Rotor structure, motor rotor and motor

A technology of rotor structure and motor rotor, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of low production cost and high production cost, achieve high production efficiency, low cost, and ensure dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

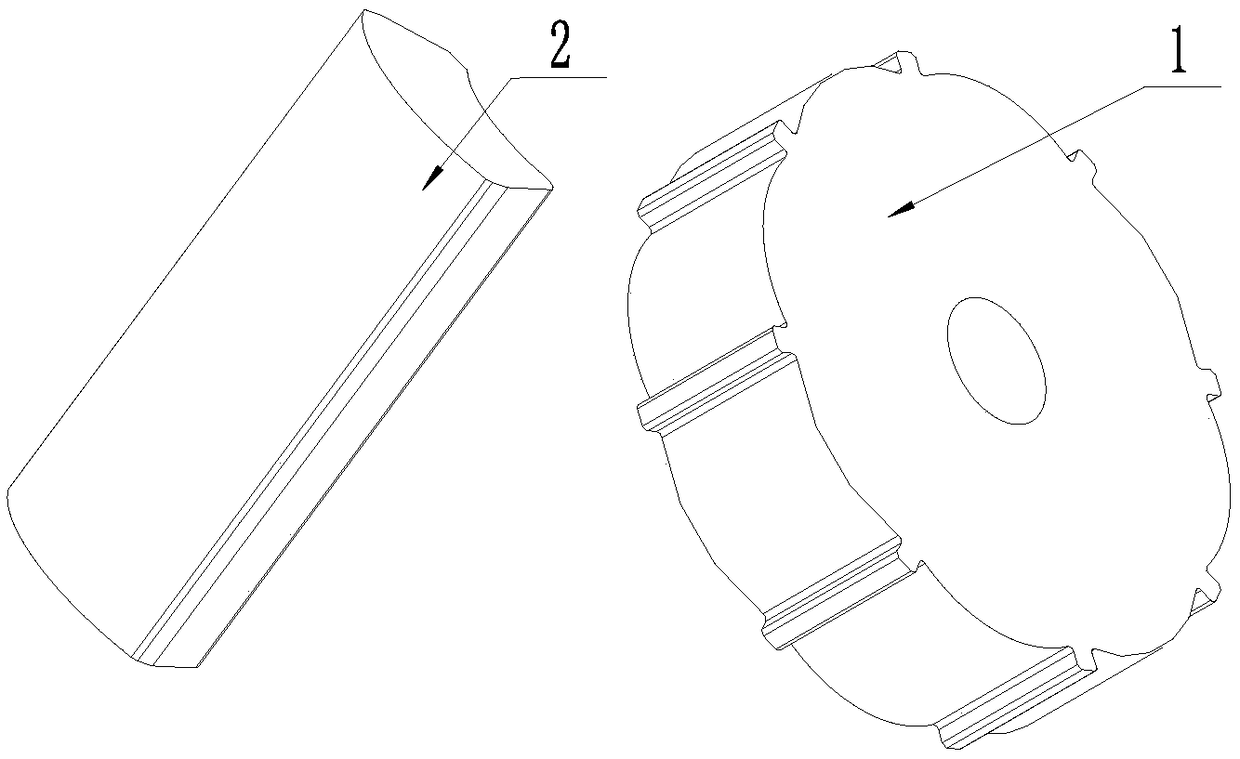

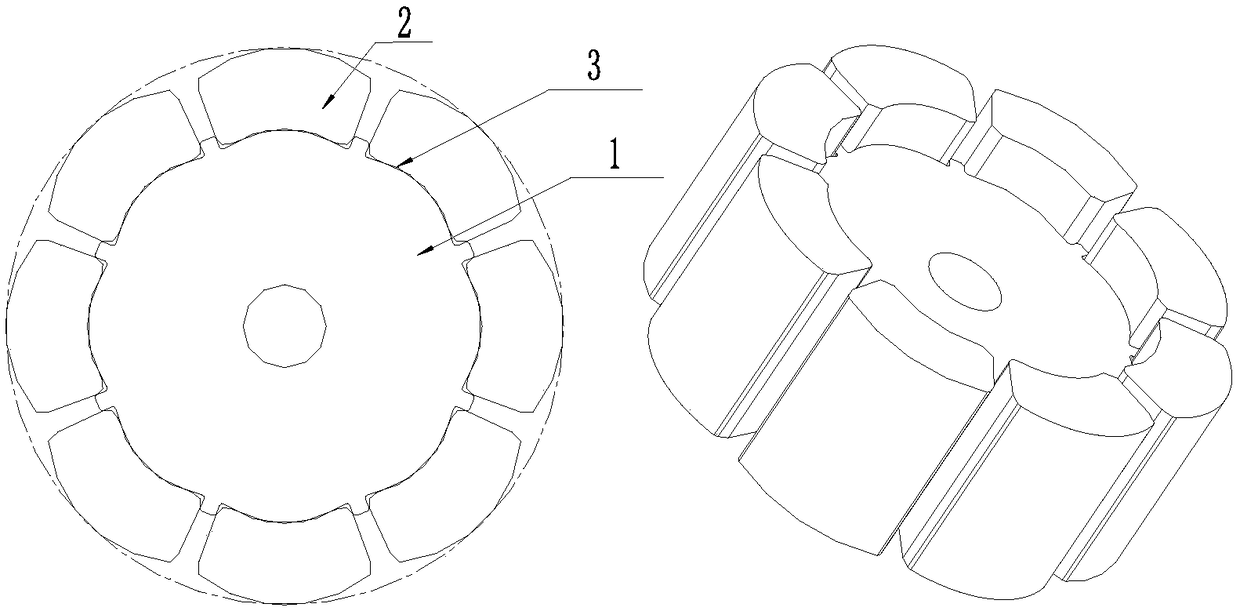

[0062] 1. According to the design requirements, design the corresponding rotor core 1 and magnetic tile 2, wherein the size of the installation groove 31 formed by the teeth of the rotor core is guaranteed to be consistent with the outer contour size of the magnetic tile 2 to meet the assembly requirements;

[0063] 2. Generally, such as Figure 7 As shown, in order to ensure that the magnetic tile 2 can be easily pressed into the installation groove 31 of the rotor core 1, the inner side of the installation groove 31 of the rotor core 1 will be set as an inclined side wall, and the angle A1 is 91 degrees, that is, the side of the installation groove 31 The wall has a slope of 1° from the vertical;

[0064] 3. Generally, such as Figure 8 As shown, in order to ensure the fastening strength between the teeth of the rotor iron core and the magnetic tile 2, the width of the teeth of the rotor iron core L2=(0.6~0.7)*L1, where L1 is the width of the magnetic tile 2;

[0065] 4. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com