Patents

Literature

121results about How to "Uniform air gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for wind turbine air gap control

Methods and apparatus for assembling a wind turbine generator are provided. The wind turbine generator includes a core and a plurality of stator windings circumferentially spaced about a generator longitudinal axis, a rotor rotatable about the generator longitudinal axis wherein the rotor includes a plurality of magnetic elements coupled to a radially outer periphery of the rotor such that an airgap is defined between the stator windings and the magnetic elements and the plurality of magnetic elements including a radially inner periphery having a first diameter. The wind turbine generator also includes a bearing including a first member in rotatable engagement with a radially inner second member, the first member including a radially outer periphery, a diameter of the radially outer periphery of the first member being substantially equal to the first diameter, the rotor coupled to the stator through the bearing such that a substantially uniform airgap is maintained.

Owner:GENERAL ELECTRIC CO

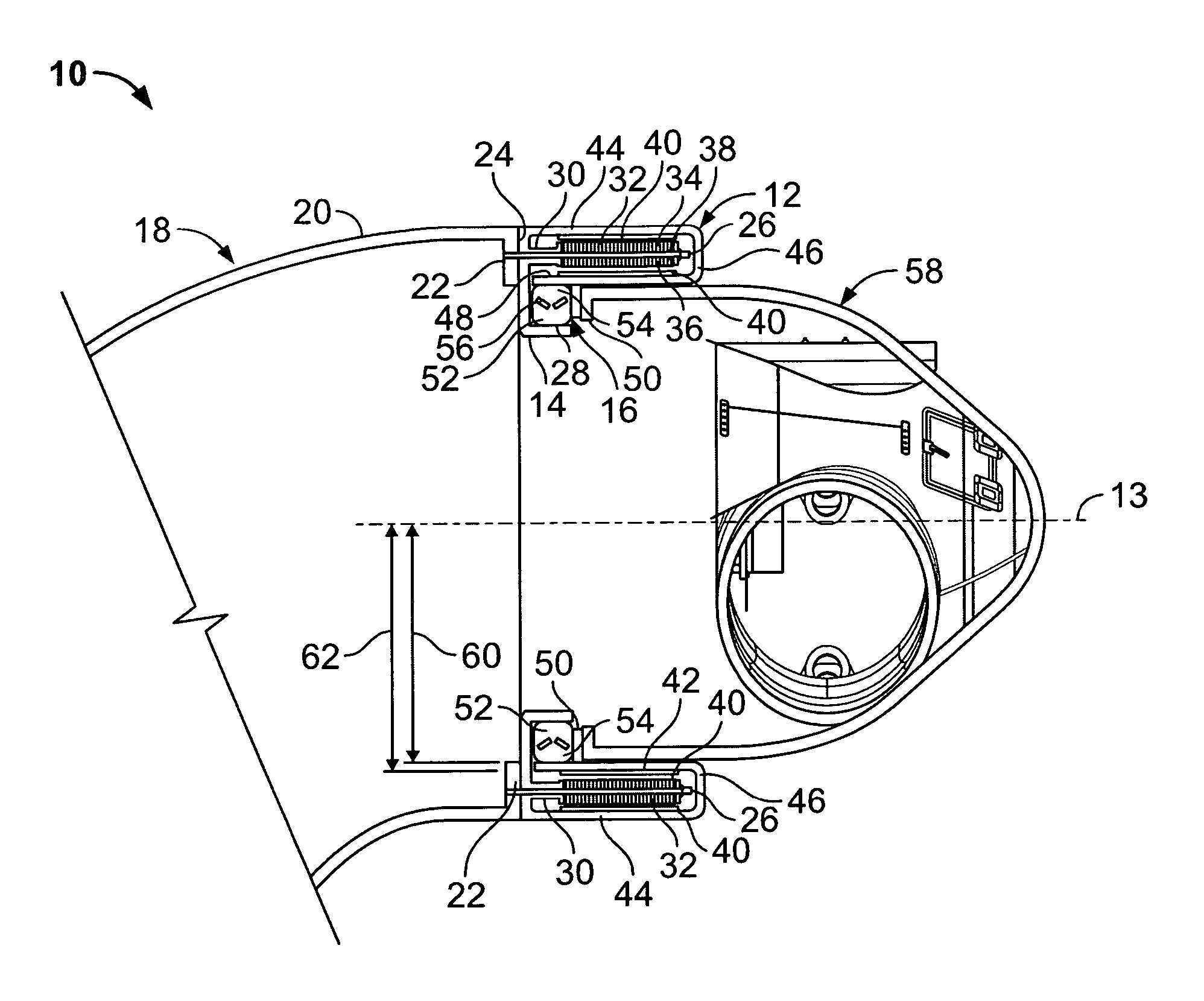

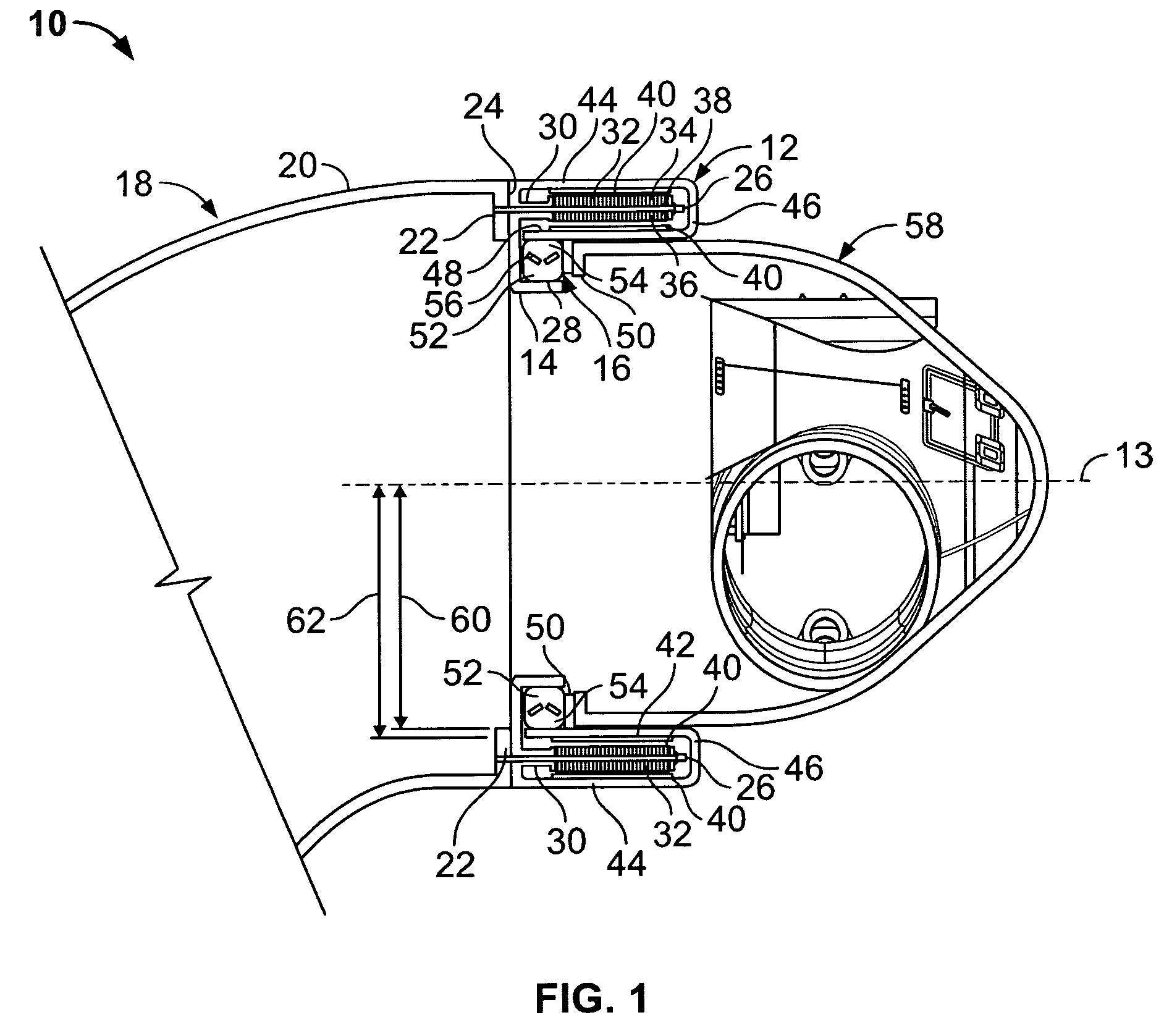

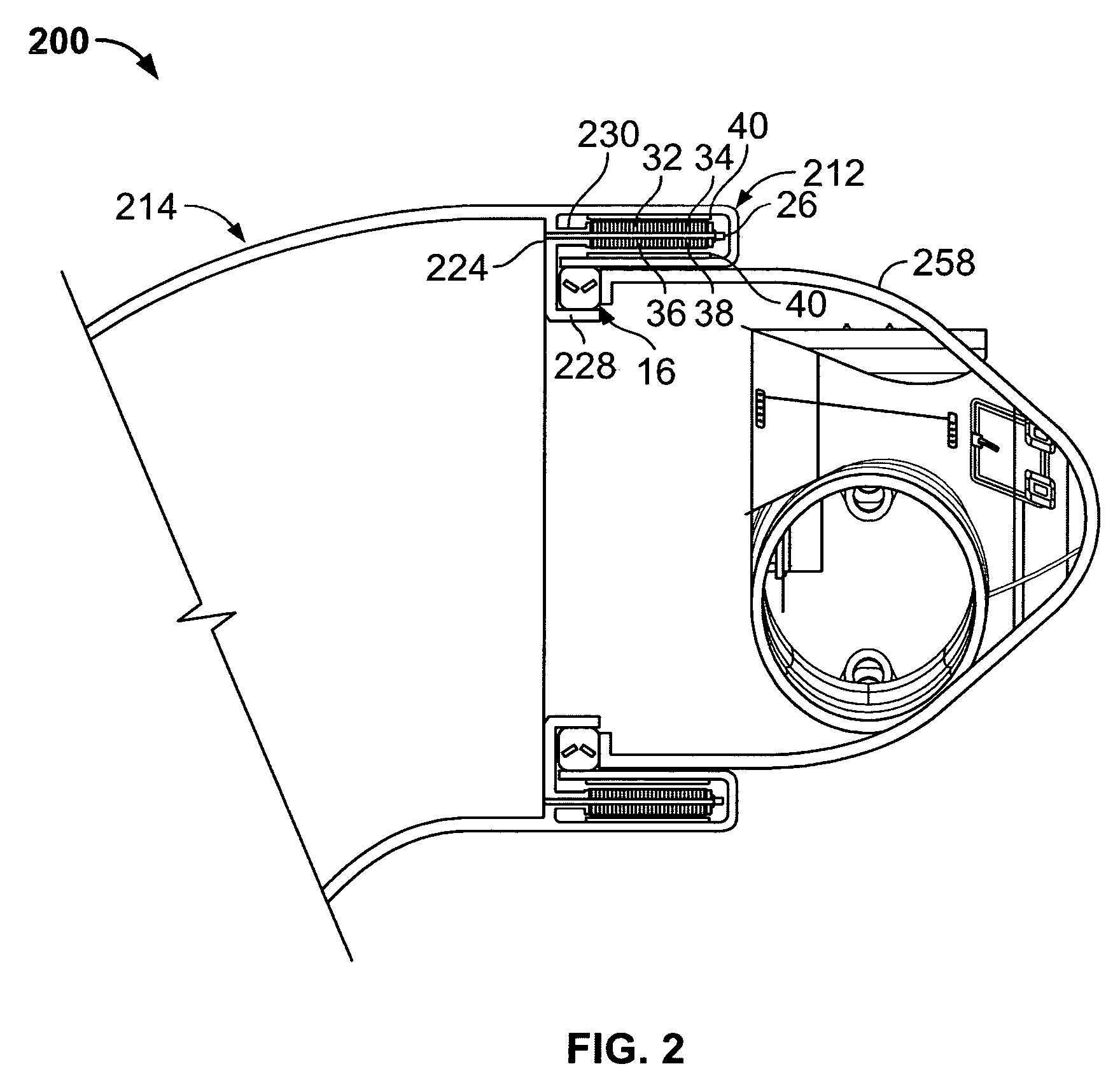

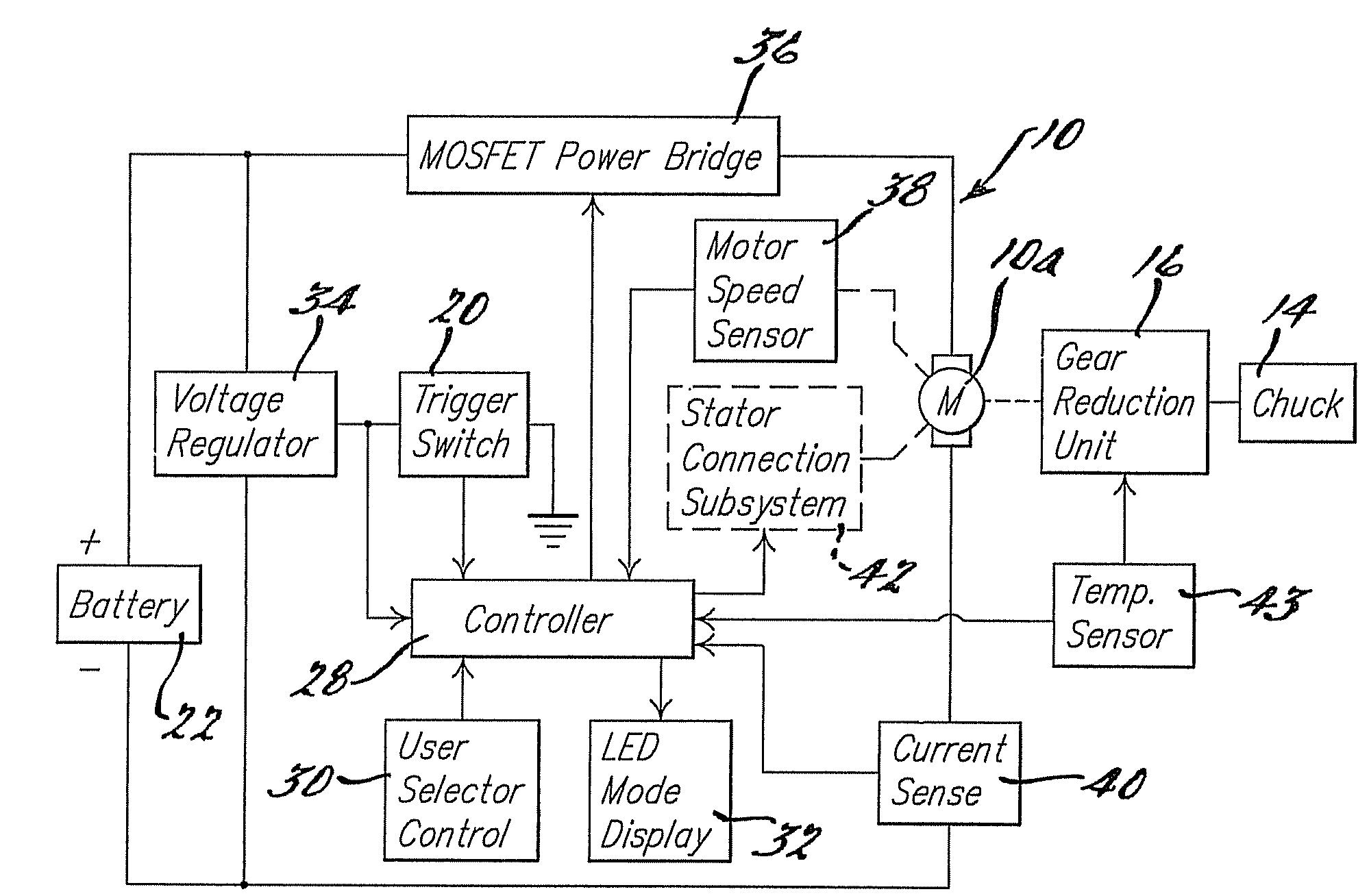

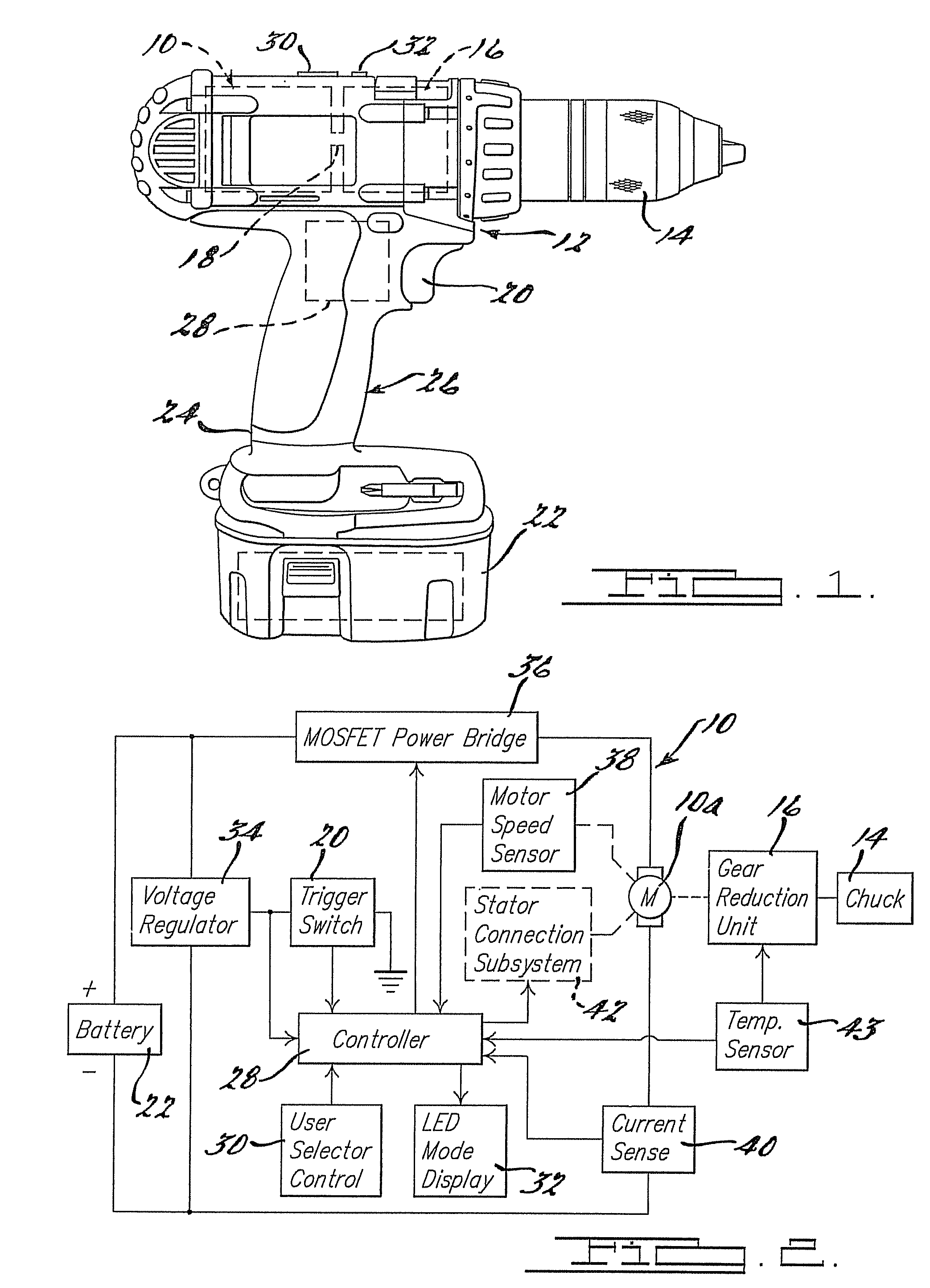

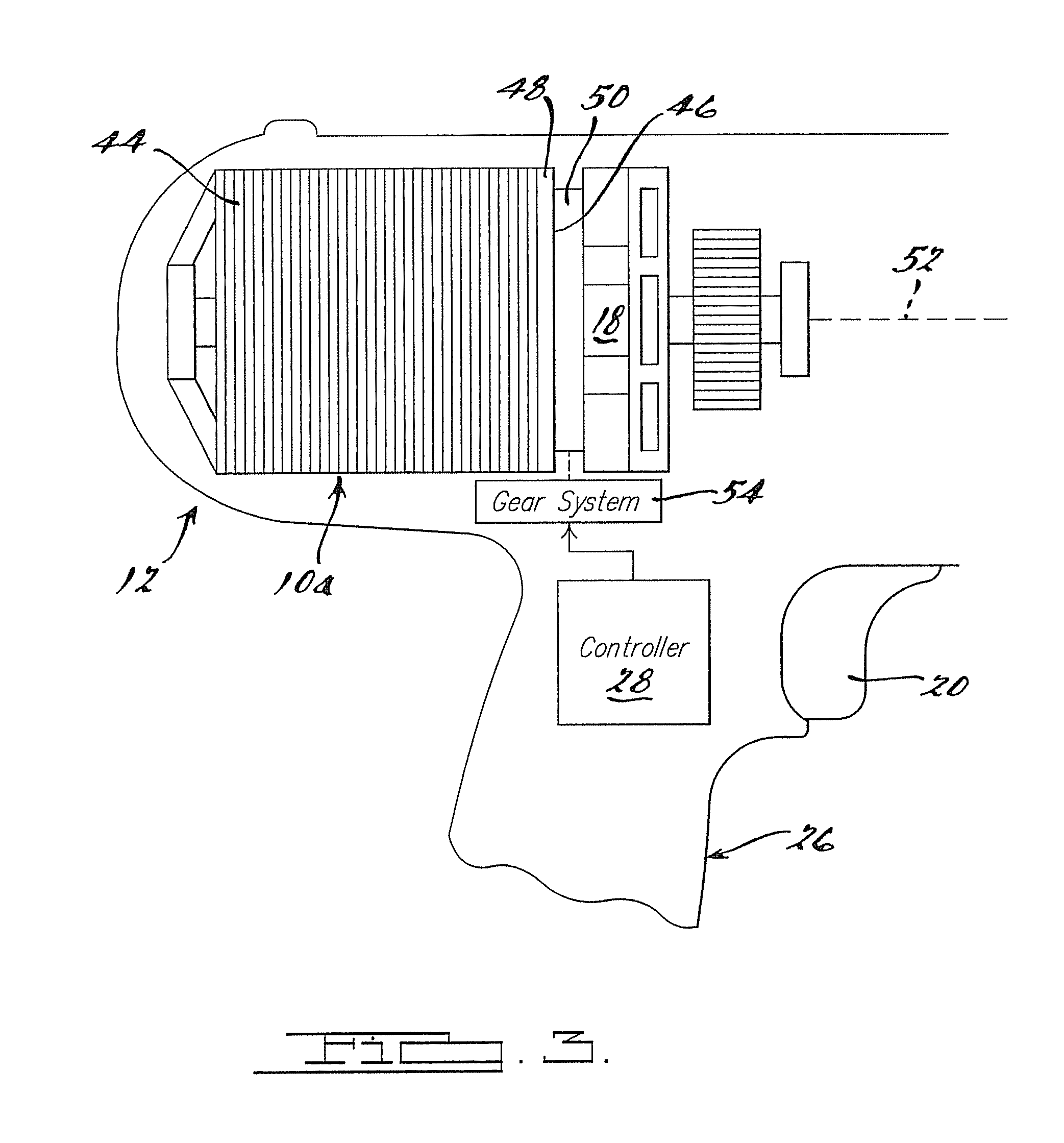

Electronically commutated motor and control system

InactiveUS7602137B2Uniform air gapIncrease outputSingle-phase induction motor startersAC motor controlPower toolThree phase windings

A power tool having an electronically commutated DC motor capable of providing various operating modes ranging from a maximum efficiency operating mode to a maximum power operating mode. The motor has a rotor having permanent magnets mounted in recesses in a back iron of the rotor. In one embodiment the motor has three phase windings, each having at least a pair of coils. The phase windings are connected in either a delta or a wye configuration via electromechanical or electronic switching components, or a combination of both, by a controller within the tool. The coils in each phase winding can also be switched between series and parallel configurations to configure the motor to provide its various operating modes. In one embodiment a dual wound motor is disclosed that has its phase coils dynamically or statically switchable between series and parallel configurations.

Owner:BLACK & DECKER INC

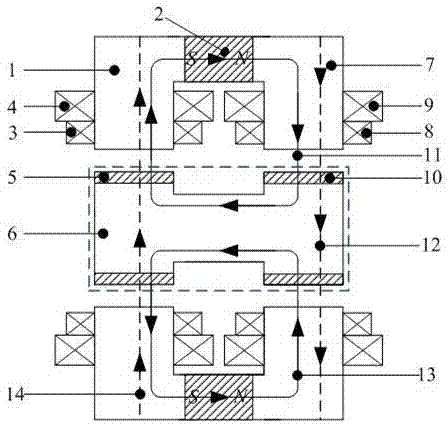

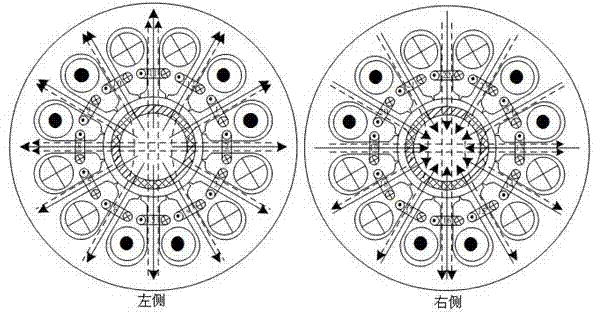

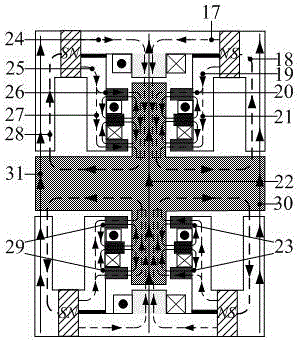

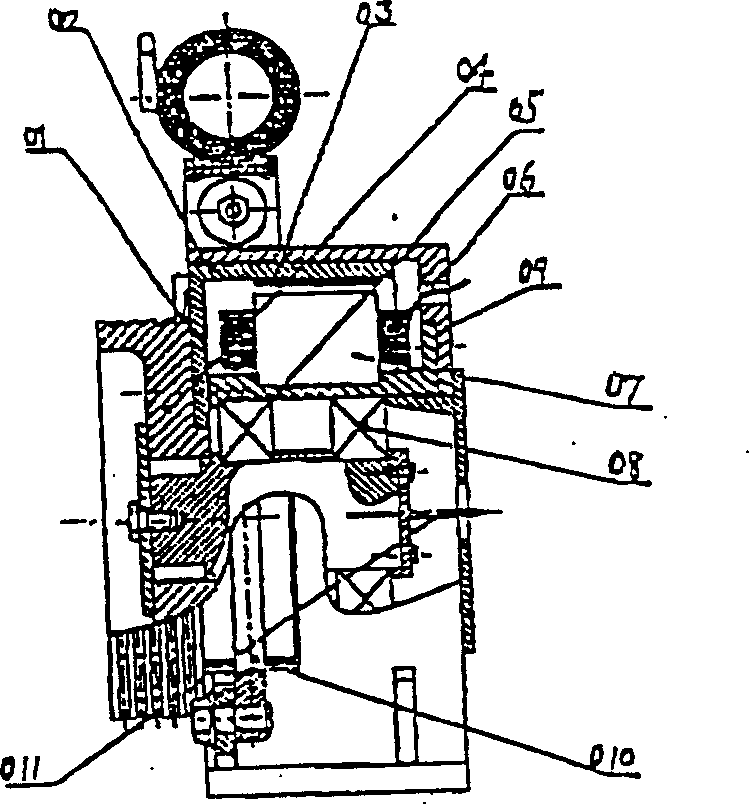

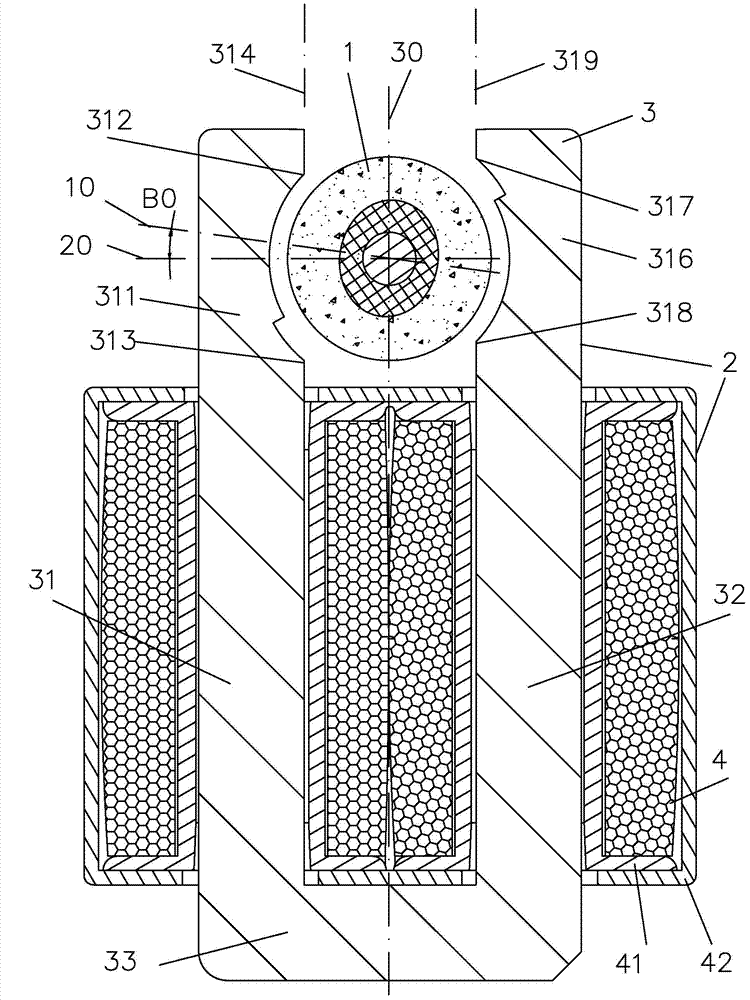

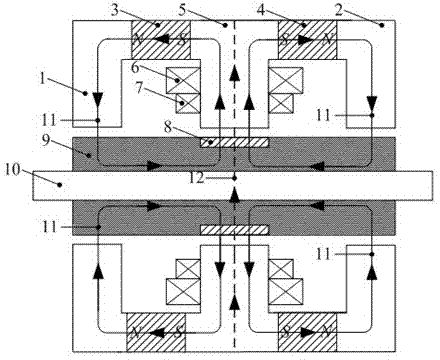

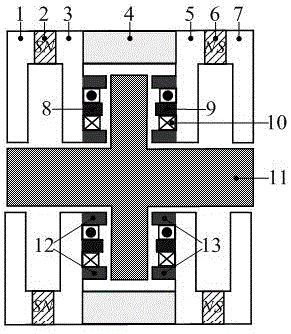

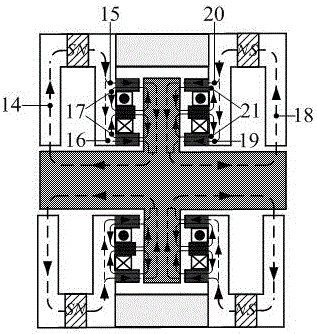

Stator permanent magnet biased permanent magnet type bearingless motor

ActiveCN103683779AUniform air gapLarge radial suspension forceMagnetic circuit stationary partsMagnetic holding devicesElectric machineEngineering

The invention discloses a stator permanent magnet biased permanent magnet type bearingless motor which comprises a motor shell. A rotor and a stator are arranged in the motor shell, and the stator comprises a left stator core and a right stator core, an axial magnetized annular stator permanent magnet is arranged between the left stator core and the right stator core, a torque winding and a suspension winding are arranged in stator slots of the left stator core, a torque winding and a suspension winding are arranged in stator slots of the right stator core. The rotor comprises a rotor core, and a radial magnetized left annular rotor permanent magnet, a radial magnetized right annular rotor permanent magnet and a rotating shaft are respectively arranged on two sides of the rotor core. The stator permanent magnet biased permanent magnet type bearingless motor aims to overcome the shortcomings of an existing permanent magnet type bearingless motor, and the structure of the stator permanent magnet biased permanent magnet type bearingless motor is simple in control, realizes mutually independent suspension control and torque control, and can generate larger radial suspension force.

Owner:淮安市清江浦区市场监管综合服务中心

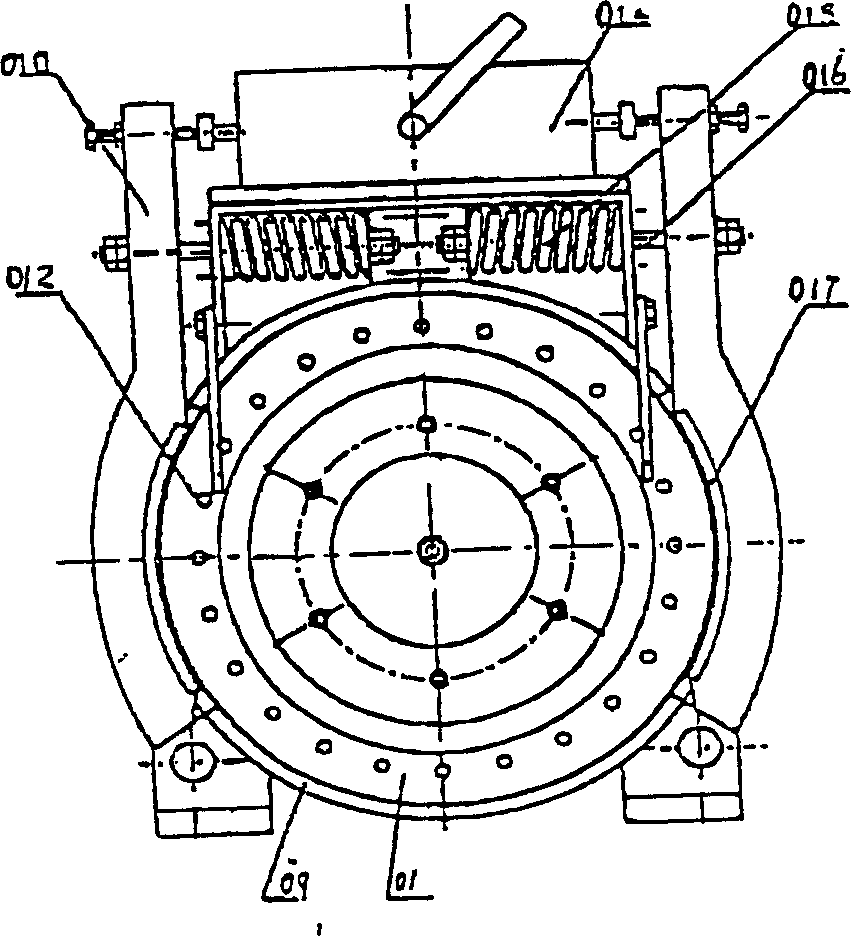

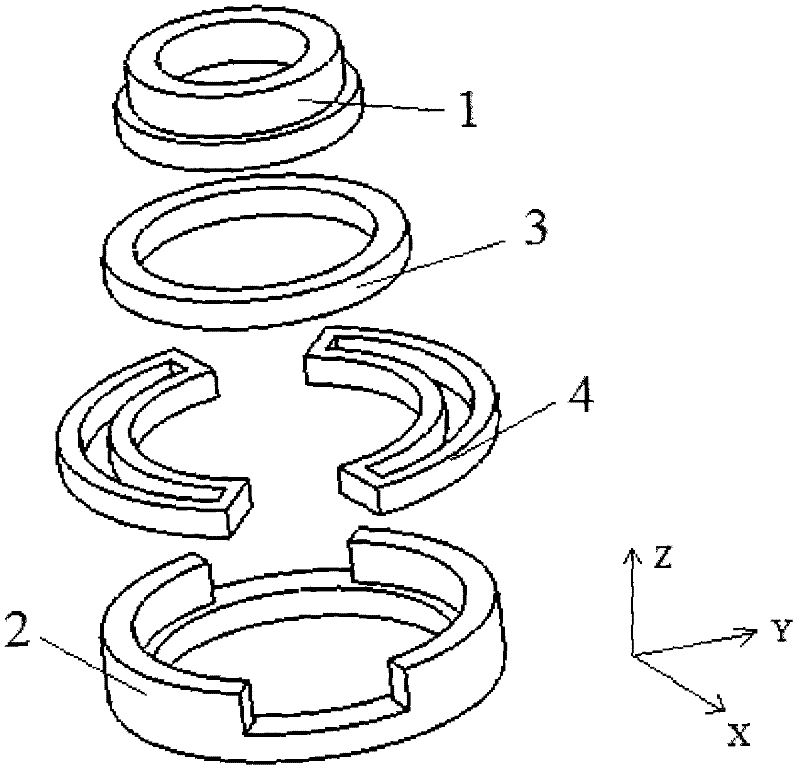

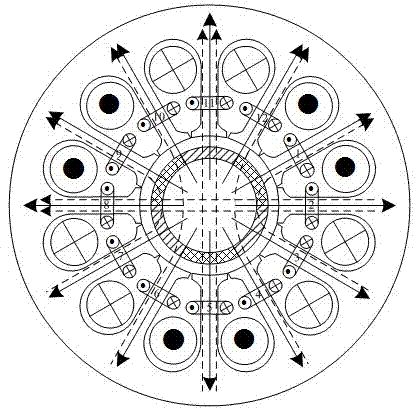

Permanent magnet biased five-degree-of-freedom integrated magnetic suspension supporting system

ActiveCN106050918AUniform air gapSuspension support is stableShaftsMagnetic bearingsSupporting systemMagnetic bearing

The invention discloses a permanent magnet biased five-degree-of-freedom integrated magnetic suspension supporting system. A stator comprises a left side radial magnetic bearing iron core, a right side radial magnetic bearing iron core, a left side annular permanent magnet, a right side annular permanent magnet, a left side axial control iron core and a right side axial control iron core; a radial control iron core is arranged between the left side annular permanent magnet and the right side annular permanent magnet; a radial control winding is wound on stator teeth; a right side magnetism dividing aluminum ring is arranged between the left side axial control iron core and the radial control iron core, and a left side magnetism dividing aluminum ring is arranged between the right side axial control iron core and the radial control iron core; a left side radial control winding is correspondingly wound on the left side radial magnetic bearing iron core in a stator groove, and a right side radial control winding is correspondingly wound on the right side radial magnetic bearing iron core in the stator groove; and the left side axial control iron core and the right side axial control iron core are each of an E-shaped structure, and axial control windings are correspondingly wound in the stator groove. The supporting system is small in axial length, high in critical rotating speed, simple in structure, easy to manufacture and assemble, and capable of generating larger axial and radial suspension force, and the axial control magnetic flux and the radial control magnetic flux do not pass through the permanent magnets.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

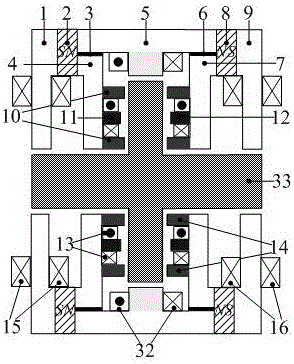

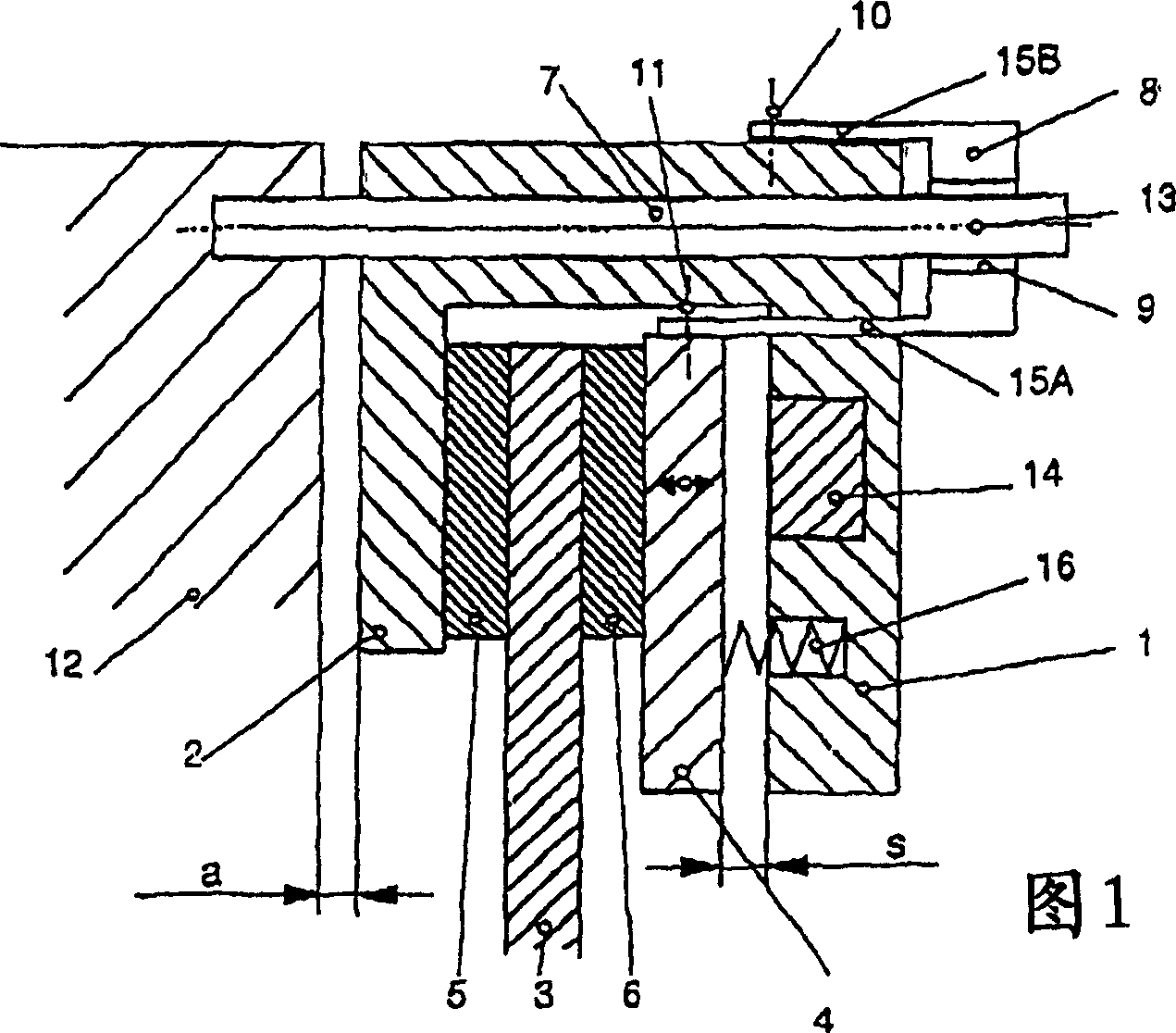

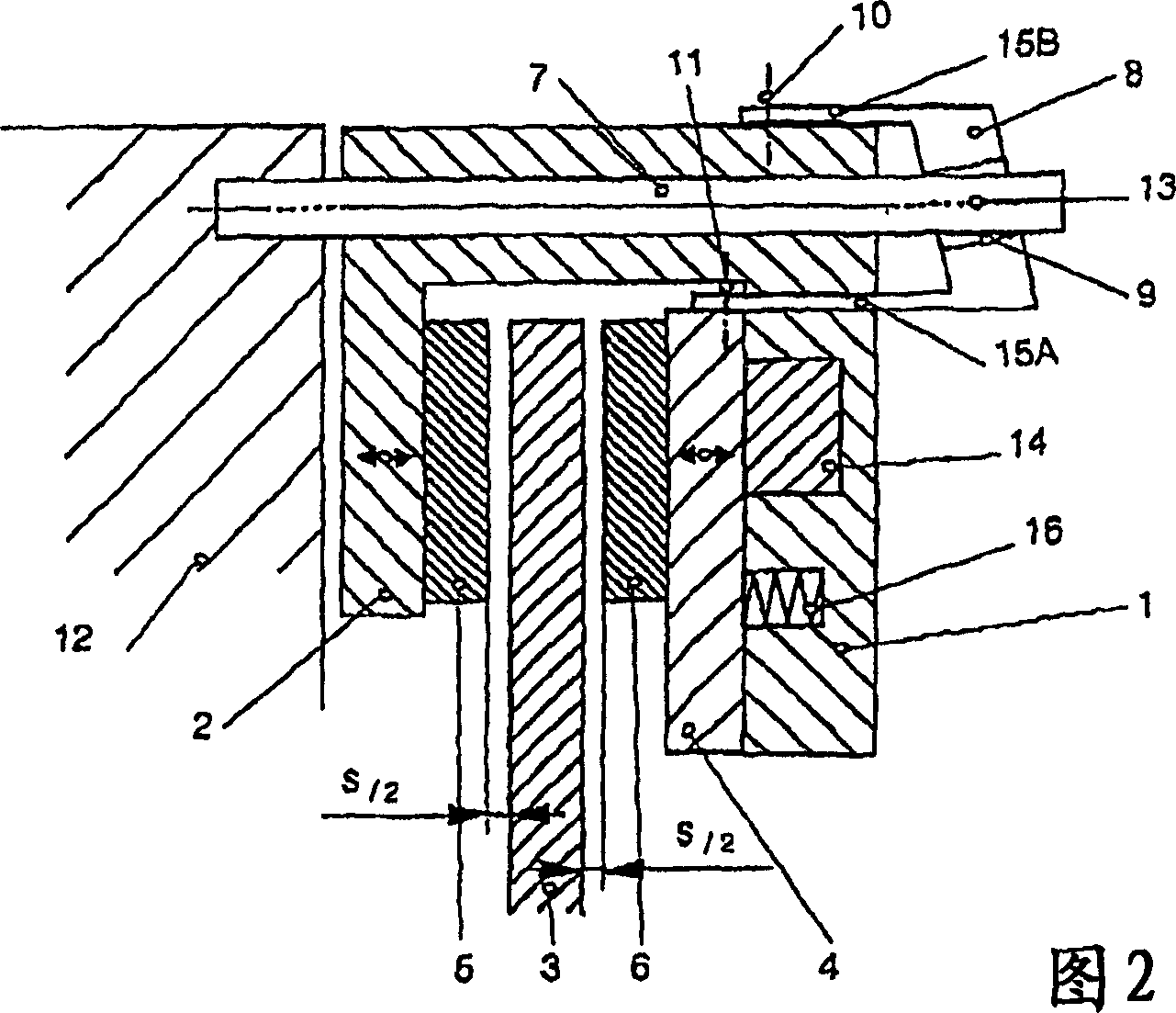

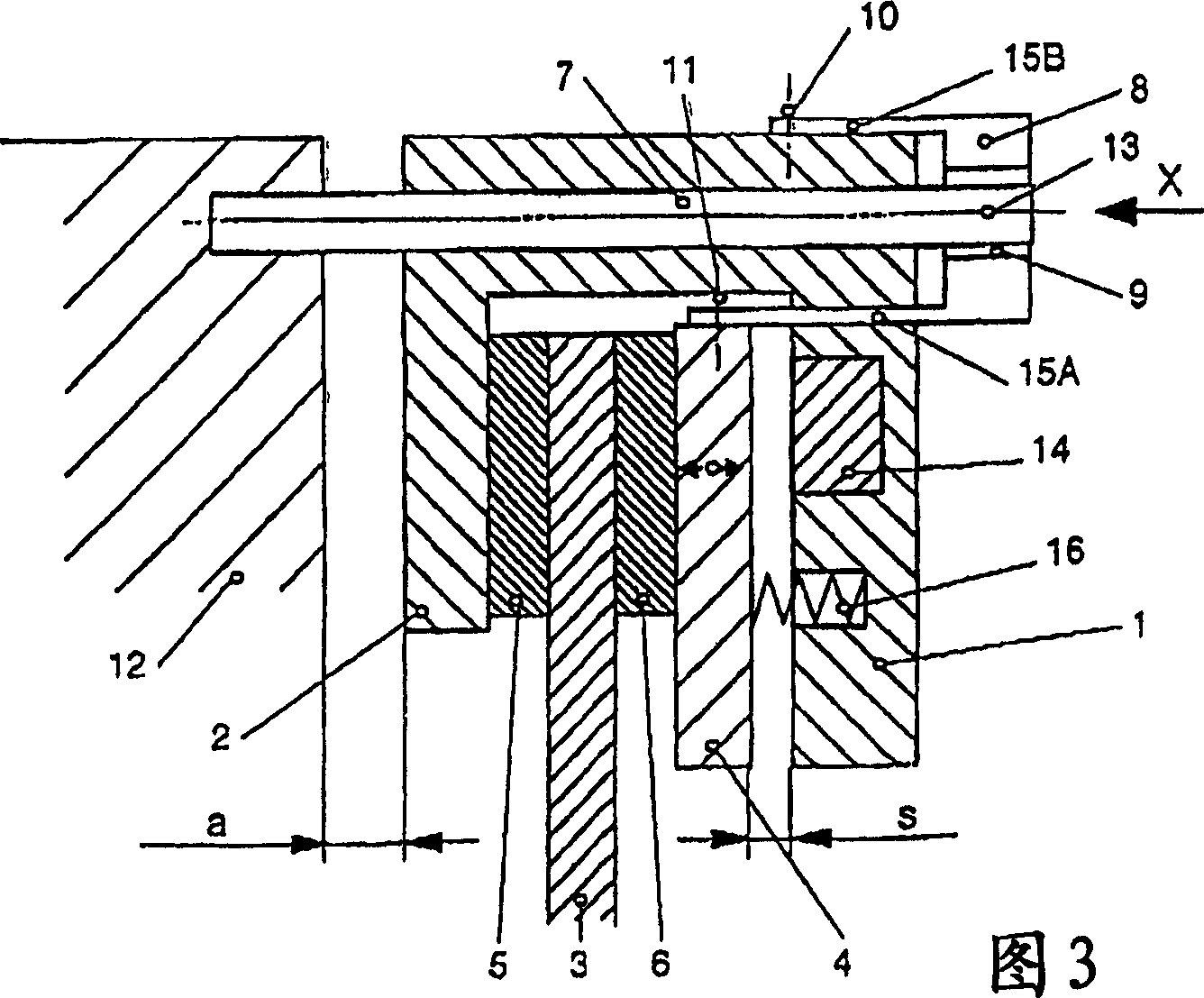

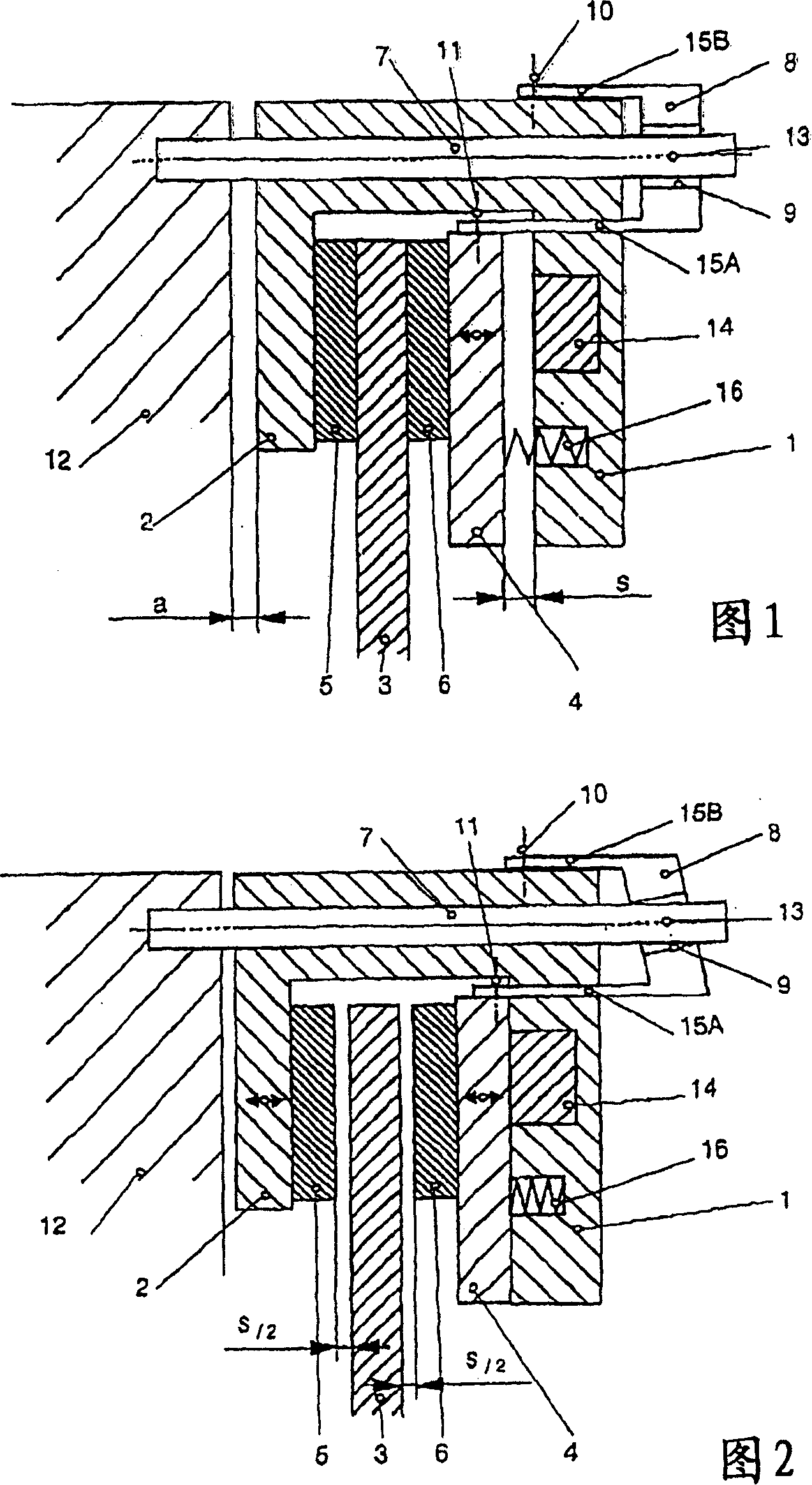

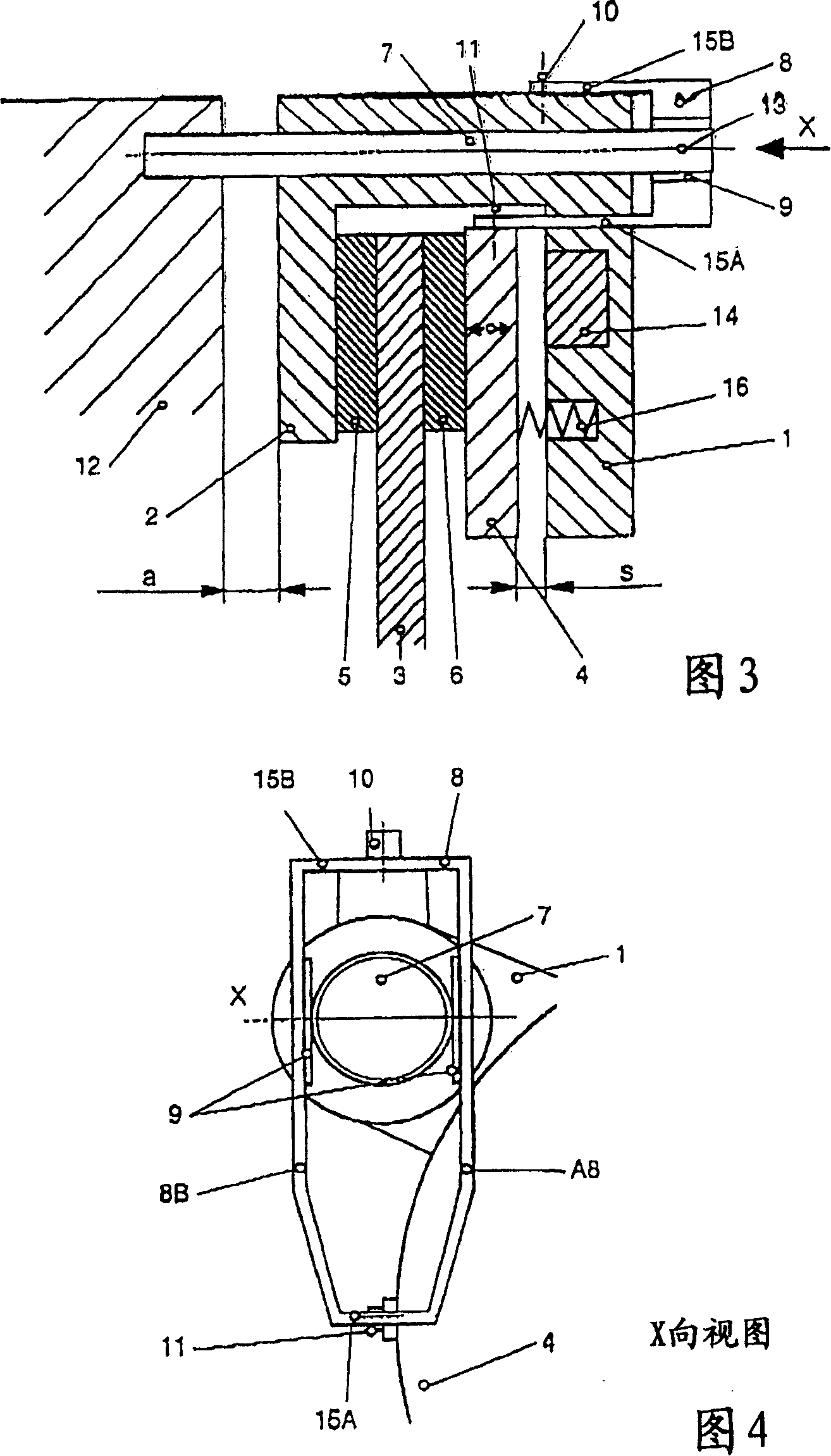

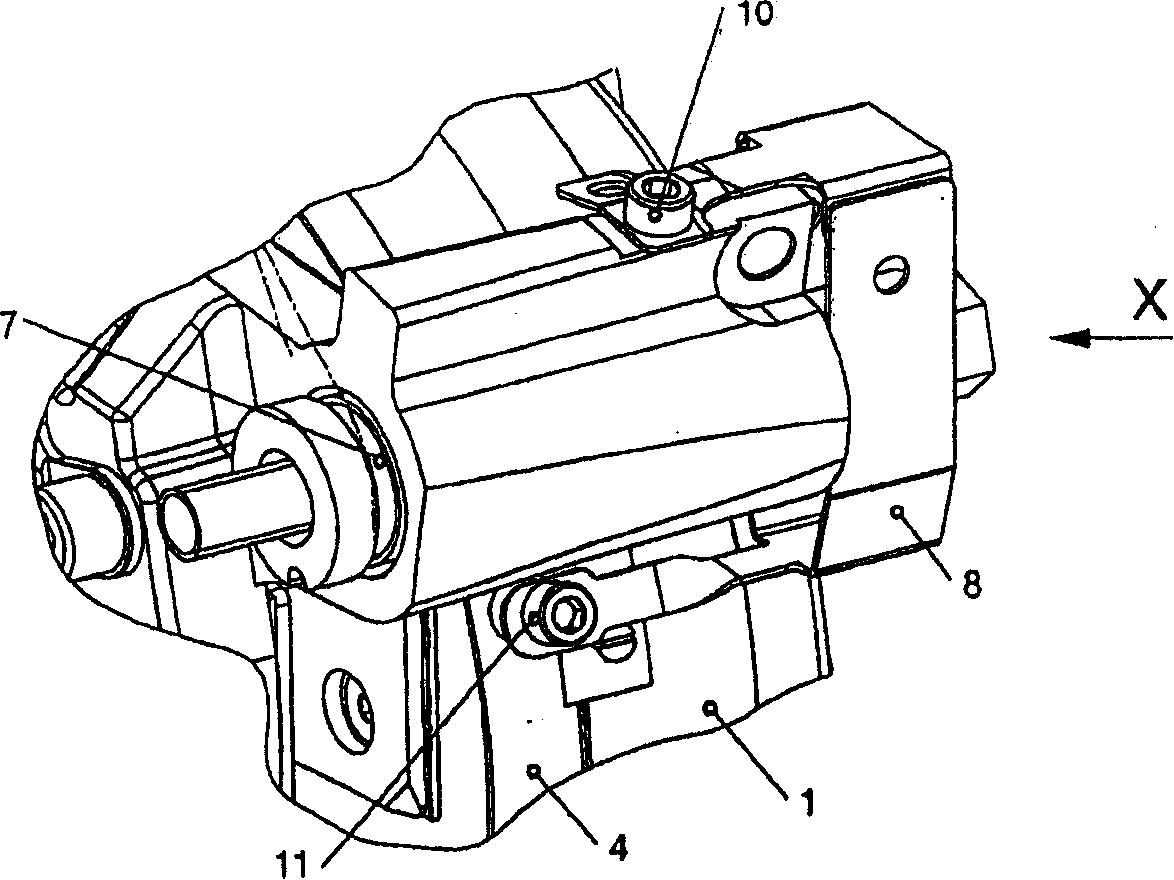

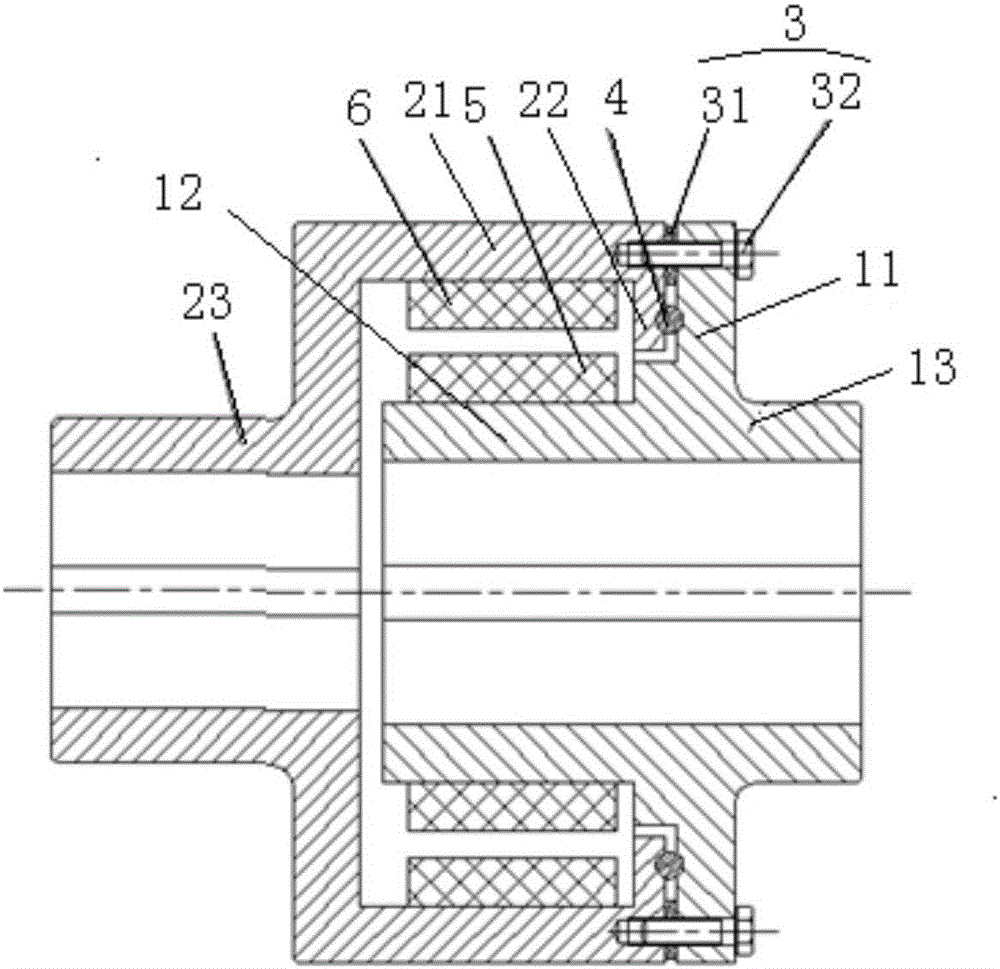

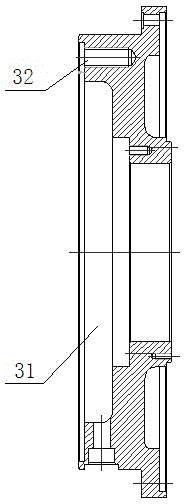

Calliper brake with disengaged position

ActiveCN1833117AUniform air gapPrevent slippageAxially engaging brakesSelf acting brakesEngineeringMechanical engineering

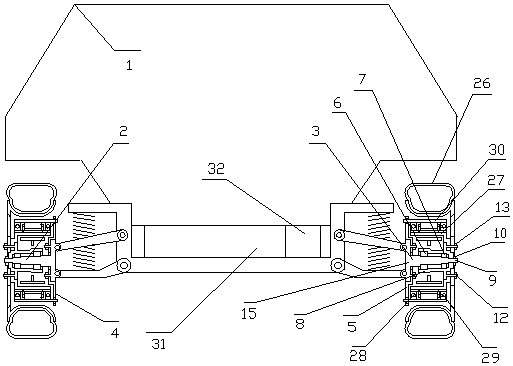

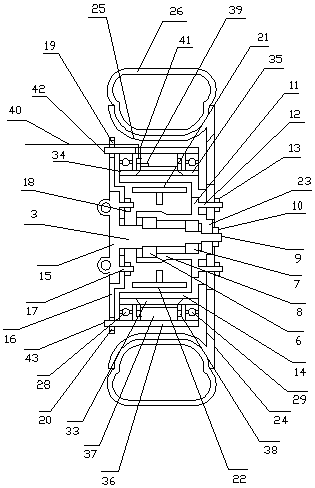

The invention relates to a calliper brake for a brake disc, in particular for elevator drives. Said brake comprises a brake body that is mounted on a fixed bolt (7) in a floating manner (1) and a brake calliper (2) that impinges on the brake disc (3) from the outer periphery of the latter, in addition to a solenoid (14) that is integrated into the brake body (1) to electromagnetically pull a spring-loaded armature disc (4) against the brake body (1). Said armature disc (4) and the section of the brake calliper (2) lying axially opposite are equipped with friction linings (5, 6) for engaging with the two end faces of the brake disc (3). To release or centre the calliper brake in relation to the brake disc at any time, a dual-arm rocker lever or bracket (8) is pivotally mounted on the fixed bolt, one limb (15B) of said lever or bracket being connected to the peripheral surface of the armature disc (4) and the other limb (15A) to the brake calliper, in such a way that the rocker lever or bracket (8) displaces the armature disc (4) when the brake is disengaged, simultaneously redirecting said movement into a displacement of the brake calliper (2) in the opposite direction, in order to obtain an air gap (s / 2) on both sides of the brake disc (3).

Owner:CHRISTIAN MAYR GMBH & CO KG

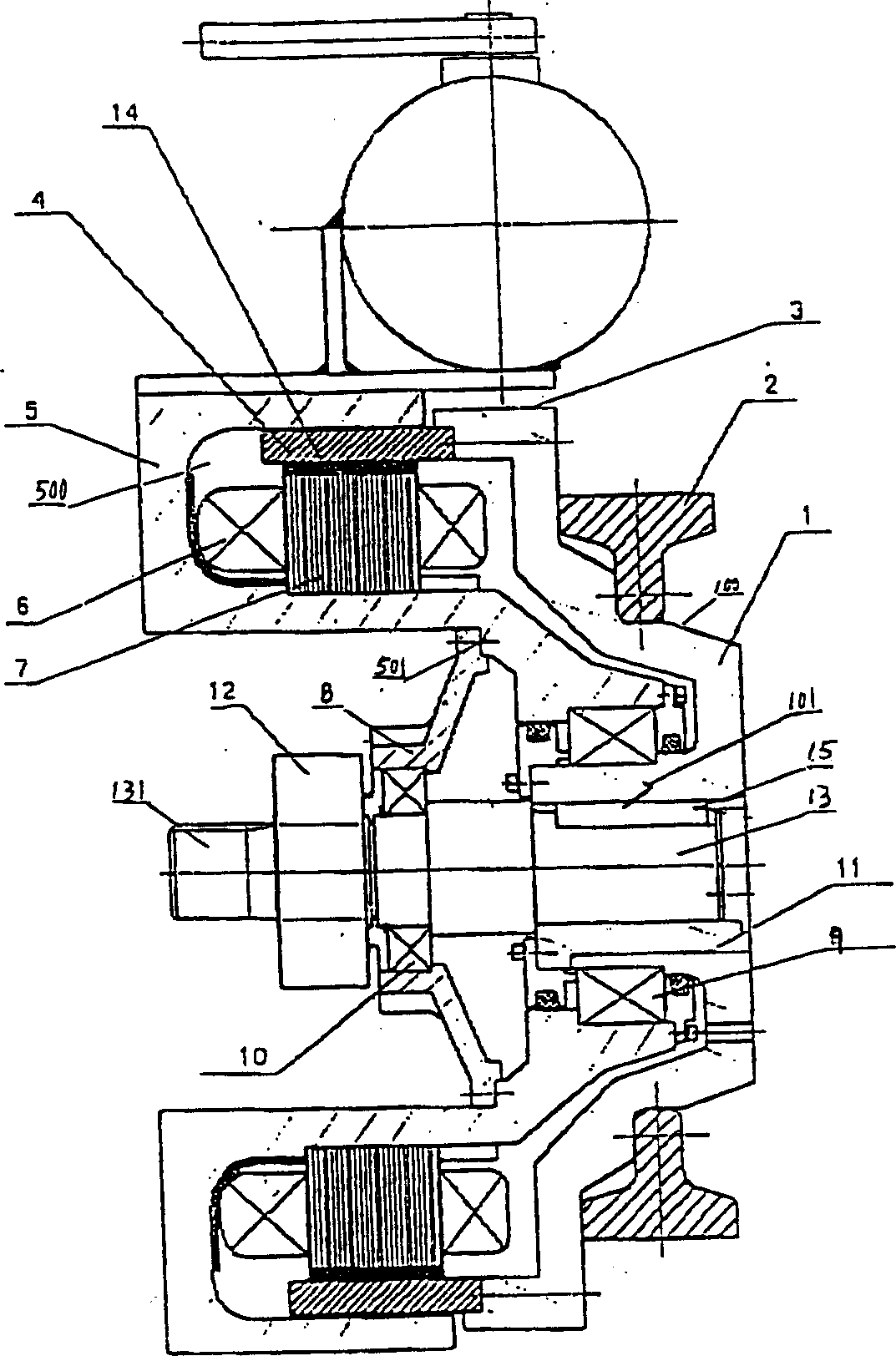

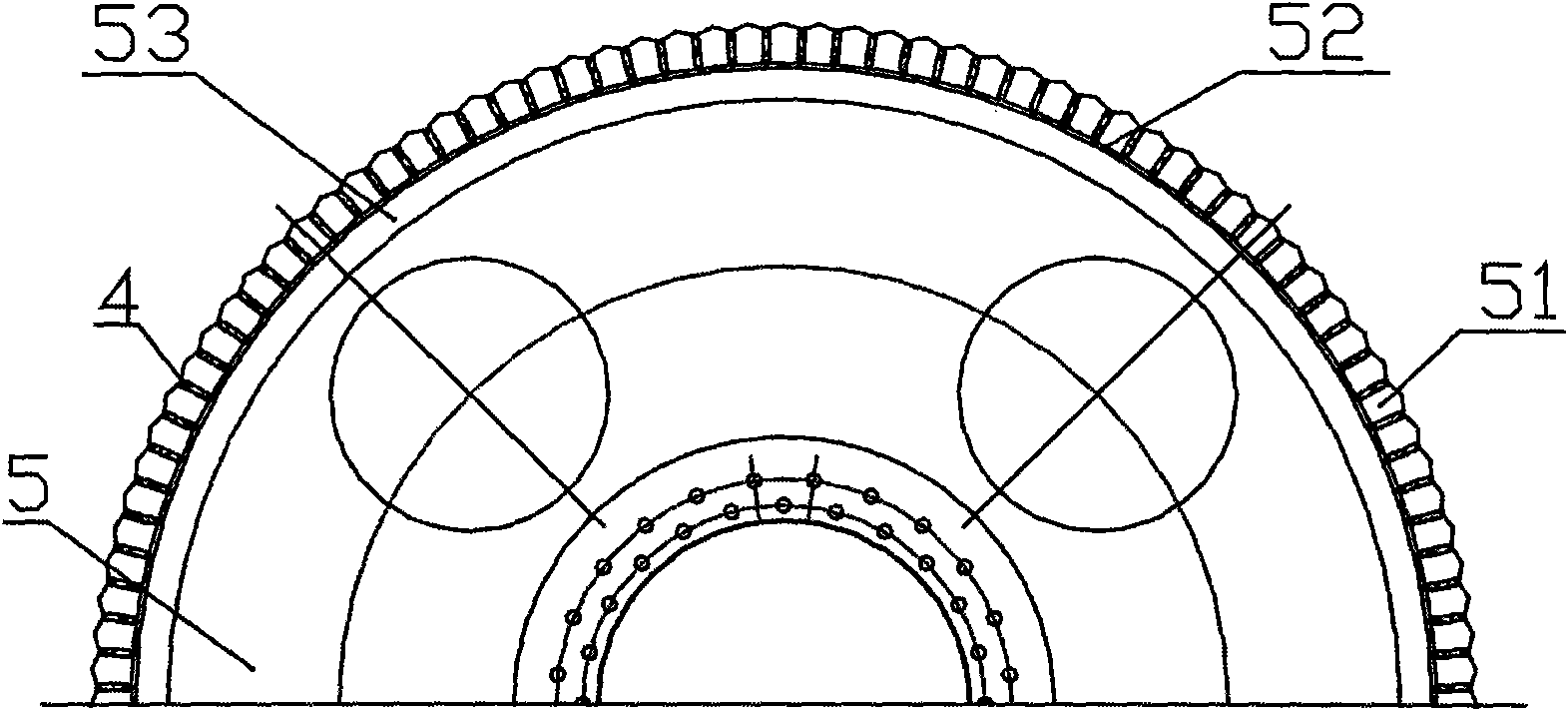

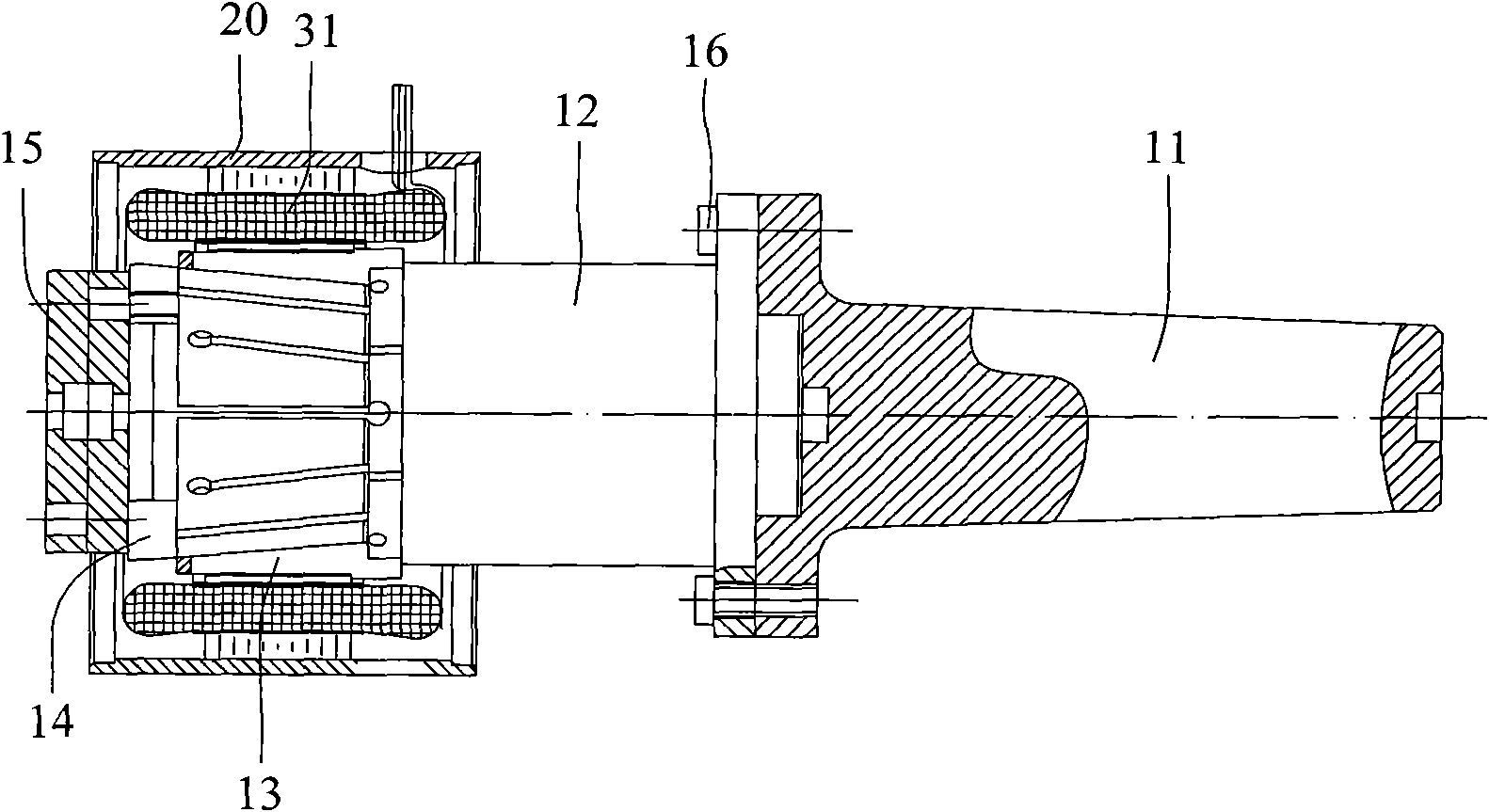

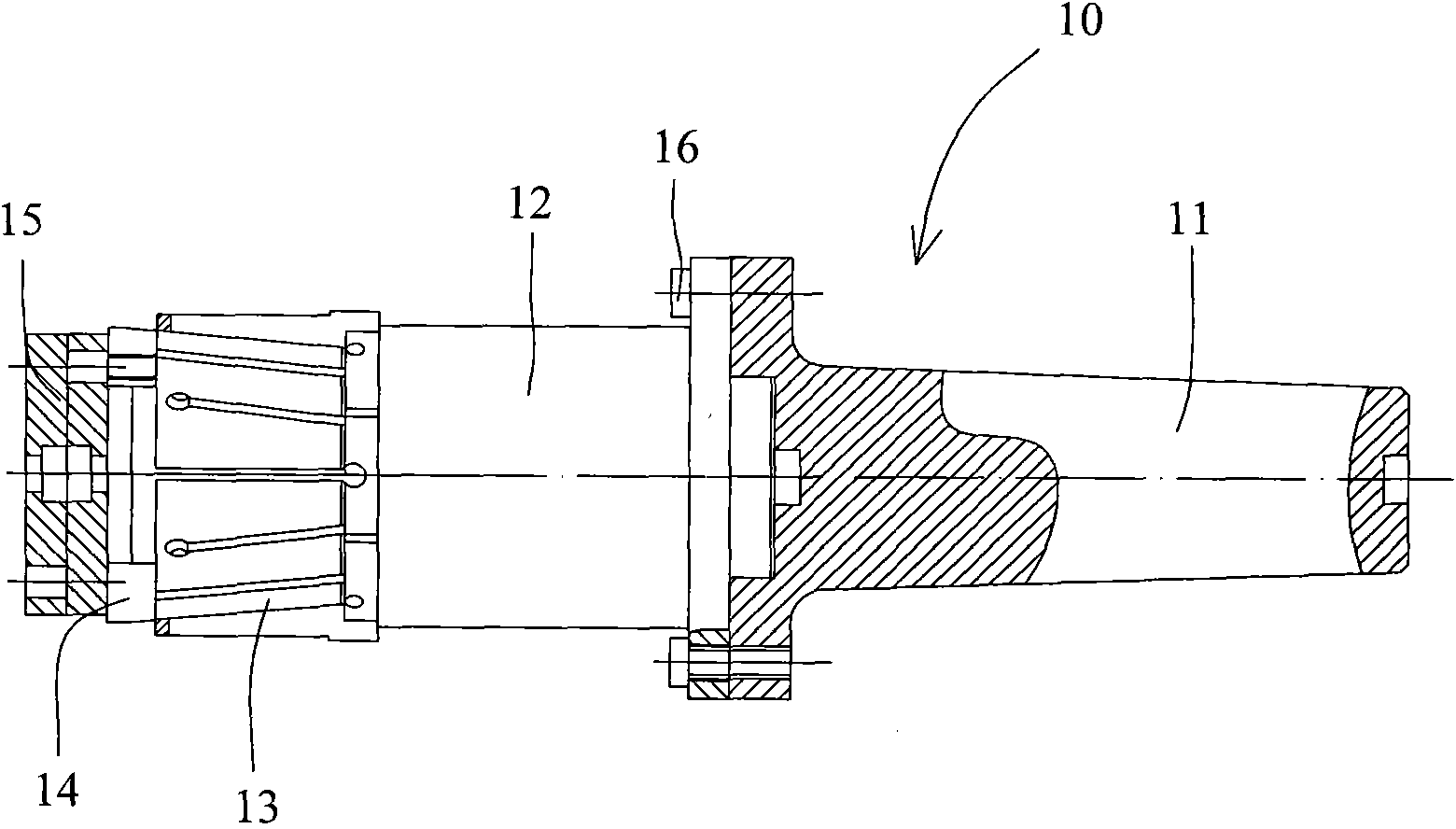

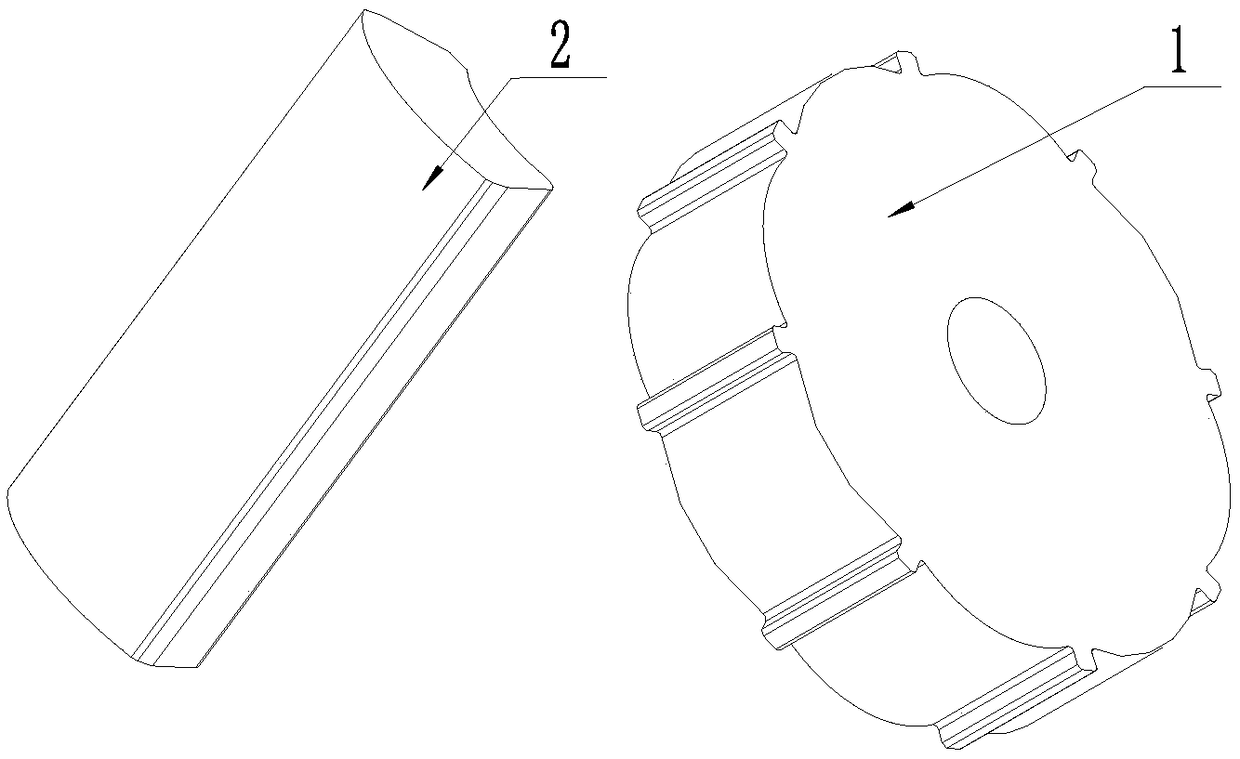

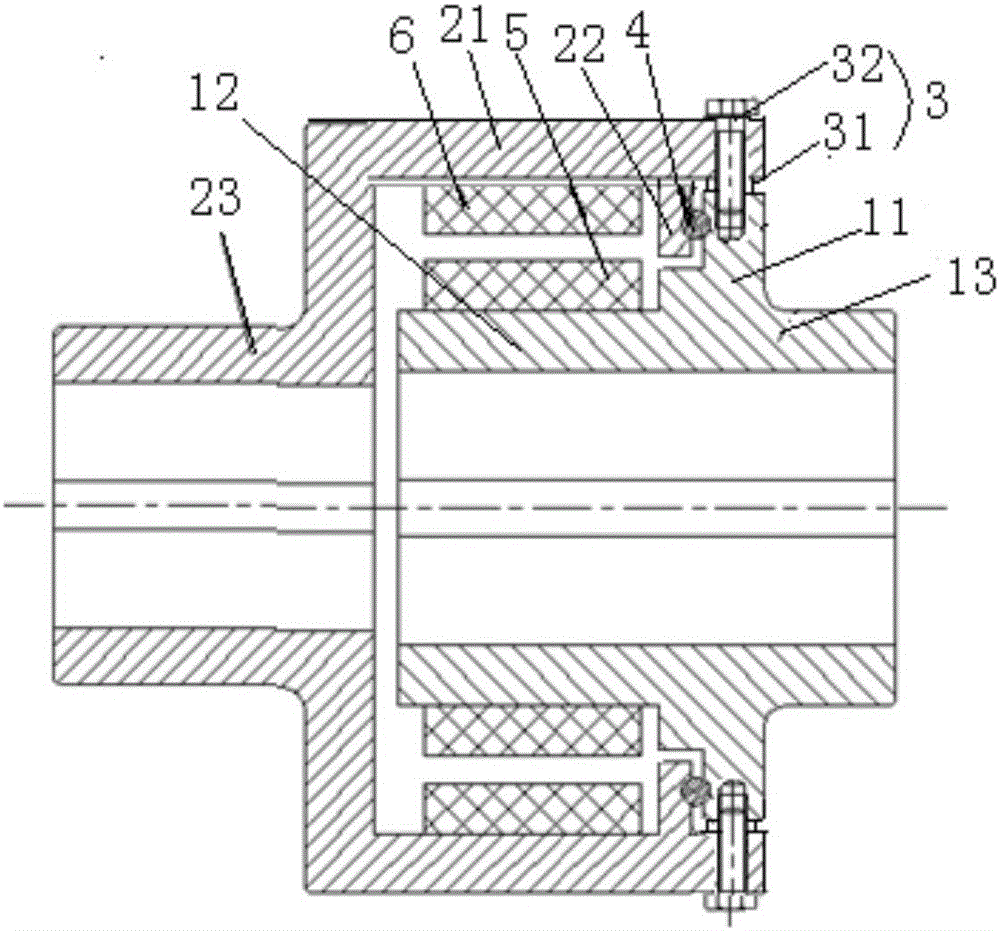

Gearless permanent-magnet synchronous traction machine

InactiveCN1464623AImprove the lubrication effectUniform air gapMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsEngineeringConductor Coil

The invention discloses a gearless permanent magnetic synchronization traction machine comprising a bowl shape rotor mounted on the main shaft using a sleeve with built-in hollow cylinder member, a traction wheel is secured to the external surface of the external rotor, a brake surface is arranged at the bowl shape neck of the external rotor, the bearing and the stator with flange are mounted in sequence on the circumcircle of the external hollow cylinder. The stator armature cores wound with stator winding are arranged in sequence into the annular groove of the stator, a magnet yoke and the joining permanent-magnet steel are arranged on the external rotor, the inner hole flange of the stator is connected with the rim of the hole bottom bowl shape member which in turn is connected with the bearing and the main shaft.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

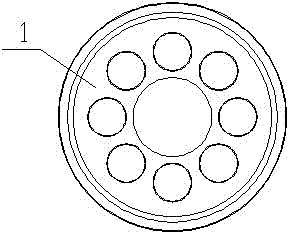

Permanent magnet brushless direct current linear motor with structure of rotor screw

InactiveCN102820730AOptimize volumeIncrease in sizeMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingBall screw

The invention provides a permanent magnet brushless direct current linear motor with a structure of a rotor screw, belonging to the technical field of direct current linear motors. A rotor consists of rotor magnetic steel and a rotor yoke, and the rotor magnetic steel is arranged on the exterior of the rotor yoke; and a stator consists of a stator punching sheet and a main case. The permanent magnet brushless direct current linear motor comprises a ball screw, a screw nut and supporting bearings, wherein a pair of supporting bearings are respectively arranged between the ball screw and the main case, the screw nut is fixed in the rotor yoke, and the ball screw is in threaded connection with the screw nut. The permanent magnet brushless direct current linear motor with the structure of the rotor screw, disclosed by the invention, has the advantages of compact structure, small volume, uniform air gaps and good heat dissipation effect, and quickness, sensitivity and freeness in starting and stopping, and is especially suitable for high-precision linear feed function locations of minitype machine tools or electric tools such as automatic drilling machines, electric screwdrivers and the like.

Owner:HARBIN INST OF TECH

Axial magnetic bearing

InactiveCN102392852AMinimizes defects of spin lossReduce copper consumptionBearingsMagnetic bearingMagnetic poles

The invention provides an axial magnetic bearing, and particularly relates to the axial magnetic bearing of which the radial torsion can be controlled. The axial magnetic bearing comprises a stator part and a rotor, wherein the stator part comprises an inner-ring stator core, an outer-ring stator core, a permanent magnet and coils; the inner-ring stator core adopts an integral ring structure; the outer-ring stator core comprises two stator core magnetic poles which are arranged in the +X direction and the -X direction (or the +Y direction and the -Y direction); the coils are wound on the stator core magnetic poles respectively; an axial magnetic airgap is formed between the stator part and the rotor; the radial inner side of the permanent magnet is connected with the inner-ring stator core; and the radial outer side of the permanent magnet is connected with the outer-ring stator core. The axial magnetic bearings provided by the invention are required to be used in pairs, so that the radial torsion of the rotors can be controlled when the outer-ring magnetic poles of two axial magnetic bearings are placed in different positions, which greatly reduces the axial size of the system. The axial magnetic bearing further has the advantages of low rotation loss, reliable performance, convenience in control, and the like.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

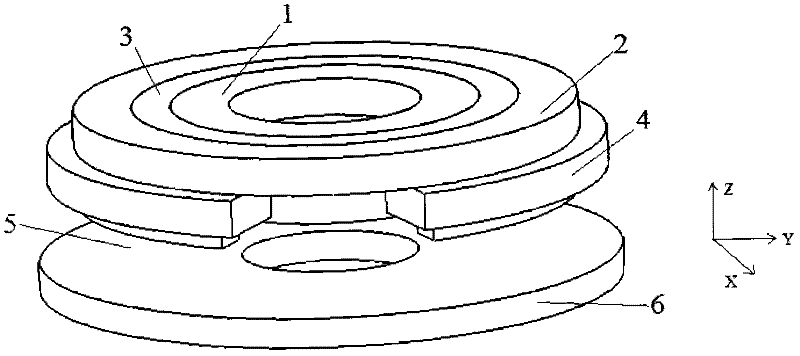

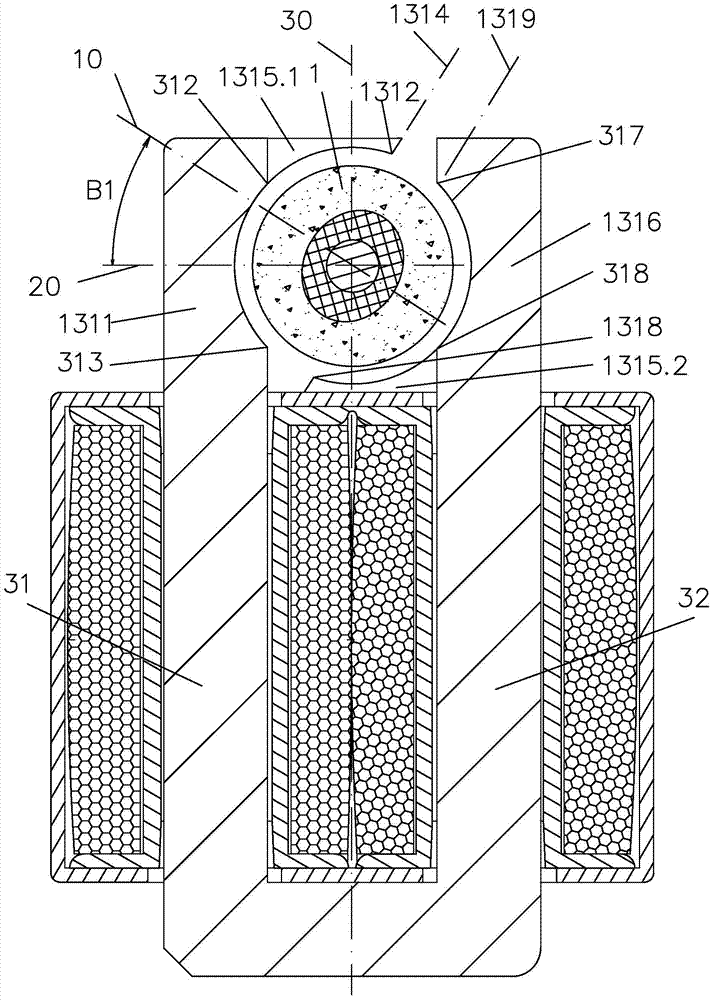

Low-power-consumption permanent-magnet bias five-degree-of-freedom integrated magnetic bearing

ActiveCN106015331AUniform air gapSuspension stabilityShaftsMagnetic bearingsMagnetic bearingEngineering

The invention discloses a low-power-consumption permanent-magnet bias five-degree-of-freedom integrated magnetic bearing which comprises a stator and a rotor iron core, wherein the stator iron core comprises an axial part and a radial part; the stator comprises a left radial magnetic bearing iron core and a right radial magnetic bearing iron core as well as a left ring-shaped permanent magnet, a right ring-shaped permanent magnet, a left axial magnetic bearing iron core and a right axial magnetic bearing iron core; and a magnetism-isolated aluminum ring is arranged between the left axial magnetic bearing iron core and the right axial magnetic bearing iron core. The invention effectively solves the defects of a current five-degree-of-freedom magnetic suspension system and provides the low-power-consumption permanent-magnet bias five-degree-of-freedom integrated magnetic bearing which is small in size, is light in mass, is short in axial length, is high in clinical rotation speed, is high in iron core utilization rate, is simple in structure, is simple to manufacture and assemble, controls magnetic flux without the permanent magnets in the axial direction and in the radial direction, and can generate greater axial suspension force and radial suspension force.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Minitype permanent-magnet synchronous motor adopting ''U''-shaped iron core and dewatering pump

ActiveCN103501095AEasy to fixUniform air gapSynchronous machine detailsSynchronous machines with stationary armatures and rotating magnetsPhysicsSynchronous motor

The invention discloses a minitype permanent-magnet synchronous motor adopting a ''U''-shaped iron core and a dewatering pump. The motor comprises a permanent-magnet rotor and a stator, wherein the permanent-magnet rotor is a cylinder of which two radial poles are magnetized; the stator comprises a ''U''-shaped stator iron core and a stator winding through which the iron core passes; the stator iron core comprises a pure ''U''-shaped pole body, a magnet yoke part, a left pole shoe and a right pole shoe, wherein the left pole shoe and the right pole shoe are formed on the upper parts of the two arms of the ''U''-shape; the pole surface of the left pole shoe is abutted against the left side of the cylindrical surface of the permanent-magnet rotor; and the pole surface of the right pole shoe is abutted against the right side of the cylindrical surface of the permanent-magnet rotor. The minitype permanent-magnet synchronous motor is characterized in that a plane on which the two pole horns of at least one pole shoe are positioned is intersectant with a symmetry axis of the ''U''-shape. The dewatering pump comprises the motor, a coaxial-transmission impeller thereof, a pump cover and a pump body, wherein the pump cover surrounds the impeller to perform the volute function, and the pump body is used for supporting the motor and the pump cover. The motor and the dewatering pump can be started by self even if non-uniform air gaps are not adopted. The problems of magnetic resistance and torque fluctuation due to the non-uniform air gaps can be eliminated, and the structural stability and the dimensional stability are improved.

Owner:HANYU GRP CO LTD

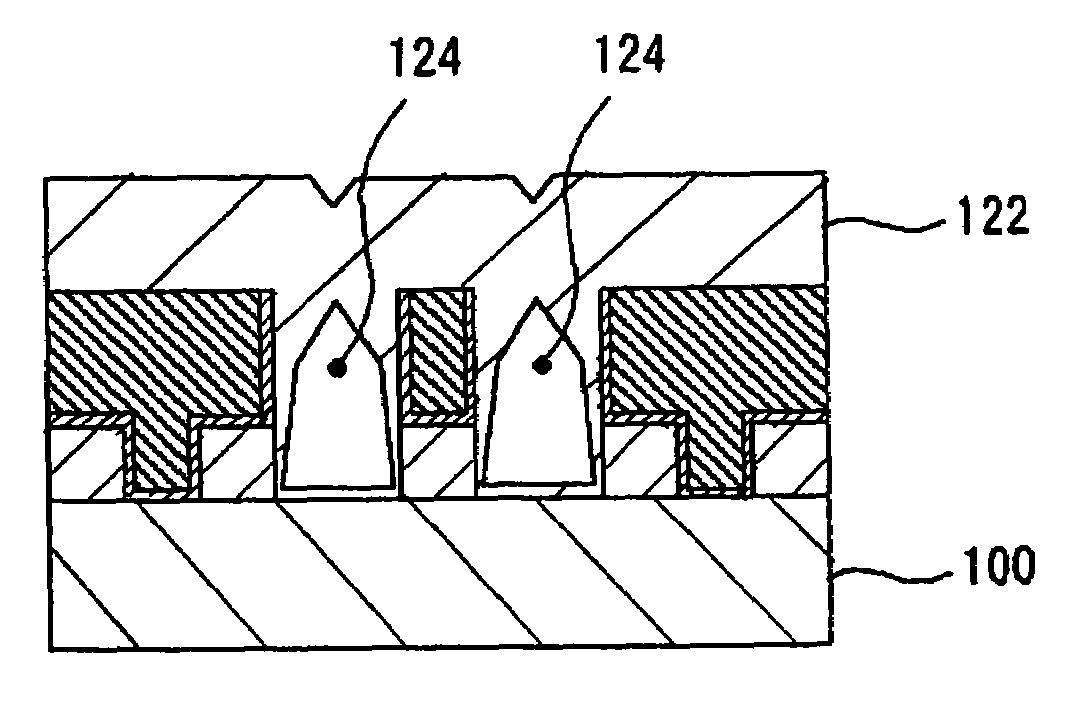

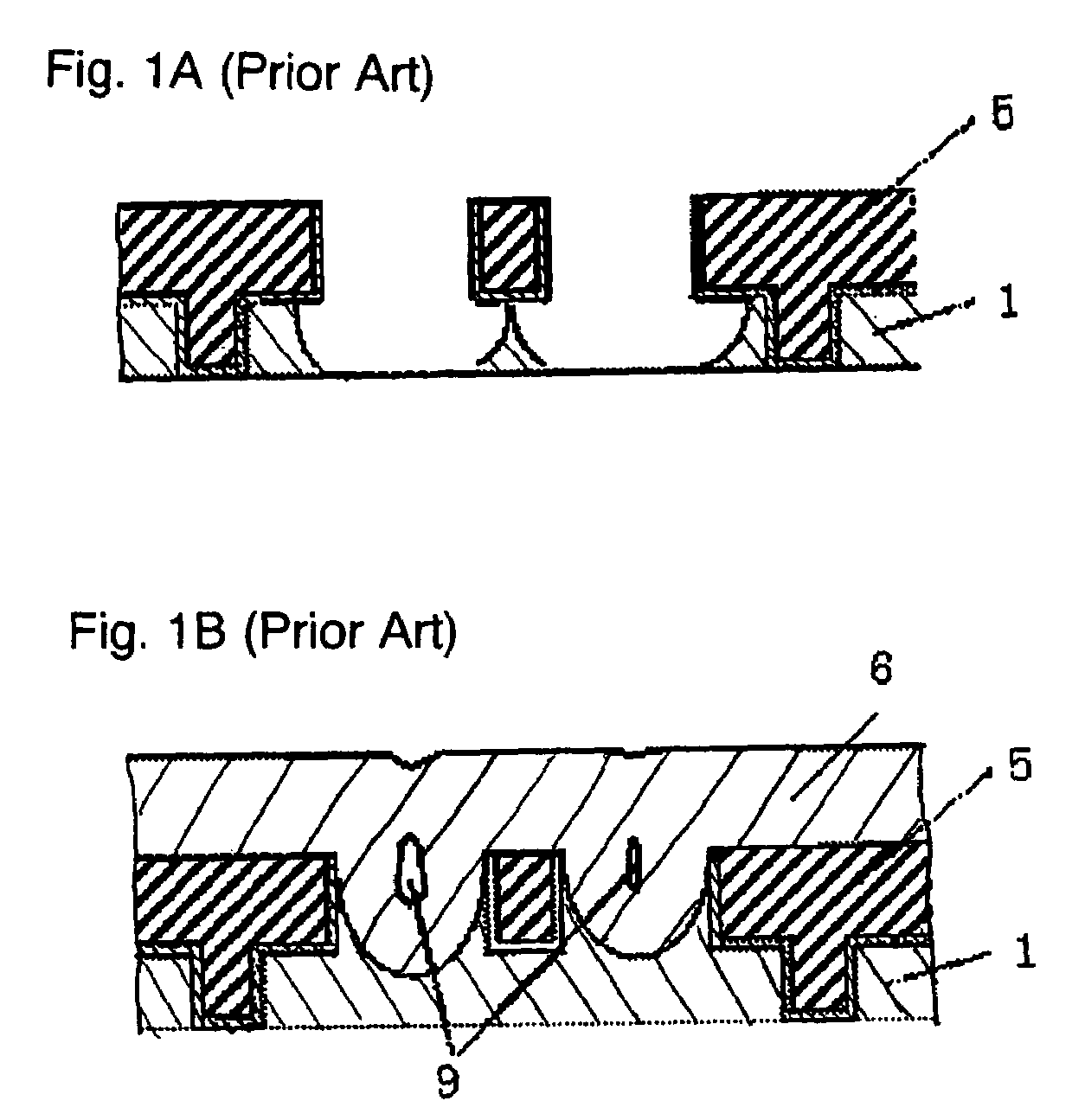

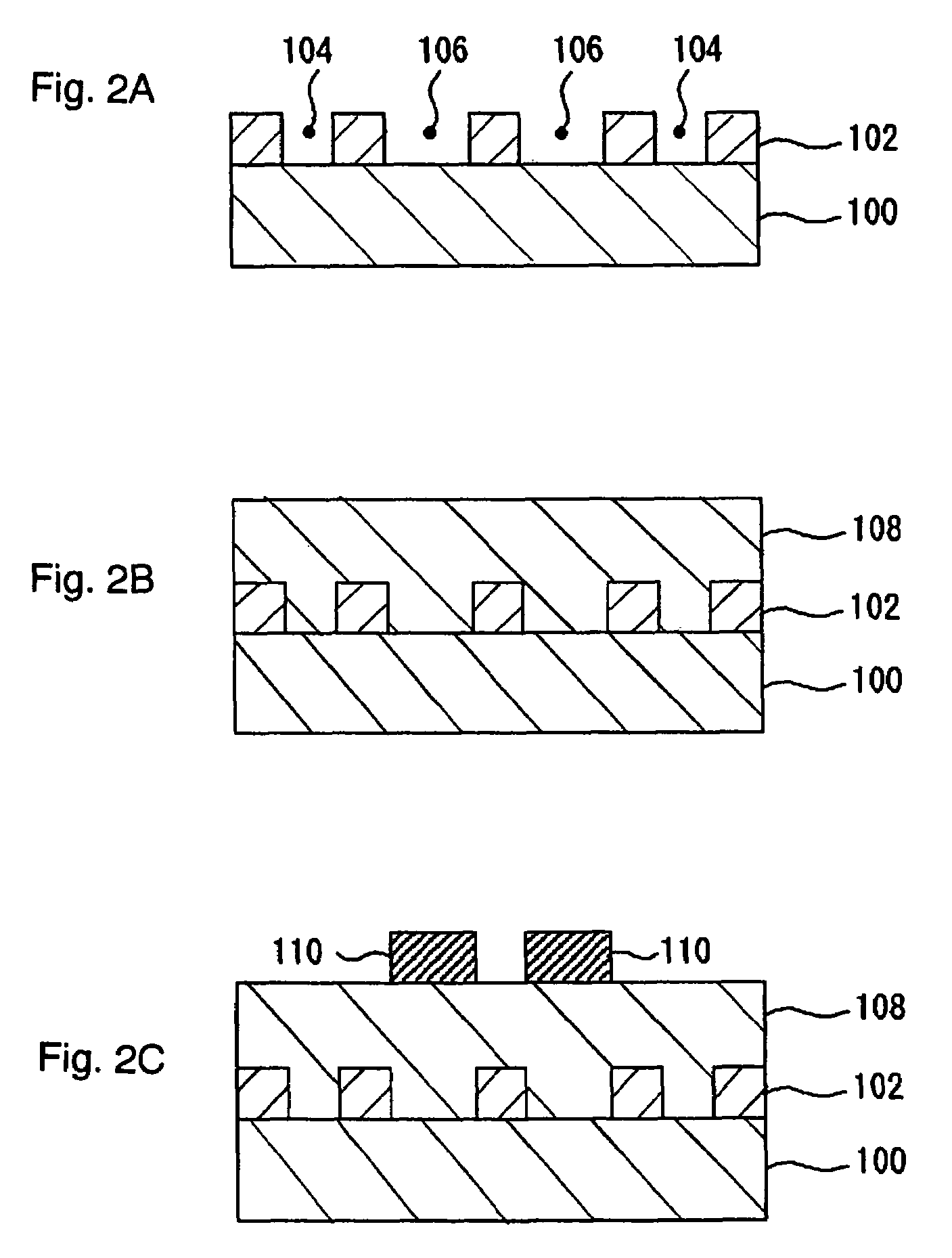

Manufacturing of a semiconductor device with a reduced capacitance between wirings

InactiveUS7112526B2Reduce capacitanceStable productionSemiconductor/solid-state device detailsSolid-state devicesCapacitanceFiller metal

In the method of manufacturing a semiconductor device, via holes and first trenches to form air gaps are concurrently formed in a first insulating film on a semiconductor substrate and a second insulating film is formed thereon. Thereafter, the second insulating film lying outside the area corresponding to the regions where the first trenches to form air gaps are formed is partially removed to form trenches for wiring by using a mask. A plurality of wirings are formed by filling in the trenches for wiring with a metal film. The second insulating film remaining in the regions where the first trenches to form air gaps are formed is then removed to form second trenches to form air gaps. Subsequently, in forming a third insulating film, air gaps are formed within the second trenches to form air gap.

Owner:NEC ELECTRONICS CORP

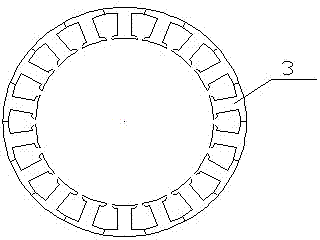

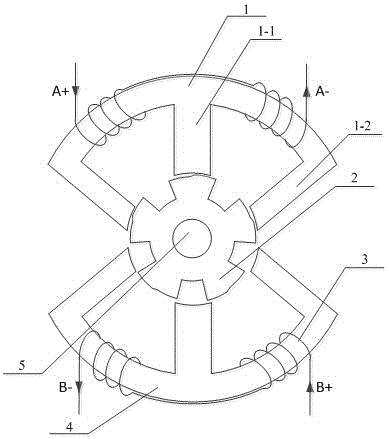

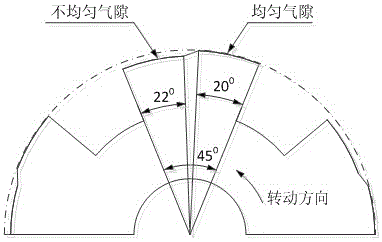

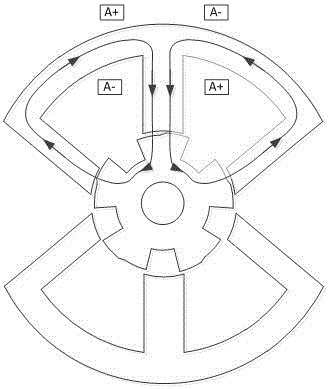

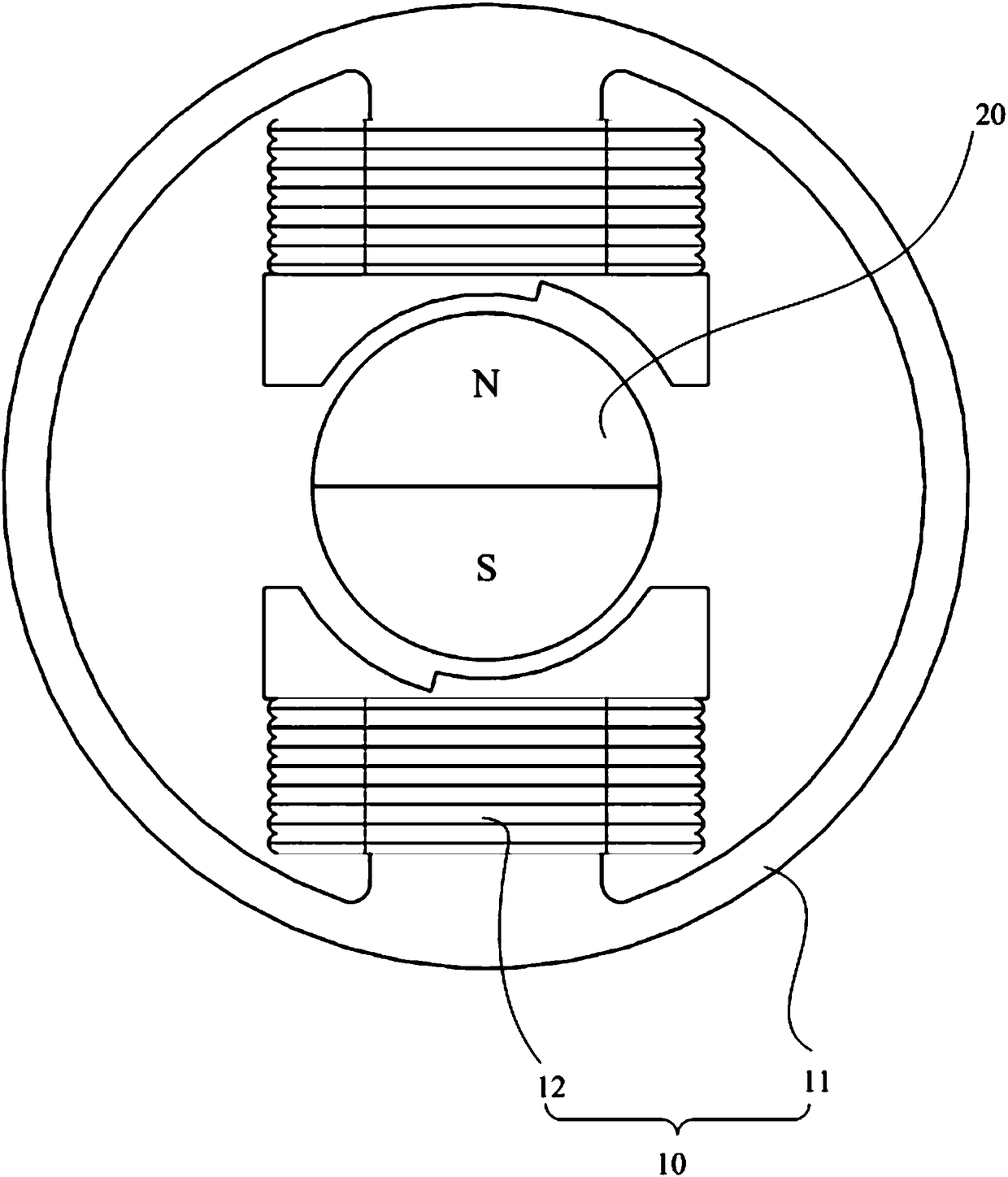

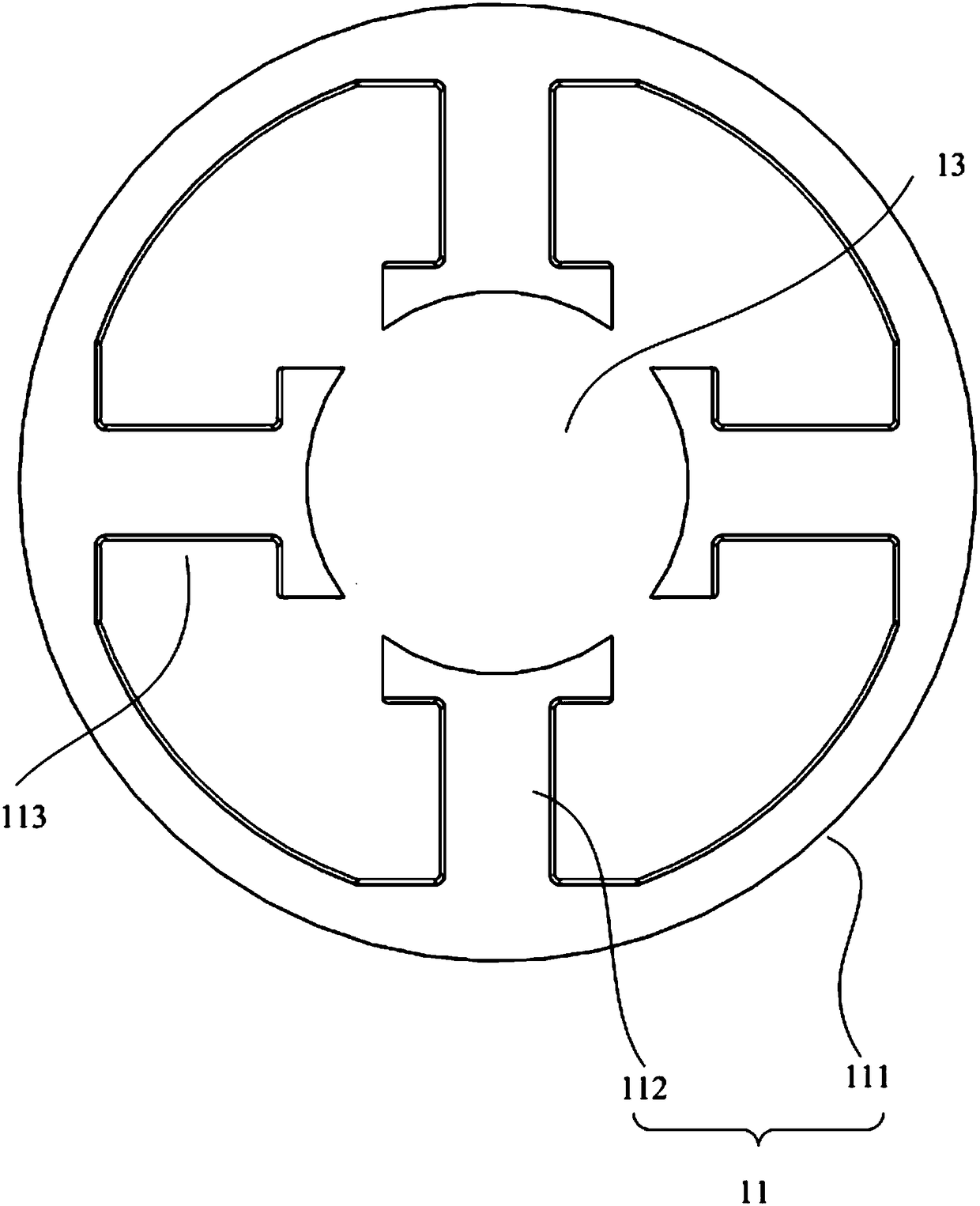

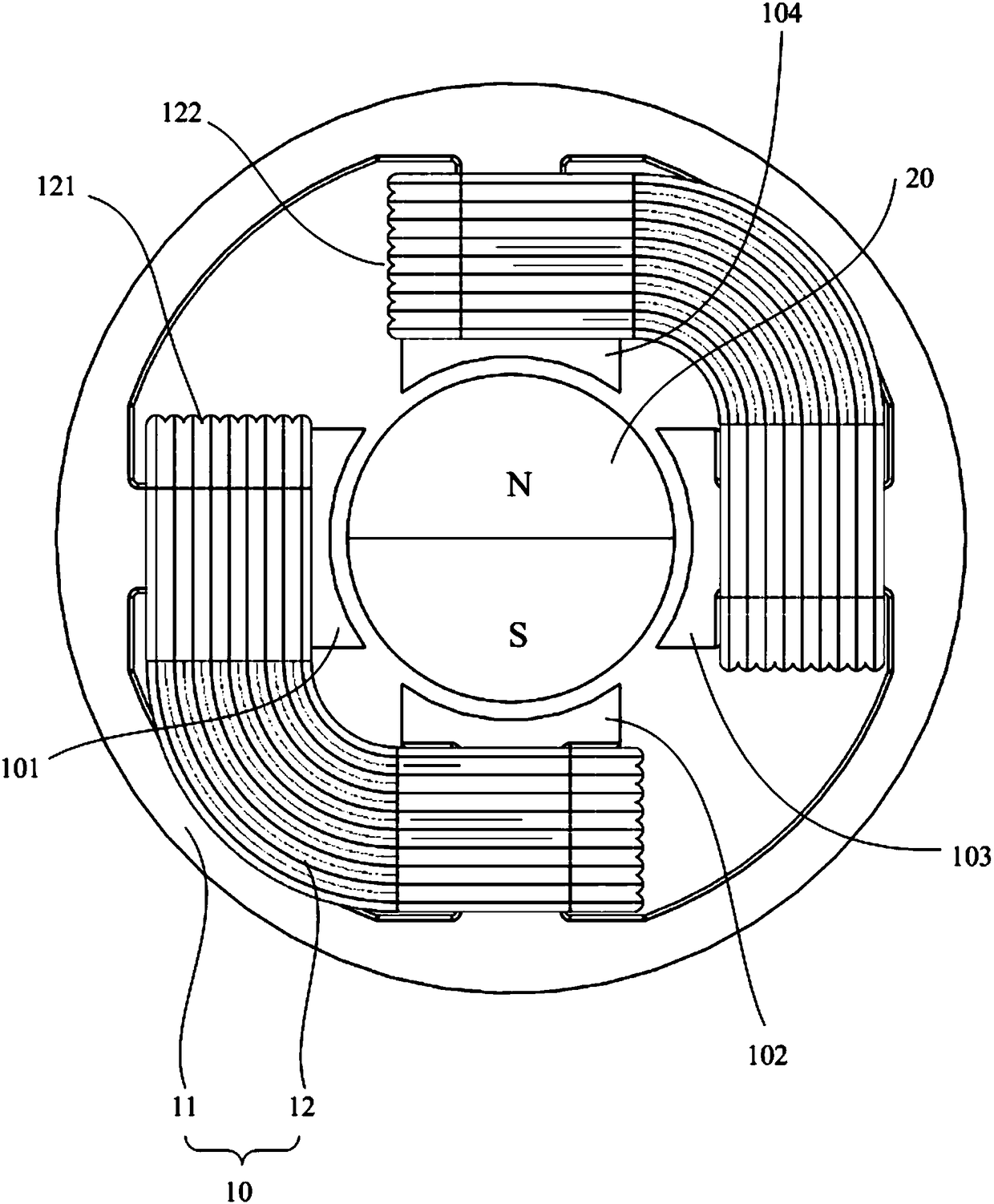

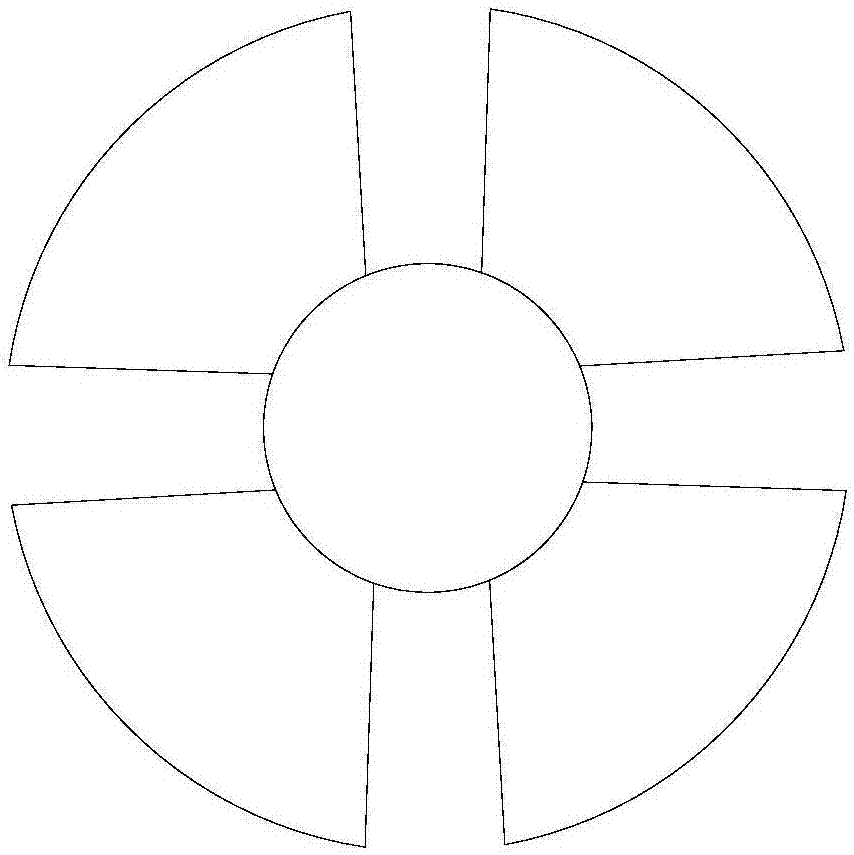

Switched reluctance motor with stator partitioned two-phase 6/5 structure

ActiveCN106385150AEasy to reduce magnetomotive forceReduce lossMagnetic circuit rotating partsSynchronous machinesReluctance motorMotor shaft

The invention relates to a switched reluctance motor with a stator partitioned two-phase 6 / 5 structure. The switched reluctance motor comprises a stator, a rotor, a winding and a motor shaft, wherein the rotor center is integrated with the motor shaft. The switched reluctance motor is characterized in that two E-shaped stators with three poles are provided, the two stators are symmetrical distributed on the periphery of the rotor and the arc center of the stators of overlaps with the center of the rotor, and the rotor is of an uneven salient pole structure with five poles. The outer diameters of the rotor poles are different, and the winding is wound on a stator yoke. The structure is simple, the design is reasonable, and installation and implement are easy. The switched reluctance motor is reliable to use, the torque ripple is reduced, and the areas with zero torque are eliminated, so that the switched reluctance motor can start automatically. The output torque of the motor is increased, the loss is reduced, and the output efficiency is increased.

Owner:BRILLIANCE AUTO

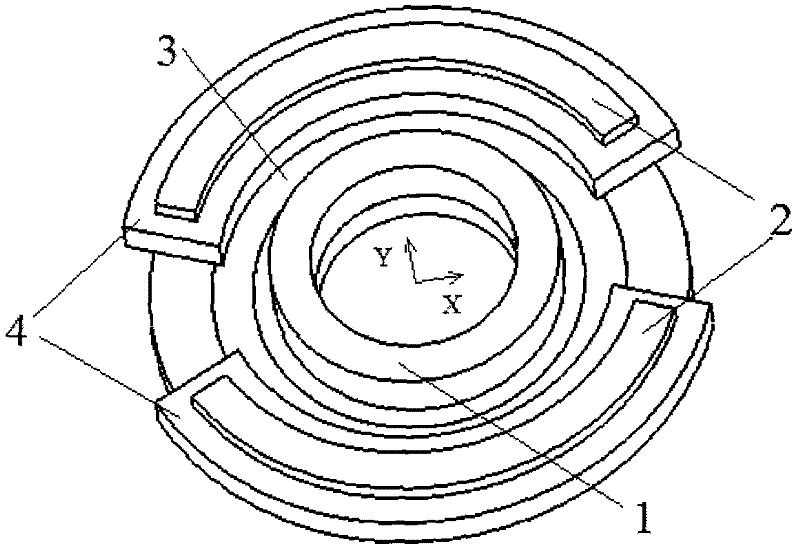

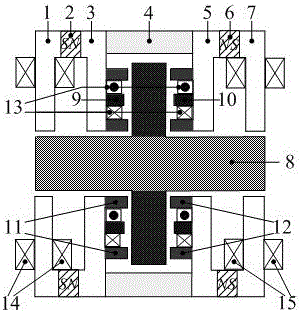

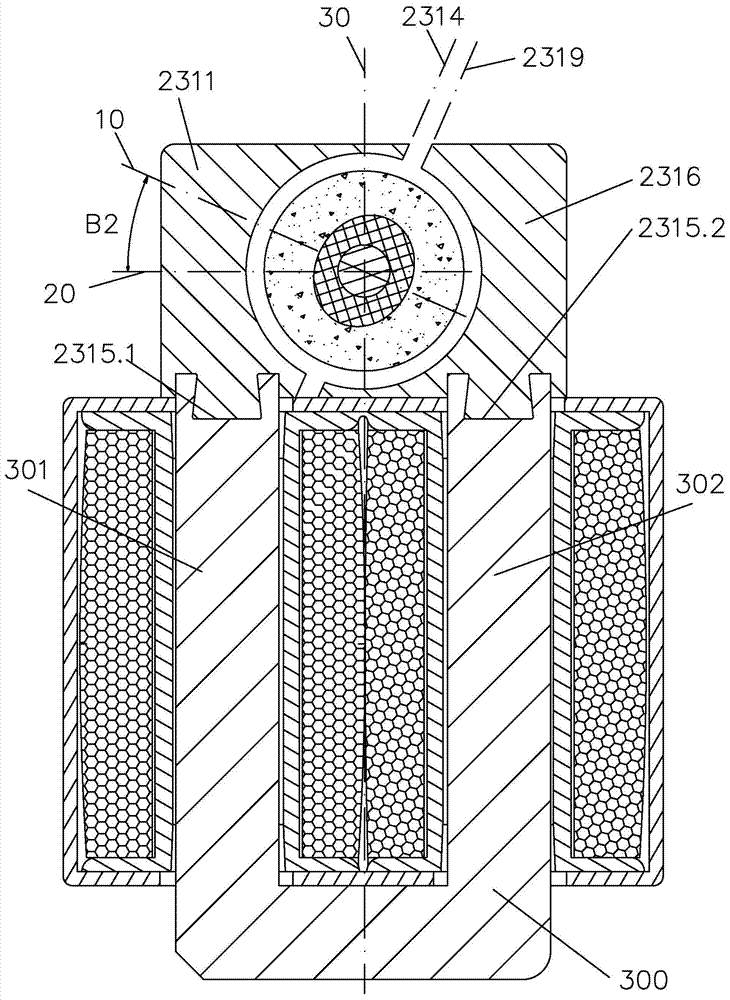

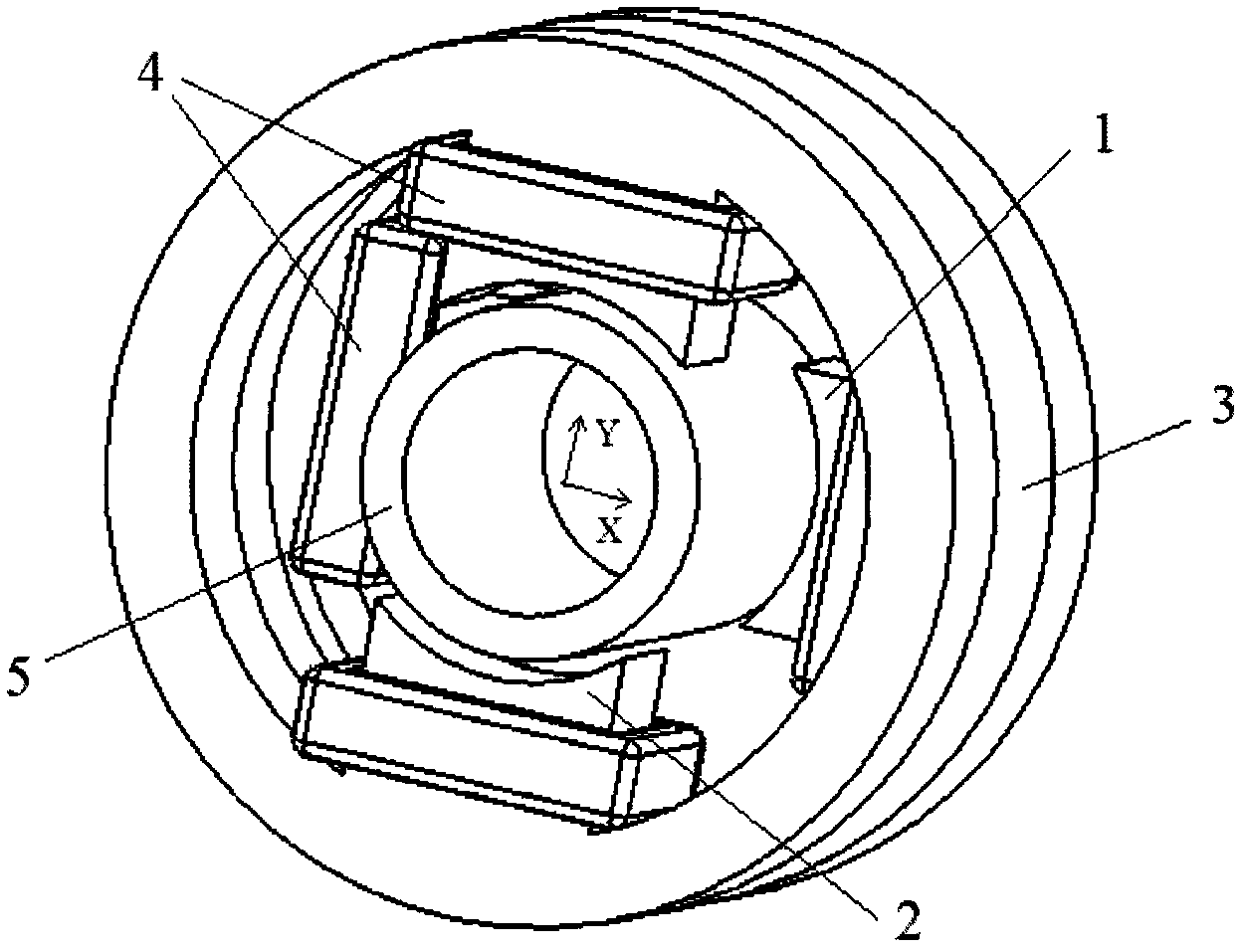

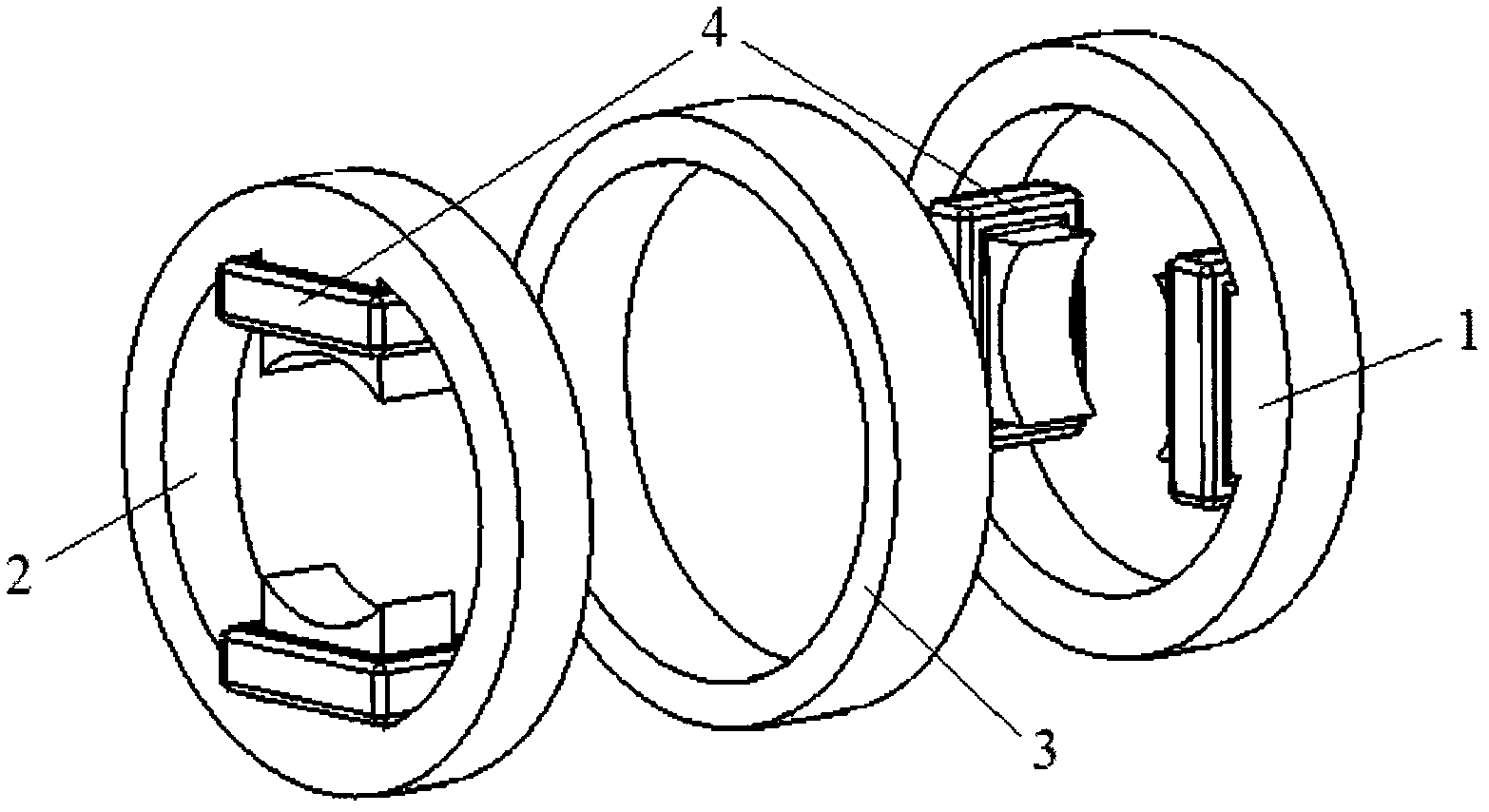

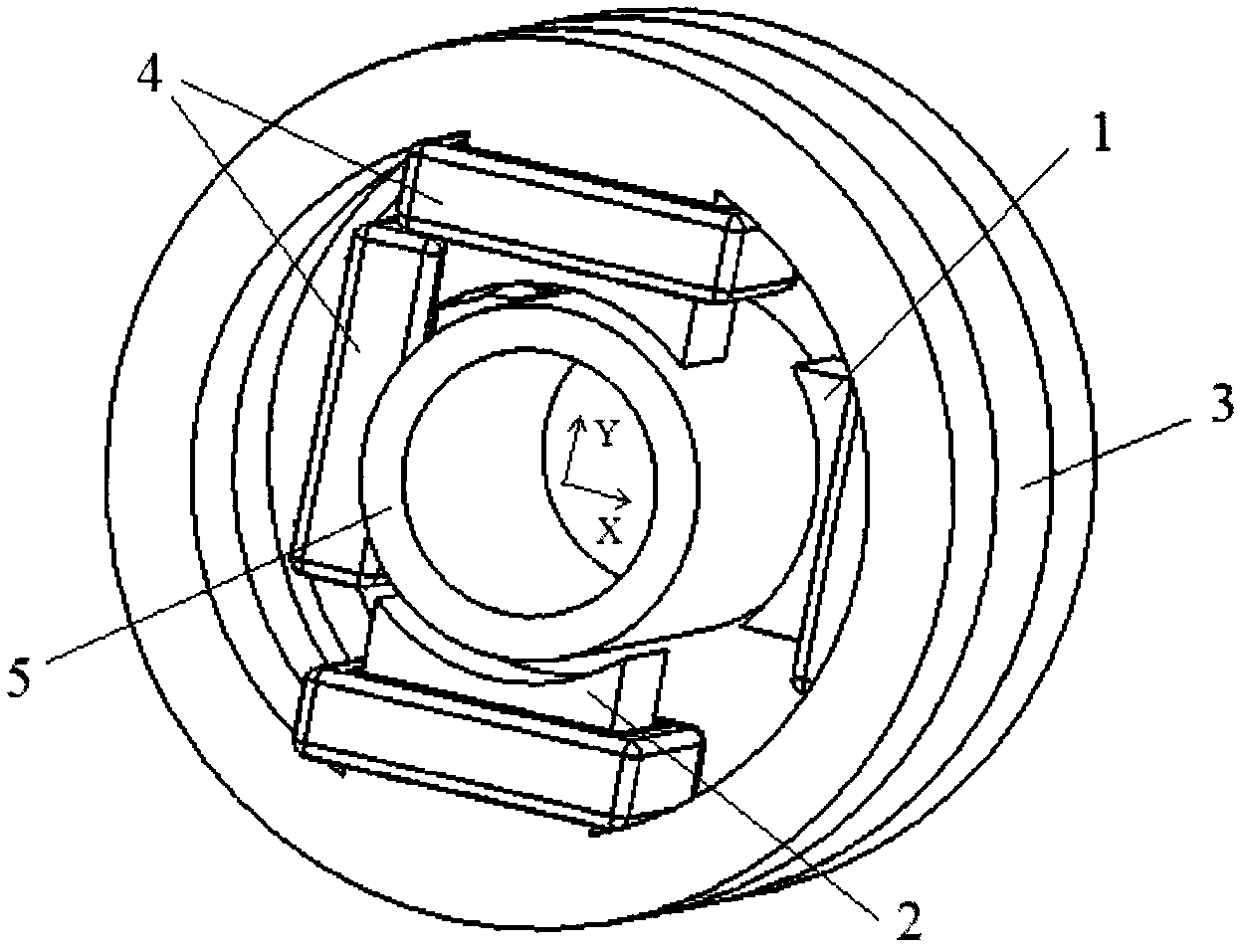

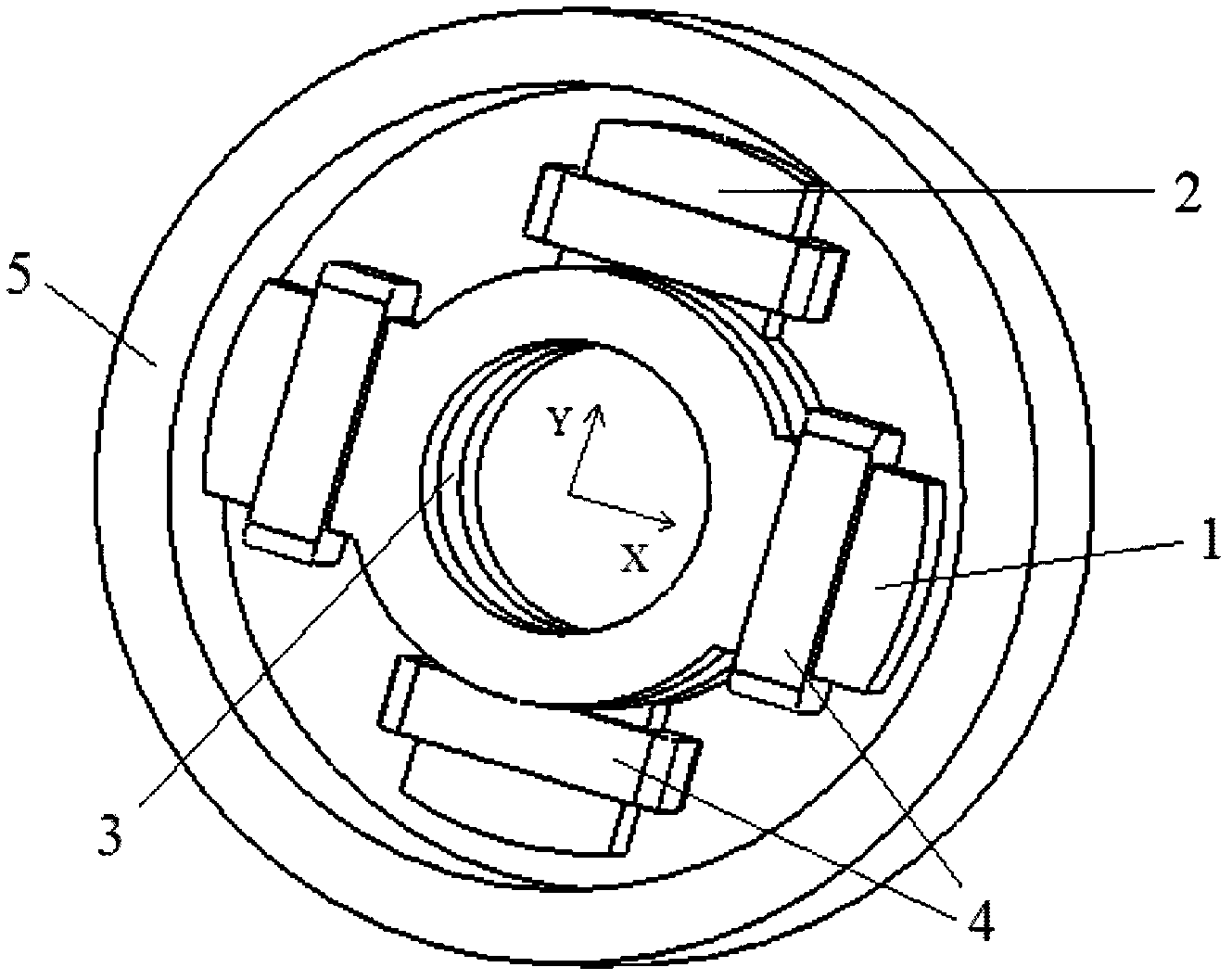

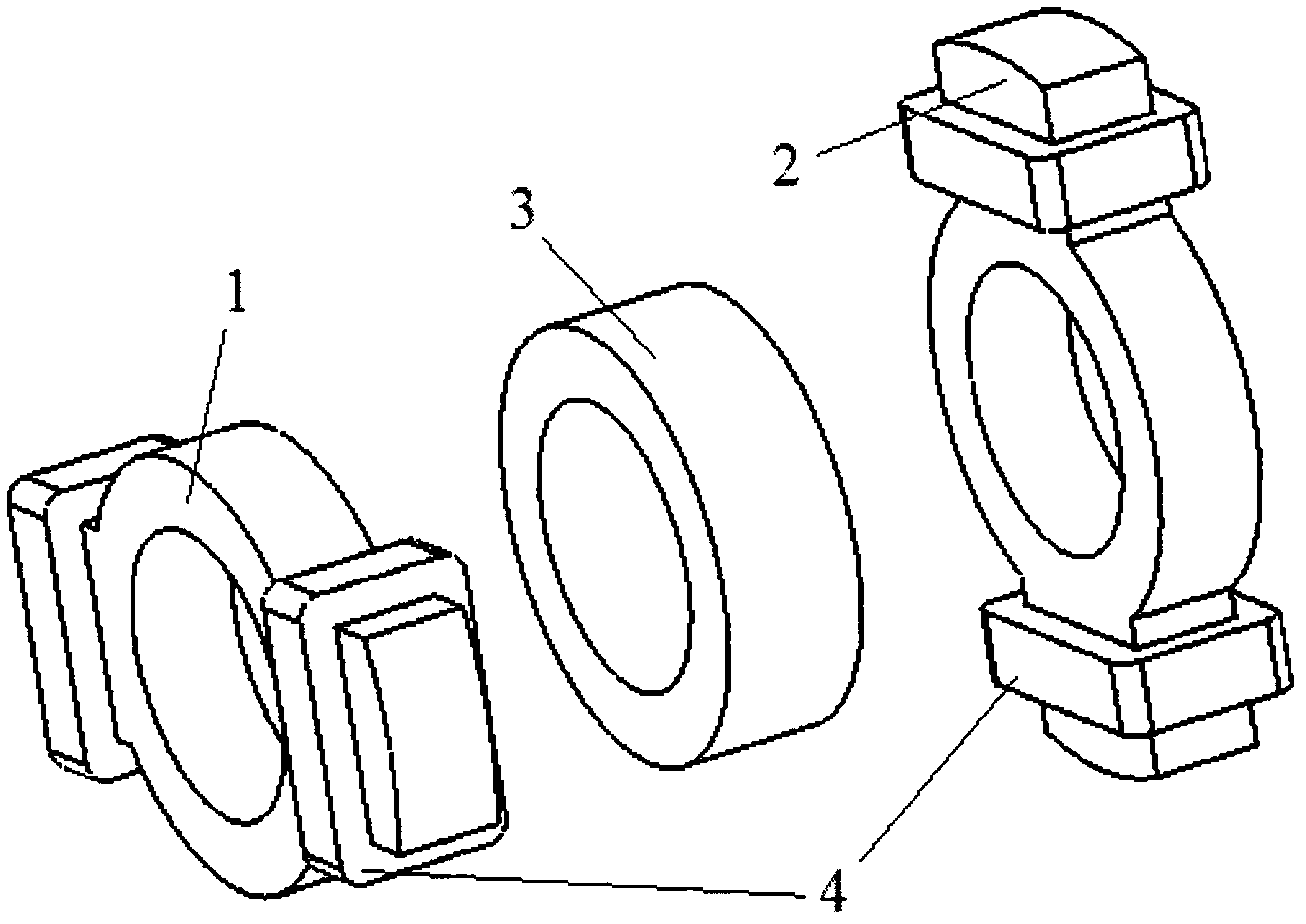

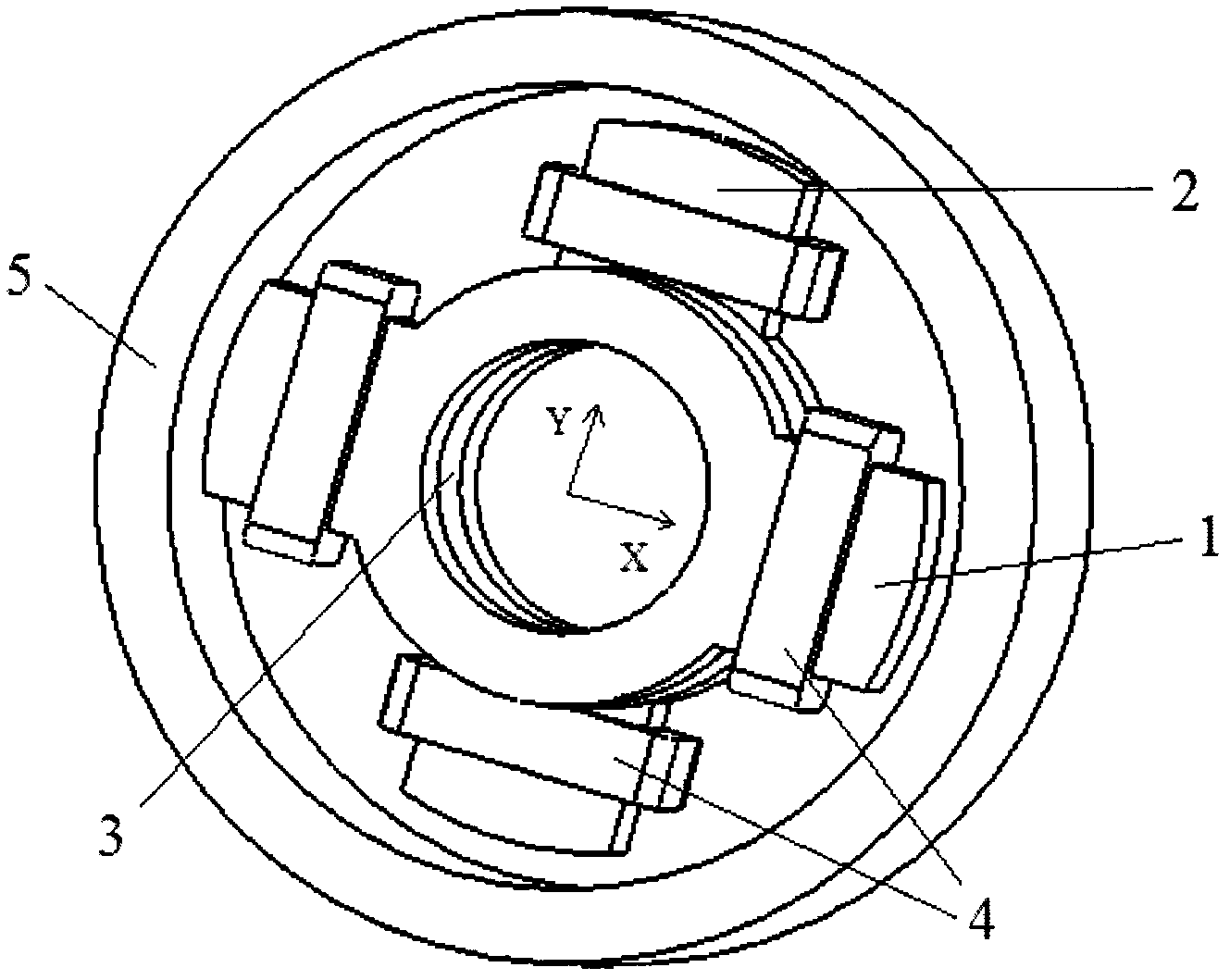

Inner rotor radial magnetic bearing

An inner rotor radial magnetic bearing comprises an x-direction outer stator core, a y-direction outer stator core, an outer permanent magnet, an outer coil, and an inner rotor core, wherein the x-direction outer stator core and the y-direction outer stator core are vertically disposed; both the x-direction outer stator core and the y-direction outer stator core comprise two magnetic poles with the outer coil winded on the poles; the outer permanent magnet is located between the x-direction outer stator core and the y-direction outer stator core; the inner rotor core is inside the x-directionouter stator core and the y-direction outer stator core in the radial direction; a magnetic air gap is formed between the inner rotor core and the x-direction outer stator core and the y-direction outer stator core. The invention allows an electromagnetic circuit to be uncoupled in the x and y directions of the outer stator cores of the radial magnetic bearing, and thus the control precision of the radial magnetic bearing is increased.

Owner:北京奇峰聚能科技有限公司

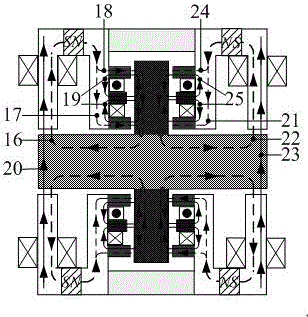

Outer rotor radial magnetic bearing

The invention relates to an outer rotor radial magnetic bearing, which comprises a x direction inner stator iron core, a y direction inner stator iron core, an inner permanent magnet, inner coils and an outer rotor iron core, wherein the x direction inner stator iron core and the y direction inner stator iron core are placed vertically, the x direction inner stator iron core and the y direction inner stator iron core are respectively provided with two magnetic poles, the inner coils are wound on the magnetic poles, the inner permanent magnet is positioned between the x direction inner stator iron core and the y direction inner stator iron core, the radial outer parts of the x direction inner stator iron core and the y direction inner stator iron core are the outer rotor iron core, and themagnetic air gaps are formed between the x direction inner stator iron core, the y direction inner stator iron core and the outer rotor iron core. According to the present invention, the electromagnetic circuit is not subjected to coupling on the x direction and the y direction in the inner stator iron core of the radial magnetic bearing so as to improve the control precision of the radial magnetic bearing.

Owner:北京奇峰聚能科技有限公司

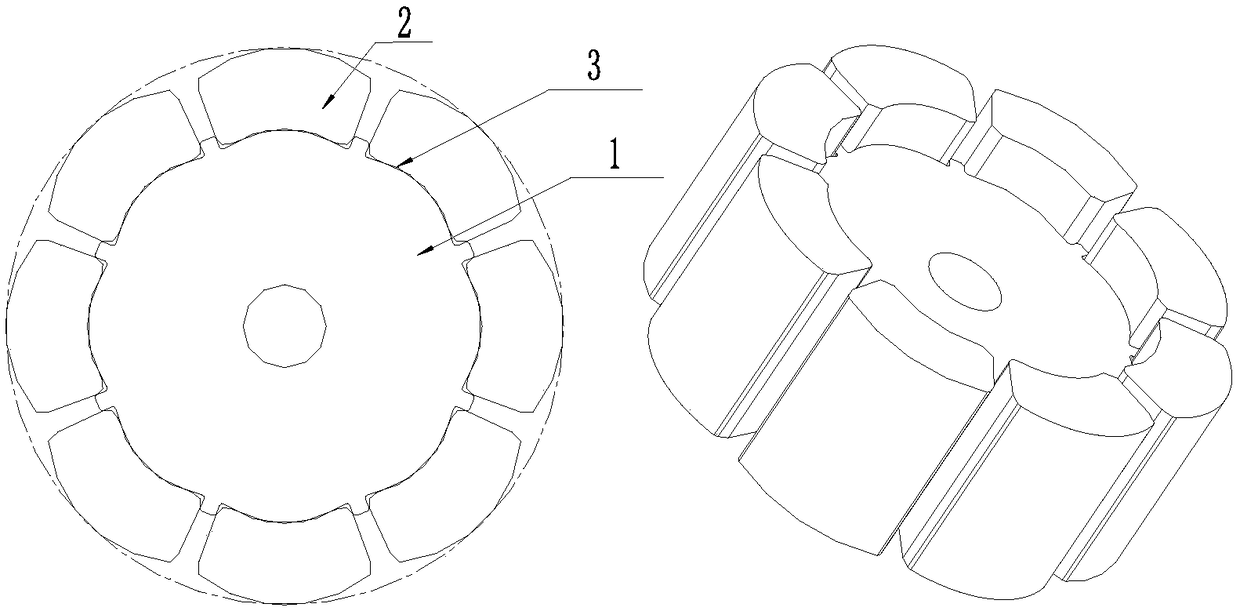

Permanent magnet synchronous motor for hoisting mechanism of direct-drive crane

InactiveCN101662195AImprove transmission efficiencyImprove reliabilityMagnetic circuit rotating partsSynchronous machinesLow speedElectric machine

The invention discloses a permanent magnet synchronous motor for a hoisting mechanism of a direct-drive crane; the permanent magnet synchronous motor comprises a permanent magnet synchronous motor shell, a stator winding, a stator iron core, a permanent magnet, a rotor, a winding drum revolving shaft and a winding drum; and the permanent magnet synchronous motor has more than 20 poles. In the invention, by increasing the number of the poles of the permanent magnet motor, a variable-frequency power source is adopted to realize low-speed operation of the motor, high torque is output, the motor directly drives the load to work, a speed reducer is canceled, the structure is simple and practical, and the working efficiency of the system is improved; a rotor structure adopted by the invention can effectively solve the problem of difficult assembly of the permanent magnet motor; rotor magnetic poles and magnetic separation steel rings commonly protect the permanent magnet from being damaged when in assembly; reluctance torque is reduced to be zero in the installation process, the installation difficulty is reduced, and requirements and dependence to installation tools (special mounting equipment) is reduced, and the quality of the rotor and the complexity of the rotor structure are greatly reduced.

Owner:大连伯顿冠力电机有限公司

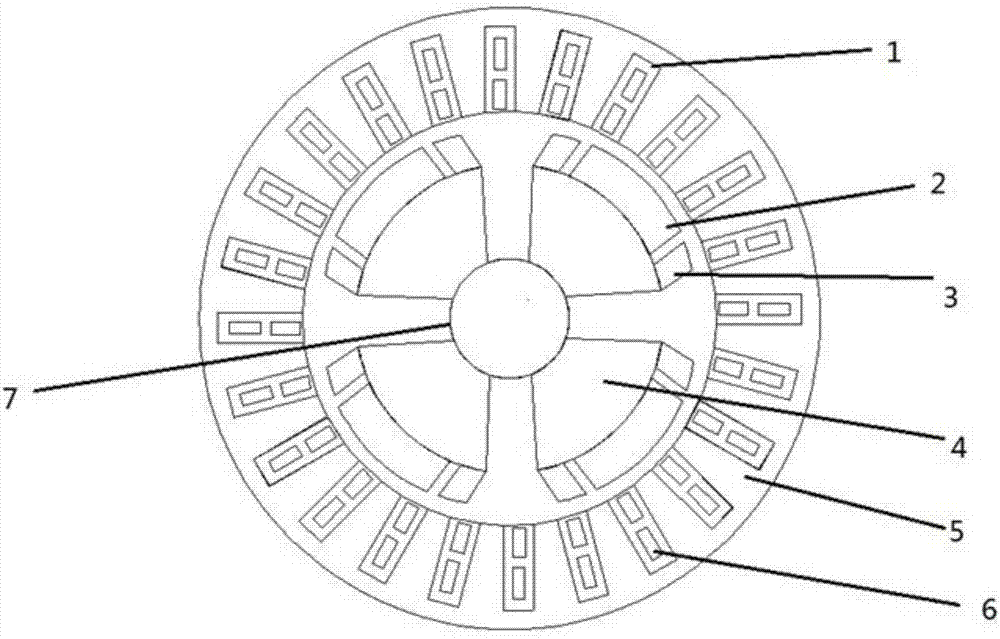

Two-degree-of-freedom stator permanent magnet biased permanent magnet bearingless motor

ActiveCN103683571AUniform air gapLarge radial suspension forceMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsStator

The invention discloses a two-degree-of-freedom stator permanent magnet biased permanent magnet bearingless motor, and aims to overcome the shortcomings of an existing permanent magnet bearingless motor. The stator permanent magnet biased permanent magnet bearingless motor comprises a motor shell, a rotor and a stator are arranged in the motor shell, the stator comprises a stator core, a left pole core and a right pole core are symmetrically arranged on two sides of the stator core, a torque winding and a suspension winding are arranged in a stator slot of the stator core, an axial magnetized annular stator permanent magnet A and an axial magnetized annular stator permanent magnet B are axially arranged on two sides of the stator core, the rotor comprises a rotor core, and the rotor core is axially provided with a radial magnetized annular rotor permanent magnet and a rotating shaft. The stator permanent magnet biased permanent magnet bearingless motor is simple to control, realizes mutually independent suspension control and torque control, and can generate larger radial suspension force.

Owner:淮安市清江浦区市场监管综合服务中心

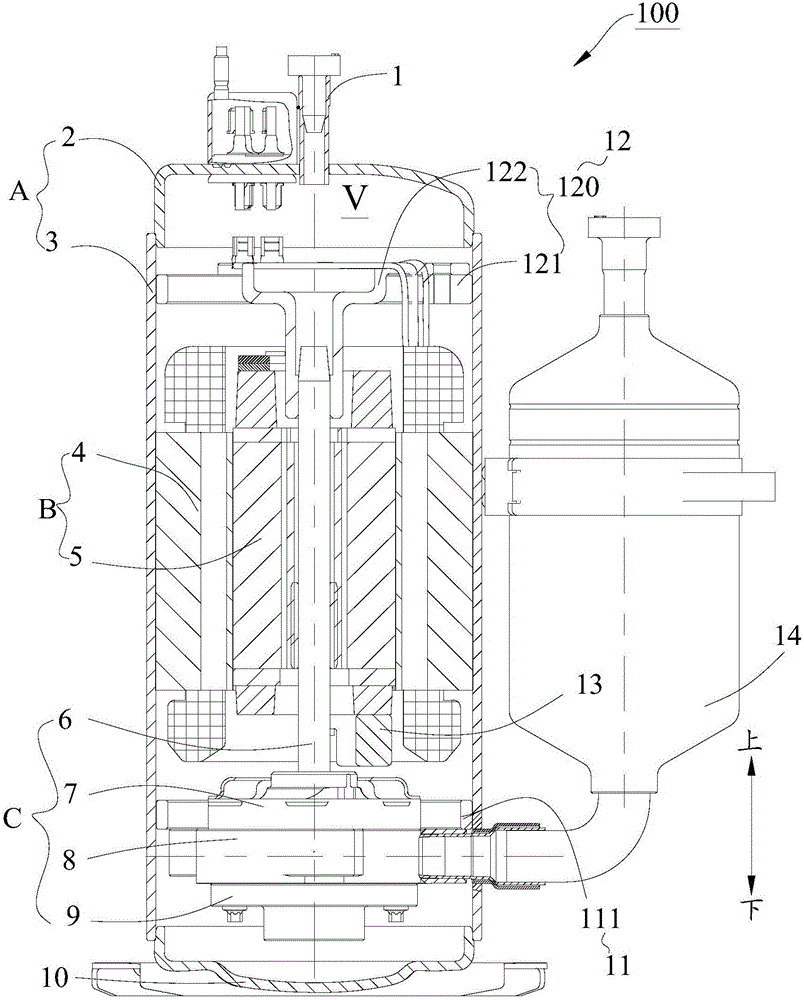

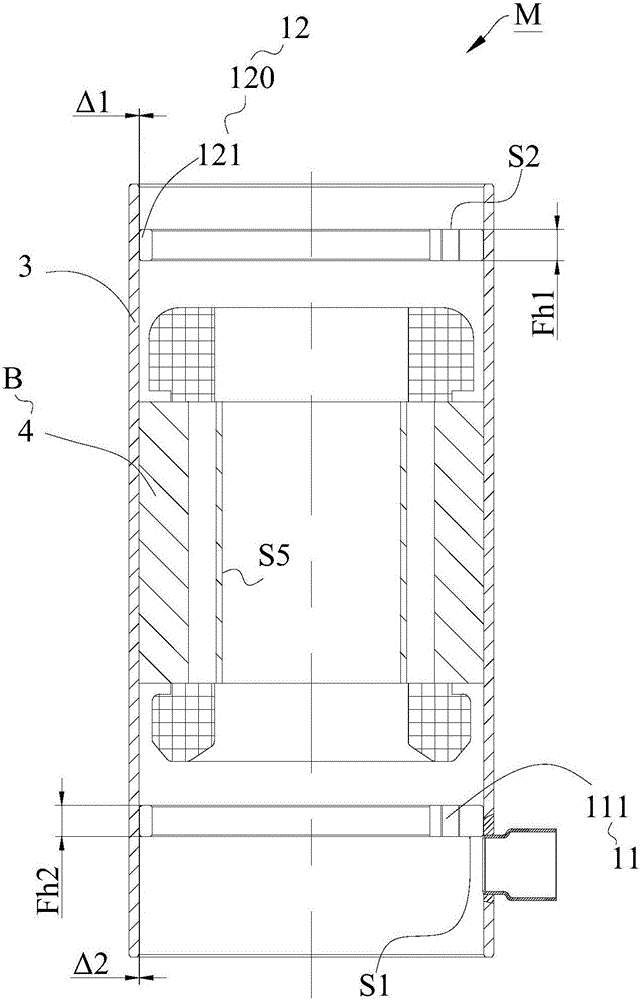

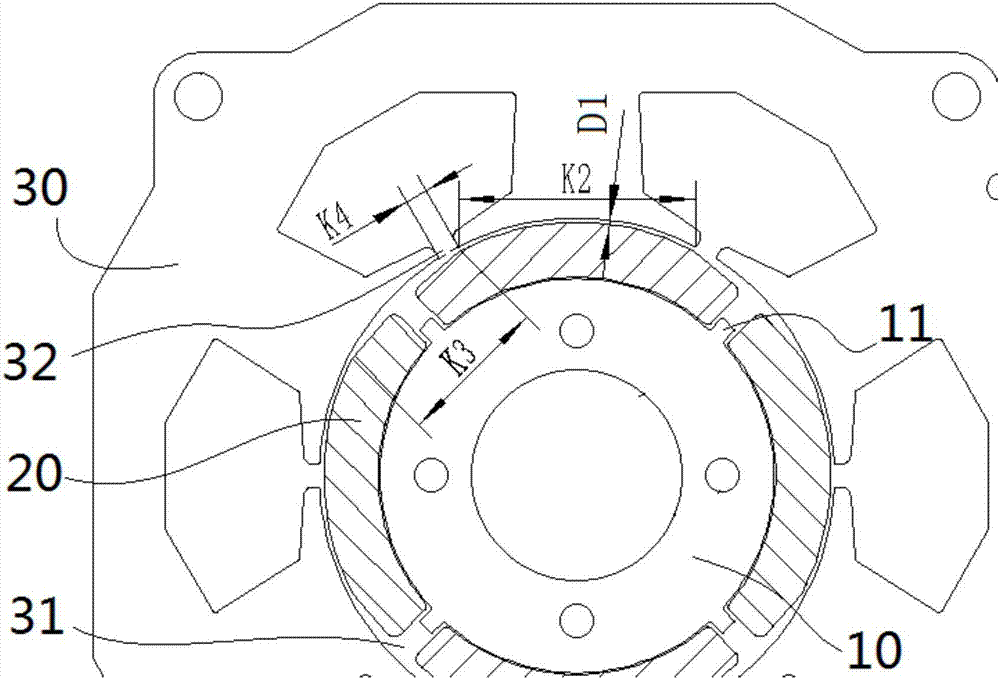

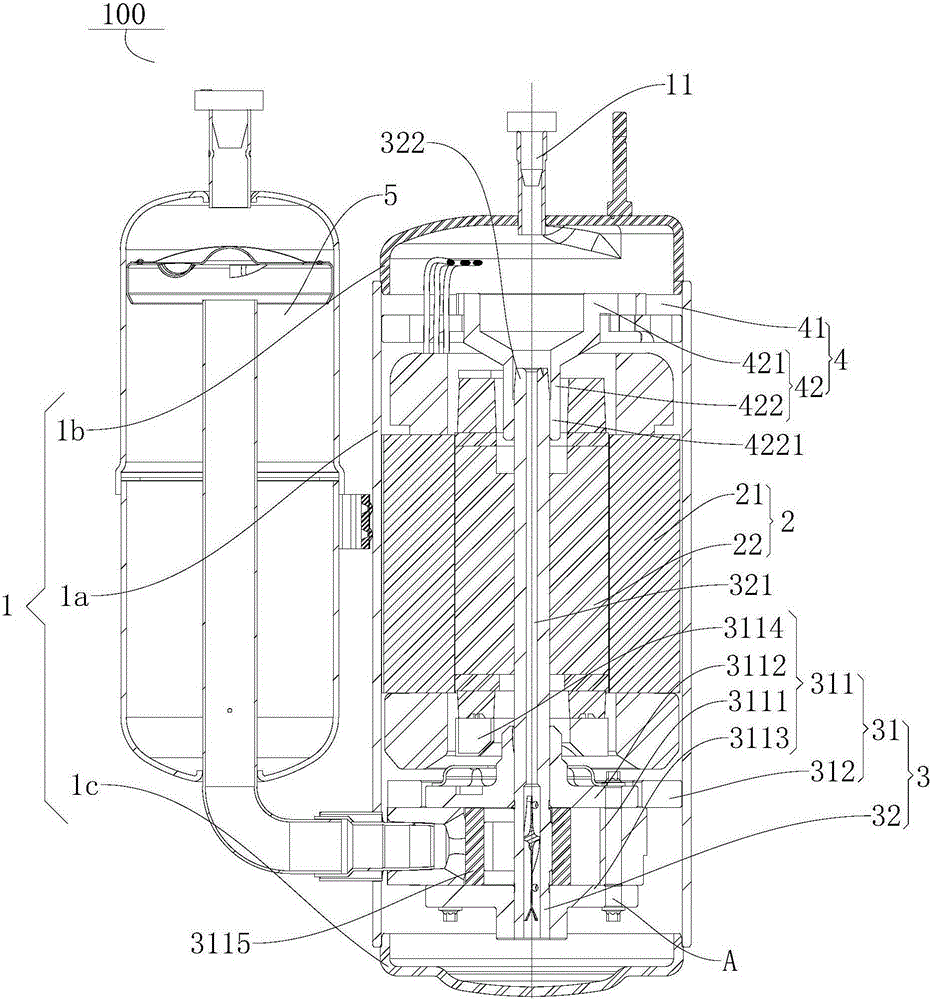

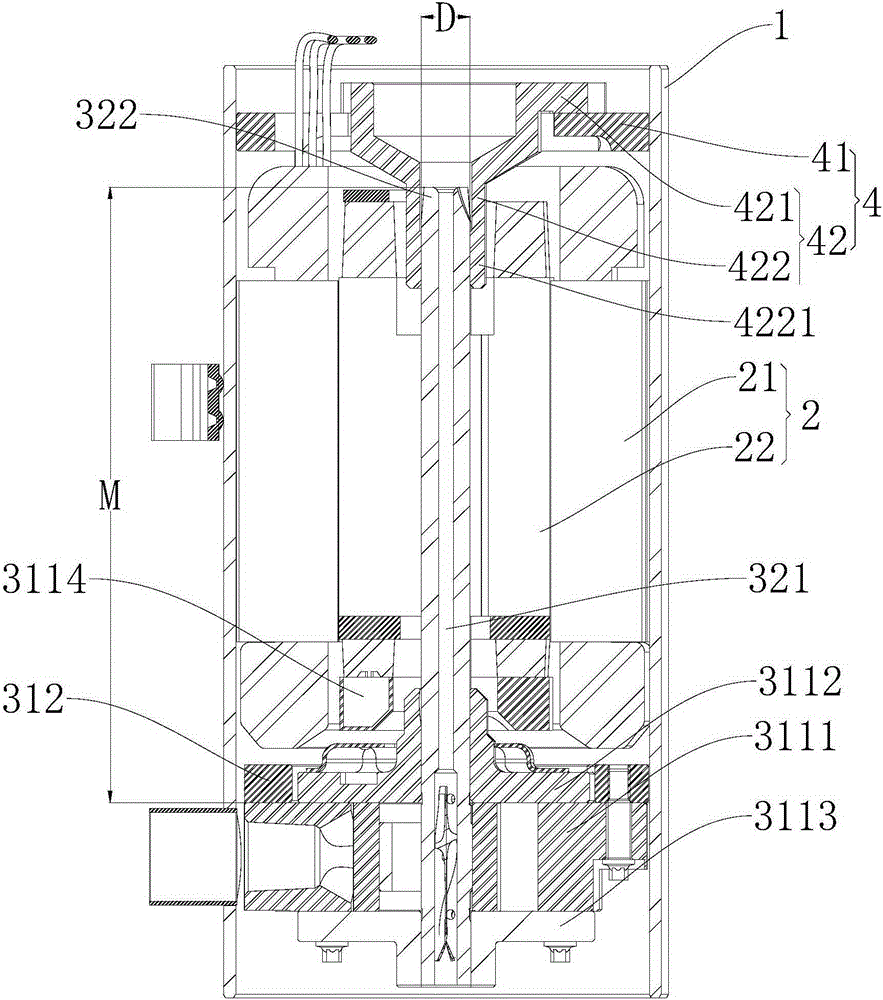

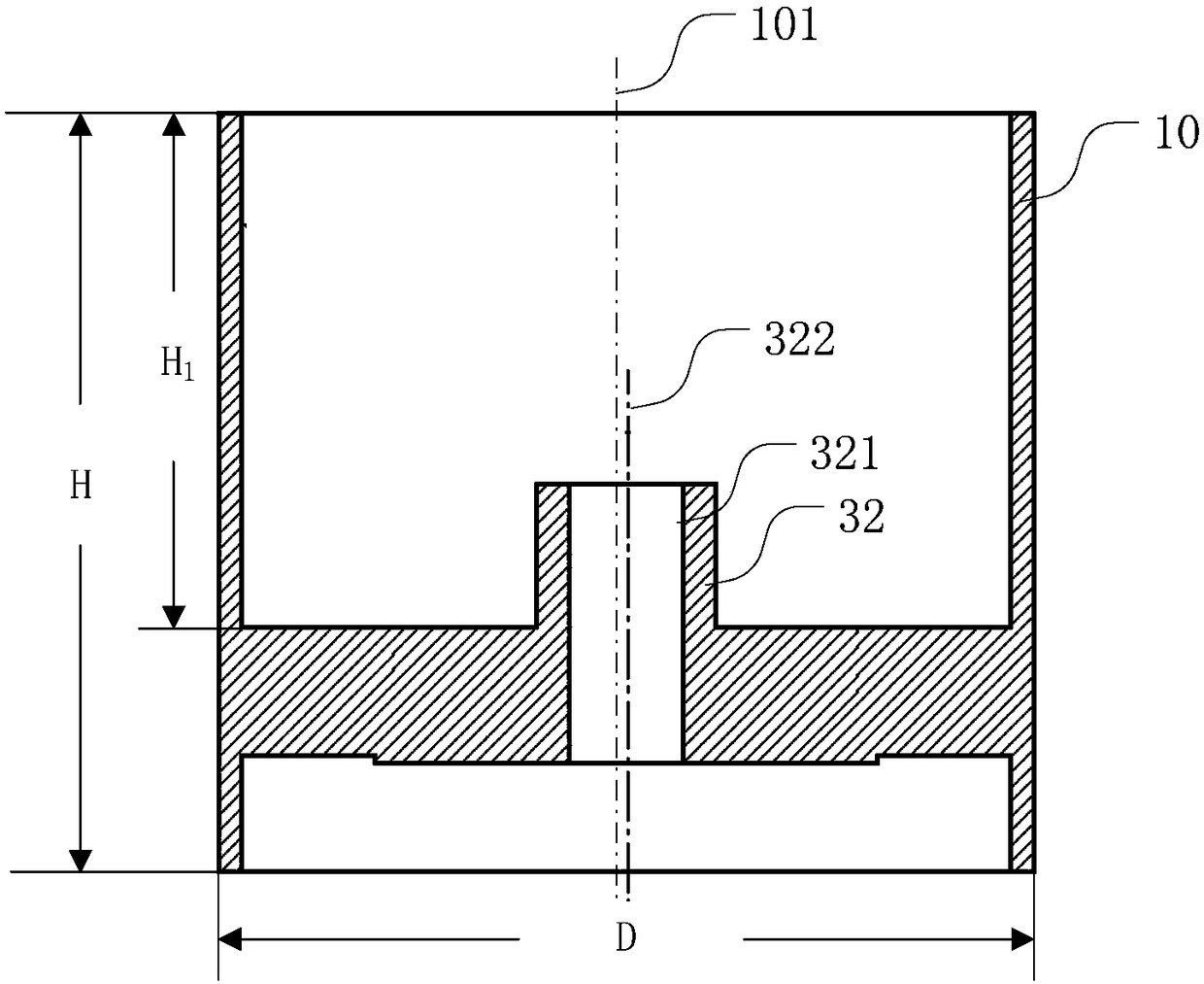

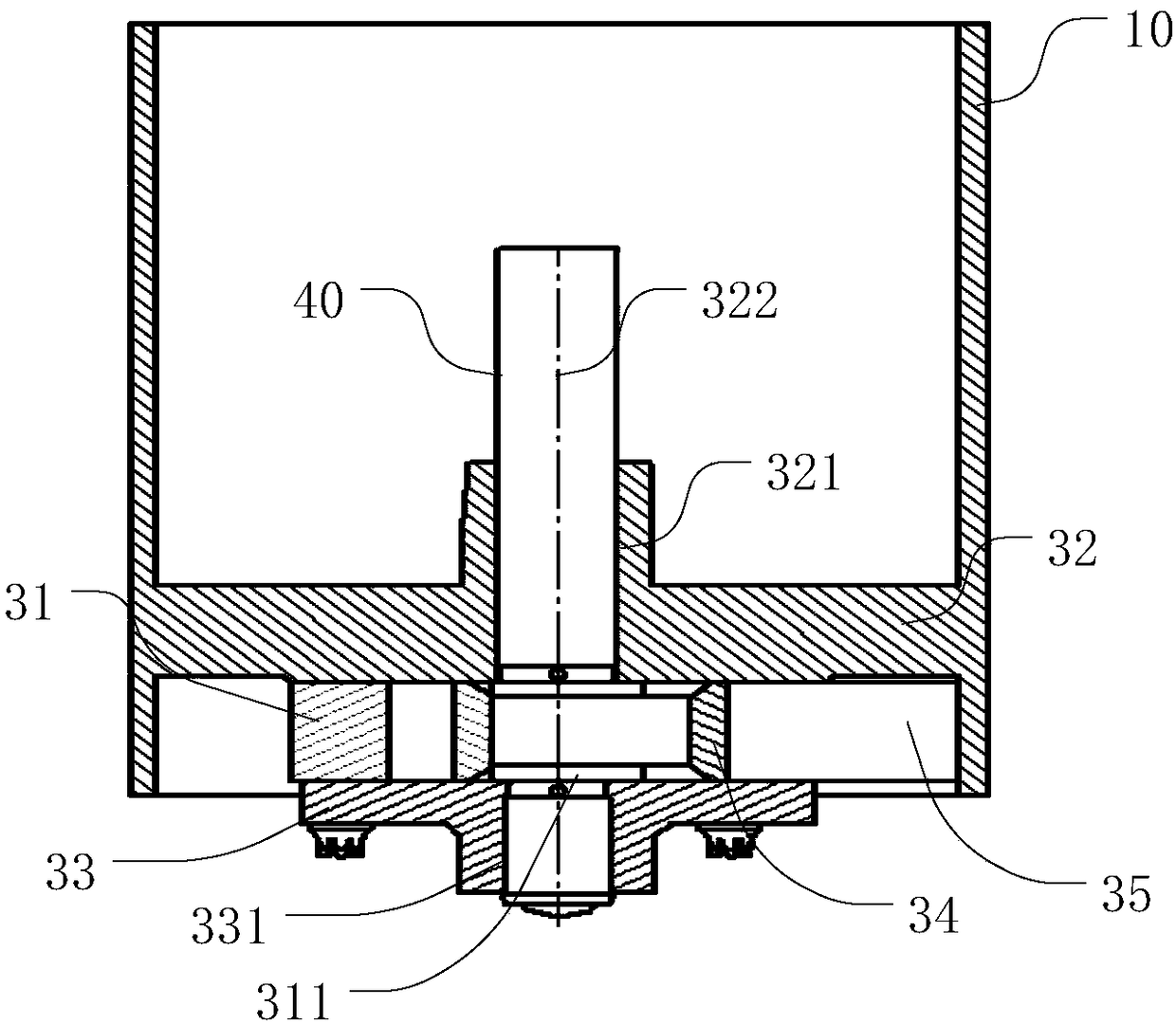

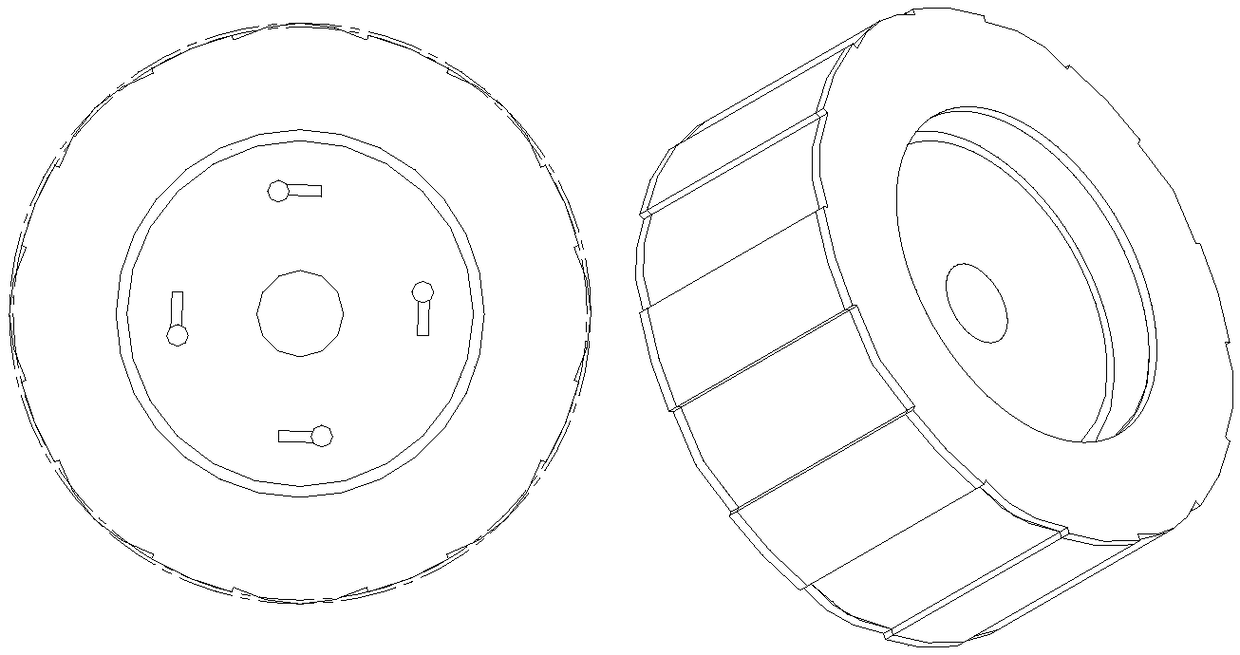

Rotary compressor

ActiveCN105041652AImprove assembly accuracySimple structureRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsMechanical engineeringCrankshaft

The invention discloses a rotary compressor. The rotary compressor comprises a shell, a compressing component, a motor component, a first machine frame and a supporting component. The peripheral wall of the first machine frame is fixed to the inner wall of the shell. A main bearing, a supplementary bearing or a cylinder or other parts such as a partition board of the compressing component are fixedly connected to the first machine frame. The supporting component comprises a second machine frame and an auxiliary bearing, wherein the peripheral wall of the second machine frame is fixed to the inner wall of the shell, and the auxiliary bearing is fixed to the upper surface of the second machine frame and arranged on the upper portion of a crankshaft in a sleeving mode. According to the rotary compressor, due to the fact that a compressing component and rotor assembly is connected to the shell in a transition mode through the first machine frame and the second machine frame, assembling precision is improved, it is guaranteed that a uniform air gap is formed between a stator and a rotor of a motor, abrasion between each bearing and the crankshaft is light, noise is low, torque power consumption caused when the crankshaft rotates is low, motor gap unbalance amount is small, and small-gap assembly of the stator and the rotor of the motor is achieved. Furthermore, the compressor is simple and reasonable in structure and high in reliability.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

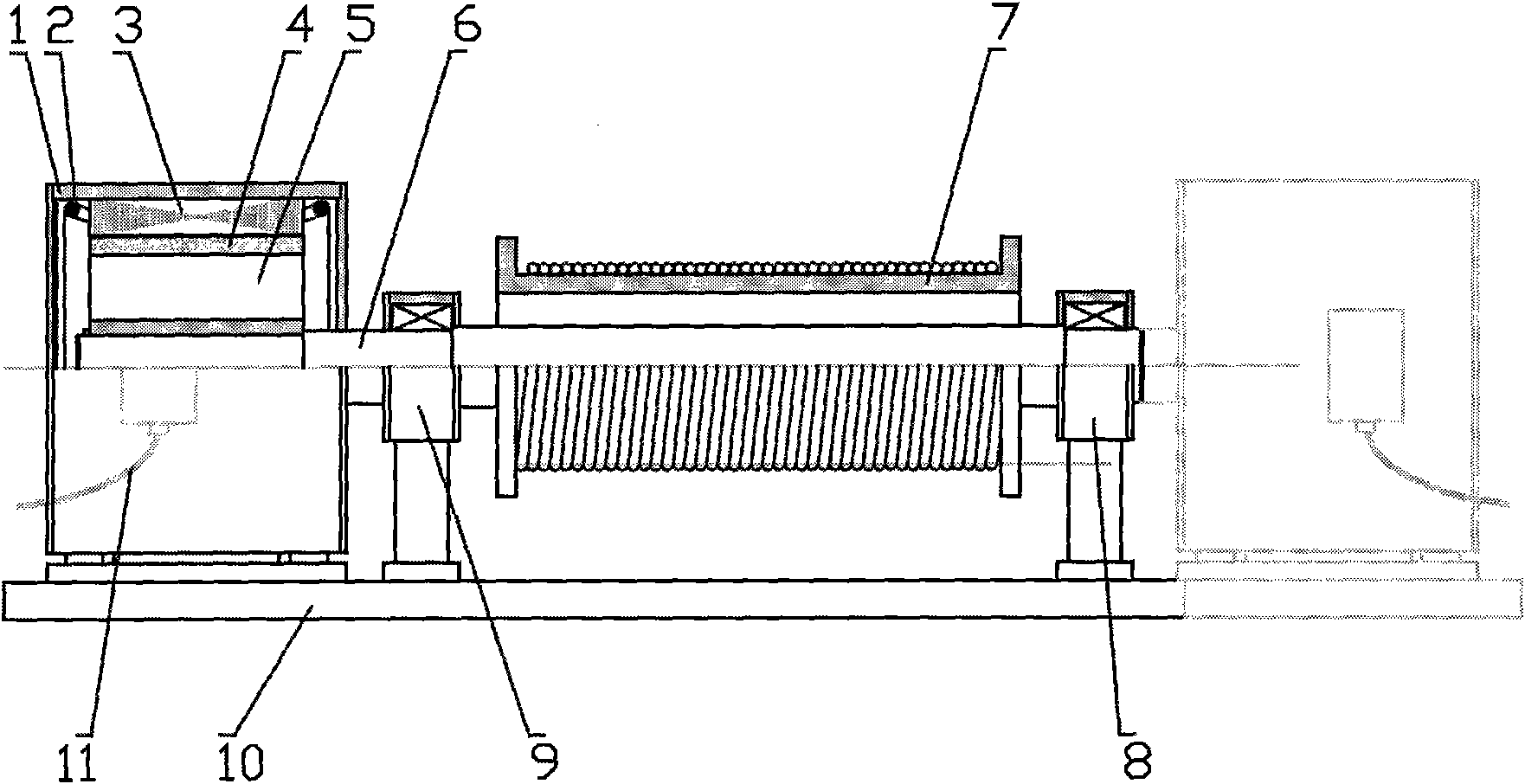

Processing method and device of alternating-current permanent-magnet servo motor stator

ActiveCN101860133AUniform air gapHigh concentricityManufacturing stator/rotor bodiesElectric machineEngineering

The invention relates to a processing method and a device of an alternating-current permanent-magnet servo motor stator. The method of the invention comprises the following steps that: 1) the processing device is arranged on a spindle of a machine tool by a taper shank, a machine base is heated, and a stator iron core is sheathed into the machine base; 2) the stator is arranged on an expanding sleeve to guarantee that the end surface of the iron core is stuck with the positioning surface of the expanding sleeve tightly; 3) the machine tool is started, spigots at the two ends of the processing machine base is processed, a screw is screwed tightly, and the expanding sleeve is expanded tightly; and 4) the screw is loosened, the stator is taken down from a clamp, aluminum skimmings on the stator are blown cleanly by compressed air. The invention solves the problem that the conventional technique influences the concentricity of the stator due to the factors of the deformation of the machine base and the like, and guarantees the concentricity of an inner hole of the stator iron core and the spigots of the machine base, thus achieving the purpose of reducing the location torque of a motor and reducing the vibration and noise of the motor.

Owner:广东伊莱斯电机有限公司

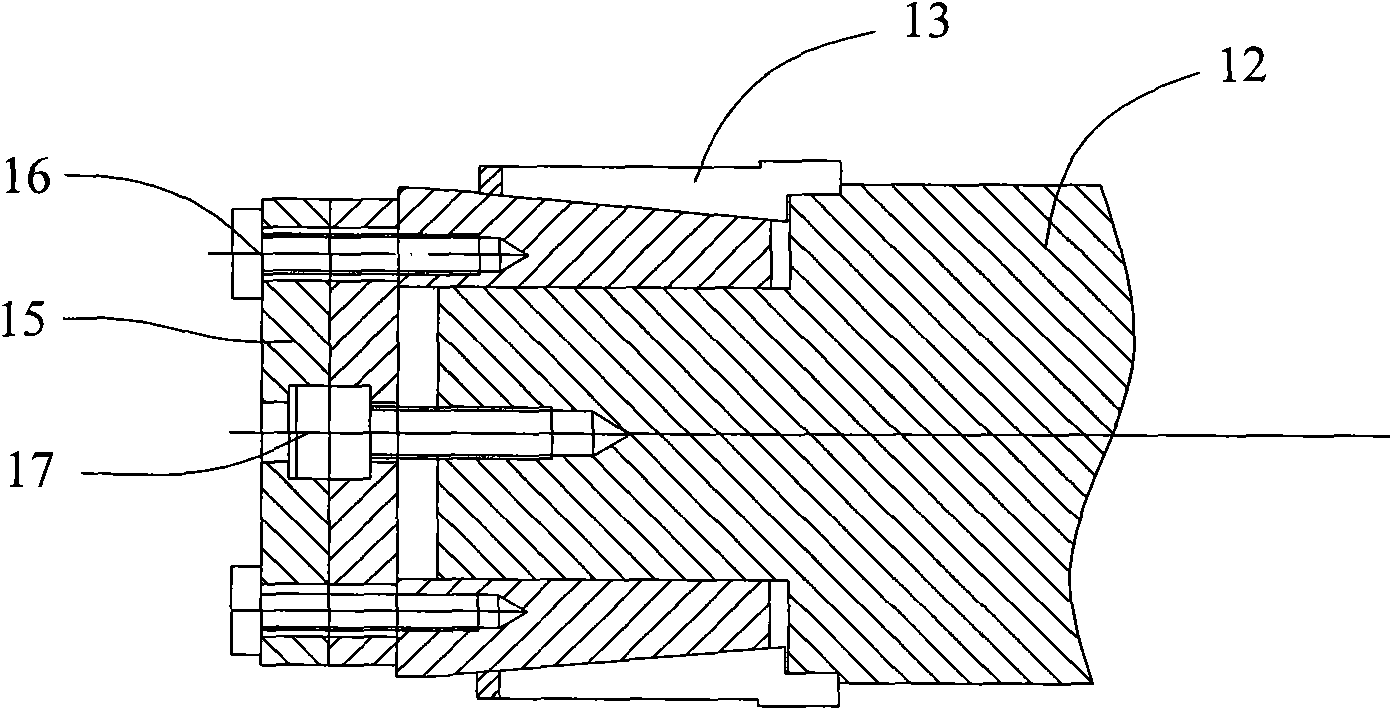

Calliper brake with disengaged position

ActiveCN100385134CUniform air gapPrevent slippageAxially engaging brakesSelf acting brakesEngineeringMechanical engineering

Owner:CHRISTIAN MAYR GMBH & CO KG

Permanent magnet bias single-degree-of-freedom axial magnetic bearing

The invention discloses a permanent magnet bias single-degree-of-freedom axial magnetic bearing. The permanent magnet bias single-degree-of-freedom axial magnetic bearing comprises a stator and a rotor iron core. The rotor iron core comprises an axial part and a radial part. The stator comprises a left side iron core bridge iron core, a right side iron core bridge iron core, a left side annular permanent magnet, a right side annular permanent magnet, a magnetic bearing left side stator iron core and a magnetic bearing right side stator iron core, wherein the left side iron core bridge iron core and the right side iron core bridge iron core are symmetrically arranged with the radial part of the rotor iron core as the symmetric center and arranged along the axial part of the rotor iron core, the left side annular permanent magnet and the right side annular permanent magnet are symmetrically arranged with the radial part of the rotor iron core as the symmetric center and arranged along the axial part of the rotor iron core, the magnetic bearing left side stator iron core and magnetic bearing right side stator iron core are symmetrically arranged with the radial part of the rotor iron core as the symmetric center and arranged along the axial part of the rotor iron core, and the left side iron core bridge iron core and the right side iron core bridge iron core, the left side annular permanent magnet and the right side annular permanent magnet and the magnetic bearing left side stator iron core and magnetic bearing right side stator iron core are sequentially arranged. A magnetism isolation aluminum ring is arranged between the magnetic bearing left side stator iron core and magnetic bearing right side stator iron core. The magnetic bearing left side stator iron core and magnetic bearing right side stator iron core are each of an E-shaped structure. A control winding is manufactured in each stator groove in a winding manner. The permanent magnet bias single-degree-of-freedom axial magnetic bearing effectively overcomes the defects of an existing axial magnetic bearing, and the low-power-consumption single-degree-of-freedom axial magnetic bearing easy to control, manufacture and assemble and capable of controlling magnetic flux not to pass through the permanent magnets and the rotor axial iron cores and generating larger axial levitation force is provided.

Owner:金湖县项目服务中心

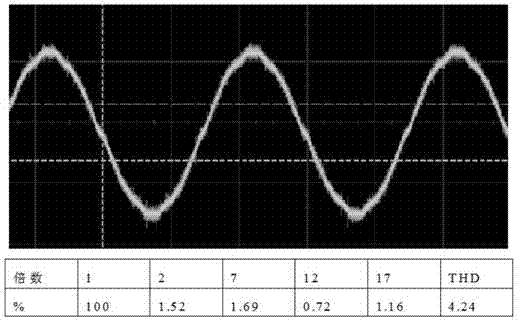

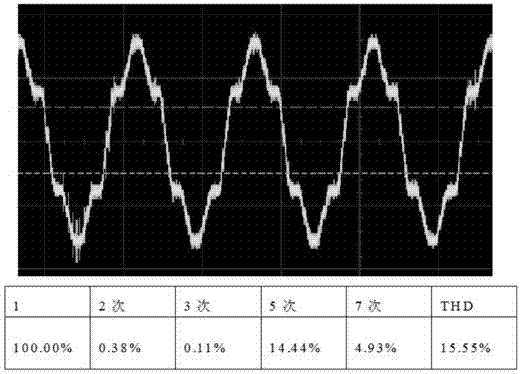

Motor and compressor

ActiveCN107425685ASave crafting materialsGuaranteed performanceSynchronous machine detailsMagnetic circuit rotating partsHarmonicManufactured material

The invention provides a motor and a compressor, wherein the motor comprises a rotor iron core and magnets arranged on the rotor iron core; each magnet is of a circular arc-shaped structure; the circular arc-shaped structure comprises an inner surface and an outer surface which are arranged at intervals; the inner surface is in a first arc surface shape matched with the rotor iron core; and the outer surface comprises an arc surface section in a second arc surface shape and tangent plane sections connected at the two ends of the arc surface section. By using the technical scheme, the magnets are of the circular arc-shaped structures, and the inner surface is in the first arc surface shape matched with the rotor iron core, so that the inner surface can be better attached to the rotor iron core; the air gap uniformity of a motor is ensured; and the performance of the motor is further ensured. Meanwhile, the outer surface also comprises the tangent plane sections connected at the two ends of the arc surface section; through the tangent plane sections, manufacturing materials of the magnets can be reduced; the air gap harmonic wave content is reduced; the goals of reducing vibration and lowering the noise can be achieved; and the problem of sinusoidal air gap flux density can be solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Single-phase permanent magnet alternating current motor

InactiveCN108539947AUniform air gapHarmonic reductionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic poles

The invention discloses a single-phase permanent magnet alternating current motor. The single-phase permanent magnet alternating current motor comprises a stator assembly and a rotor assembly. The stator assembly comprises a stator core and a winding, the stator core comprises a plurality of teeth, and the winding is wound on the teeth; the rotor assembly is mounted on an inner hole, the rotor assembly is provided with at least one pair of magnetic poles, and the specific value of the quantity of the number of pole pairs and the quantity of the teeth is 1: 4. Through the technical scheme, thespecific value of the quantity of the number of pole pairs and the quantity of the teeth is 1: 4, when the motor is static, the rotor assembly remains at four specific positions, and starting torquescan be generated at the four specific positions under the condition that a structure with large and small sides is not arranged. The structure with large and small sides is not arranged, and the air gap of the single-phase permanent magnet alternating current motor in the invention is uniform, so that the harmonic wave of an air-gap magnetic field is reduced compared with that in the prior art, and the noise can be reduced to a certain extent.

Owner:FORTIOR TECH SHENZHEN

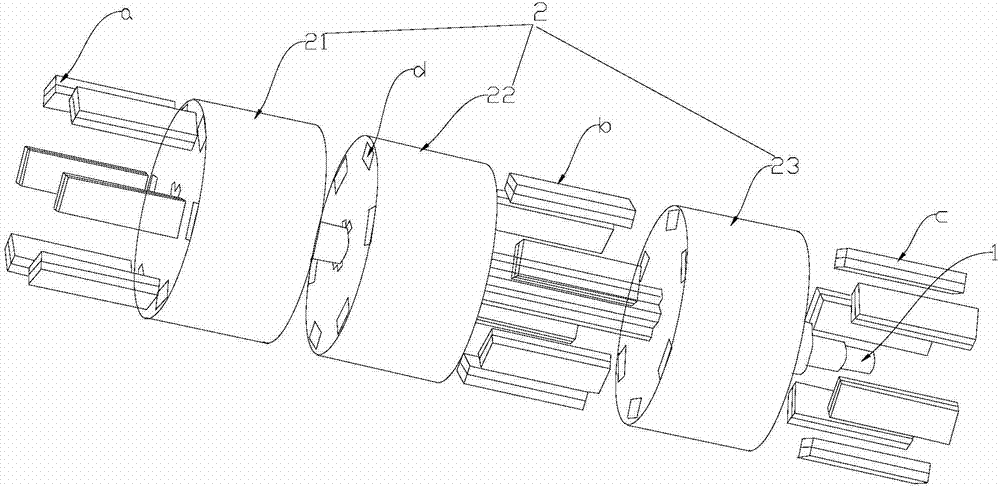

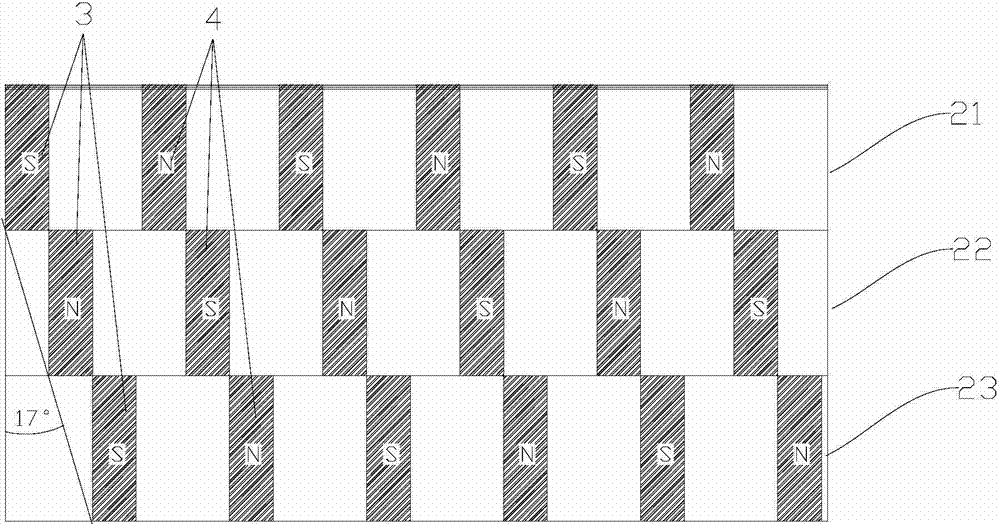

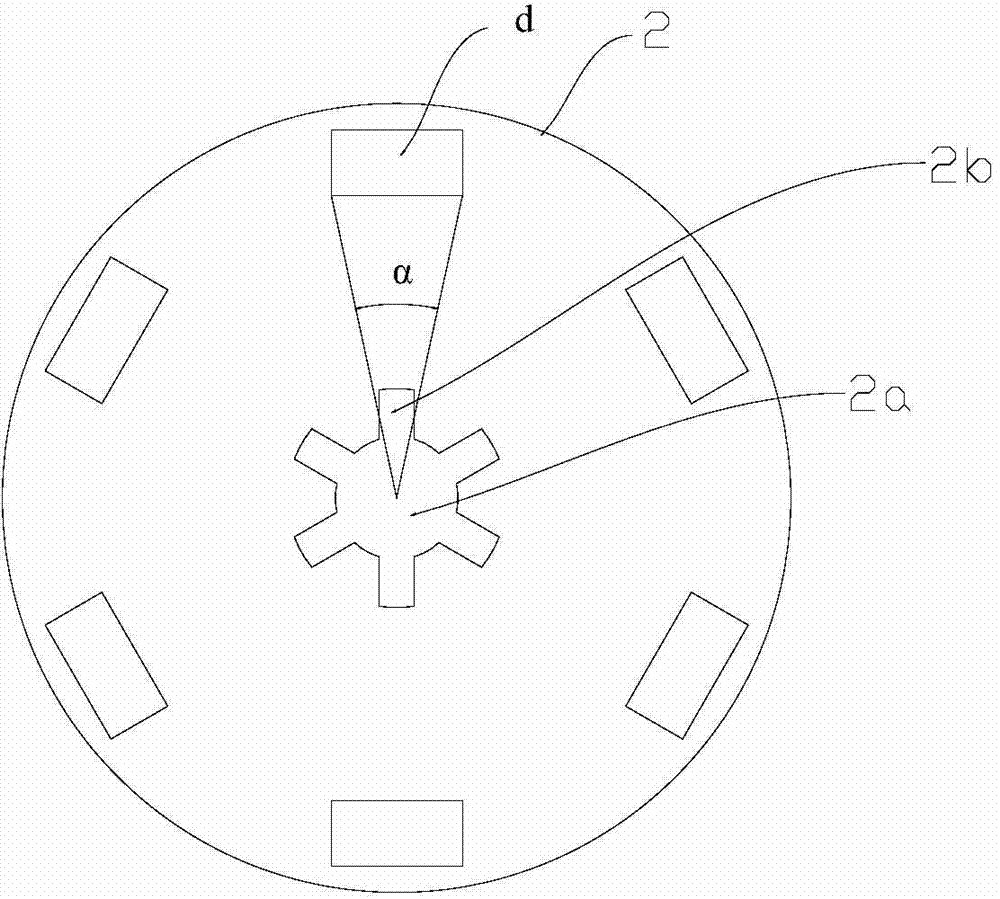

Rotor and motor comprising same

ActiveCN104779721AImprove electricity efficiencyUniform air gapMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineEnergy conservation

The invention provides a rotor and a motor comprising the same. The rotor comprises a rotating shaft, a rotor magnetic conduction yoke, multiple first permanent magnet groups and multiple second permanent magnet groups, wherein the multiple first permanent magnet groups and the multiple second permanent magnet groups are distributed alternately at equal intervals in the circumferential direction of the rotor magnetic conduction yoke, projections of the first permanent magnet groups and the second permanent magnet groups in a plane perpendicular to the rotating shaft are adjacent, and edges of the projections are overlapped. The rotor and the motor comprising the same have the benefits that torque pulsation caused by electromagnetic factors is reduced, and external work of torque is increased, so that the power utilization efficiency of the motor is improved, and energy resources are saved.

Owner:SHENZHEN TIANTIAN NEW ENERGY TECH

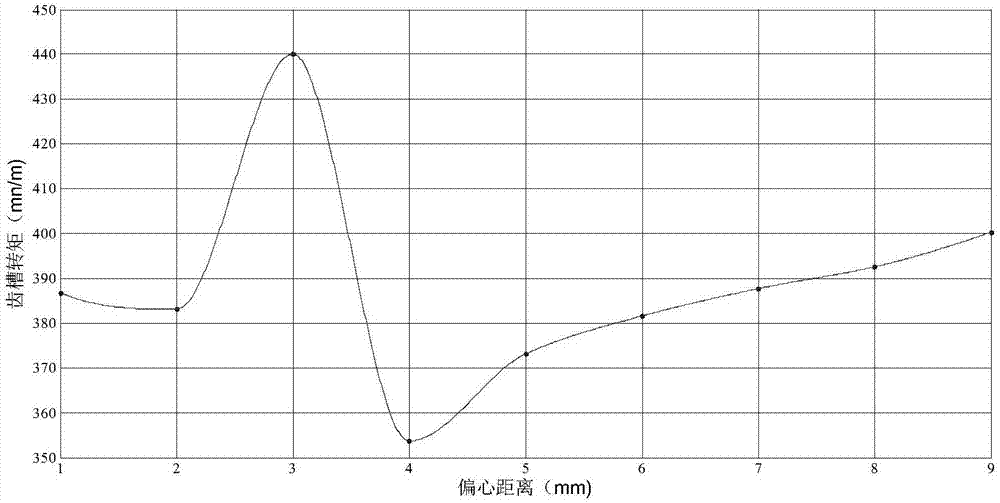

New type surface mounted permanent magnet synchronous motor with reduced cogging torque

ActiveCN107482804AReduce cogging torqueReduce dosageMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsPermanent magnet synchronous motor

The present invention discloses a new type surface mounted permanent magnet synchronous motor with reduced cogging torque, which belongs to the technical field of electric motor manufacturing. The motor comprises a rotor and a stator. The stator is provided with a stator slot, and the stator slot is wound by rectangular armature windings. The structure of the rotor is that four evenly distributed fan-shaped rotors are welded on the rotor shaft, and the two end surfaces at the circumferences of the fan-shaped rotors are mounted with first permanent magnets in the same size, and the middle surfaces are mounted with second permanent magnets. There exist inclined angles among the second permanent magnets and the first permanent magnets. The thickness of the first permanent magnets gradually narrows from the middle to the two ends; and the thickness of the second permanent magnets gradually narrows from one end of the first permanent magnets to the other end. The invention is capable of weakening the cogging torque of permanent motors significantly; and at the same time, the use quantity of the silicon steel sheets of the rotation shaft makes the rotor lighter, which increases the output torque of the motor and improves the performance of the motor.

Owner:JIANGSU UNIV

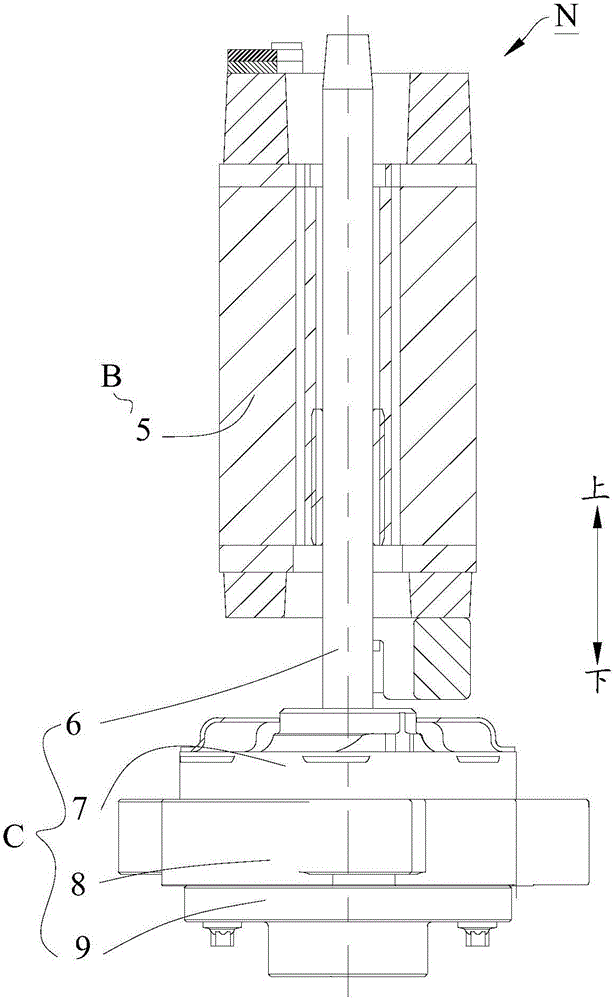

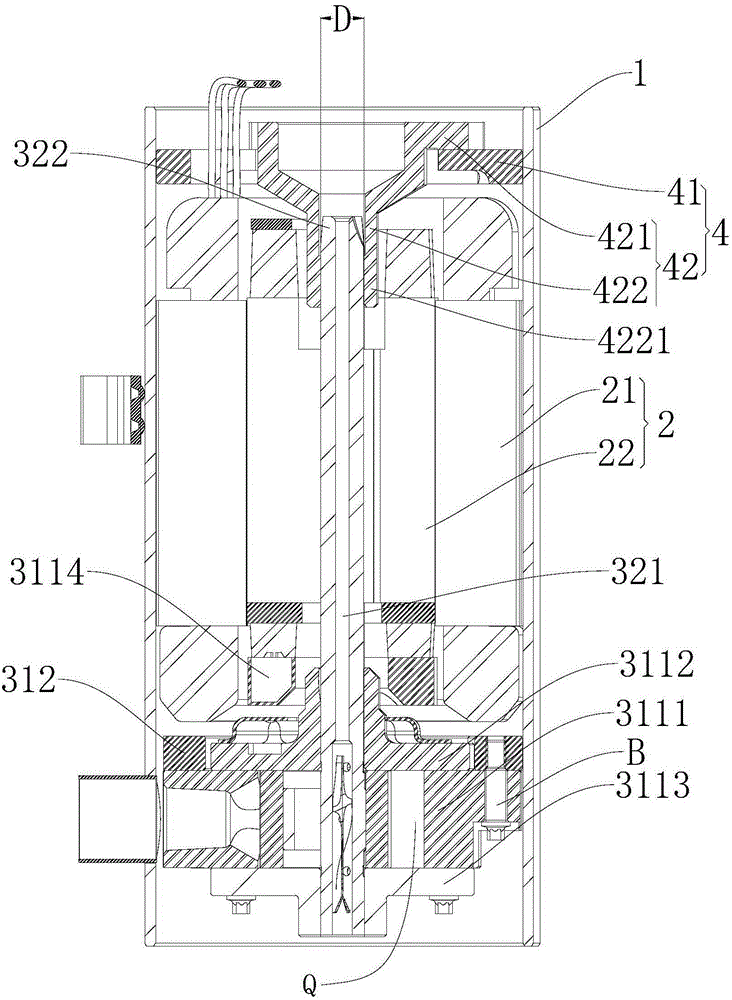

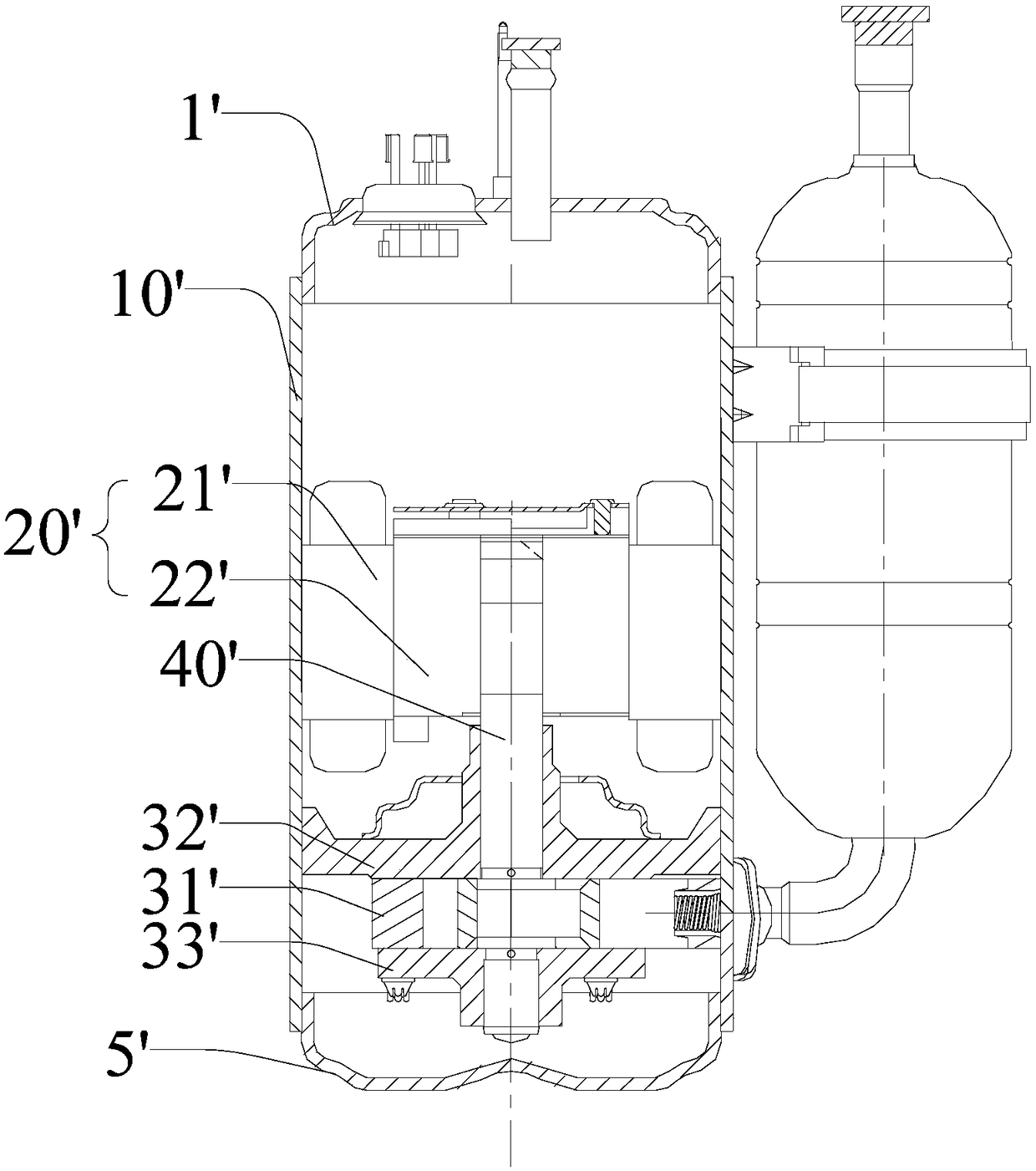

Rotary compressor

ActiveCN105201845AImprove assembly accuracyUniform air gapRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsDrive motorStator

The invention discloses a rotary compressor which comprises a housing, a driving motor, a compressing mechanism and a supporting component. The driving motor is arranged inside the housing and comprises a stator and a rotor which is rotatablely arranged inside the stator. The compressing mechanism is disposed inside the housing and contains a compression component and a crankshaft. The compression component is fixed on the housing and at least comprises an air cylinder component. The supporting component is arranged inside the housing and is positioned at one side of the driving motor, far from the compression component. The supporting component is fixed on the housing and is in supporting fit with one end of the crankshaft that passes through the rotor. The rotary compressor is configured under the following condition: Q / D is less than or equal to 22 cm<2> and greater than or equal to 10 cm<2>, wherein Q is displacement of the rotary compressor, and D is shaft diameter of a main shaft section of the crankshaft positioned at one side of the air cylinder component near the driving motor. According to the rotary compressor, assembly accuracy is raised, and collision between rotor and stator bore is reduced as well as abrasion between the crankshaft and the compression component. Thereby, performance and reliability of the compressor are enhanced.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

Compressor and manufacturing method thereof

ActiveCN109424515AImprove noiseReduce offsetPositive displacement pump componentsPiston pumpsEngineeringMechanical engineering

The invention provides a compressor and a manufacturing method thereof. The compressor comprises a shell, an upper cylinder cover, a lower cylinder cover, a motor, an air cylinder and a crankshaft; the shell is provided with a central shaft; the upper cylinder cover is located in the shell and provided with a first inner hole which is axially parallel to the central shaft; the lower cylinder coveris located in the shell and provided with a second inner hole coaxial with the first inner hole; the motor and the air cylinder are contained in the shell, and the air cylinder is provided with a third inner hole which is axially parallel to the central shaft; the crankshaft is used for transmitting rotating force of the motor to a piston of the air cylinder to compress a refrigerating agent, andthe crankshaft is inserted into the first inner hole, the third inner hole and the second inner hole; and before the crankshaft is inserted into the first inner hole, the upper cylinder cover or theair cylinder and the shell are an integrated part, or the upper cylinder cover or the air cylinder and the shell are connected with each other. According to the compressor and the manufacturing methodthereof, noise of the compressor can be reduced.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

Rotor structure, motor rotor and motor

ActiveCN108880031AGuaranteed dimensional accuracy of outer diameterImprove Noise PerformanceMagnetic circuit rotating partsBrushless motorsInterference fit

The invention provides a rotor structure, a motor rotor and a motor, and relates to the technical field of a DC brushless motor. By the rotor structure, the motor rotor and the motor, the technical problem of high production cost of the rotor structure is solved. The rotor structure comprises an iron core and a magnetic tile, wherein a plug structure is arranged on the iron core and / or the magnetic tile, the magnetic tile can be arranged on the iron core in a plug mode by the plug structure, the magnetic tile is fixedly connected with the iron core in an interference fitting mode, the plug structure is an installation groove formed between two iron core tooth parts and arranged along a circumferential direction of the iron core, the magnetic tile is inserted into the installation groove, the magnetic tile and the installation groove are connected in the interference fitting mode, a side wall of the installation groove is an inclined side wall inclining outwards by 1 degree, so that theinstallation groove which is large in upper part and small in lower part is formed. The rotor structure has the characteristics of low cost, motor running reliability, rotor air gap uniformity, highrotor magnetic field utilization ratio and high motor efficiency, the motor cogging torque and the torque pulse are reduced, and the motor noise performance is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

Magnetic coupling and mounting method thereof

ActiveCN106059249ACompact structureReduce weightManufacturing dynamo-electric machinesPermanent-magnet clutches/brakesPermanent magnet rotorCoupling

The invention provides a magnetic coupling and a mounting method thereof. The magnetic coupling comprises an inner permanent magnet rotor, an outer permanent magnet rotor and a plurality of positioning connectors, wherein the inner permanent magnet rotor comprises an inner permanent magnet and an inner cylinder part for bearing the inner permanent magnet, and the outer wall of the inner cylinder part is provided with an annular flange convex radially; the outer permanent magnet rotor comprises an outer permanent magnet and an outer cylinder part for bearing the outer permanent magnet, one side surface of the outer cylinder part is provided with an annular flange convex radially, and the outer cylinder part sleeves the inner cylinder part to enable magnetic poles of the inner permanent magnet and the outer permanent magnet to be mutually matched and enable an air gap to be left; and the plurality of positioning connectors are uniformly and circumferentially arranged around the axis of the coupling, and are detachably connected between the end surface of the outer cylinder part and the annular flange of the inner cylinder part to enable the two to be connected and positioned. The inner permanent magnet rotor and the outer permanent magnet rotor are not adsorbed together, the coaxiality of the two permanent magnet rotors are ensured, stability and reliability during a high-speed rotation process can be ensured, and thus, the structure is compact, the mounting is convenient, the weight is light, and the operation is stable and reliable.

Owner:JIANGSU MAGNET VALLEY TECH

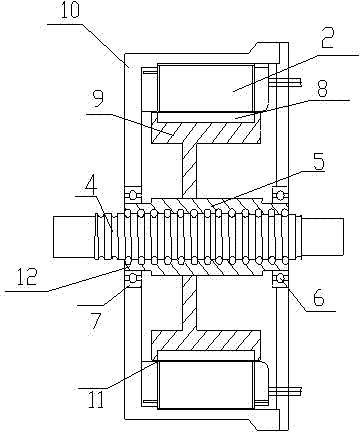

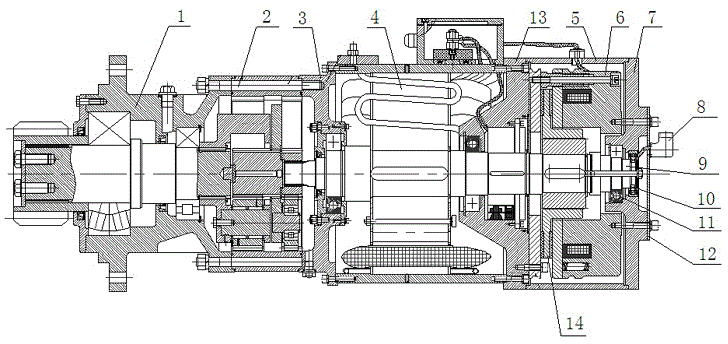

Multifunctional integrated electric driver

InactiveCN104467275ASolve the problem of large volume and heavy weightWon't hurtMechanical energy handlingReduction driveReducer

A multifunctional integrated electric driver comprises a speed reducer, a front end cover, a rear end cover, a motor, a brake and a friction disc. The speed reducer is fixedly connected to a motor shell through a screw rod and the front cover. The brake is fixedly connected to the motor shell through the friction disc and the rear end cover. The axial two ends of the motor shell are connected with the front end cover and the rear end cover respectively. A tail cover is additionally mounted at the tail end of the brake. A bearing and a rotating transformer are additionally mounted in the tail cover. The multifunctional integrated electric driver overcomes the defects that the motor, the speed reducer and the brake are arranged in a scattered mode, the occupied space is large, the mounting duration is long, and working efficiency is low, and the multifunctional integrated electric driver is widely suitable for being used in cooperation with various electric driving devices.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

Multi-drive new energy car

InactiveCN108016272ALow costQuality improvementGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingLow speedNew energy

A multi-drive new energy car consists of an average car, brake motor assemblies, a lithium battery box, an intelligent control box, a speed sensor, a Hall speed governor, a throttle solenoid valve anda brake solenoid valve. Coil type motors of the brake motor assemblies fully and reasonably utilize the space between aluminum alloy rims and drum brakes. Upper and lower connection claws of the coiltype motors are under the up-and-down equilibrium condition of forces, so that output torque driven by the coil type motors does not generate radial pressure on ultra-thin bearings between stators and rotors and does not bear vehicle loading pressure. In addition to the power driven by an engine, the left and right low-speed coil type motors of the multi-drive new energy car drive front wheels and the left and right high-speed coil type motors of the multi-drive new energy car drive rear wheels, so that the multi-drive new energy car has hybrid power. The reasonable matching of a variety of power, automatic switching of power and automatic shifting of gears are achieved through artificial intelligence control, so that the multi-drive new energy car can work in the best state of energy saving and environmental protection. The brake motor assemblies can easily upgrade the average car into the multi-drive new energy car, so as to not only reduce the cost of the new energy car but also improve the quality of the new energy car.

Owner:朱幕松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com