Short circuit fault tolerant control method for five-phase fault tolerant permanent magnet motor

A permanent magnet motor, fault-tolerant control technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve problems such as five-phase fault-tolerant permanent magnet motor control problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

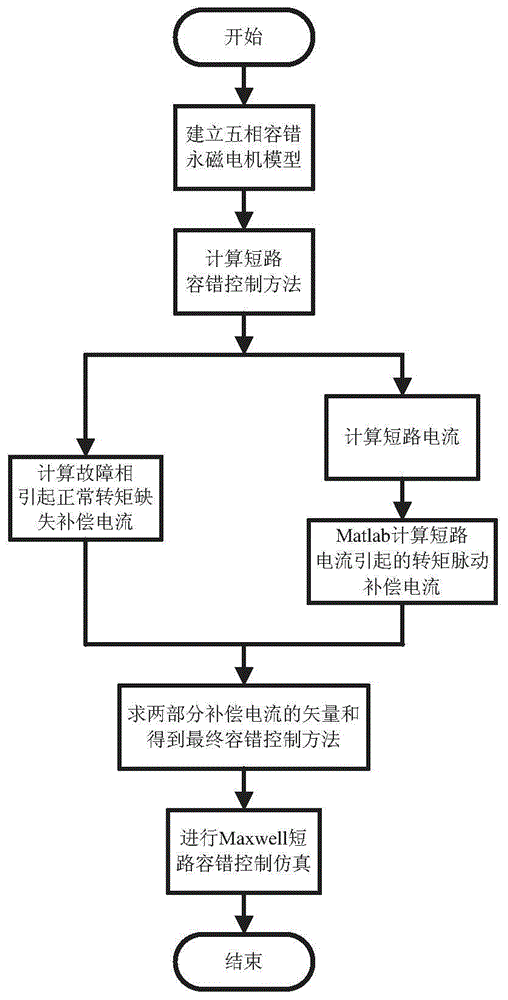

[0039] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

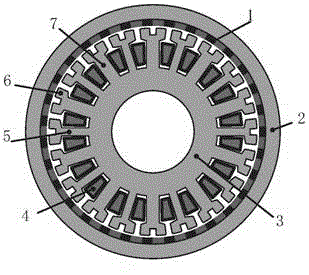

[0040] Such as figure 1 As shown, this is a five-phase fault-tolerant permanent magnet motor. Its structure includes a coaxial inner stator 3 and an outer rotor 2. A permanent magnet 1, an armature winding 4, and an armature tooth 7 are arranged between the inner stator 3 and the outer rotor 2. Fault-tolerant teeth 5 and modulation poles 6, permanent magnets 1 are fixed on the inner surface of the outer rotor 2 along the circumferential direction, the magnetization direction of the permanent magnets 1 is radial and N poles and S poles are arranged alternately, and the inner stator 3 is arranged on the circumference 10 armature teeth 7 and 10 fault-tolerant teeth 5 interlaced with each other. A single-layer concentrated armature winding 4 is wound on the armature teeth 7, and the concentrated armature windings 4 on two radially oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com