Calliper brake with disengaged position

A caliper brake, brake technology, applied in the direction of brake type, automatic brake, axial brake, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

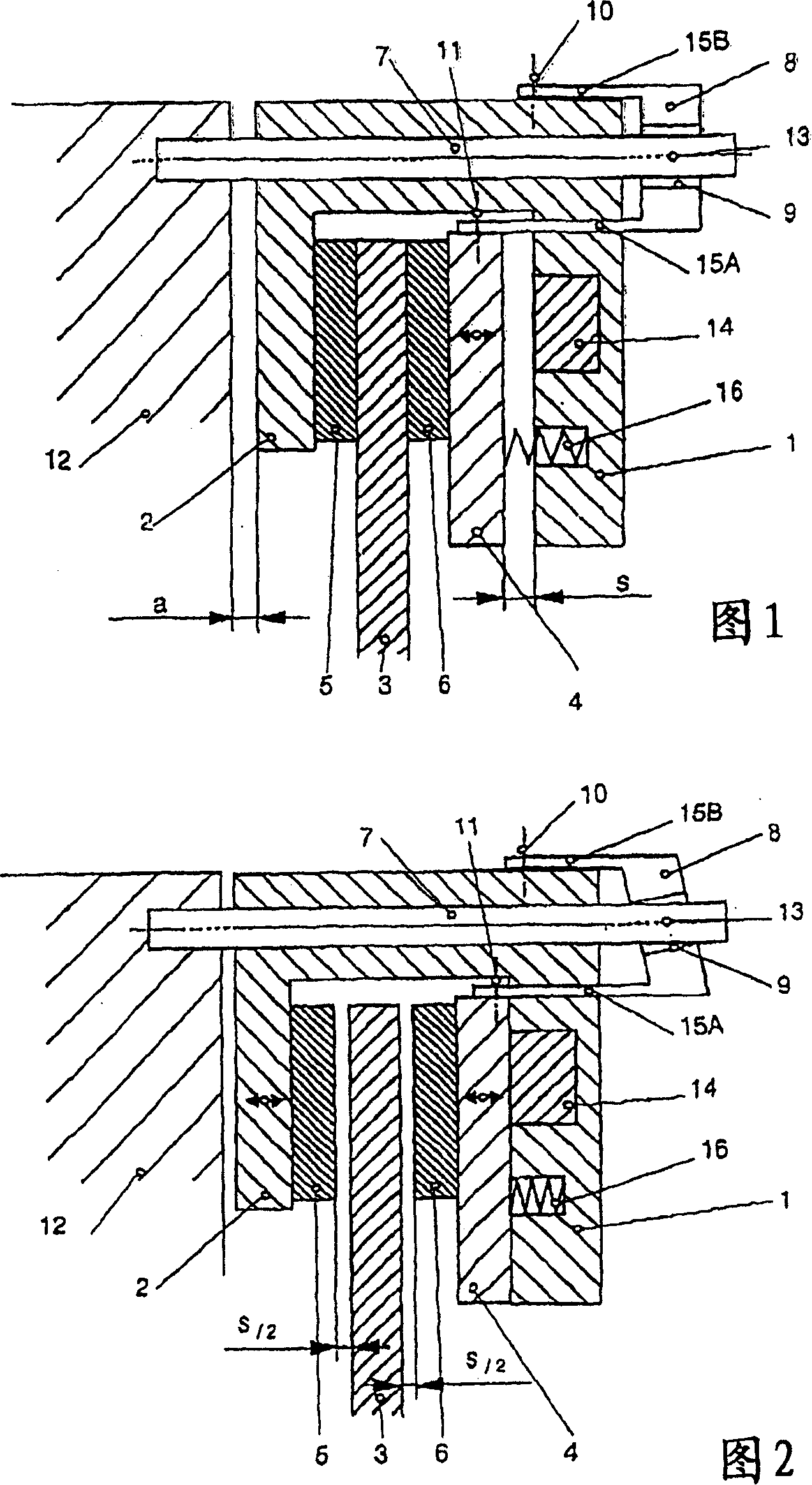

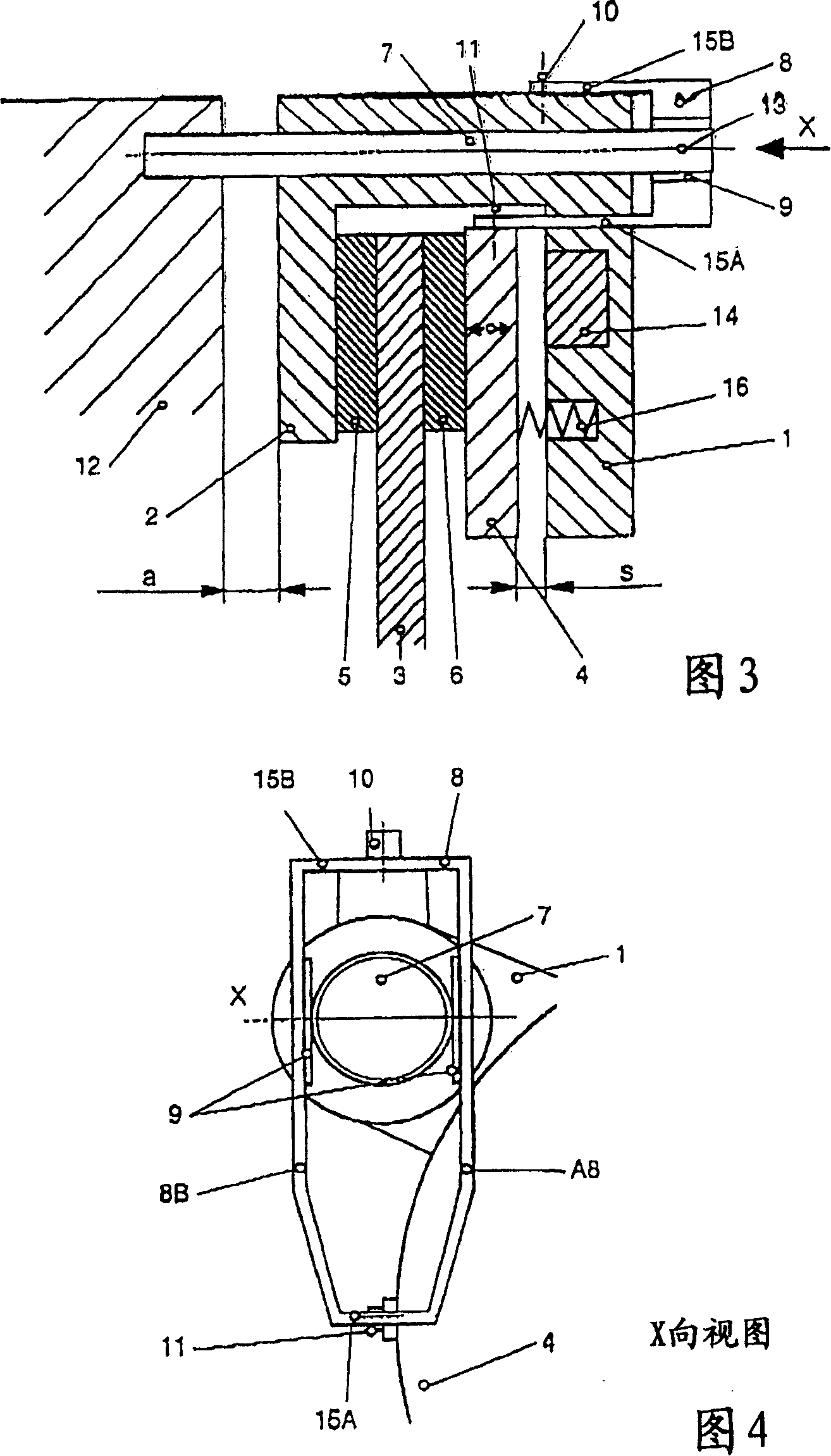

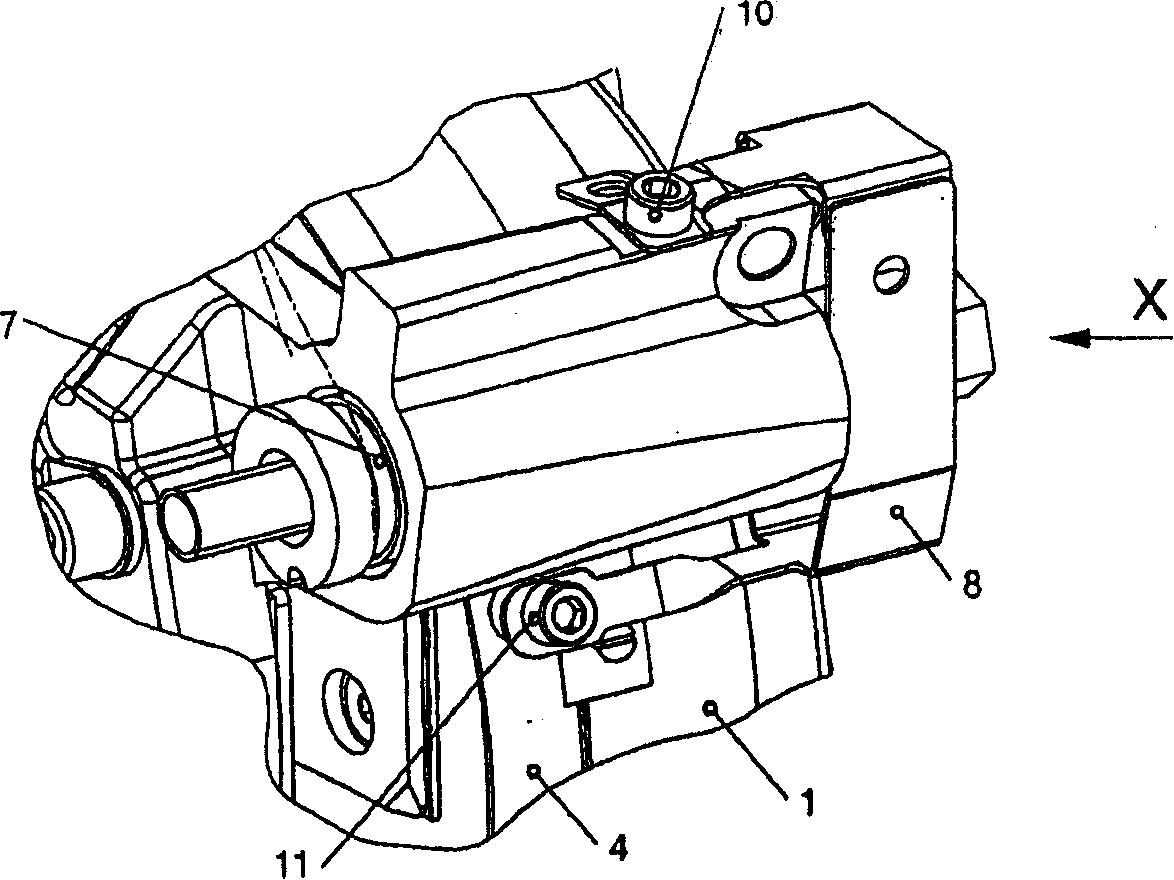

[0018] The basic idea of the invention is to convert the movement of the armature relative to the coil carrier into a counter-movement of the coil carrier and therefore also of the opposite friction surface on the caliper side, since it is fixed to the coil carrier connected. The respective initial position of the armature disk is adjusted by frictional engagement of the pivot lever 8 on the fixed guide pin 7 .

[0019] The swing lever 8 is a formed part made of a spring steel strip, with two opposite arms 8A, 8B, which abut on both sides of the fixed pin 7, and are provided with a friction plate 9 on its inner surface, so that As shown in FIG. 4 , the swing rod is fixed on the fixed pin shaft 7 in a frictional engagement manner. The amount of elastic deformation and the friction plate determine the axial friction force on the guide pin shaft. The rocker has two opposing flexible tongues 15A and 15B, of which one tongue 15A is connected to the armature disk 4 and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com