Multifunctional integrated electric driver

An integrated, electric-driven technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of relatively low efficiency of devices, inability to hoist as a whole, large installation space, etc., achieve compact structure, avoid output signal distortion, and layout reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

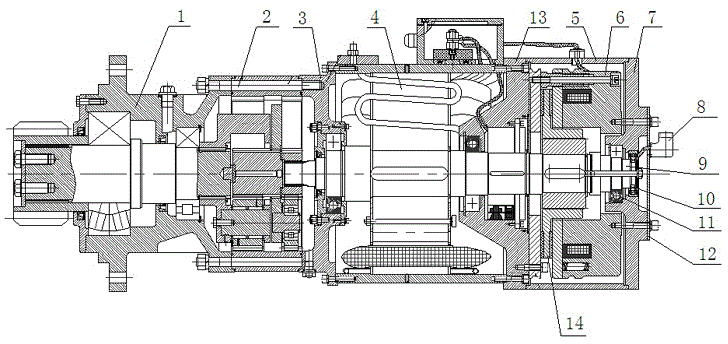

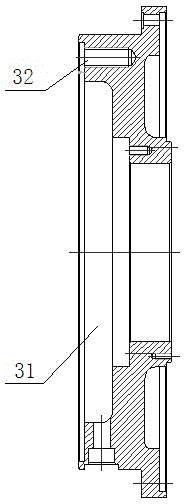

[0022] With reference to the accompanying drawings, the present invention is realized in the following way: a multifunctional integrated electric drive device, which includes a reducer 1, a front end cover 3, a rear end cover 13, a motor 4, a brake 6, and a friction disc 14, and the reducer 1 is fixedly connected to the housing of the motor 4 through the screw 2 and the front end cover 3, the brake 6 is fixedly connected to the housing of the motor 4 through the friction disc 14 and the rear end cover 13, and the two ends of the axial housing of the motor 4 are respectively connected to the front cover 3 and the rear An end cover 13; a tail cover 7 is installed at the tail end of the brake 6, the support frame 5 is installed between the rear end cover 13 and the tail cover 7, and the baffle plate 12 is fixedly connected to the end cover 7.

[0023] Such as figure 1 and Figure 4 As shown, a bearing 11 and a rotary transformer 10 are installed in the tail cover 7 of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com