Method for constructing multistep predictive controllers for switch reluctance motors

A switched reluctance motor, multi-step prediction technology, applied in motor control, AC motor control, motor vibration suppression control and other directions, can solve problems such as motor operation interference and affecting control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in further detail below in conjunction with the accompanying drawings.

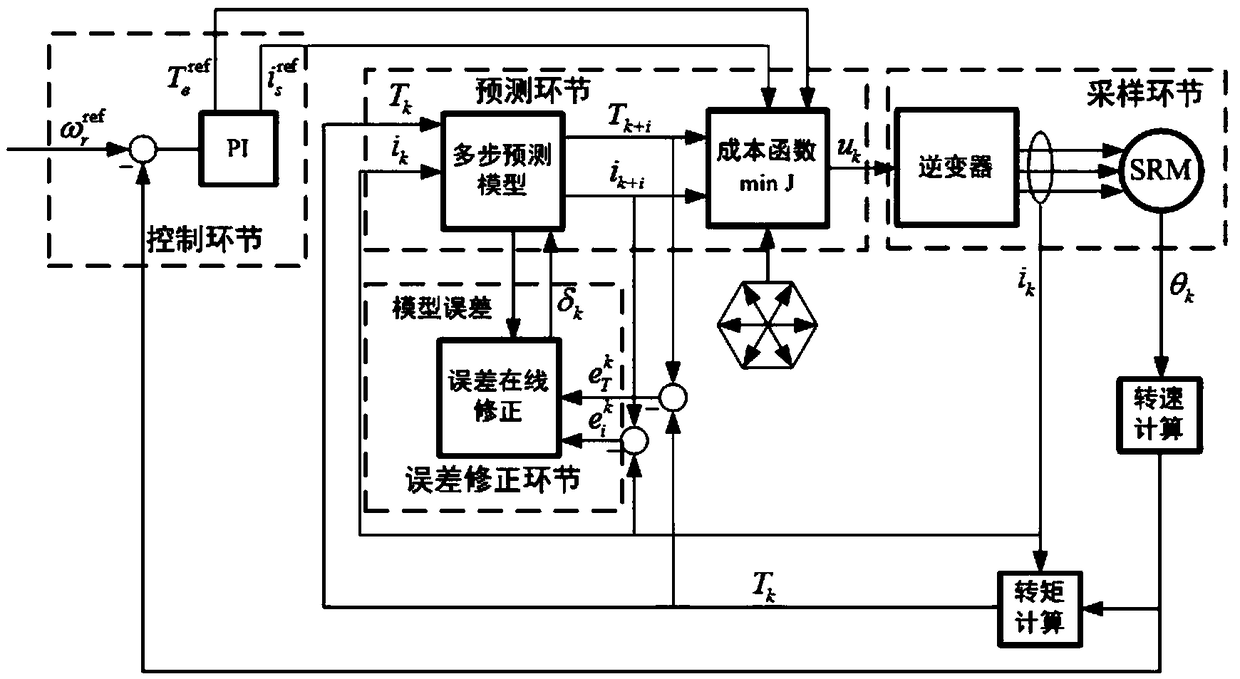

[0066] The specific implementation of the present invention is divided into the following four steps. Through the construction of the sampling link, the prediction link, the control link and the error correction link, a multi-step multi-target torque prediction controller block diagram of the switched reluctance motor is formed, as shown in the attached figure 1 .

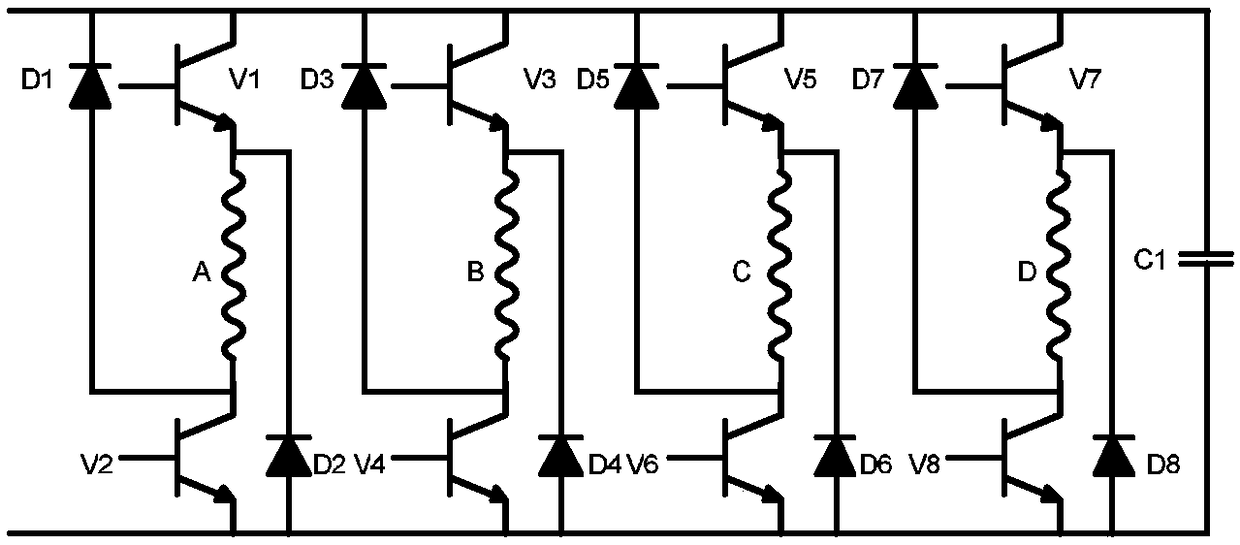

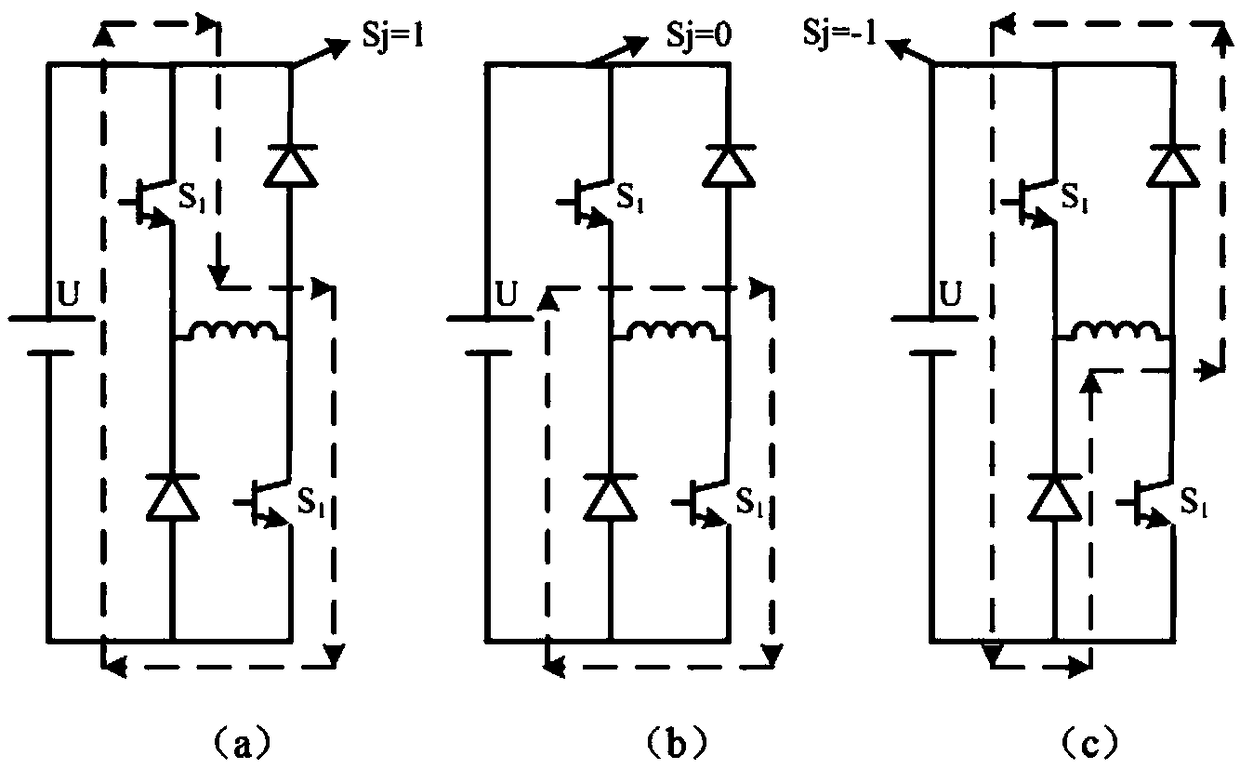

[0067] Construct a multi-step multi-objective predictive control method for switched reluctance motors, as shown in the attached figure 1 , the system is composed of prediction module, sampling module, control module and error correction module. 1) The function of the sampling module is to collect the current signal i of the motor at time k through the current sensor and the Hall position sensor k and position signal θ k . Input the collected current and position signals to the torque and spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com