Switched reluctance motor with stator partitioned two-phase 6/5 structure

A switched reluctance motor and stator technology, applied in the magnetic circuit shape/style/structure, magnetic circuit, synchronous machine, etc., can solve problems such as the increase of motor winding ends, the reduction of motor output torque, and the long magnetic flux path of the motor. , to achieve the effect of small core mass, low torque ripple and noise, and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Attached below Figure 1~4 The present invention will be described in detail with specific embodiments, and the following description is only for demonstration and explanation, and does not limit the present invention in any form.

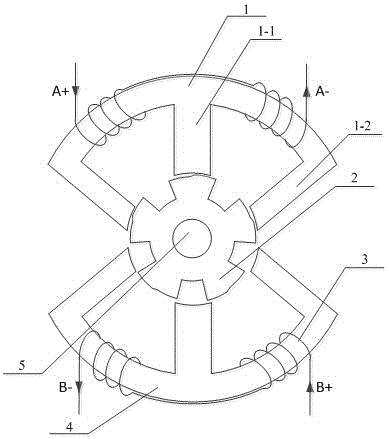

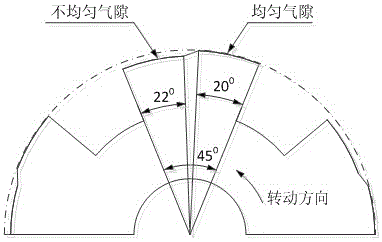

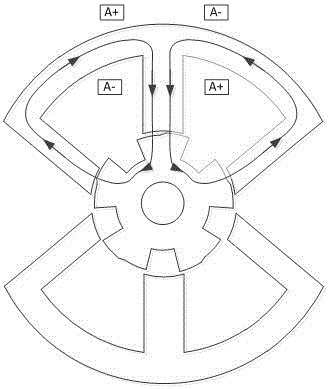

[0026] The stator block two-phase 6 / 5 structure switched reluctance motor includes a stator 1, a rotor 2, a winding 3 and a motor shaft 5, the center of the rotor 2 is fixed with the motor shaft 5, and the number of the stator 1 is two The blocks are of E-type structure, the number of poles is 3, the two stators 1 are symmetrically distributed on the outer periphery of the rotor 2 and the arc center of the stator 1 coincides with the center of the rotor 2, and the rotor 2 has an uneven salient pole structure, and the number of poles is 5 , the outer diameter of the rotor poles is inconsistent, and the outer peripheral surface of each rotor pole of the rotor is composed of a uniform air gap surface, an uneven air gap surface and a transition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com