Magnetic coupling and mounting method thereof

A technology of magnetic coupling and installation method, which is applied in the direction of permanent magnet clutch/brake, electromechanical device, electric brake/clutch, etc., can solve the problem that the coaxiality of two permanent magnet rotors is difficult to guarantee, and achieve light weight and structure Compact and guarantee the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

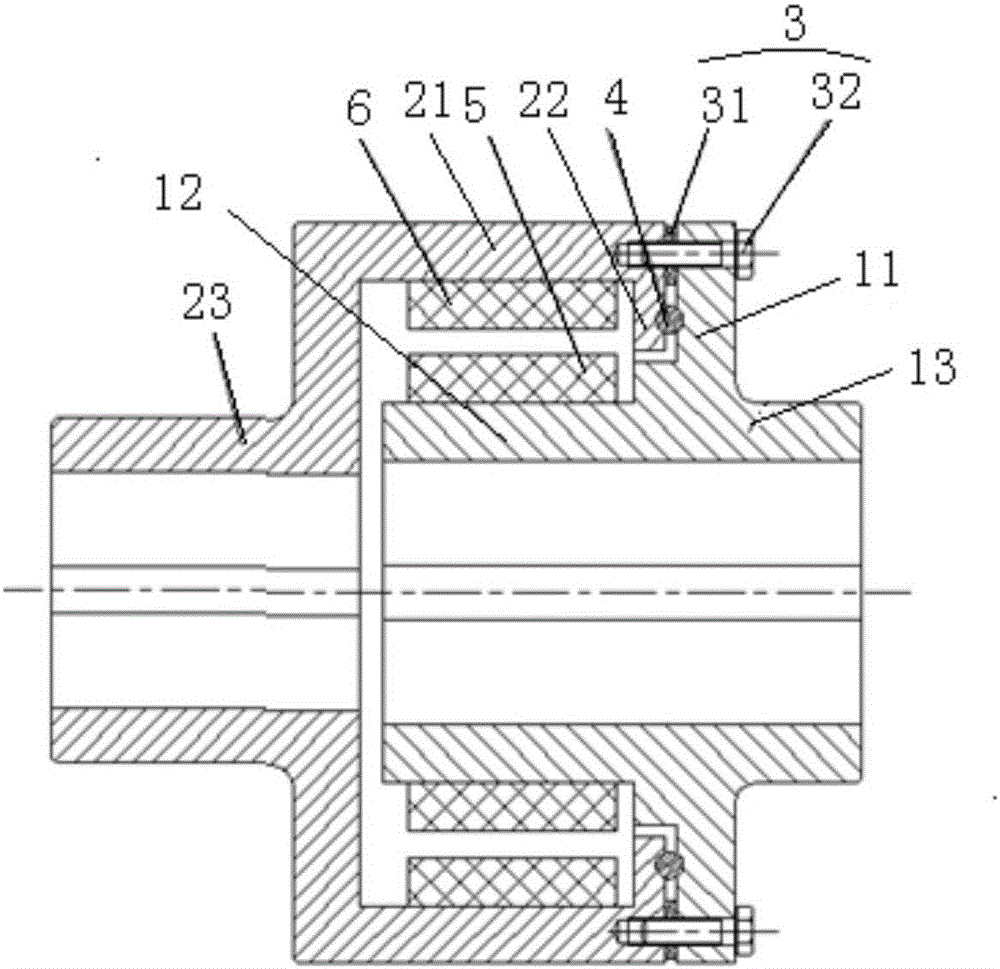

[0025] This embodiment provides a magnetic coupling, such as figure 1 shown, including:

[0026] The inner permanent magnet rotor includes an inner permanent magnet 5 and an inner cylinder part 12 for carrying the inner permanent magnet 5, and an annular flange 11 is provided on the outer wall of one end surface of the inner cylinder part 12;

[0027] The outer permanent magnet rotor includes an outer permanent magnet 6 and an outer cylinder part 21 for carrying the outer permanent magnet 6, the outer cylinder part 21 sleeves the inner cylinder part 12 and is away from the annular flange On the 11 side, there is an air gap between the inner permanent magnet 5 and the outer permanent magnet 6 and the magnetic poles are correspondingly matched;

[0028] The positioning connectors 3 are set to be several evenly arranged around the axis of the coupling, and are detachably connected to the end surface of the outer cylinder 21 close to the end of the annular flange 11 and the end o...

Embodiment 2

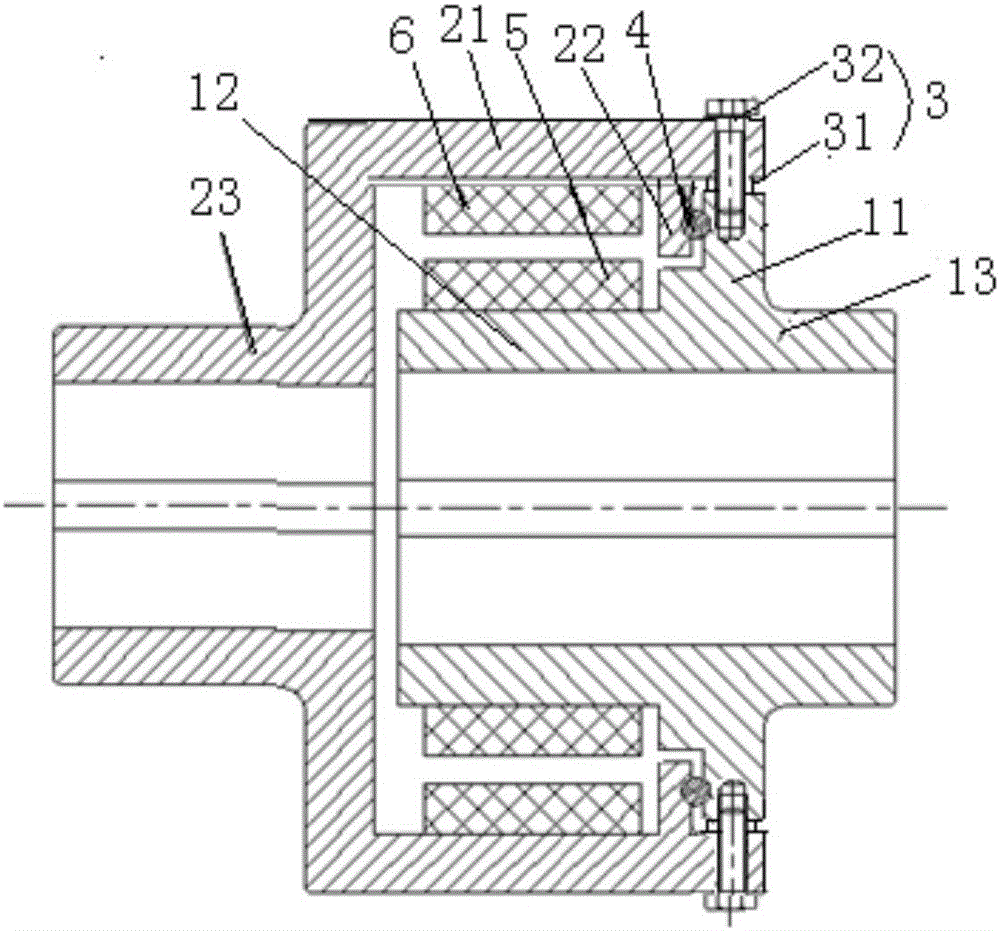

[0046] This embodiment provides a magnetic coupling, such as figure 2 shown, including:

[0047] The inner permanent magnet rotor includes an inner permanent magnet 5 and an inner cylinder part 12 for carrying the inner permanent magnet 5, and an annular flange 11 is provided on the outer wall of one end surface of the inner cylinder part 12;

[0048] The outer permanent magnet rotor includes an outer permanent magnet 6 and an outer cylinder part 21 for carrying the outer permanent magnet 6, the outer cylinder part 21 sleeves the inner cylinder part 12 away from the annular flange 11 On one side, the magnetic poles of the inner permanent magnet 5 and the outer permanent magnet 6 are matched with each other and an air gap is reserved;

[0049] The positioning couplings 3 are set to be several uniformly arranged around the axis of the coupling, and are connected and arranged between the end of the outer cylinder 21 close to the annular flange 11 and the top end of the annular ...

Embodiment 3

[0065] This embodiment provides a method for installing the magnetic coupling provided in the present invention, including the following steps: coupling the drive shaft with the outer (or inner) permanent magnet rotor of the magnetic coupling, and connecting the load shaft with the The inner (or outer) permanent magnet rotor of the magnetic coupling is connected, and then the positioning coupling of the magnetic coupling is removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com