Permanent magnet bias single-degree-of-freedom axial magnetic bearing

An axial magnetic bearing and permanent magnet bias technology, applied in the field of bearing manufacturing, can solve the problems of low rotor strength, low rotational speed, large magnetic leakage, low critical rotational speed, etc., and achieve large axial suspension force, low power consumption, and reduced leakage. magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

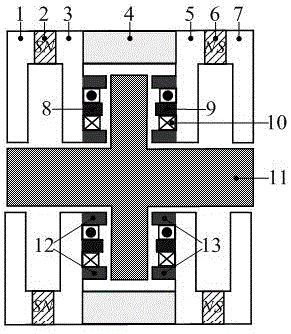

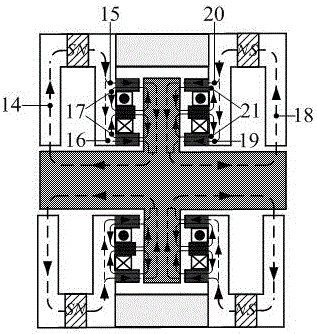

[0026] The present invention is based on the principle that the axially magnetized left annular permanent magnet 2 generates a left static bias magnetic flux 14, and the left static bias magnetic flux 14 starts from the N pole of the left annular permanent magnet 2 and passes through the magnetic field. The stator core 3 on the left side of the bearing is divided into two parts, namely the magnetic flux 15 and the magnetic flux 16, which enter the axial working air gap from the suction disc 12, the radial part of the rotor core 11, and the axial part of the rotor core 11 , left iron core bridge iron core air gap, left iron core bridge iron core 1 returns to the S pole of left annular permanent magnet 2, forms a closed magnetic circuit. The axially magnetized right annular permanent magnet 6 generates the right static bias magnetic flux 18, and the right static bias magnetic flux 18 starts from the N pole of the right annular permanent magnet 6 and passes through the right stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com