Gearless permanent-magnet synchronous traction machine

A synchronous traction machine and gearless technology, which is applied in the field of elevator traction machines, can solve the problems of uneven air gap between the stator and rotor, unfavorable heat dissipation of the motor, and inability to lubricate well, and achieve compact structure, uniform air gap, good The effect of lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

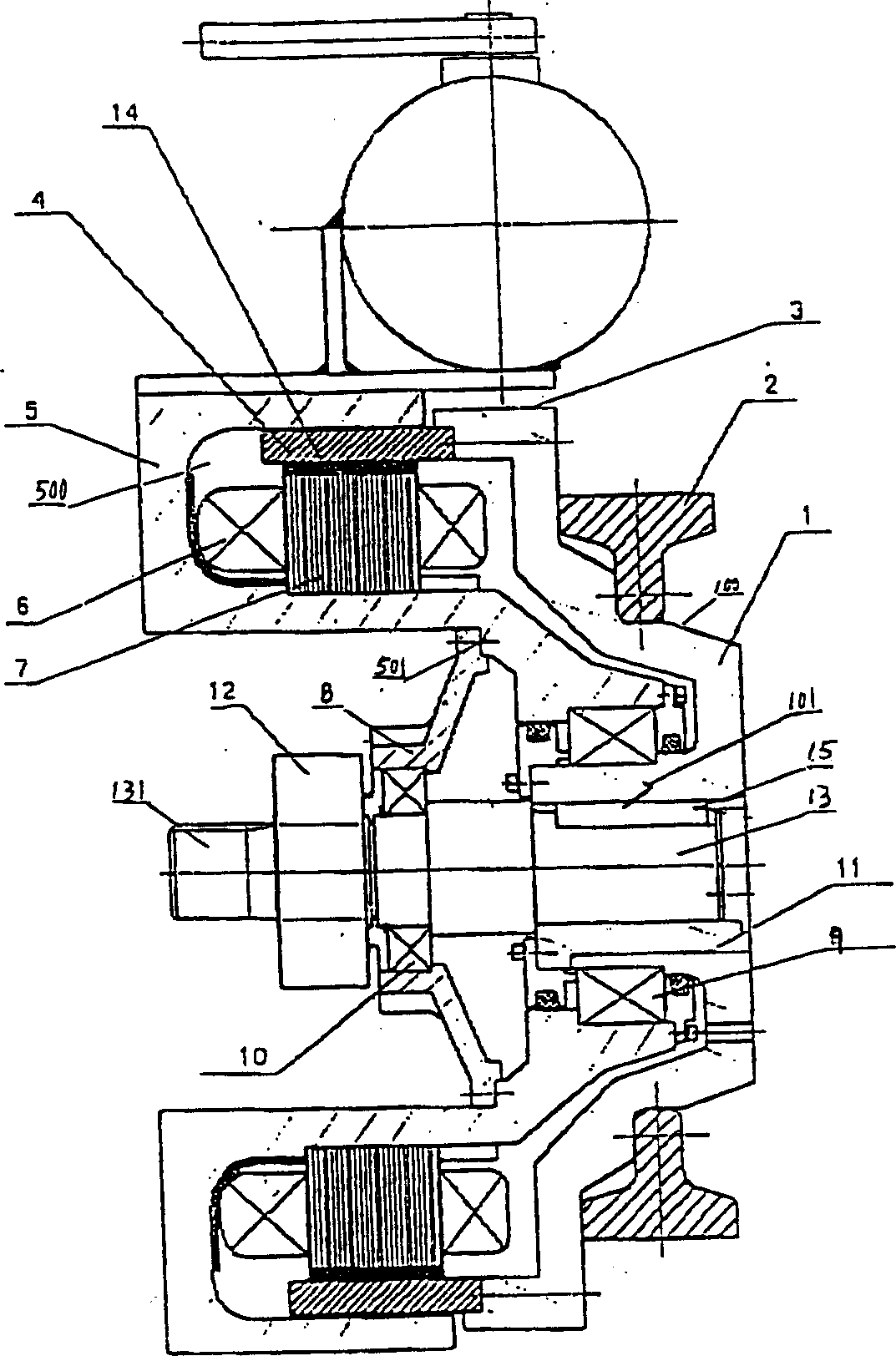

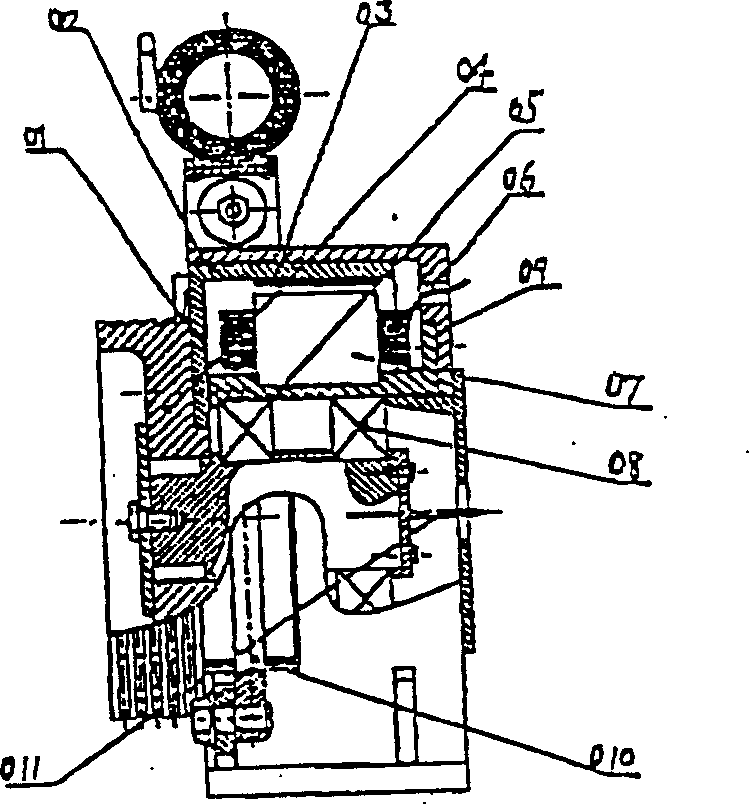

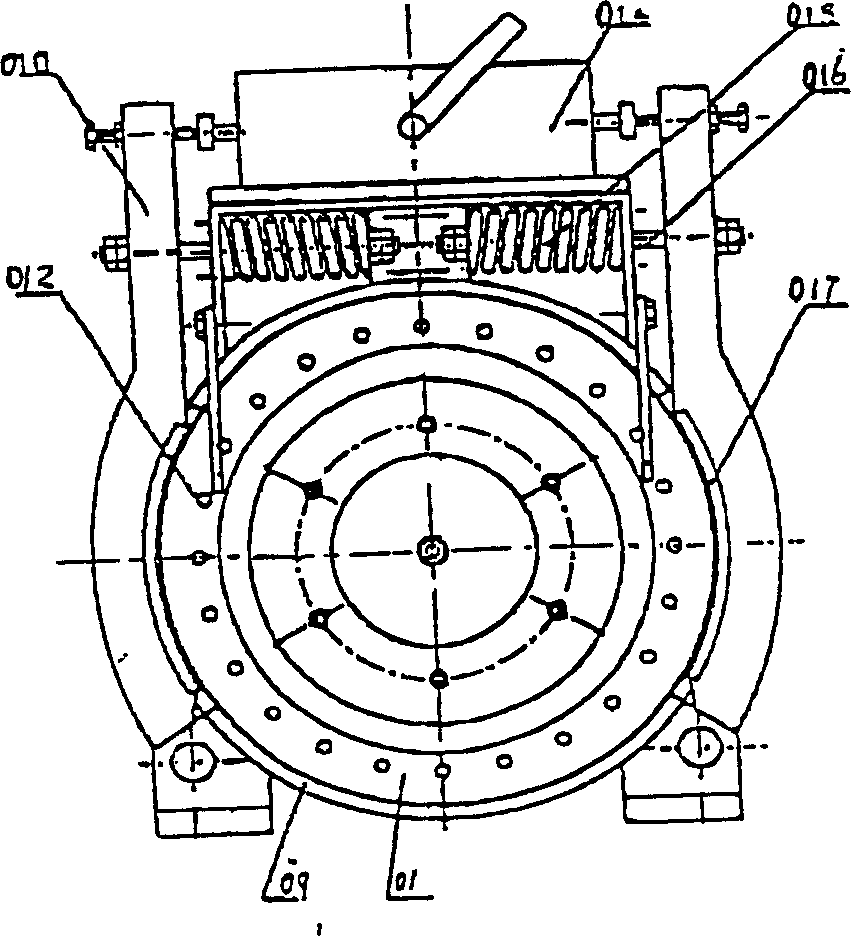

[0010] Such as figure 1 As shown, the structure of the present invention includes a bowl-shaped outer rotor 1 with a key 15 set on the hollow cylinder 101 of the main shaft 13, a traction sheave 2 is fixed on the outer surface 100 of the outer rotor 1, and a bowl mouth of the outer rotor is provided. There is a braking surface 3, and the outer circle of the hollow cylinder 101 of the outer rotor 1 is sequentially fitted with bearings 9 and in the shape of a swallow, and the wings are bent backward to form an inner hole of an open annular groove 500. The inner hole of the stator 5 has a flange 501, and the stator 5 The stator armature iron core 7 wound with the stator winding 6 is sequentially loaded into the annular groove 500, and the outer rotor 1 is equipped with a yoke 4 and a permanent magnet 14 docked with it, and the bowl edge of the hole bottom bowl 8 is connected to the stator The inner hole flange 501 of the bowl bottom hole is connected with the bearing 10 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com