Minitype permanent-magnet synchronous motor adopting ''U''-shaped iron core and dewatering pump

A permanent magnet synchronous motor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine components, etc., can solve problems such as increased reluctance, increased vibration and noise, and reduced operating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

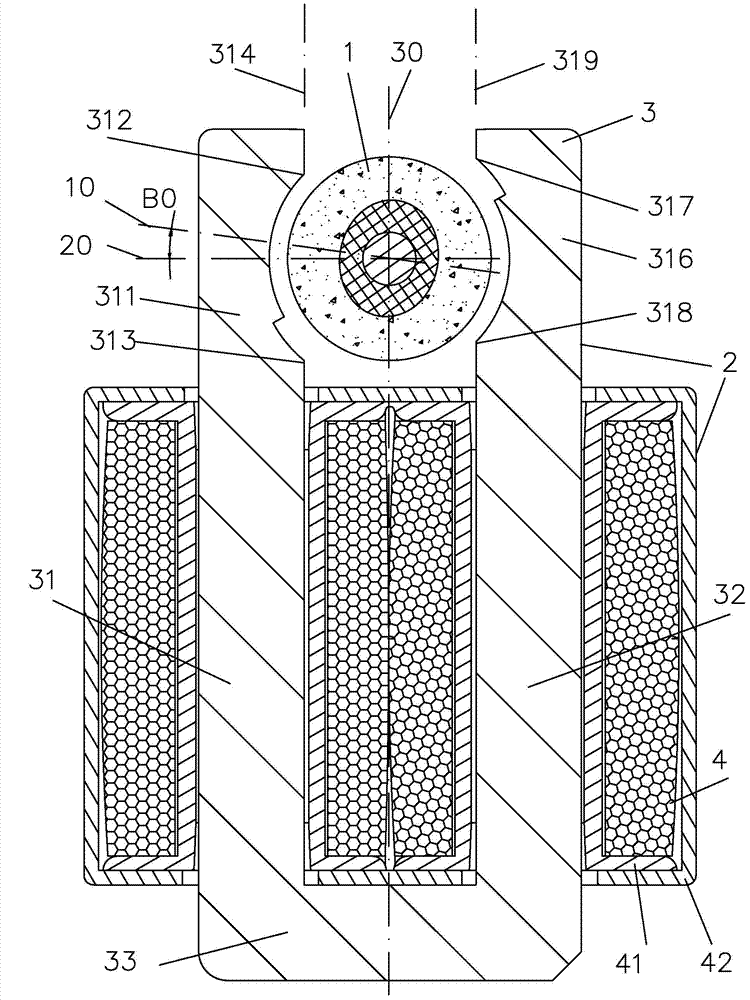

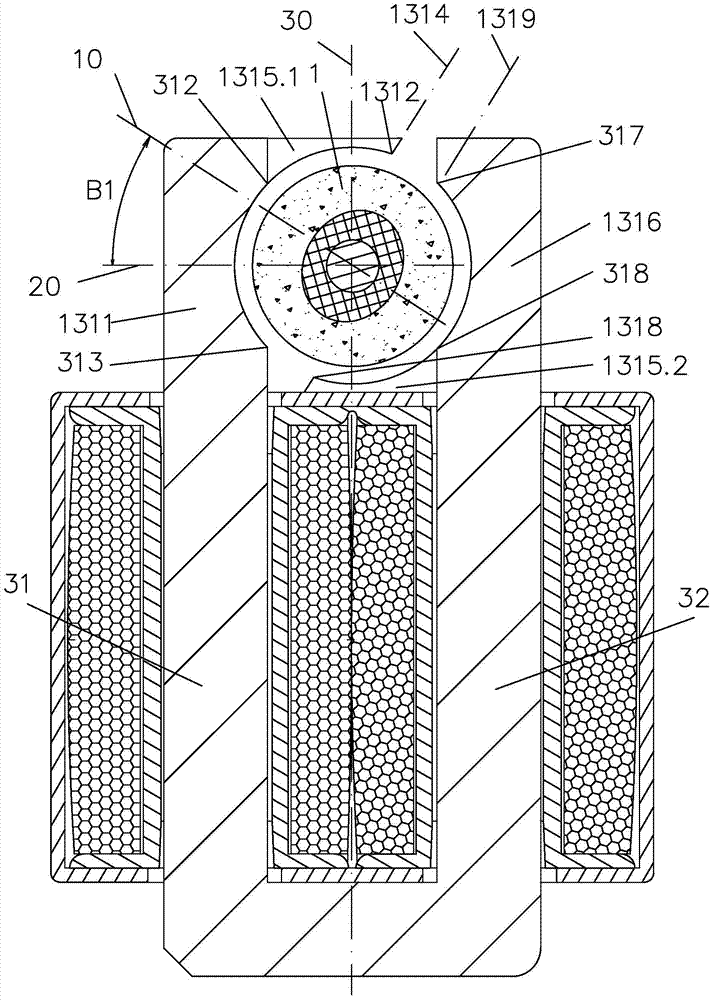

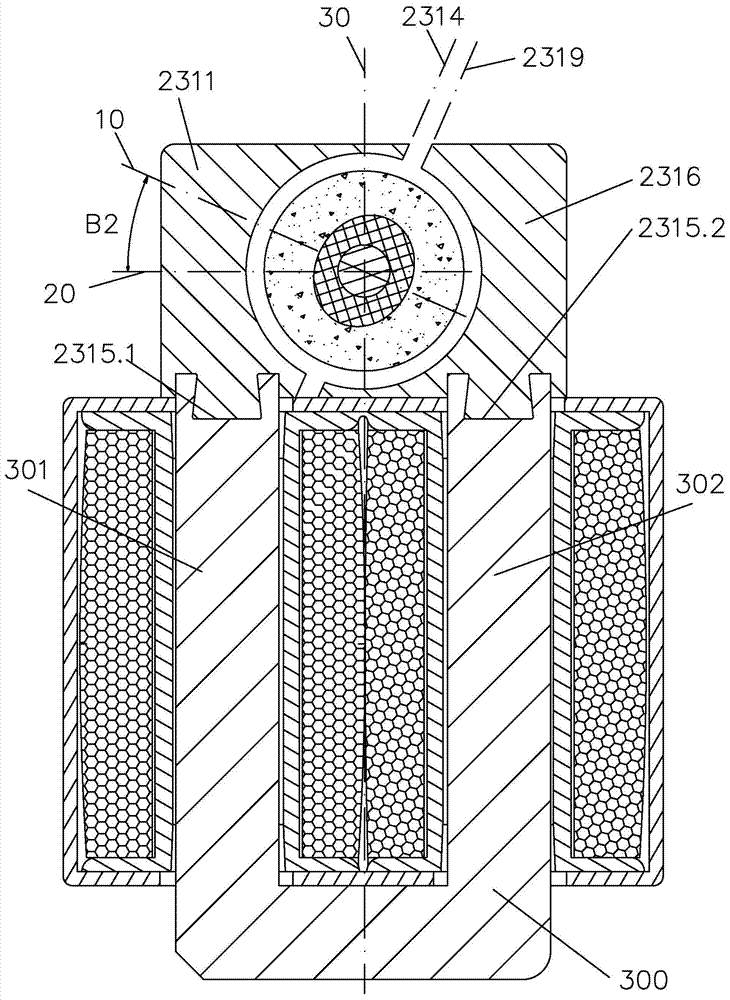

[0029] The motor of the embodiment of the present invention is improved on the basis of the miniature permanent magnet synchronous motor using a "U"-shaped iron core in the prior art described in the background art. The basic structure of the motor in the prior art is as figure 1 shown, including:

[0030] - Cylindrical permanent magnet rotor 1 magnetized at two radial poles;

[0031] ——Stator 2, including "U"-shaped laminated iron core 3 and stator winding 4; stator winding 4 is wound on the left and right two plastic bobbins 41 and then plastic-sealed as a whole by surface plastic 42; the left side of iron core 3 Arm 31 and right arm 32 respectively pass through the left and right inner holes of the plastic coil frame 41, and the upper parts exposed respectively form a left pole piece 311 and a right pole piece 316 whose pole surface is close to the left and right sides of the cylindrical surface of the rotor 1; The shape of the surface is concave and the arc surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com