Method for connecting powder ridge apparatus to tractor

A connection method and tractor technology, which are applied in the fields of tillage equipment, agricultural machinery and equipment, and application, can solve the problems of large size and heavy weight of the powder ridge device, and achieve the effect of solving the problem of large size and lightening the burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0026] A method for connecting a powder ridge device to a tractor. The powder ridge device is fixed on the tractor through a vertical lifting system, and the power source of the tractor drives the powder ridge device through a transmission device.

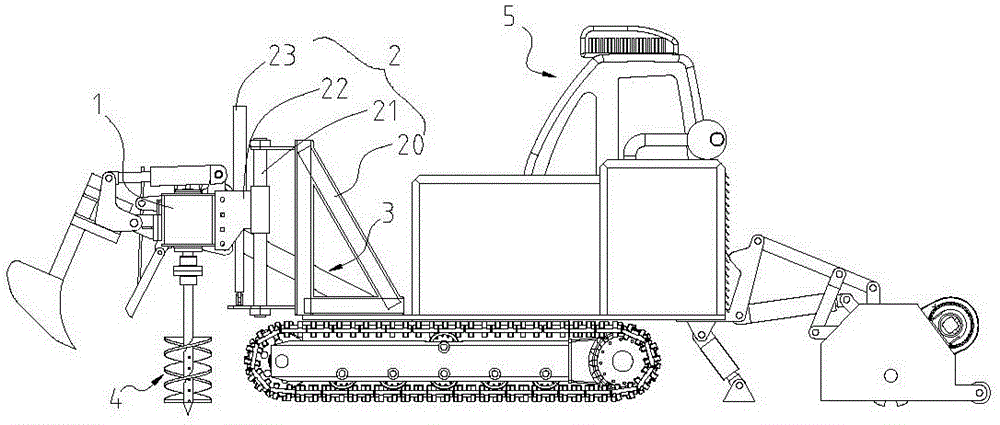

[0027] Such as figure 1 As shown, the powder ridge device includes a powder ridge box and a plurality of auger rods arranged in-line. The Fenlong box 1 is rectangular, with an installation space inside, and the top of the Fenlong box 1 is a movable plate; the side of the Fenlong box 1 is provided with a number of inspection ports, and the inspection ports are provided with inspection panels to block , when it is necessary to overhaul the internal equipment of the Fenlong box, just open the inspection panel; the two sides of the Fenlong box along the length direction are provided with installation ears (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com