Low-power-consumption permanent-magnet bias five-degree-of-freedom integrated magnetic bearing

A technology of permanent magnet bias and magnetic bearing, which is applied in the field of bearing manufacturing to achieve the effects of reducing magnetic flux leakage, high critical speed and short axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

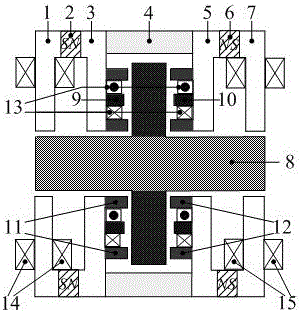

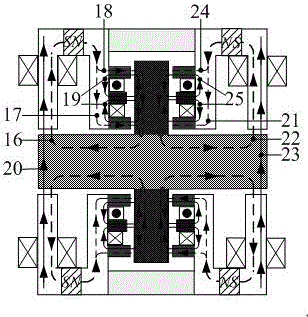

[0028] The present invention is based on the principle that the axially magnetized left annular permanent magnet 2 provides the left side bias magnetic fluxes 16, 17 and 18 to the left radial magnetic bearing core 1 and the left axial magnetic bearing core 3; The axially magnetized right annular permanent magnet 6 provides the right bias magnetic fluxes 22, 21 and 24 to the right radial magnetic bearing core 7 and the right axial magnetic bearing core 5; the control winding 14 generates the left radial magnetic flux The control winding 15 interacts with the left bias flux 16 to generate the left radial levitation force; the control winding 15 generates the right radial control flux 23, which interacts with the right bias flux 22 to generate the right Radial levitation force; the control winding 13 produces left and right axial control magnetic fluxes 19 and 25 respectively, the left axial control magnetic flux 19 interacts with the left bias magnetic flux 17, 18, and the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com