Compressor and manufacturing method thereof

A manufacturing method and compressor technology, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of uneven force on the stator and rotor, loud noise, etc., to reduce welding deformation, reduce offset, The effect of machine noise improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

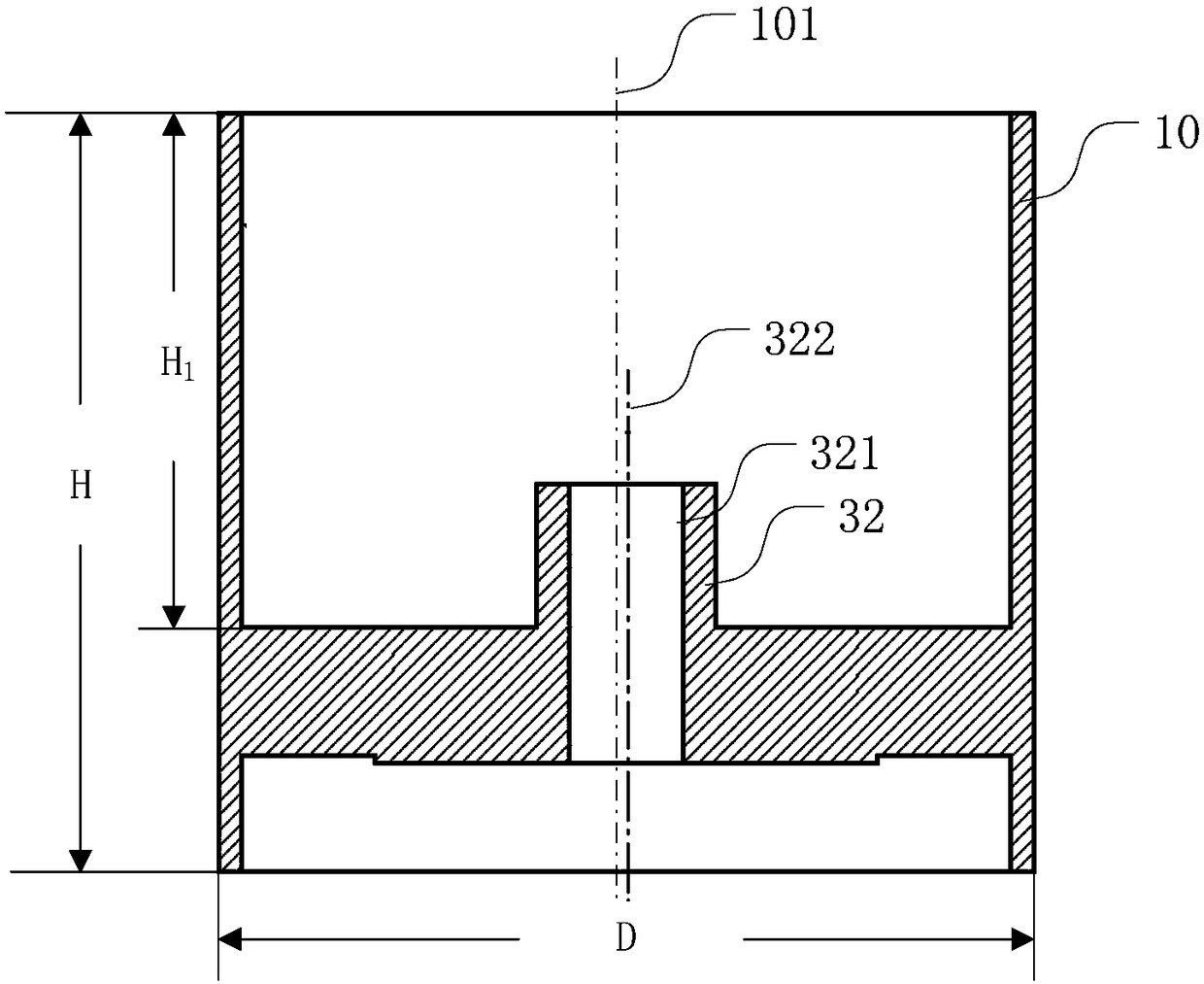

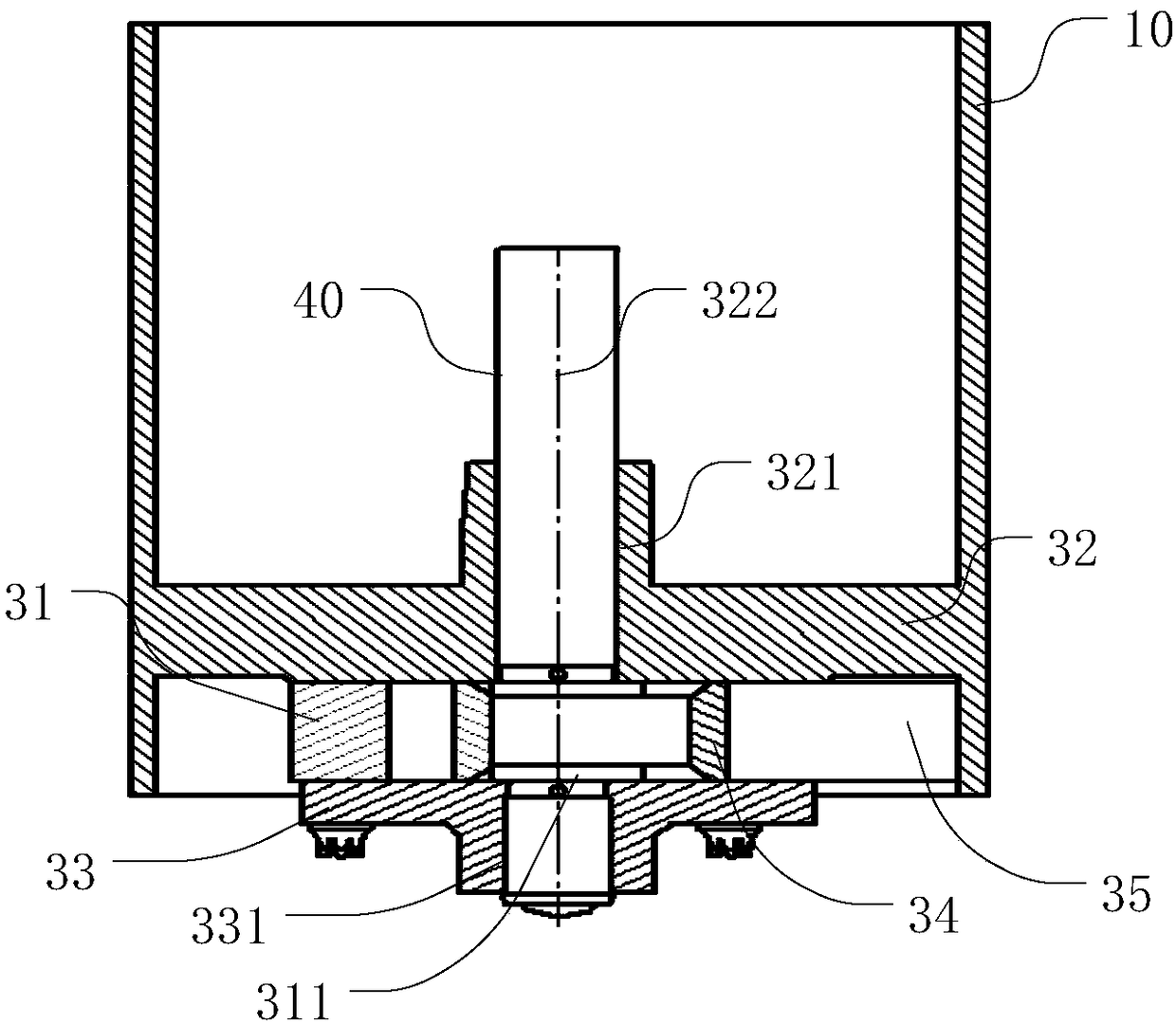

[0054] like Figure 2 to Figure 4 , figure 2 It is a sectional view of the integration of the casing and the upper cylinder head according to the first embodiment of the present invention; image 3 It is a cross-sectional view of the internal assembly of the compressor housing of the first embodiment of the present invention; Figure 4 It is a sectional view of the crankshaft in the first embodiment of the present invention.

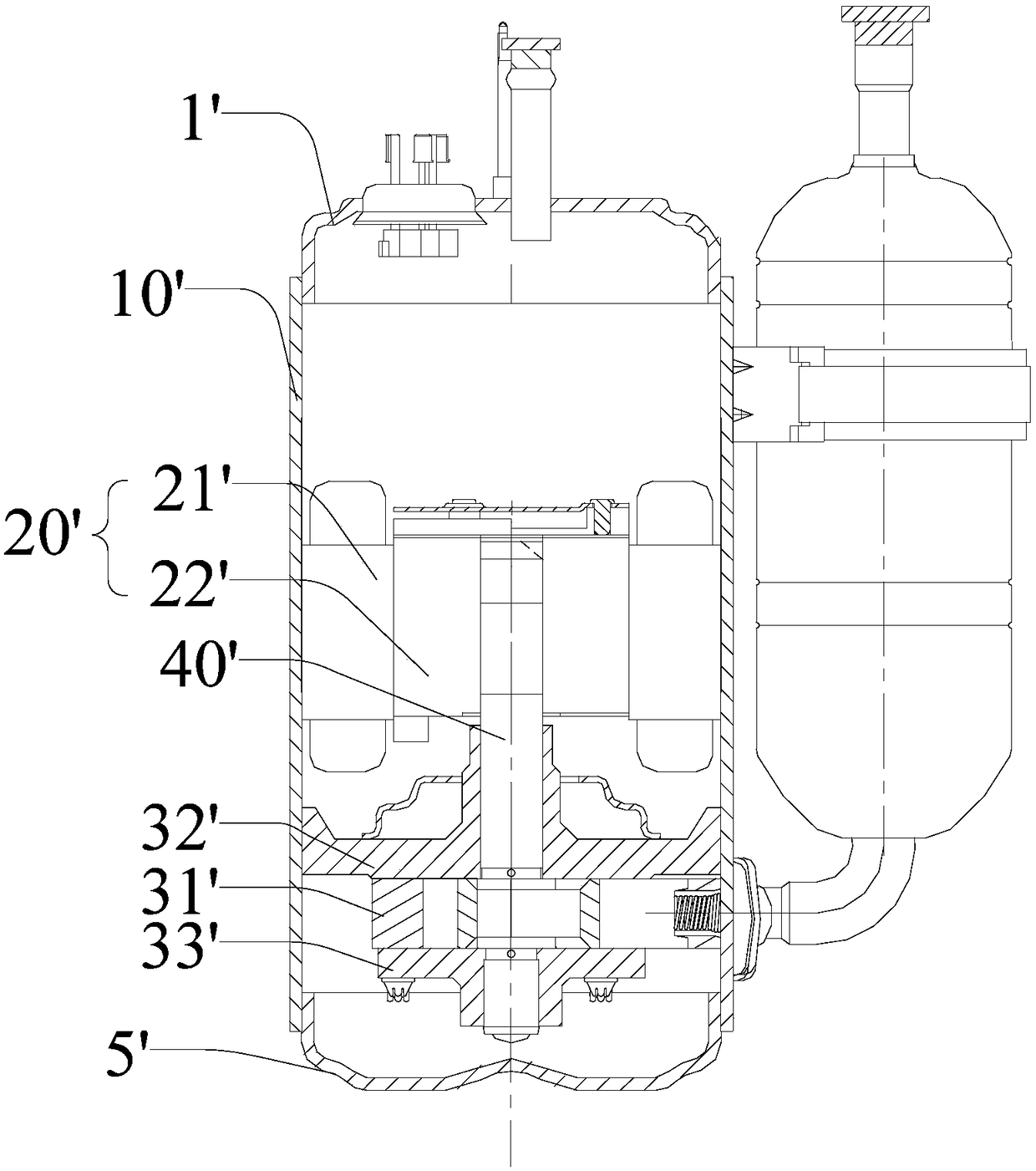

[0055] Compressor comprises housing 10, upper cylinder cover 32, lower cylinder cover 33, motor (as figure 1 Middle mark 20 '), cylinder 31, crankshaft 40. The casing 10 has an accommodating space. The housing 10 is optionally a cylindrical shell with a central axis 101 . The ratio H / D of the height H of the housing 10 on the central axis 101 to the outer diameter D of the housing 10 is greater than or equal to 0.3. In the vertical compressor embodiment, since the components are connected axially, the housing 10 needs to have sufficient height to ac...

no. 2 example

[0061] see Figure 5 , Figure 5 It is a cross-sectional view of the internal assembly of the compressor housing when the housing and the cylinder are integrated in the second embodiment of the present invention.

[0062] Compressor comprises housing 10, upper cylinder cover 32, lower cylinder cover 33, motor (as figure 1 Middle mark 20 '), cylinder 31, crankshaft 40. The casing 10 has an accommodating space. The upper cylinder head 32 is located in the casing 10 and has a first inner hole 321 with an axis 322 parallel to the central axis 101 .

[0063] The lower cylinder cover 33 is located in the casing 10 , and the lower cylinder cover 33 has a second inner hole 331 coaxial with the first inner hole 321 . The motor and cylinder 31 are accommodated in the casing 10 . The cylinder 31 has a third inner hole 311 whose axis is parallel to the central axis 101 . The crankshaft 40 is inserted into the upper first inner hole 321 , the third inner hole 311 and the second inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com