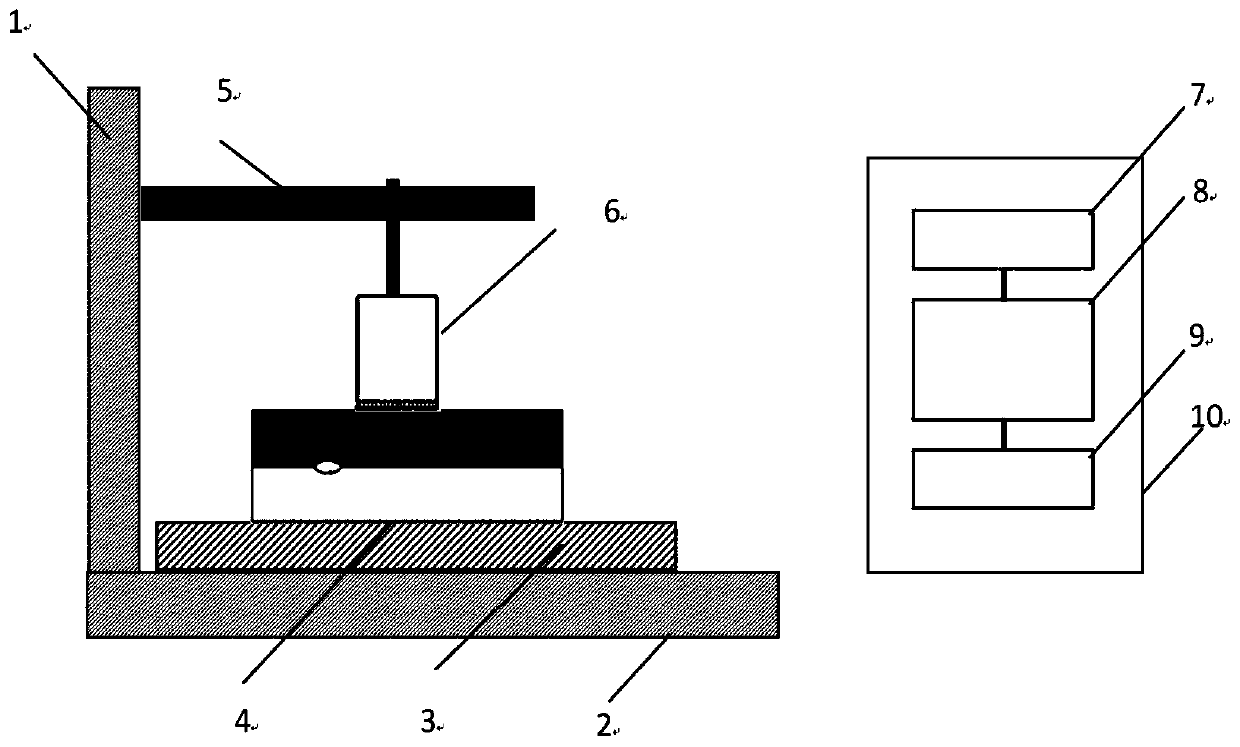

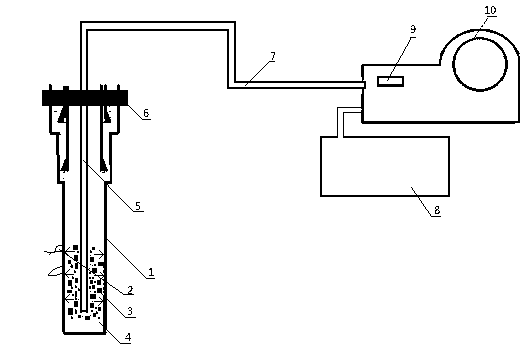

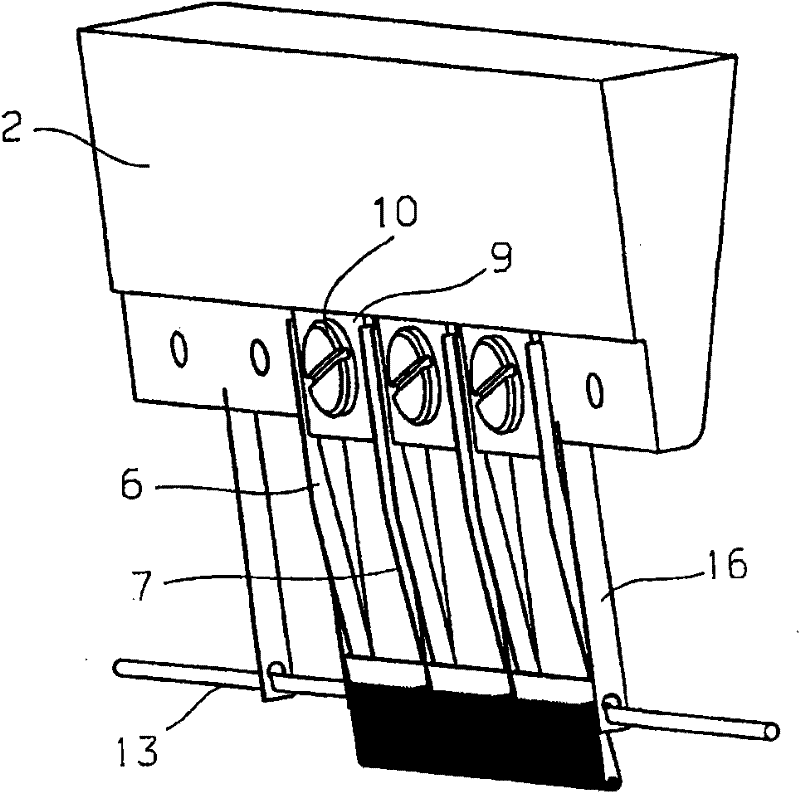

Mining steel wire rope online detection device and method based on giant magnetoresistance sensor array

InactiveCN103760222AHigh sensitivityImprove anti-interference abilityMaterial magnetic variablesSensor arrayGiant magnetoresistance

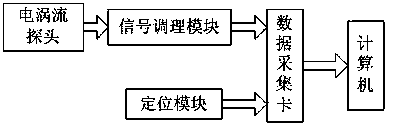

The invention discloses a mining steel wire rope online detection device and a mining steel wire rope online detection method based on a giant magnetoresistance sensor array. The device comprises a probe, a signal conditioning module, a data acquisition card, a computer and a positioning module. The method comprises the following steps: magnetizing the steel wire rope by using an excitation device in the probe, and detecting a leakage magnetic field generated by damage by using a giant magnetoresistance sensor in the probe; processing an output signal of the probe by using the signal conditioning module, and inputting the processed output signal into the computer together with a signal of the positioning module through the data acquisition card; displaying the probe signal in real time on the computer, and comparing the probe signal with a preset threshold value to determine whether damage exists on the steel wire rope to be detected; if the probe signal is higher than the preset threshold value, indicating that damage exists on the steel wire rope to be detected, further determining the type and size of the damage, and determining a damage position according to the signal of the positioning module. The detection device and the detection method have the outstanding characteristics that by adopting the probe consisting of the giant magnetoresistance sensor array, the sensitivity of the detection device can be increased remarkably. The device and the method have good application prospects in damage detection of the mining steel wire rope.

Owner:CHINA UNIV OF MINING & TECH

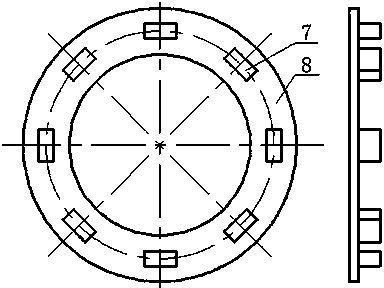

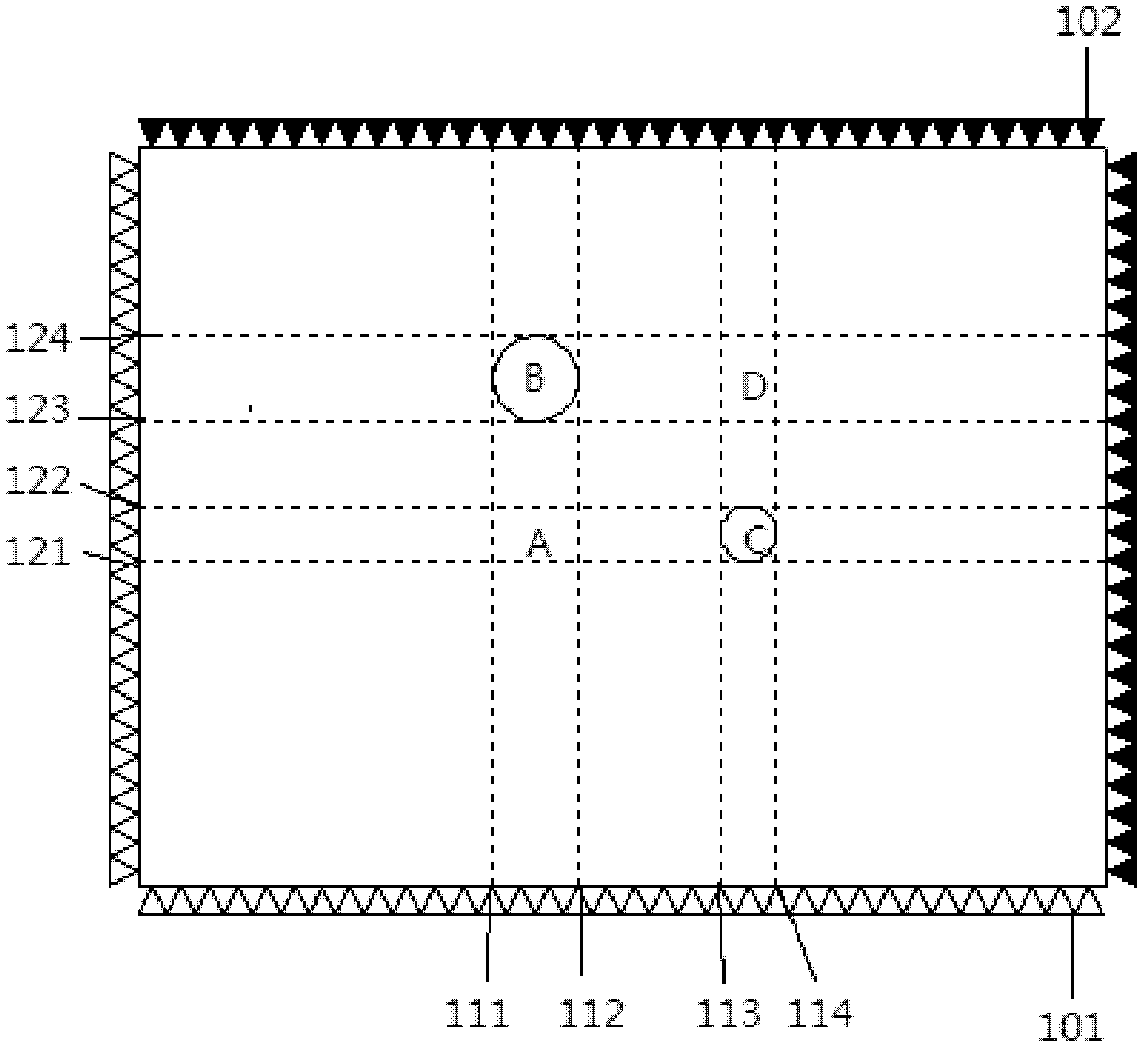

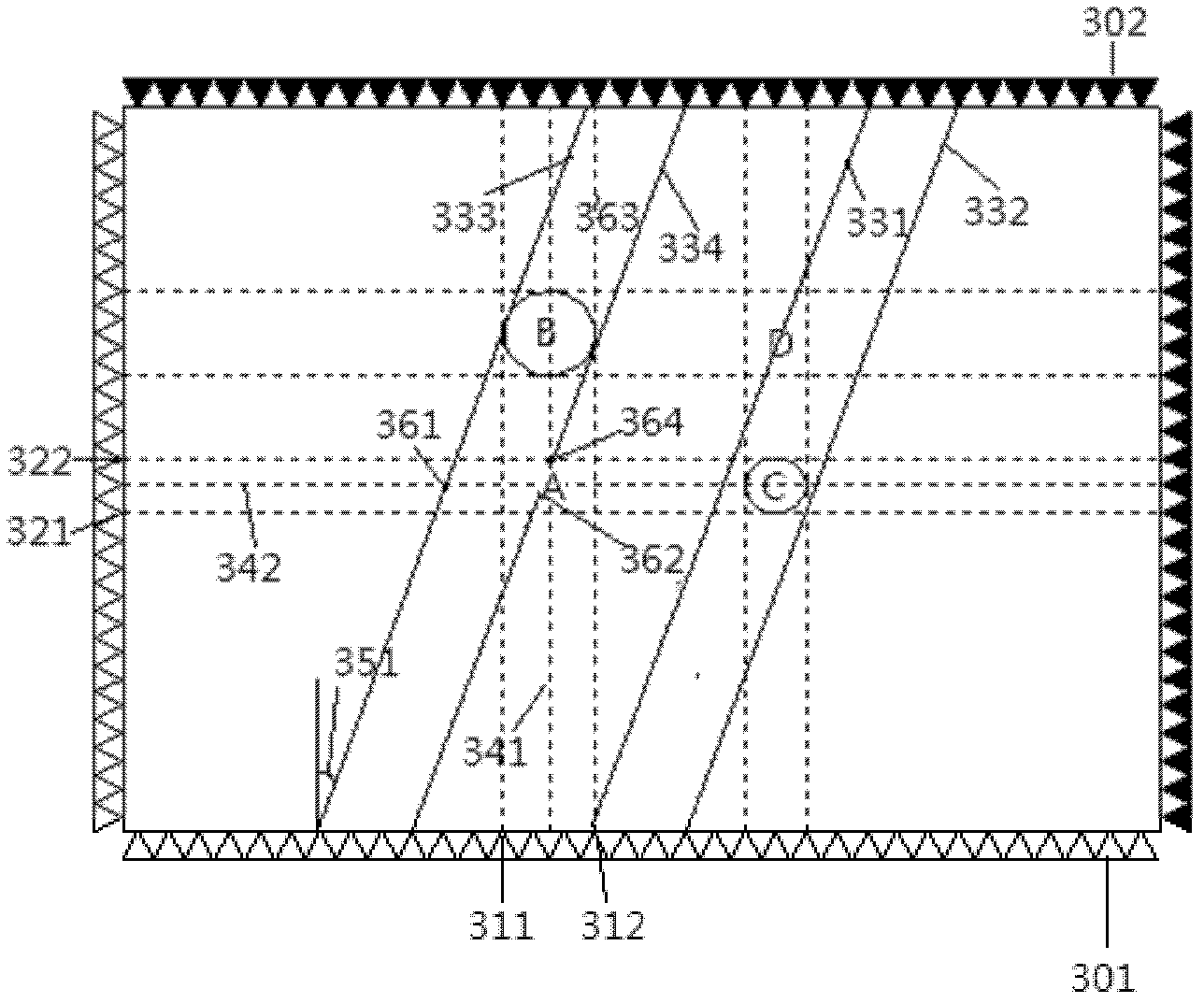

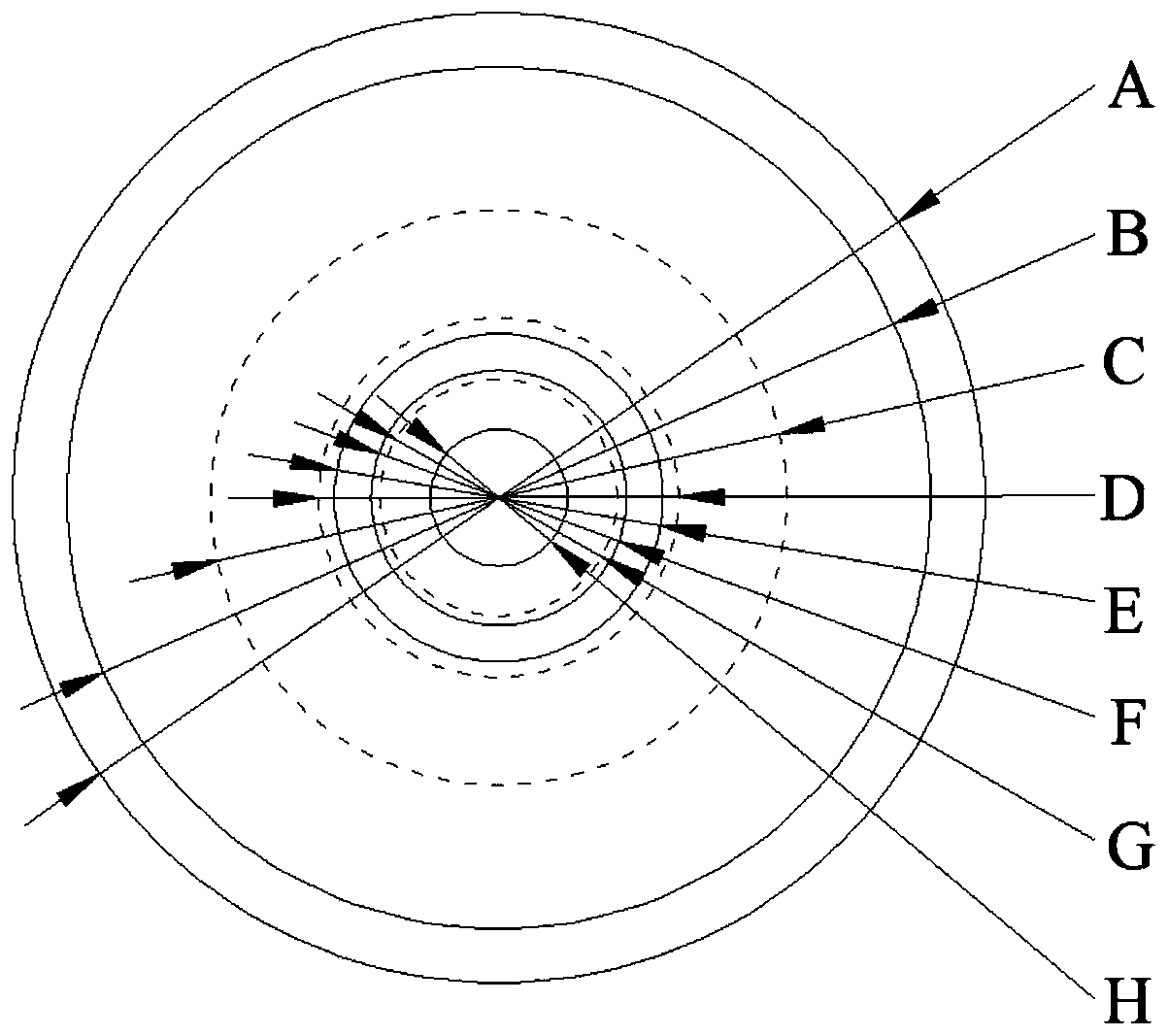

Multi-point positioning method for infrared matrix touch screen

InactiveCN103019461ADetermine the sizeLocation determinationInput/output processes for data processingTouchscreenComputer science

The invention relates to a multi-point positioning method for an infrared matrix touch screen. The multi-point positioning method comprises the following steps of: S1, predetermining the number of axes to be scanned and corresponding angles; S2, scanning the axes of different angles in sequence, and generating logic data reflecting axis touch information after processing; S3, combining data intervals obtained in scanning of the X axis and the Y axis to obtain possible touch points; S4, calculating the intersection of the scanning area corresponding to the data interval in a single inclined scanning direction and one touch area generated by S3, and updating the long axis and the short axis in the touch area if the intersection exists; S5, repeating Step S4, calculating intersections of scanning areas corresponding to data intervals in other inclined axial directions and the touch point updated in Step S4, wherein the point does not exist when the intersections of the scanning areas corresponding to all the data intervals in one direction and the touch point updated in Step S4 is 0; otherwise, the point may be a real point; and S6, repeating Step S4 and S5, and calculating other possible touch areas in Step S3.

Owner:SHANGHAI IRM TOUCH ELECTRONICS TECH

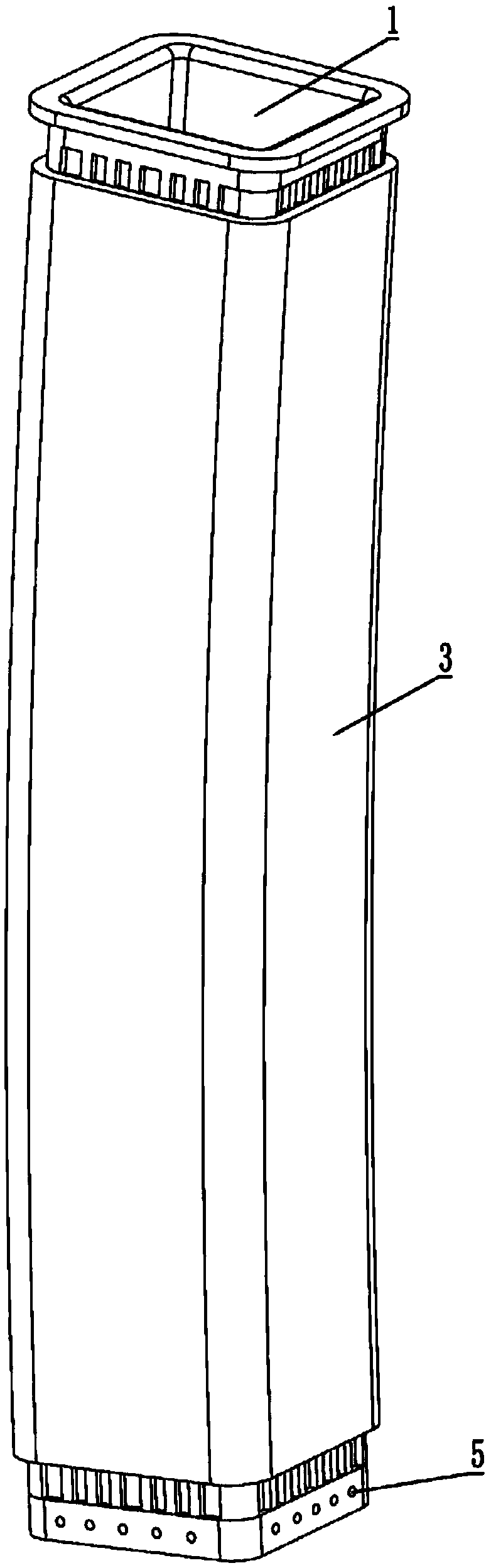

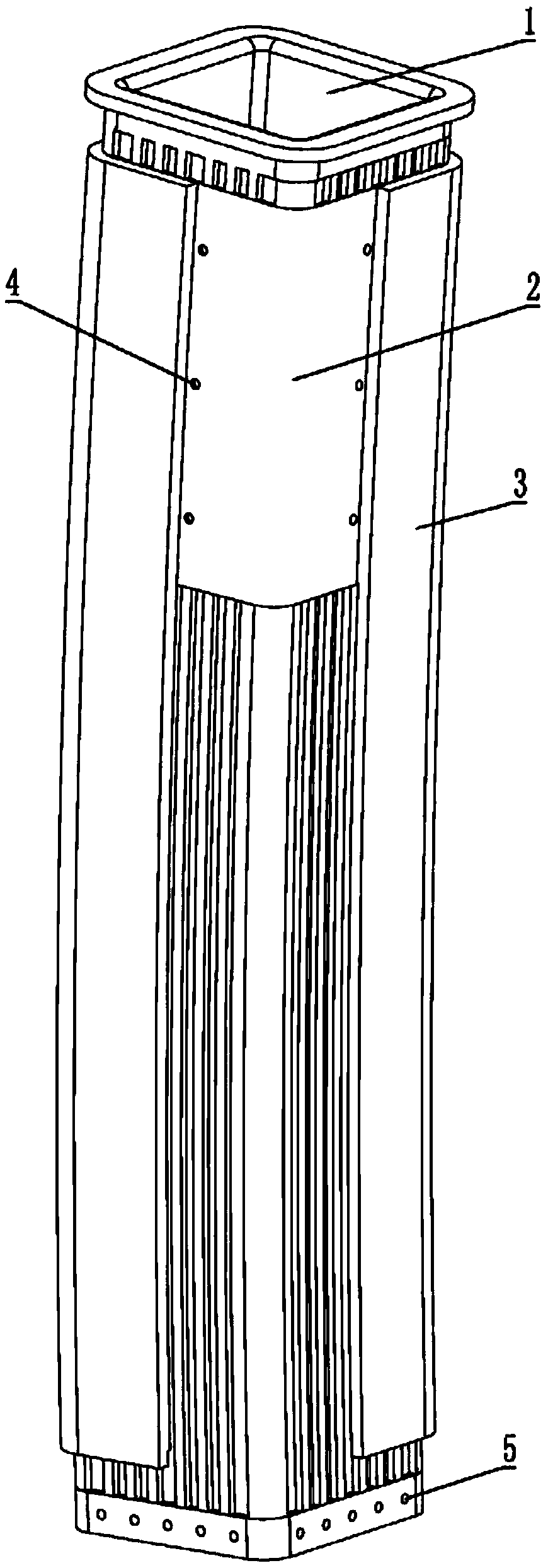

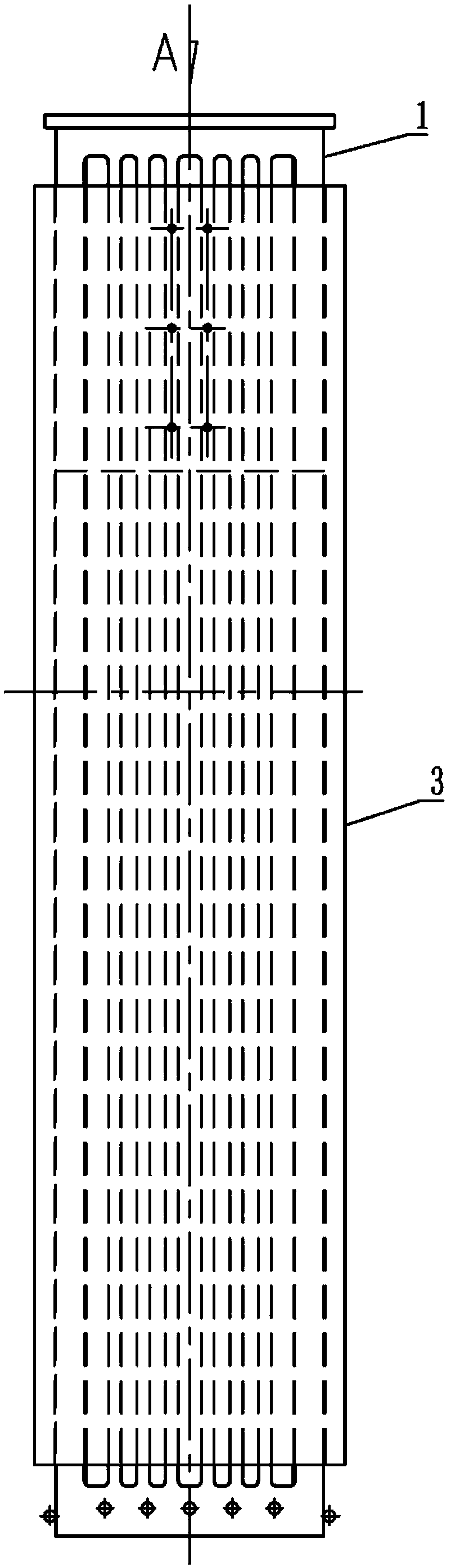

Crystallizer with the double-water-jacket structure

PendingCN108838352AImprove deformation resistanceReduced flow areaProcess efficiency improvementEngineeringWater jacket

The invention discloses a crystallizer with the double-water-jacket structure. The crystallizer comprises a tubular main body, an external water jacket and a two-part water jacket; the external waterjacket is arranged outside the tubular main body, and the two-part water jackets are embedded between the tubular main body and the external water jacket; hard particles are arranged on the lower portion of the tubular water jacket, longitudinal grooves with different depths and widths are longitudinally machined in the periphery of the tubular water jacket, and a gap is formed between the inner cavity of the external water jacket and the top surface of each rib; the circumferential dimension of the external frame of the two-part water jacket is consistent with the front height of the ribs; agap is reserved between the inner cavity of the two-part water jacket and the rib and is fixedly connected with the tubular main body through a fastener, the two-part water jacket are located in the range of 50 mm above the liquid level of the metal to 150-250 mm below the liquid level of the metal liquid level, and the rigidity of the material is higher than the rigidity of the material of the tubular body. According to the crystallizer with the double-water-jacket structure, the flow speed of the cooling liquid in the two-part water jacket can be accelerated, the requirement for meeting thechange of the heat exchange strength between the shell and the crystallizer is met, the deformation resistance of the tubular main body is improved, the drawing speed is increased, and the quality ofthe casting blank is also improved.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Flip transparent reelable flexible film LED display screen and production process thereof

PendingCN109873073AIncrease productivityEasy to useSolid-state devicesIdentification meansEngineeringAdhesive

The invention discloses a flip transparent reelable flexible film LED display screen and a production process thereof. The display screen comprises a transparent film, circuit layers, driving ICs, flip LED chips and a transparent adhesive; the display screen totally comprises multiple layers of structures, which are a first flexible film, a first circuit layer, a second flexible film, a second circuit layer, a third flexible film, a third circuit layer and the like sequentially from bottom to top; circuits and the high-temperature-resistant flexible films are superposed to present a multilayerFPC flexible circuit board; the LED chips are welded on the FPC flexible circuit board in a flip mode; and the driving ICs are arranged on the FPC flexible circuit board. The flip LED chips are directly welded on the FPC flexible circuit board, so that the costs of traditional lamp bead supports, gold wires, patches and the like are reduced; and connecting boards are provided with bonding pads, and through mutual connection of the bonding pads, a user can carry out free splicing according to actual requirements, so that the size of the LED flexible screen is determined.

Owner:深圳市华科莱特电子有限公司

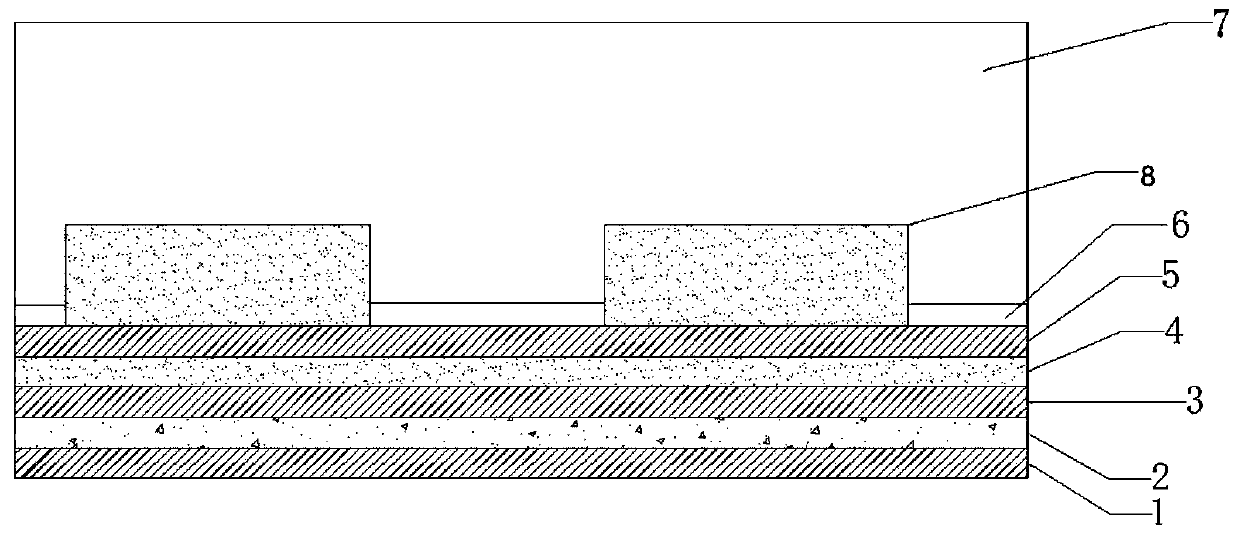

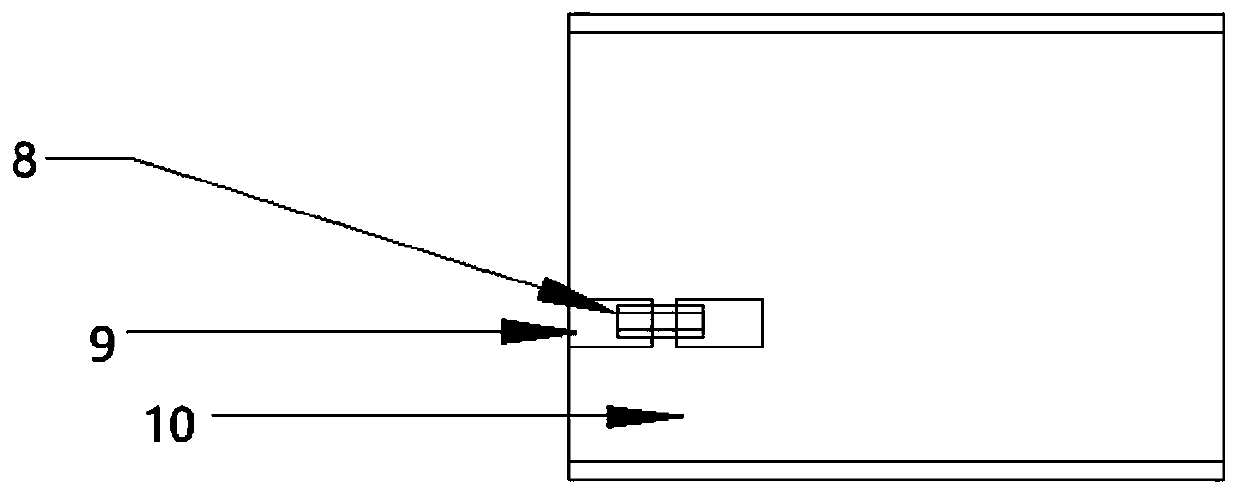

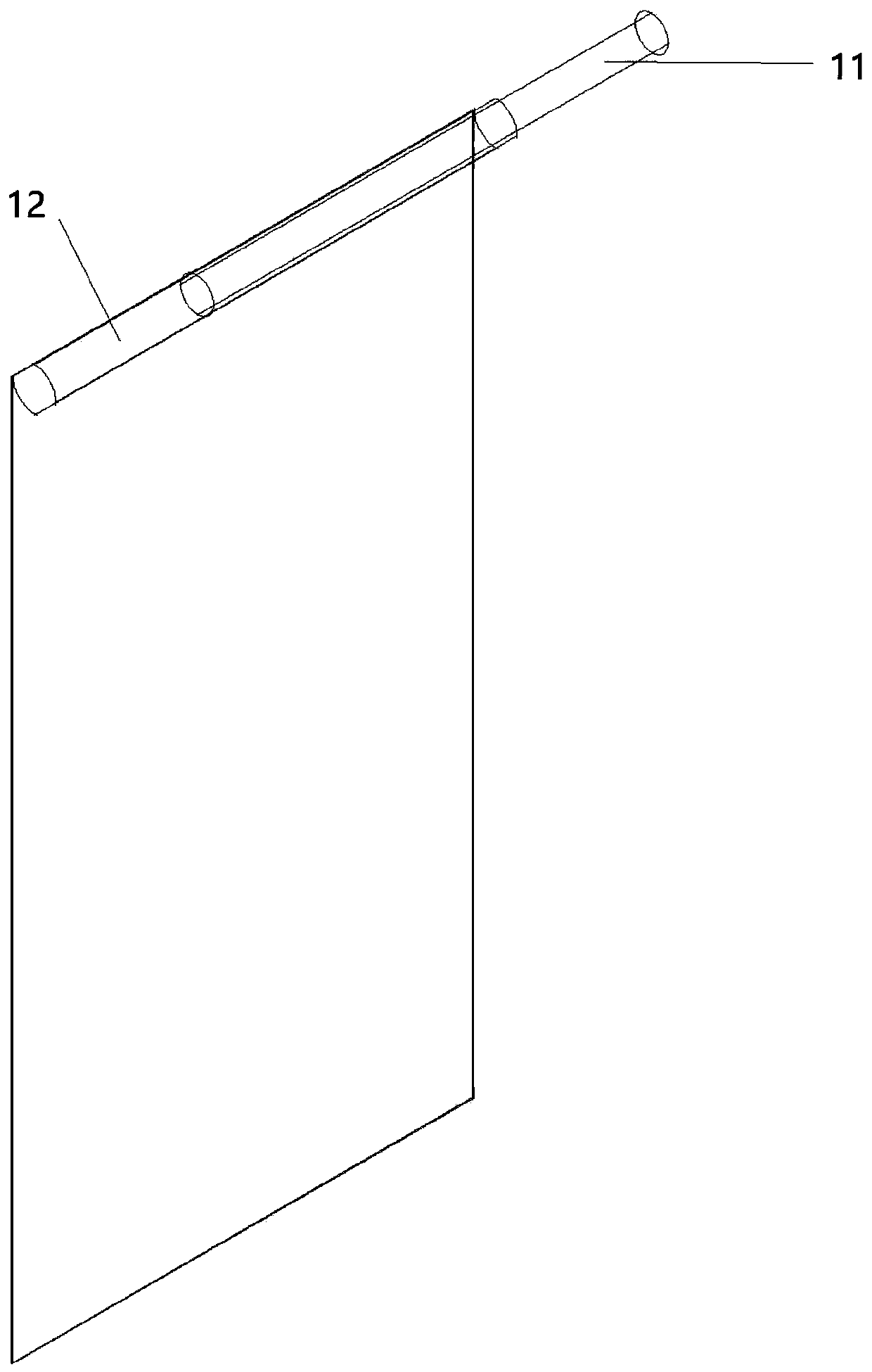

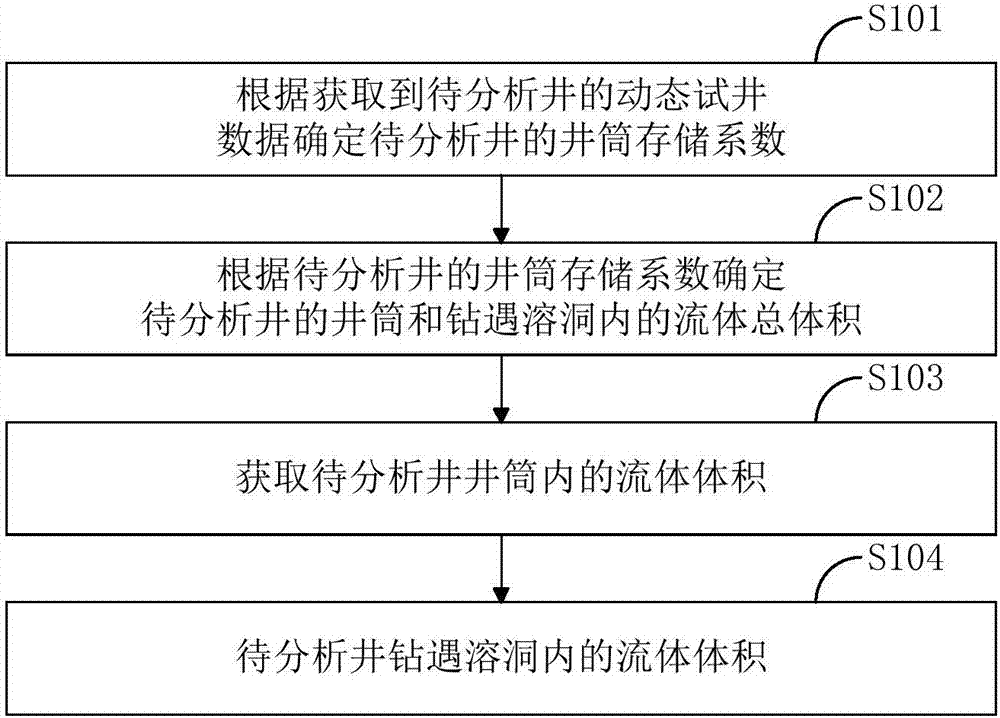

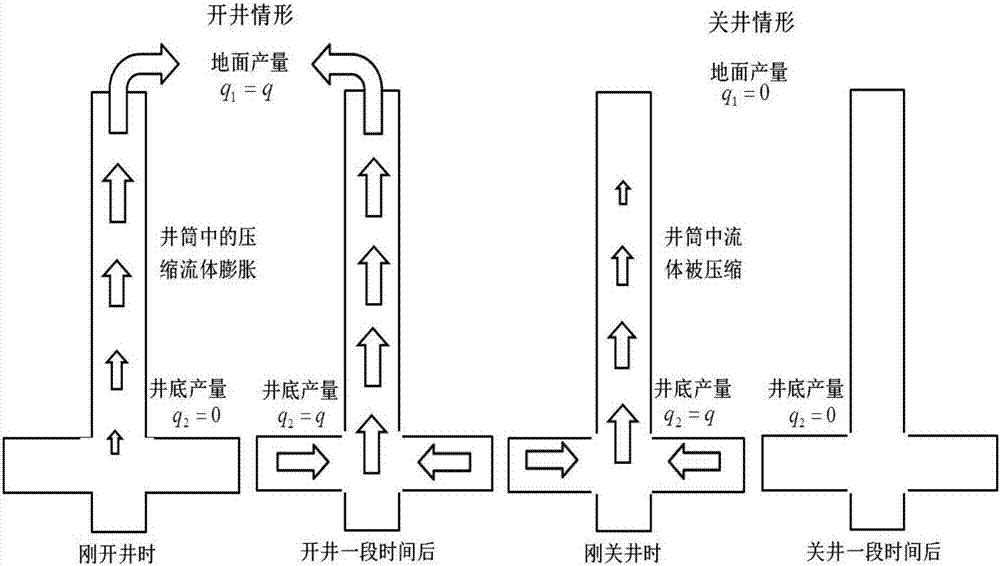

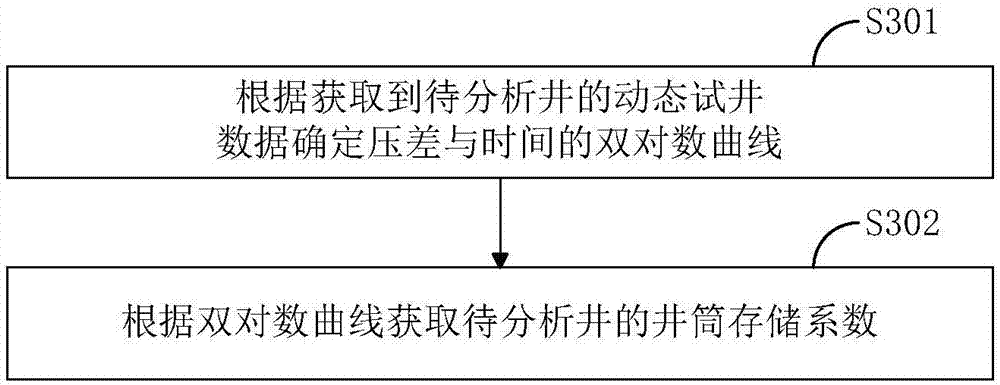

Method for determining volume of well drilling cave

ActiveCN107237626AOvercome volumeOvercome the lack of vertical sizeBorehole/well accessoriesWell drillingHydrology

A method for determining the volume of a well drilling cave comprises the steps that a wellbore storage coefficient is determined, specifically, the wellbore storage coefficient of a to-be-analyzed well is determined according to obtained dynamic well-testing data of the to-be-analyzed well; the total volume of fluid is determined, specifically, the wellbore of the to-be-analyzed well and the total volume of the fluid in the drilling cave are determined according to the wellbore storage coefficient of the to-be-analyzed well; and the volume of the cave is determined, specifically, the fluid volume in the wellbore of the to-be-analyzed well is obtained, and by combining the wellbore of the to-be-analyzed well and the total volume of the fluid in the drilling cave, the fluid volume in the drilling cave of the to-be-analyzed well is determined, so that the volume of the drilling cave of the to-be-analyzed well is obtained. According to the method for determining the volume of the well drilling cave, the defect that the cave volume or the longitudinal size is determined through a static method can be overcome, by utilizing a dynamic well-testing analysis method, the volume size of the well drilling cave can be accurately determined, and thus a more accurate evidence is provided for later development of a fracture-vug type carbonate-reservoir-rock cave reservoir body.

Owner:CHINA PETROLEUM & CHEM CORP +1

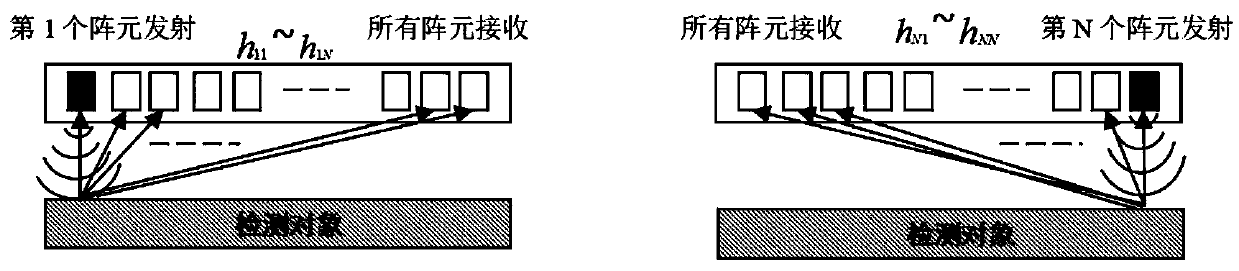

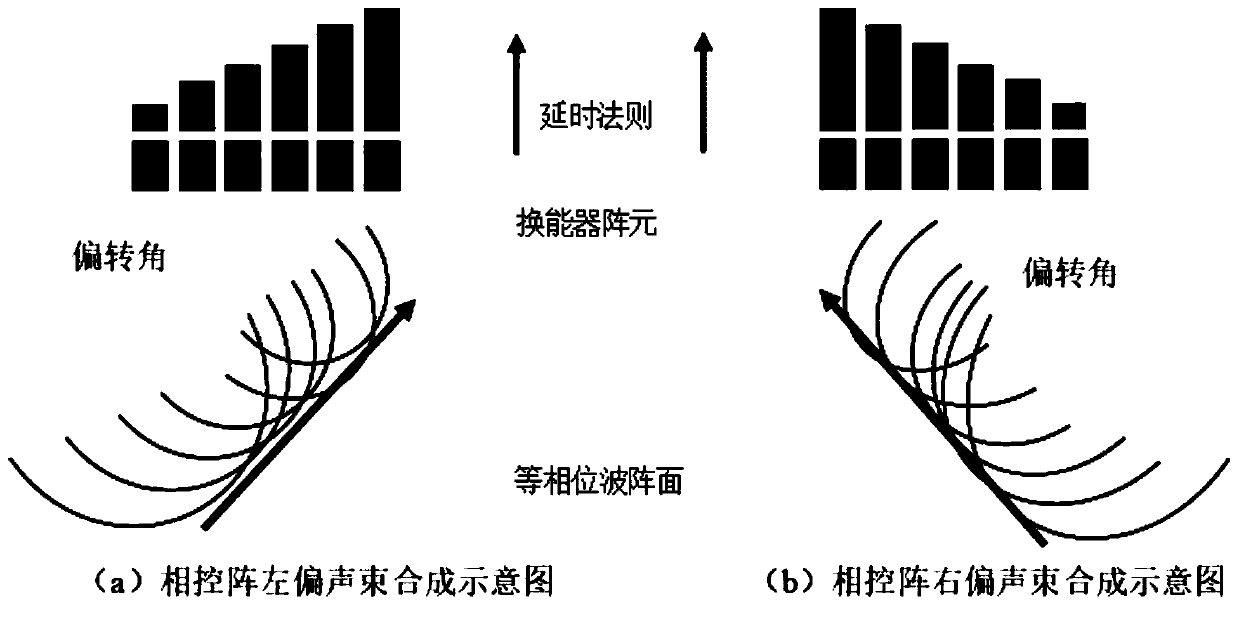

Composite component interface rapid imaging quantitative detection method based on full-matrix data

ActiveCN111175381AComprehensive bonding statusSmall amount of calculationAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalRapid imagingData acquisition

The invention belongs to the technical field of defect detection, and particularly relates to a composite component interface rapid imaging quantitative detection method based on full-matrix data. Themethod comprises the following steps: 1) full-matrix data acquisition; 2) adopting a sector-scanning rapid imaging algorithm or a full-focusing rapid imaging algorithm based on the full-matrix data to realize rapid sector-scanning or full-focusing imaging of a component; 3) carrying out threshold processing on the imaging result by adopting a quantitative method aiming at the debonding detectioncharacteristics of the composite component, and determining an effective debonding area; and 4) performing binarization processing on the imaging result after threshold processing to obtain position and size information of the debonding defect, thereby realizing quick imaging quantitative detection of the interface bonding quality of the composite component based on the full-matrix data. Accordingto the method, the full-matrix data acquisition mode is adopted, when each sampling point is acquired, all array elements are acquired and echo information with a more comprehensive composite component interface bonding state can be obtained.

Owner:ZHONGBEI UNIV

Process for improving bearing capacity of formation

The invention discloses a process for improving bearing capacity of a formation. The process for improving the bearing capacity of the formation comprises the following steps of: a, working out respective sizes of formation pores according to formation fracture data obtained by block coring, and preparing different sealing slurry by using gel and sealing particles of corresponding dimensions according to the respective sizes of the formation pores; b, pumping the prepared sealing slurry into a shaft, and closing a blowout preventer after the sealing slurry is full of the shaft; c, continuously pumping the sealing slurry into the shaft to enable the sealing slurry in the shaft to be extruded into the formation; and d, respectively building frameworks at the formation pores by rigid sealing particles in the manner of bridging, filling and compacting flexible sealing particles among the rigid sealing particles to fill pores near the formation of the shaft to the greatest extent so as to enable the casing pressure value of the blowout preventer to be increased continuously, therefore improving the bearing capacity of the formation. According to the process for improving the bearing capacity of the formation, bearing sealing is performed on the formation in advance, through the formation fracture data obtained by the block coring, the sealing is performed on the formation by using the chemical gel which is equivalent to formation porosity and the rigid and flexible sealing particles when drilling is performed, and therefore, the bearing capacity of the formation is artificially improved, the phenomenon that drilling fluid leaks from the formation due to the fact that drilling fluid density rises at the later stage of construction is prevented, and drilling construction can be smoothly performed.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Method for determining intermittent force of sound barrier in rapid transit railway and application

InactiveCN101906758APrecisely determine the sizeDetermine the sizeNoise reduction constructionFluid fieldRapid transit

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

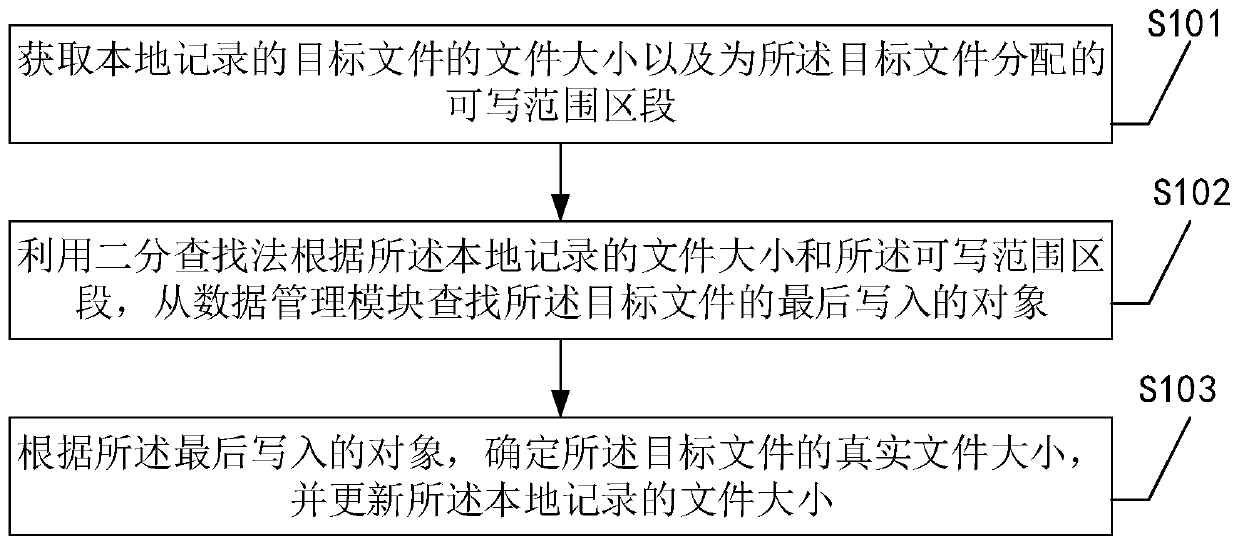

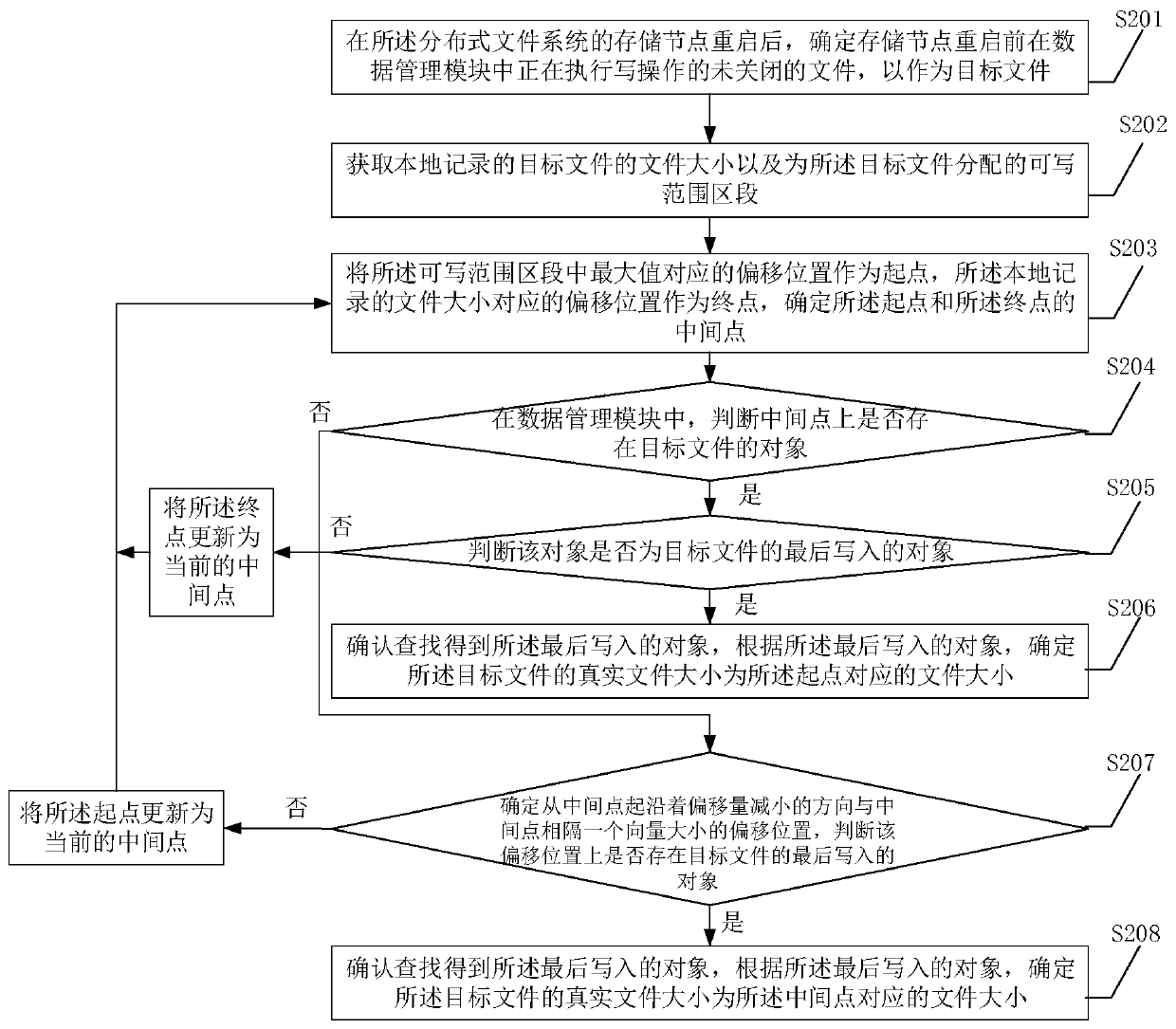

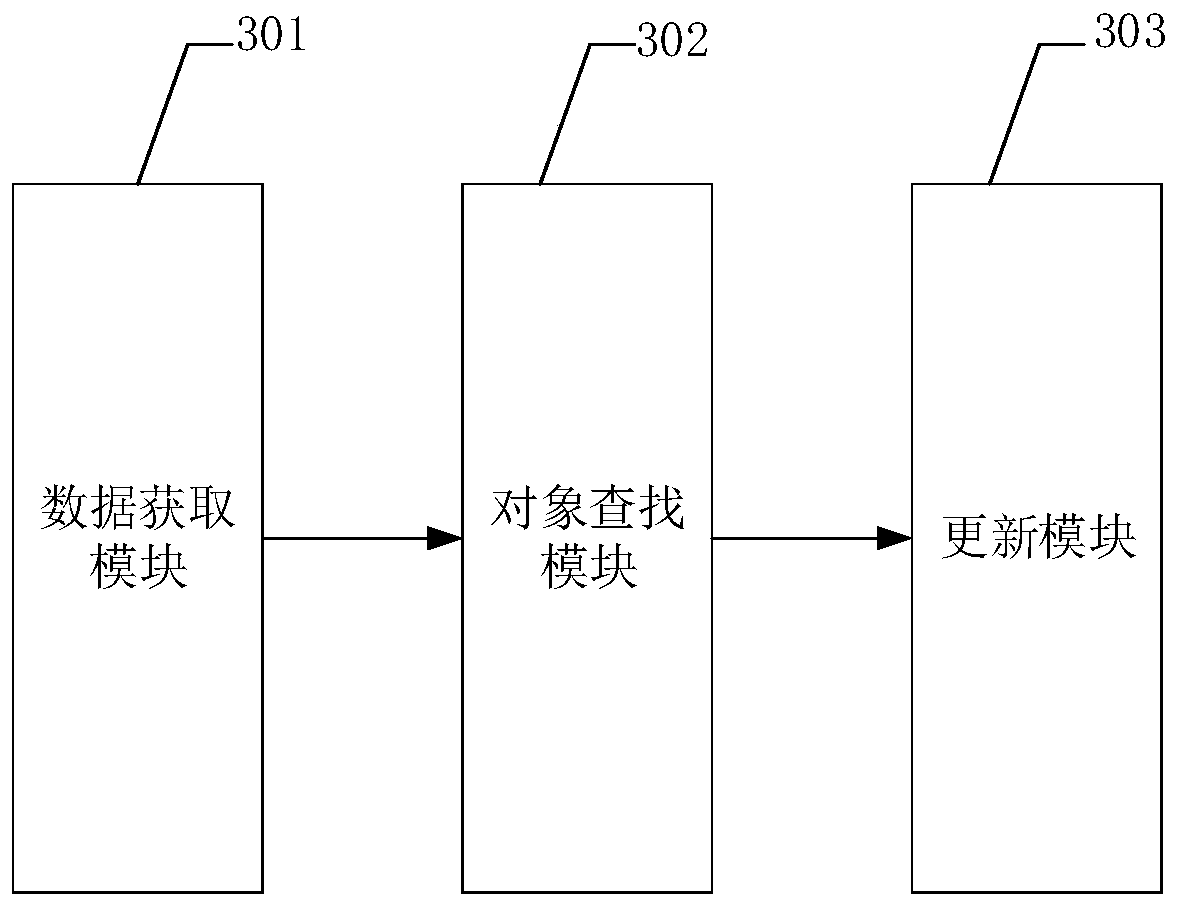

Metadata updating method and device and metadata server

ActiveCN110647514ADetermine the sizeImprove recovery efficiencyDatabase updatingSpecial data processing applicationsFile sizeFile (record)

The invention discloses a metadata updating method and device, a metadata server and a readable storage medium. According to the scheme, the metadata updating method comprises the steps of acquiring the file size of a locally recorded target file and a writable range section allocated to the target file; searching a last written object of the target file from the data management module by utilizing a binary search method according to the locally recorded file size and writable range section; and determining the real file size of the target file according to the finally written object, and updating the locally recorded file size. Visibly, according to the file size of the target file recorded on the metadata server and the writable range section allocated to the target file, the object which is finally written into the target file is searched by utilizing the binary search method, so that the problem of overlong consumed time caused by one-by-one search in a traditional scheme is avoided, and the file metadata recovery efficiency is remarkably improved.

Owner:北京浪潮数据技术有限公司

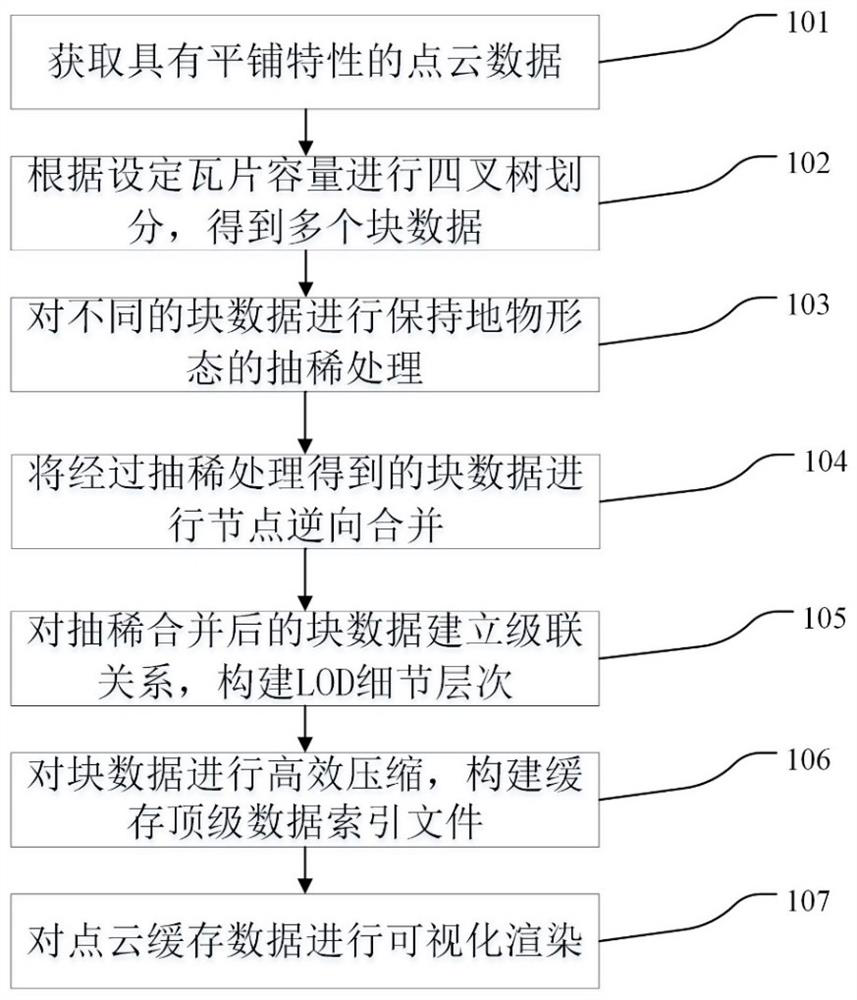

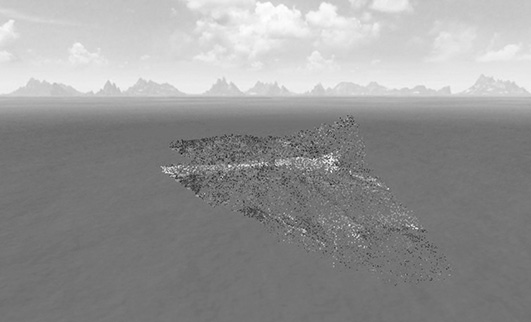

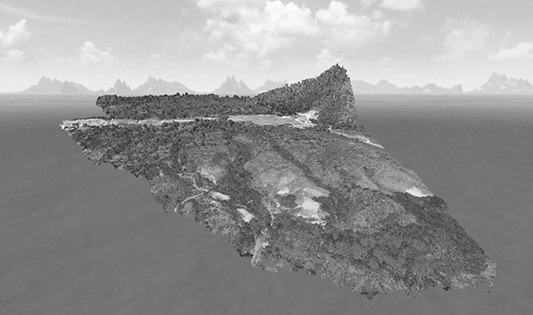

Massive point cloud data processing and visualization method and system

PendingCN113781631AImprove display efficiencyImprove the display effectStill image data browsing/visualisationSpecial data processing applicationsComputational sciencePoint cloud

The invention relates to the technical field of point cloud data processing, in particular to a massive point cloud data processing and visualization method and system. The method are characterized by comprising the following steps: S1, carrying out data acquisition: acquiring a point cloud data file with a tiling characteristic; S2, carrying out data partitioning: performing quadtree partitioning on the point cloud data according to set tile capacity to obtain a plurality of pieces of block data; S3, carrying out data thinning: carrying out thinning processing of keeping a surface feature form on the divided different blocks of data; S4, carrying out node combination: carrying out node reverse combination on the block data obtained through thinning processing; S5, establishing a cascade relationship for the thinned and merged block data, and constructing an LOD detail level model; S6, constructing an index file: efficiently compressing the block data, and constructing a cache top-level data index file; and S7, carrying out visual rendering. The problems of low loading speed, long time consumption, insufficient memory and the like of the massive point cloud data are solved, and the display efficiency and the display effect are improved.

Owner:深圳市中地软件工程有限公司

Gas cooker light-emitting device and gas cooker

ActiveCN108019800AAvoid enteringObservation is obviously labor-savingDomestic stoves or rangesElectric circuit arrangementsEngineeringLuminescence

The invention belongs to the gas cooker related field, and discloses a gas cooker light-emitting device and a gas cooker. The gas cooker light-emitting device comprises: a potentiometer located belowthe panel of the gas cooker, sleeving the valve rod of a gas valve and rotating with the valve rod; a lamp ring located above the potentiometer and locked on the outside of the panel, wherein the valve rod goes through the lamp ring; a knob fixedly connected to one end, going through the lamp ring, of the valve rod; a control plate connected to the potentiometer and the lamp ring respectively, wherein the control plate controls the on and off of the lamp ring and changes the luminescence color when the knob is pressed for igniting and the valve rod is rotated. When the knob is pressed for igniting and the valve rod is rotated, the flame size of the gas cooker changes with the rotation of the valve rod, the potentiometer also rotates with the valve rod, the resistance value of the potentiometer changes, a resistance value signal is sent to the control plate, and the control plate controls the lamp ring to emit lights having different colors according to different resistance values ofthe potentiometer to correspond to different flame sizes, so a user can easily determine the flame size according to the color of lights emitted by the lamp ring.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

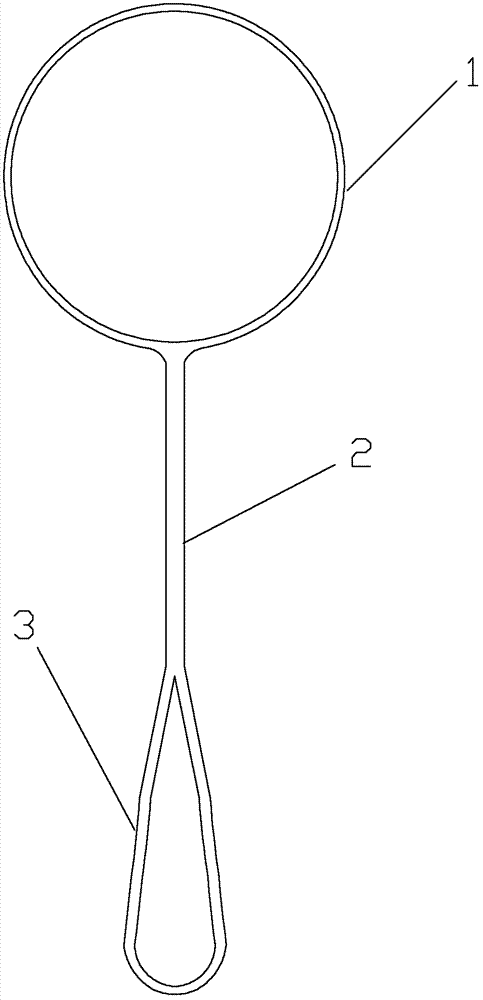

Nipple and areola shaping and positioning ring

InactiveCN102949238ADetermine the extent of resectionAccurately simulate the shapeDiagnosticsInstruments for stereotaxic surgeryMedicineBreast augmentation

The invention relates to a medical instrument and discloses a nipple and areola shaping and positioning ring which comprises a circular ring, a supporting rod and a handle. One end of the supporting rod is connected with the circular ring while the other end of the supporting rod is connected with the handle. The nipple and areola shaping and positioning ring is convenient in positioning and can guarantee the nipple and areola to be positioned accurately pre-operation and in operations of breast augmentation, breast reduction mammaplasty and areola reduction mammaplasty, errors generated in positioning by experience of operators are avoided, quickness and accuracy in positioning are achieved, the areola is uniform in shape and controllable in size, operations are simple and easy in operation, and operation quality is improved.

Owner:PLASTIC SURGERY HOSPITAL CHINESE ACAD OF MEDICAL SCI

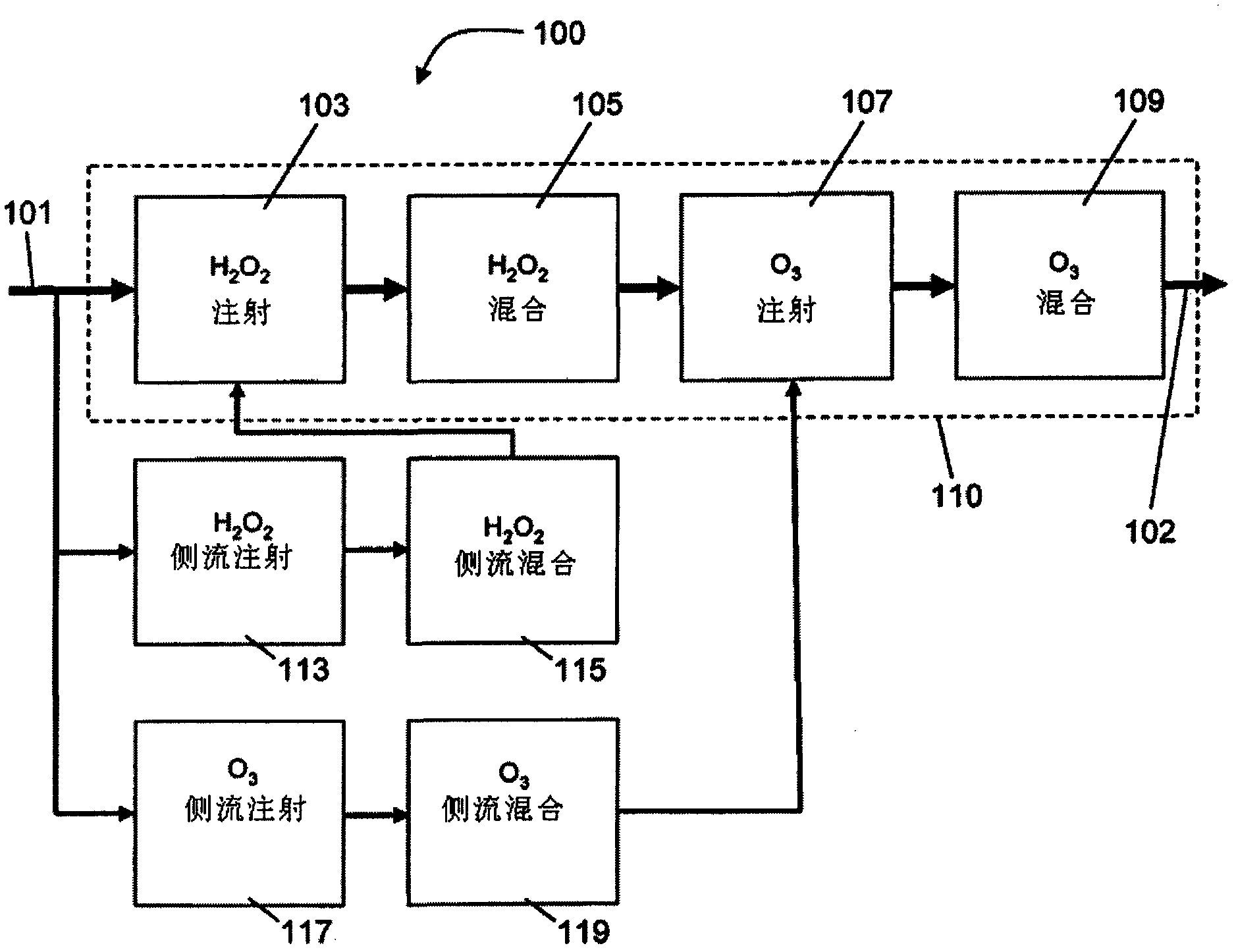

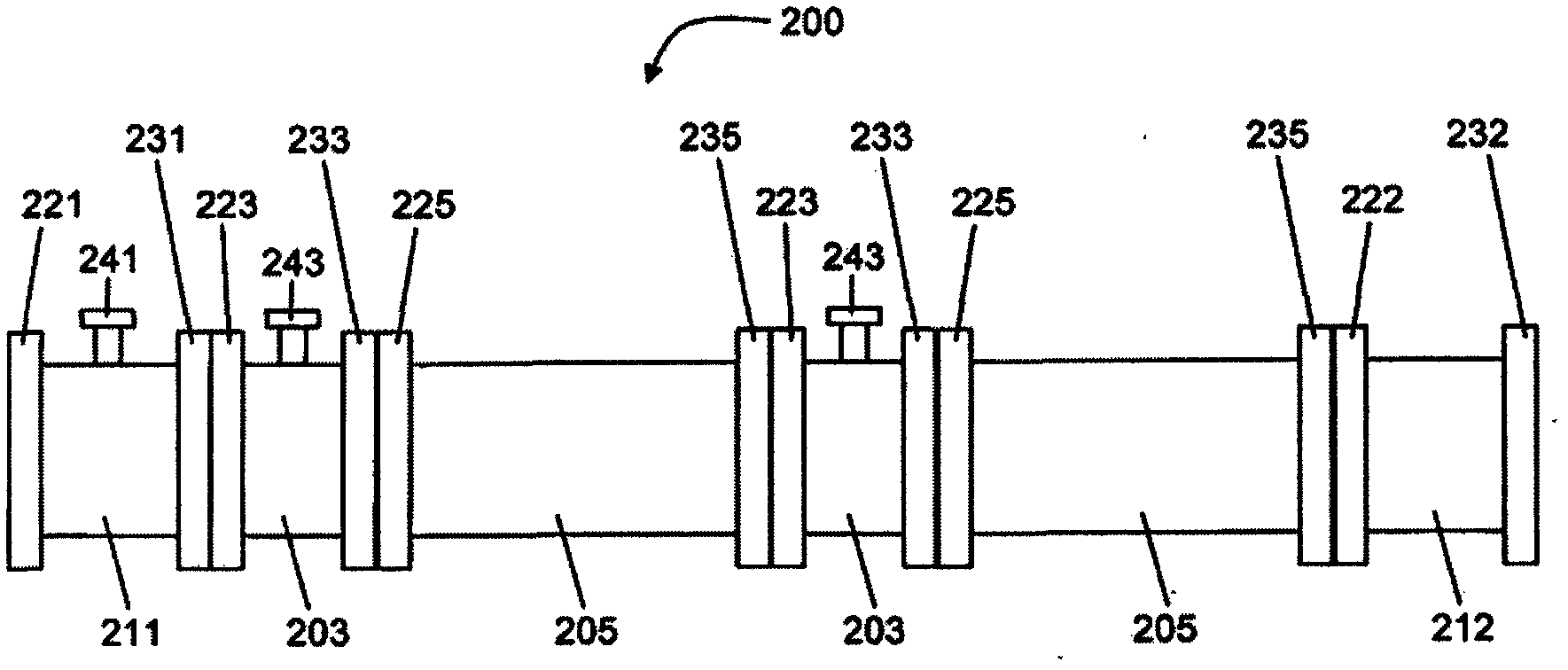

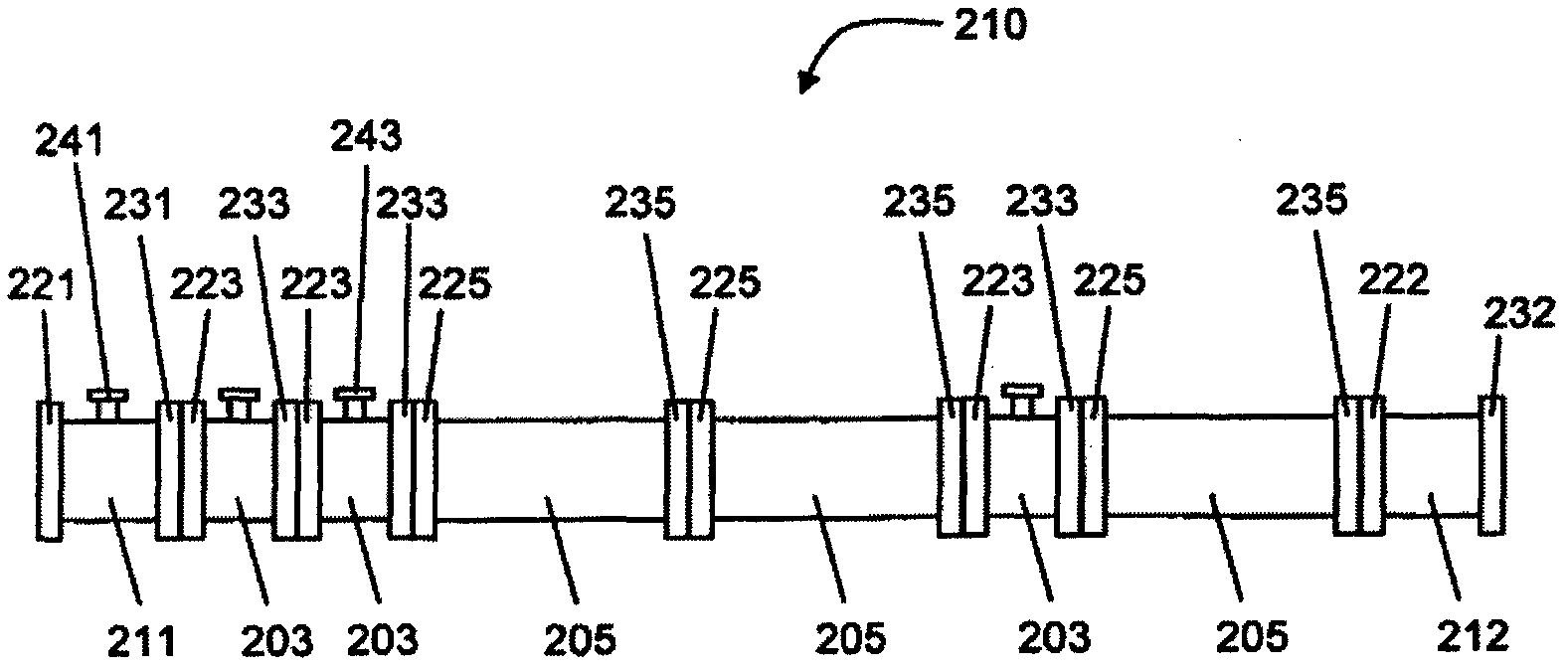

Apparatus, systems, and methods for water treatment

ActiveCN102046295ADetermine the sizeImprove solubilityWater treatment parameter controlFlow mixersWastewaterWater treatment

An apparatus, system, and method relating to a modular water treatment apparatus that utilizes sidestream injection coupled to static mixing are described. The apparatus, system, and method utilizes ozone, with or without hydrogen peroxide, for effective disinfection and / or decontamination of contaminants present in waste water. The disinfected, decontaminated water is suitable for reuse.

Owner:APTWATER

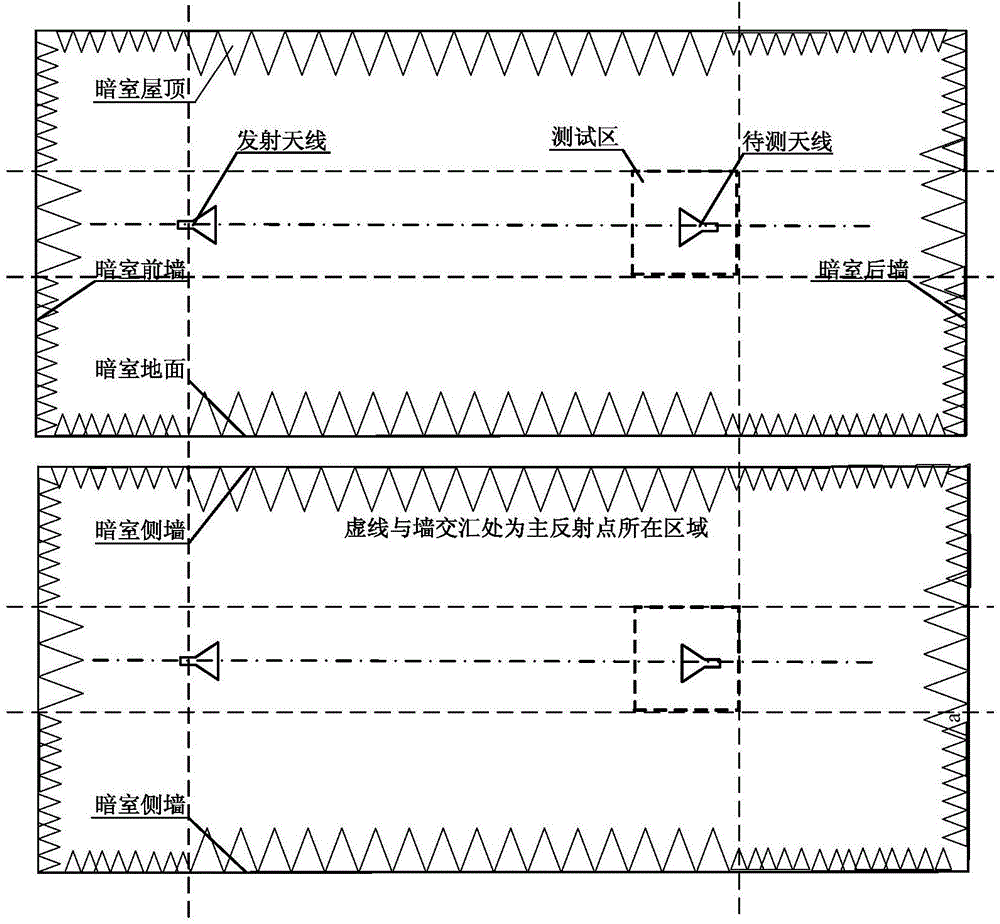

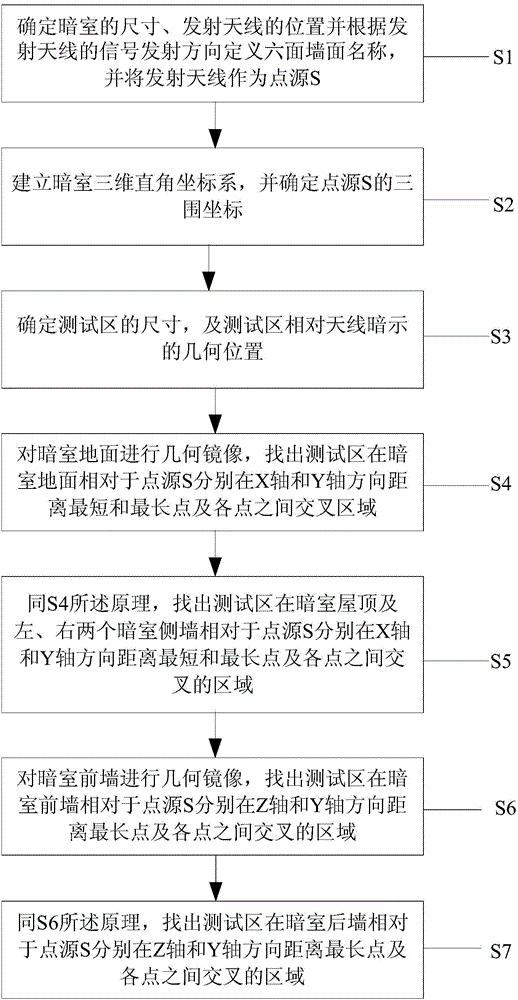

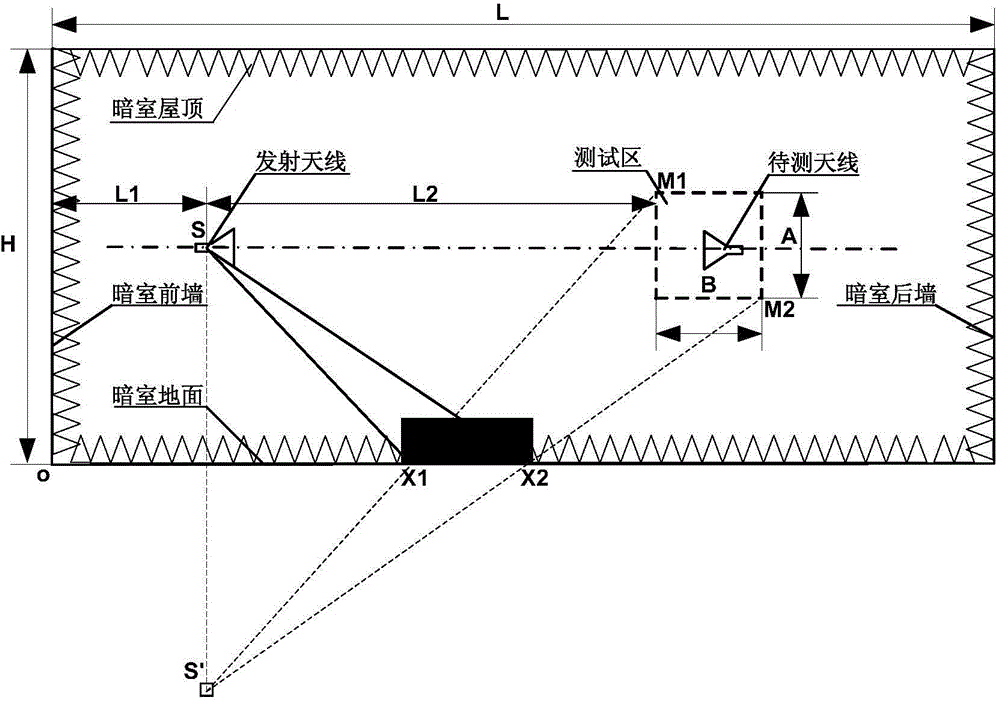

Main reflection point area determining method of antenna measurement darkroom

The invention discloses a main reflection point area determining method of an antenna measurement darkroom. The method comprises steps as follows: a transmitting antenna in the darkroom is used as a point source, each surface in the darkroom is used as a mirror surface, geometric mirroring is performed on the point source and all the mirror surfaces, and a mirror point of each surface is obtained; each position of a test area of the darkroom is connected with the mirror point of each surface, and an intersectional area of each connecting line and each surface is obtained on each surface; the intersectional area on each surface is used as a main reflection point area of the test area of the darkroom on each surface of the darkroom. With the adoption of the method, the main reflection point areas of the test area on all walls can be determined accurately, and waste of wave-absorbing materials can be reduced.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

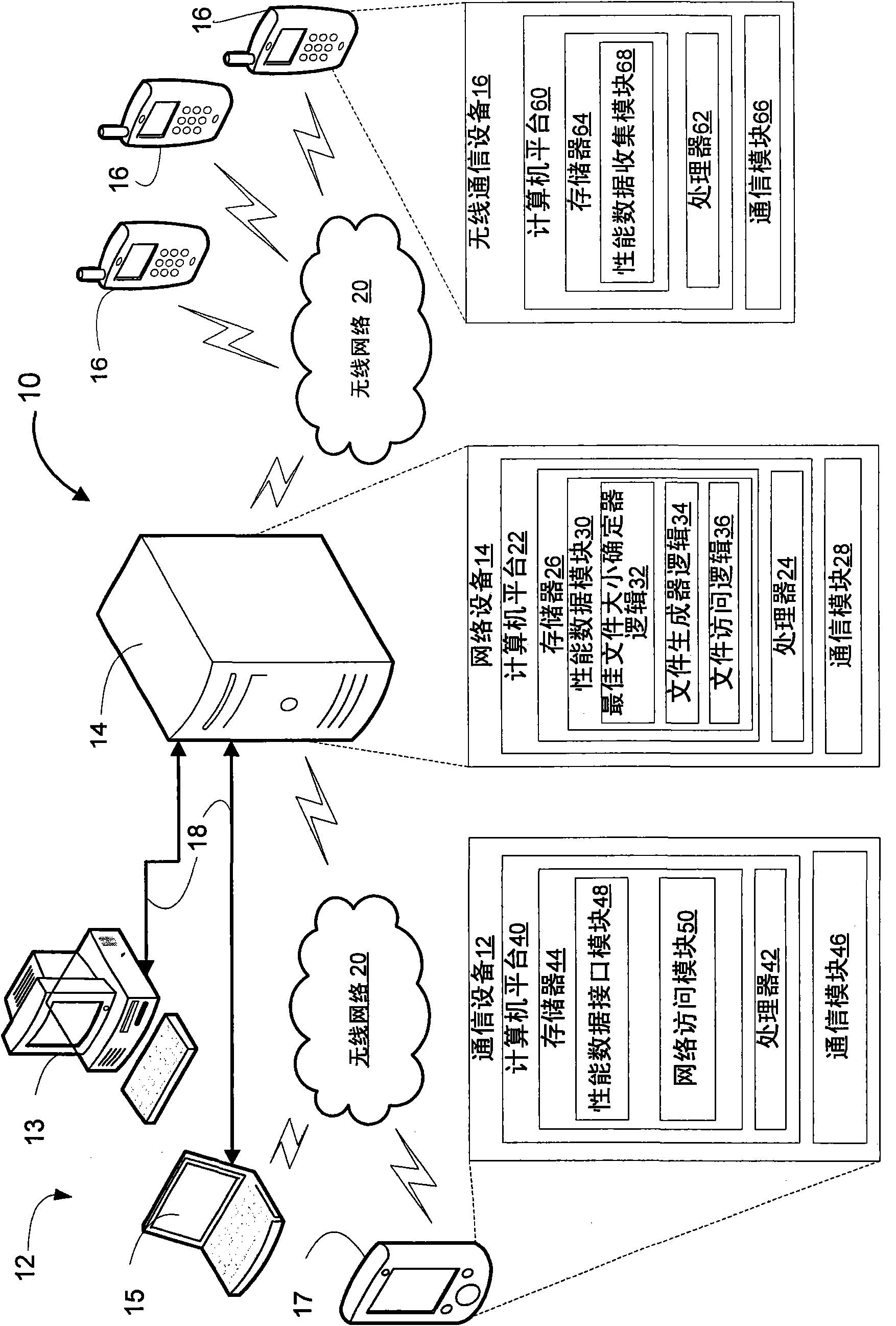

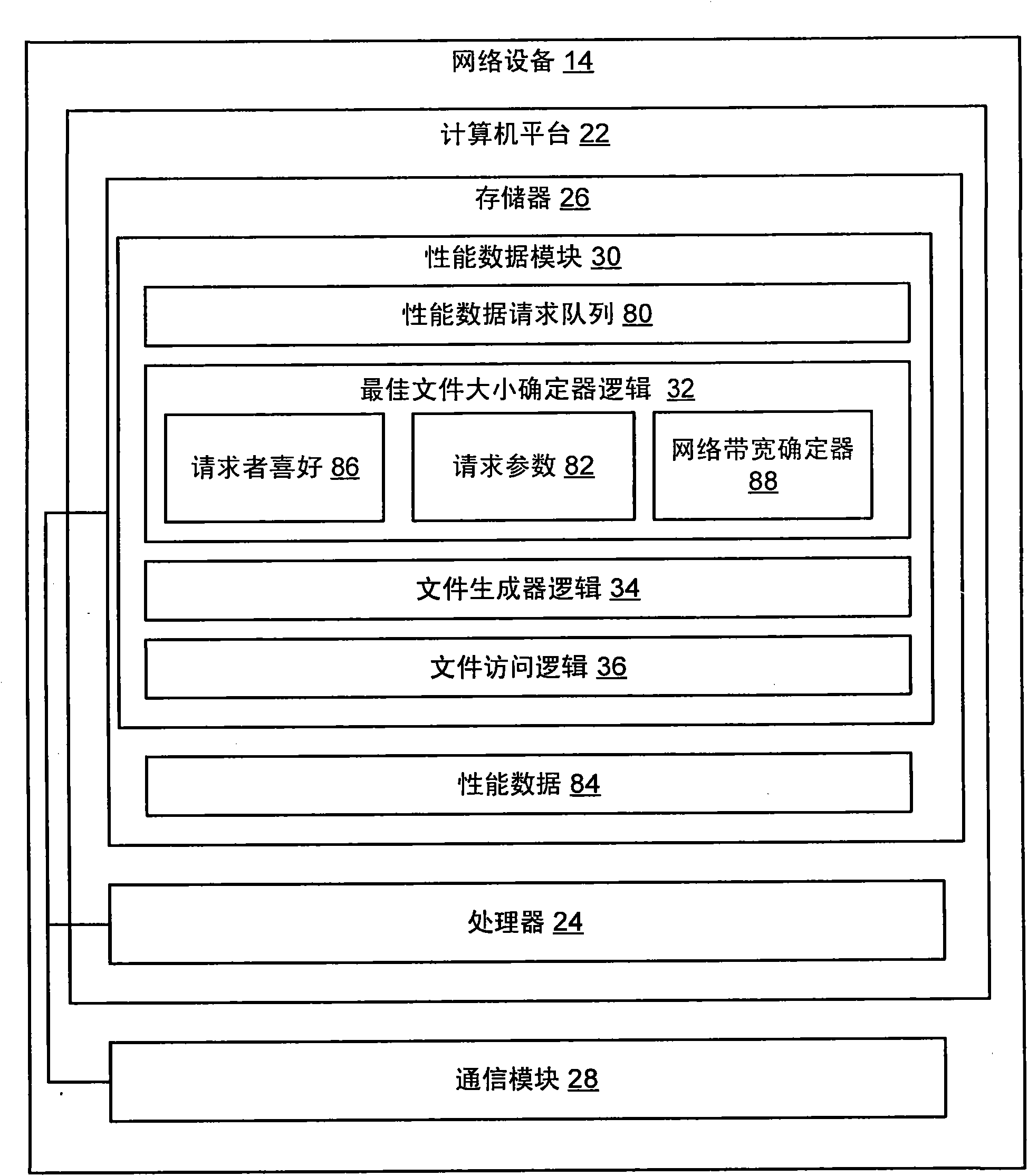

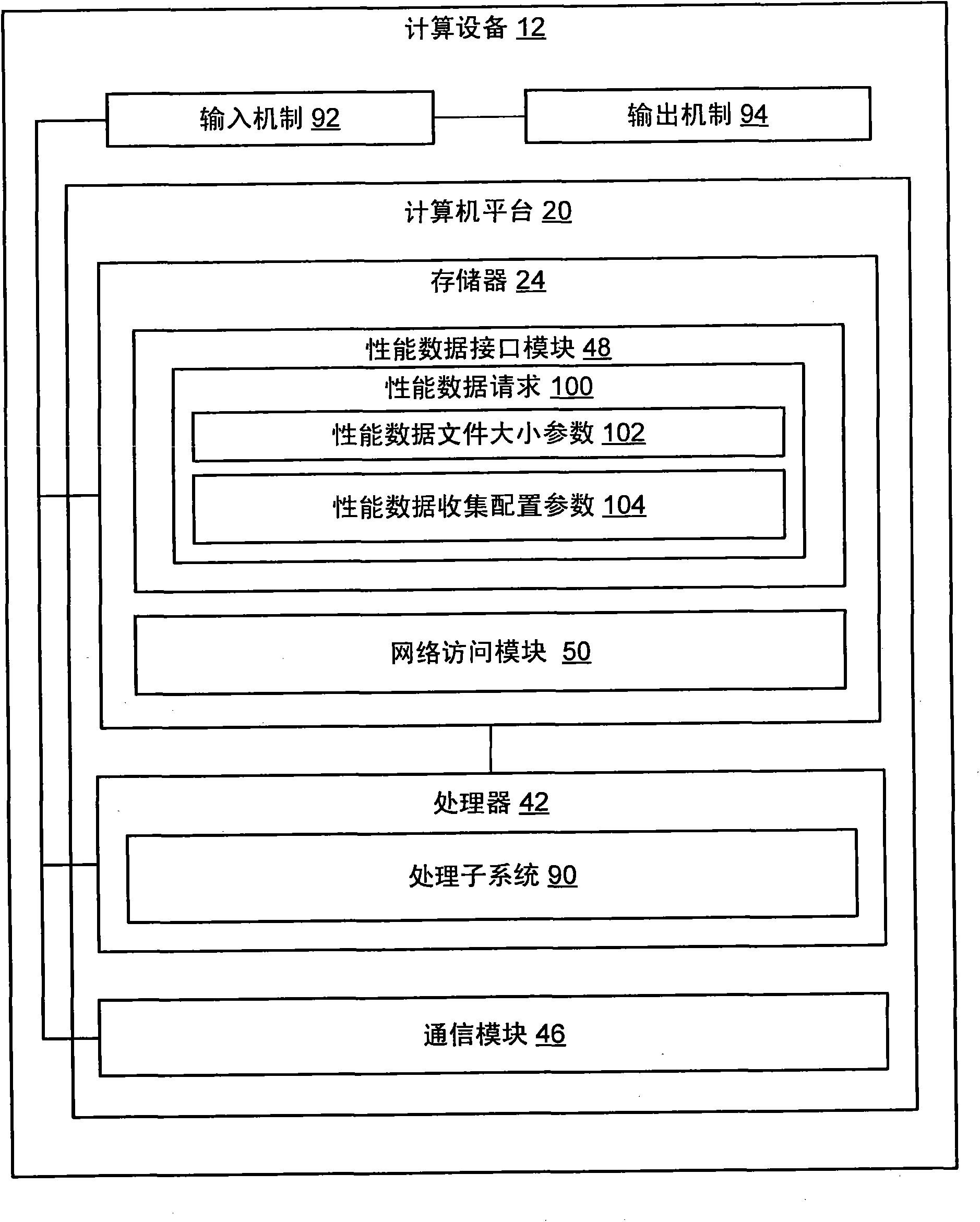

Methods and apparatus for requesting wireless communication device performance data and providing the data in optimal file size

InactiveCN101554034ASmall sizeDetermine the sizeNetwork traffic/resource managementWireless commuication servicesData fileFile size

Methods, systems, devices and computer program products are presented for requesting wireless device performance data and providing an optimal file size for the performance data. Present aspects provide for estimating the size of requested performance data, at the time of the request, and assessing other factors, such as requesting party preferences, to determine optimal performance data file size. In this regard, the performance data service provider is able to prepare and make accessible optimally sized performance data files, as the data becomes available as opposed to creating one comprehensive performance data file when all of the requested data is available. Additionally, some present aspects may provide for performance data requesting parties to implement Extensible Markup Language(XML) as the communication tool between the requesting device and the performance data-supplying network entity.

Owner:QUALCOMM INC

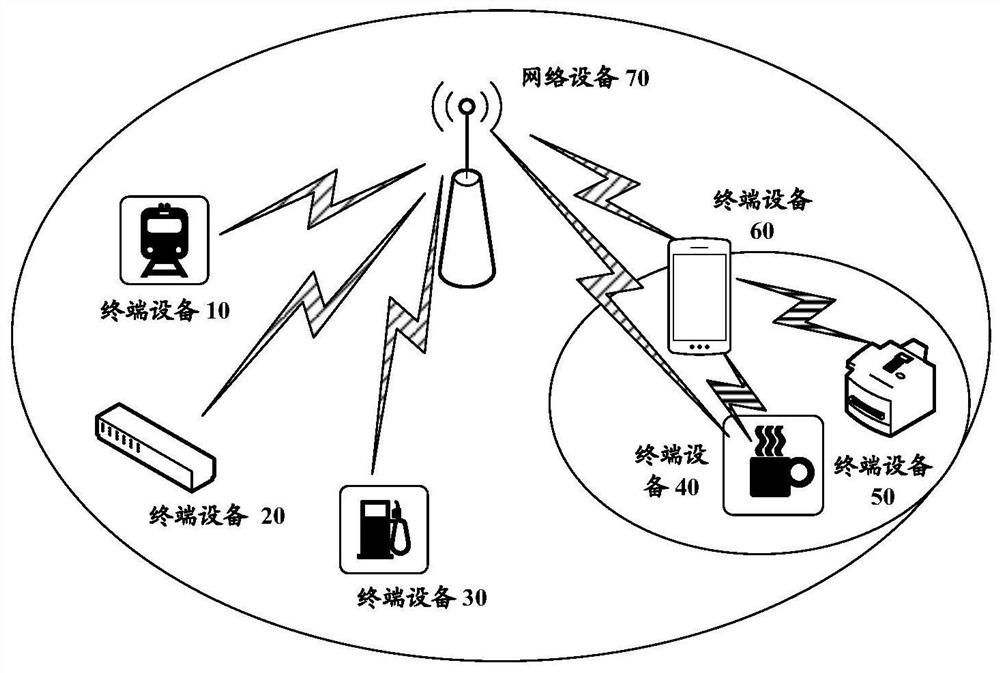

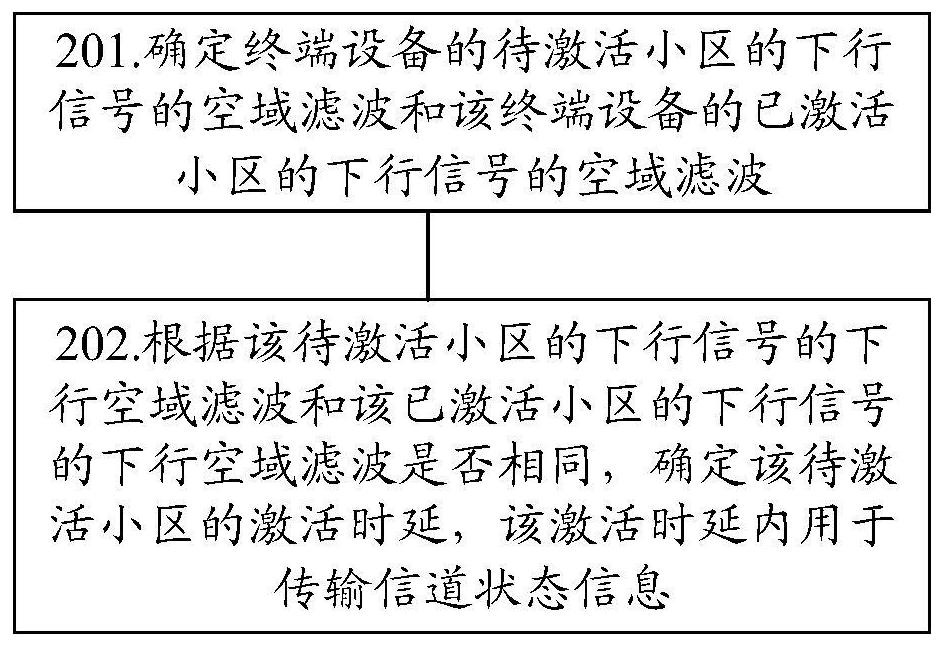

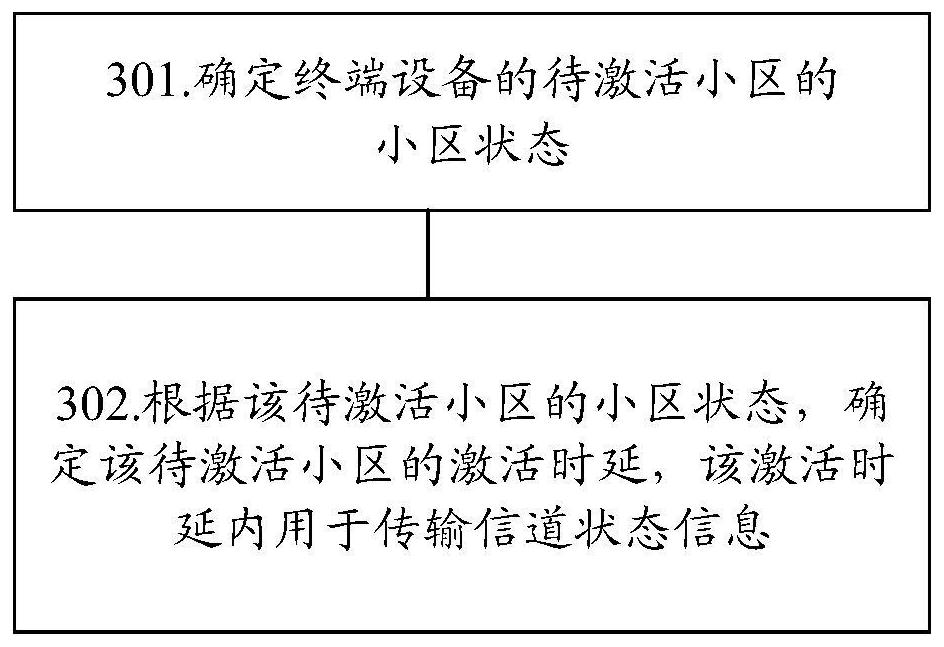

Method and device for determining cell activation delay

ActiveCN112019313AImprove activation success rateDetermine the sizeSynchronisation arrangementTransmission path divisionEngineeringReal-time computing

The invention provides a method and a device for determining cell activation time delay. The method comprises the following steps that: terminal equipment or network equipment can respectively determine activation time delay corresponding to a to-be-activated cell according to the fact that downlink spatial filtering of a downlink signal of the to-be-activated cell is the same as or different fromdownlink spatial filtering of a downlink signal of an activated cell. In this way, the terminal equipment sends the CSI in the activation time delay, and the network equipment receives the CSI in theactivation time delay and judges whether the to-be-activated cell is successfully activated according to whether the CSI is received or not. That is to say, the terminal equipment and the network equipment in the embodiments of the present application can determine a reasonable activation time delay, and avoid misjudgment of whether the terminal device and the network device are successfully activated by the terminal device and the network device due to too long or too short activation time delay, thereby improving the success rate of cell activation on the premise of ensuring the power consumption overhead of the device.

Owner:HUAWEI TECH CO LTD

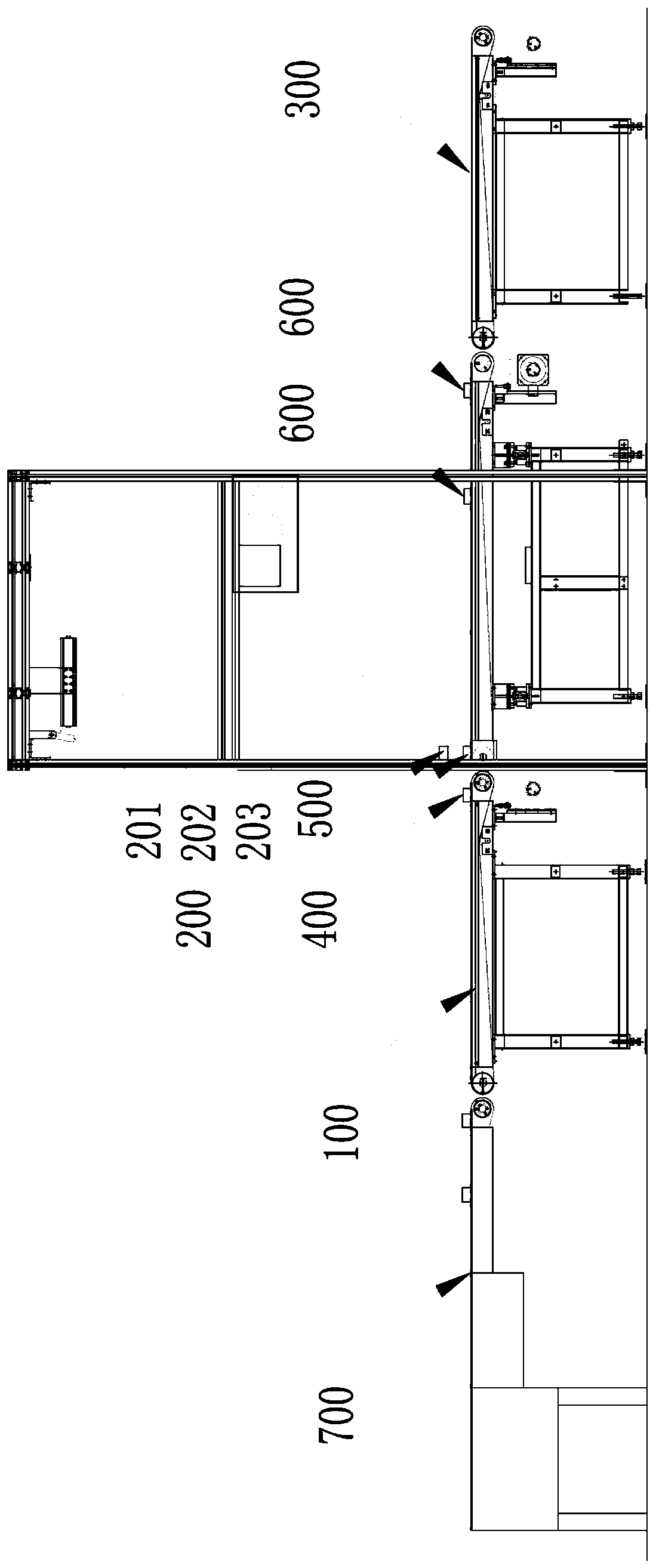

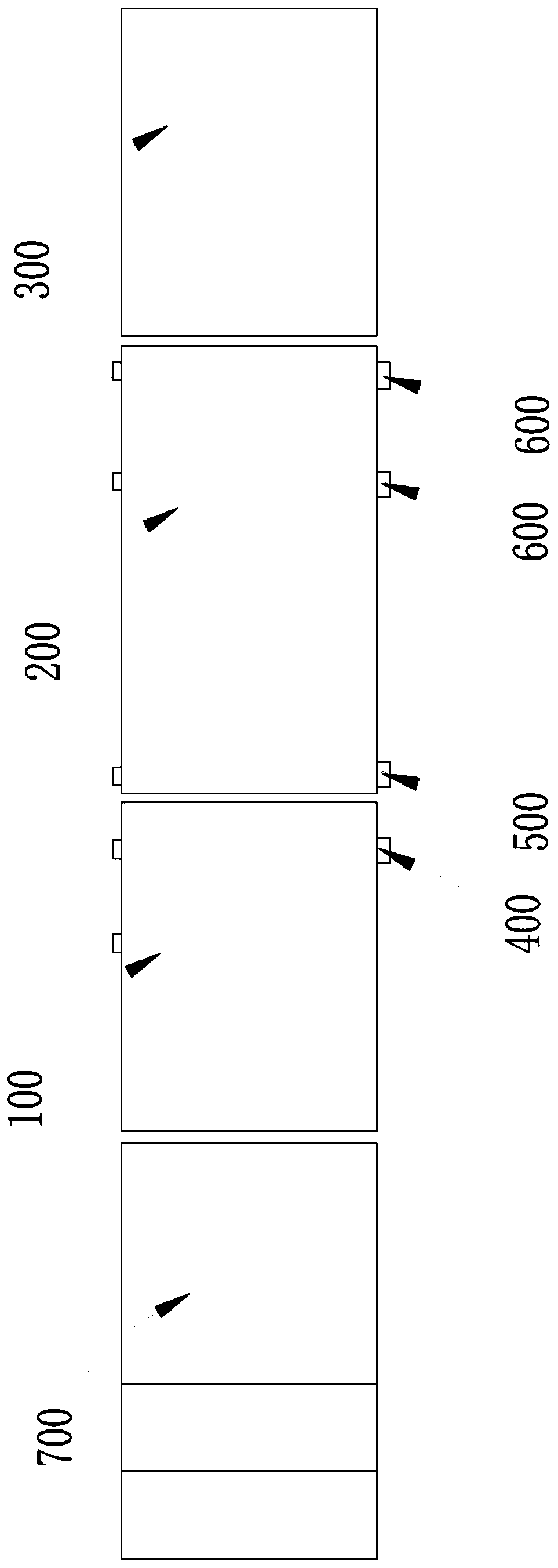

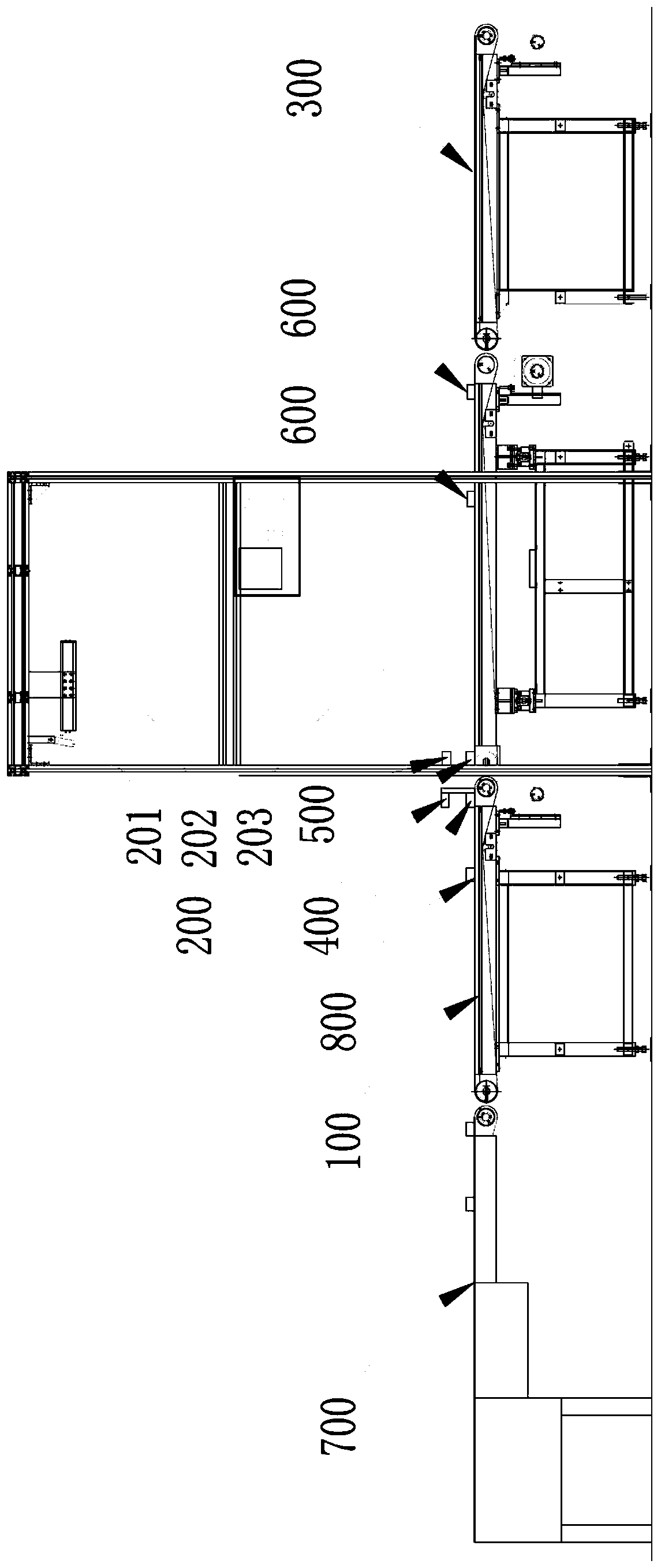

Package-following-prevention dynamic-scale package-loading control method and system and cross-band package-loading line for preventing DWS from being triggered by special-shaped part by mistake

The invention discloses a package-following-prevention dynamic-scale package-loading control method and system and a cross-band package-loading line for preventing a DWS from being triggered by a special-shaped part by mistake. According to the package-following-prevention dynamic-scale package-loading control method, judgment of a data integration condition and package starting control of a cacheconveying line are performed by combination of triggering of a photoelectric sensor, and the optimal package supply efficiency of the cache conveying line can be maintained no matter whether data integration triggering is completed or photoelectric triggering is performed when data integration is normal; and a through hole controls the cache conveying line to stop conveying when data integrationis abnormal, and a signal is sent to start the cache conveying line for package loading after abnormal processing is completed. By the package-following-prevention dynamic-scale package-loading control method, the package-following problem can be effectively solved, the problem of data disorder of a plurality of packages caused by continuous package supply of the cache conveying line is prevented,meanwhile, package damage caused by package collision is prevented, and the whole method takes package-loading efficiency, abnormal condition processing timeliness and package safety into consideration.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

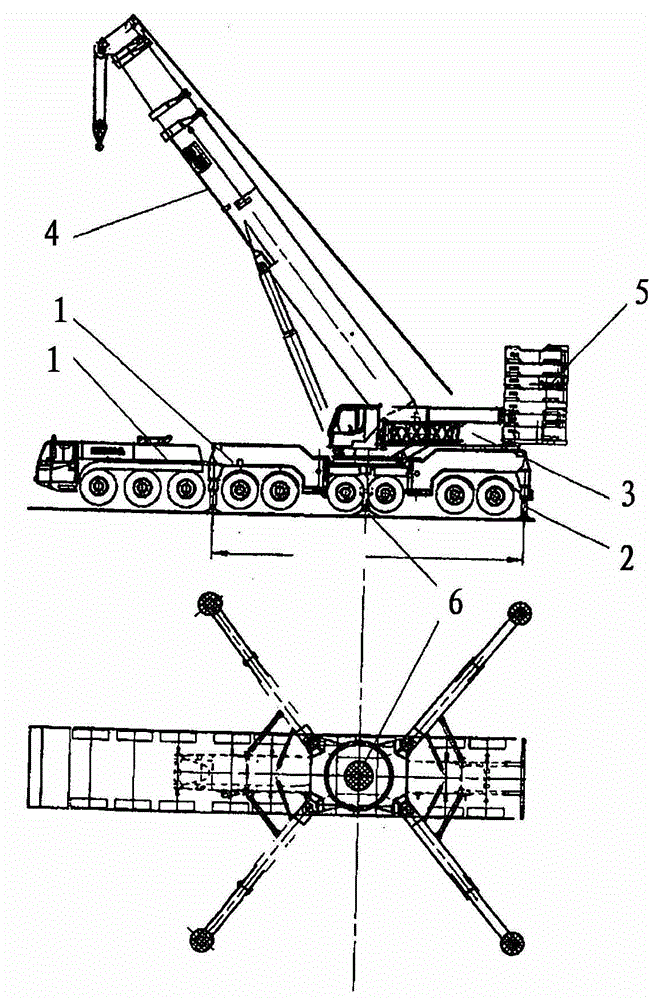

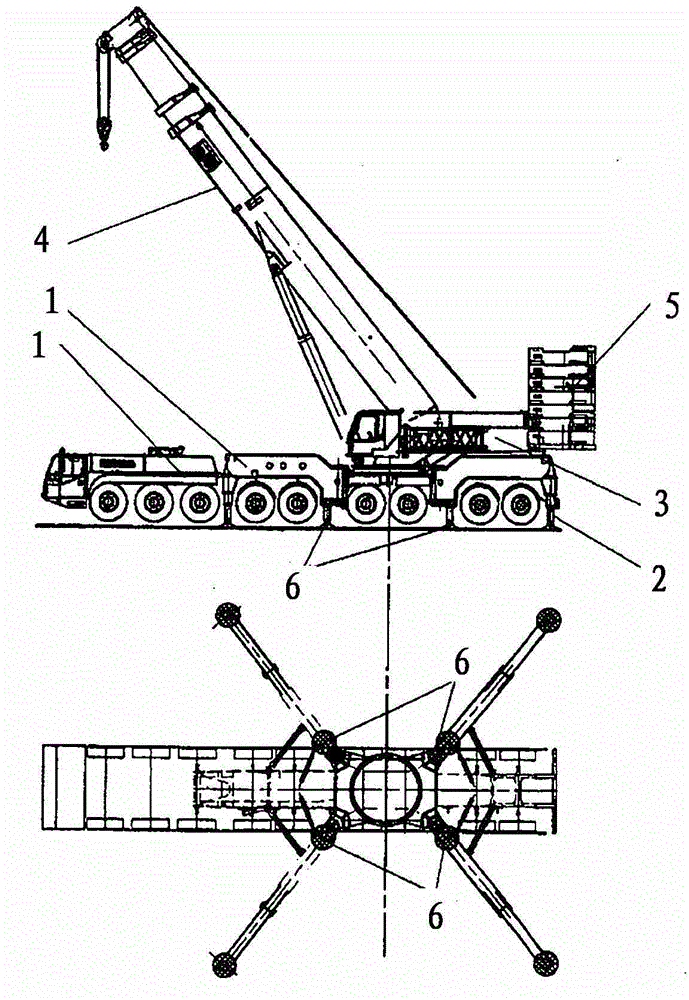

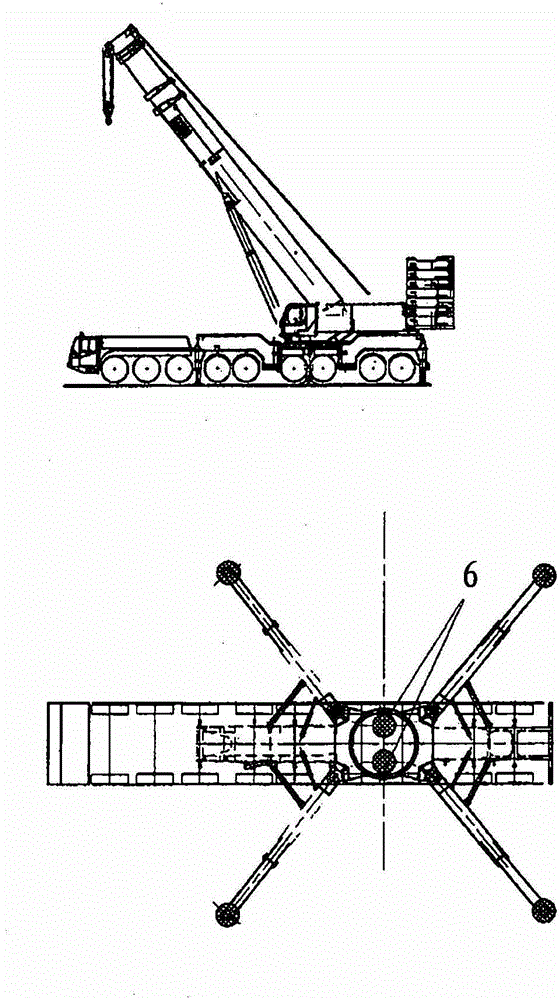

Movable working device, in particular mobile crane

InactiveCN103910293AEasy to stuffEven local loadLoad-engaging elementsCranesMechanical engineeringMobile work

The present invention relates to a mobile working machine, especially a mobile crane, having an undercarriage (1) and a support device with support cylinders (2) to create the support base required for operation, a top carriage (3) mounted pivotably on the undercarriage (1), as well as an apparatus compatible with the type of the working machine, in particular outriggers (4) and a counterweight arrangement (5). One or more additional hydraulic supports (6) are arranged on the undercarriage (1) underneath or in the proximity of the pivot bearing of the top carriage (3), as well as a control unit (7, 8, 9), which monitors the loads of the support device (2) and controls and monitors the additional supports (6).

Owner:TEREX CRANES GERMANY

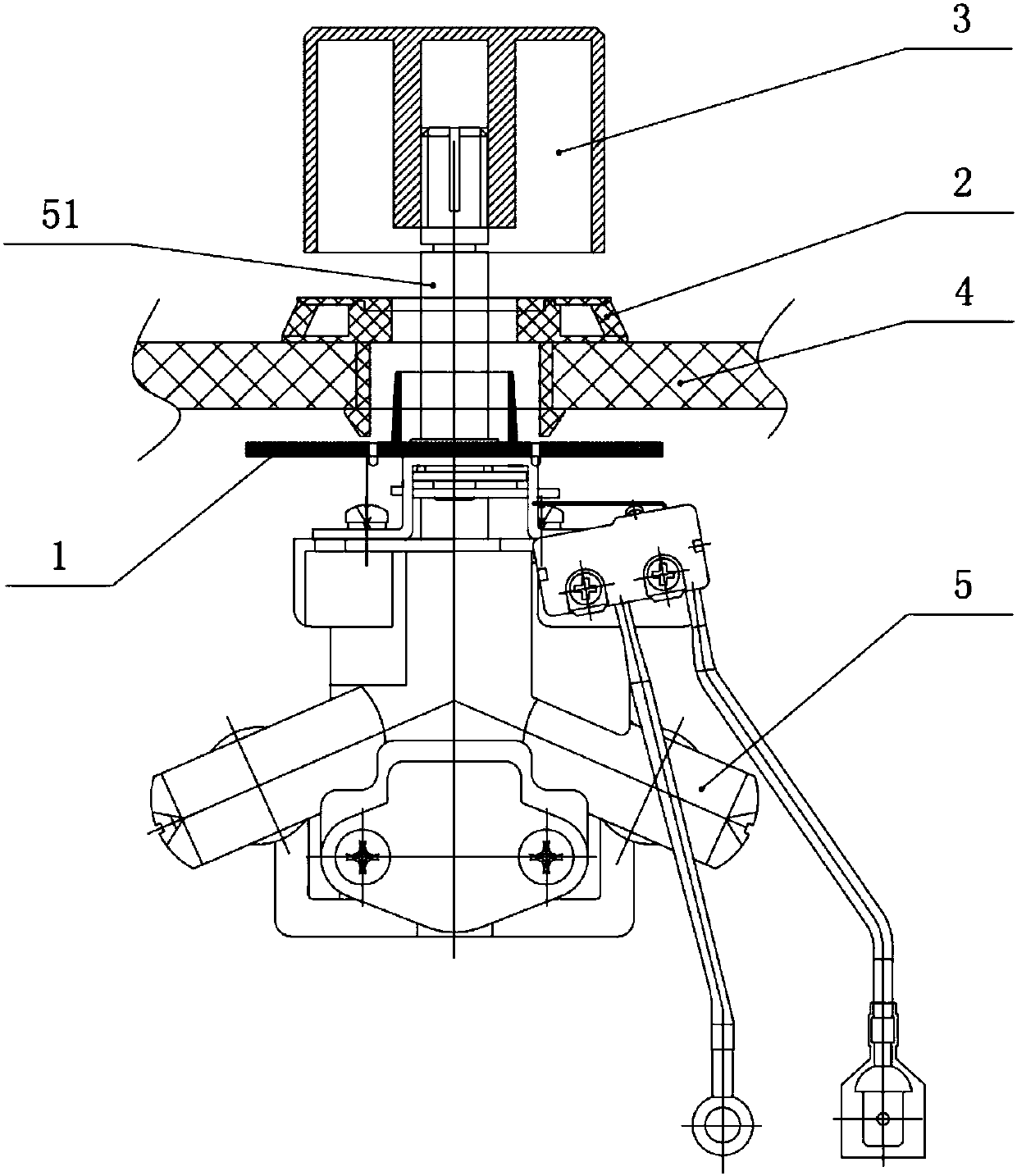

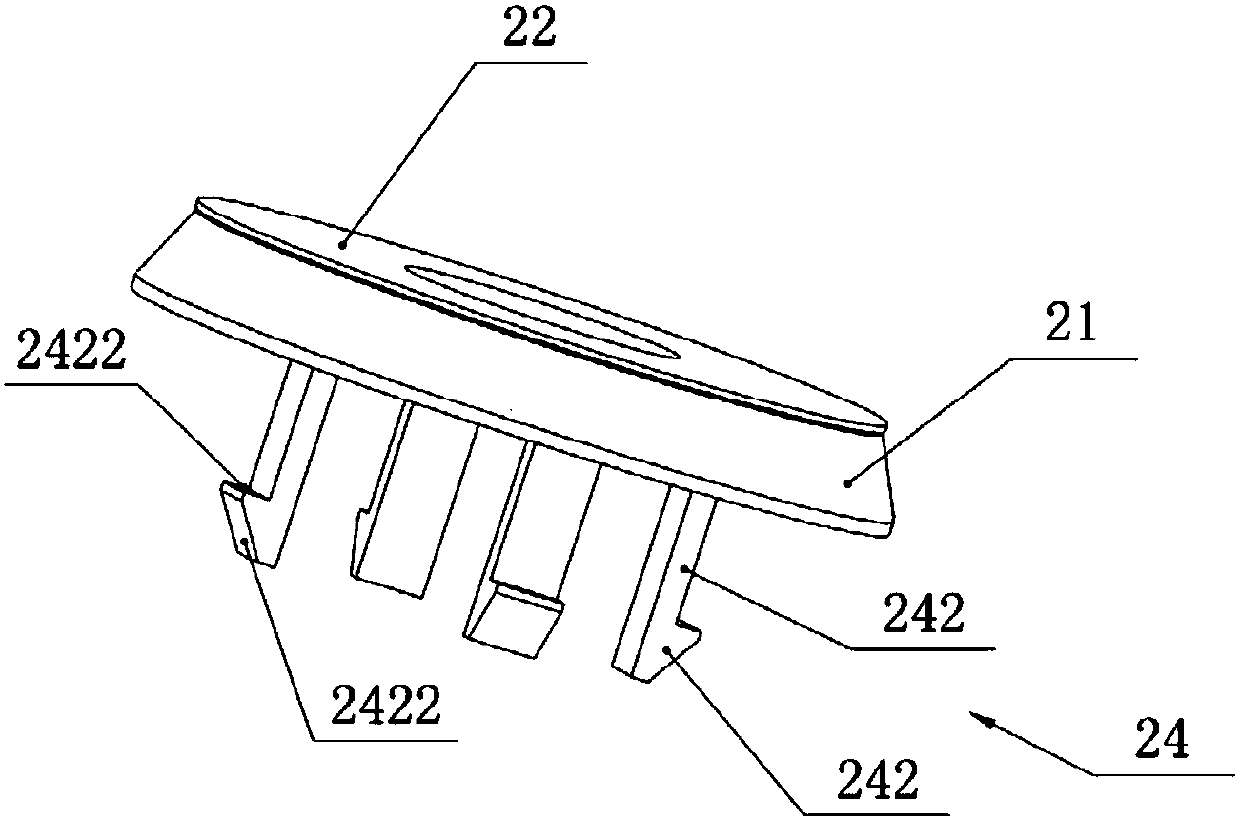

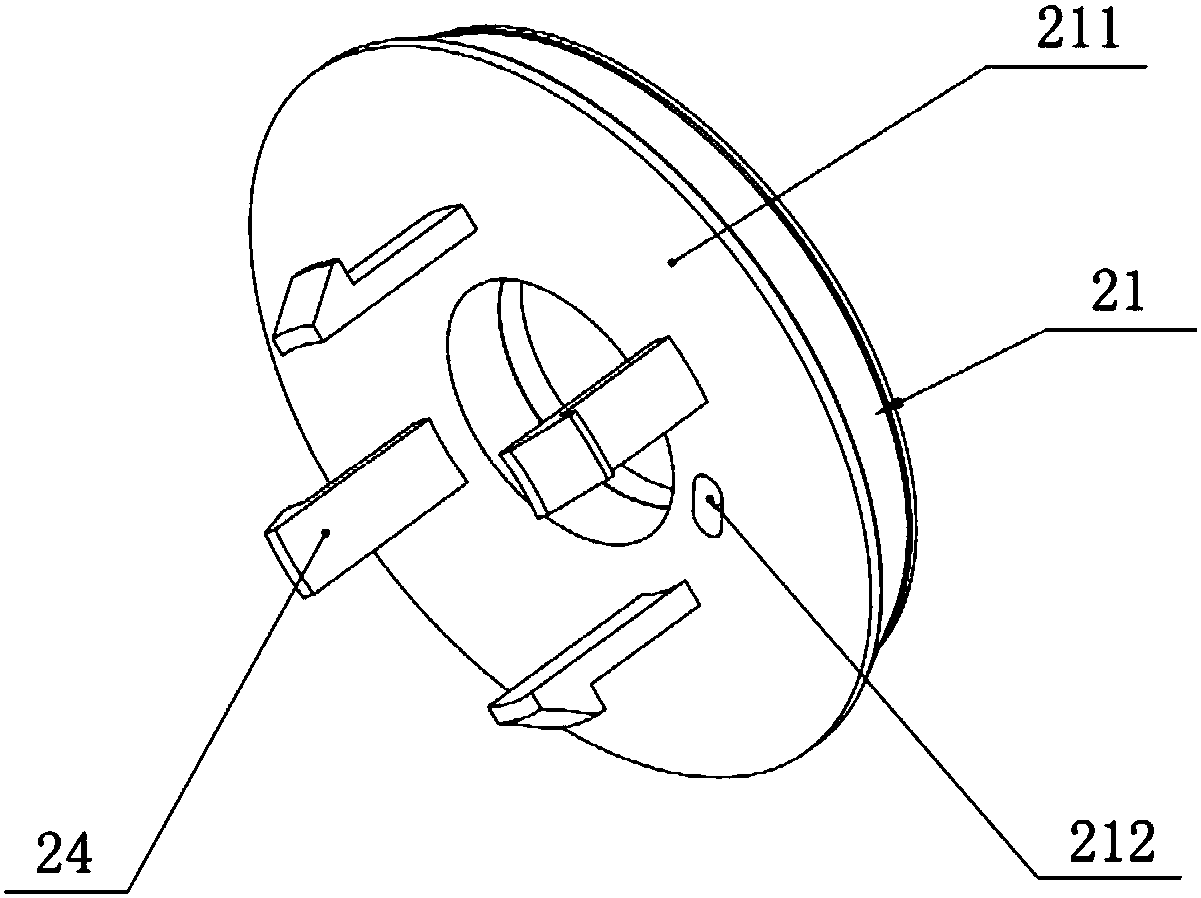

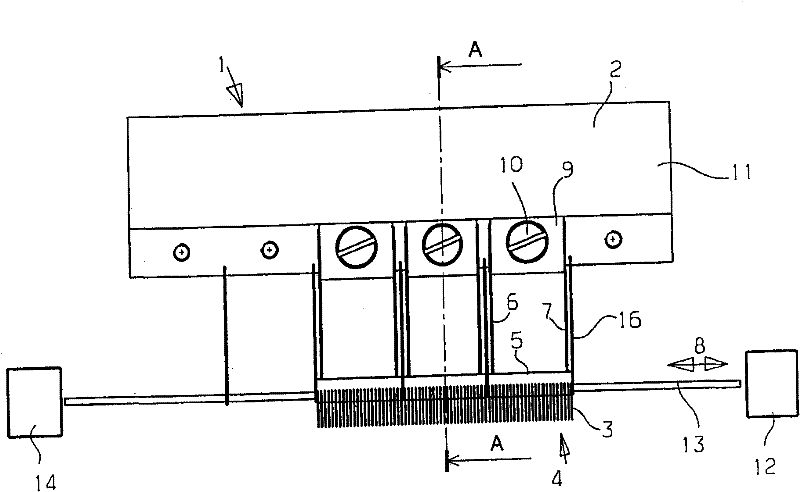

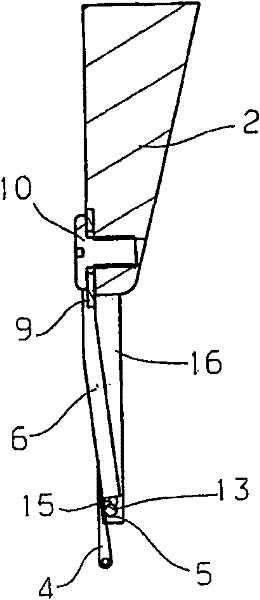

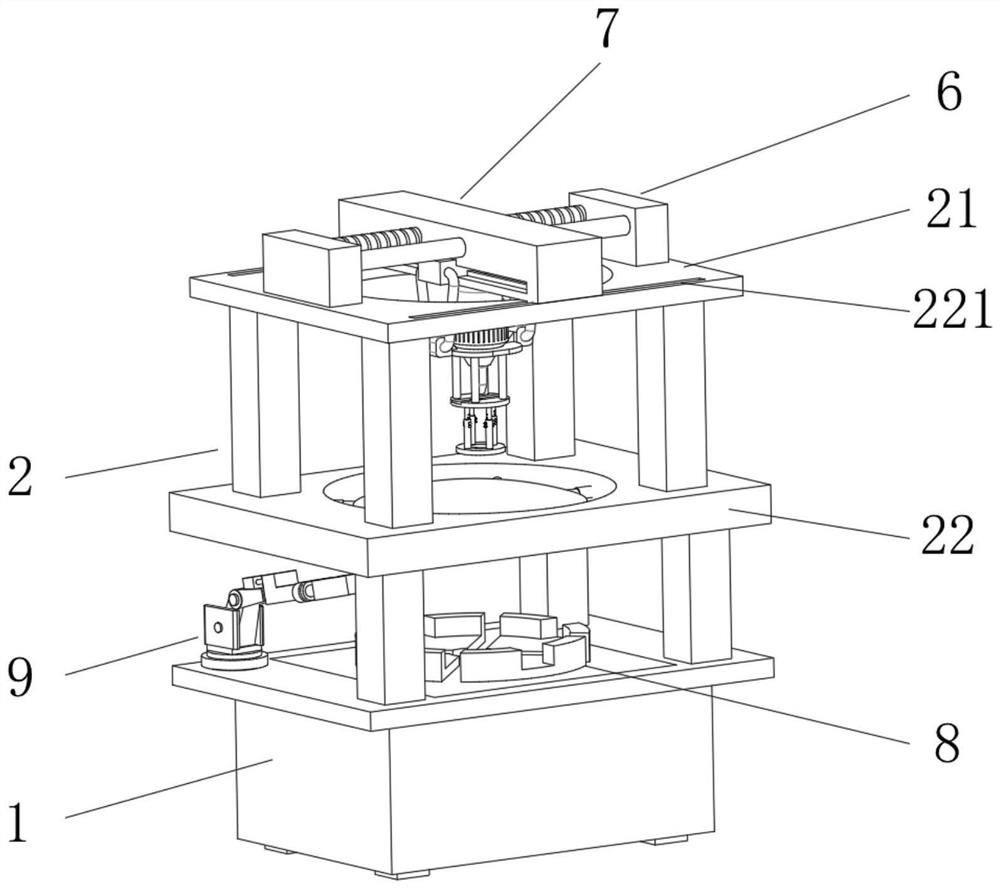

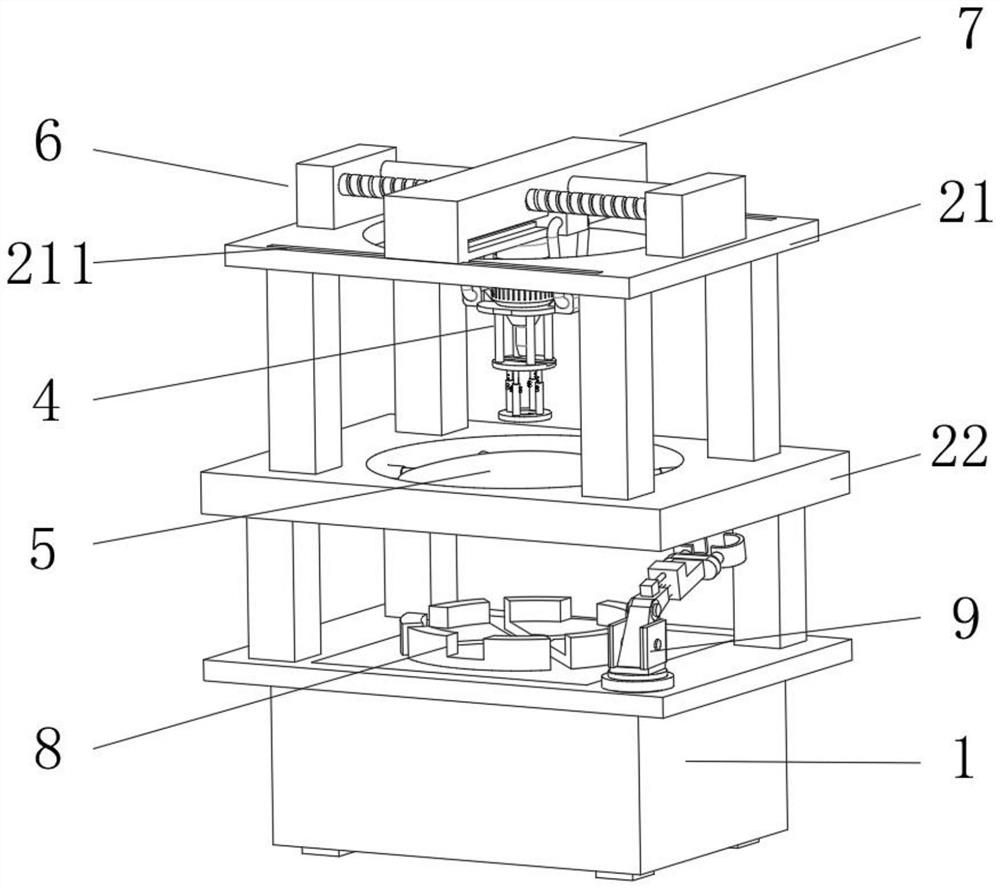

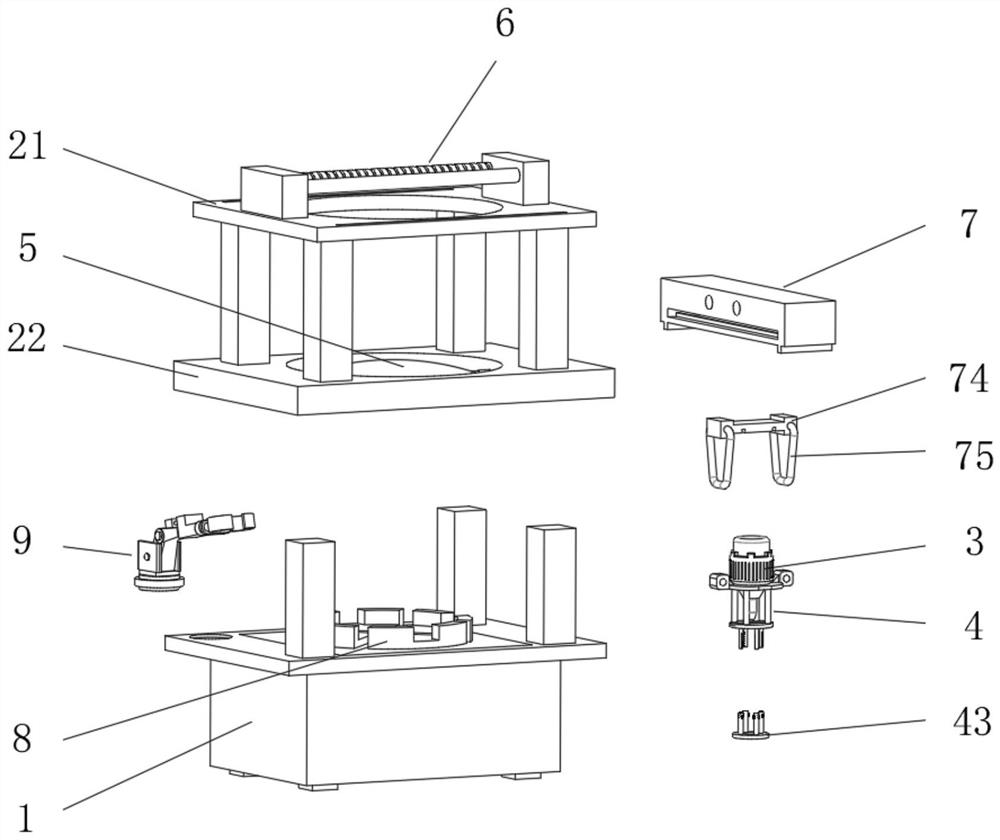

Guide bar arrangement of warp knitting machine

ActiveCN102345206AReduced risk of wear and tearReduce the overall heightWarp knittingEngineeringMechanical engineering

The invention provides a guide bar arrangement (1) of a warp knitting machine with a bar (2), a plurality of guide needles (3) group-wise combined into needle segments (4), and a drive mechanism (12) for generating the offset movement of the guide needles (3). For this purpose, the needle segments (4) are movably connected with the bar (2) in the displacement direction (8) and the drive mechanism (12) acts on the needle segments (4).

Owner:KARL MAYER STOLL R&D GMBH

Laser etching equipment for chip silicon wafer and chip production process

ActiveCN112756795AVertical position changeDetermine the sizeSemiconductor/solid-state device manufacturingMetal working apparatusLaser etchingWafer

The invention relates to the technical field of laser etching and discloses laser etching equipment for a chip silicon wafer and a chip production process. The equipment comprises a worktable, a double-layer mounting rack, a laser gun and a mechanical arm, wherein an adjustable hoisting rack is arranged at the bottom end of the laser gun and comprises a top hoisting rack, an etching template mounting rack and a movable lens rack. By arranging a primary lens capable of being disassembled and replaced, a laser beam emitted by the laser gun is subjected to a filtering action of the etching template and is collected preliminarily under the action of the primary lens, so that the laser beam can be controlled to generate a focal point on the surface of a wafer and the size of a spot etched by the laser beam every time is determined. Moreover, the vertical position of the etched focal point can be changed conveniently by replacing the primary lens, so that the size of the spot can be adjusted conveniently to determine the depth and size of a circuit groove formed by etching every time.

Owner:深圳市凤翔光电电子有限公司

Bundling size determination method, user terminal and network side equipment

ActiveCN109818711ADetermine the sizeCriteria allocationSignalling characterisationSize determinationComputer terminal

The embodiment of the invention provides a binding size determination method. The invention discloses a user terminal and network side equipment. The method comprises the following steps that the userterminal reports the capability information to the network side equipment, wherein the capability information is used for representing whether the user terminal supports PRB bundling or not; and a bundling size set configured for the user terminal by the network side device according to the capability information is received, in which one PRB bundling is supported to indicate that the PRB bundling function is supported to be closed. And / or if the network side device closes the function of dynamically adjusting the binding size, the user terminal uses the binding size configured by default orhigh-level signaling when transmitting data. According to the embodiment of the invention, the binding size of the user terminal can be determined.

Owner:DATANG MOBILE COMM EQUIP CO LTD

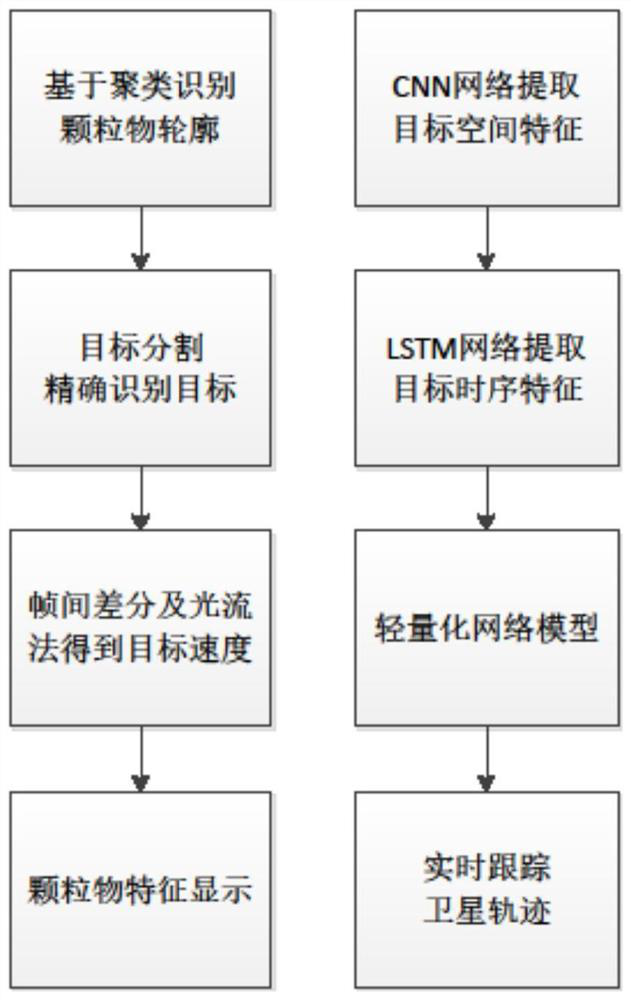

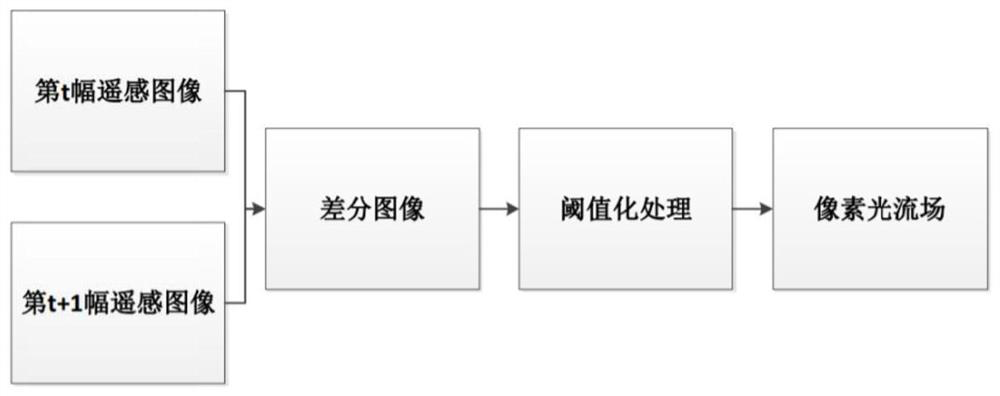

Space environment monitoring method based on rocket telemetry video

PendingCN112270661AReduce the burden onDetermine the sizeImage enhancementImage analysisParticulatesData set

The invention discloses a space environment monitoring method based on a rocket telemetry video, and the method comprises the following steps of collecting a rocket telemetry video image, identifyingeach pixel point in each frame of the rocket telemetry video image as a background pixel point, a rocket body pixel point or a particulate matter pixel point based on Kmeans clustering of pixel values; using a Mask R-CNN target segmentation model obtained by training on a Cityscapes data set, labeling and counting a particulate matter pixel point set obtained by clustering according to the Mask R-CNN target segmentation model to obtain an unconnected region, and performing segmentation according to the unconnected region to obtain the particulate matter information; and obtaining the moving speed and the moving track of the particulate matters according to the particulate matter optical flow. According to the method, the particle atomization concentration and range, the particle number, the average movement speed and the radius of the surrounding environment of an engine can be effectively analyzed, and the satellite position can be dynamically and accurately tracked at a satellite-rocket separation stage.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

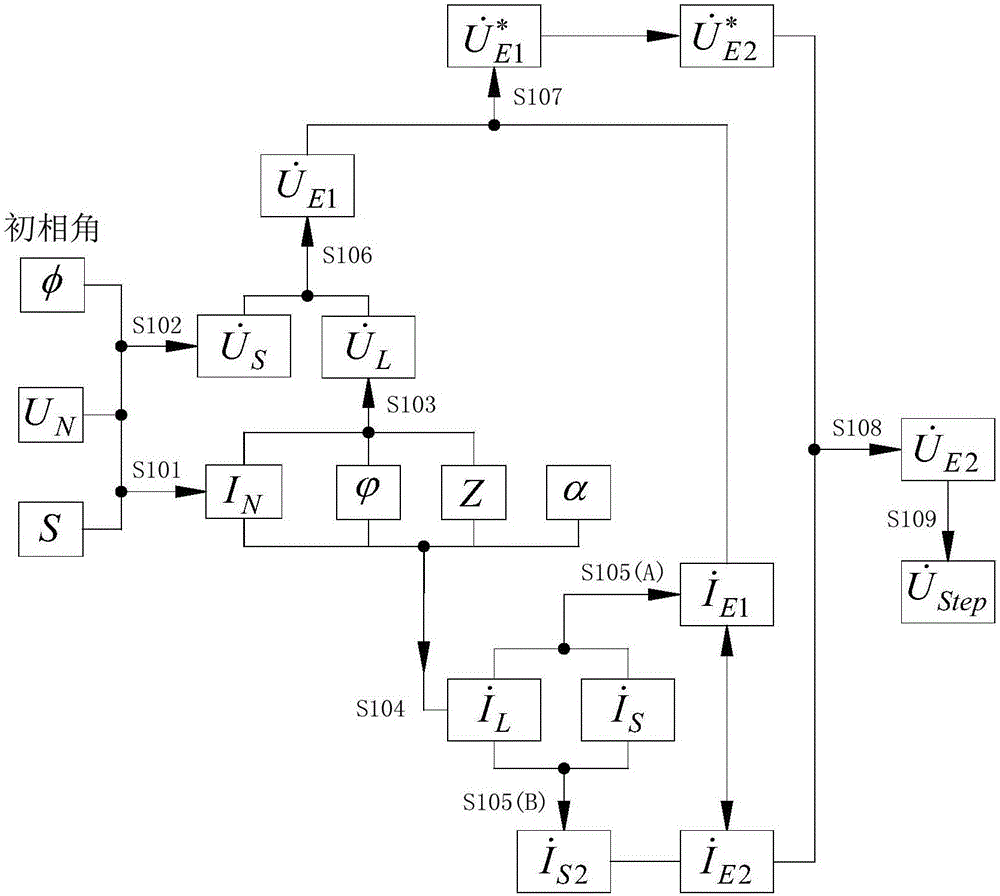

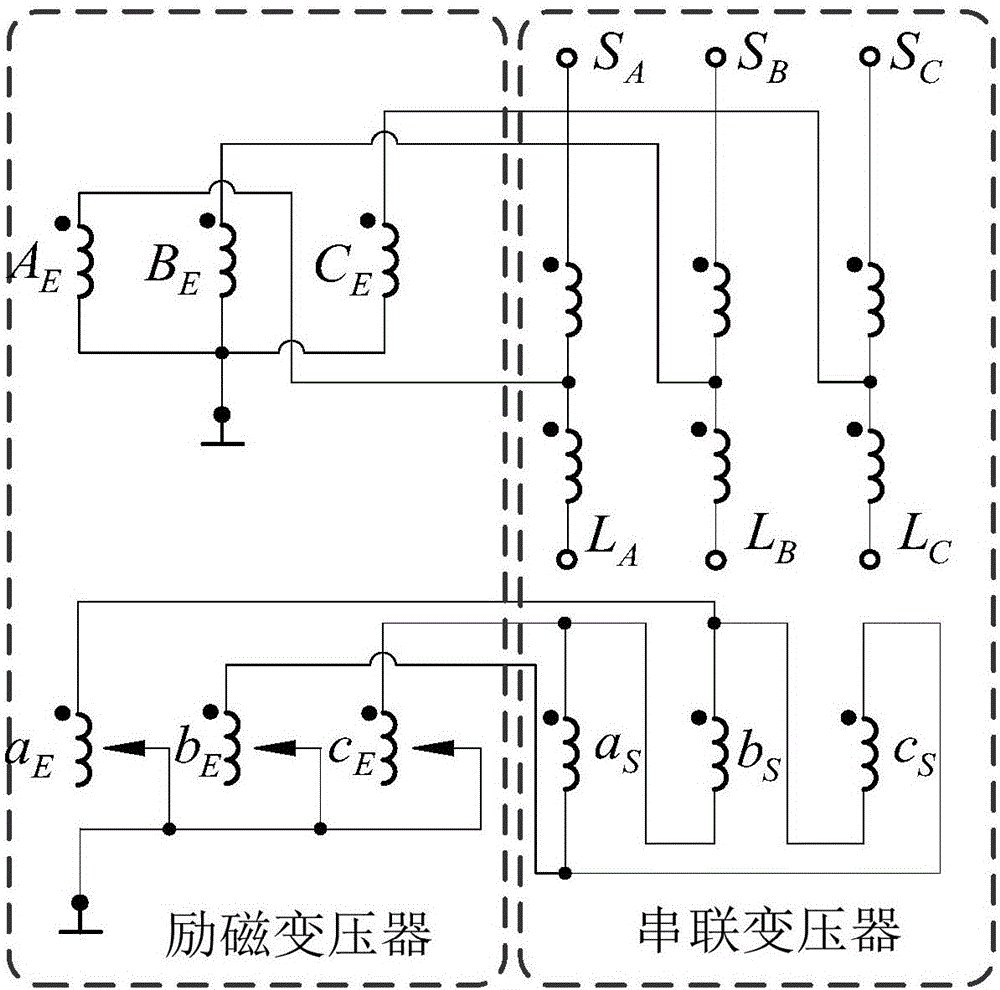

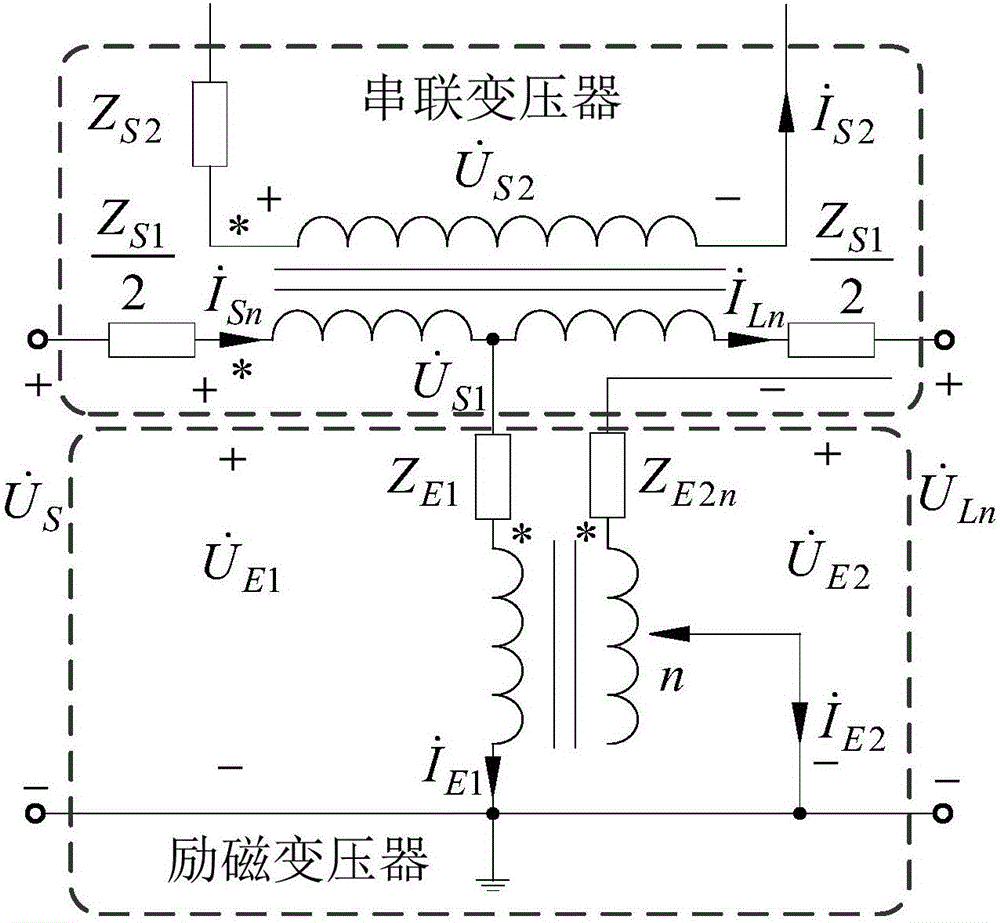

Step voltage calculation method under symmetrical double-core phase shift transformer load condition

The invention relates to a step voltage calculation method under a symmetrical double-core phase shift transformer load condition. The calculation method comprises a step of determining rated current IN and series transformer power supply side voltage Us according to the rated pass capacitance S and the rated voltage UN of a phase-shifting transformer, a step of determining series connection transformer load side voltage UL according to the rated current IN,overall leakage impedance Z and power factor angle phi, and combined with the phase shift angle in an empty load, determining series connection transformer power supply side current Is and load side current IL, a step of determining excitation transformer primary side current IE1 and second side current IE2 according to the series connection transformer power supply side current Is and the load side current IL, a step of determining excitation transformer primary side voltage UE1 according to the series transformer power supply side voltage Us, the load side voltage UL excitation transformer primary side current IE1, and secondary side current IE2, and thus determining excitation transformer secondary side voltage UE2, and a step of determining a load tap-changer level voltage Ustep according to the excitation transformer secondary side voltage UE2. The invention provides a method for calculating overall leakage impedance Zn and a phase shift angle an in an empty load in a selected n gear of the phase shift transformer.

Owner:CHINA ELECTRIC POWER RES INST +3

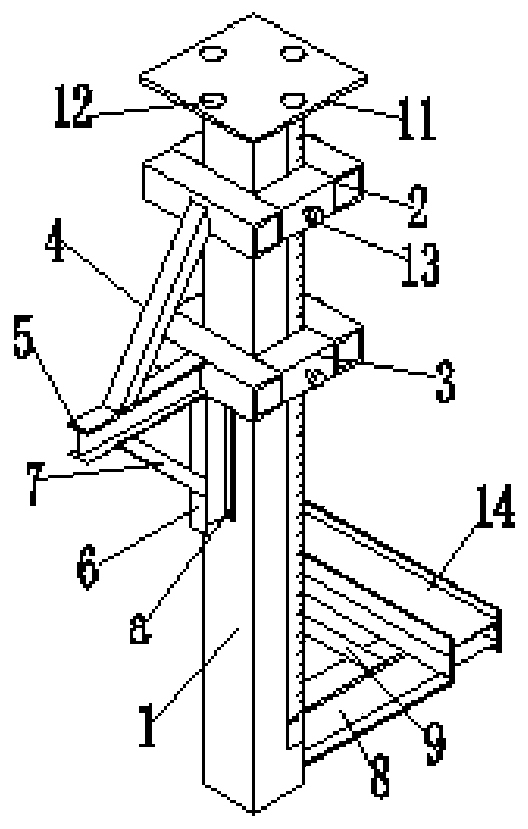

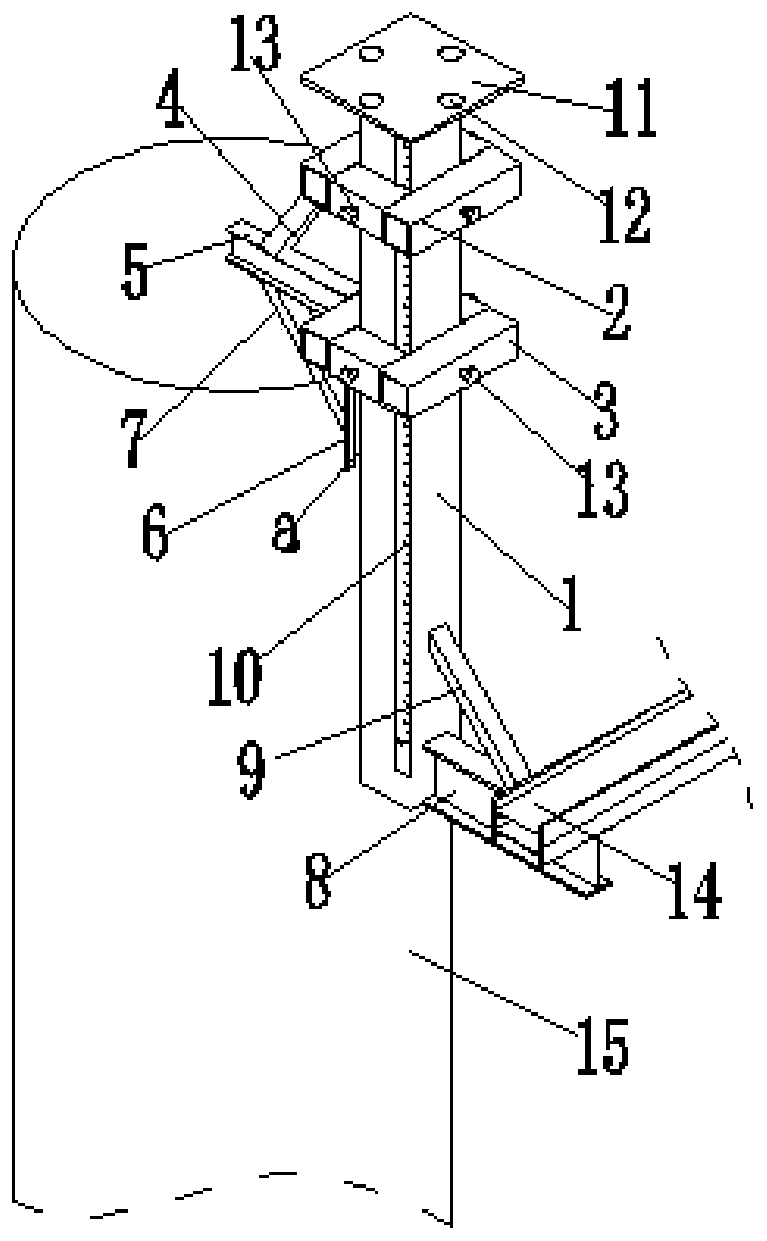

Recyclable temporary bracket for installing steel sheet pile cofferdam purlin

PendingCN110318408ADetermine the sizeChange the construction processFoundation engineeringPurlinArchitectural engineering

Disclosed is a recyclable temporary bracket for installing a steel sheet pile cofferdam purlin. The recyclable temporary bracket for installing the steel sheet pile cofferdam purlin is characterized in that a bolt is used for installing an upper ring and a lower ring on a stand column provided with a graduated scale; a first transverse rod is welded to the side wall of the lower ring, and the twoends of a first inclined rod are welded to the top surface of the left end of a first transverse rod and one lateral side of the upper ring correspondingly, so that the upper ring and the lower ring constitute a triangular bracket structure; the upper end of a baffle block is welded to the lower bottom surface of the first transverse rod, the two ends of a second inclined rod are welded to the left end of the first transverse rod and the bottom end of the baffle block correspondingly, and a groove is formed between the baffle block and the stand column; the two ends of a third inclined rod arewelded to the right end portion of the second transverse rod and the stand column correspondingly, and a third triangular supporting seat structure is formed; one end of the purlin is welded to the top surface of the right end of the second transverse rod; the groove between the baffle block and the stand column in the temporary bracket is clamped on the cylinder wall of a steel protective cylinder; and the recyclable temporary bracket for installing the steel sheet pile cofferdam purlin is formed through the structure.

Owner:NO 1 ENG CO LTD OF CR11BG +1

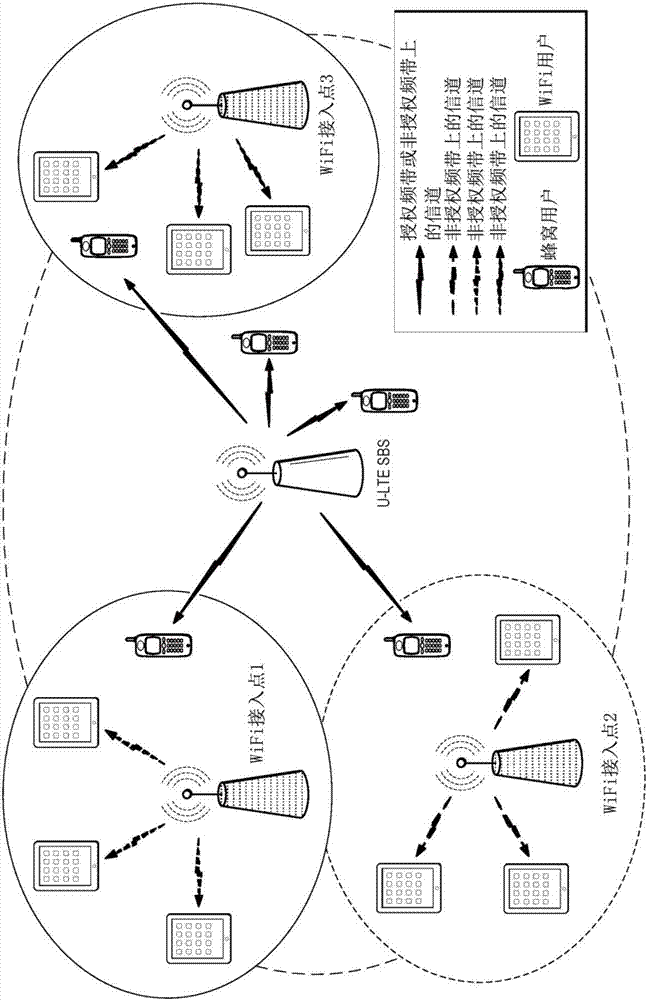

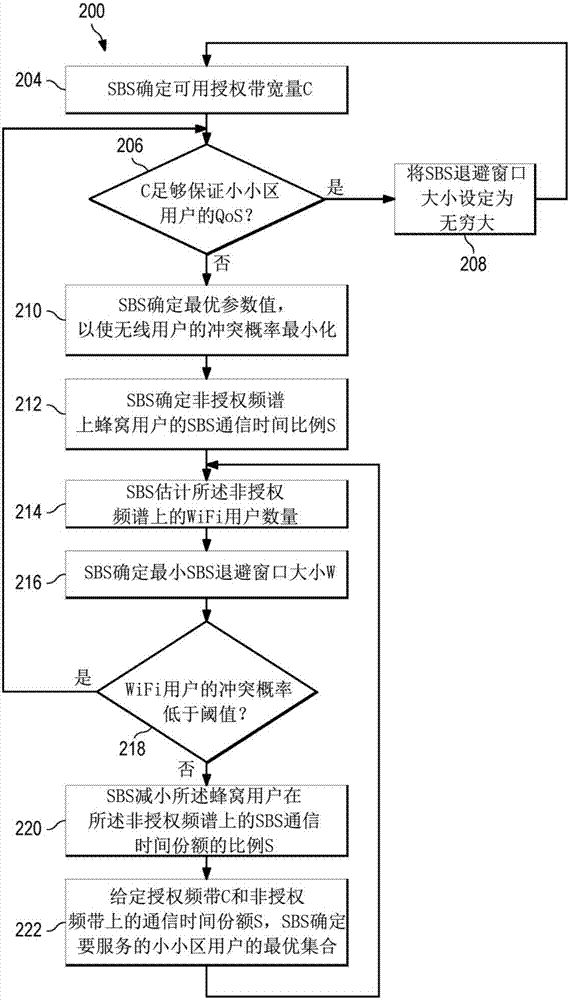

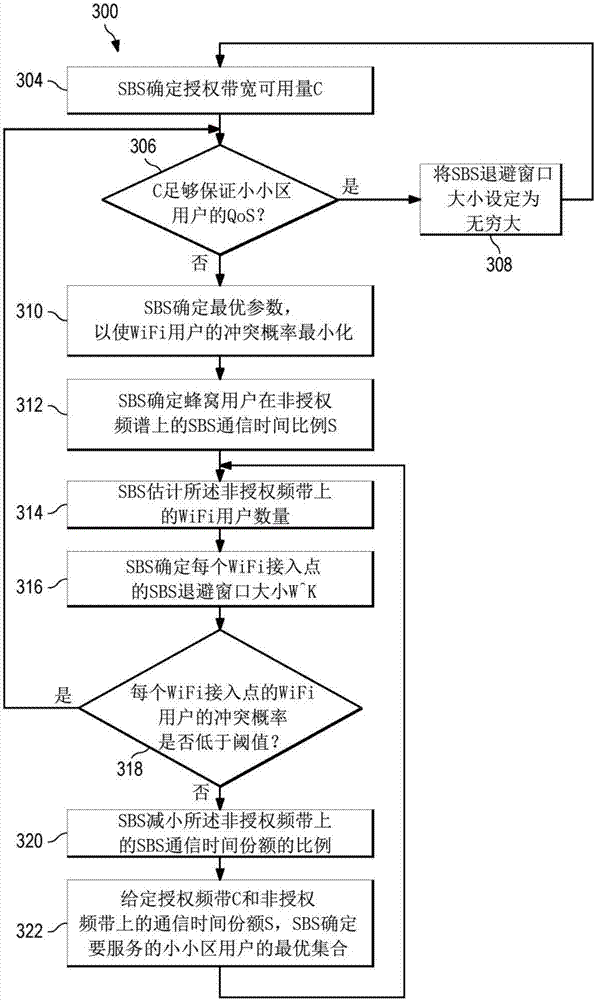

Method and system for adaptive channel access in unlicensed spectrum

ActiveCN107432039ADetermine the sizeMinimize the probability of conflictAssess restrictionNetwork topologiesQuality of serviceSmall cell

The invention discloses a method and system for adaptive channel access in unlicensed spectrum. A method and a device for adaptive channel access are disclosed. In an embodiment includes adaptively adjusting, by a small base station (SBS), access parameters for small cells to ensure quality of service (QoS) to mobile wireless users while minimizing collision probability for WiFi users.

Owner:HUAWEI TECH CO LTD

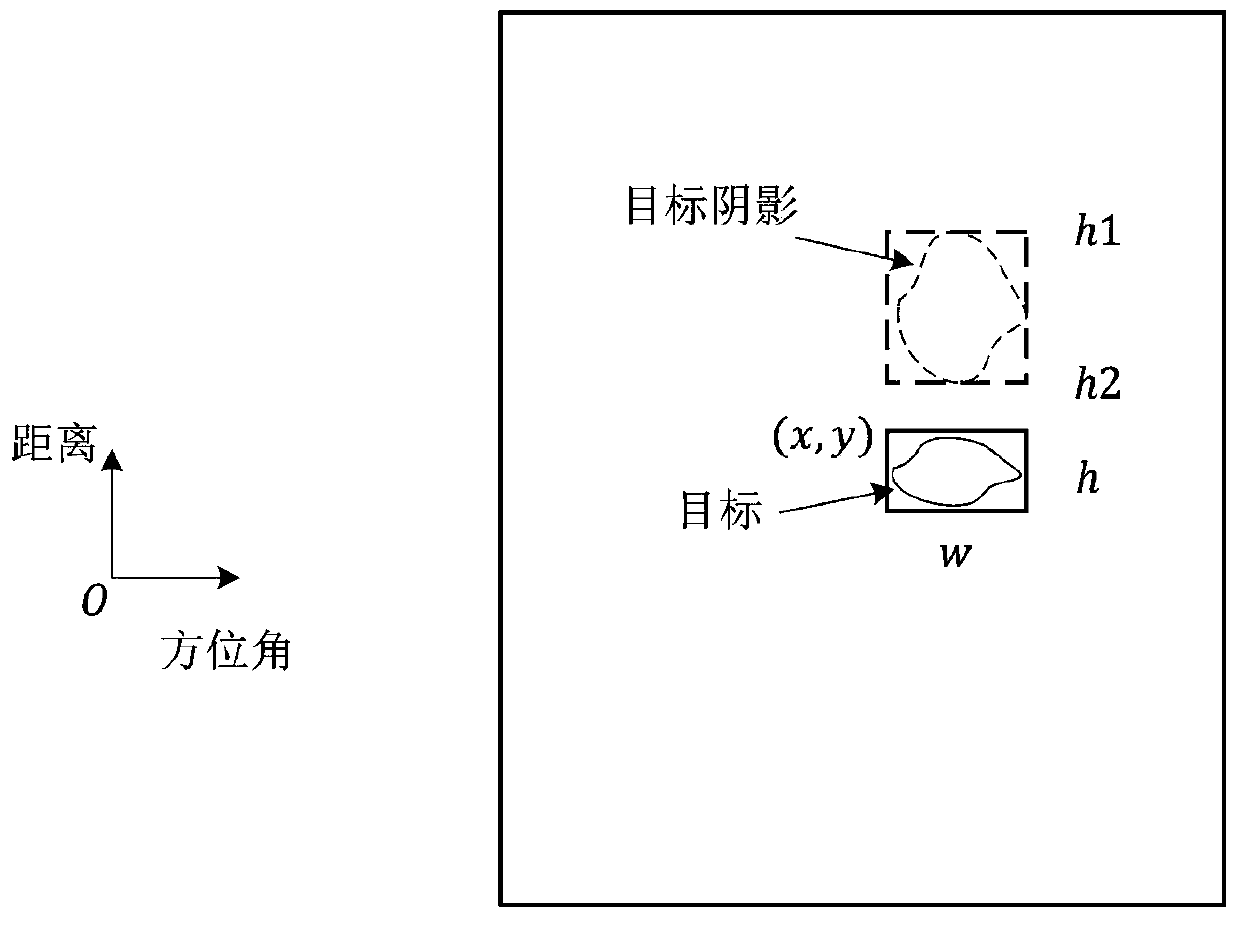

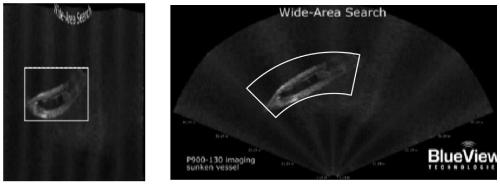

Forward-looking sonar target detection marking method capable of simultaneously marking shadows

ActiveCN111444777ACause wasteNo change in sizeCharacter and pattern recognitionComputer graphics (images)Radiology

The invention provides a forward-looking sonar target detection marking method capable of simultaneously marking shadows, belongs to the field of forward-looking sonar image target detection, and aimsto mark the shadows of a target while marking the target. According to an existing forward-looking sonar target detection marking method, only the target is marked, for the forward-looking sonar image, the shadow of the target contains the shape characteristics of the target, the shadow of the target is marked in the marking process, and richer information can be provided for a detector. For thenewly proposed mark box, evaluation needs to be carried out by two parts of a target and a shadow, and a target detection frame uses the existing intersection-to-parallel ratio IOU evaluation; for a shadow detection frame, a plurality of position relations may occur between the shadow and the target, the invention provides an improved shadow key point similarity OKSS to evaluate the regression precision of the shadow detection frame.

Owner:HARBIN ENG UNIV

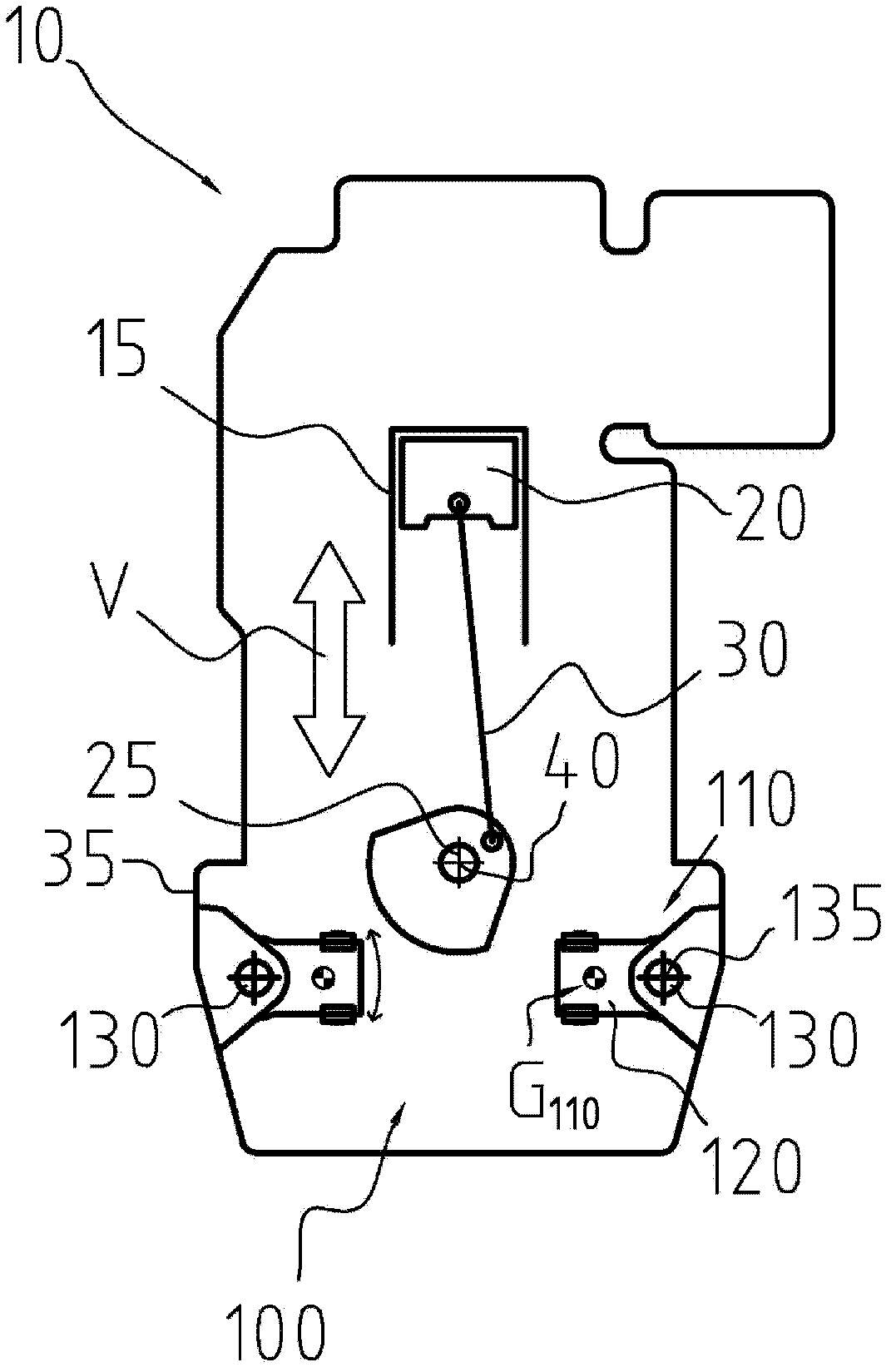

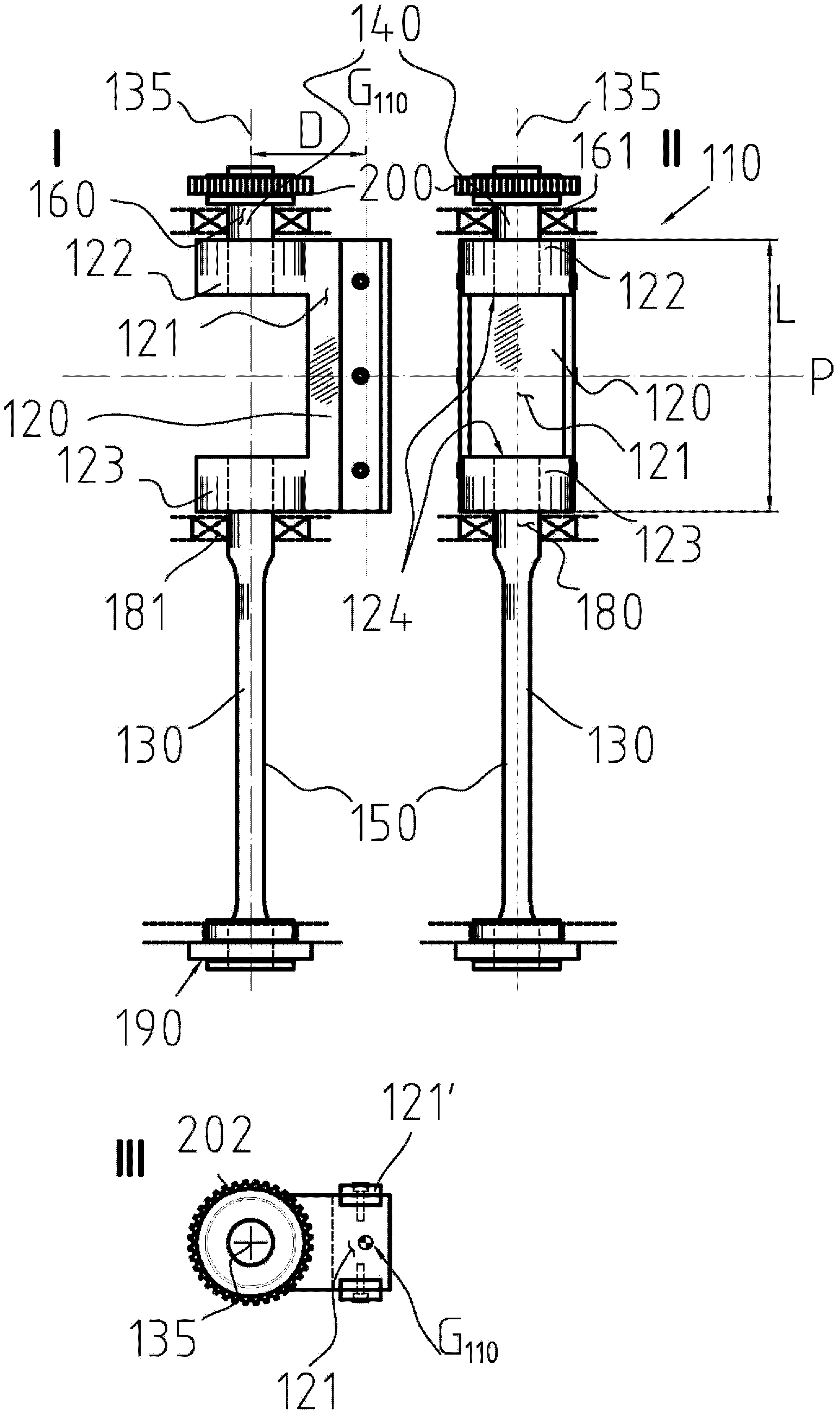

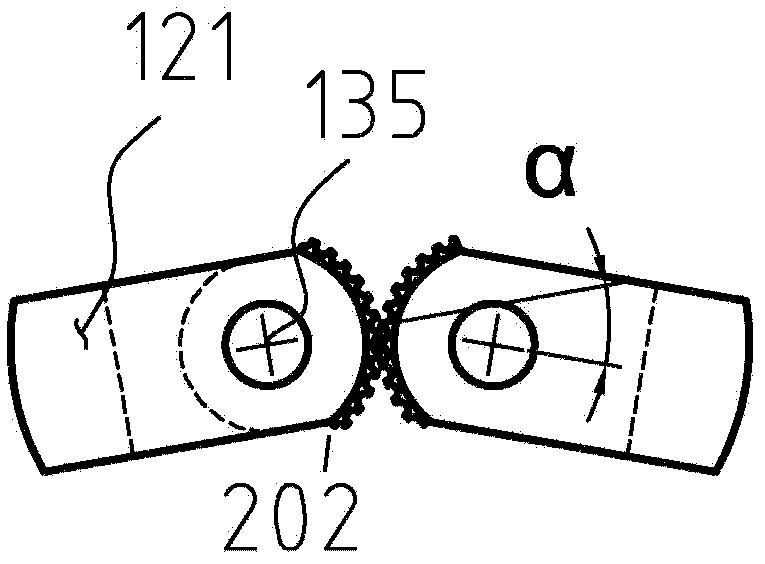

Arrangement for and method of attenuating the vibration of a piston engine and a piston engine

ActiveCN102326012AReduce vibrationDetermine the sizeInertia force compensationSpringsRotational axisRest position

The invention relates to an arrangement for attenuating the vibration of a piston engine comprising a tuned mass damper (110) having at least one mass element (120) and at least one spring element (130). The mass element is rotationally supported so that the rotational axis is set off from the axis of the center of gravity of the mass element (120) and the at least one spring element (130) is arranged to the mass element (120), driving the mass element to a rotational rest position of the tuned mass damper (110).

Owner:WARTSILA FINLAND OY

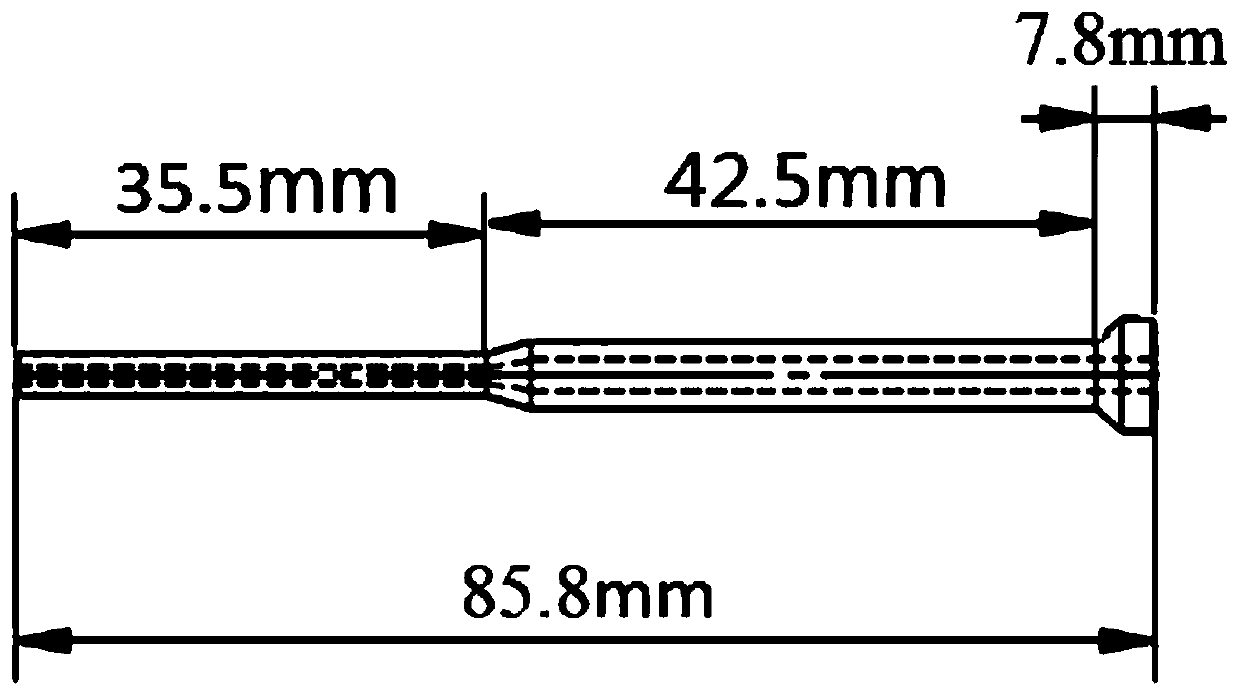

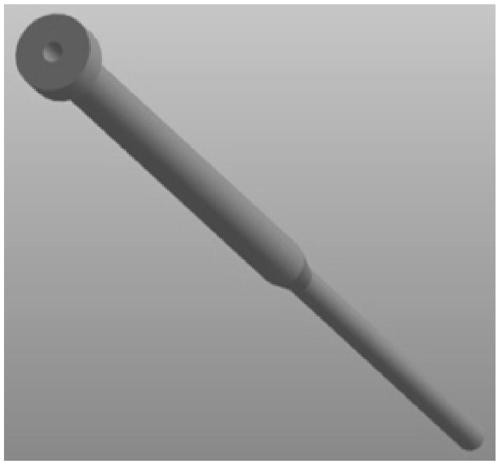

Machining method of specially-shaped titanium alloy needle tubes

The invention discloses a machining method of specially-shaped titanium alloy needle tubes. The method includes the following steps that 1, titanium alloy wires are cut sequentially, two ends are flattened, and cylindrical rods are obtained; 2, deep holes are drilled in the centers of the end surfaces of the cylindrical rods, and thick-wall tubes are obtained; 3, the outer diameters of the thick-wall tubes are machined; 4, the thick-wall tubes with the outer diameters machined are forged rotationally, and specially-shaped tube crude products are obtained; 5, fine grinding, rough polishing andfine polishing are performed on the specially-shaped tube crude products sequentially; 6, margins of the specially-shaped tube crude products after fine polishing are removed; and 7, the specially-shaped tube crude products after margin removal are chamfered, and the specially-shaped titanium alloy needle tubes are obtained. The specially-shaped titanium alloy needle tubes prepared with the methodare high in strength and hardness, light in mass, excellent in corrosion resistance, smooth in liquid flow and high in biocompatibility with living bodies, cross-infection phenomena during testing are prevented, the sample transfer precision requirements are met, the service life of the needle tubes is prolonged, the sample injection effect during injection is improved, and the needle tubes can be widely applied to various major instruments.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for building continuous efficient artificial seaweed cultivation system

InactiveCN106465677ALarge biomassPersistentClimate change adaptationCultivating equipmentsGrowth coefficientSeaweed food

The invention relates to the technical field of seaweed cultivation, and discloses a method for building a continuous efficient artificial seaweed cultivation system. The method comprises the steps of establishing the continuous efficient artificial seaweed cultivation system, determining the initial cultivation input amount W'0 of the system, evaluating the harvesting amount, determining the culture period, and determining the size of each cultivation tank at each stage. The cultivation tanks are used in a serial connection way and regarded as an integral cultivation system, the maximum biomass can be obtained in a limited space, the harvesting amount is continuous, and the harvest period is greatly shortened. The growth period, the growth coefficient R and the relative growth rate mu of the seaweeds can be artificially controlled according to the growth state of the seaweeds. According to the size of the last stage of the cultivation tank in the cultivation system, the growth coefficient R and the number of the cultivation tanks, the size of the cultivation tanks in other stages in the system can be determined. According to a regular formula of the growing periodicity of the cultivation objects, the initial input amount, the harvesting time and the harvesting amount are set.

Owner:杭州旭文海洋科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com