Six-phase flux switching type permanent magnet motor

A magnetic flux switching motor and flux switching technology, applied in the directions of magnetic circuit static parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of increasing the difficulty and reliability of power converter design, increasing Difficulty in designing coils for each phase winding, increasing design requirements and costs, etc., to achieve the effect of improving low-speed running performance, small positioning torque, and strong fault tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

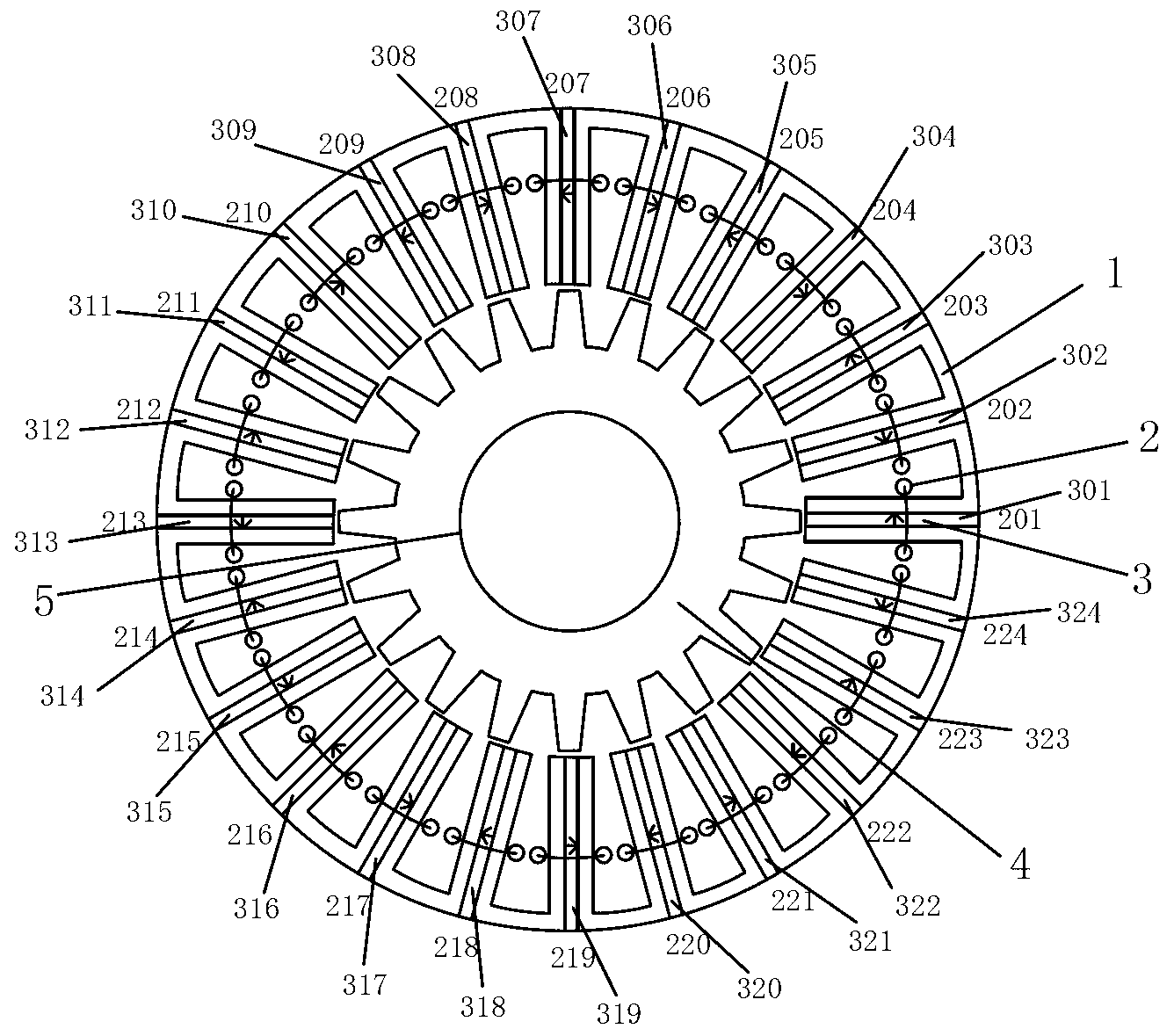

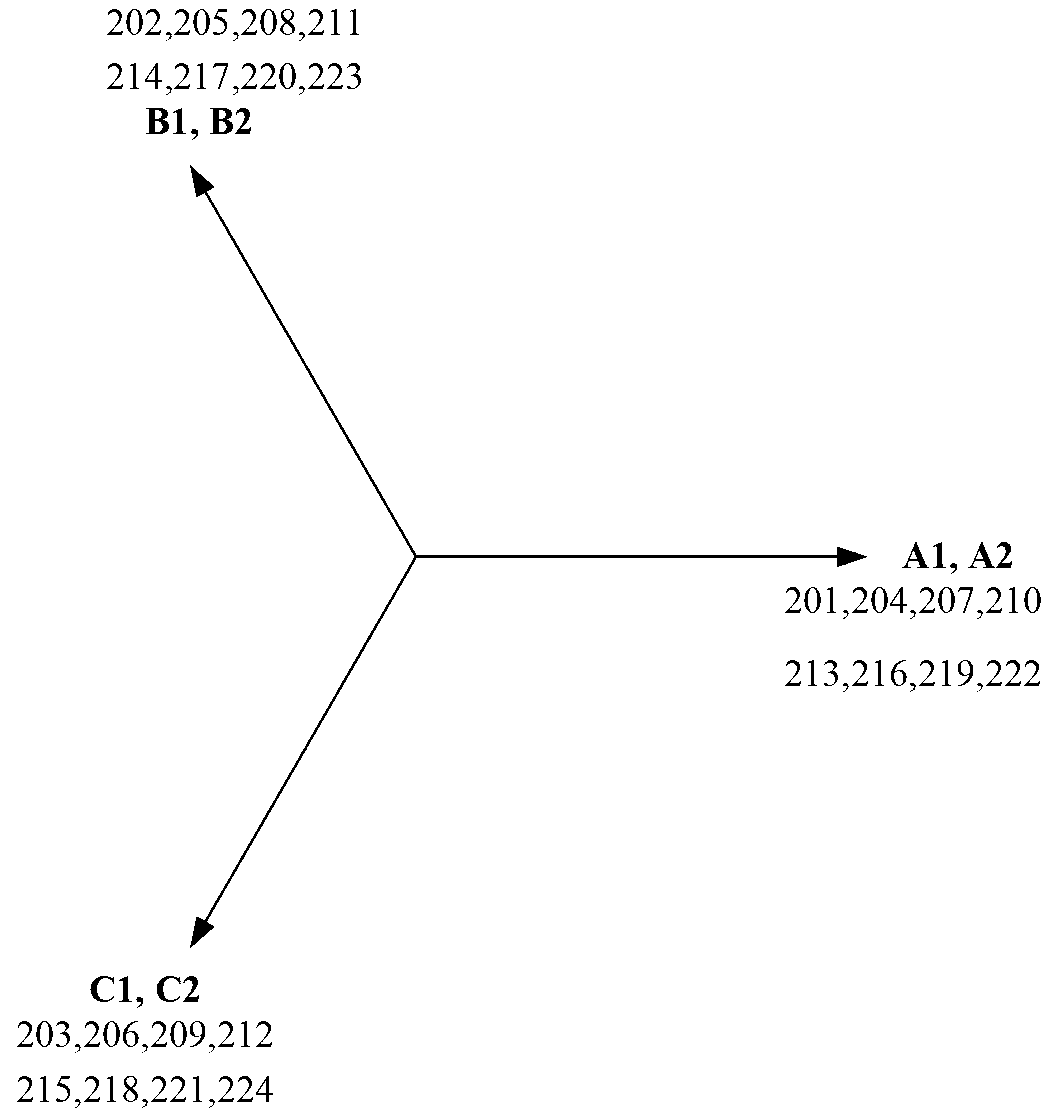

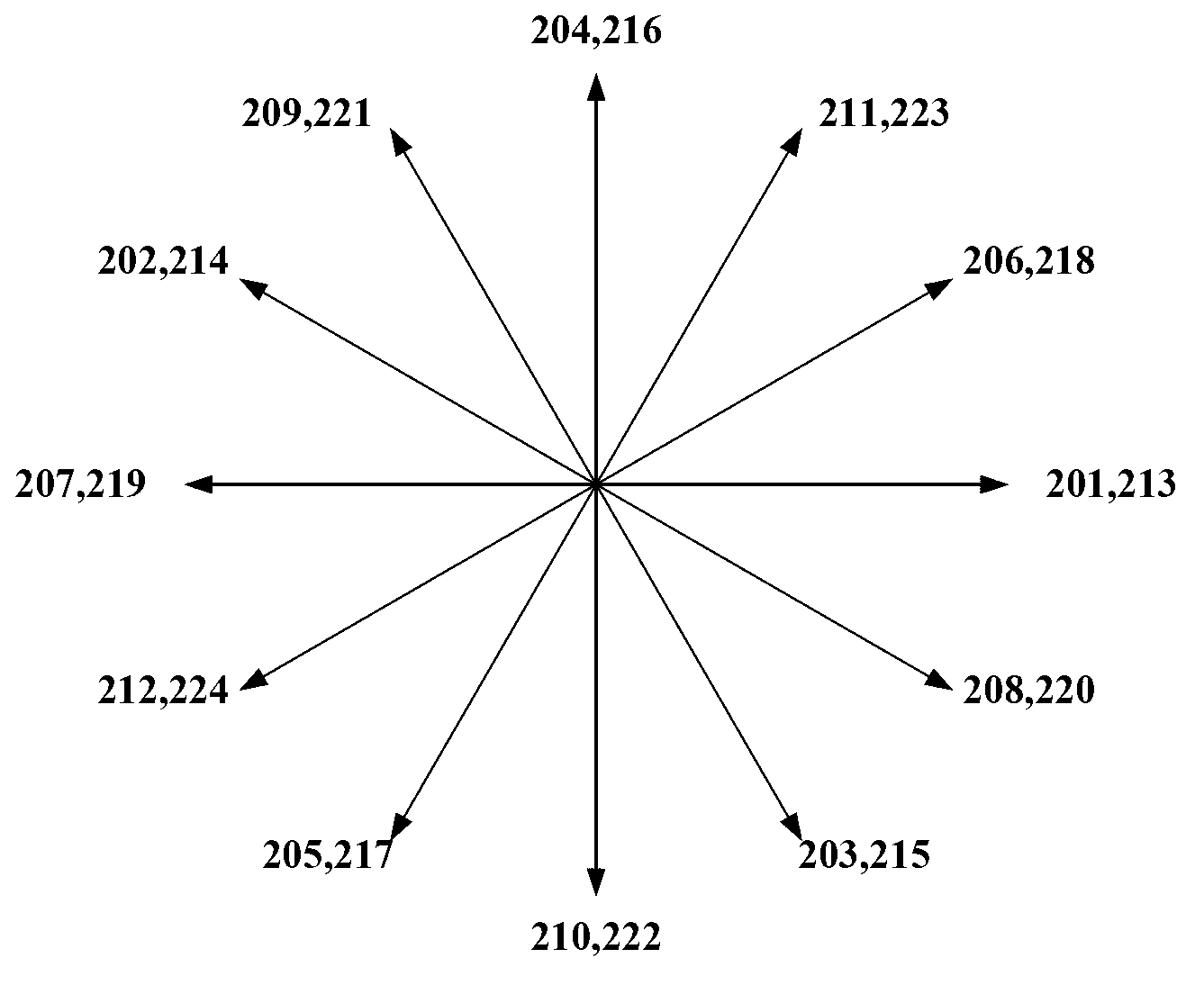

[0037] Taking a six-phase stator with 24 slots / rotor with 20 poles pure permanent magnet structure flux switching motor as an example, such as figure 1 As shown, the permanent magnet flux switching motor of the present invention includes a stator 1 , a concentrated armature winding 2 , a permanent magnet 3 , a rotor 4 and a rotating shaft 5 . Among them, the rotor 4 is located inside the stator 1 (it can also be made into an outer rotor structure), the stator 1 and the rotor 4 are both salient pole structures, and the stator part is composed of 24 "U" shaped stator cores and 24 alternating tangential charging poles. The magnetic permanent magnet and the six-phase symmetrical concentrated armature winding 2 are composed. The six-phase concentrated armature winding 2 includes a first concentrated armature coil 201, a second concentrated armature coil 202, a third concentrated armature coil 203, a fourth concentrated armature coil 204, a fifth concentrated armature coil 205, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com