Processing method and device of alternating-current permanent-magnet servo motor stator

A permanent magnet servo motor and processing device technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of reducing the positioning torque of the motor and affecting the concentricity of the stator, and achieve the effect of improving concentricity and uniform air gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

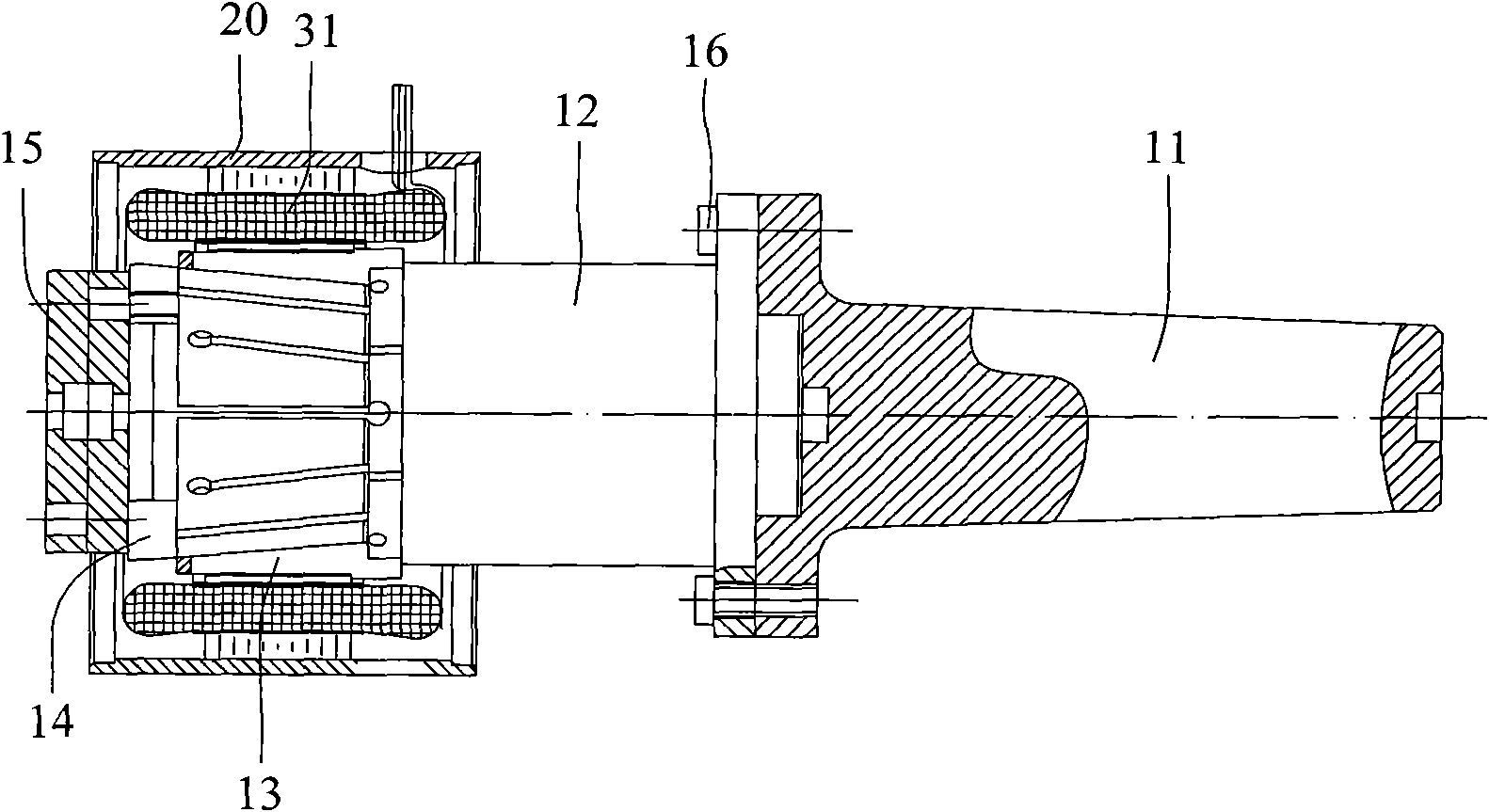

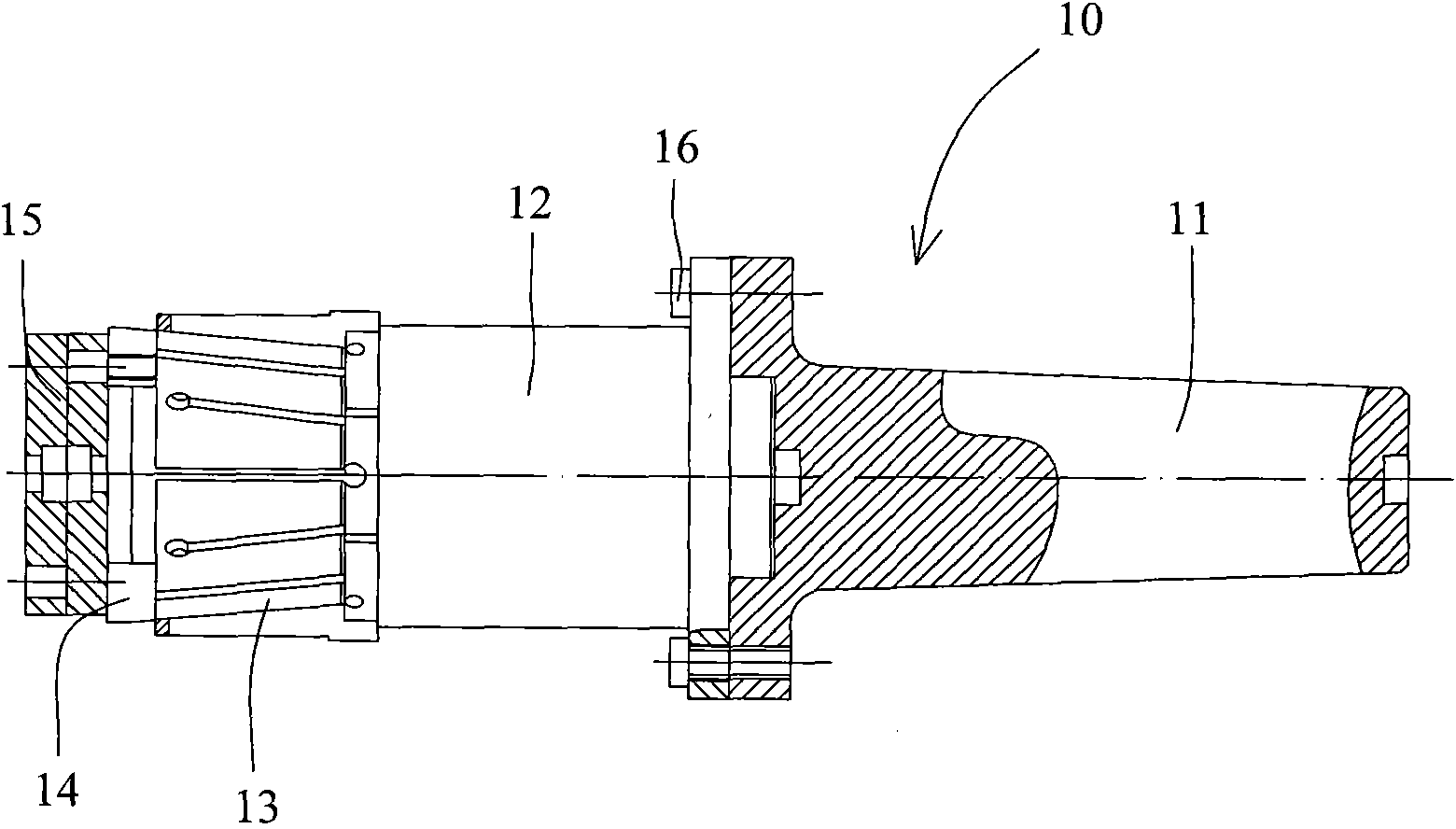

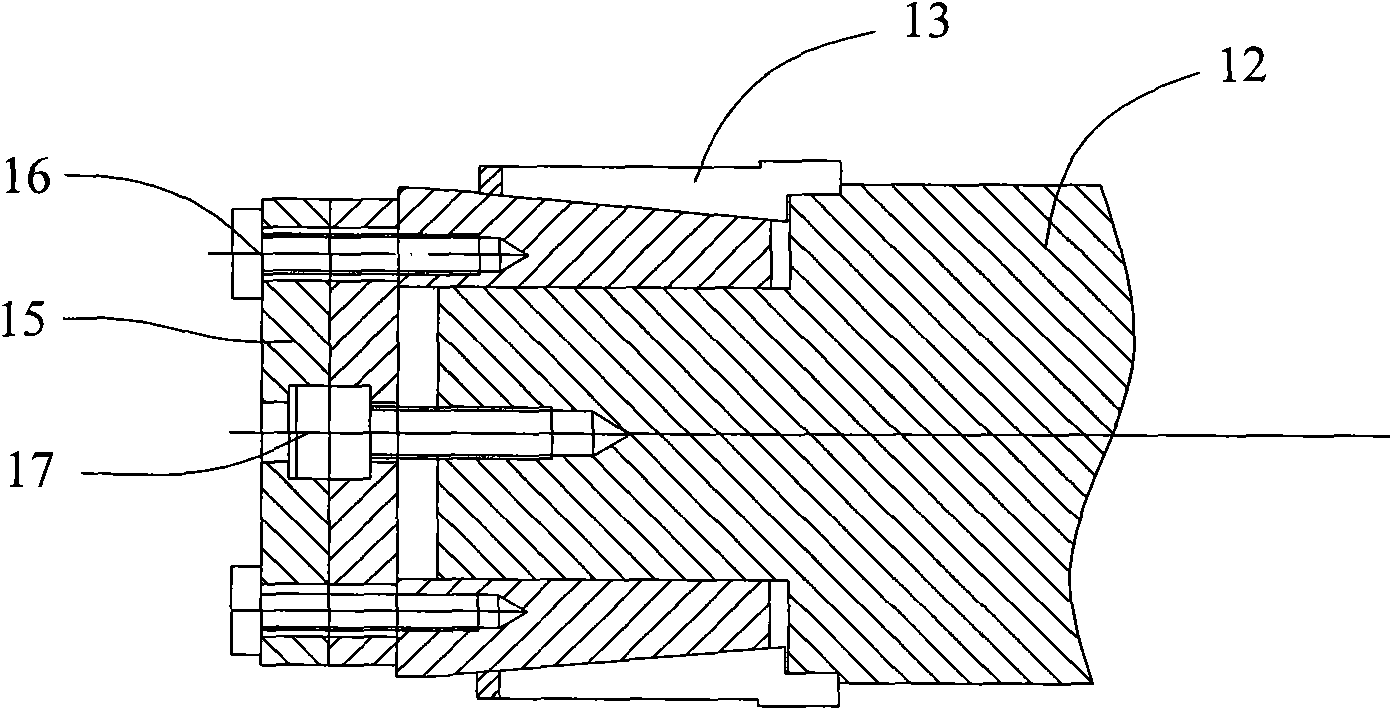

[0029] see Figure 1~3 As shown, the processing device 10 of the AC permanent magnet servo motor stator of the present invention includes: a tapered handle 11, a mandrel 12 fixed on one end of the tapered handle 11, an expansion sleeve 13 installed on the mandrel 12, and installed on one end of the mandrel 12 The taper shaft 14, and the pressure plate 15 fixed on the taper shaft 14. The taper of the taper shank 11 is consistent with the taper of the machine tool spindle; the outer diameter of the expansion sleeve 13 should be 0.15-0.2mm smaller than the inner hole of the processed stator core 31, so that the stator 30 can be easily loaded and unloaded; the taper of the taper shaft 14 Same as the taper of the inner hole of the sleeve 13. The processing device of the present invention is positioned by the inner hole of the iron core 31, which can ensure the concentricity of the notch of the machine base 20 and the inner hole of the iron core 31; the expansion sleeve 13 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com