Patents

Literature

1109results about How to "Reduce torque ripple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

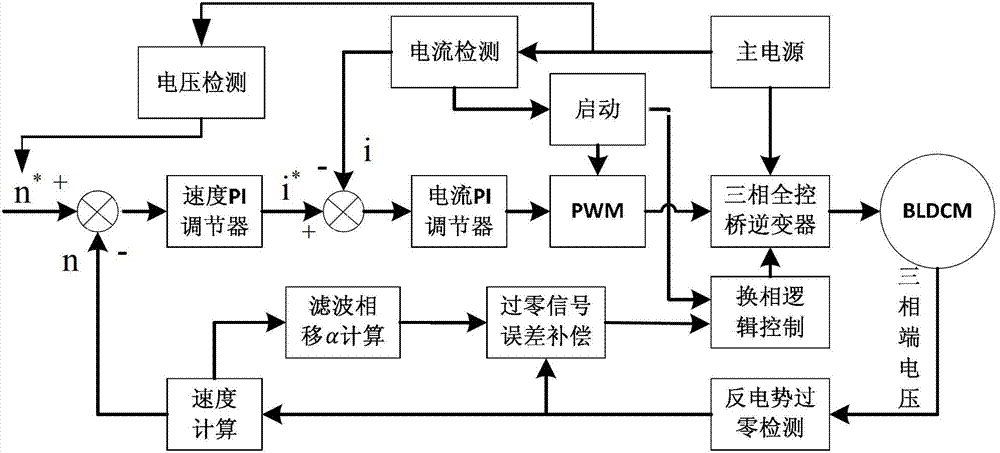

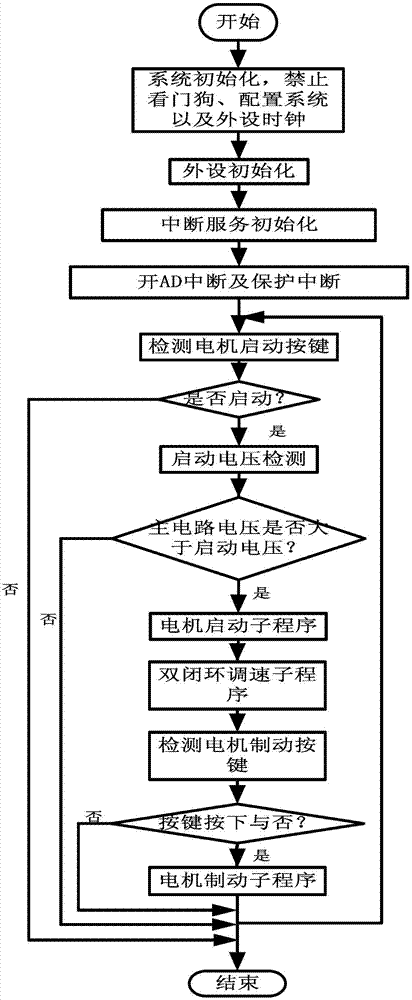

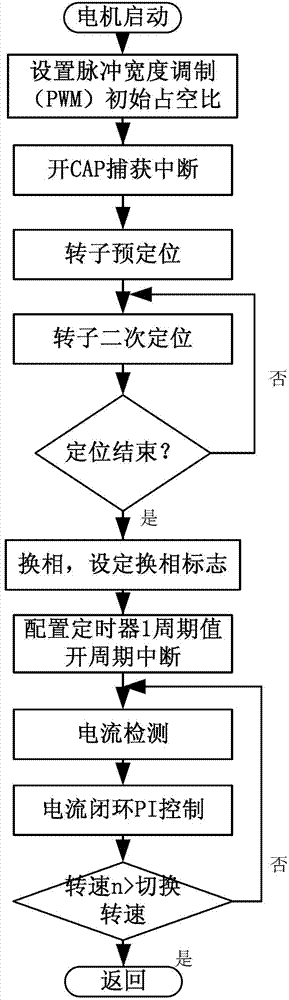

Position sensor-free double closed-loop speed regulation control method for brushless DC motor

InactiveCN103248294AAccurate control of different speedsSolve the problems of large volume and low speed accuracyTorque ripple controlSingle motor speed/torque controlClosed loopEngineering

A position sensor-free double closed-loop speed regulation control method for a brushless DC motor comprises the following steps: (1) initializing functional modules and peripherals; (2) opening AD (Analog-Digital) interruption and protection interruption; (3) detecting the start key of the motor, judging whether to start the motor, if yes, executing the next step, and if not, continuing to execute the step; (4) starting voltage detection, judging whether the voltage of a main circuit is larger than starting voltage, if yes, executing the next step, and if not, returning to the step (3); (5) entering a motor starting subprogram and beginning operating the motor; (6) entering a double closed-loop speed regulation subprogram, and regulating the rotational speed and the current of the motor according to voltage value; and (7) detecting a motor brake key, judging whether to press the key, if yes, entering a motor brake subprogram, and if not, returning to the step (3). The method provided by the invention overcomes the defects of larger size, low rotational speed accuracy and the like of the conventional motor controller, can accurately control different rotational speeds of the motor, and can simultaneously realize counter electromotive force zero-cross comparison position sensor-free reversing and Hall position signal reversing.

Owner:TIANJIN UNIV

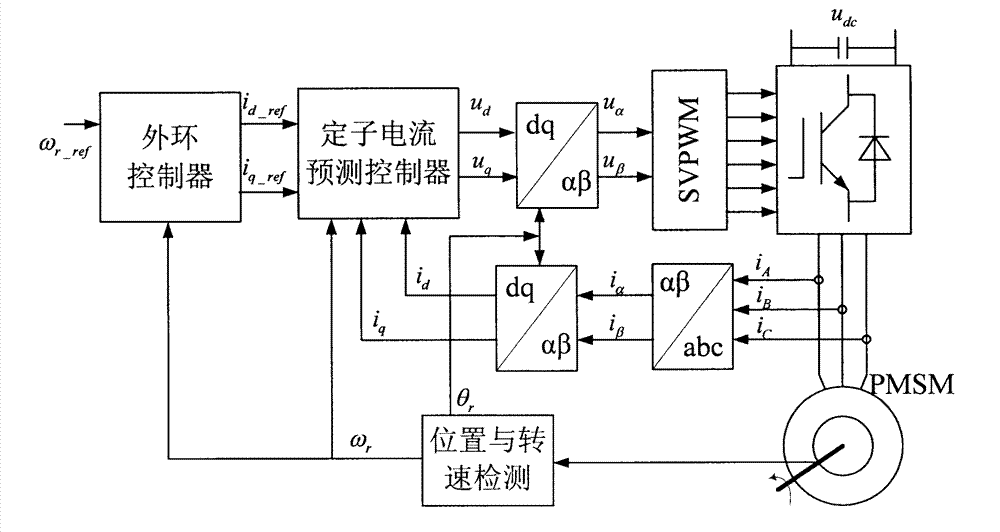

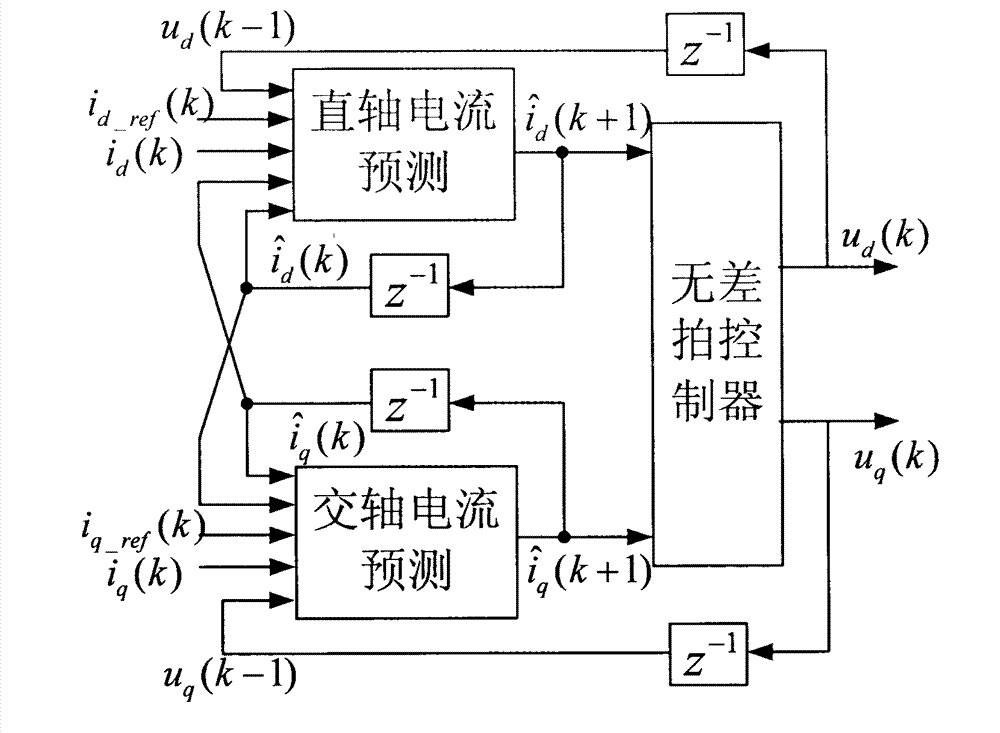

Current predictive control method of permanent magnet synchronous motor

InactiveCN102904520AFast startShorten the timeElectronic commutation motor controlAC motor controlStator voltageControl signal

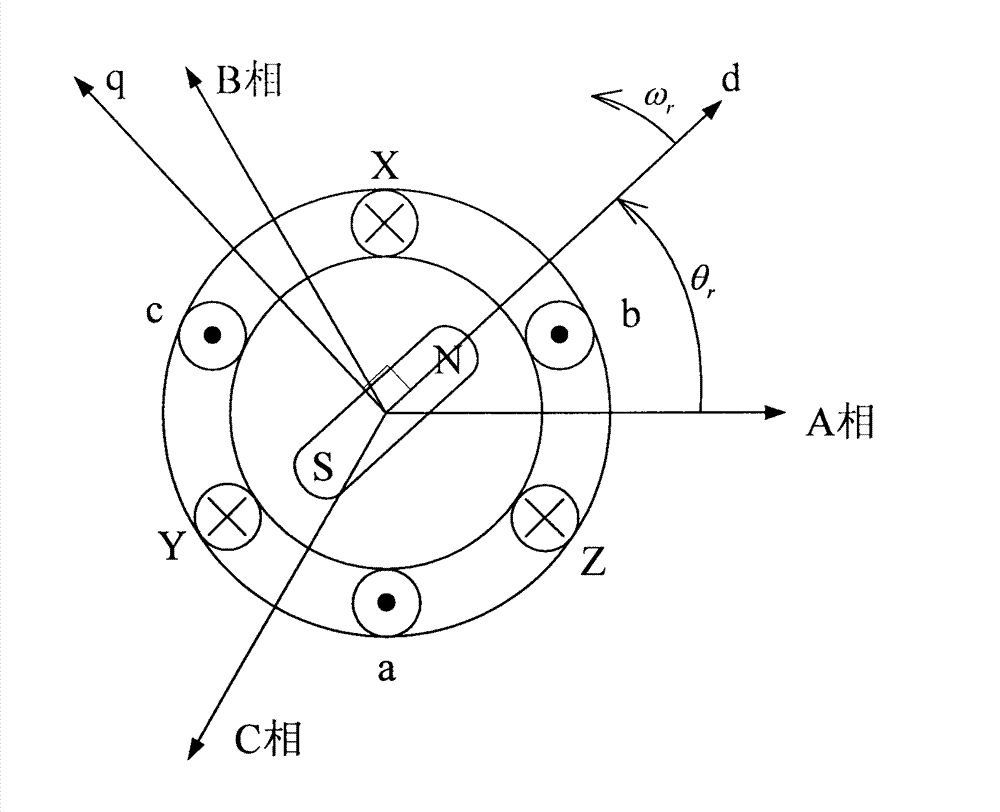

The invention relates to a current predictive control method of a permanent magnet synchronous motor, which belongs to the electric control field. The dynamic response speed and the control accuracy for the stator current control of the permanent magnet synchronous motor are improved through stator current prediction and deadbeat control, and the system delaying is compensated, so that the noise and the torque ripple of the motor in operation are reduced. The method comprises the steps as follows: obtaining a three phase stator current signal, and the electrical angle and the electrical angular speed of the motor rotor through the technologies of sensor sampling and a photoelectric coded disc or position sensorless detection; carrying out Clarke transformation and Park transformation on the stator current signal to obtain the stator current in a synchronous revolution dq coordinate system; substituting the obtained stator current signal in the dq coordinate system into a control equation of a current predictive controller of the permanent magnet synchronous motor, carrying out deadbeat control according to the given value of the obtained stator current in the dq coordinate system in an outer ring controller to obtain a stator voltage vector in the dq coordinate system; carrying out Park inverse transformation on the obtained stator voltage vector in the dq coordinate system, to obtain a pulse-width modulation (PWM) control signal of an inverter by a space vector pulse width modulation (SVPWM) method, controlling the stator current through the inverter, and then implementing the current predictive control over the permanent magnet synchronous motor.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

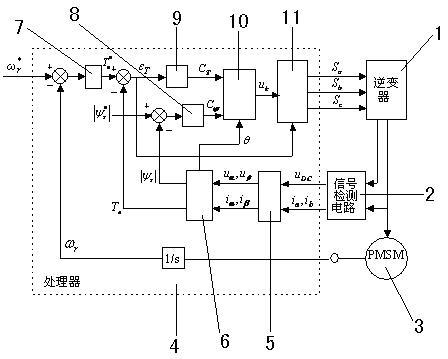

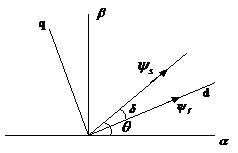

Direct torque control device and method for permanent magnet synchronous motor

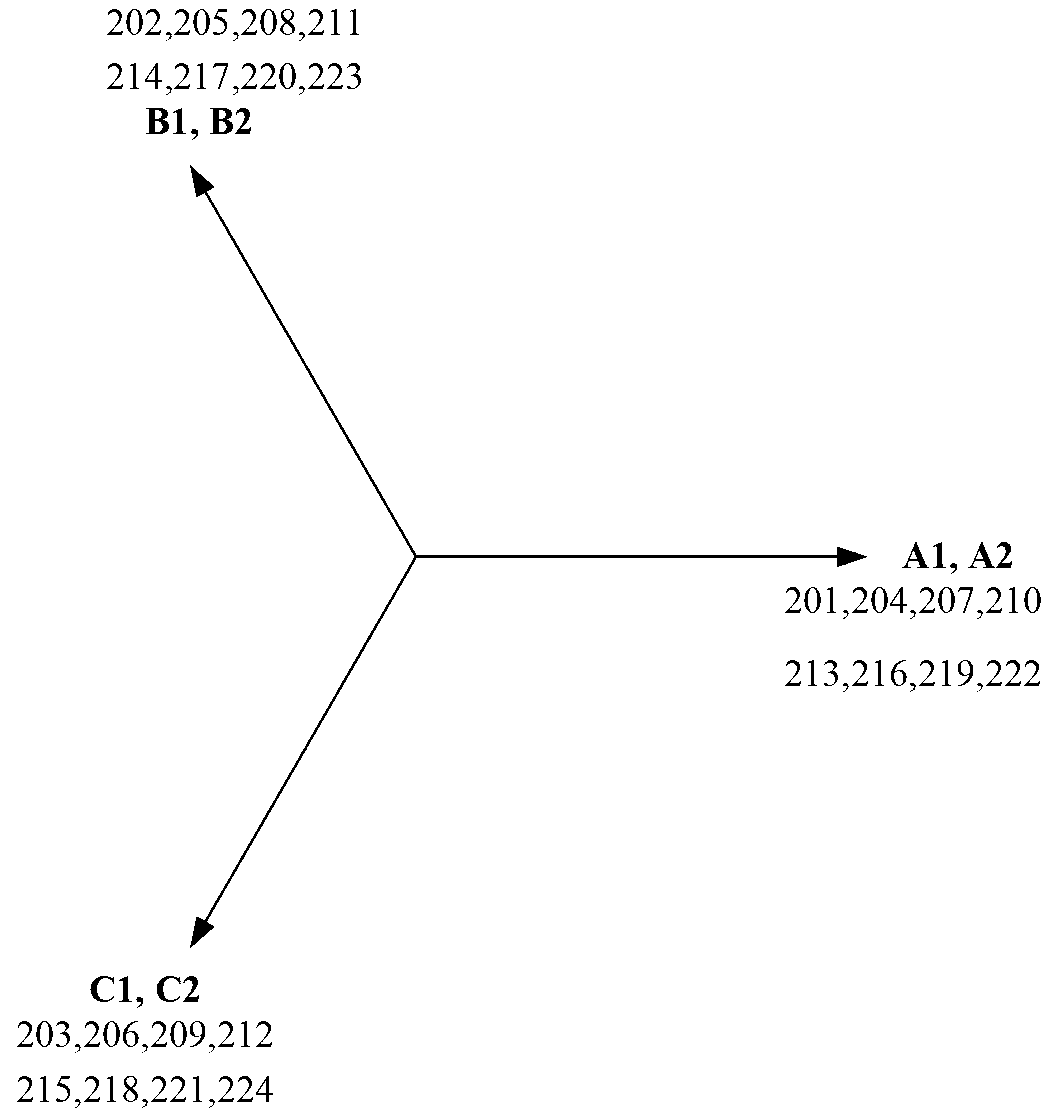

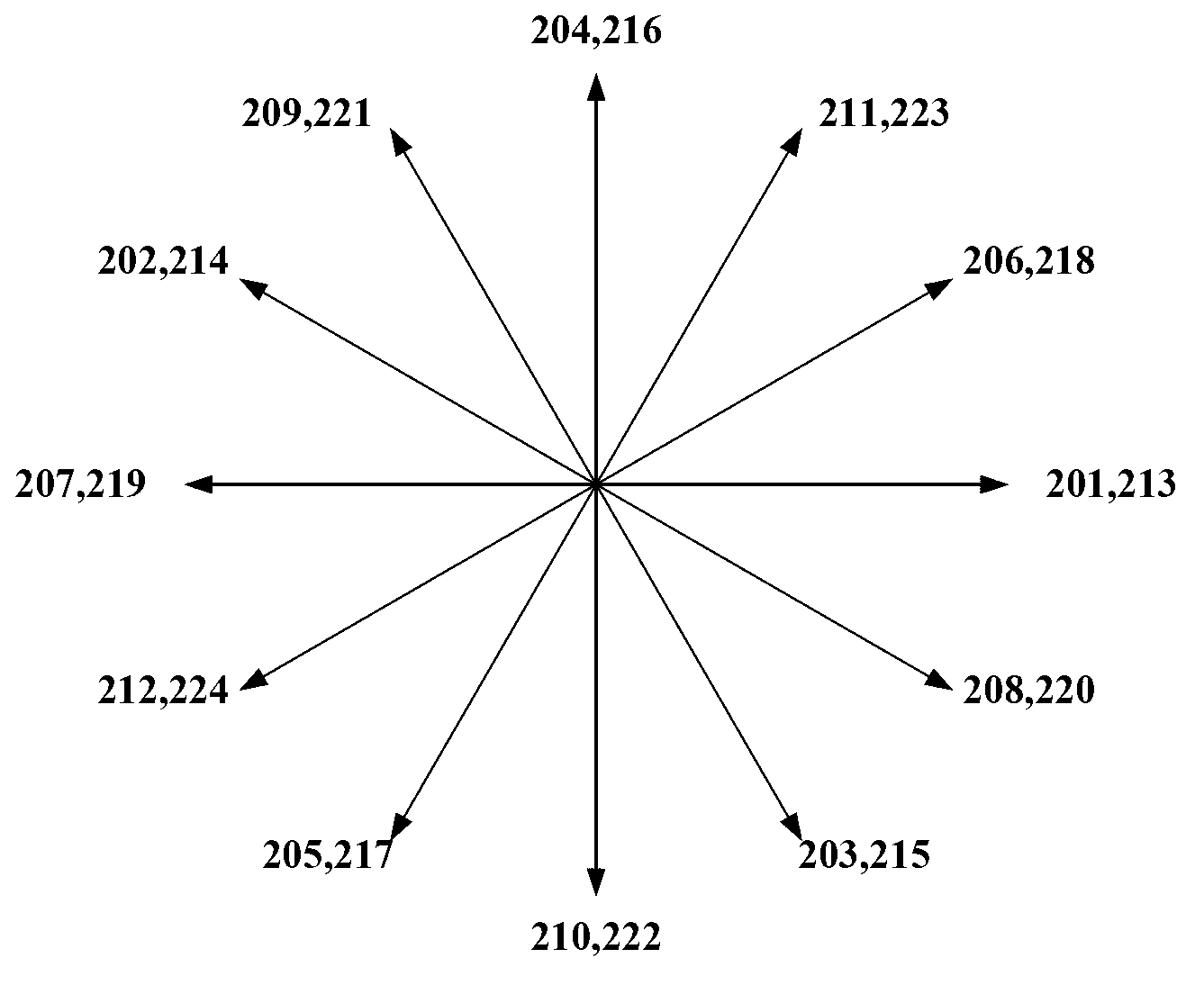

InactiveCN101931362AIncrease the number of optional vectorsReduce torque rippleTorque ripple controlVector control systemsVoltage vectorPermanent magnet synchronous motor

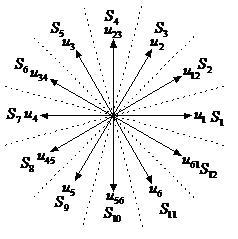

The invention discloses a direct torque control device and a direct torque control method for a permanent magnet synchronous motor. The DC bus voltage of an inverter and a current signal of the permanent magnet synchronous motor are output to a signal detection circuit; the signal detection circuit outputs the DC bus voltage and the current signal to a processor; meanwhile, a rotating speed pulse signal of the permanent magnet synchronous motor is output to the processor and is processed by the processor to form a proper switch signal which is then output to the inverter so as to control the motor. A proper voltage vector is selected from twelve synthesized voltage vectors according to a flux linkage error and a torque error and the position of the flux linkage in twelve sectors, and the duty ratio of the selected voltage vector is determined in real time according to the torque error so as to generate a proper inverter switch signal for controlling the permanent magnet synchronous motor. The number of the selectable voltage vectors in the traditional direct torque control is increased, the duty ratio of an acting vector is adjusted in real time according to the torque error, and the torque pulsation in the traditional direct torque control can be effectively reduced.

Owner:XIAN UNIV OF TECH

Compensation calculation method of heavy load phase of brushless direct current (DC) motor without position sensor

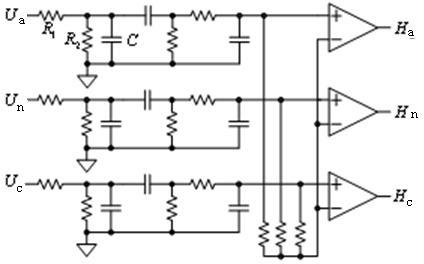

InactiveCN102437805AGood conditionReduce torque rippleTorque ripple controlElectronic commutatorsPhase currentsTerminal voltage

The invention relates to the technical field of brushless direct current (DC) motors, and in particular relates to a compensation calculation method of the heavy load phase of a brushless DC motor without a position sensor. The method is characterized by adopting a back electromotive force detection method to detect the three-phase terminal voltage with a back electromotive force detection circuit, carrying out depth filtering with a filter circuit, comparing the voltage with an analog neutral point, generating a rotor position signal with a digital signal processor (DSP), dividing the terminal voltage into a back electromotive force signal and a follow current interference signal, calculating the phases and amplitudes of the two signals to obtain a phase advance angle, caused by the follow current, of the rotor position signal and compensating the phase advance angle. The method has the following beneficial effects that: the controller can determine the phase advance angle in real time by only detecting the phase current of the motor; and phase angle compensation can be appropriately carried out according to the current and the rotating speed as the advance phase change of the phase angle is beneficial to the reduction of the torque ripple of the brushless DC motor, thus ensuring the motor to reach the best operation state.

Owner:WEIHAI CREDITFAN VENTILATOR

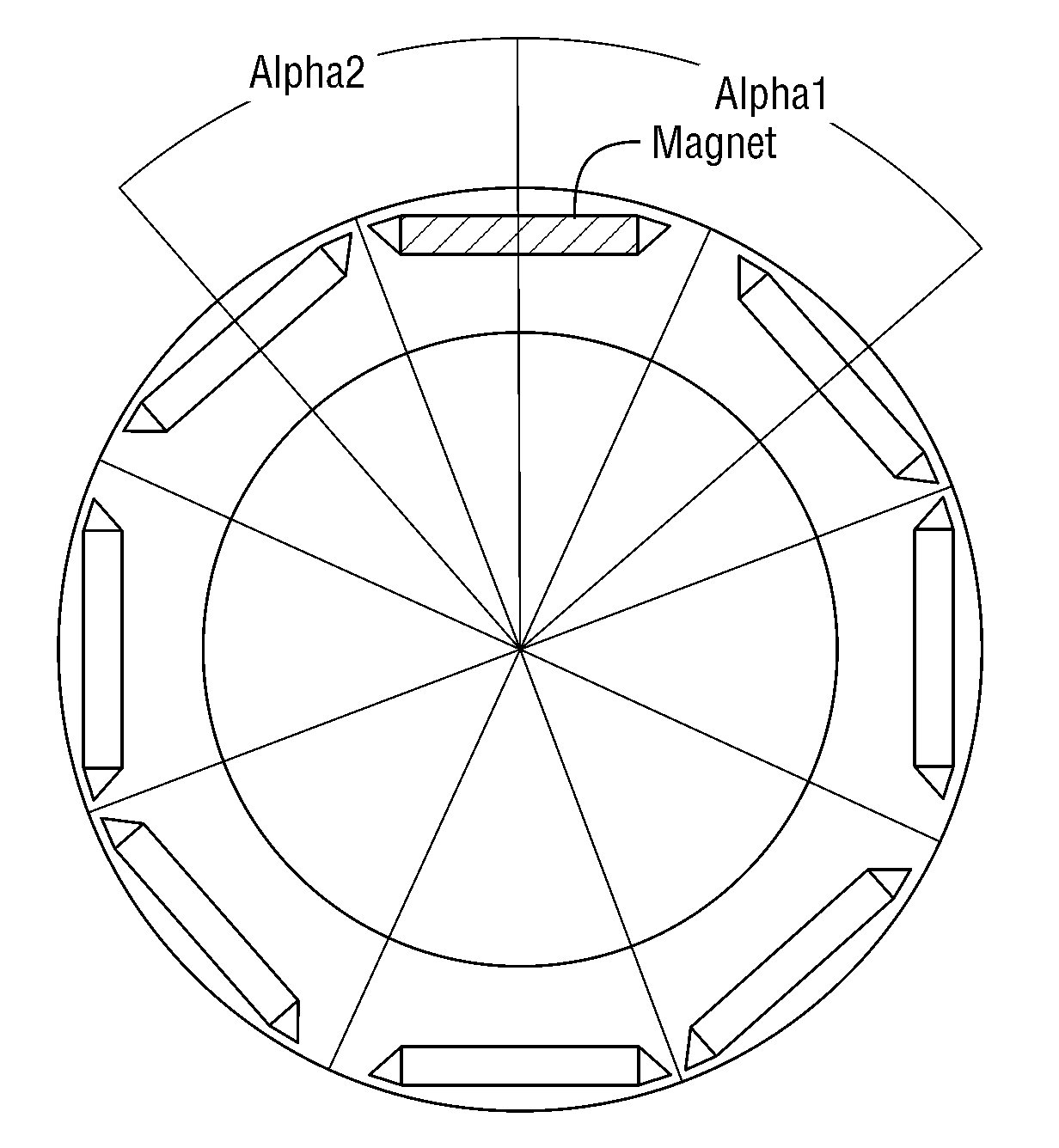

Permanent Magnet Machine with Offset Pole Spacing

InactiveUS20100117475A1Reduce the amplitudeMinimize a so-called torque rippleMagnetic circuitManufacturing dynamo-electric machinesHarmonicEngineering

An internal permanent magnet machine has multiple rotor sections, each section having multiple rotor laminations. Permanent magnets are placed asymmetrically in lamination openings to attenuate oscillations in torque caused by harmonic components of magnetic flux.

Owner:FORD GLOBAL TECH LLC

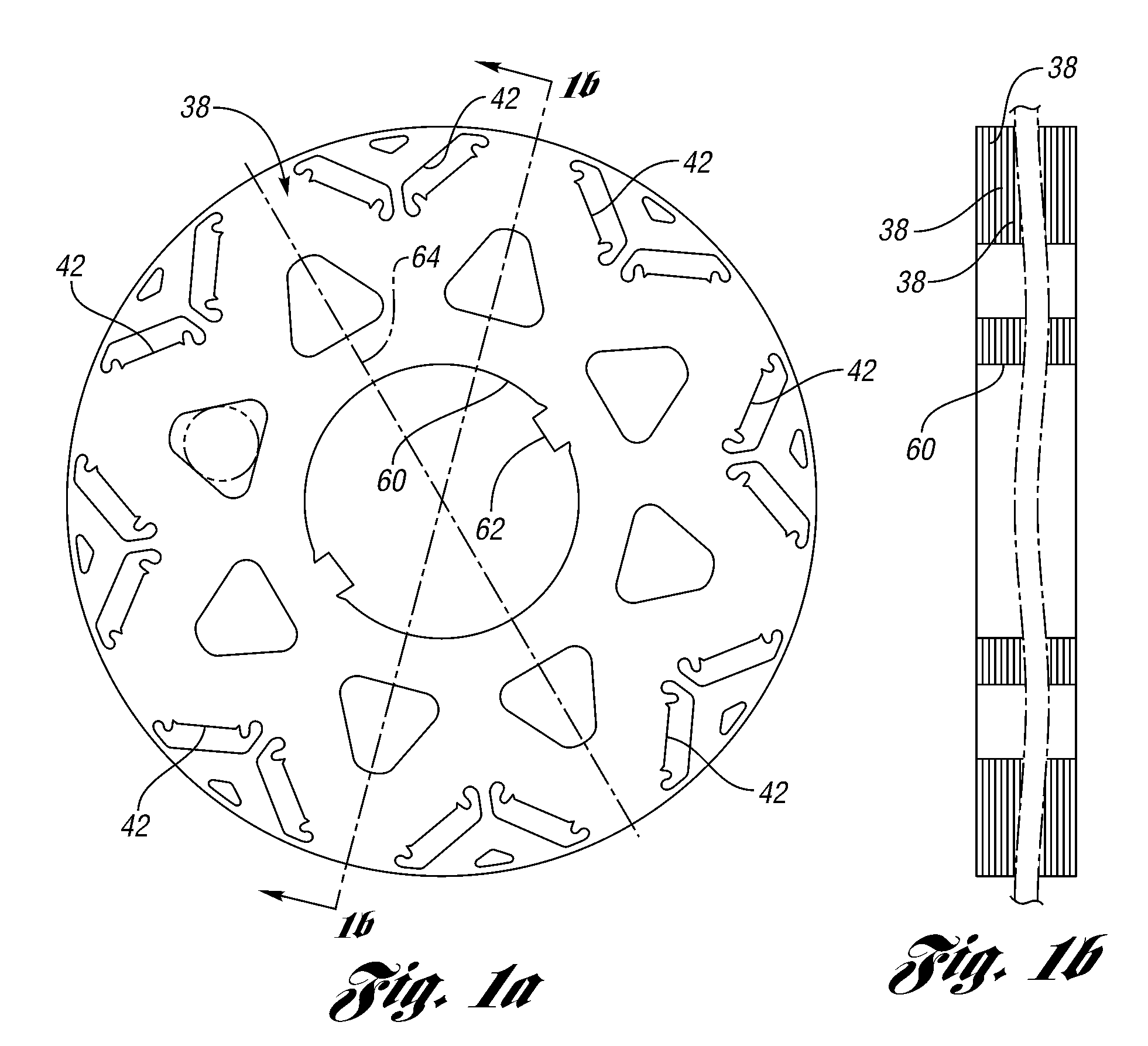

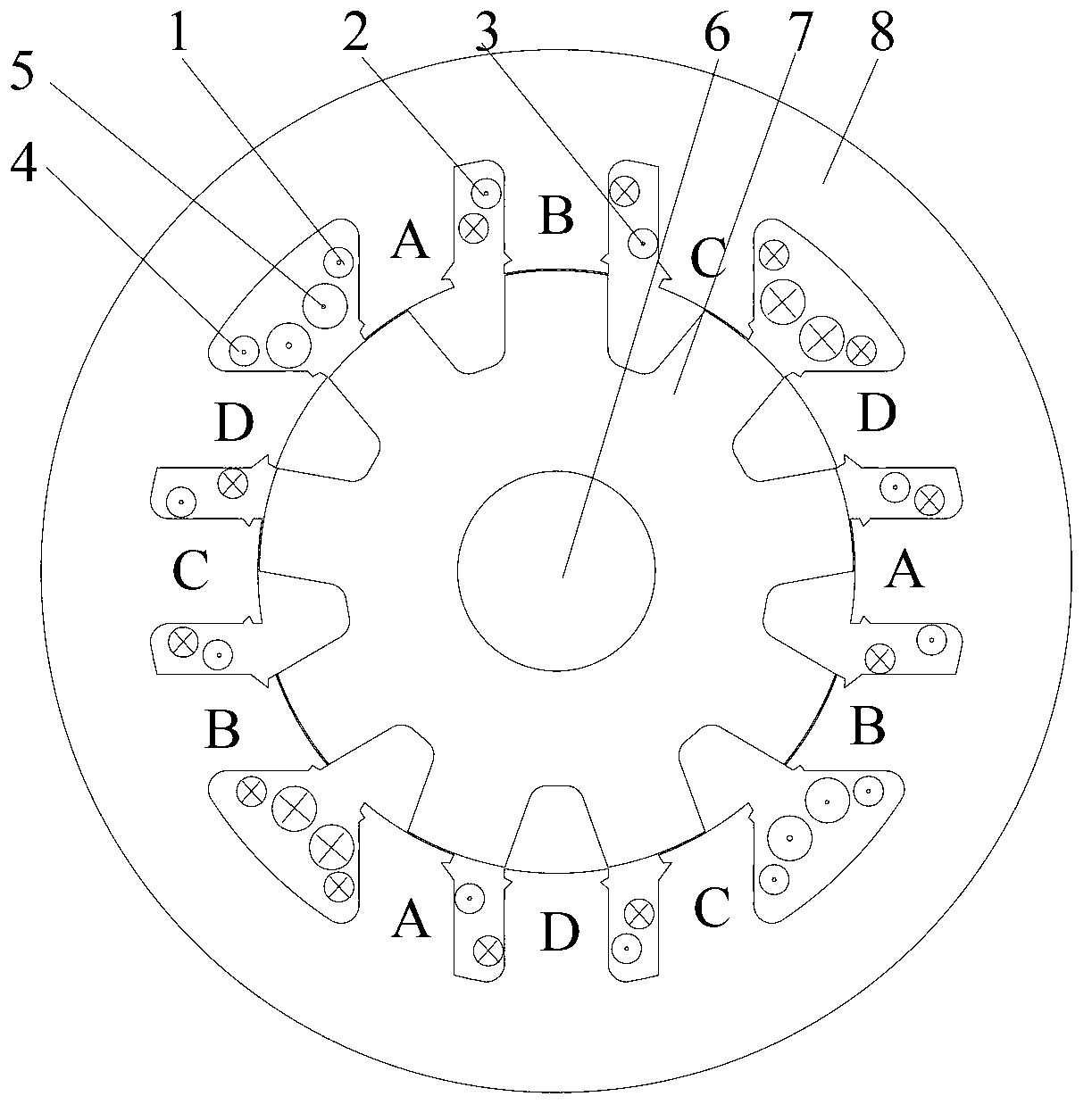

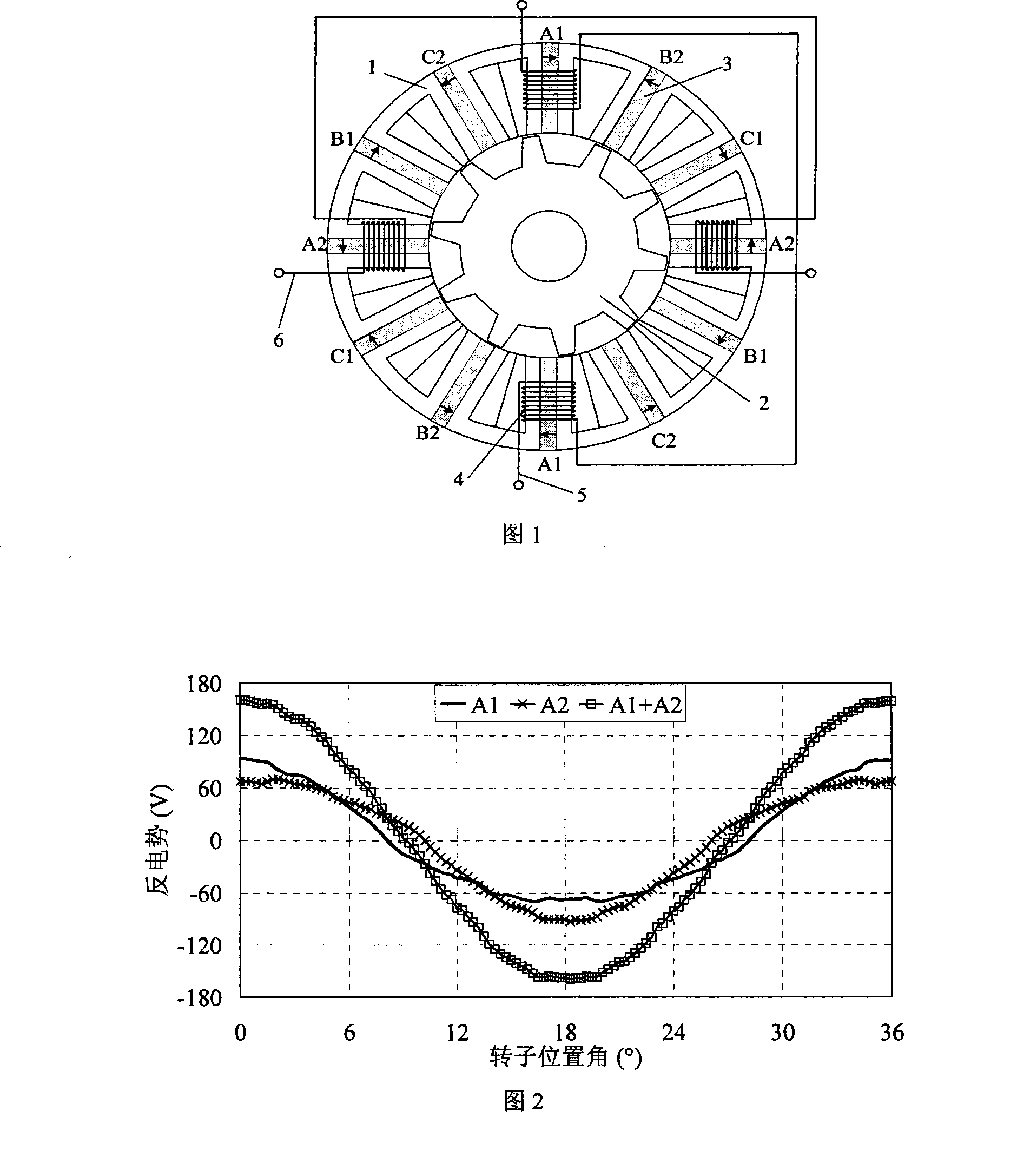

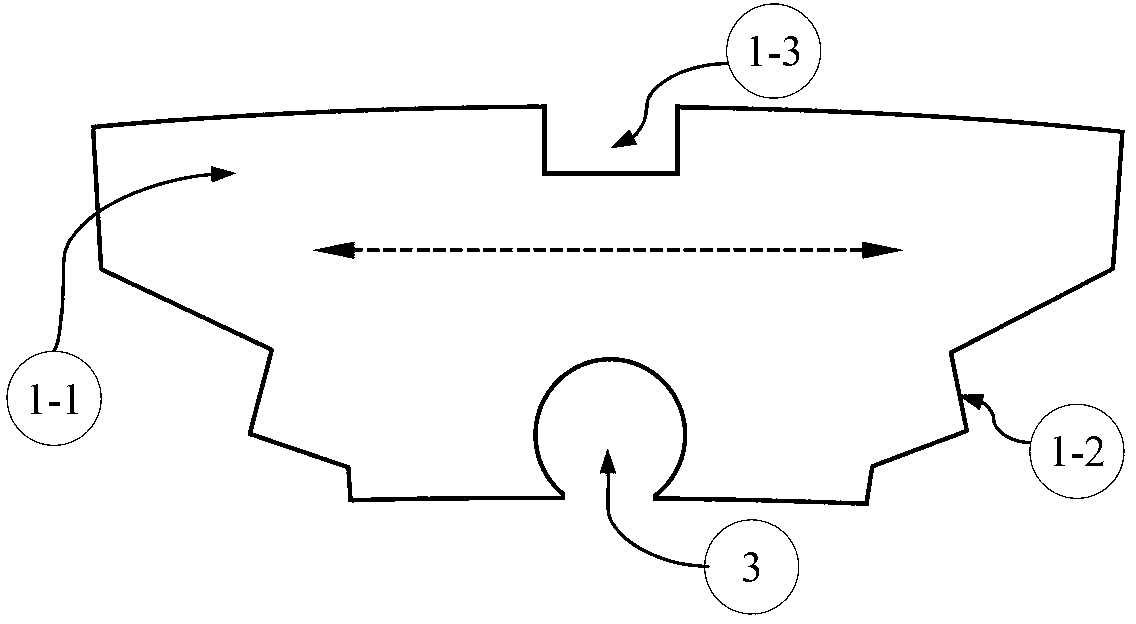

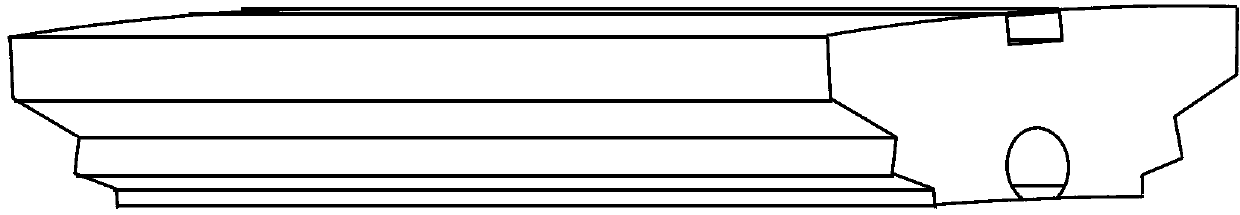

Four-phase and double-salient brushless direct current motor with symmetrical phase inductances

ActiveCN103187846AReduce torque rippleSmall positioning torqueMagnetic circuit rotating partsMagnetic circuit stationary partsFault toleranceStator coil

The invention discloses a four-phase and double-salient brushless direct current motor with symmetrical phase inductances. According to the four-phase and double-salient brushless direct current motor, a unit motor is of a novel 12 / 9 salient structure or a novel 12 / 15 salient structure, each excitation element is wound after spanning three stator poles, each stator coil of each phase stator winding is distributed at different positions, and the symmetry of the phase inductances is achieved by a mode of symmetrically distributing the four phase stator windings; the pole-arc coefficient matching size of motor stators and rotors is determined by theoretical analysis and emulation verification methods, so that the phase inductances of the motor are hoisted and decreased by an electrical angle of 180 degrees, the total permeance of exciting windings remain basically unchanged, the positioning torque of the motor is small, and the four phases are electrified at the same time to operate. In addition, the four phase stator windings are independent in pairs, so that the motor can operate by only using the two phases after one phase is in fault, and the fault tolerance performance is favorable. Moreover, the total permeance of the exciting windings is unchangeable, so that the four-phase and double-salient brushless direct current motor has the advantages of small positioning torque and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

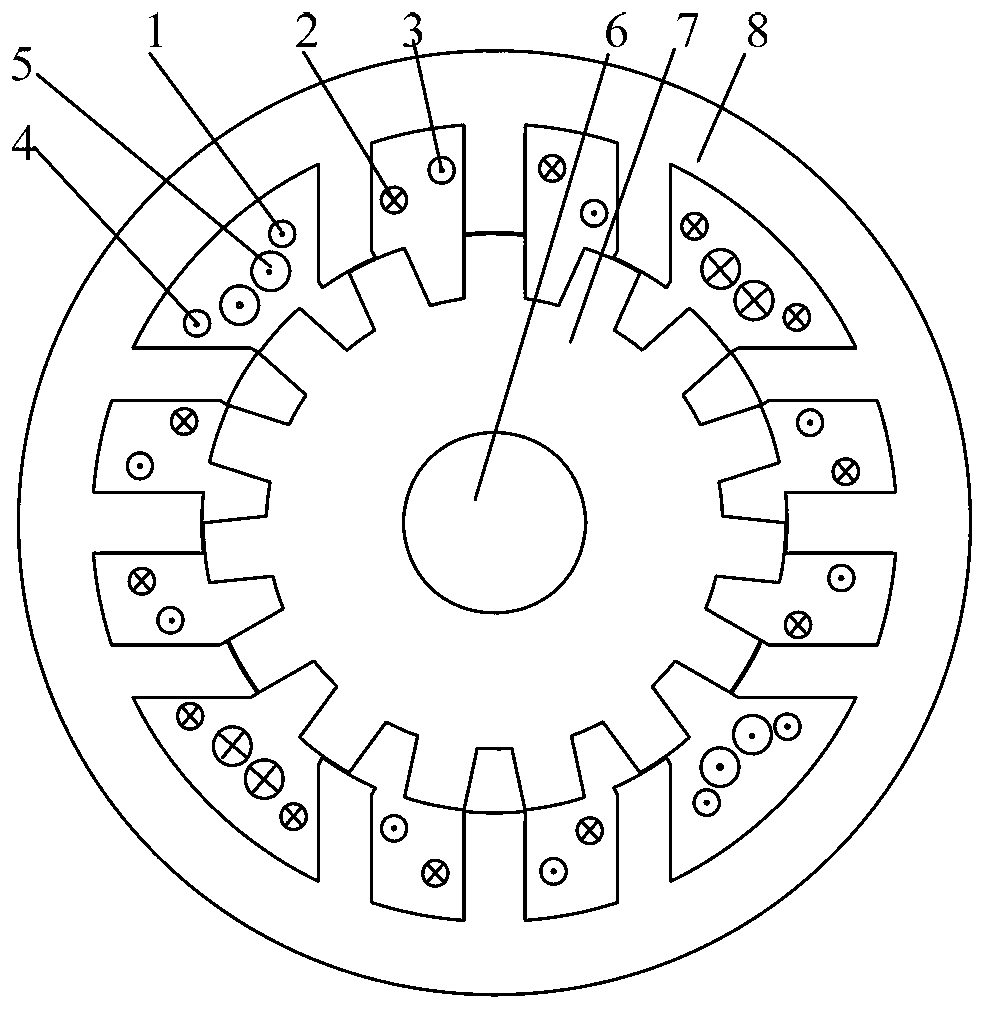

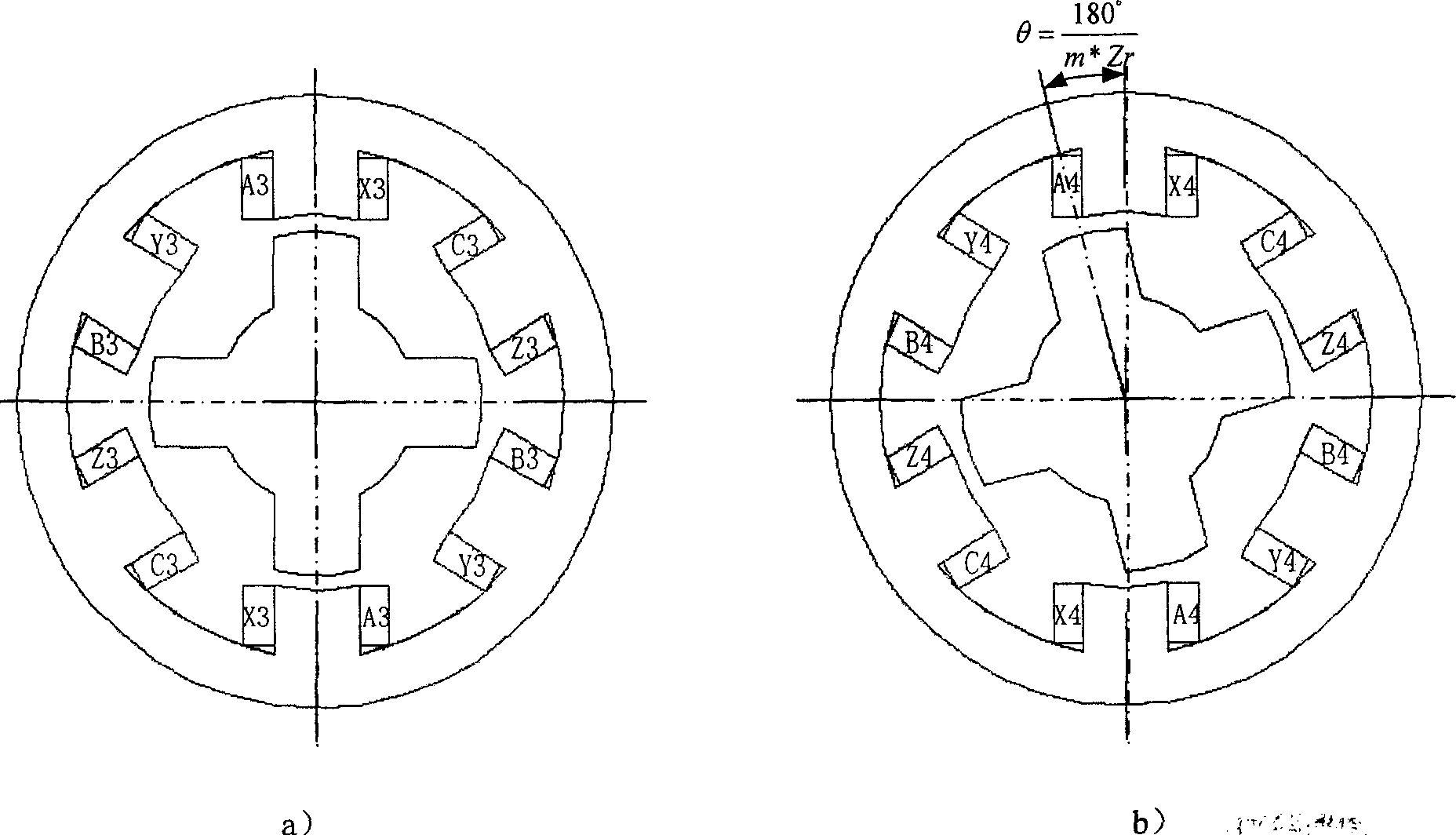

Magnetic resistant electric motor with double stator switch

InactiveCN1645712AReduce torque rippleMagnetic circuit shape/form/constructionWindings conductor shape/form/constructionEngineeringConductor Coil

The invention consists of stator and rotator that both have salient pole type tooth socket structure made by pressed stack silicon steel sheet. The iron core of rotator and stator is composed of two stage iron cores having same length. The two stage iron cores of rotator or stator are installed by staggering 180 / phase number degree electrical degree. The two groups of centralizing armature winding are separately sleeved on the stator tooth. The armature winding sleeved in two neighboring teeth having same phase is series connected or parallel connected to form one phase. The generated torque ripple is the combination of torque ripple generated from left side of motor and torque ripple generated from right side, so that combination of torque ripple can be increased and frequency can be increased one time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for suppressing torque ripple of permanent-magnet motor based on space vector modulation

InactiveCN101860300ANo need to increase drive control costsNo additional costTorque ripple controlLinearityFlux linkage

The invention relates to a method for suppressing the torque ripple of a permanent-magnet motor based on space vector modulation. The method comprises the following steps of: adopting a vector control strategy that a permanent-magnet motor has a zero direct axis current so that electromagnetic torque and a quadrature axis armature current form a linear connection; and solving an additional quadrature axis injection harmonic current according to the linear connection of the electromagnetic torque of the permanent-magnet motor and the quadrature axis armature current so that an additional electromagnetic torque high-harmonic component generated by coupling the quadrature axis injection harmonic current and the direct axis permanent-magnet chain and fundamental and high-harmonic components in the orientation torque of the permanent-magnet motor have identical amplitude and opposite phases and can be mutually counteracted to suppress the torque ripple. The invention adopts the permanent-magnet motor as an implementation object, and the motor of the type can adopt advanced control protocols of vector control, direct torque control, and the like so that the method is simple and practical by editing control software without increasing the hardware cost of a control system and can obviously suppress the torque ripple of the motor and remain the constant motor characteristics of idling magnetic potential, torque output capability, and the like.

Owner:SOUTHEAST UNIV

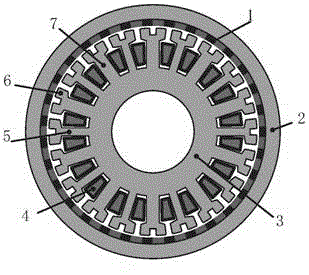

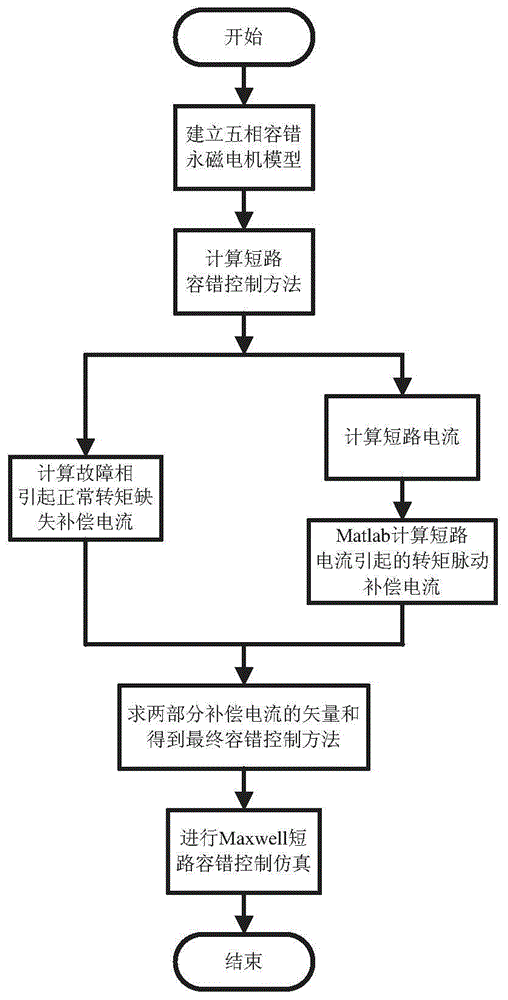

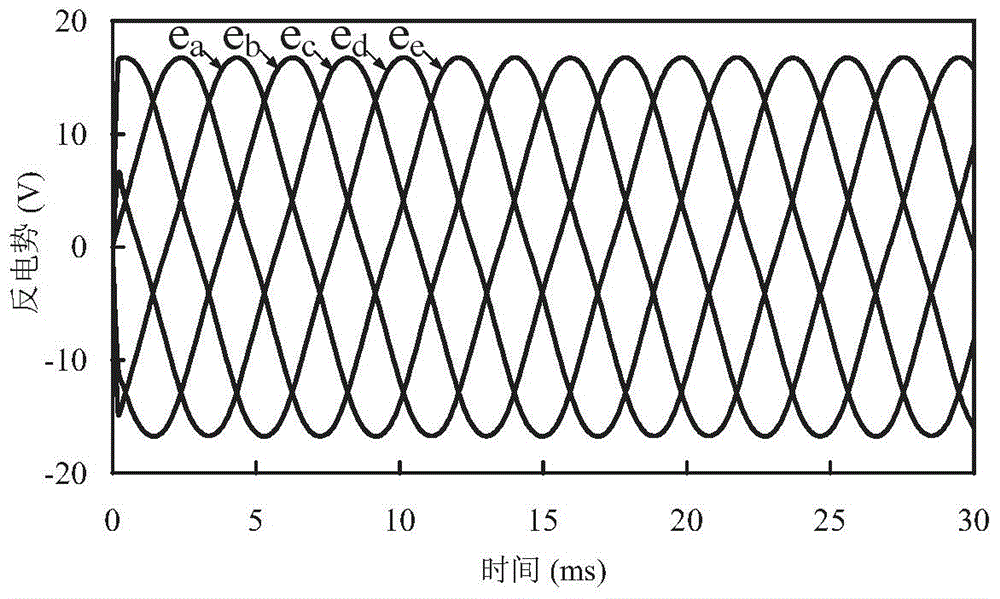

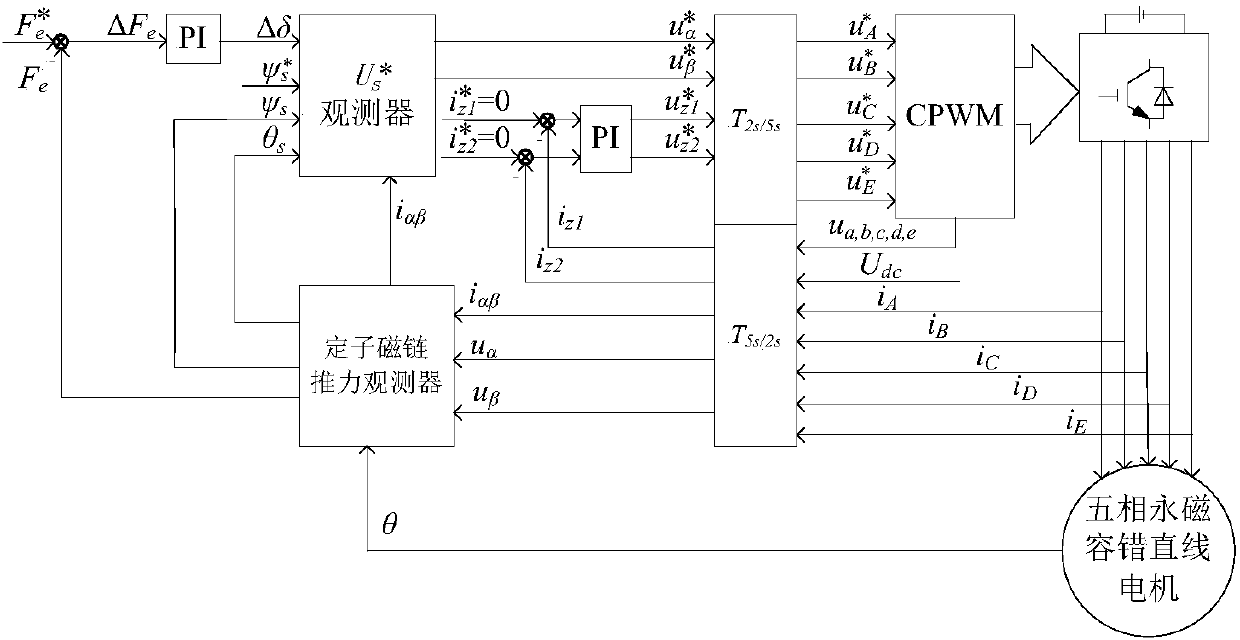

Short circuit fault tolerant control method for five-phase fault tolerant permanent magnet motor

ActiveCN104682807AReduce torque rippleRealize short-circuit fault operationElectronic commutation motor controlVector control systemsPhase currentsMagnetomotive force

The invention discloses a short circuit fault tolerant control method for a five-phase fault tolerant permanent magnet motor. The method comprises the following steps: establishing a five-phase fault tolerant permanent magnet motor model; compensating a short circuit fault phase normal torque loss by using non-fault phase current by directly adopting a compensation strategy of an open fault; compensating the fluctuated magnetic motive force caused by the short circuit fault phase current by using non-fault phase current, so that the synthetic magnetic motive force is zero; eliminating torque ripple caused by the short circuit current; synthesizing the vectors of the compensating current of the steps 2 to 3 to obtain the short circuit fault tolerant current; performing control and simulation on Maxwell short circuit fault tolerant. According to the short circuit fault tolerant control method for the five-phase fault tolerant permanent magnet motor, one-phase short circuit fault tolerant control is performed on the motor according to the specific situation of the no-load counter electromotive force of the motor, so that the fault is equivalent to the output torque in a normal operating state; the torque ripple is reduced; the operation of the five-phase fault tolerant permanent magnet motor with a short circuit fault is realized.

Owner:JIANGSU UNIV

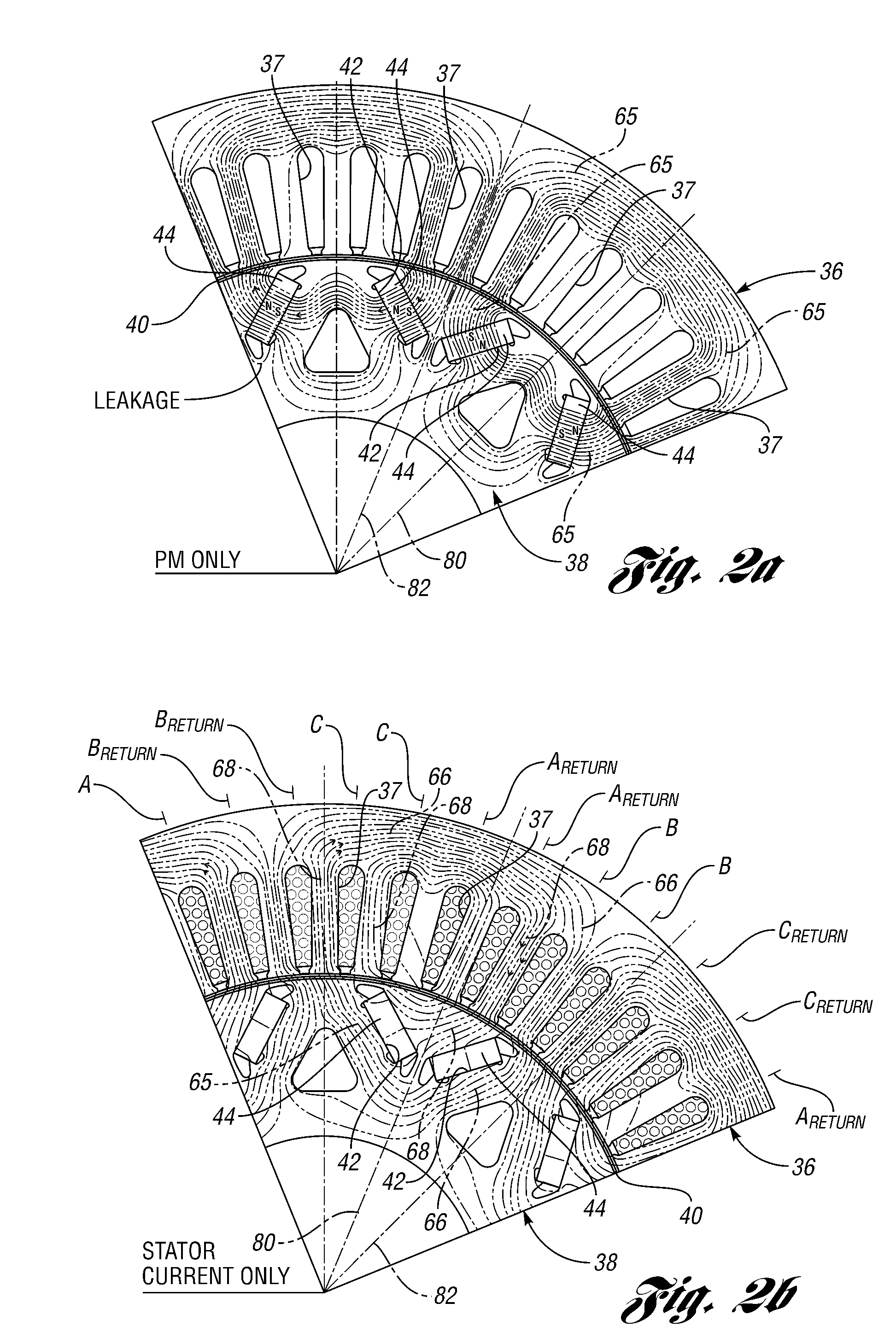

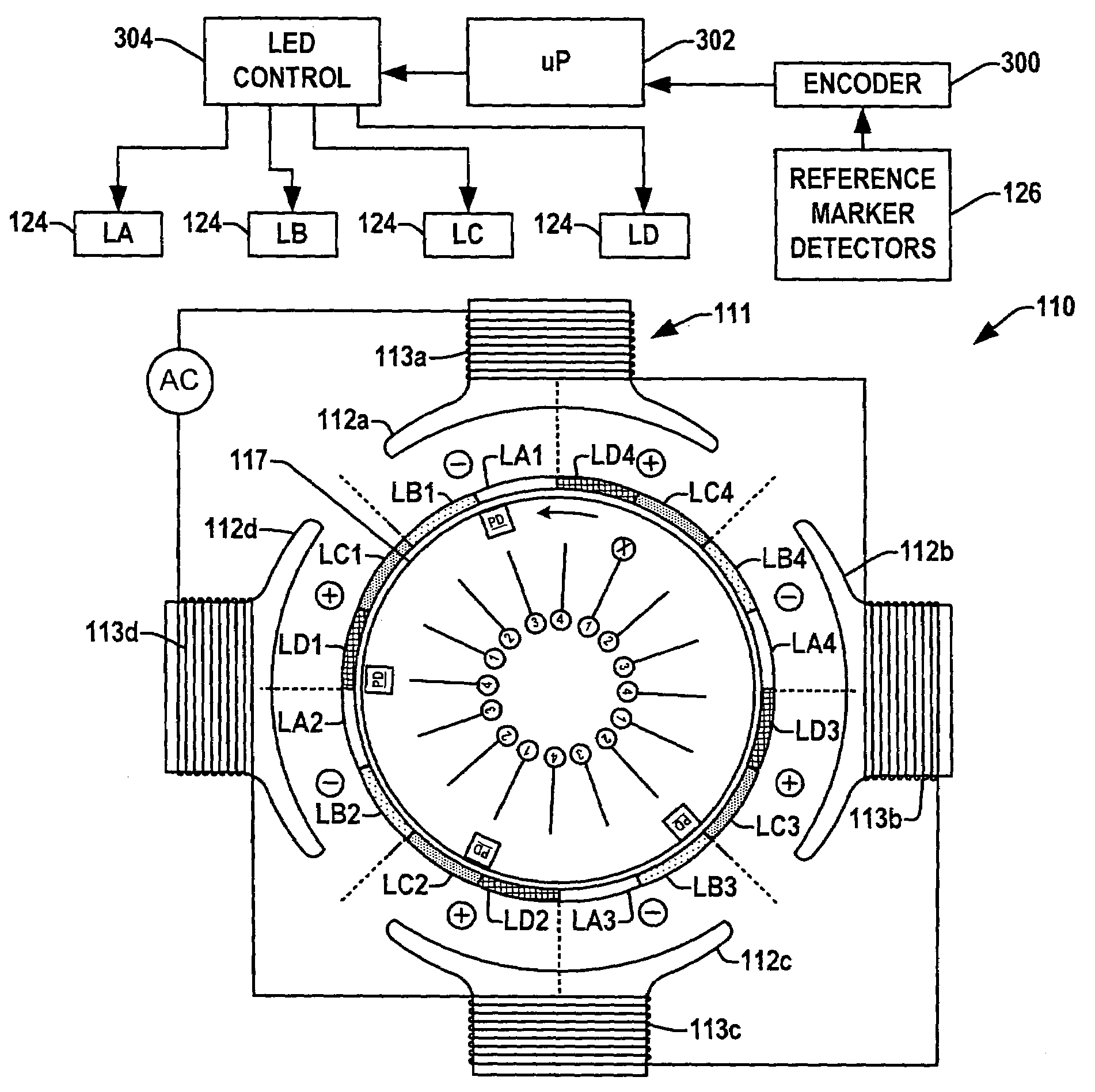

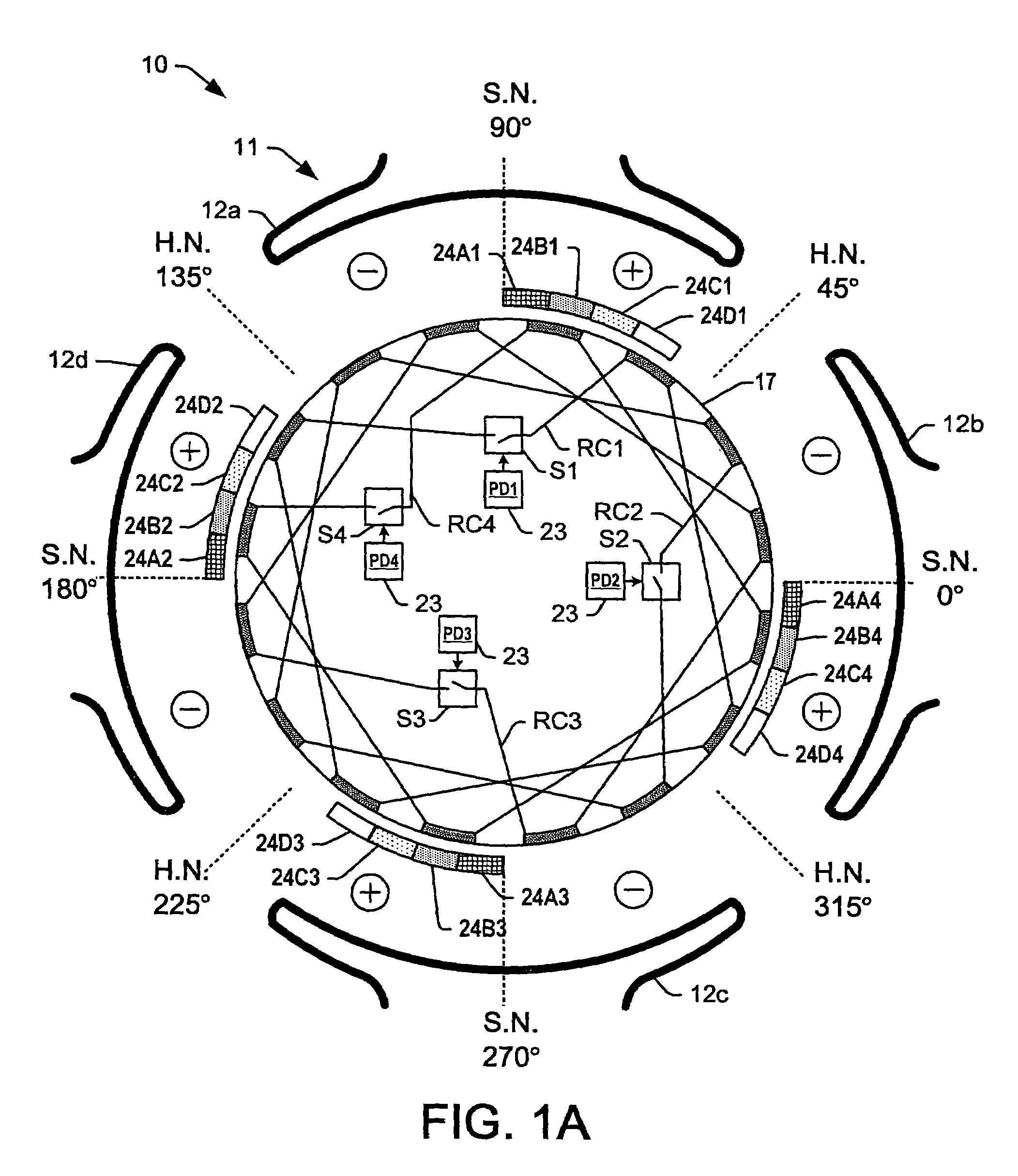

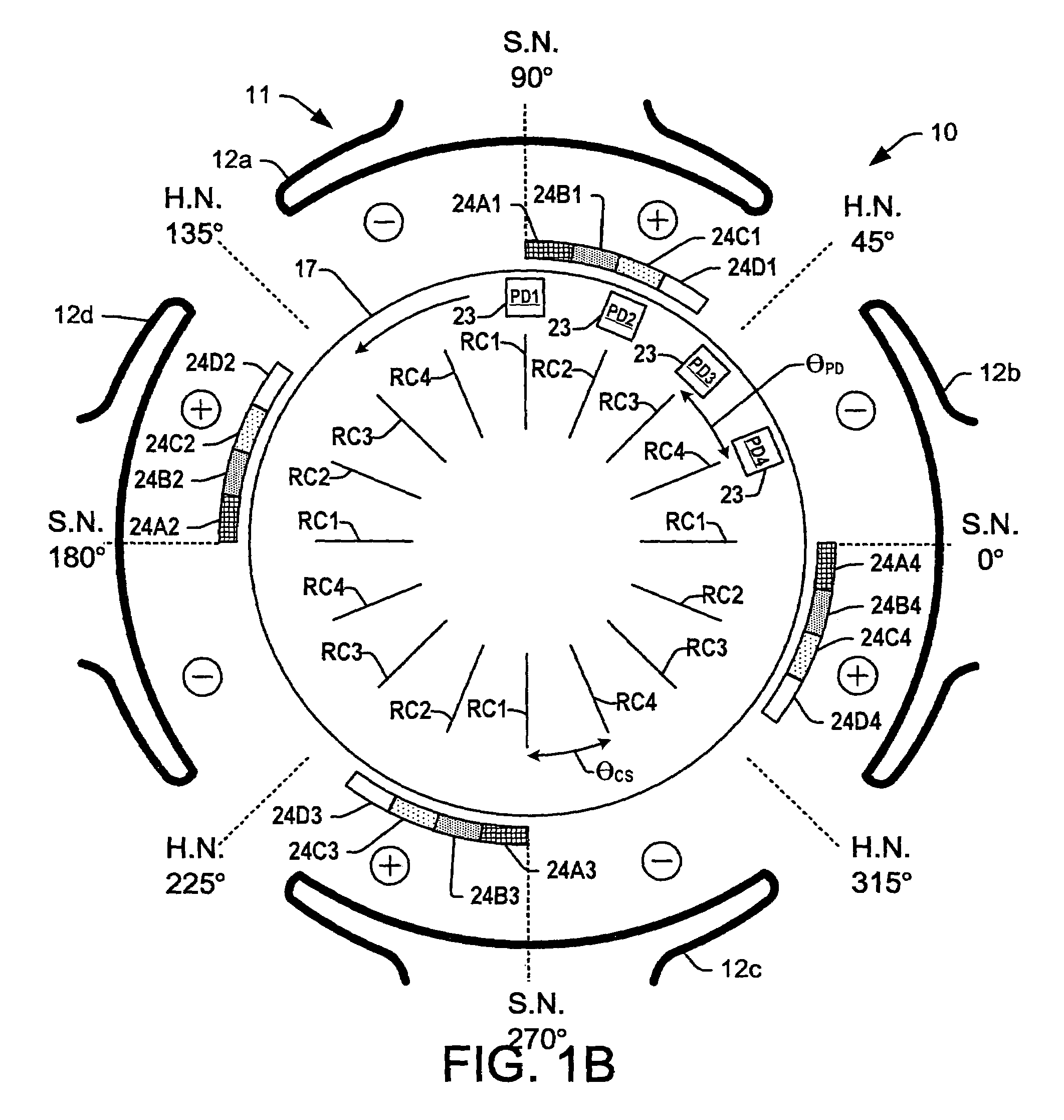

Signaling and reduced torque ripple in brushless repulsion motors

InactiveUS7166984B1Improving ability selectively controlAdditional costTorque ripple controlMotor/generator/converter stoppersRepulsion motorSwitching signal

Brushless repulsion motors are presented, in which rotor coils switching signal detectors are selectively located in spaced angular relationship on the rotor and signaling sources are distributed around all or most of the stator circumference to allow looser tolerances for motor manufacturing and improved controllability of rotor coil actuation during operation. Asymmetric stator poles are also provided for brushless repulsion motors to mitigate torque ripple and vibration, in which the shape of the stator pole tips is tailored by varying the angular length of the pole section.

Owner:DYNAMOTORS

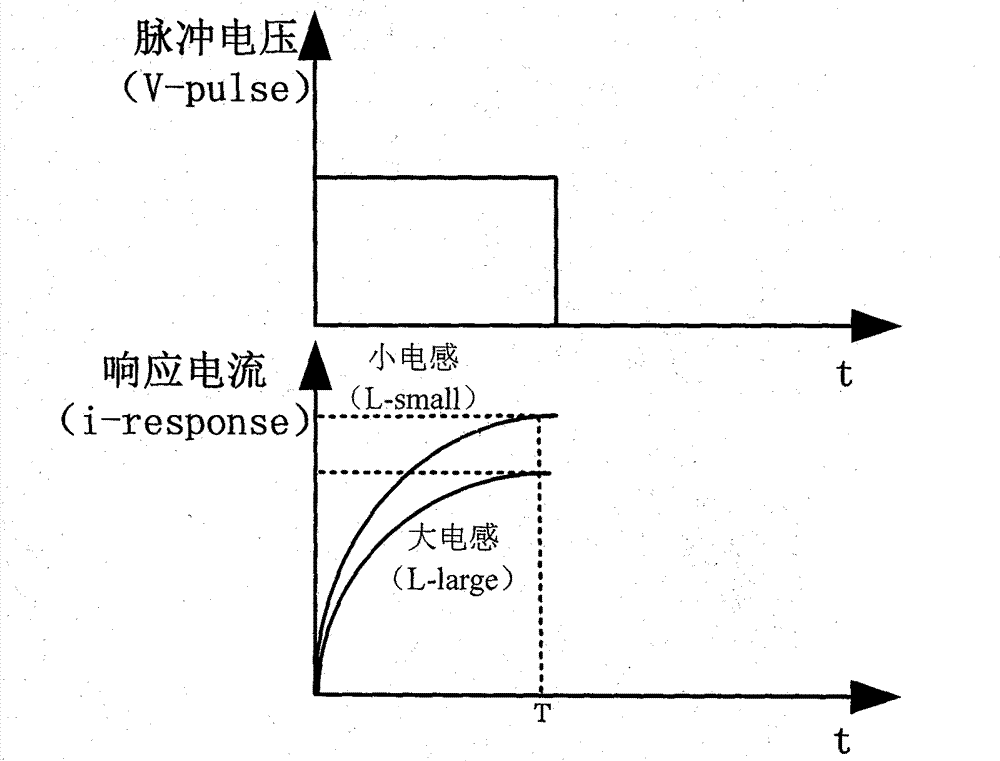

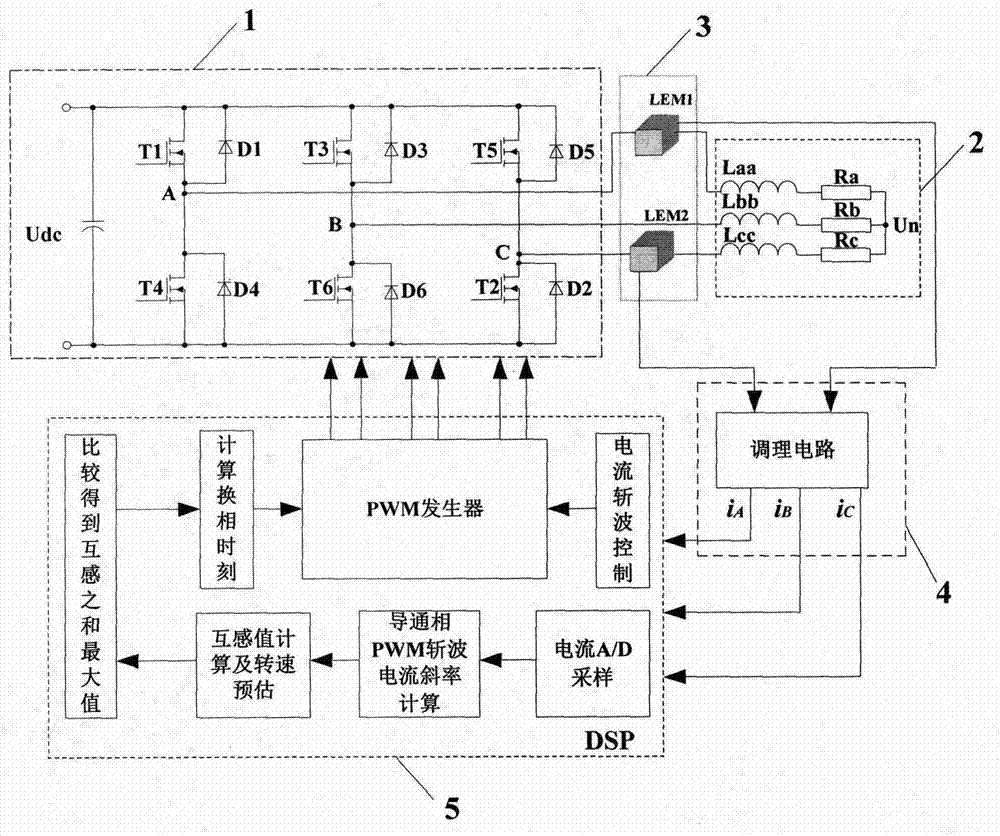

Non-location technology for three-phase electro-magnetic double-salient pole machine starting and accelerating based on induction method

InactiveCN103078586APrecise positioningPrecise location sectorMotor parameters estimation/adaptationPhase currentsLow speed

The invention discloses a non-location sensor technology for three-phase electro-magnetic double-salient pole machine starting and low-speed accelerating processes. According to the characteristics of an electro-magnetic double-salient pole machine, exciting current is not applied in a static state, but fixed-cycle low voltage pulse signal judging phase current is applied on armature windings, double-phase series connection self inductance is then calculated, and a rotor position is estimated. During a low-speed accelerating process, the mutual inductance sum of two phases of series connection windings and an excitation winding is calculated according to the armature current gradient when chopped waves are acquired in real time, so that the non-location low-speed accelerating technology for accelerating a motor is carried out. By utilizing the method, the initial rotor position can be accurately positioned, a rotor sector can be identified and fed back in real time during the low-speed accelerating, the maximum inductance is obtained through comparison, and the phase shifting time is determined after time delay. Consequently, the rotor positions can be fed back during the whole starting and accelerating processes, so that the motor cannot be out of step during the starting process and has strong antijamming capability. By utilizing the technology, the three-phase electro-magnetic double-salient pole machine can be enabled to start and accelerate stably and reliably.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

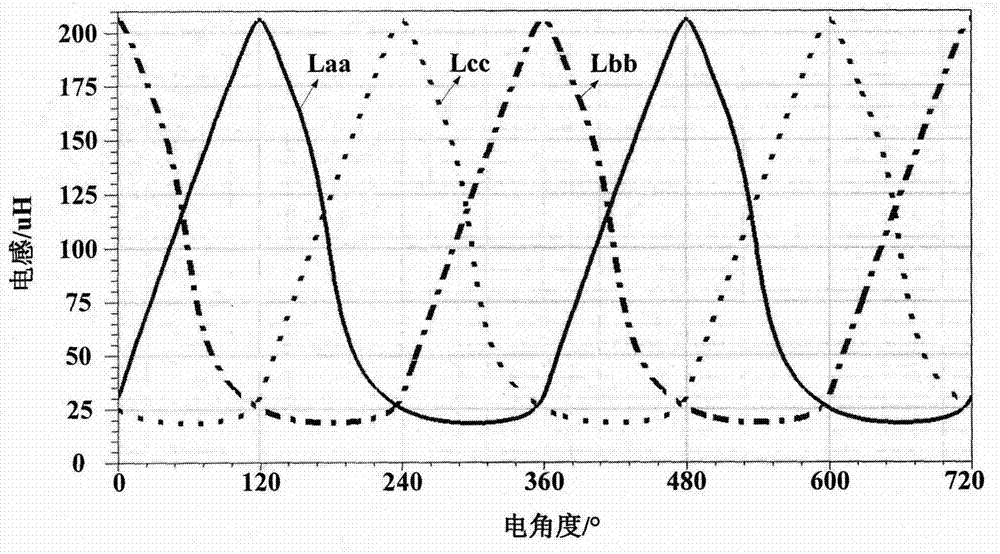

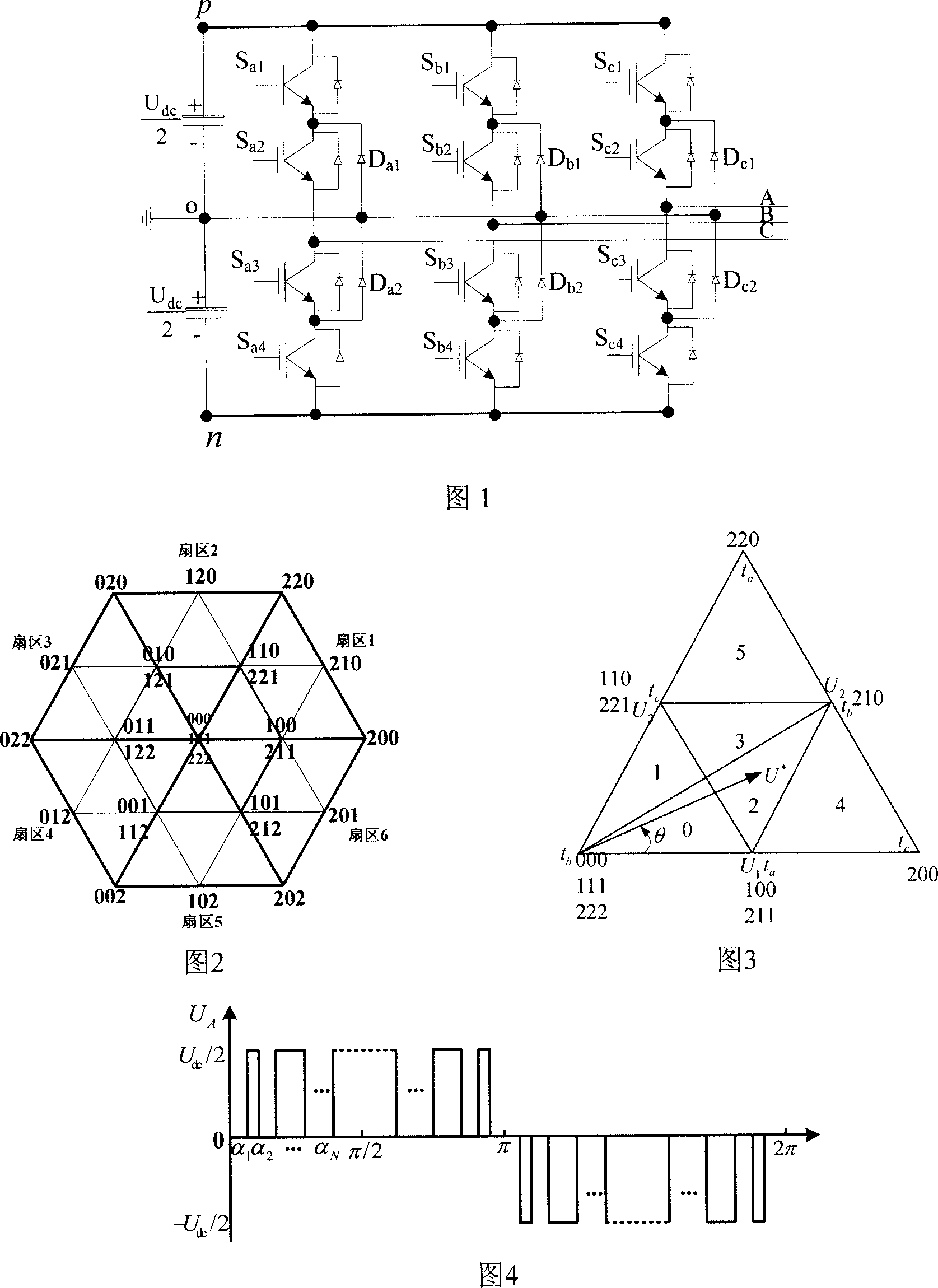

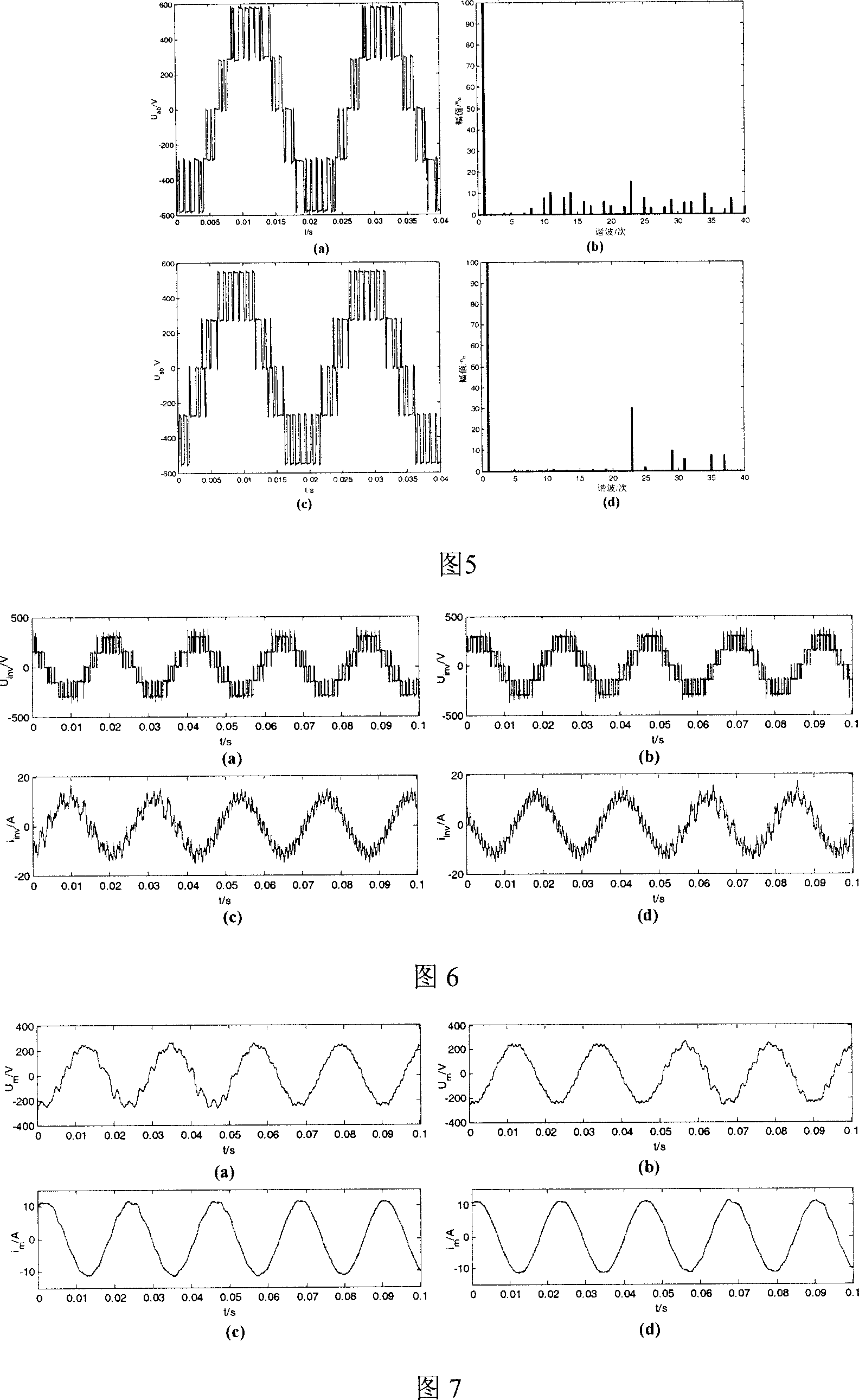

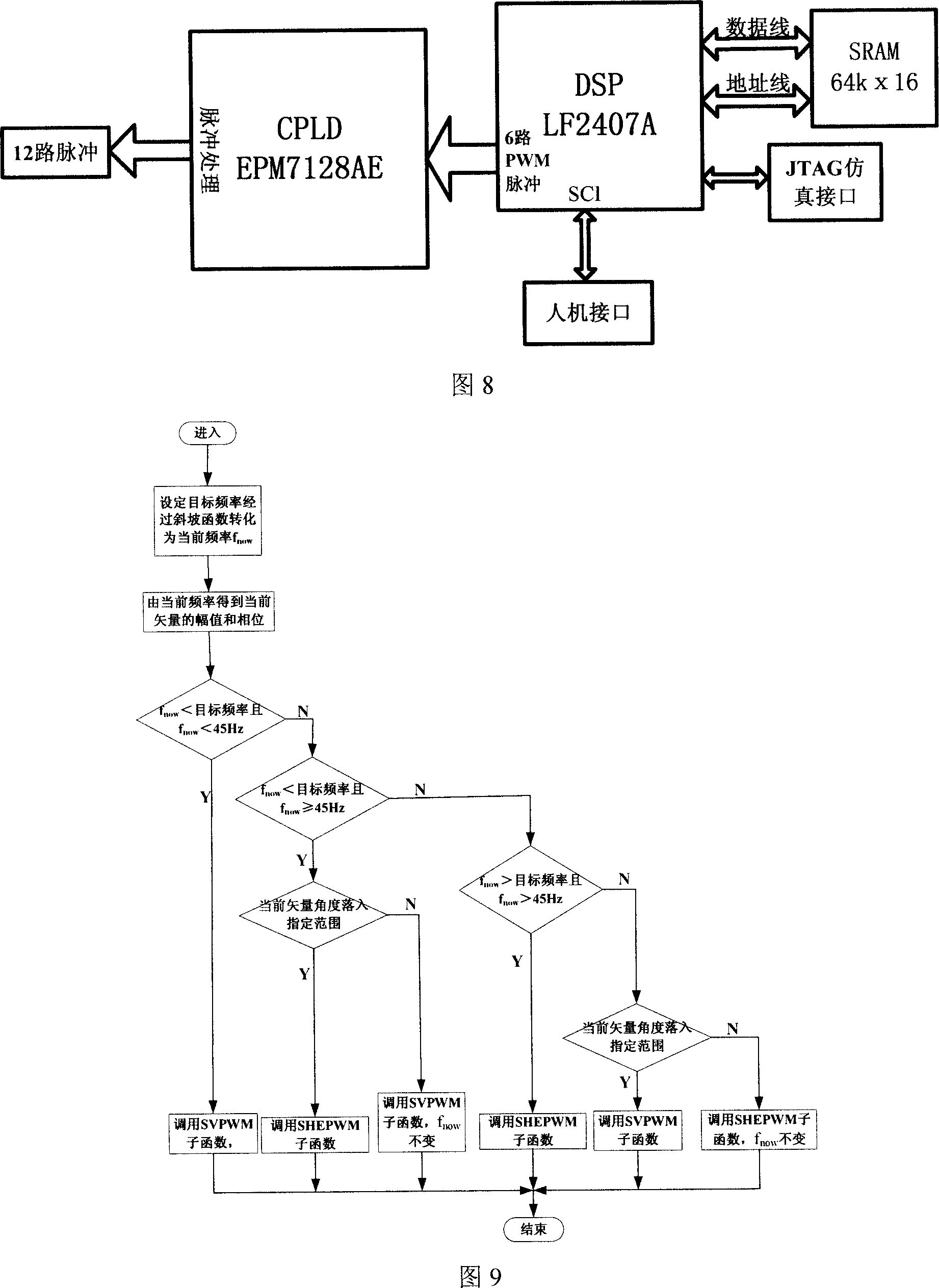

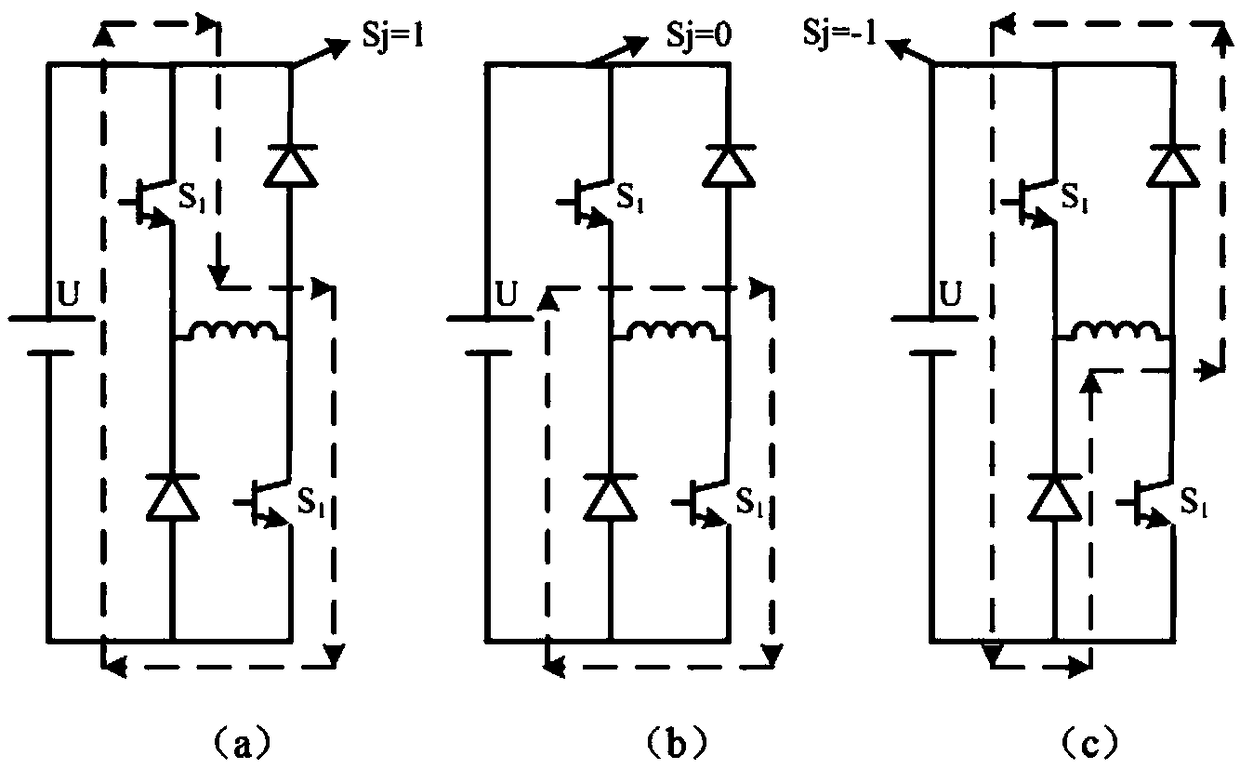

A mixed modulating method for three level high-voltage transducer

InactiveCN101018020AReduce torque rippleReduce noiseDc-ac conversion without reversalFrequency changerThree level

The disclosed modulation technology for three-level high-voltage frequency converter comprises: to three-level NPC frequency converter, using asynchronous SVPWM when frequency less than 45Hz, and obtaining switch frequency as 600Hz; using special eliminating-harmonic PWM when frequency over 45Hz, and obtaining the switch number is seven. This invention avoids defects of space-vector PWM and special eliminating-harmonic PWM, improves waveform quality, reduces heat loss and request on filter, and ensures system security and reliability.

Owner:TSINGHUA UNIV +1

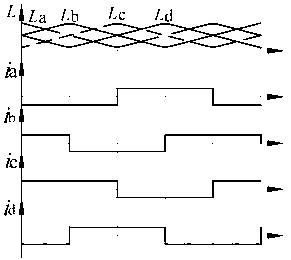

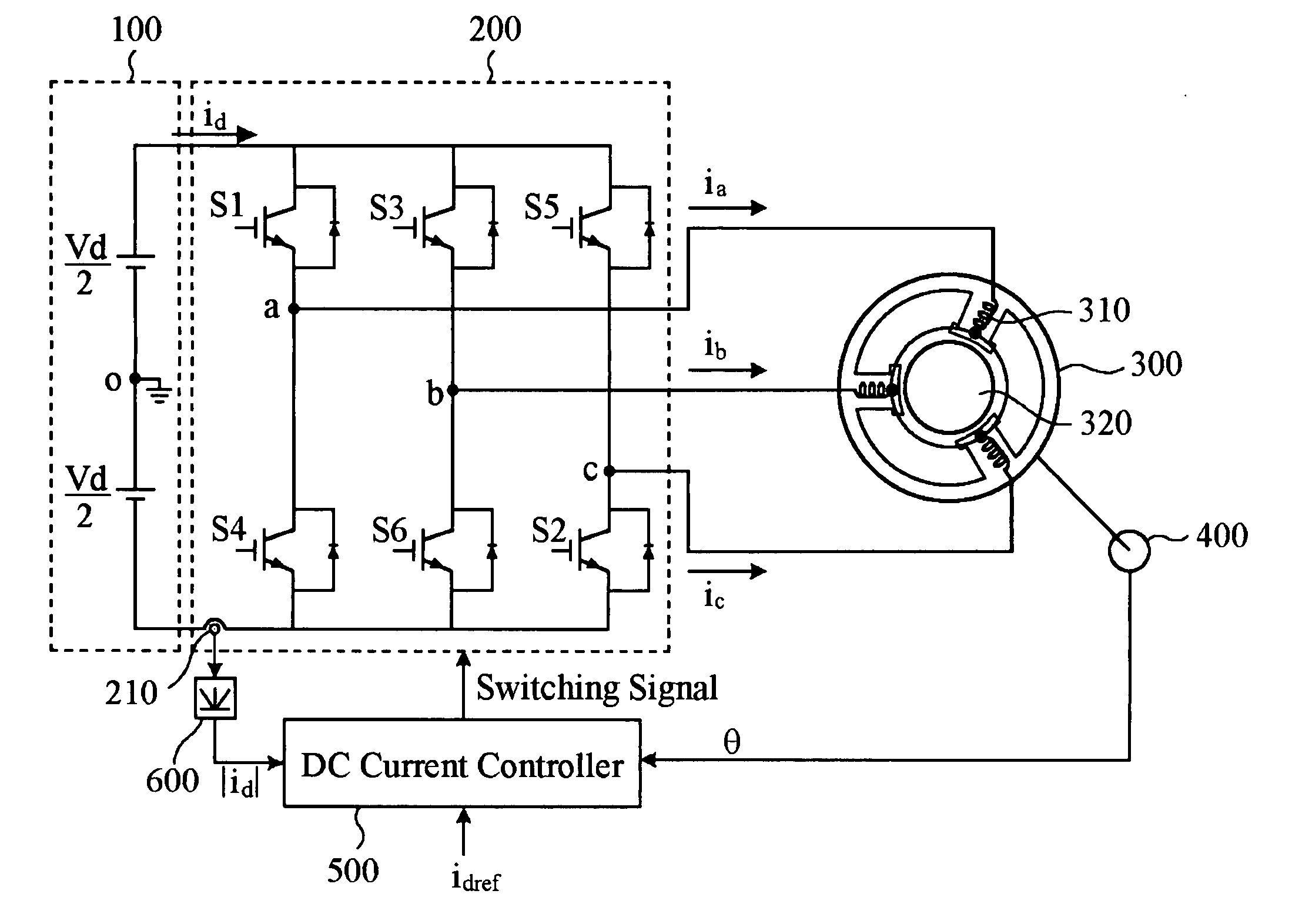

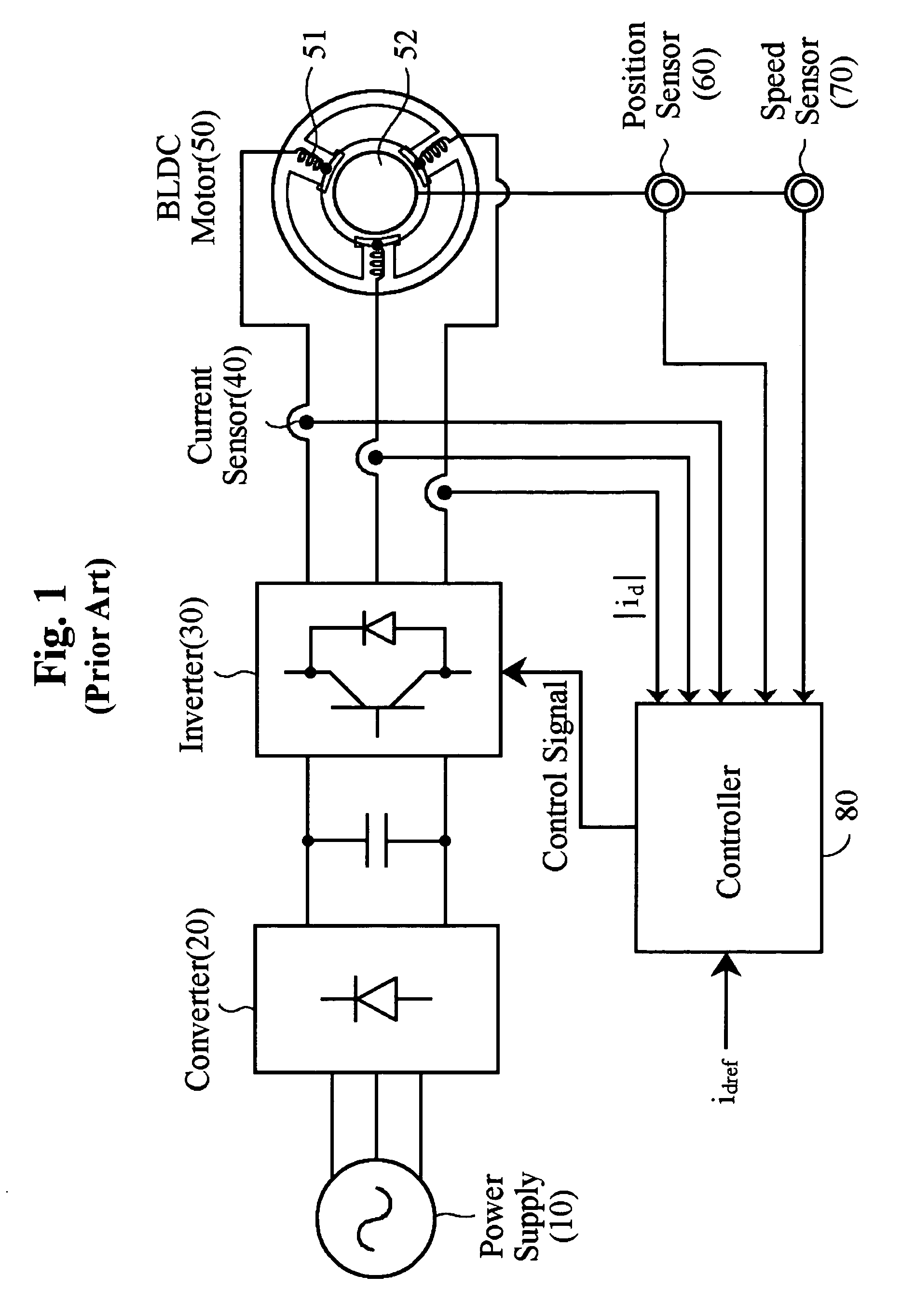

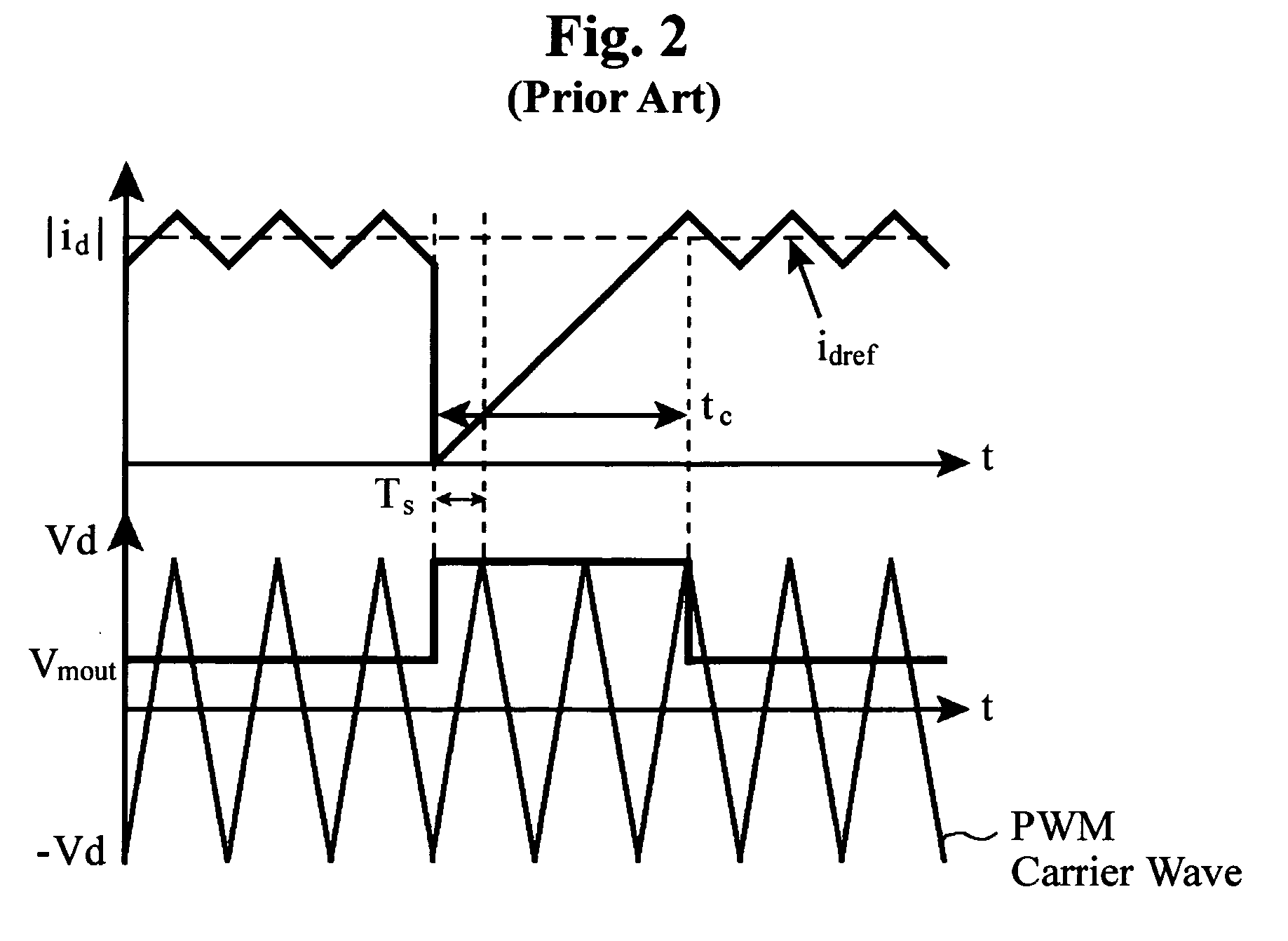

Brushless DC motor system and method of controlling the same

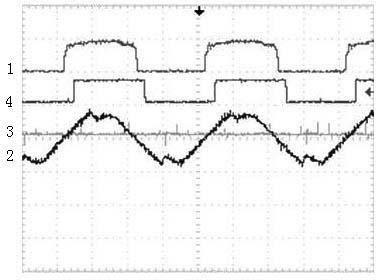

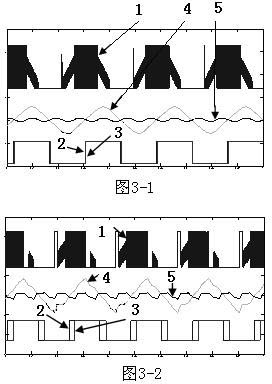

InactiveUS20060145639A1Reduce torque rippleReduce a torque rippleMotor/generator/converter stoppersSynchronous motors startersSwitched currentReference current

A brushless DC (BLDC) motor system and a method of controlling the same are provided. The BLDC motor system comprises a BLDC motor including a rotator and a stator, a plurality of switches, a DC current sensor, a position detector and a controller. The stator has a plurality of coils to which currents having different phase are applied. The switches are driven with switching pulses for switching the currents applied to the coils. The position detector detects a position change of the rotator to thereby generate a counter-electromotive force and the DC current sensor senses currents when the currents are applied from the switches to the coils. Based on a magnitude of the counter electromotive force, the controller generates a compensation voltage in order to control the switches during the commutation interval. Further, a duty ratio of the switching pulse is controlled based on the differences between the currents applied to the coils and a reference current.

Owner:KOREA INST OF SCI & TECH

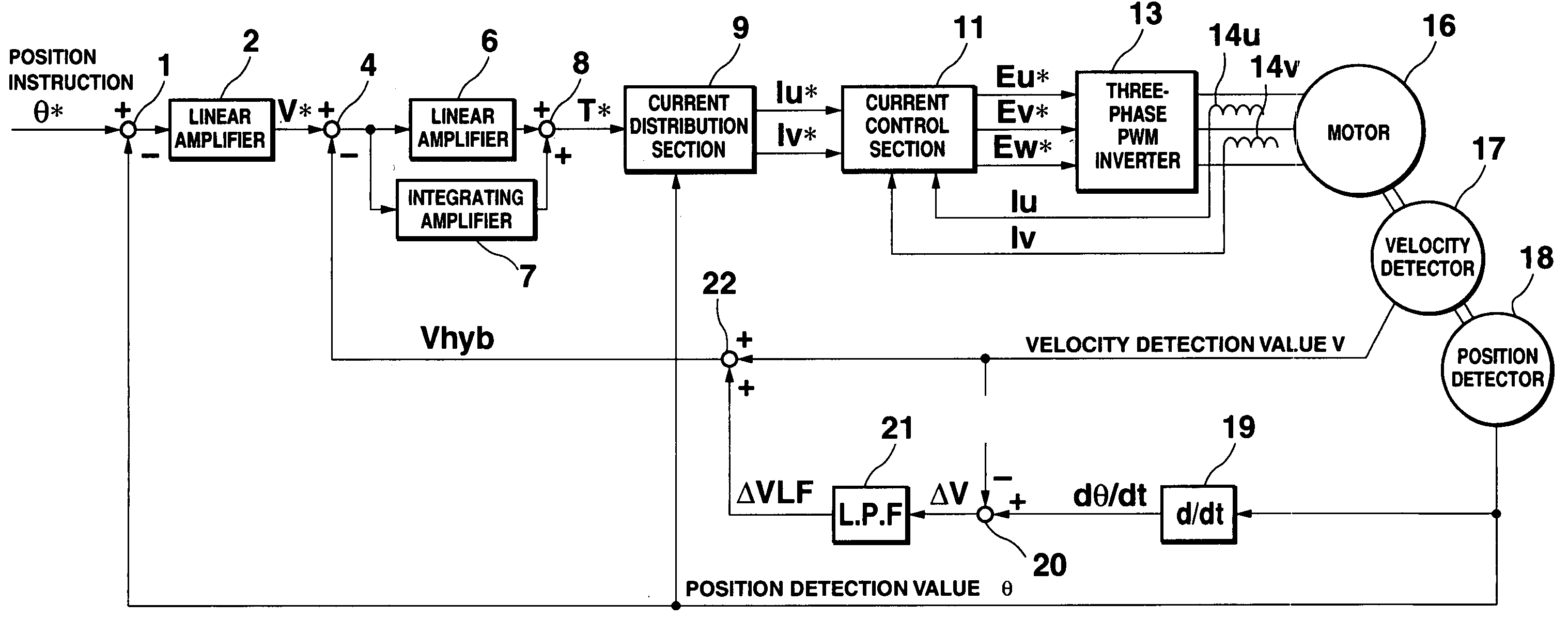

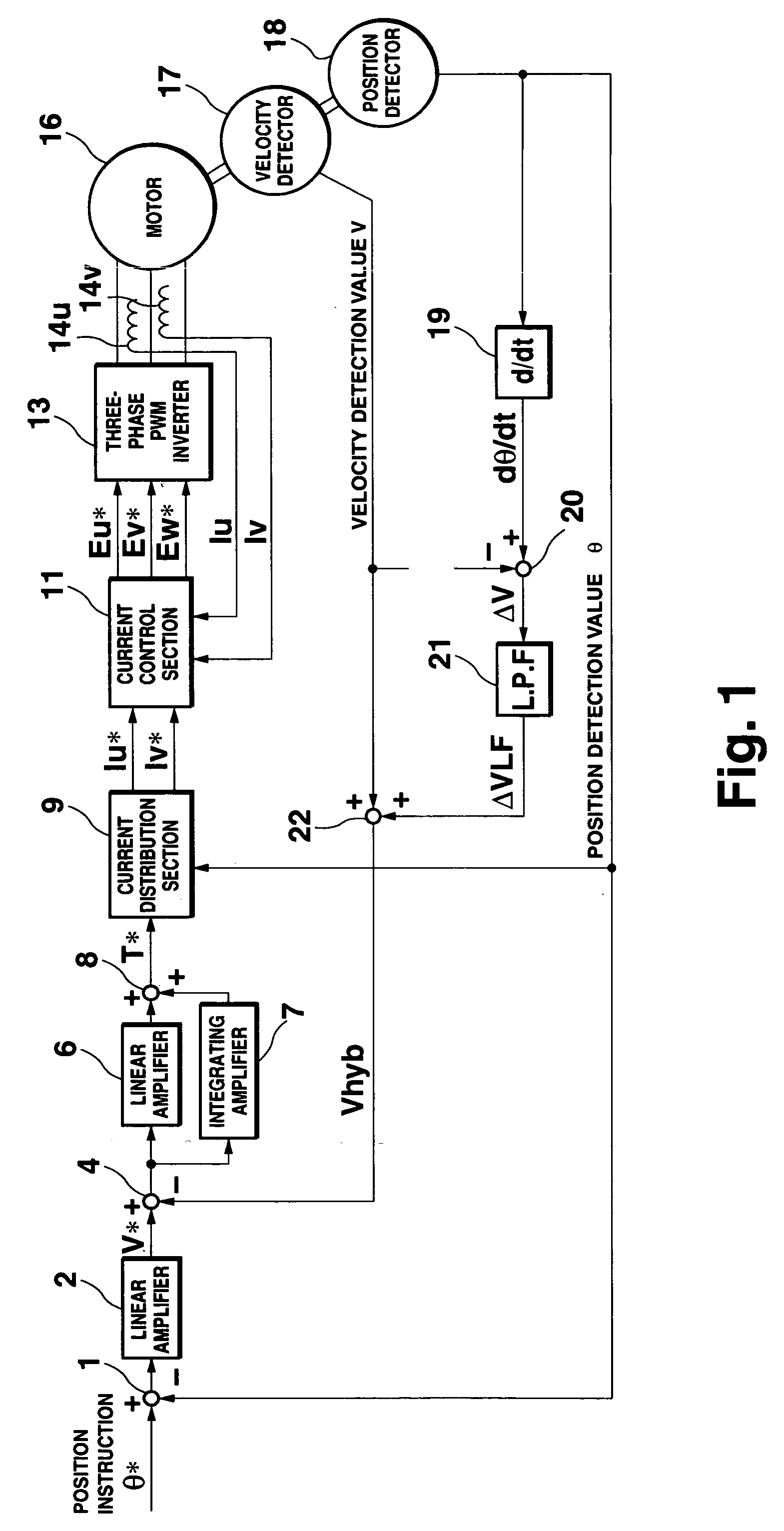

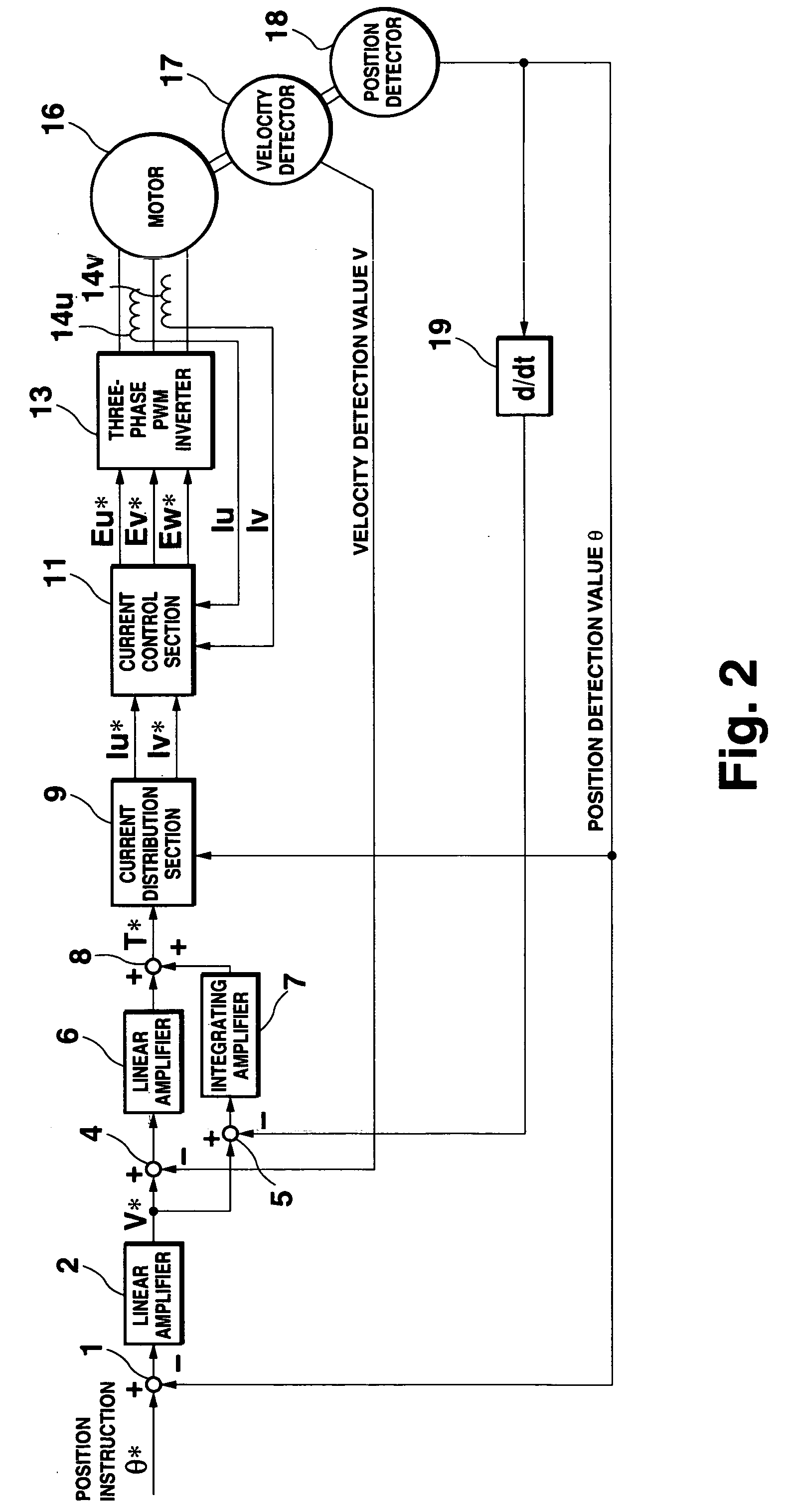

Motor control apparatus for controlling operation of mover of motor

InactiveUS20050067996A1Reduce gain errorReduce offset errorElectronic commutation motor controlElectric motor controlDifferentiatorLinear amplification

A motor control apparatus of the present invention comprises a velocity detector for detecting a rotation velocity of a mover of a motor, a position detector for detecting a position of the mover, a differentiator for performing time differentiation with respect to the position detected by the position detector to obtain a velocity calculation value, a feedback signal generating circuit for generating a feedback signal including the velocity detection value obtained by the velocity detector as a high frequency component and the velocity calculation value obtained by the differentiator as a low frequency component, and a linear amplifier and an integrating amplifier for performing PI control, the linear amplifier and the integrating amplifier performing linear amplification and integrating amplification of a difference between the velocity instruction and the feedback signal, respectively.

Owner:OKUMA CORP

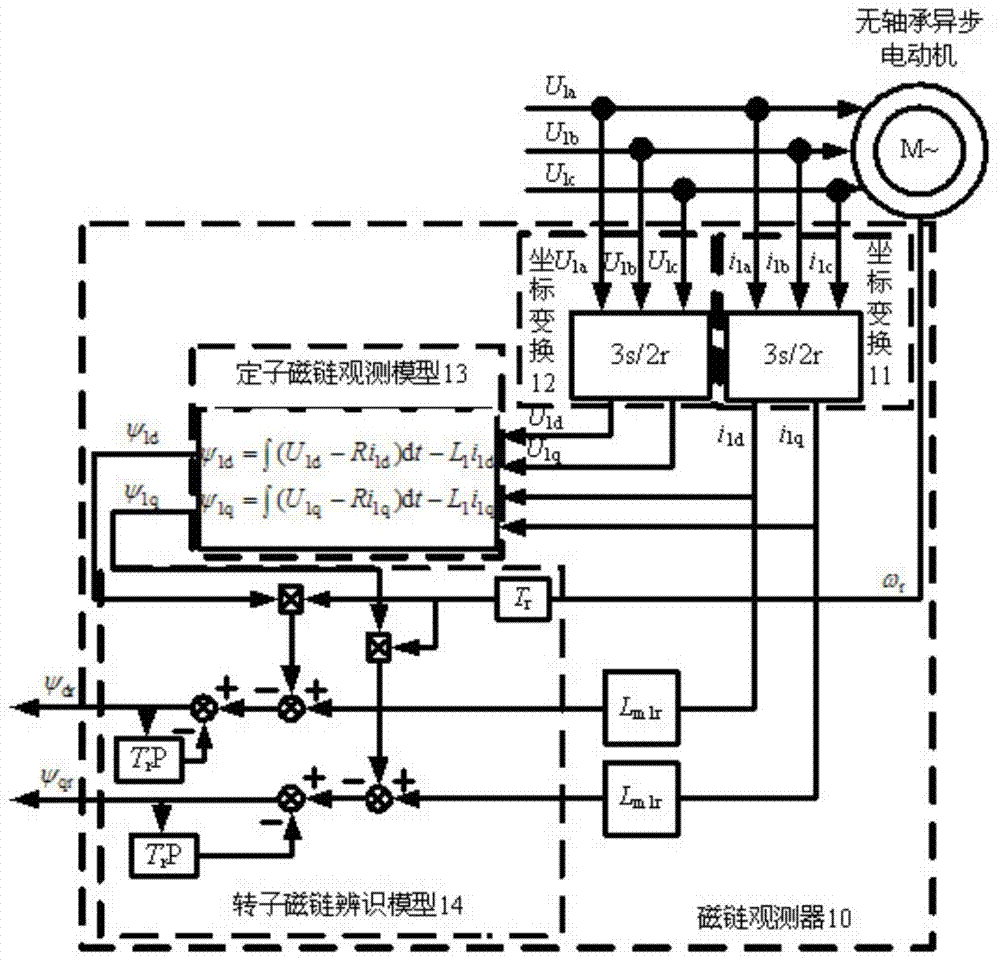

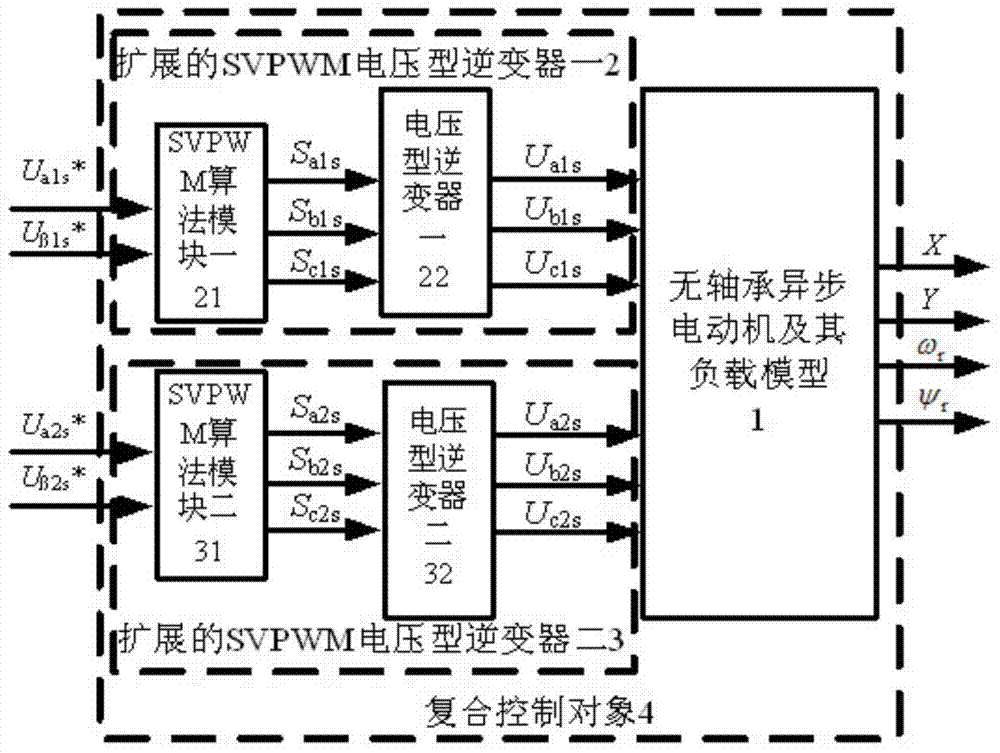

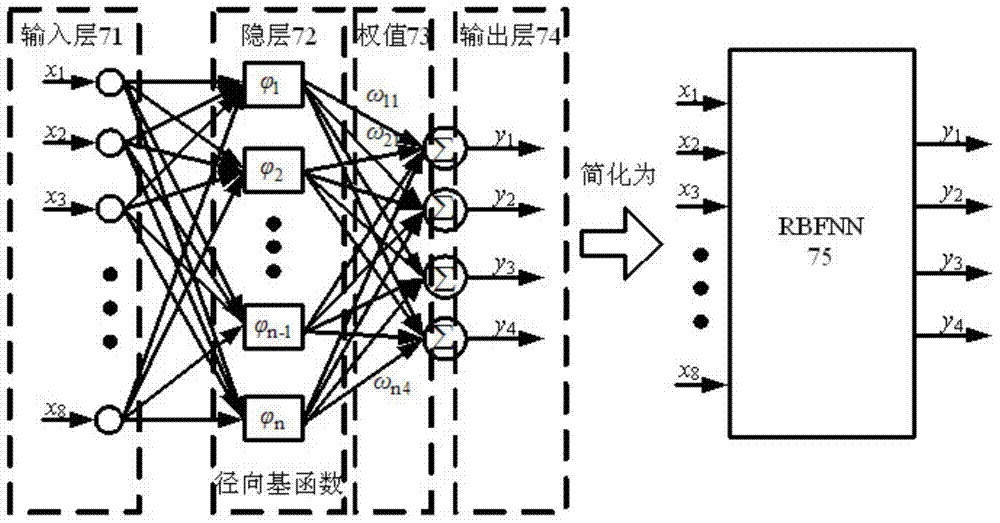

Bearing-free asynchronous motor RBF neural network self-adaptive inverse decoupling control and parameter identification method

InactiveCN104767449AFrictionlessNo wearElectronic commutation motor controlVector control systemsRadial basis function neuralVoltage inverter

The invention discloses a bearing-free asynchronous motor RBF neural network self-adaptive inverse decoupling control and parameter identification method. An SVPWM module, a voltage inverter, a bearing-free asynchronous motor and a load of the bearing-free asynchronous motor form a whole serving as a composite controlled object. Two radial basis function neural networks are adopted to achieve inverse control and parameter identification conducted on the composite controlled object. A self-adaptive inverse controller is formed by using an RBF neural network through learning, and is serially connected in front of the composite controlled object, errors of a feedback signal and a given signal are input into an inverse controller, and accordingly closed-loop control is formed, then a self-adaptive parameter identifier is formed by using one RBF neural network through learning and identifies output quantity speed and displacement of the composite controlled object, speed-less and displacement-free sensor control is achieved, online learning of an estimation signal is aided by means of a learning algorithm, and non-linear dynamic decoupling control of the bearing-free asynchronous motor is achieved. The bearing-free asynchronous motor RBF neural network self-adaptive inverse decoupling control and parameter identification method is high in control speed and higher in identification accuracy, and a control system is excellent.

Owner:JIANGSU UNIV

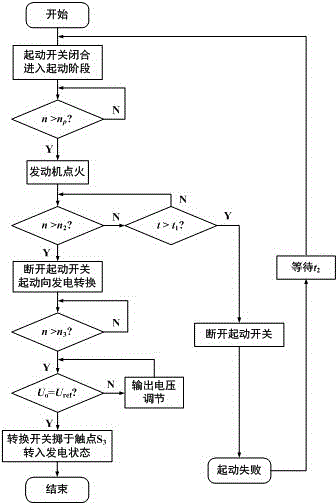

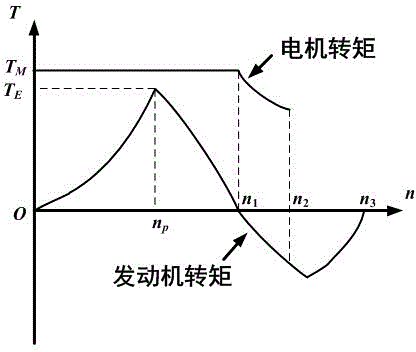

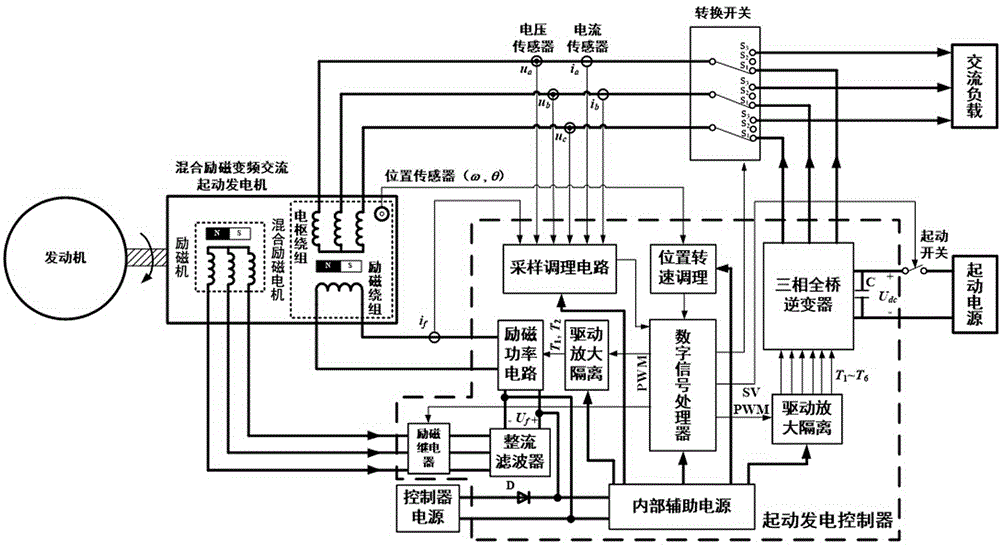

Hybrid excitation type variable frequency AC starting generating system and control method thereof

ActiveCN104702186AThe overall structure is simple and reliableEasy to realize the integration of starter and power generationElectronic commutation motor controlVector control systemsStarter generatorAviation

The invention discloses a hybrid excitation type variable frequency AC starting generating system and a control method thereof. The hybrid excitation type variable frequency AC starting generating system comprises a hybrid excitation type variable frequency AC starting generator, a first current sensor for detecting excitation current, a second, current sensor, a third current sensor, three voltage sensors, a position sensor, a changeover switch, a starting switch and a starting generating controller, wherein the second current sensor and the third current sensor are used for detecting armature current. The control method comprises the steps of performing the vector control method based on inverter voltage compensating during starting, and adjusting the excitation current according to the motor armature current and the real-time rotating speed; performing the sectional PI control method based on the output voltage frequency change during generating the power, and adding a load current compensating ring; controlling the changeover switch to switch according to the motor rotating speed and the output voltage during switching from starting to power generation. The method has important application value in the field of aviation independent power starting generating systems.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

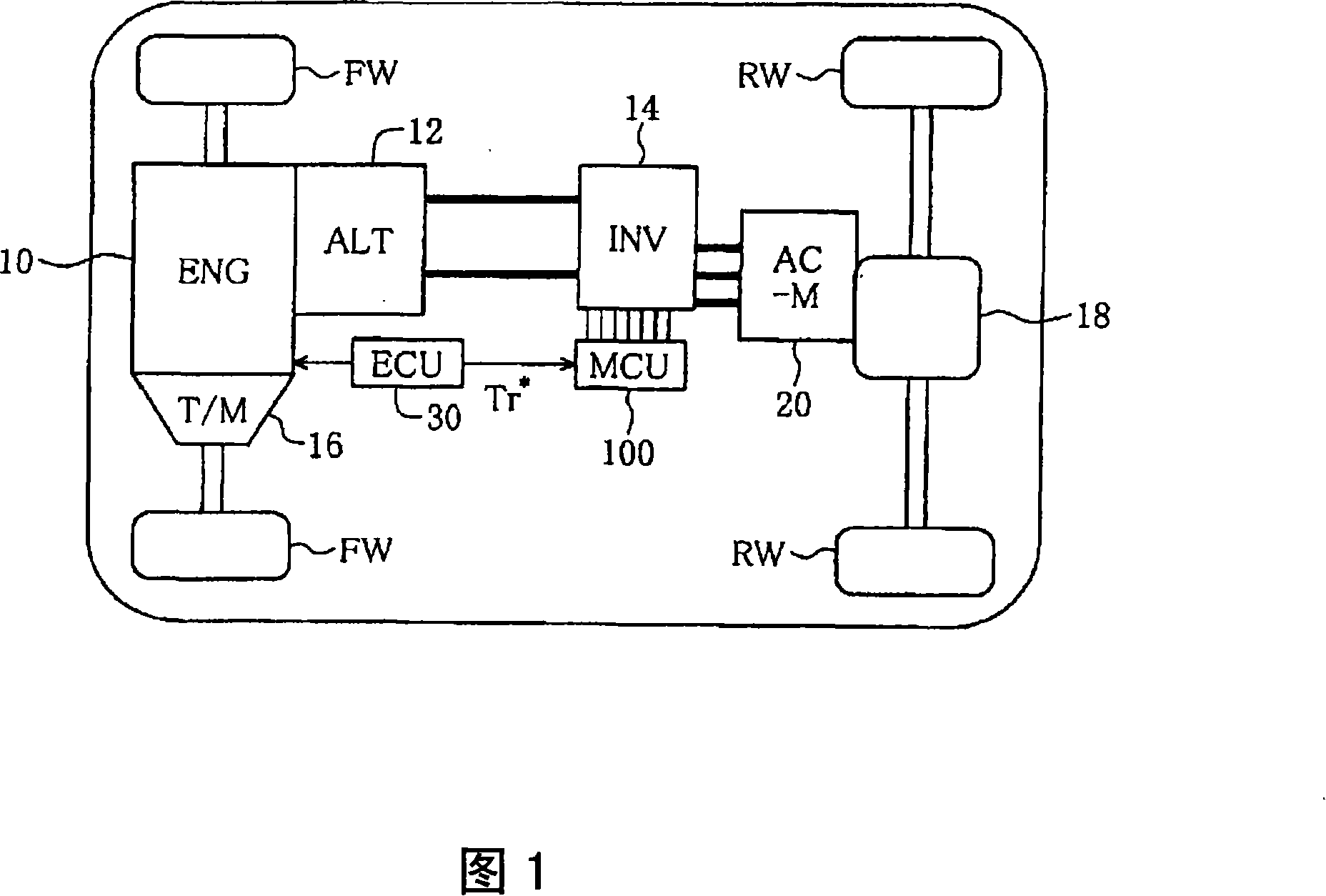

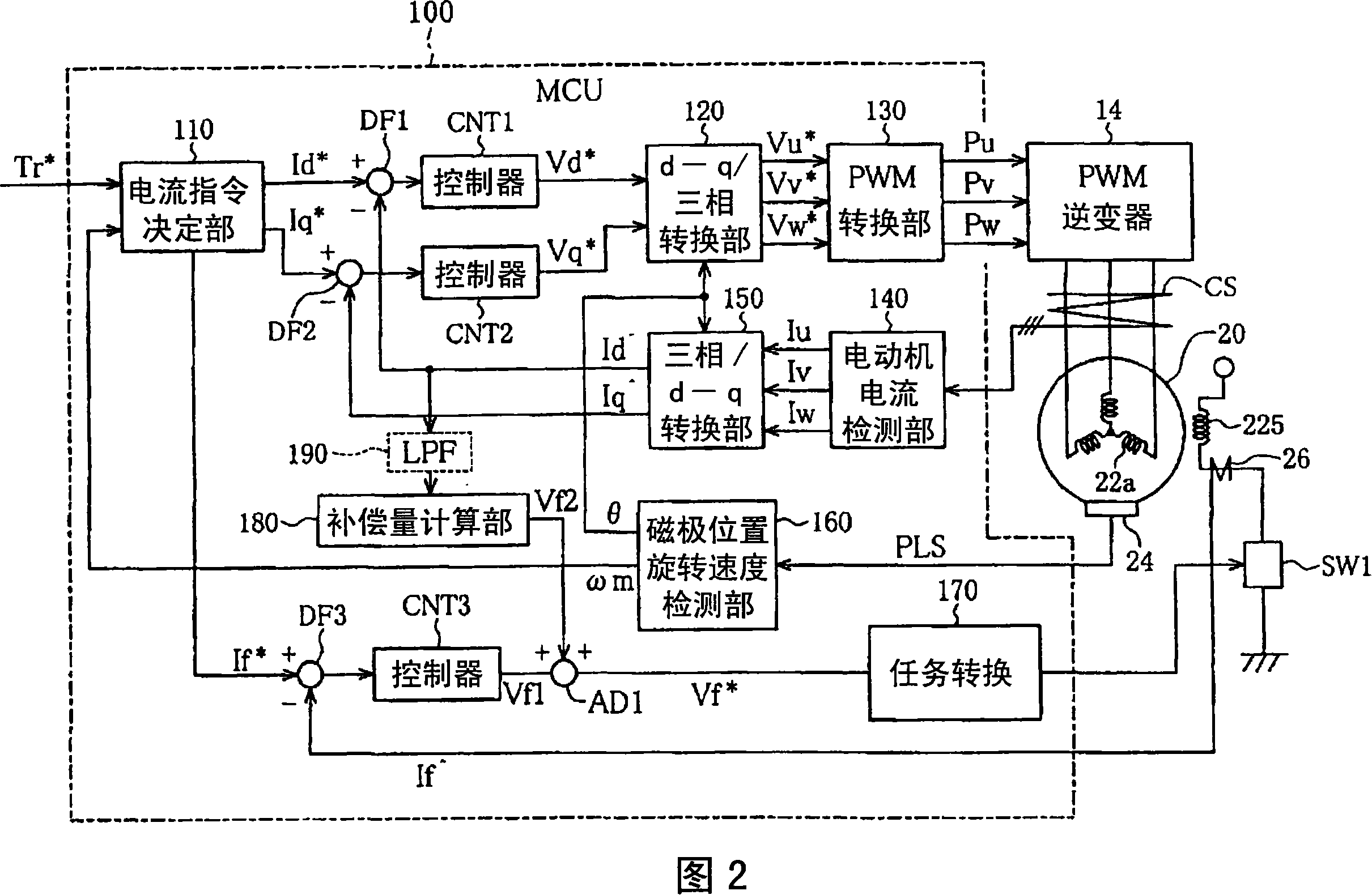

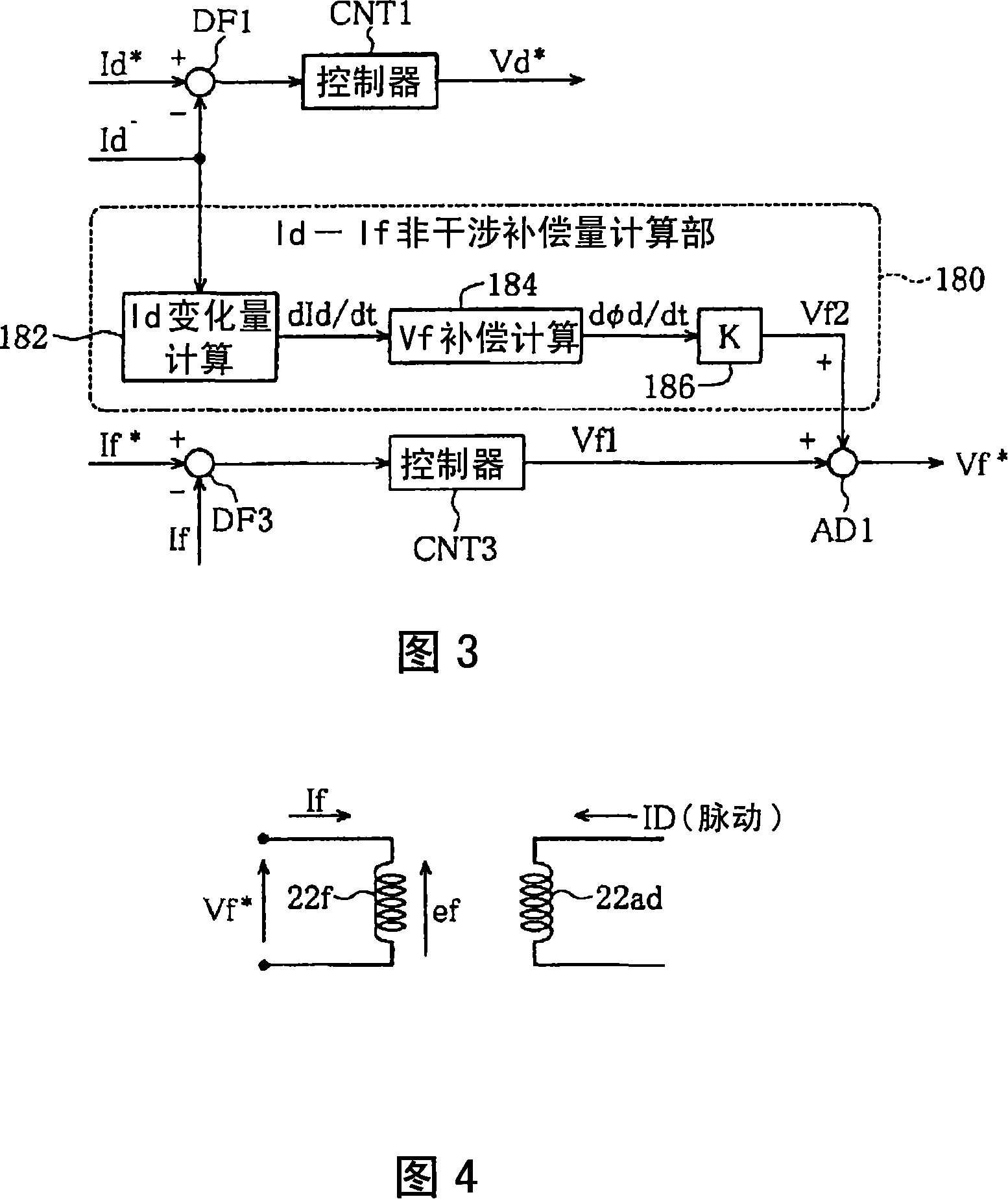

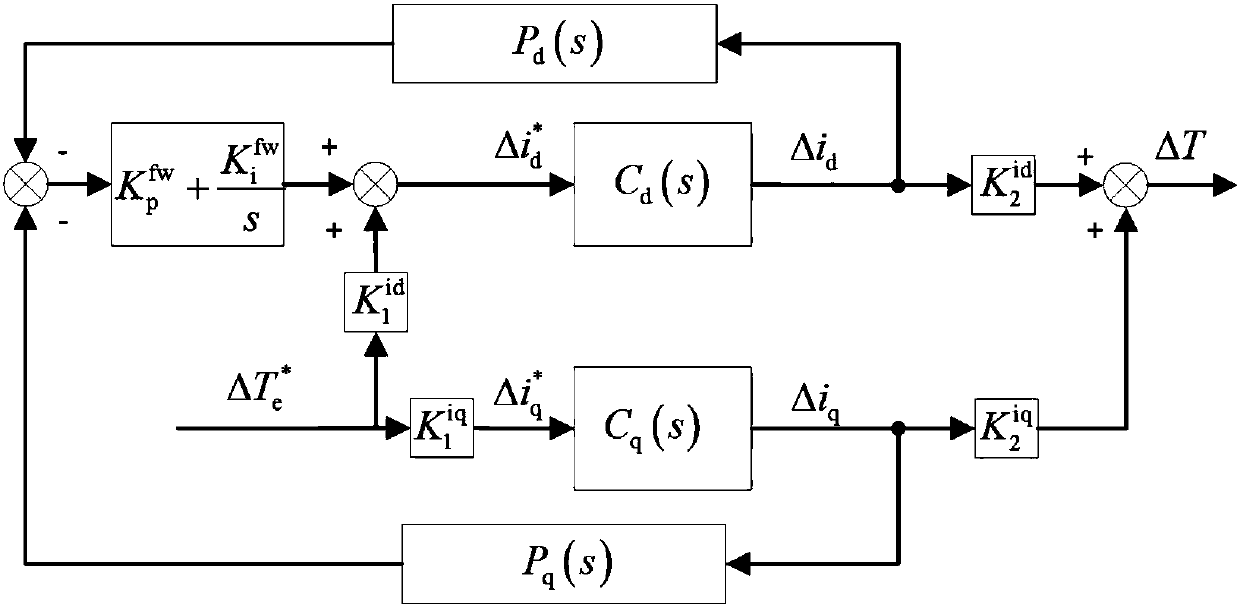

Controller of field winding type synchronous motor, electric drive system, electric four wheel driving vehicle, and hybrid automobile

InactiveCN101194415AStable outputReduce torque rippleVector control systemsSingle motor speed/torque controlSynchronous motorEngineering

An object of the present invention is to provide a controller of a field winding type synchronous motor that can stably output torque even if the d-axis current pulsates by reducing torque pulsation without causing fluctuations in the magnetic flux acting on the torque, and also provide an electric drive system, an electric four wheel driving vehicle, and a hybrid automobile. A motor control unit 100 performs control so that a desired torque be generated from a field winding type motor 20 having a field winding 22f on the rotor. Based on a current Id flowing in the d-axis direction out of the currents flowing in a stator winding 22a of the field winding type motor 20, the motor control unit 100 calculates an induced voltage Vf2 being induced in the field winding 22f and compensates a field voltage Vf of the field winding based on the induced voltage Vf2, thus suppressing pulsation of the field current flowing in the field winding of the field winding type motor 20.

Owner:HITACHI LTD

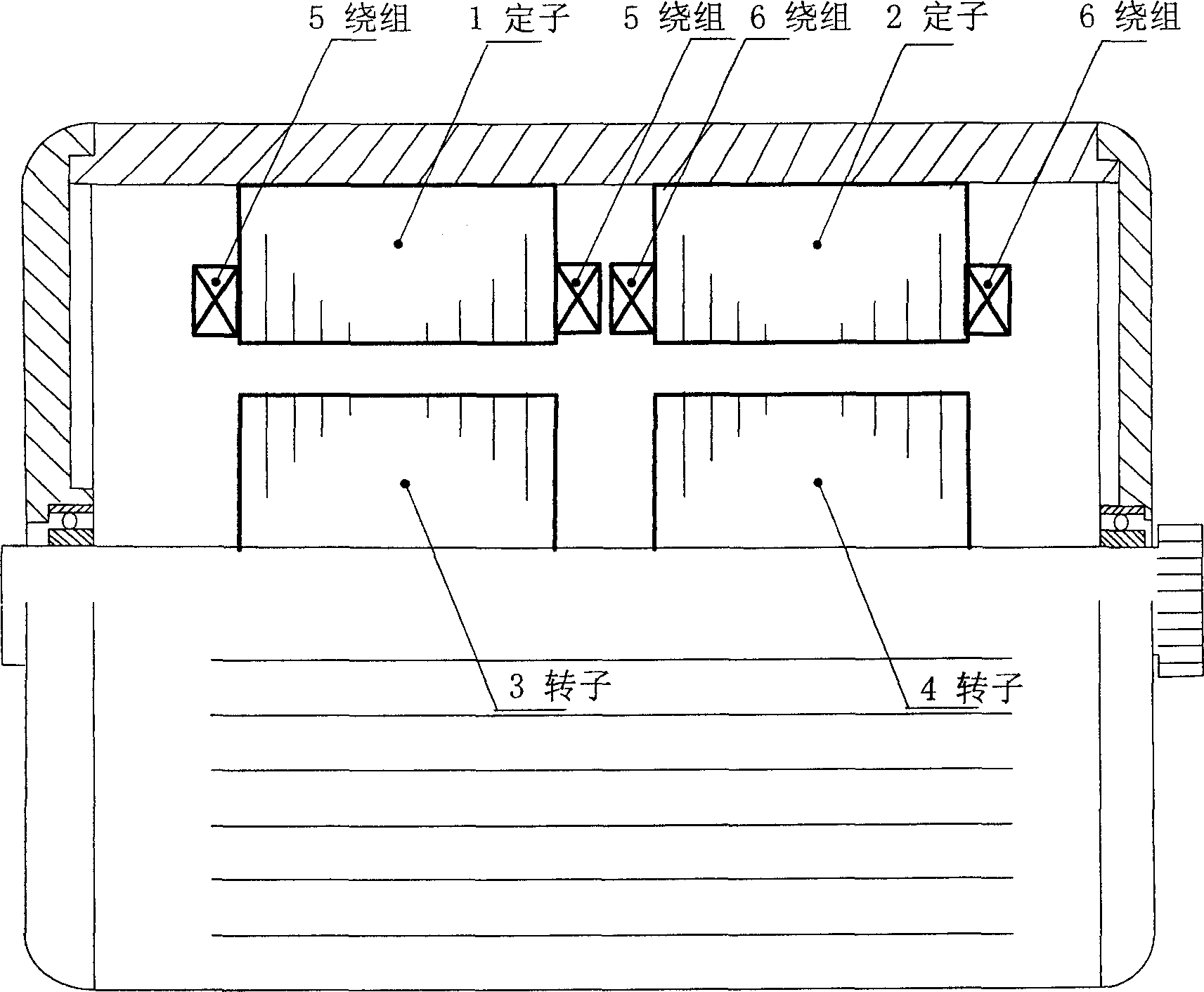

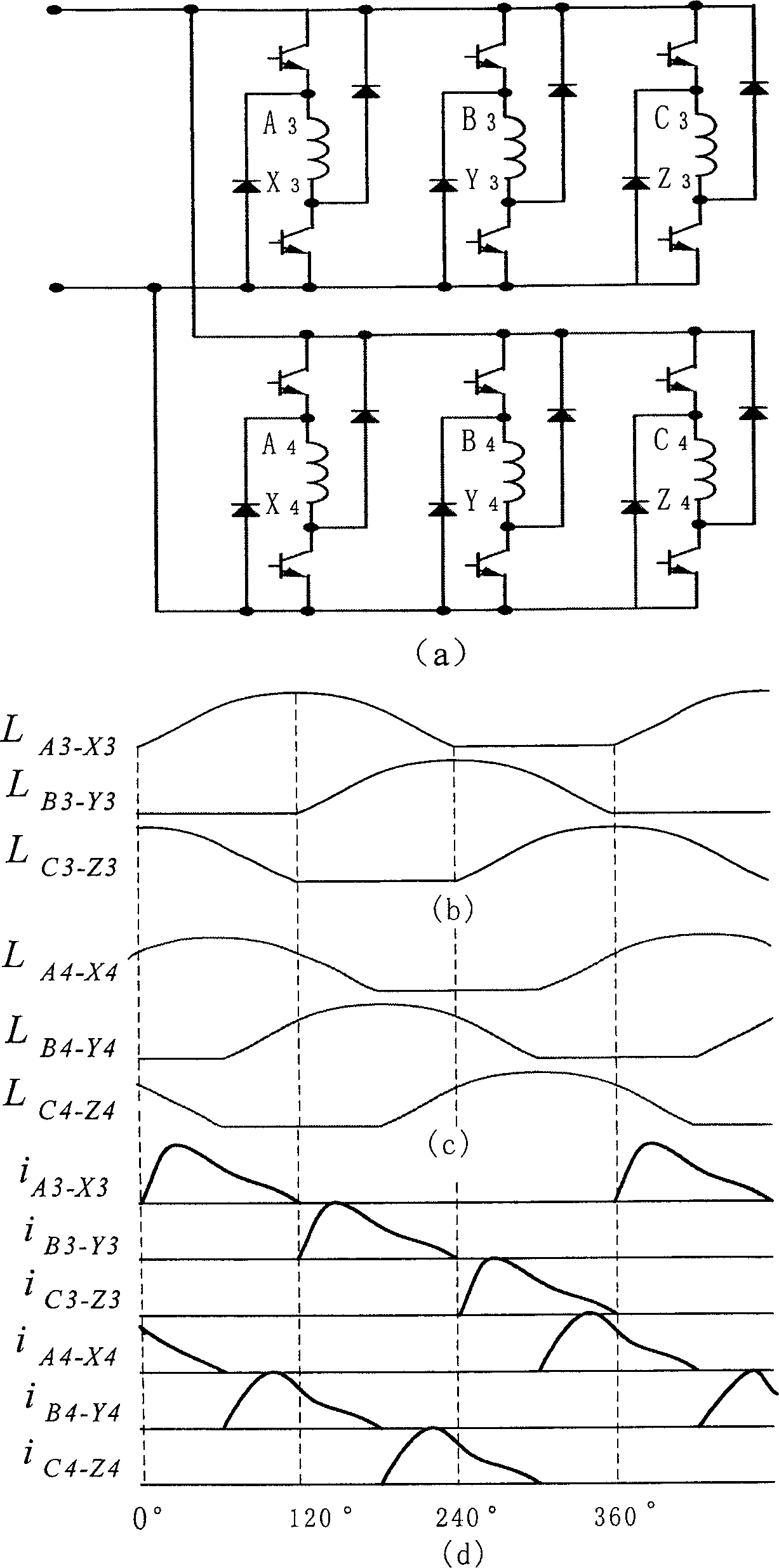

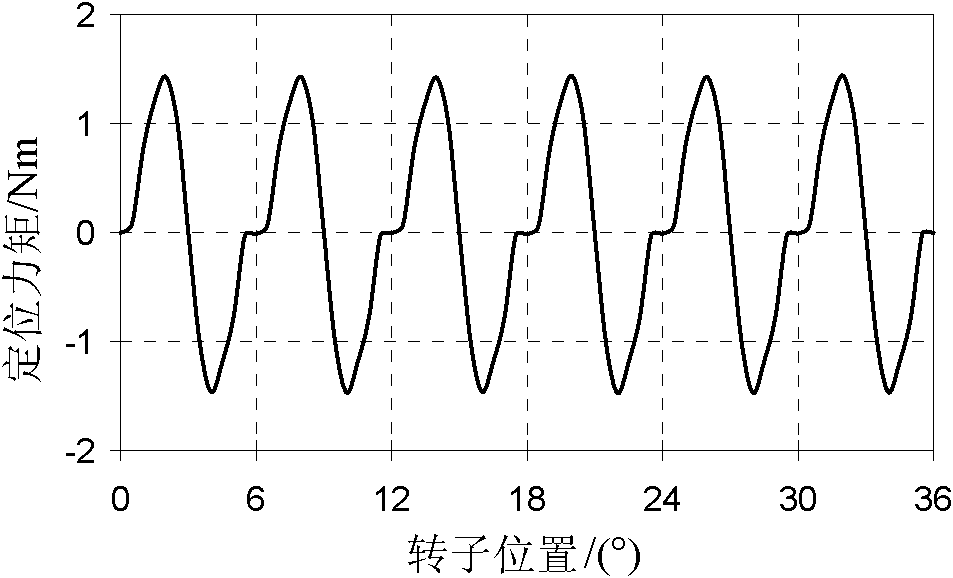

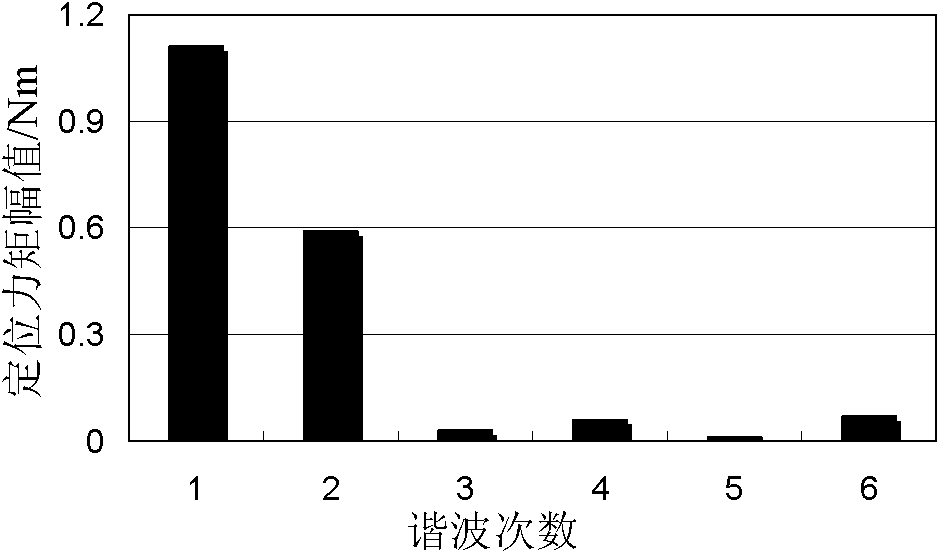

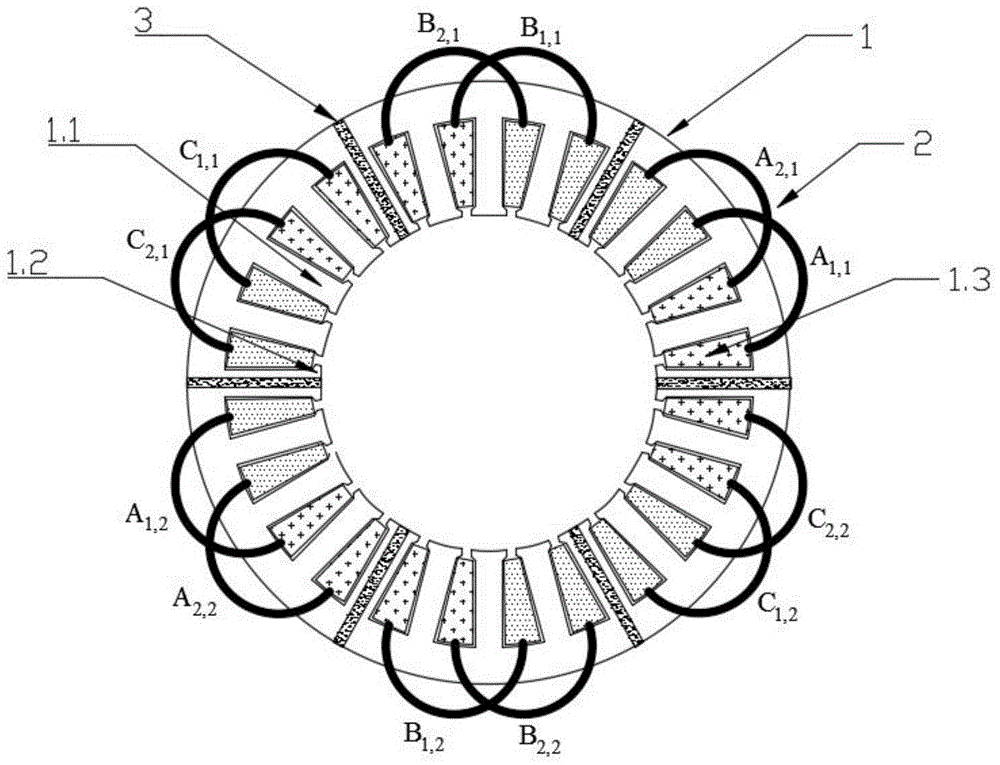

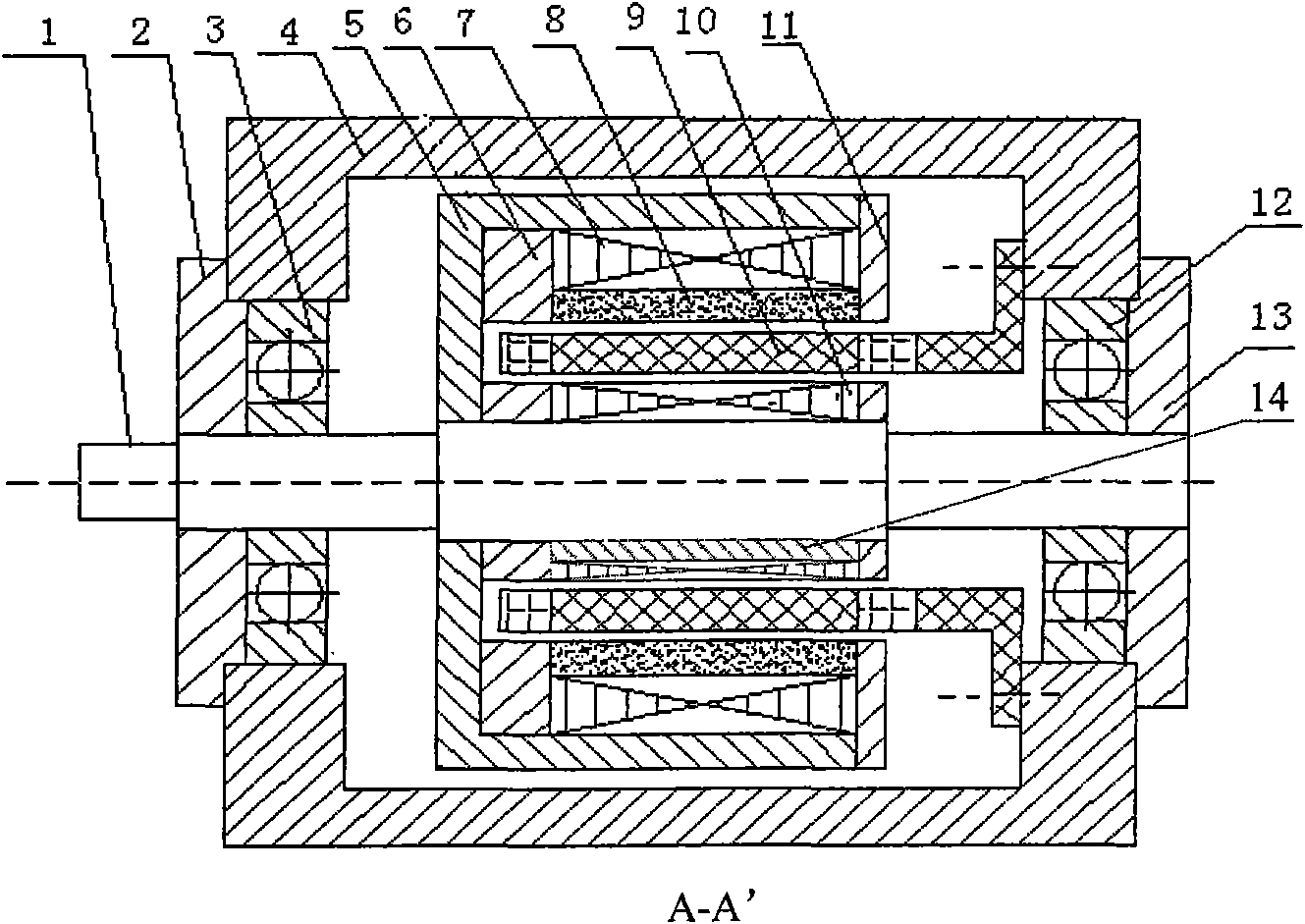

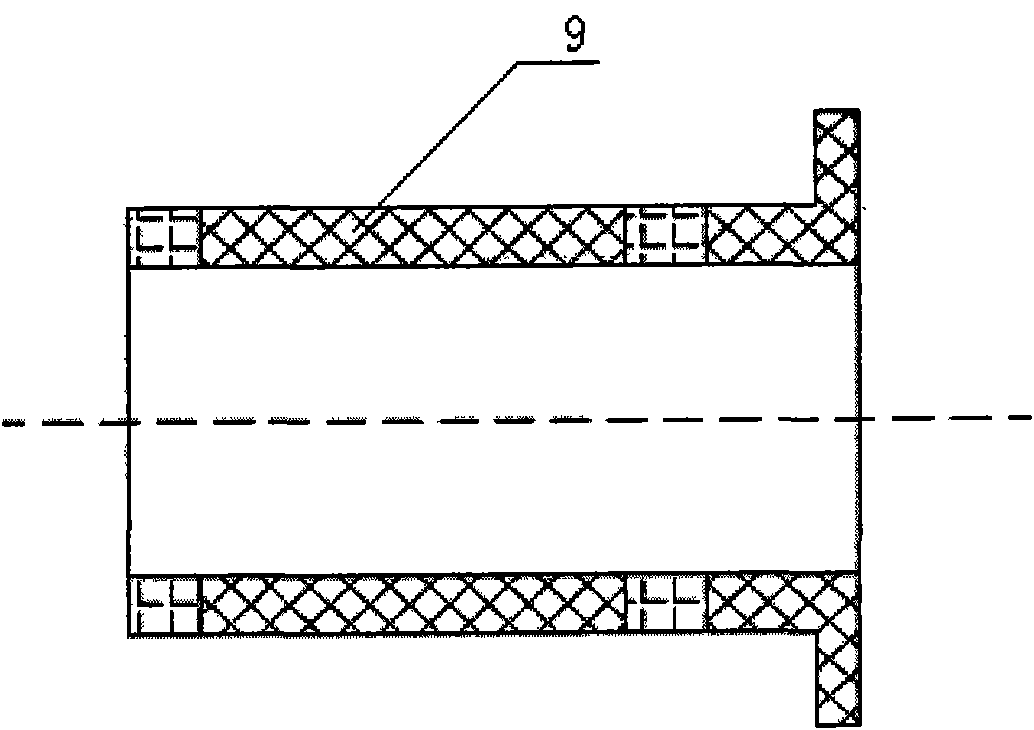

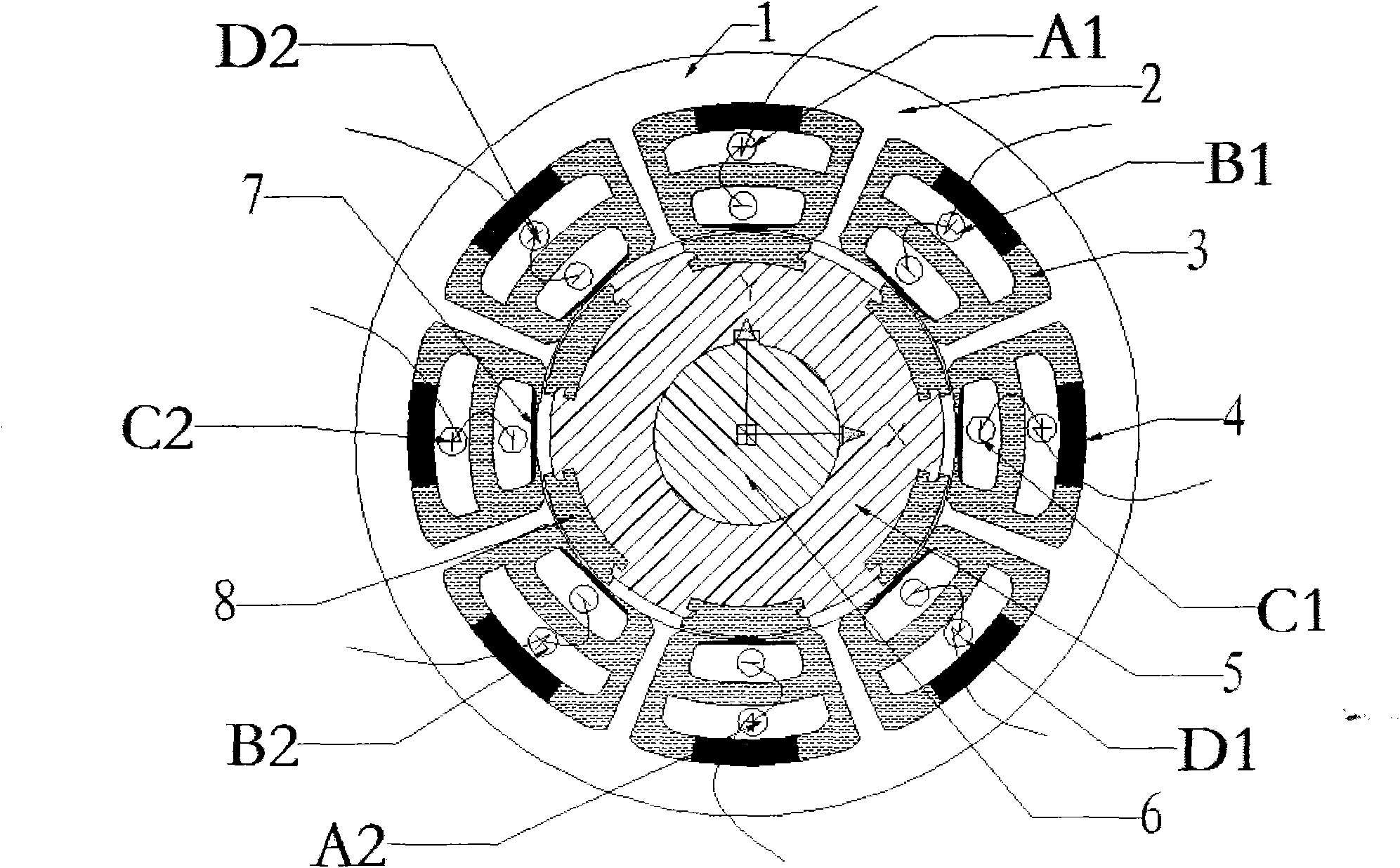

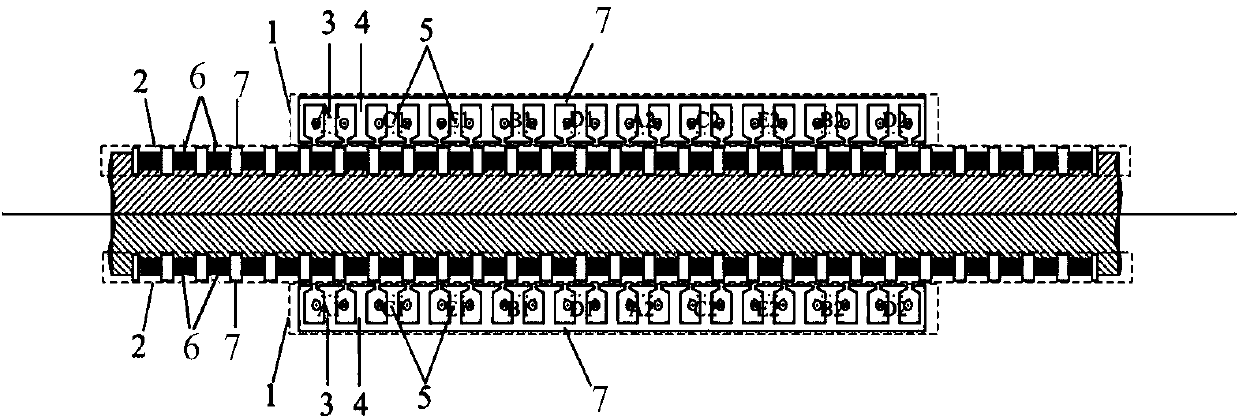

Double-channel fault tolerant type flux switch permanent magnet motor and control method thereof

InactiveCN101159391AImprove reliabilityImprove power densityTorque ripple controlMagnetic circuit rotating partsFault tolerancePhase currents

A dual-channel fault tolerant flux switch permanent magnet motor is a novel stator permanent magnet motor. The fault tolerant motor adopts a doubly salient structure, and the inner loop of the stator (1) is provided with salient poles evenly. Permanent magnets (3) are arranged onto the circle of the stator in pairs, which can be cooled easily; the rotor (2) adopts a simple salient structure, without windings nor permanent magnets. The fault tolerance motor integrates the advantages of a switch magnet resistance motor and a rotator permanent magnet fault tolerance motor, and has the advantages of high credibility, high power density, and preferable operating capacity when a failure occurs. The invention provides a fault tolerance strategy, and can improve the electromagnetic performance of the motor when a failure occurs by adjusting the phase and amplitude of non-fault phase current; the invention can accomplish the torque output in the approximately normal running status and have high theory and practical value.

Owner:SOUTHEAST UNIV

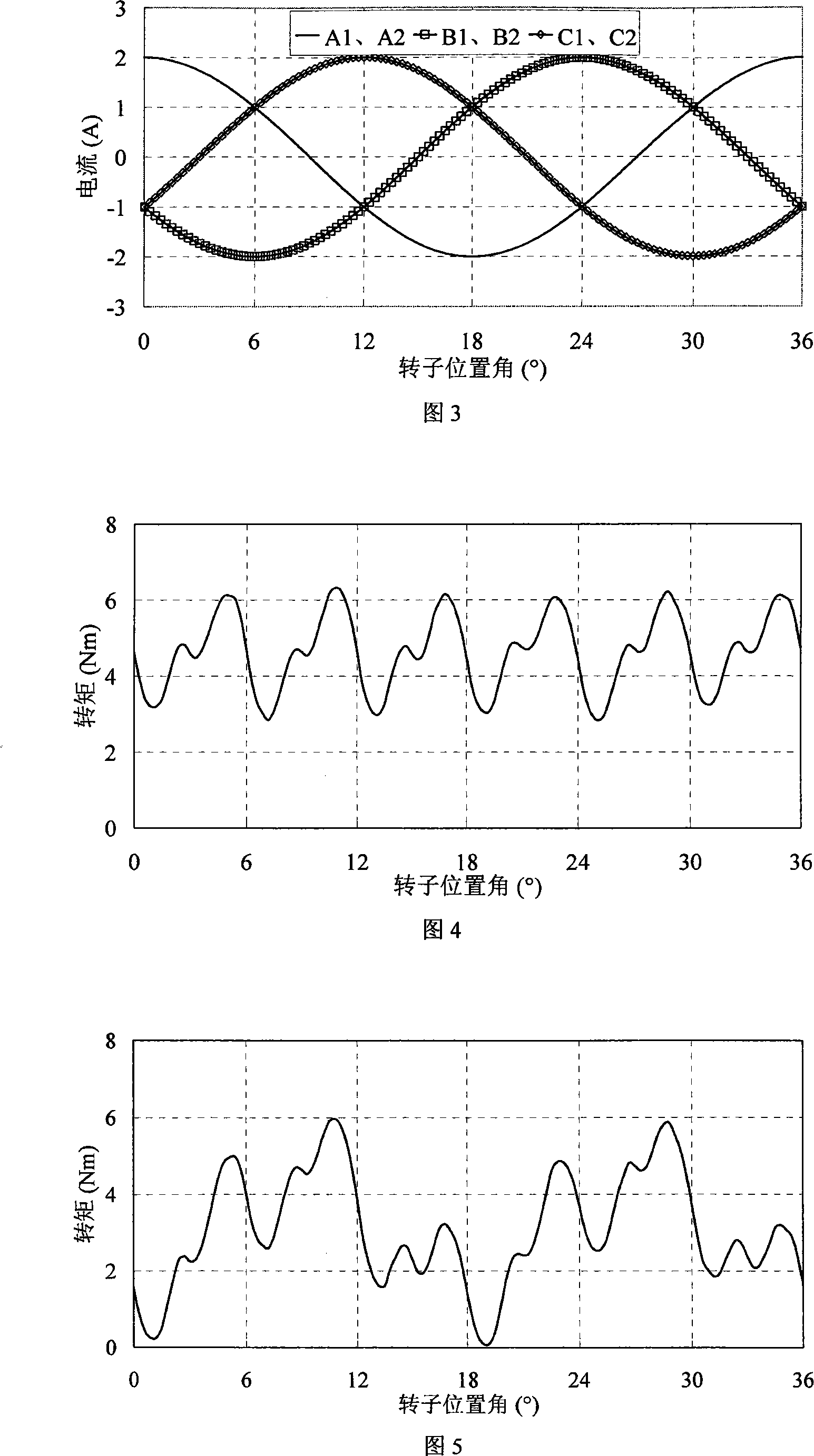

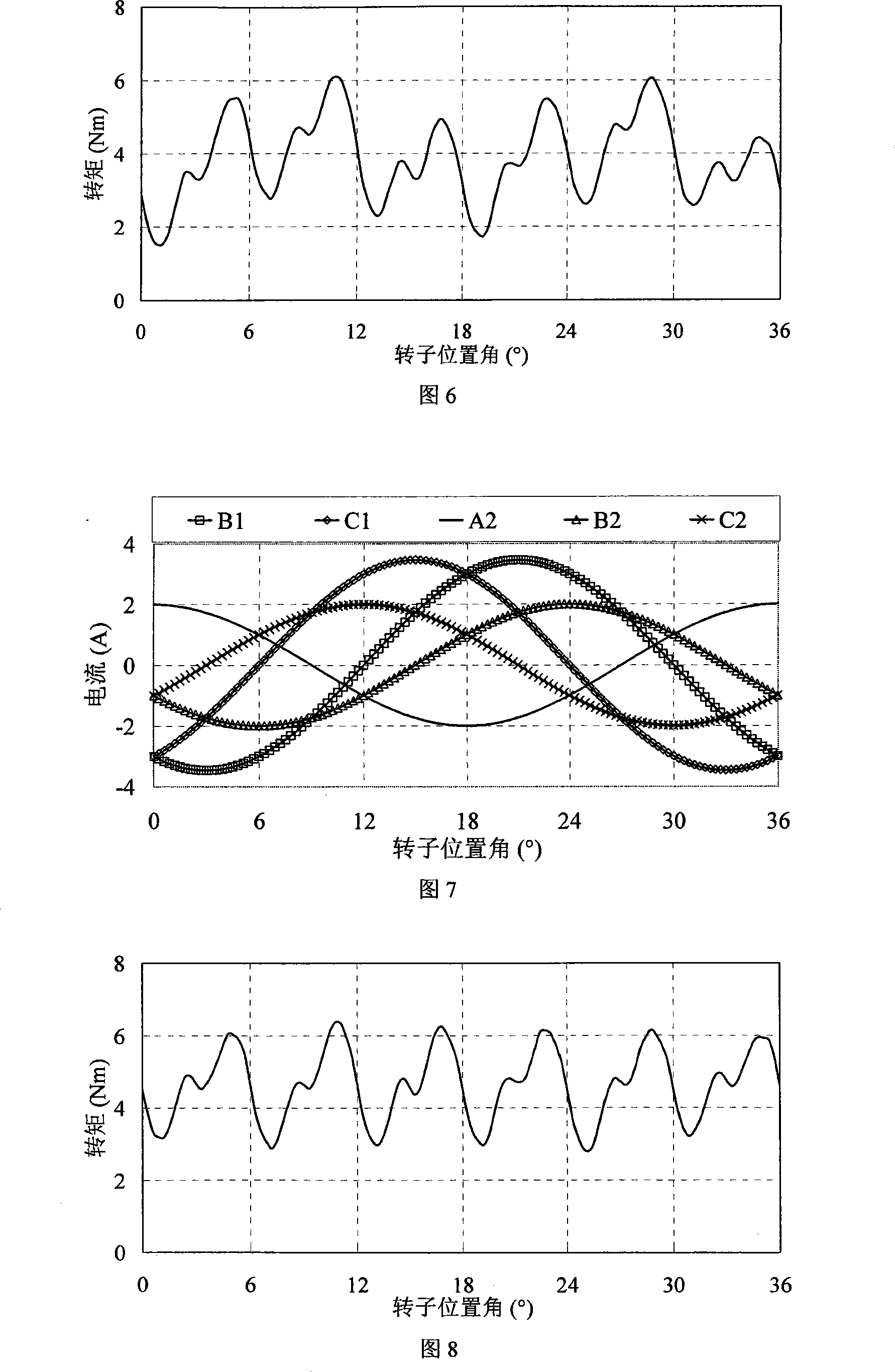

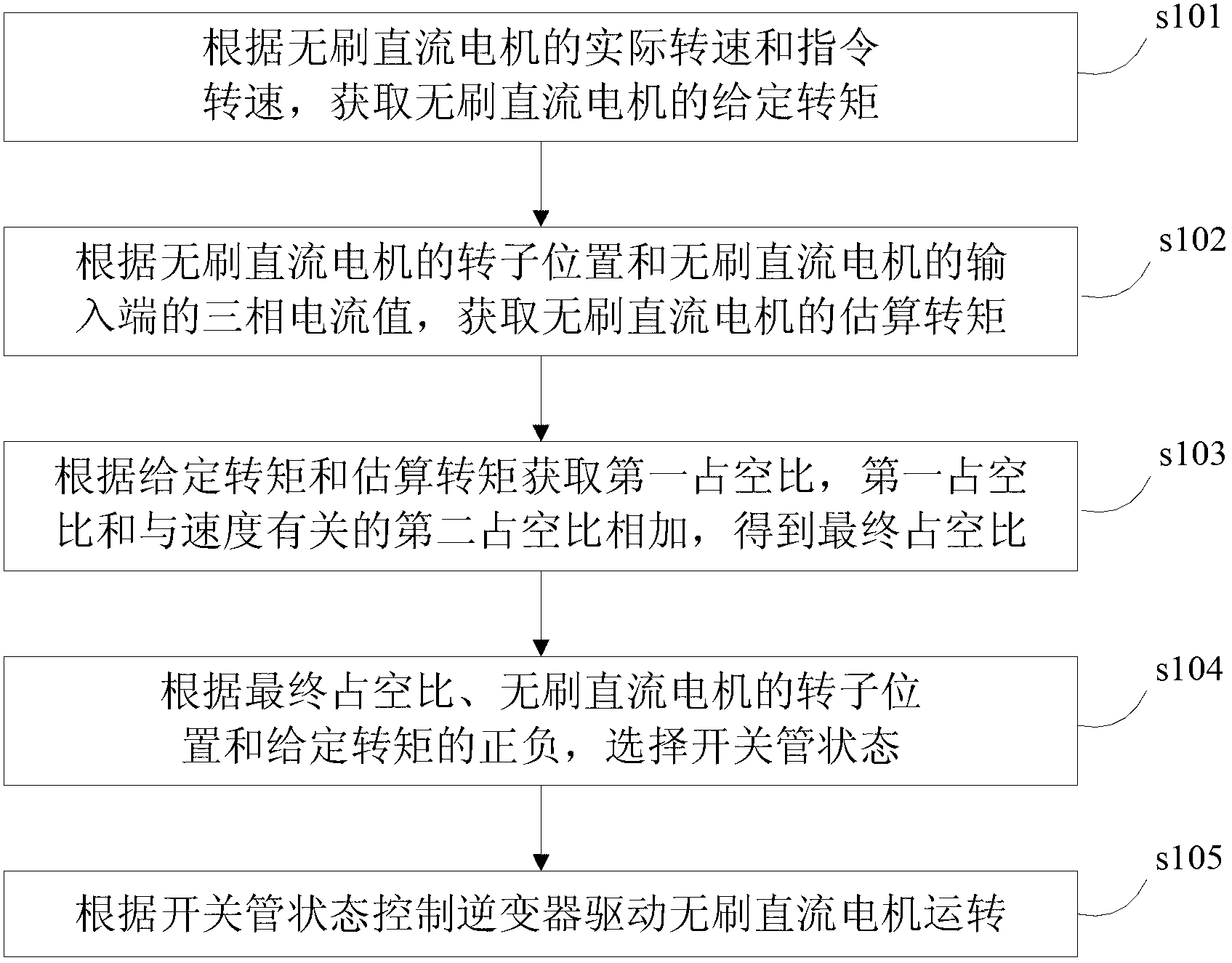

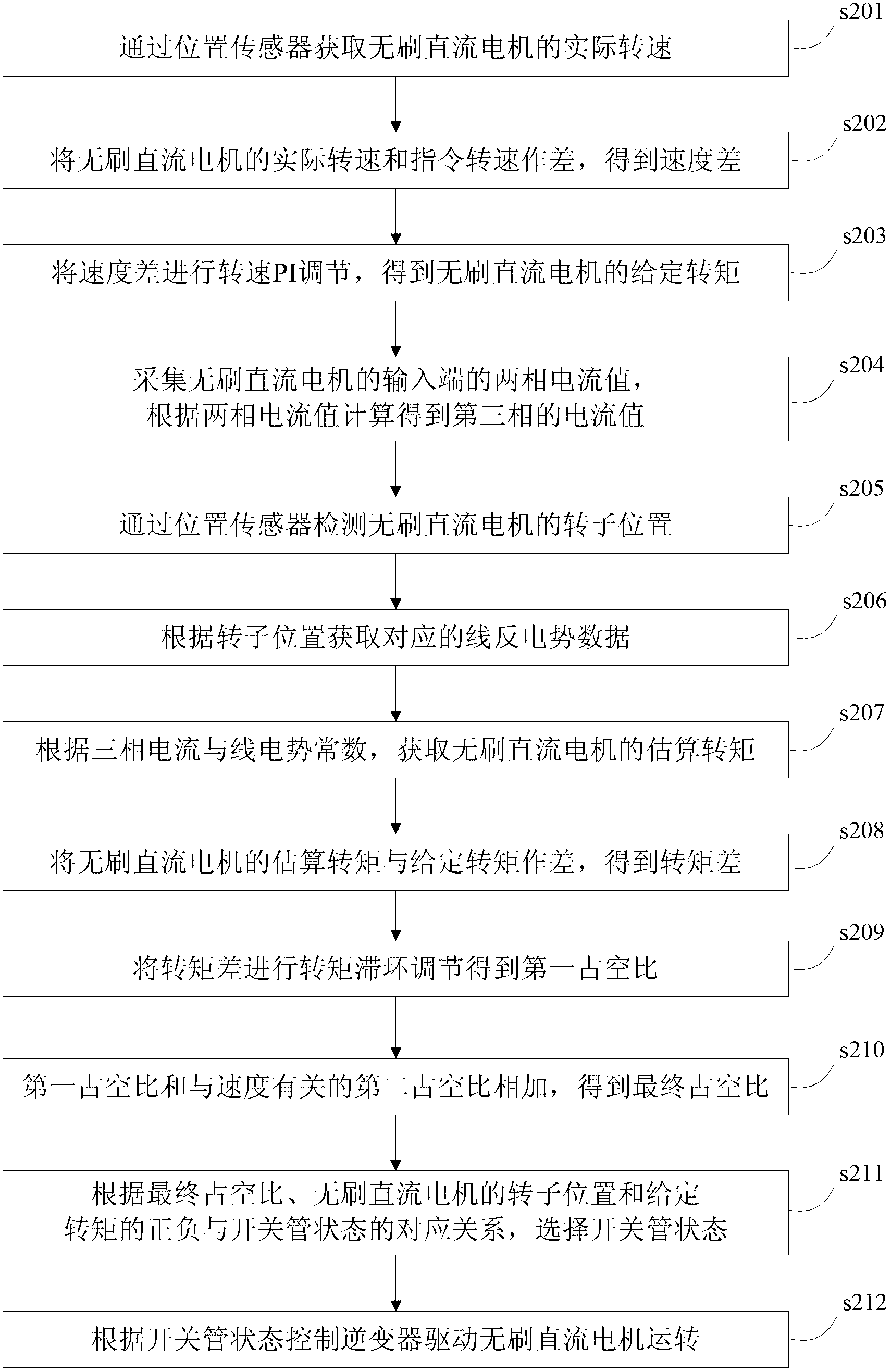

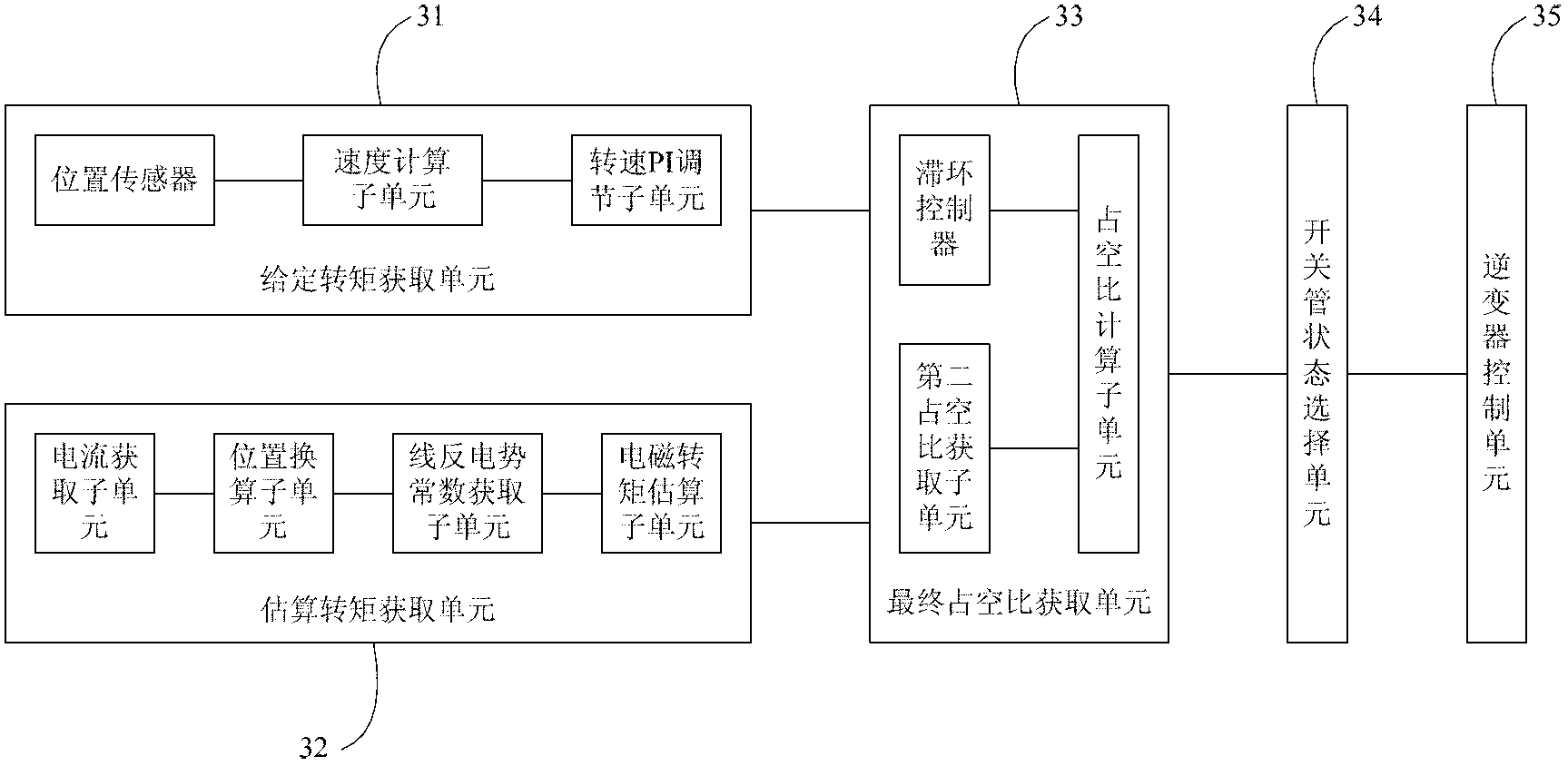

Direct torque control method and device of brushless continuous current dynamo

InactiveCN102710188AShorten the control cycleReduce inductanceSingle motor speed/torque controlElectronic commutatorsControl periodWave shape

The invention belongs to the field of control technology of brushless continuous current dynamo, and discloses a direct torque control method of a brushless continuous current dynamo. The method comprises the following steps: A. a preset torque is obtained according to the actual rotational speed and the command rotational speed of the dynamo; B. an estimating torque is obtained according to the rotor position and the three-phase current value of the input end of the dynamo; C. a first duty ratio is obtained according to the preset torque and the estimating torque, and is added with a second duty ratio related to the speed, and then a final duty ratio is obtained; D. the state of a switch tube is selected according to the final duty ratio, the rotor position and the plus-minus of the preset torque; E. an inverter is controlled to drive the dynamo to rotate according to the state of the switch tube. The invention also discloses a direct torque control device of the brushless continuous current dynamo. According to the invention, a linear counter emf form factor is adopted to calculate the torque, and control period is shortened; PWM (pulse width modulation) technology is combined, and a torque hysteresis regulator is improved, so that torque pulsation inhibition when the inductance of the dynamo is small is realized, and four-quadrant operation of the brushless continuous current dynamo is also realized.

Owner:YANSHAN UNIV

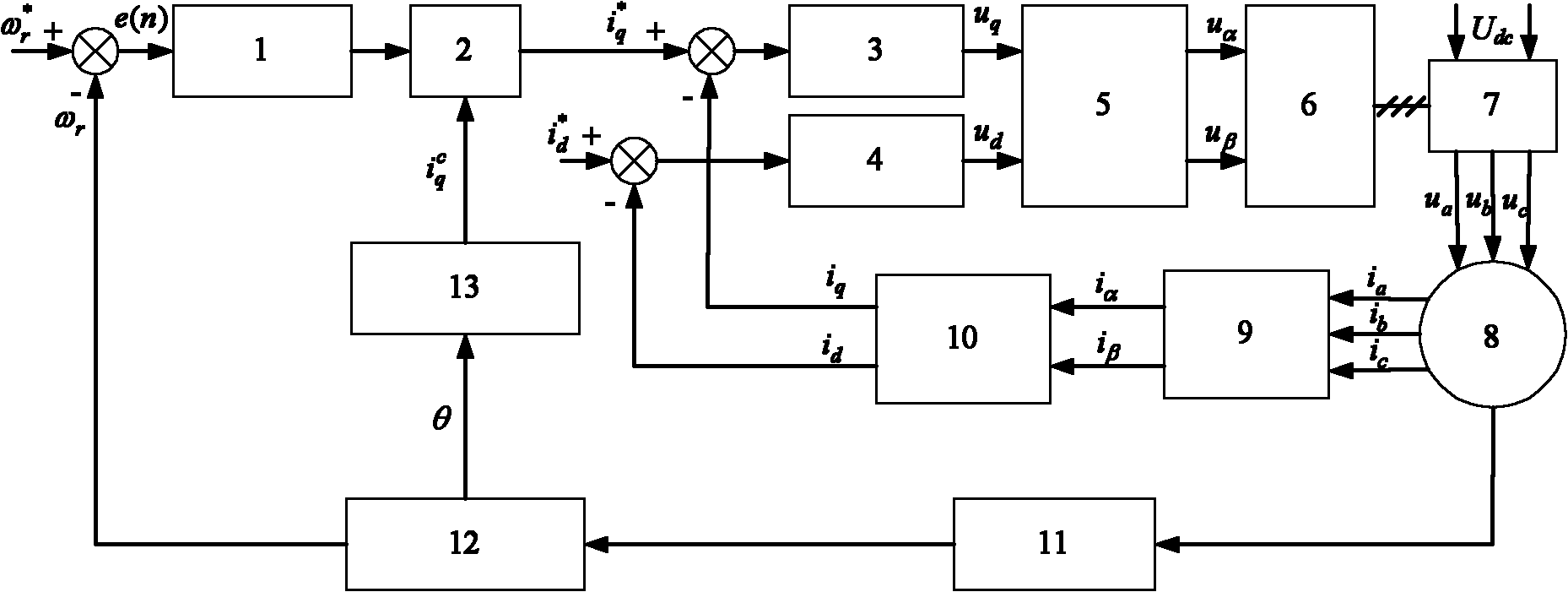

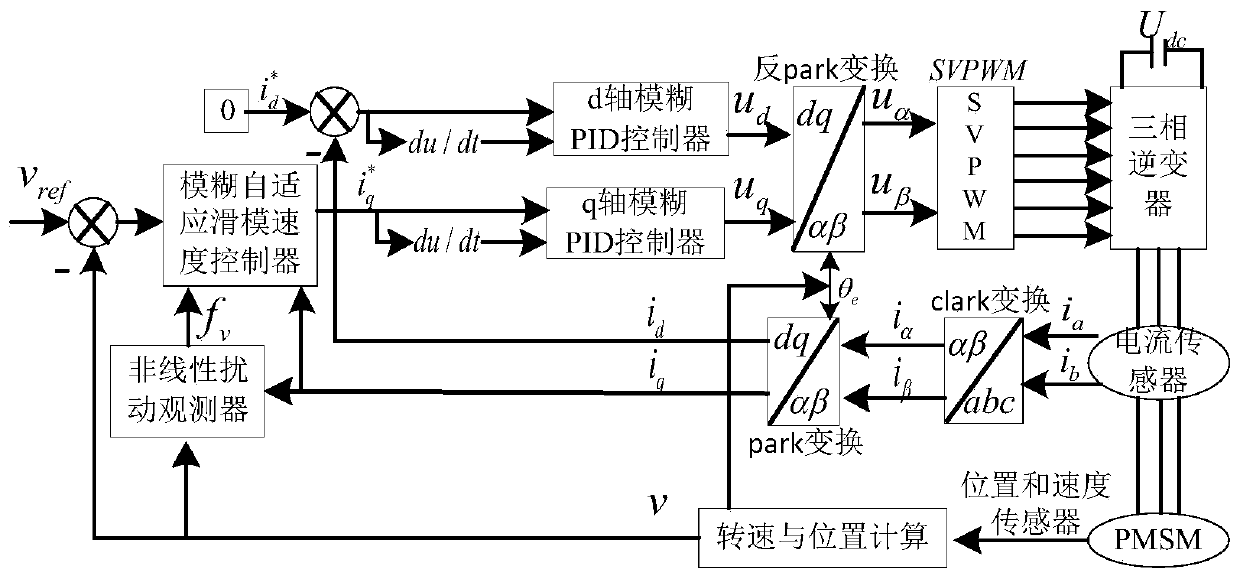

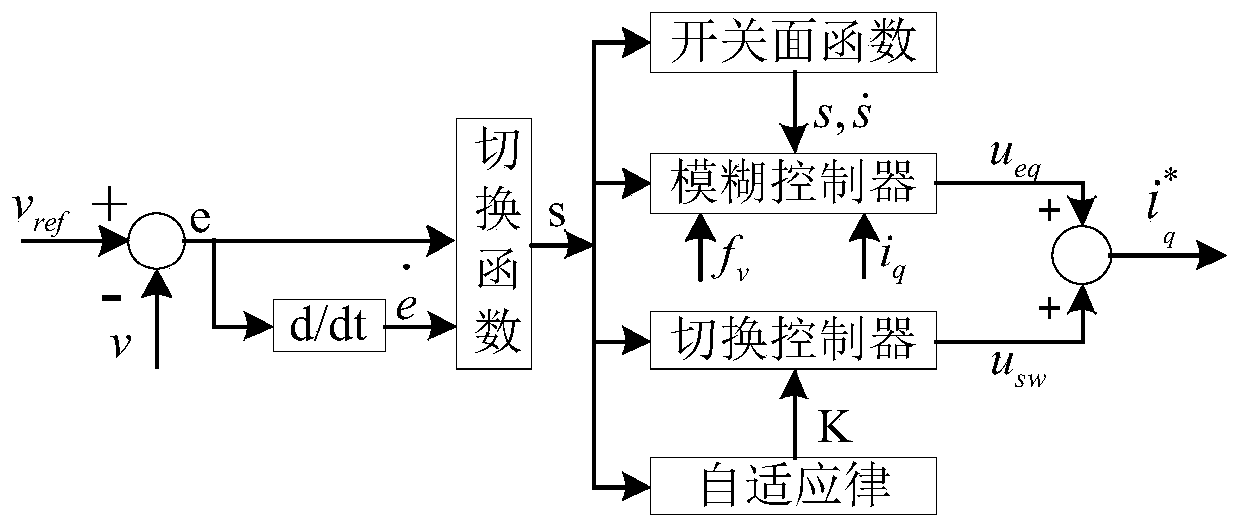

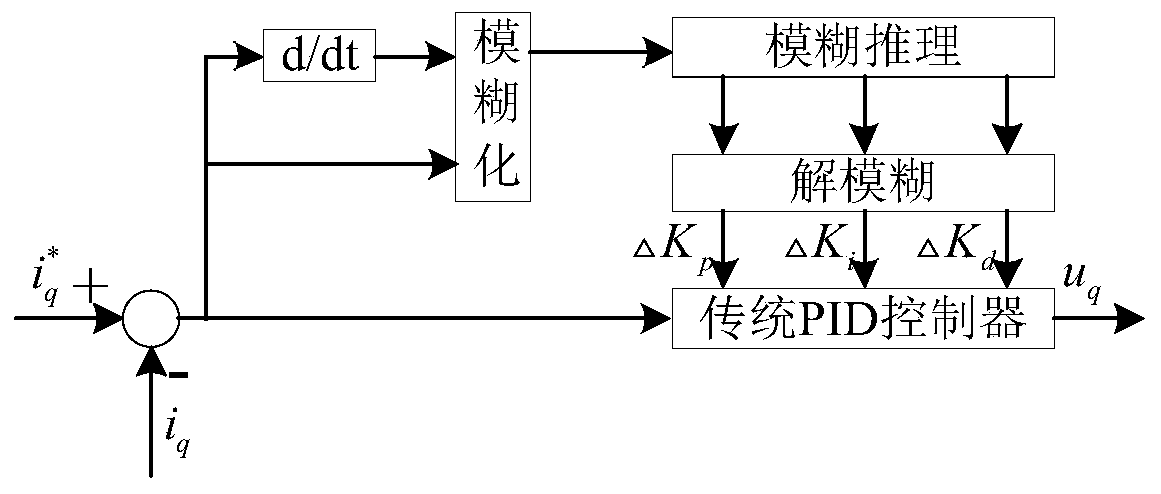

Speed and current double closed-loop control system and method for permanent magnet synchronous linear motor

ActiveCN110138297AHigh precisionGood precisionElectronic commutation motor controlVector control systemsReference currentPermanent magnet synchronous motor

The invention discloses a speed and current double closed-loop control system and method for a permanent magnet synchronous linear motor. The method comprises the steps of: designing a permanent magnet synchronous linear motor vector control system; designing a fuzzy adaptive sliding-mode speed controller; designing a nonlinear disturbance observation; designing a d-axis fuzzy PID controller; designing a q-axis fuzzy PID controller; obtaining a desired q-axis current reference value as an input of the q-axis fuzzy PID controller according to the designed nonlinear disturbance observer and thedesigned fuzzy adaptive sliding-mode speed controller; setting a d-axis reference current value as 0, and using the id obtained by subtracting park transform from 0 as the input of the d-axis fuzzy PID controller; after the processing by the d-axis fuzzy PID controller and the q-axis fuzzy PID controller, obtaining the ud, uq of the vector control system, and finally outputting the current operating driving voltage of the permanent magnet synchronous linear motor by the anti-park transformation and SVPWM modulation through the vector control and an inverter. The method enhances the robustnessof the system.

Owner:SOUTHEAST UNIV

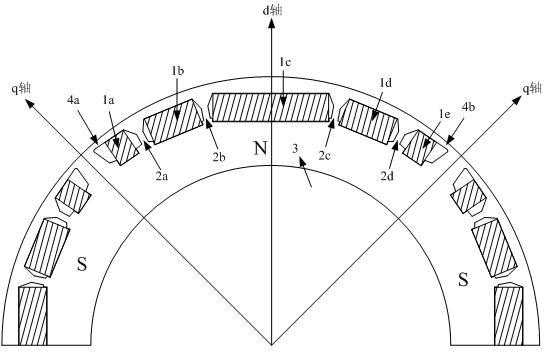

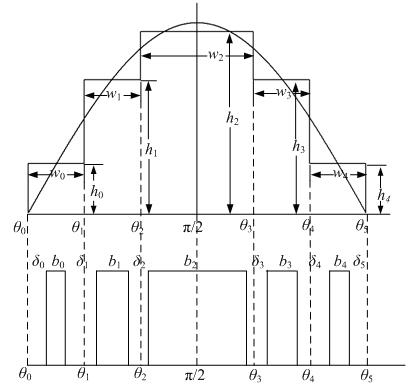

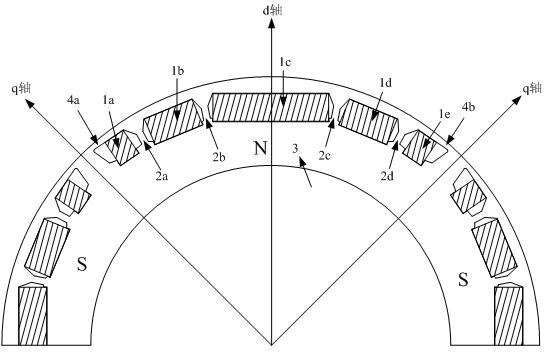

Rotor of built-in permanent magnet motor and magnetic steel structural parameter determining method thereof

InactiveCN102157998AHigh mechanical strengthIncrease stiffnessMagnetic circuit rotating partsElectric machinePermanent magnet motor

The invention relates to a rotor of a high-quality and high-speed built-in permanent magnet motor and a magnetic steel structural parameter determining method thereof. In the invention, the whole section magnetic steel of each electrode of the rotor of a conventional built-in permanent magnet motor is divided into multiple sections of magnetic steel which have the same polarity and different widths; the multiple sections of the magnetic steel are respectively arranged in a rotor core; and reinforcing ribs with the function of magnetic isolation are arranged among the multiple sections of the magnetic steel. By reasonably modulating and determining the width and distribution of each section of the magnetic steel, the air gap magnetic density waveform approaches sine distribution; harmonic components are reduced to the greatest extent; the eddy current loss of the magnetic steel and the torque pulsation of the motor are simultaneously reduced; and the electromagnetic performance of the motor is enhanced. Furthermore, the multiple sections of the magnetic steel are arranged in the circumference along the rotor; the highest rotating speed of the safe operation of the rotor is greatly enhanced on machinery; the radial thickness which is needed by the magnetic circuit of the rotor is obviously reduced on the structure; the rotational inertia and weight of the rotor are reduced; the dynamic response of the motor is improved; and the requirements of a high-speed driving system on the performance of the motor are met.

Owner:SHANGHAI UNIV

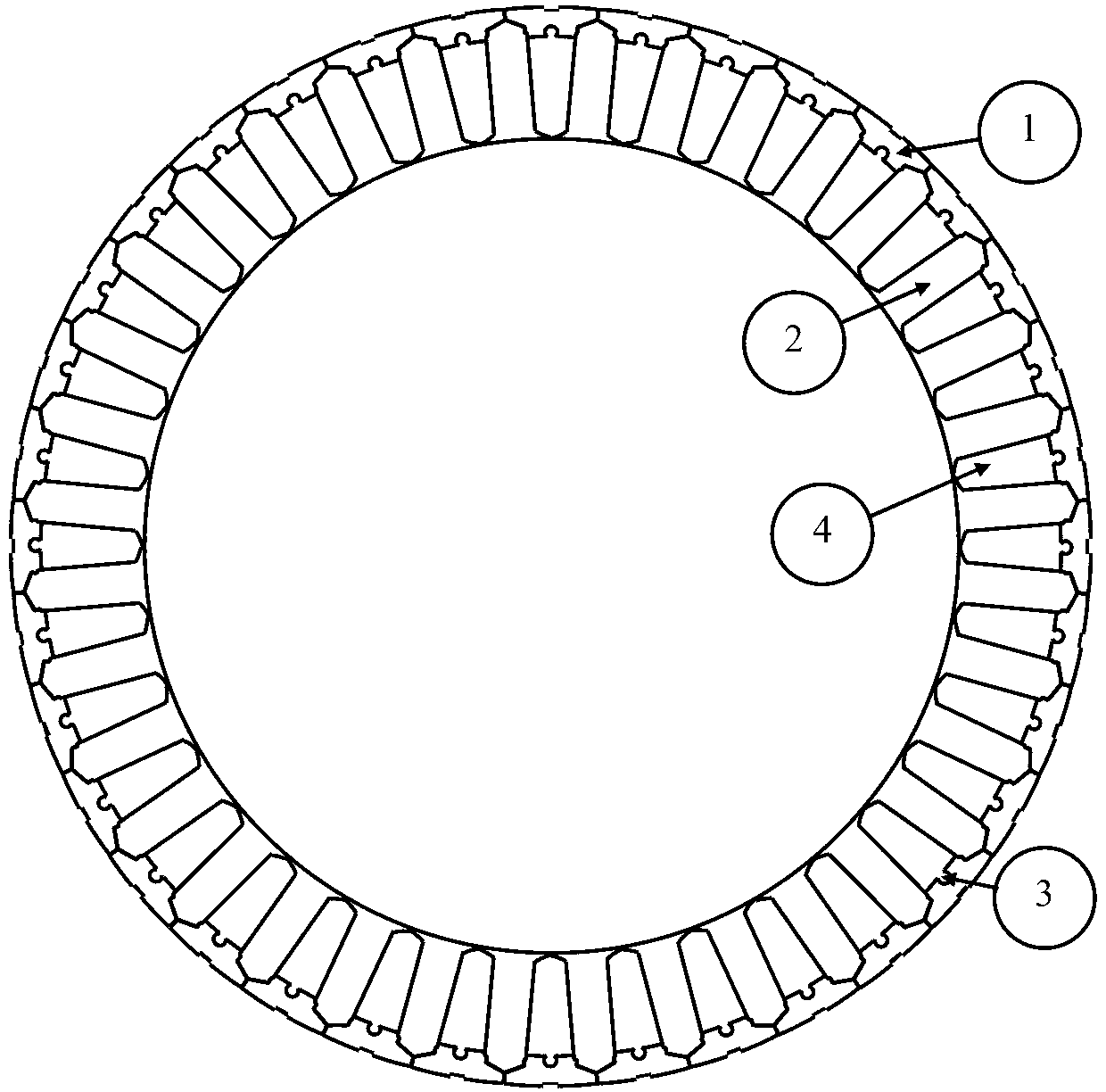

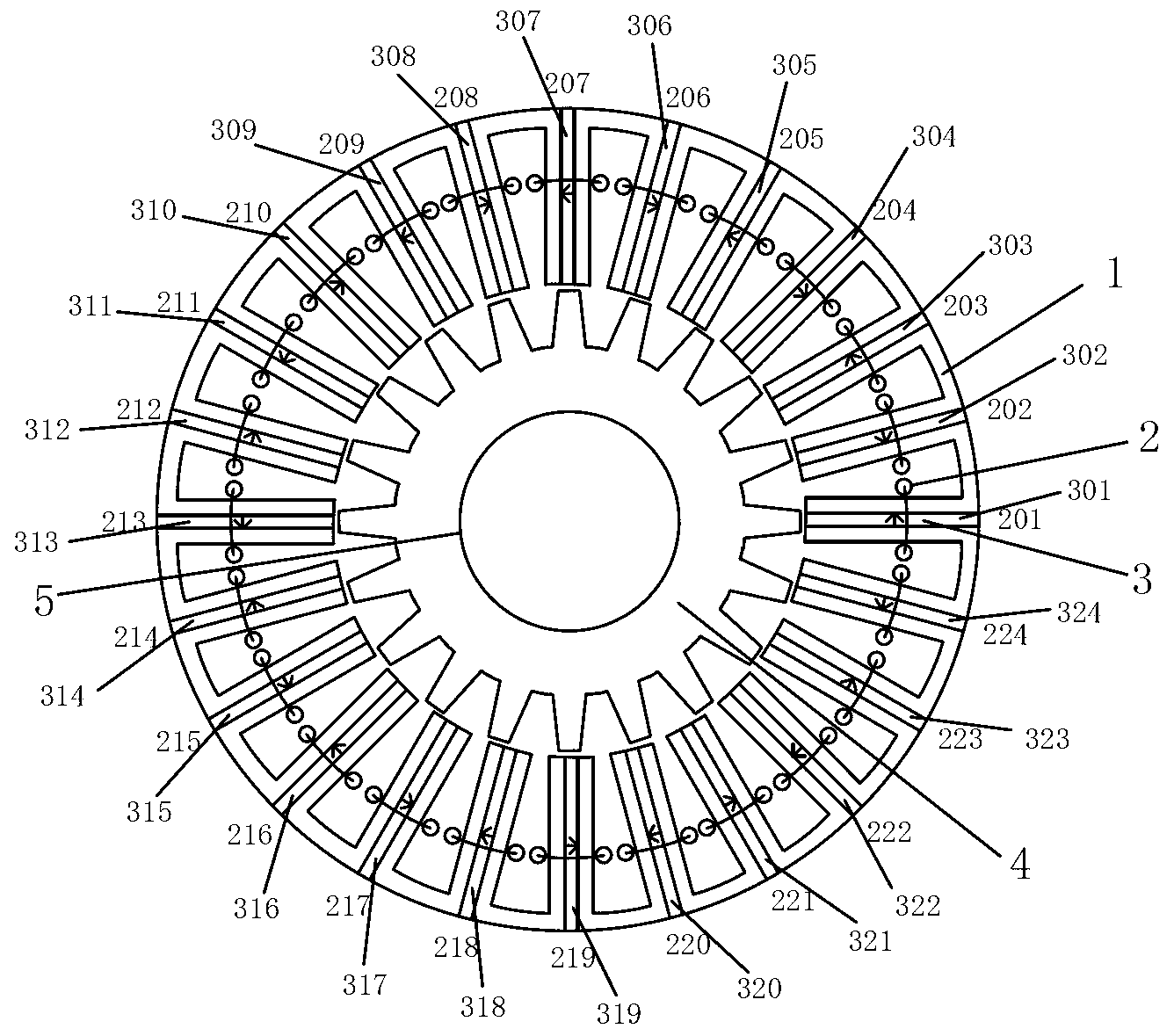

Structure of motor stator core and cooling method for motor stator based on structure of motor stator core

ActiveCN103280903ALow ferromagnetic lossImprove efficiencyWindings insulation shape/form/constructionMagnetic circuit stationary partsWater coolingOil cooling

The invention relates to a structure of a motor stator core and a cooling method for a motor stator based on the structure of the motor stator core. The structure is characterized in that the stator core is formed by splicing and combining stator yoke units and stator tooth units, wherein the quantities of the stator yoke units and the stator tooth units are the same, and are equal to the slot number Z1 of a stator; the stator yoke units and the stator tooth units are formed by laminating oriented silicon steel sheets; a stator yoke unit is connected between every two adjacent tooth units; the tooth units and the stator yoke units are in joggle joint; the silicon steel sheets of the stator yoke units are oriented circumferentially; and the silicon steel sheets of the stator tooth units are oriented radially. The cooling method is selected from one of air cooling, water cooling and oil cooling. The structure has the advantage that the motor has the characteristics of low ferromagnetic loss, high efficiency, low torque pulsation, low slot effect, low running noise, low wind resistance, high slot fullness rate of a stator winding, high utilization ratio of a silicon steel sheet material, suitability of the stator for automatic mass production and the like.

Owner:曹宇轩

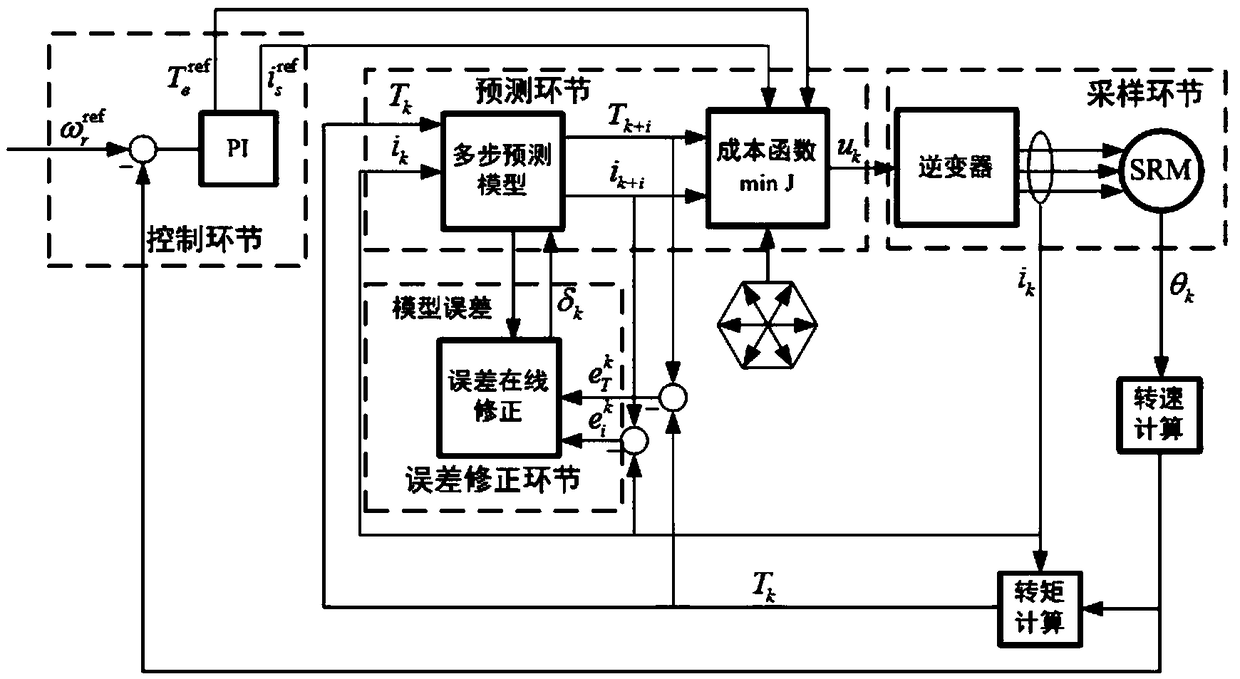

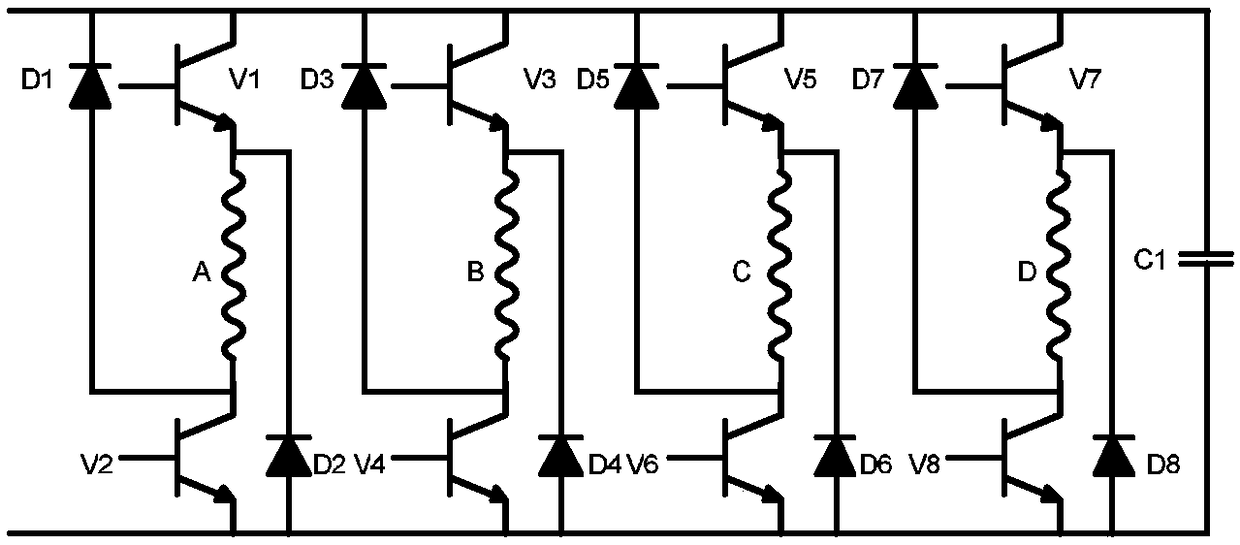

Method for constructing multistep predictive controllers for switch reluctance motors

ActiveCN109327178AImprove accuracyEasy to controlElectric motor controlMotor parameters estimation/adaptationControl modelsControlling for a variable

The invention discloses a method for constructing multistep predictive controllers for switch reluctance motors. The method includes detecting current signals and position signals at k moments by current sensors and position Hall sensors; carrying out differential computation on the position signals to obtain rotational speed signals; computing difference values of the rotational speed signals andgiven rotational speed signals, converting the difference values into torque reference values and current reference values by PI (proportion and integration) control modules and providing reference values for multistep predictive control on currents and torque; building multistep predictive control models, predicting current values and torque values in prediction time domains by the aid of sampled values at the k moments and acquiring the optimal control variables and switch vectors by means of cost function computation; ultimately establishing error correction modules. The method has the advantages that error correction links are adopted, compensation values are computed by the aid of least recursive square processes, model errors can be compensated, and accordingly the accuracy of models can be improved.

Owner:JIANGSU UNIV

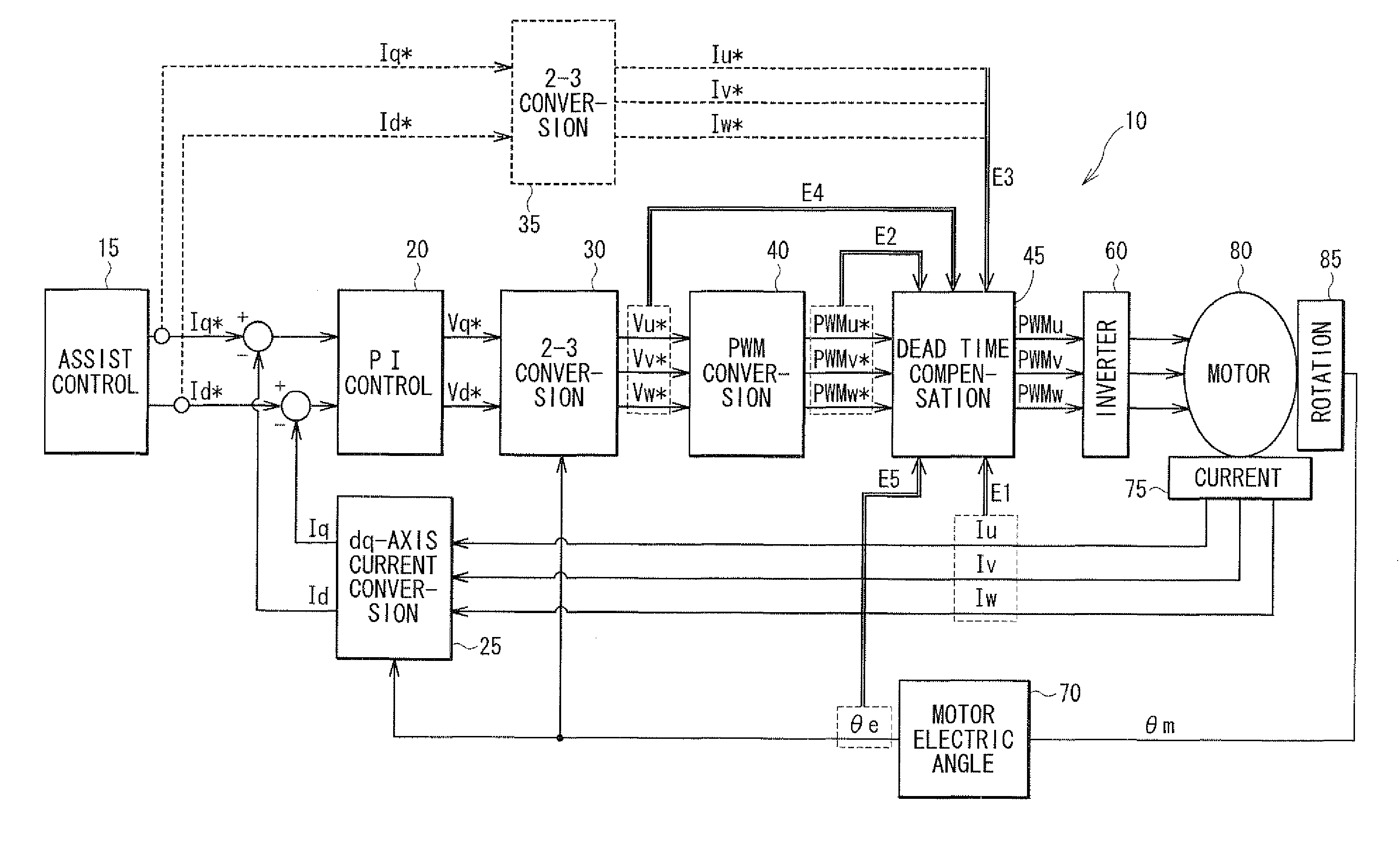

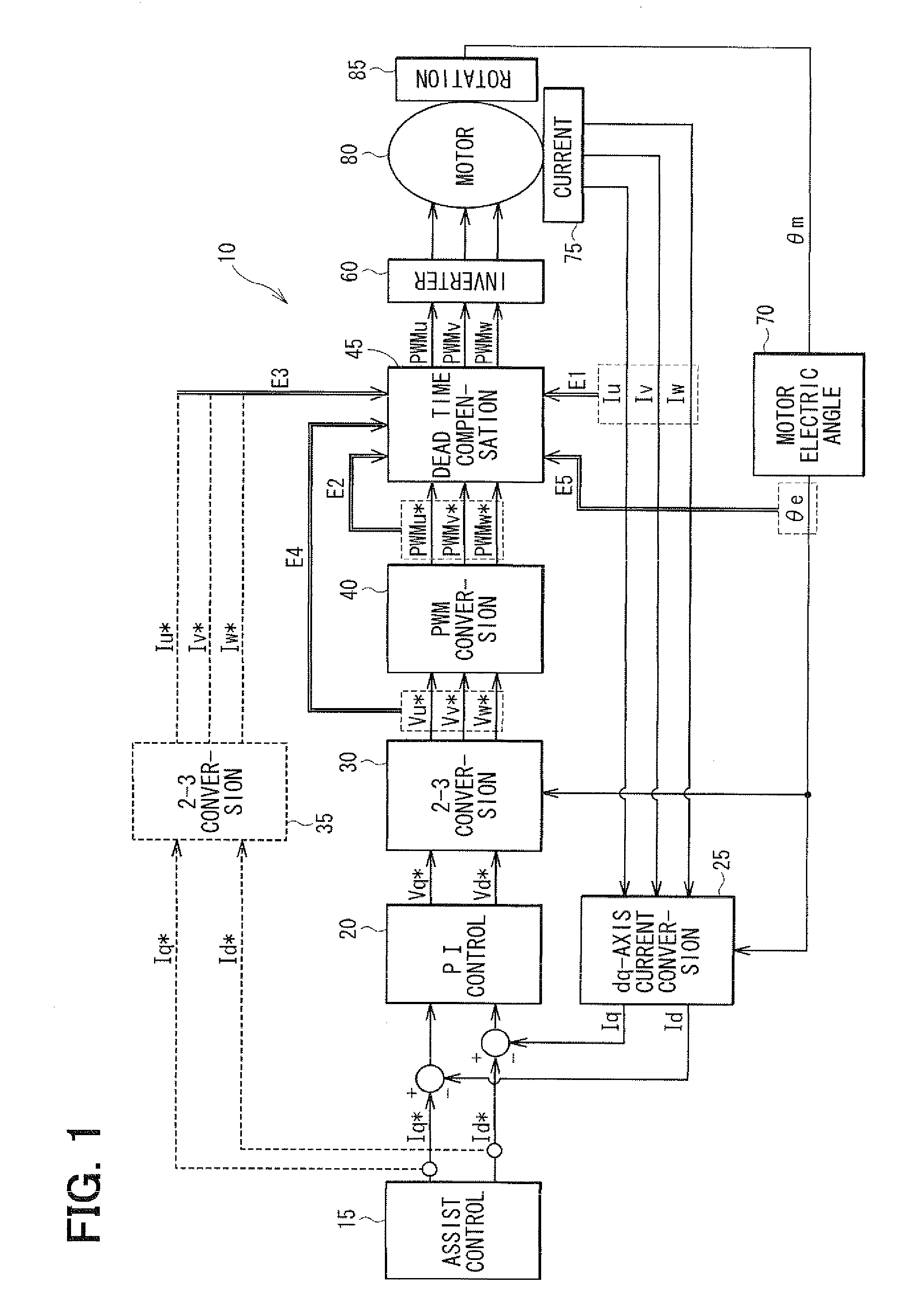

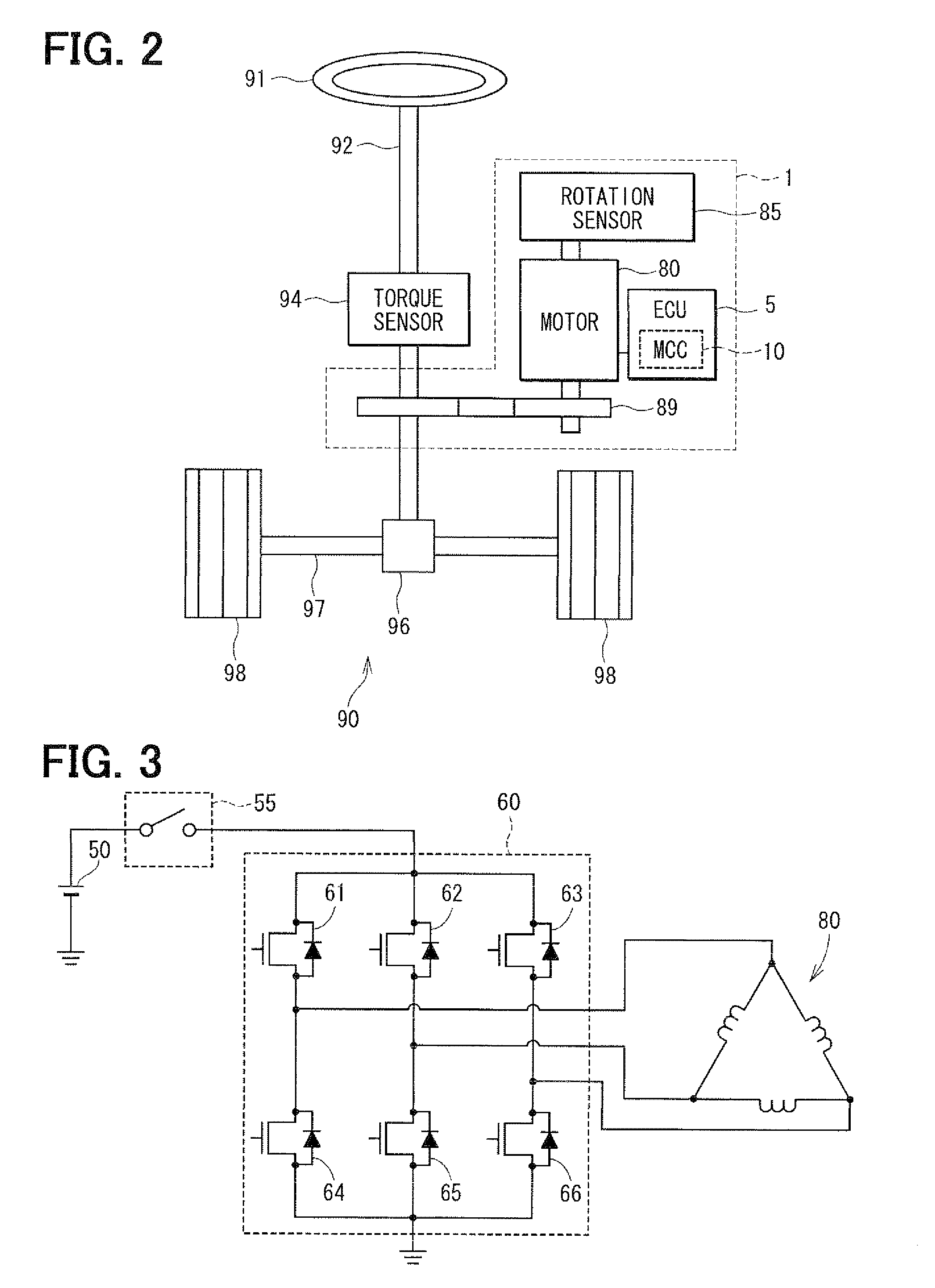

Motor control method and apparatus and electric power steering system

InactiveUS20110221382A1Reduce torque rippleSufficient dead time compensationElectronic commutation motor controlVector control systemsThree-phaseTorque ripple

In a motor control method for driving a three-phase motor by an inverter, a dead time compensation operation is performed to compensate for output voltage loss caused by a dead time, in which both a high-side FET and a low-side FET in the inverter are turned off. For example, in a range between 0° and 60° and a range between 120° and 180°, a reference value is provided stepwise to a PWM command value of a U-phase. In a range between 60° and 120°, a doubled reference value is provided stepwise to the PWM command value. A compensated PWM voltage is supplied to the inverter. The stepwise change at zero-cross points, 0° and 180°, is reduced relative to a case, in which a fixed dead time compensation value is provided in a range between 0° and 180°. Torque ripple near the zero-cross point is thus suppressed.

Owner:DENSO CORP

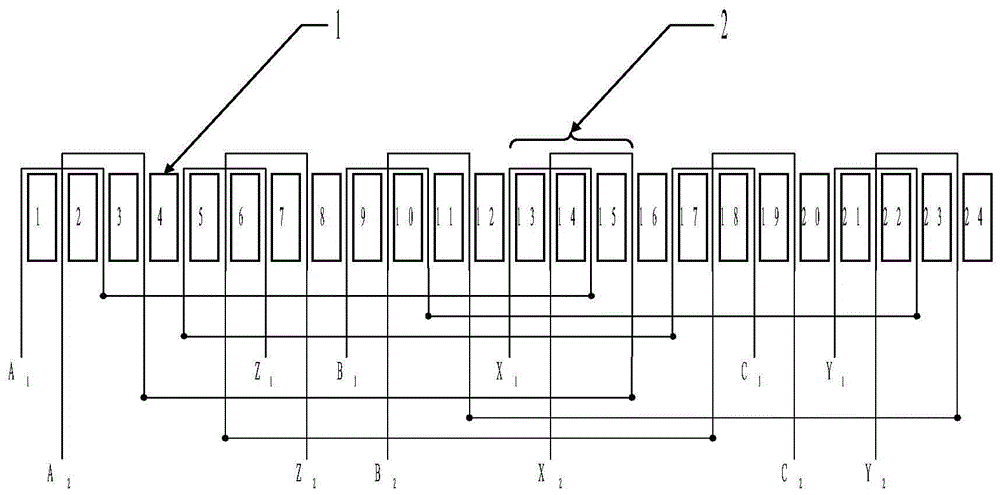

Structure for modular motor stator and end part overlapping fractional slot windings of modular motor stator

ActiveCN105680585ASmall torqueReduce torque rippleMagnetic circuit stationary partsWindings conductor shape/form/constructionMagnetomotive forceHarmonic

The invention provides a structure for a modular motor stator and end part overlapping fractional slot windings of the modular motor stator. The number of stator slots and the number of winding pole pairs are set to be 2Z and p respectively, wherein the stator slots are evenly distributed on the circumference; the stator comprises two sets of three-phase symmetric AC windings; the windings are evolved from traditional single-layer concentrated fractional slot windings; the arrangement of each set of windings is the same as that of the traditional single-layer concentrated fractional slot windings with Z slots and p pole pairs; the staggered angle of two sets of windings is one half of a coil span mechanically; overlapping regions at the end parts of the windings are distributed on the circumference of the stator at intervals; and modularization can be achieved by cutting the stator in the non-overlapping regions at the end parts of the windings. The structure can greatly reduce the non-working tooth harmonic content in magnetomotive force of the traditional concentrated fractional slot windings, so that the motor loss can be reduced; torque pulsation is stabilized; the noise is reduced; meanwhile, the structure has the advantage that the motor stator with the concentrated fractional slot windings can be modularized; manufacturing, transportation and assembly of a large motor are facilitated; the interphase mutual inductance is small; and improvement of the fault-tolerant capability of the motor is facilitated.

Owner:SOUTHEAST UNIV

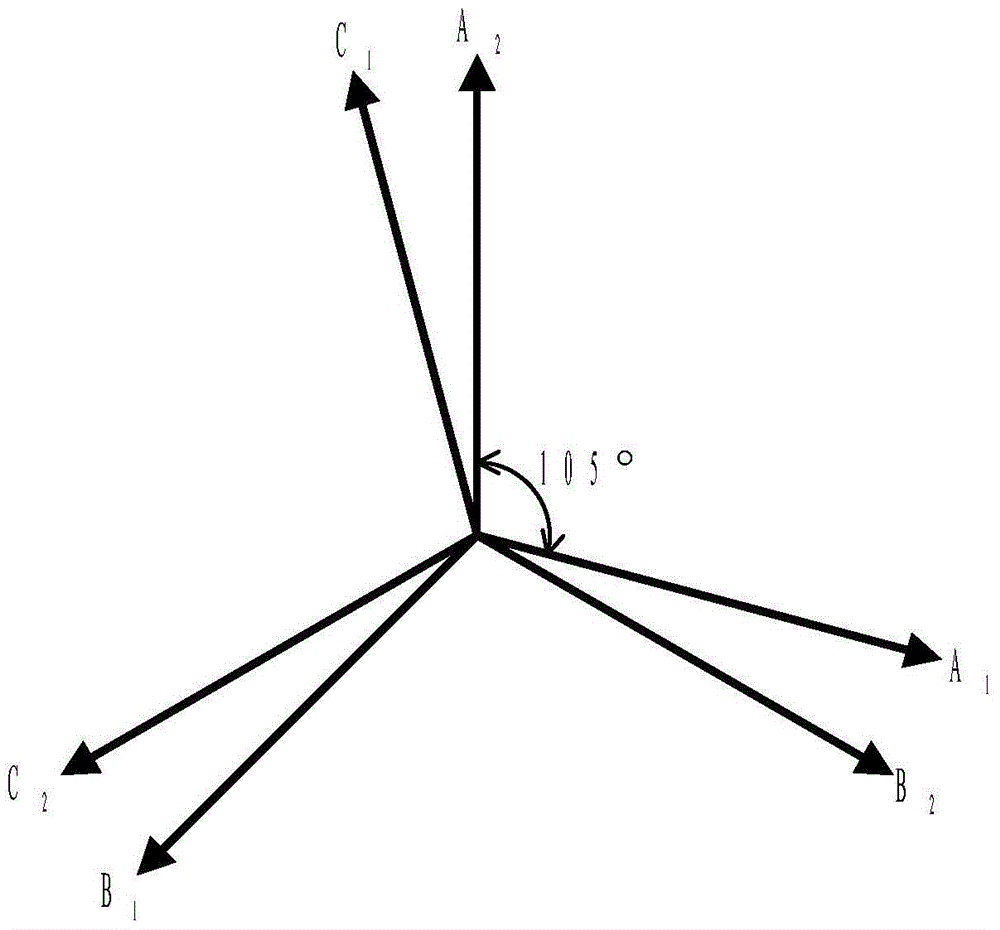

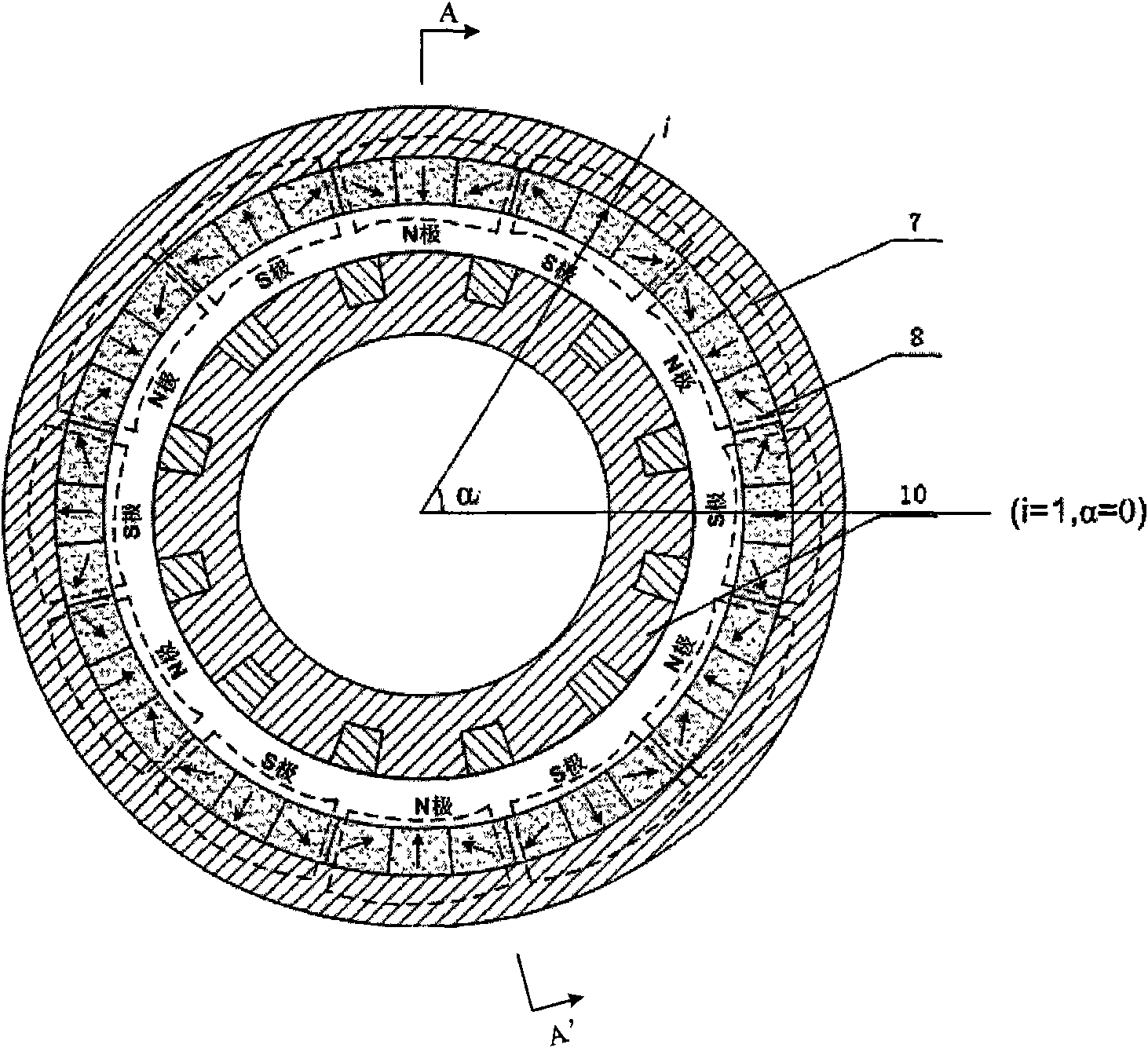

Six-phase flux switching type permanent magnet motor

InactiveCN103248158ASmall positioning torqueStable output torqueMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsMagnetic core

The invention provides a six-phase flux switching type permanent magnet motor which comprises stators, rotors and a rotating shaft, wherein each stator adopts a permanent magnet double salient structure, that is, the permanent magnet, the stator core and the armature winding are arranged on each stator, the stator core is assembled by an U-magnetic core and each permanent magnet embedded in the magnetic core, and the permanent magnets are of tangential alternate magnetization; the armature winding is of six-phase armature winding arranged on the stator, the six-phase armature winding adopts centralization coils, and the rotors are made of permeability magnetic material; the magnetizing directions of the permanent magnets are of the tangential of the stator circle, and the magnetizing directions of two adjacent permanent magnets are opposite to each other; the number of the armature coil and the stator groove is even number times of the phase number; and each phase 2n coils winding, and n coils are distributed at the two ends of the diameter of the stator circle respectively. And two three-phrase winding can conduct independent power supplying and generating.

Owner:SOUTHEAST UNIV

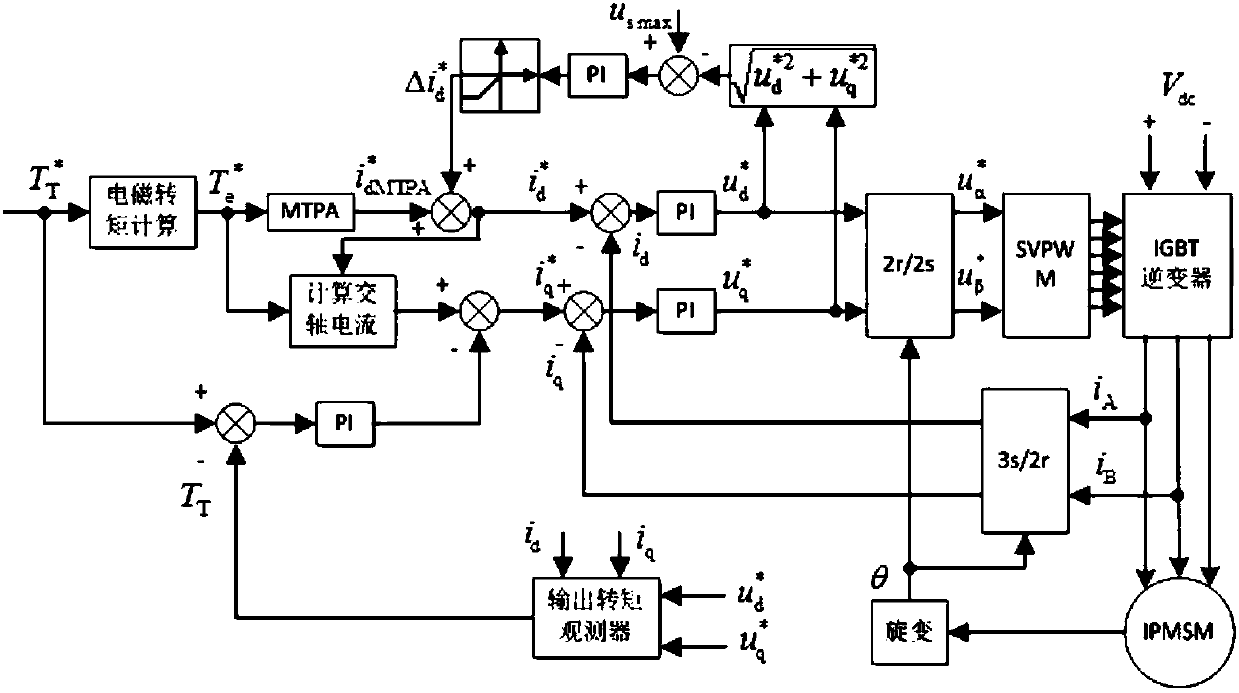

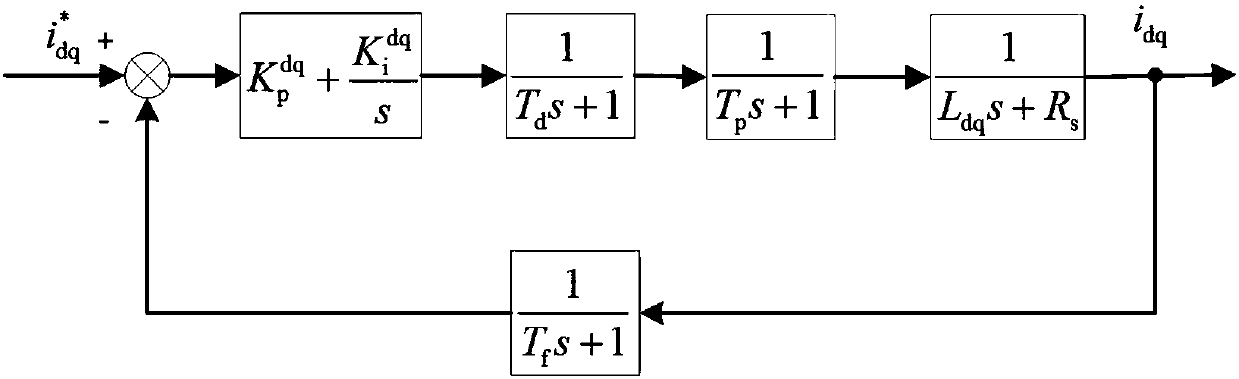

Torque closed-loop control method of interior permanent magnet synchronous motor driving system for automobile

ActiveCN108551287AHigh control precisionImprove operational efficiencyElectronic commutation motor controlVector control systemsLoop controlClosed loop

The invention provides a torque closed-loop control method of an interior permanent magnet synchronous motor driving system for an automobile. The torque closed-loop control method combines a maximumtorque to current ratio algorithm with dual current loop flux-weakening control, utilizes an invented torque observer, corrects a set value of a quadrature axis current in real time by means of a torque closed loop PI adjuster, ensures that the motor output torque can track a torque instruction quickly and precisely in the case of errors in motor parameters, and further realizes high-precision torque closed-loop control of the driving system. The torque closed-loop control method has the advantages of clear principle and simple calculation, can be widely applied to interior permanent magnet synchronous motor driving systems for automobiles, can be popularized to the servo control of permanent magnet synchronous motor in other fields, and has high theoretical significance and engineering application value.

Owner:NAVAL UNIV OF ENG PLA

Permanent magnet synchronous motor without stator iron core

InactiveCN101783557AReduce volumeReduce weightMagnetic circuit rotating partsSynchronous machinesHarmonicClosed loop

The invention relates to a permanent magnet synchronous motor without a stator iron core, which mainly comprises a rotor shaft, an inner rotor iron core, a magnetic isolation block, a hollow cup stator (including a skeleton and a fractional slot concentrated winding), a Halbach permanent magnet and an outer rotor iron core, wherein the magnetic isolation block is embedded in the inner rotor iron core and forms an inner rotor core component part with the inner rotor iron core, the inner rotor iron core, the outer rotor iron core and the permanent magnet are all connected with the rotor shaft, the Halbach permanent magnet is stuck to the outer rotor iron core, and the hollow cup stator is fixed on a motor shell. The permanent magnetic circuit is formed into a closed loop circuit via the inner rotor iron core, the magnetic air gap, the Halbach permanent magnet and the outer rotor iron core. The invention utilizes the magnetic isolation block to achieve a salient pole structure of the motor so as to realize control by the difference of A-axis and D-axis inductance, the concentrated winding is utilized to weaken harmonic content in winding induced electromotive force and greatly increase the sinusoidal property of the winding induced electromotive force and winding current, so the torque impulse is reduced, and the stationarity of the output torque is improved.

Owner:BEIHANG UNIV

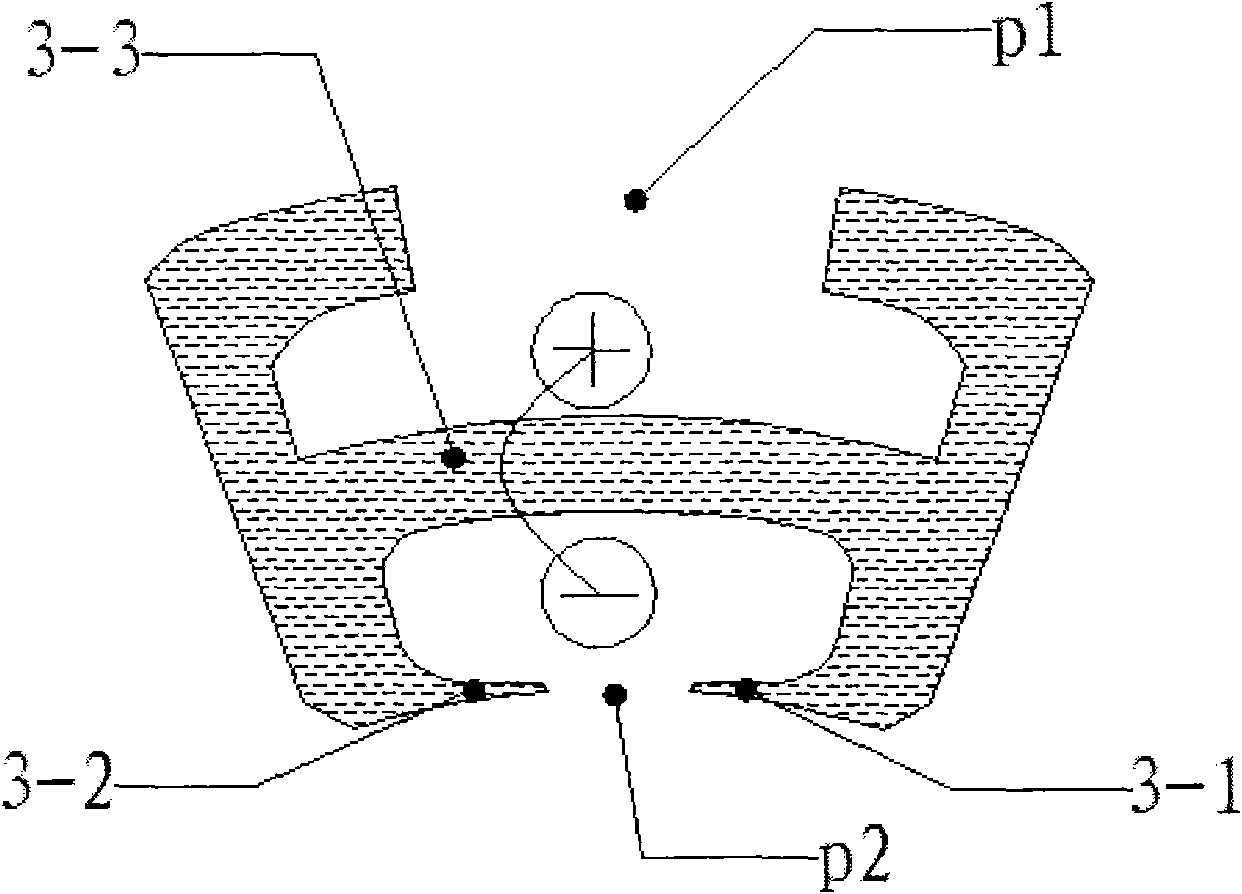

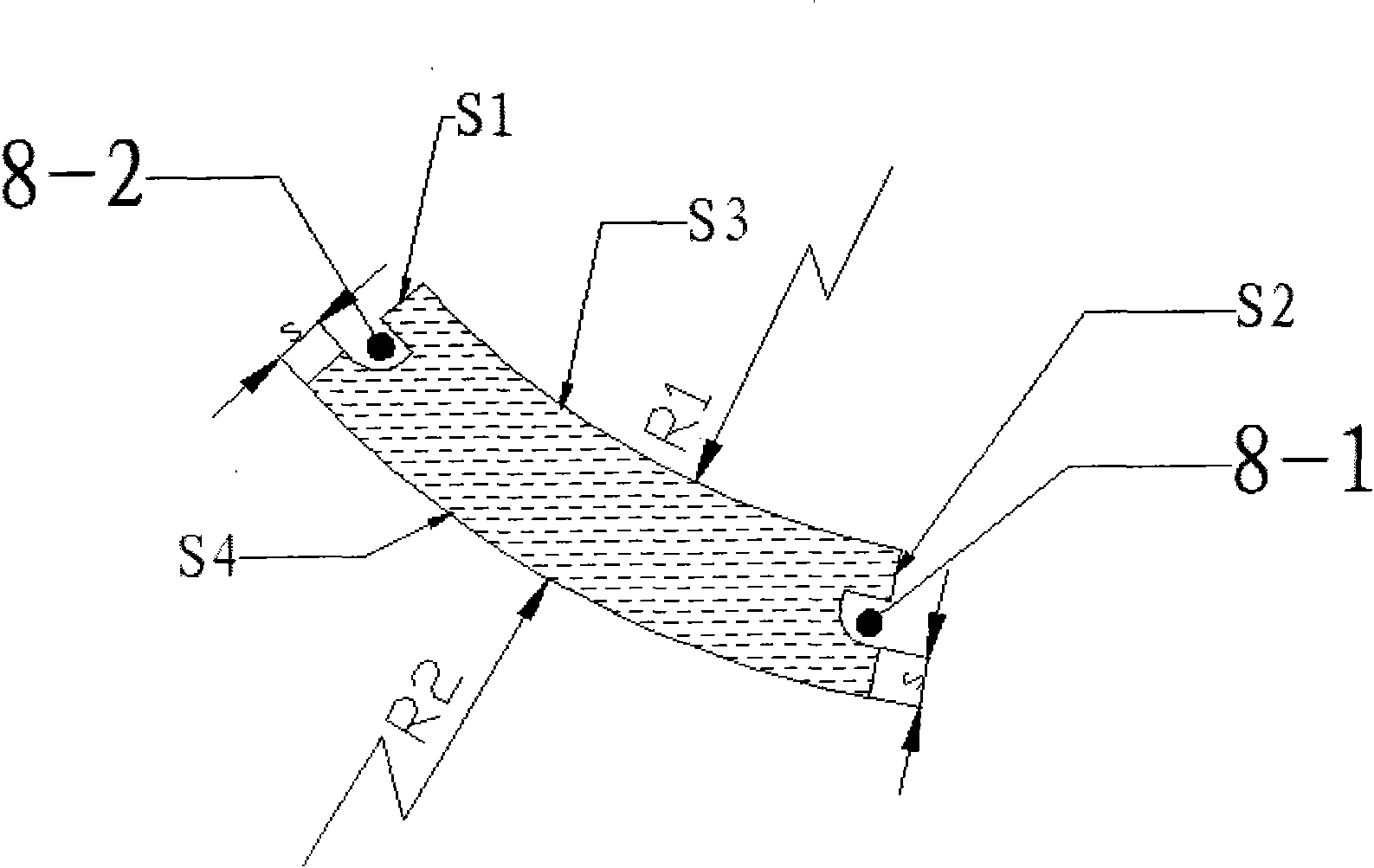

Mixed excitation short-magnetic-circuit variable-reluctance motor

InactiveCN102315746AEasy to installFlexibleMagnetic circuit rotating partsMagnetic circuit stationary partsNoise levelElectrical polarity

The invention discloses a mixed excitation short-magnetic-circuit variable-reluctance motor 1 as well as a stator structure and a rotor structure thereof. An inner circular face t of a base part 2 of the mixed excitation short-magnetic-circuit variable-reluctance motor is provided with modules 2-1 which protrude inwards in a preset interval angle; the stator part comprises a plurality of H-shaped stator sections 3 and first permanent magnets 4 (1) arranged at all the H-shaped stator sections p1, and the polarities of the permanent magnets of the stator sections are opposite; an exciting winding coil is embedded into two stator slots of each H-shaped stator section 3; and the rotor part comprises a rotor body 5 and a plurality of annular body rotor sections 8 arranged on the rotor body and / or second permanent magnets 4 (2), wherein the second permanent magnets are arranged on the s3 surfaces of the annular body rotor sections, and open grooves 8-1 and 8-2 are arranged on the lateral surfaces of the annular body rotor sections. According to the invention, the rotating force of the variable-reluctance motor can be increased, the energy density is improved, the torque ripple and the vibration and noise level are reduced, the performance is stable, and the size is smaller under the requirement of same output torque.

Owner:SOUTH CHINA UNIV OF TECH

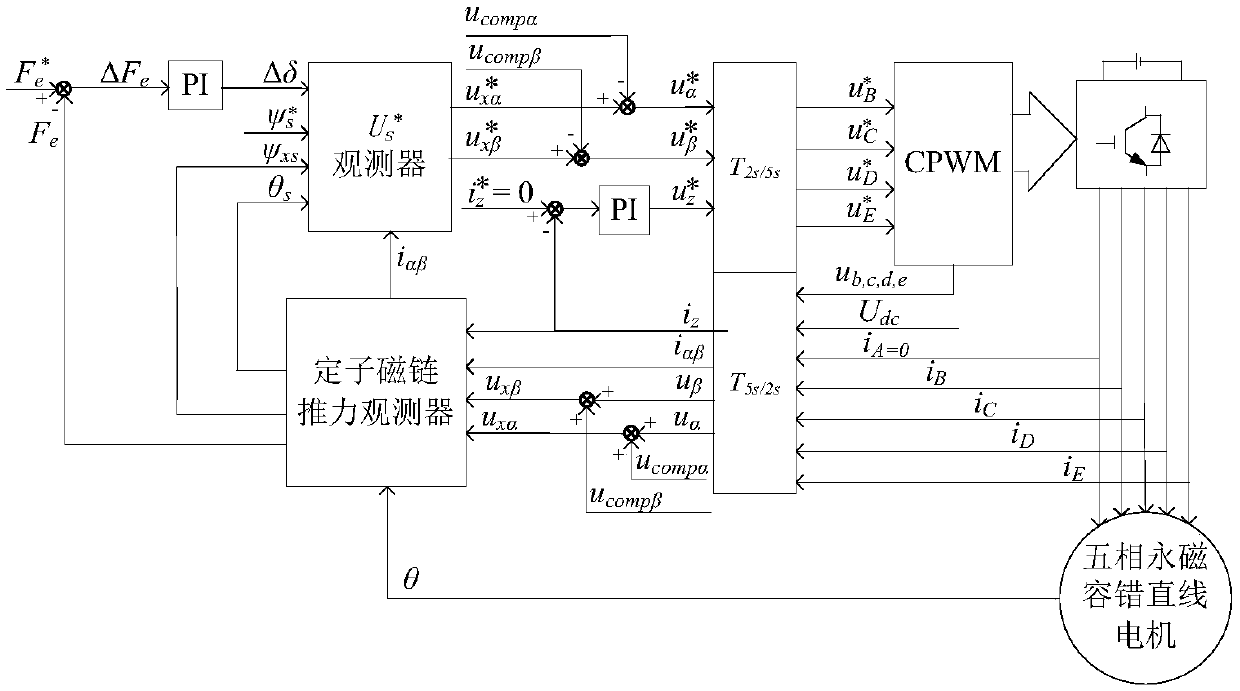

One-phase open-circuit fault-tolerant direct thrust control method for five-phase permanent magnet linear motor

InactiveCN108306571AIncreased complexitySave memory resourcesElectric motor controlVector control systemsPhase currentsModulation function

The invention discloses a one-phase open-circuit fault-tolerant direct thrust control method for a five-phase permanent magnet linear motor. Firstly, a Clark transform matrix and an inverse matrix thereof are derived based on fault-tolerant phase current. On the above basis, a stator flux linkage on alpha-beta is derived, a stator virtual flux linkage is defined according to the requirements of acircular stator flux linkage trajectory, and thus the voltage compensation on alpha-beta is derived. The stator actual voltage on the alpha-beta is derived by a modulation function of a voltage sourceinverter, and voltage is combined with voltage compensation and stator current, and a stator virtual flux linkage and thrust are observed by a stator flux observer and a thrust observer. Then statorvirtual target votlage is calculated according to given thrust, a given stator flux linkage amplitude and the observed stator virtual flux linkage and thrust. Finally, the stator actual voltage is calculated by the voltage and the voltage compensation, and the motor is controlled by the voltage by the voltage source inverter. According to the method, a thrust fluctuation caused by a motor failureis suppressed, and more importantly, the dynamic performance and steady state performance are consistent with that in a normal condition.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com