Patents

Literature

37results about How to "Improve air gap flux density waveform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

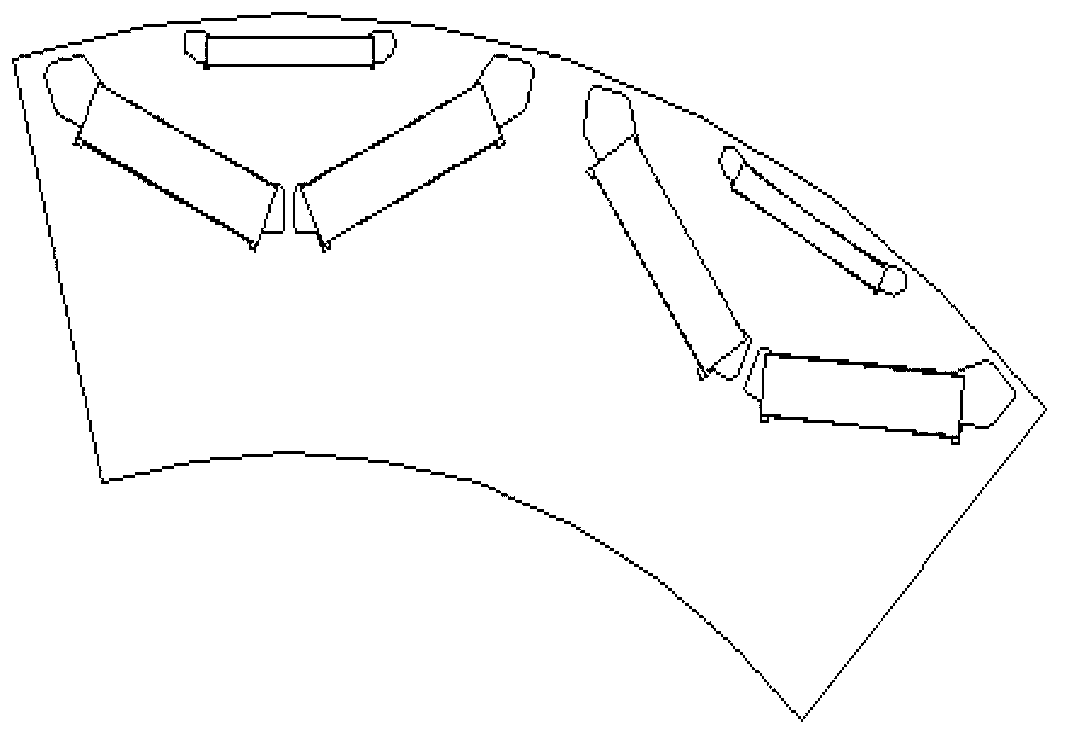

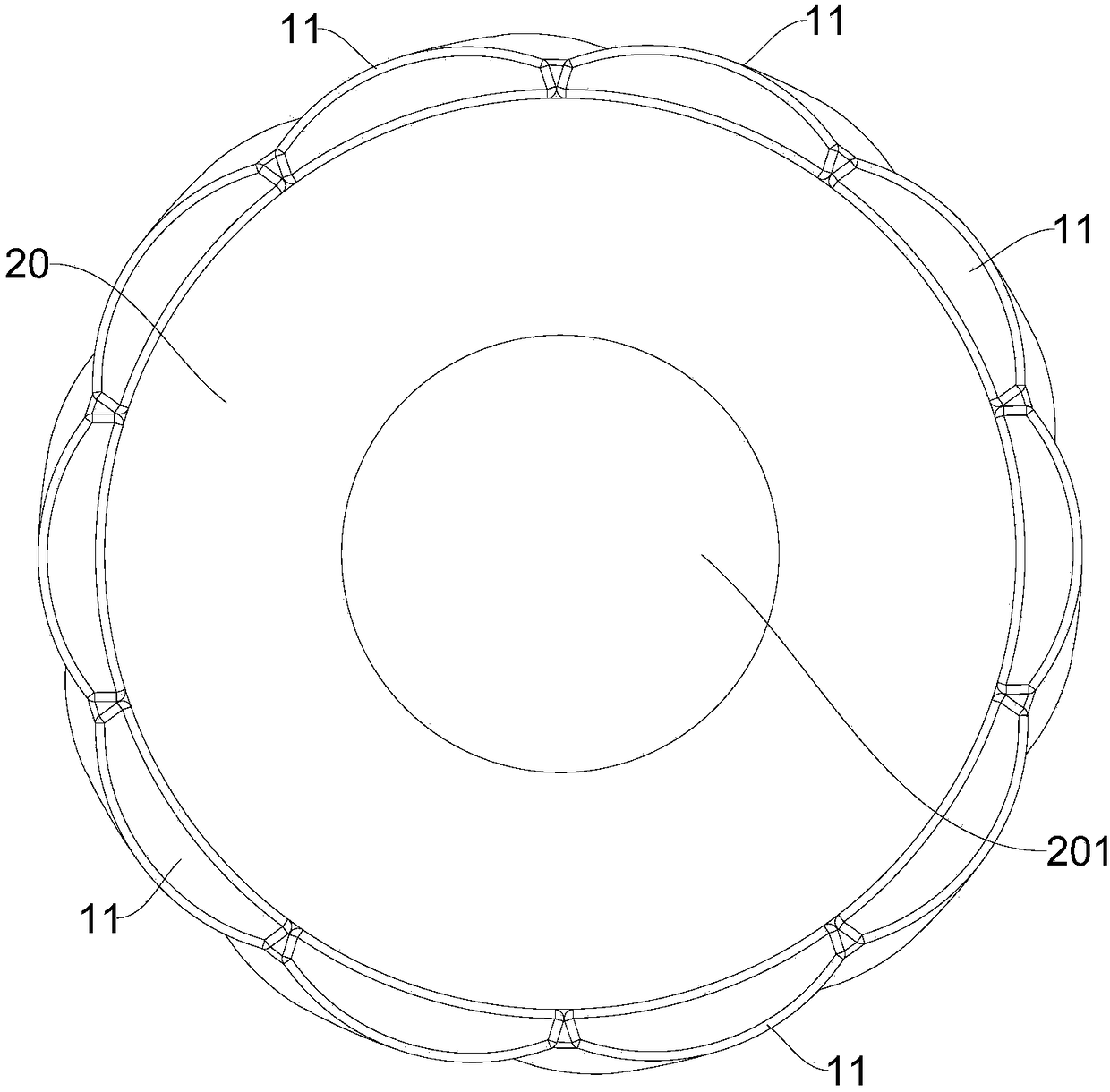

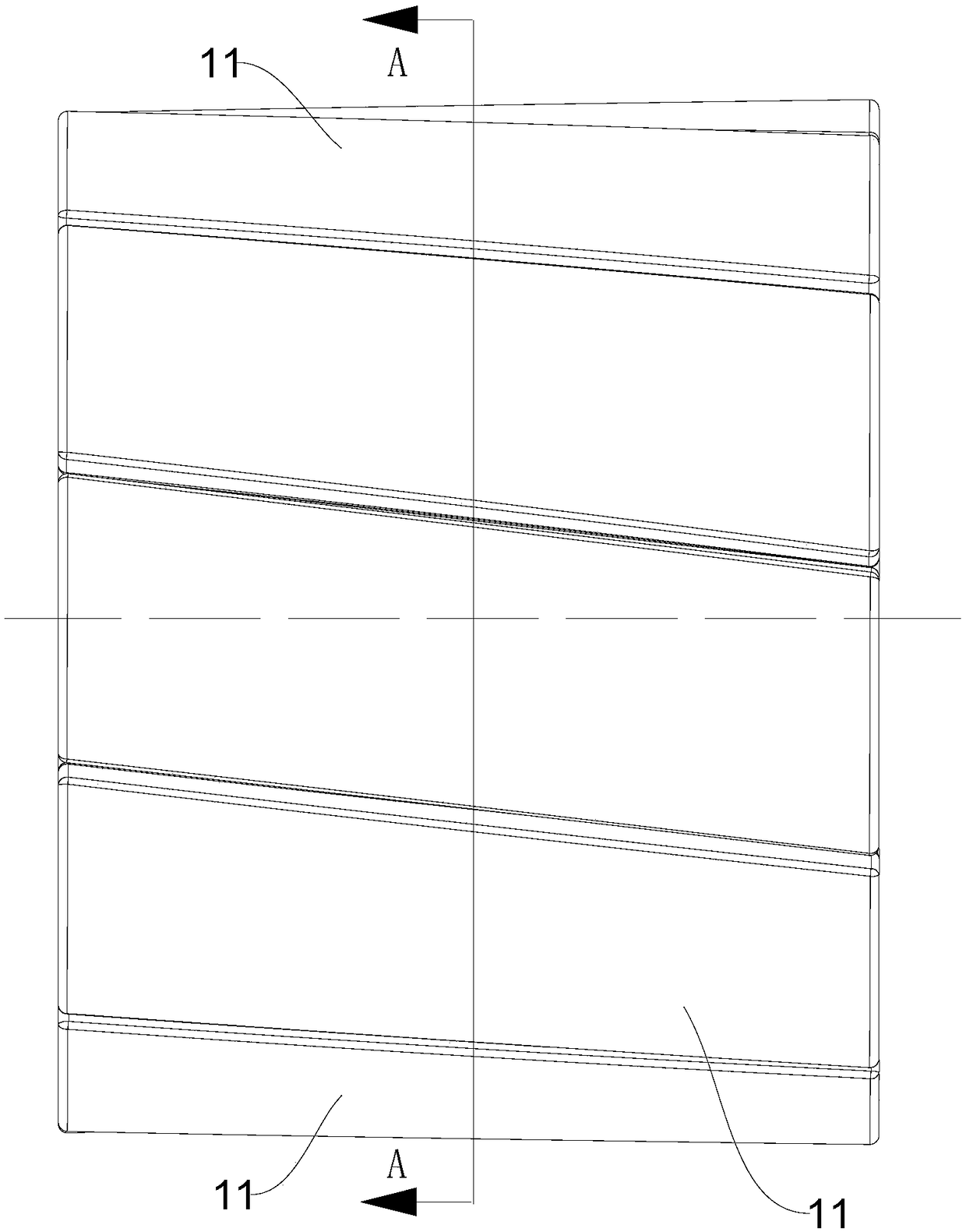

Magnetic pole structure of permanent magnet synchronous direct-driven motor and design method thereof

ActiveCN102545436AGuaranteed uptimeExtend working lifeMagnetic circuit rotating partsMagnetic polesPermanent magnet synchronous motor

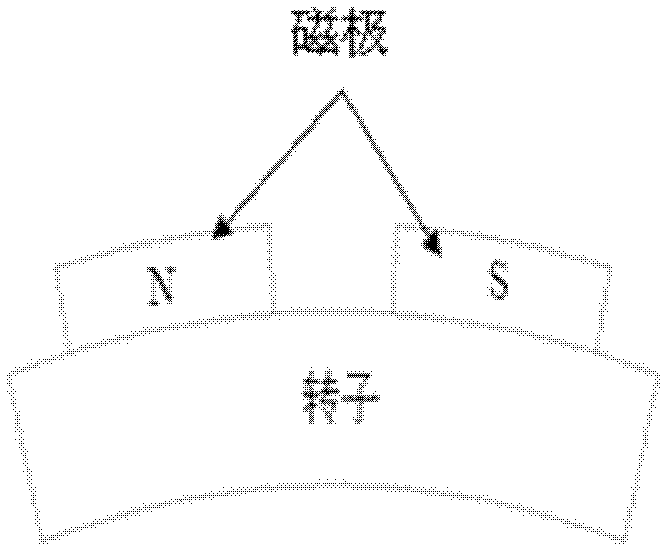

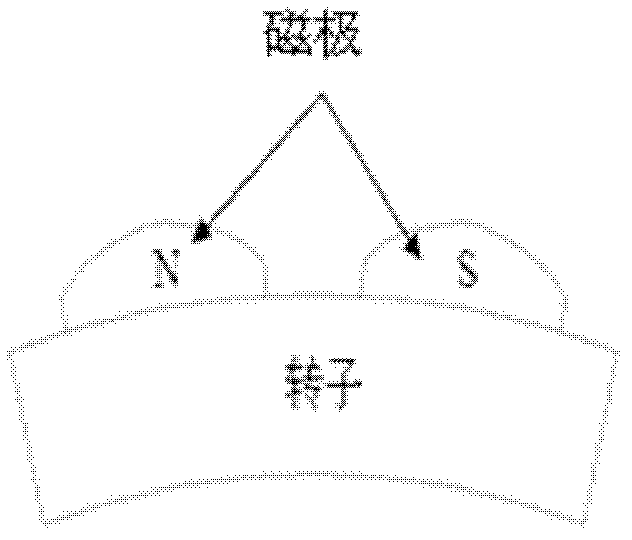

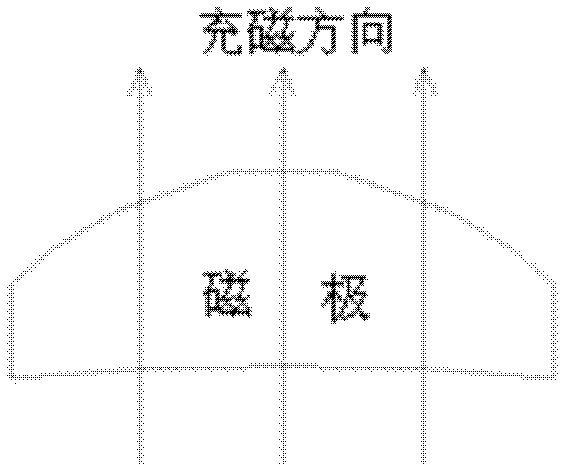

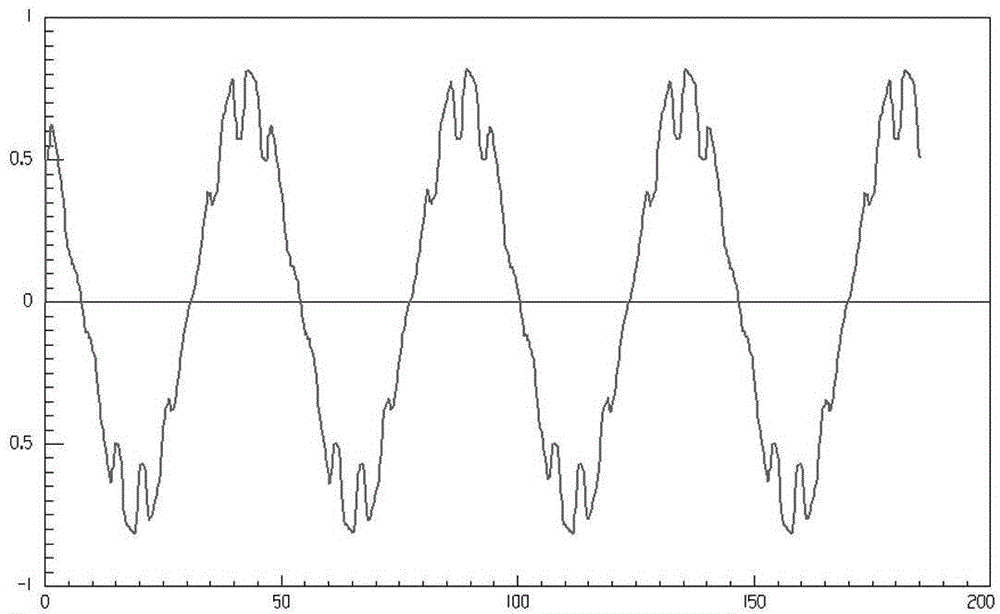

The invention relates to a magnetic pole structure of a permanent magnet synchronous direct-driven motor. The magnetic poles are embedded in the circumference of the surface of a rotor in a manner that an N pole and an S pole are alternated, and are opposite to a stator; and a layer of air gap is arranged between the stator and the rotor. The stator comprises an iron core and a winding; and the rotor is of a hollow shaft structure or a solid shaft structure. The magnetic poles of the rotor adopt the magnetic poles with unequal thicknesses, and are uniformly distributed around the surface of the rotor of the motor, so that a no-load magnetic flux density waveform of the air gap is approximate to a sine wave. According to the magnetic pole, a design idea of an inverse problem of an electromagnetic field is adopted, the centers of the magnetic poles with equal thickness are used as a symmetrical axial line, and the thicknesses on two ends of the magnetic poles are gradually reduced, so that an initial scheme of the magnetic poles with unequal thicknesses is obtained. Electromagnetic field software simulation is utilized to obtain the magnetic flux density waveform of the air gap, a fundamental wave and a harmonic component are analyzed, partial size of each magnetic pole is adjusted according to design requirements, and multiple replication is carried out until a design goal is optimized. Due to the adoption of the magnetic pole structure, the vibration and the noise of the permanent magnet synchronous direct-driven motor can be reduced.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

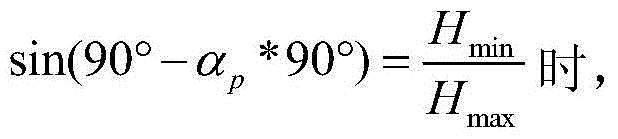

Dual-stator magnetism-gathering permanent magnet linear motor with concentrated winding of phase windings

ActiveCN110165852AImprove performanceReduce manufacturing costPropulsion systemsWindings conductor shape/form/constructionPermanent magnet linear motorMagnetization

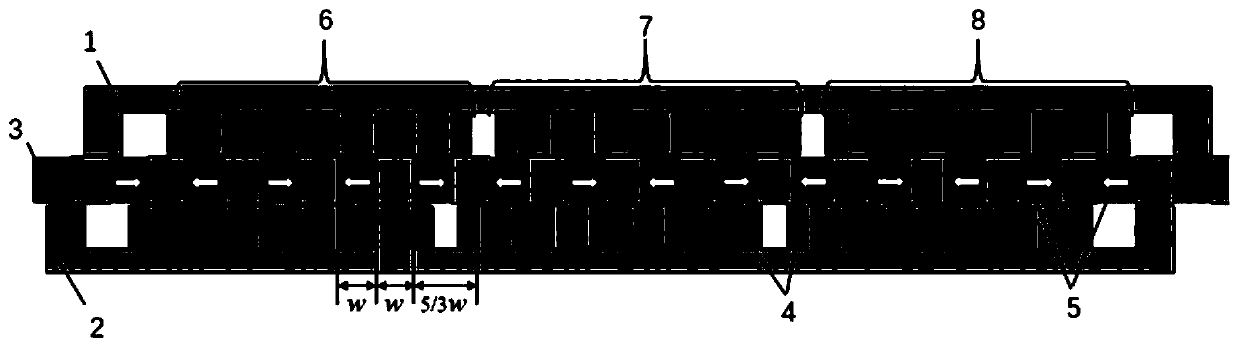

The invention provides a dual-stator magnetism-gathering permanent magnet linear motor with concentrated winding of phase windings, which comprises a mover and two single-sided stators arranged at twosides of the mover face to face, wherein the mover is a magnetism-gathering permanent magnet mover structure, permanent magnets are horizontally magnetized along the movement direction of the mover,and two adjacent permanent magnets are opposite in magnetization direction; at least one of the single-sided stators is provided with windings and has a mode of concentrated winding of the phase windings. Each single-sided stator is a certain air gap distance away from the mover, the two air gap distances are equal, and the two single-sided stators has an offset of one stator tooth width along themovement direction of the mover. The permanent magnet linear motor provided by the invention has high power density and output thrust, and effectively suppresses the magnetic resistance and thrust fluctuation.

Owner:SHANDONG UNIV

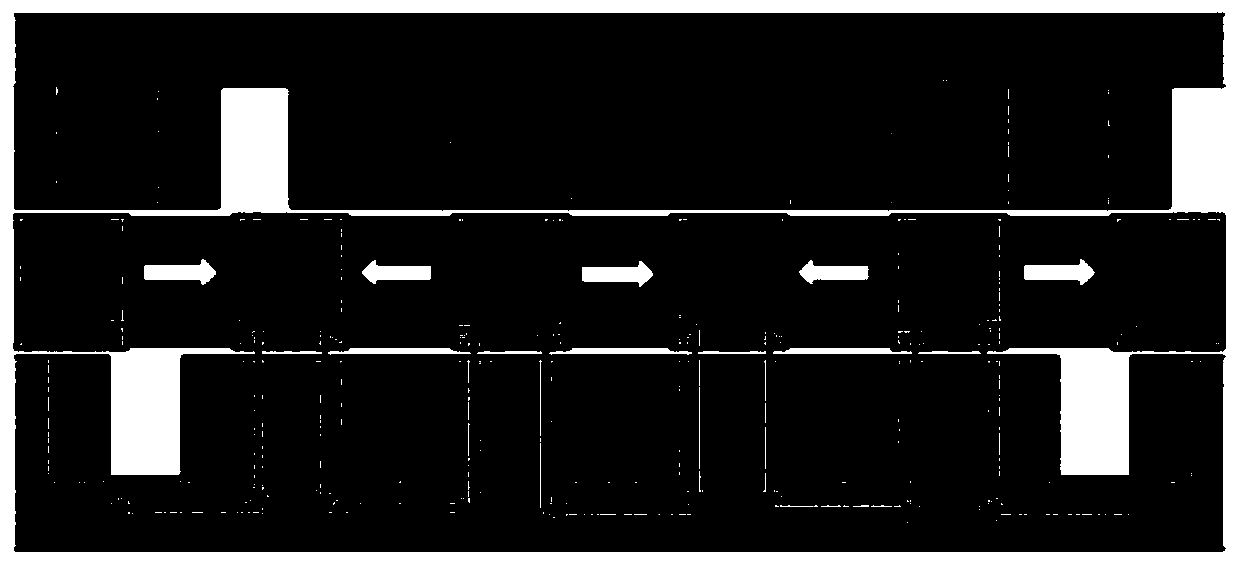

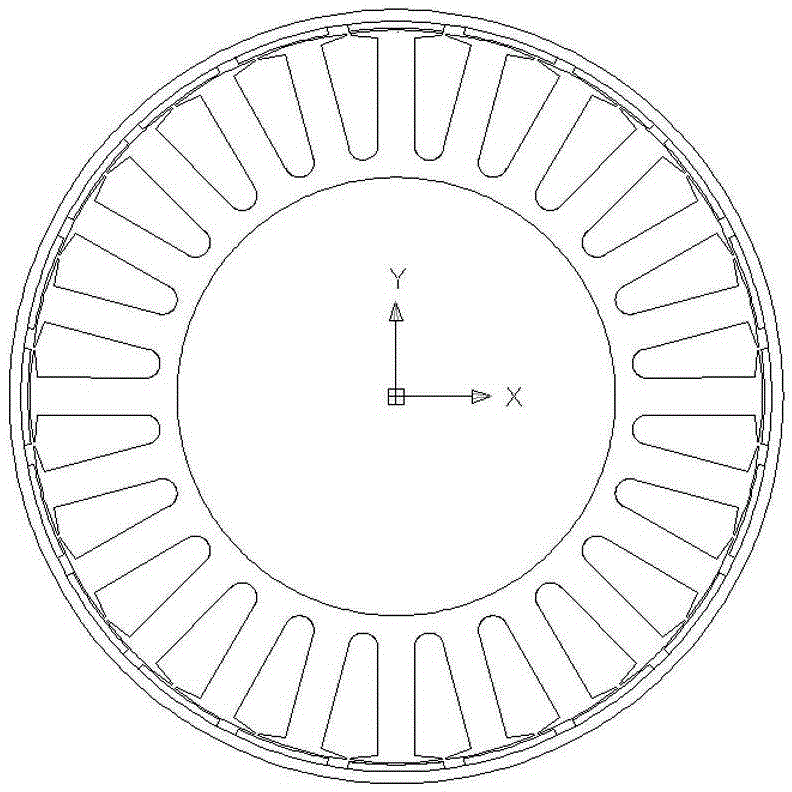

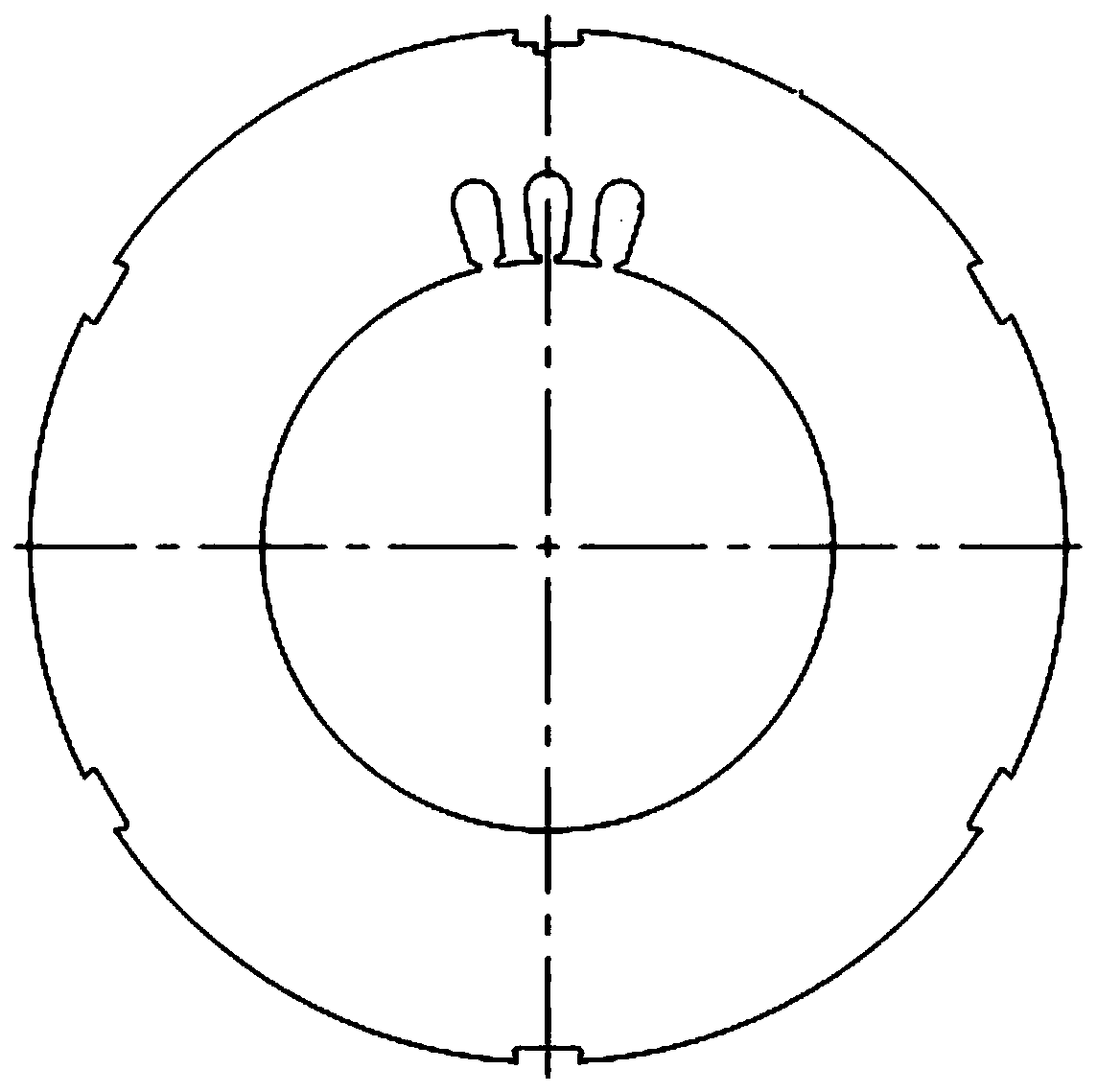

Stator punching structure of permanent magnet motor

InactiveCN104410236AReduce distortion rateImprove performanceMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsElectric machineEngineering

The invention mainly relates to a stator punching structure of a permanent magnet motor, and belongs to the technical field of permanent magnet motors. The air-gap magnetic flux density waveforms are optimized by cutting angles from two ends of a stator tooth; the ratio of a distance between two start points of each cut angle at a tooth part to the angle and the ratio of each stator tooth to the angle are set within a range of 0.4-0.6; the angle theta of each cut angle is set within a range of 5-15 degrees. According to the structure, the harmonic content of the air-gap magnetic flux density is reduced, loss and vibration noise of the motor are reduced, and the performance of the motor is improved. The punching structure is simple, is convenient to manufacture, is lower in cost and is suitable for popularization and application.

Owner:SHENYANG POLYTECHNIC UNIV

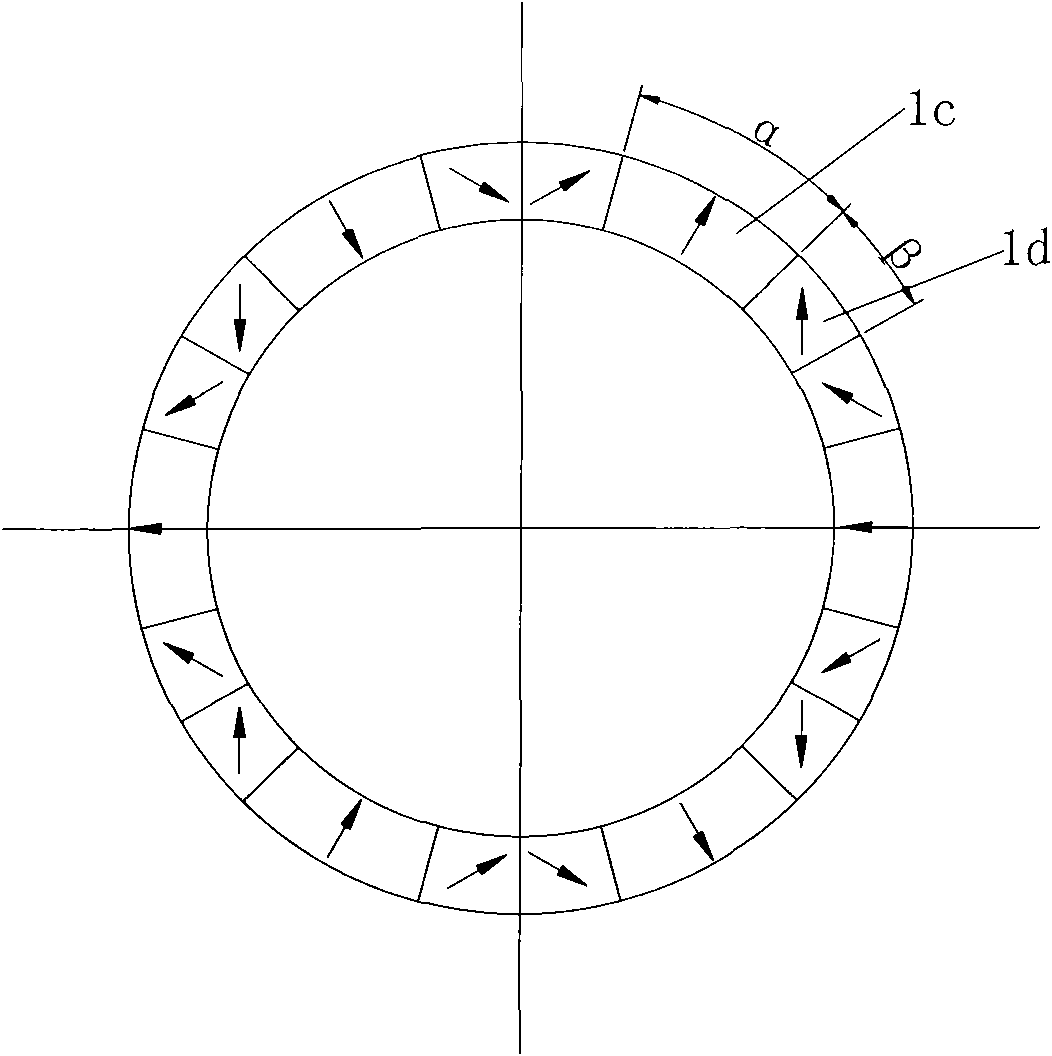

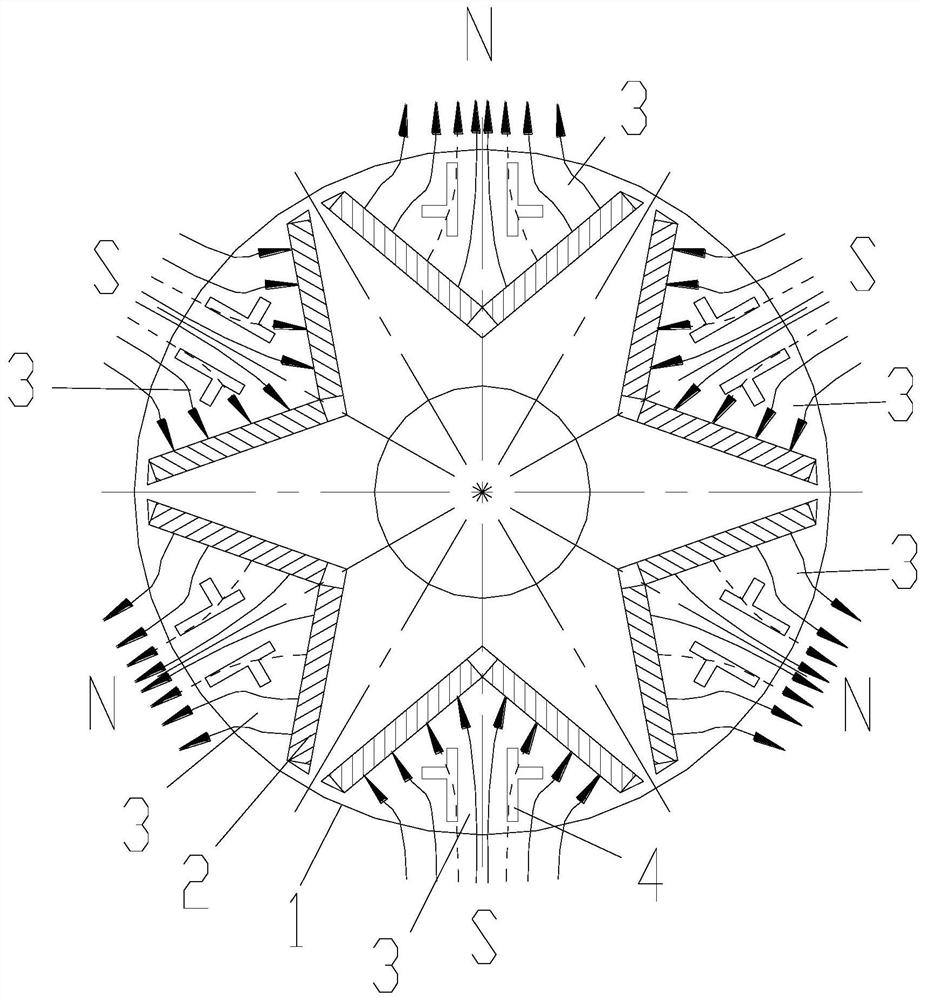

High-precision low-fluctuation permanent magnetic brushless servomotor for solar tracking system

InactiveCN101572468AHigh precisionImprove overload capacityMagnetic circuit rotating partsLight radiation electric generatorLow noiseMagnetic poles

The invention relates to a high-precision low-fluctuation permanent magnetic brushless servomotor for a solar tracking system, which comprises a machine shell as well as a stator and a rotor in the machine shell, wherein the stator comprises a stator core fixed on the inner wall of the machine shell and a stator winding; the rotor comprises a main shaft and a rotor core; the outer circumference of the rotor core is sleeved with an annular magnetic pole consisting of radial magnetized magnetic steels which are evenly arranged along the circumferential direction and adjacent oblique angled magnetized magnetic steels; one radial magnetized magnetic steel and two adjacent oblique angled magnetized magnetic steels in the annular magnetic pole form a rotor magnetic pole; the radial magnetized magnetic steels are main magnetic poles; and the two adjacent oblique angled magnetized magnetic steels on both sides are auxiliary magnetic poles. Radial and oblique angled mixed anisotropic magnetized magnetic poles in the annular magnetic pole of the rotor ensure that the motor can also remarkably improve air gap flux density waveform of the motor even if the even air gap is adopted, obtain a sinewave magnetic field, does not reduce power output, can also reduce moment fluctuation, and improve the precision of the solar tracking system. The motor can perform steady operation with high efficiency, low fluctuation, low noise, quick response and high precision.

Owner:苏州工业园区美能新能源有限公司 +1

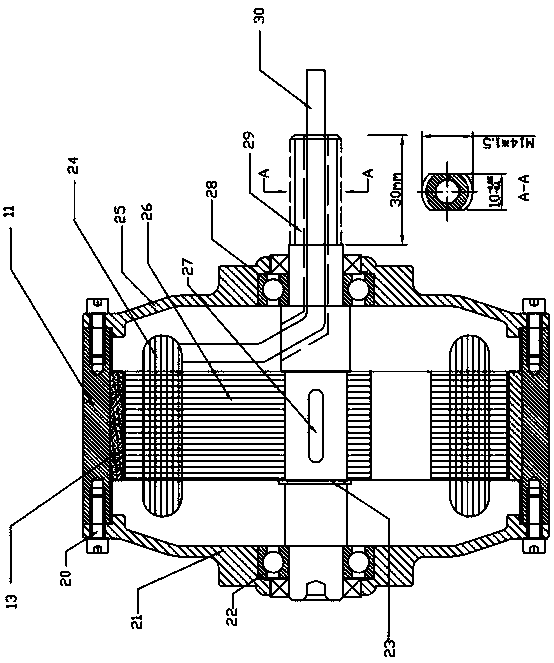

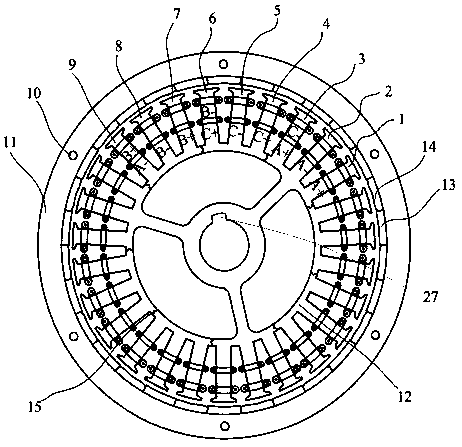

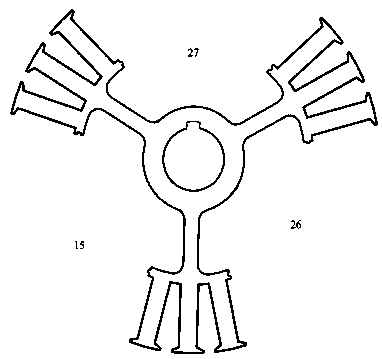

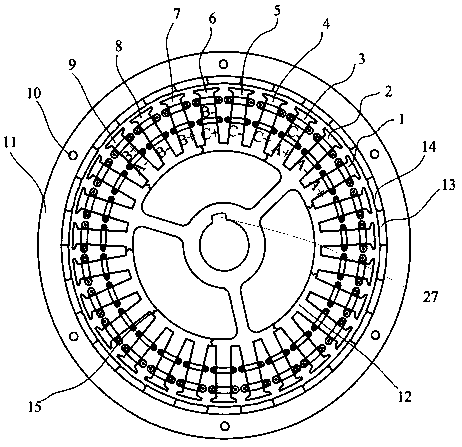

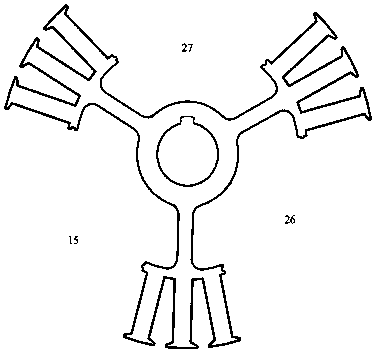

Winding misaligned hub motor stator and winding misaligned hub motor device

ActiveCN108768016AEase of mass productionEasy to assembleMagnetic circuit rotating partsMagnetic circuit stationary partsHarmonicThree-phase

The invention relates to a winding misaligned hub motor device, comprising a stator core and a rotor core disposed on the periphery of the stator core, wherein the stator core comprises a plurality ofmodular stator cores, each modular stator core comprises a middle tooth and two side teeth respectively located on two sides of the middle tooth, the plurality of modular stator cores are connected to each other along the circumference to form a plurality of teeth arranged along the circumference, the stator core is provided with three-phase dislocation windings, the winding mode of the three-phase dislocation windings is that the adjacent three modular stator cores are grouped, the windings on one or the two side teeth of the same position in each modular stator core in each group are woundby a plurality of layers, the side teeth having a plurality of layers of wound windings are wound with current phase winding and the phase windings on adjacent modular stator cores, and the other teeth are provided with single phase windings. The invention is capable of improving the electromagnetic characteristics of the motor output by weakening the even harmonics induced by the continuous polemagnetic imbalance in the back electromotive force and reducing the torque ripple.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

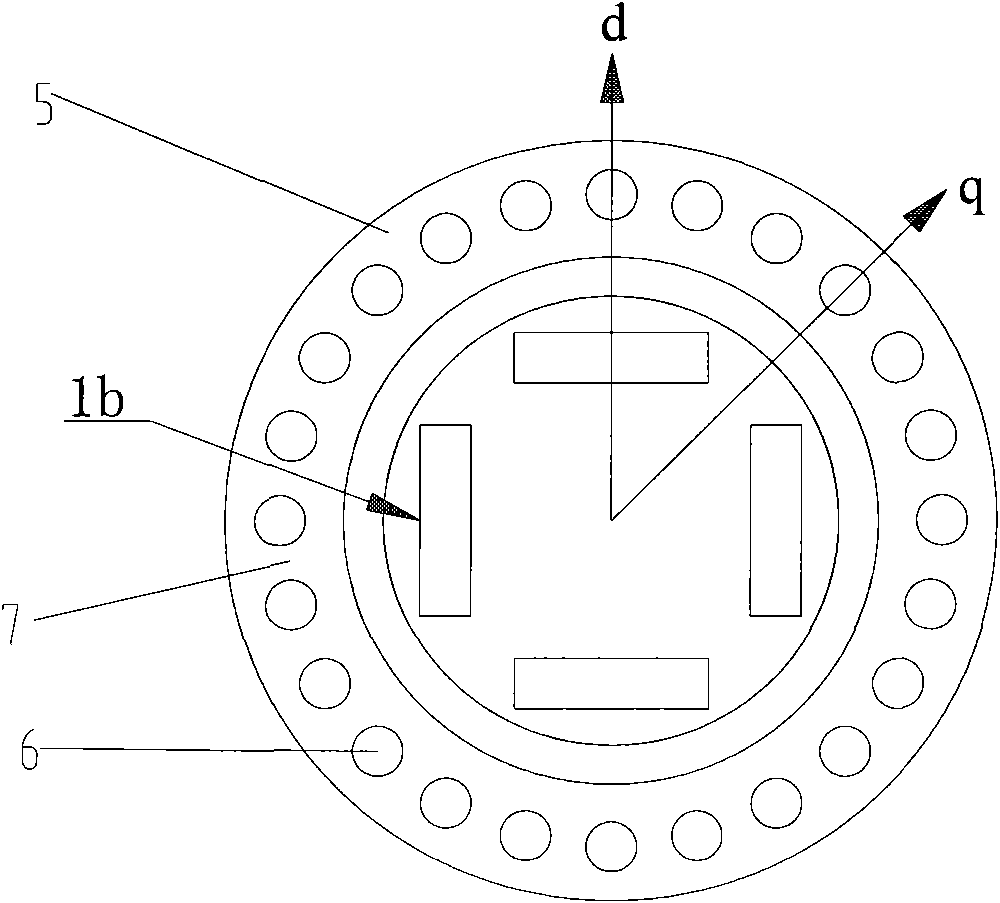

Built-in permanent magnet synchronous motor

ActiveCN103078464AImprove qualityImprove air gap flux density waveformMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsBand shapePermanent magnet synchronous motor

The invention discloses a built-in permanent magnet synchronous motor, relates to the technical field of a motor and aims to solve the technical problem of improving the comprehensive quality of the motor. Multiple permanent magnet slots are axially and symmetrically arranged in a rotor of the motor along the central axis of the rotor at intervals, three permanent magnets distributed in an arc band shape are arranged in each permanent magnet slot, wherein one permanent magnet is a middle steel magnet, and the other two permanent magnets are side steel magnets; the built-in permanent magnet synchronous motor is characterized in that each middle steel magnet adopts the normal magnetization vertical to the surface of the steel magnet, and each two side steel magnets in one slot adopt the non-normal magnetization, so that the arc center of a magnet arrangement arc of each permanent magnet slot is enabled not to coincide with the magnetization orientation point of permanent magnets in the corresponding permanent magnet slot. According to the motor provided by the invention, the comprehensive quality of the motor is greatly improved.

Owner:SHANGHAI TOP MOTOR +2

Stator of a winding dislocation hub motor and a winding dislocation hub motor device

ActiveCN108768016BEase of mass productionEasy to assembleMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineEngineering

The invention relates to a winding misaligned hub motor device, comprising a stator core and a rotor core disposed on the periphery of the stator core, wherein the stator core comprises a plurality ofmodular stator cores, each modular stator core comprises a middle tooth and two side teeth respectively located on two sides of the middle tooth, the plurality of modular stator cores are connected to each other along the circumference to form a plurality of teeth arranged along the circumference, the stator core is provided with three-phase dislocation windings, the winding mode of the three-phase dislocation windings is that the adjacent three modular stator cores are grouped, the windings on one or the two side teeth of the same position in each modular stator core in each group are woundby a plurality of layers, the side teeth having a plurality of layers of wound windings are wound with current phase winding and the phase windings on adjacent modular stator cores, and the other teeth are provided with single phase windings. The invention is capable of improving the electromagnetic characteristics of the motor output by weakening the even harmonics induced by the continuous polemagnetic imbalance in the back electromotive force and reducing the torque ripple.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

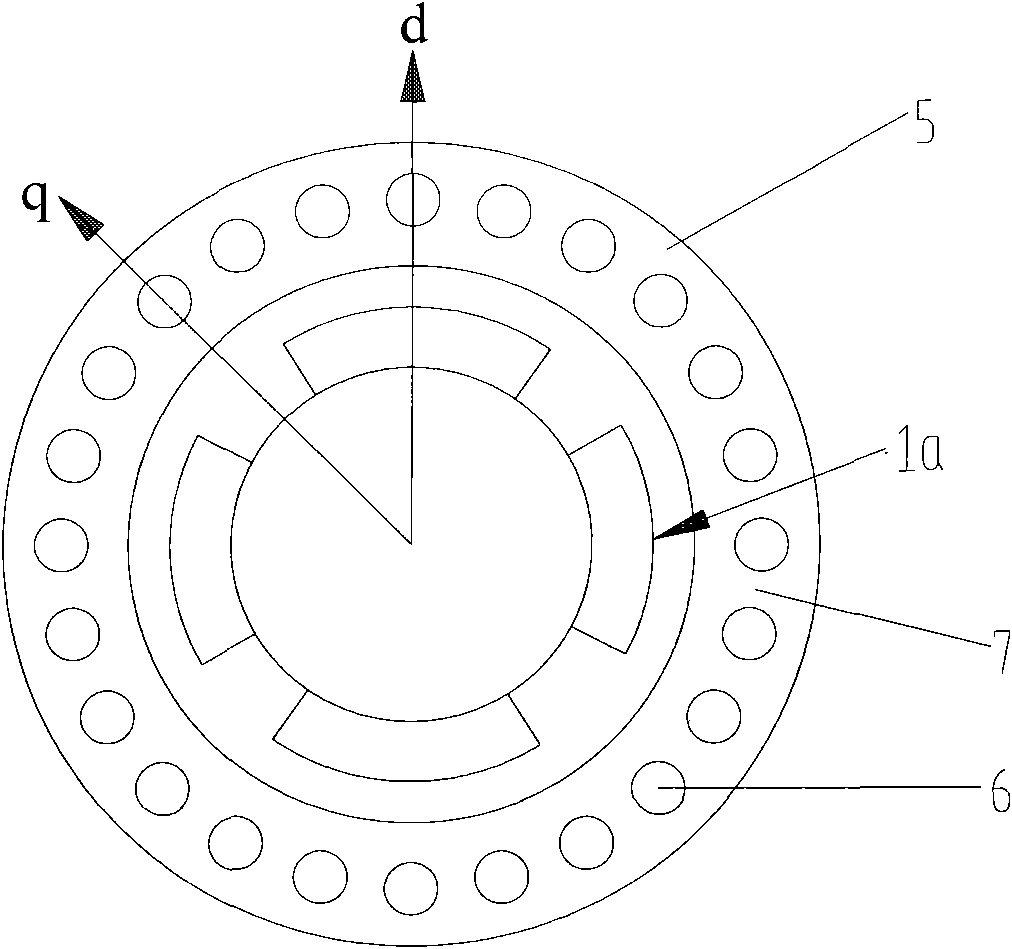

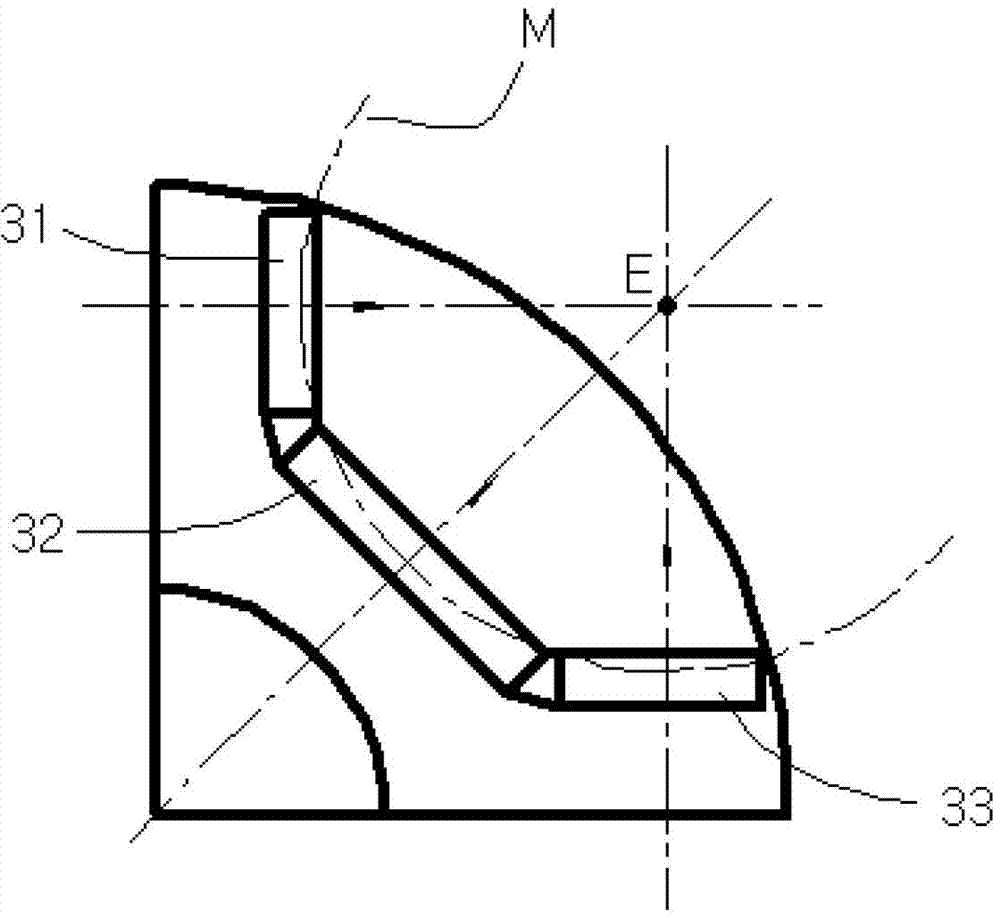

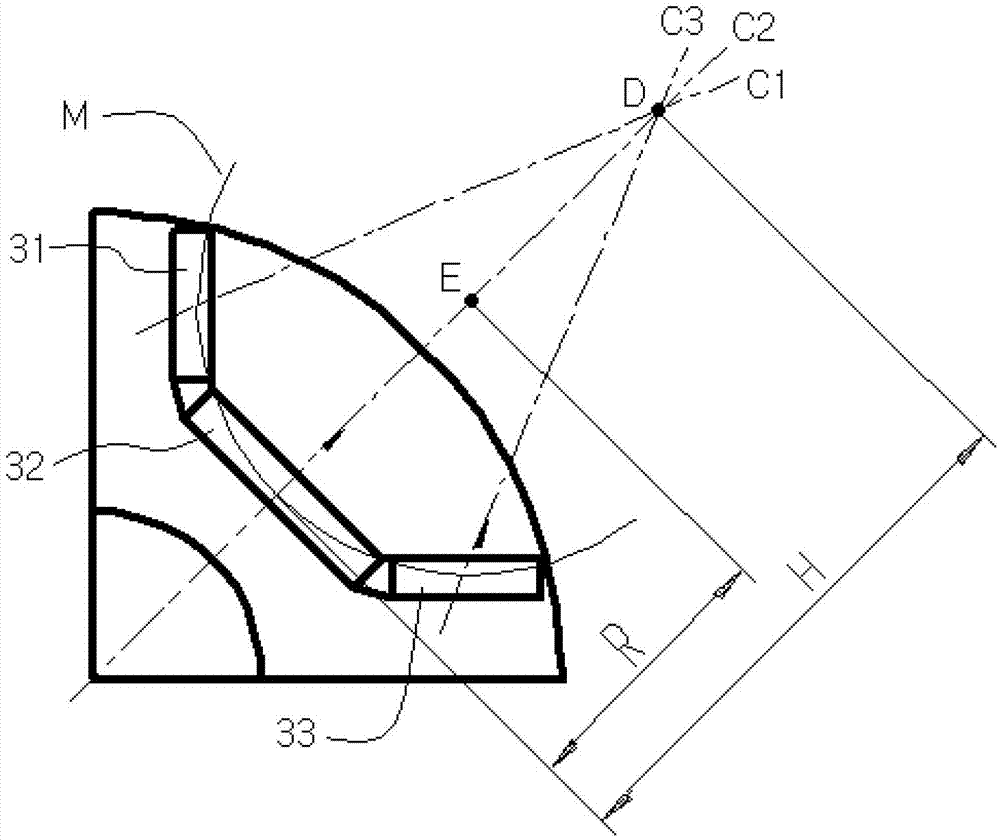

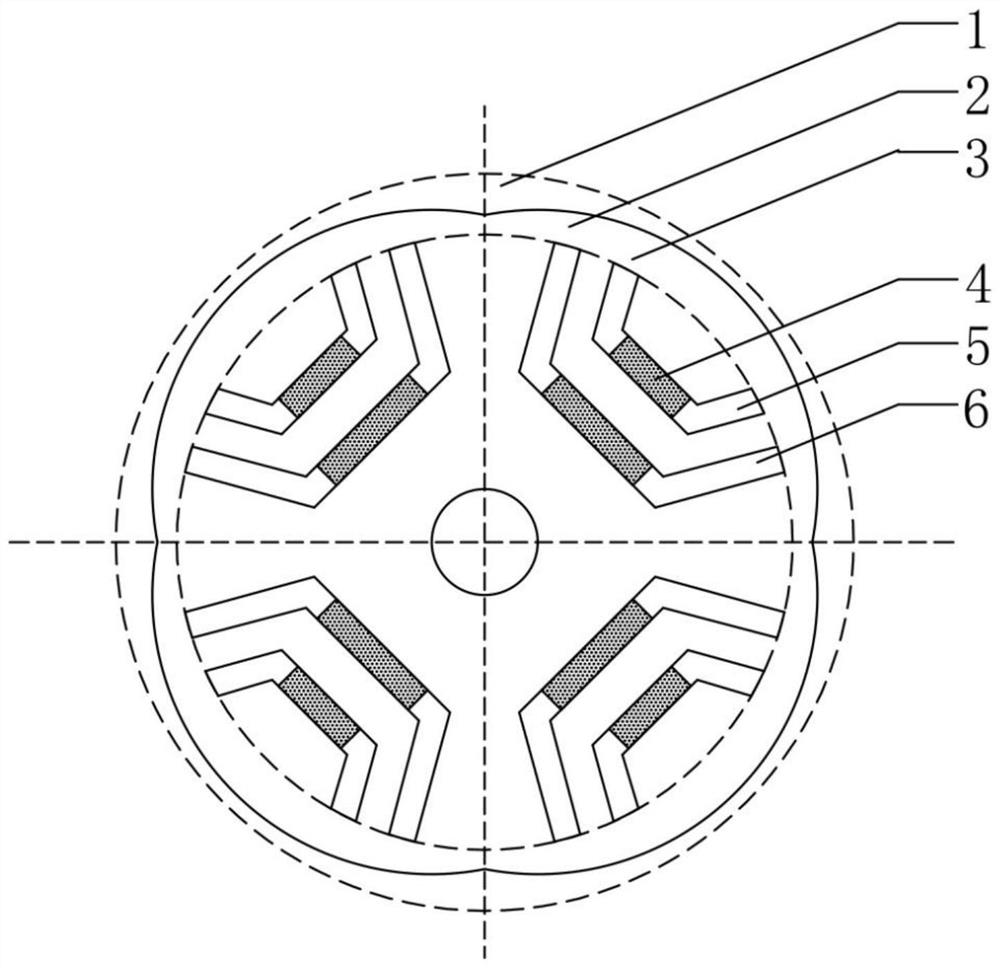

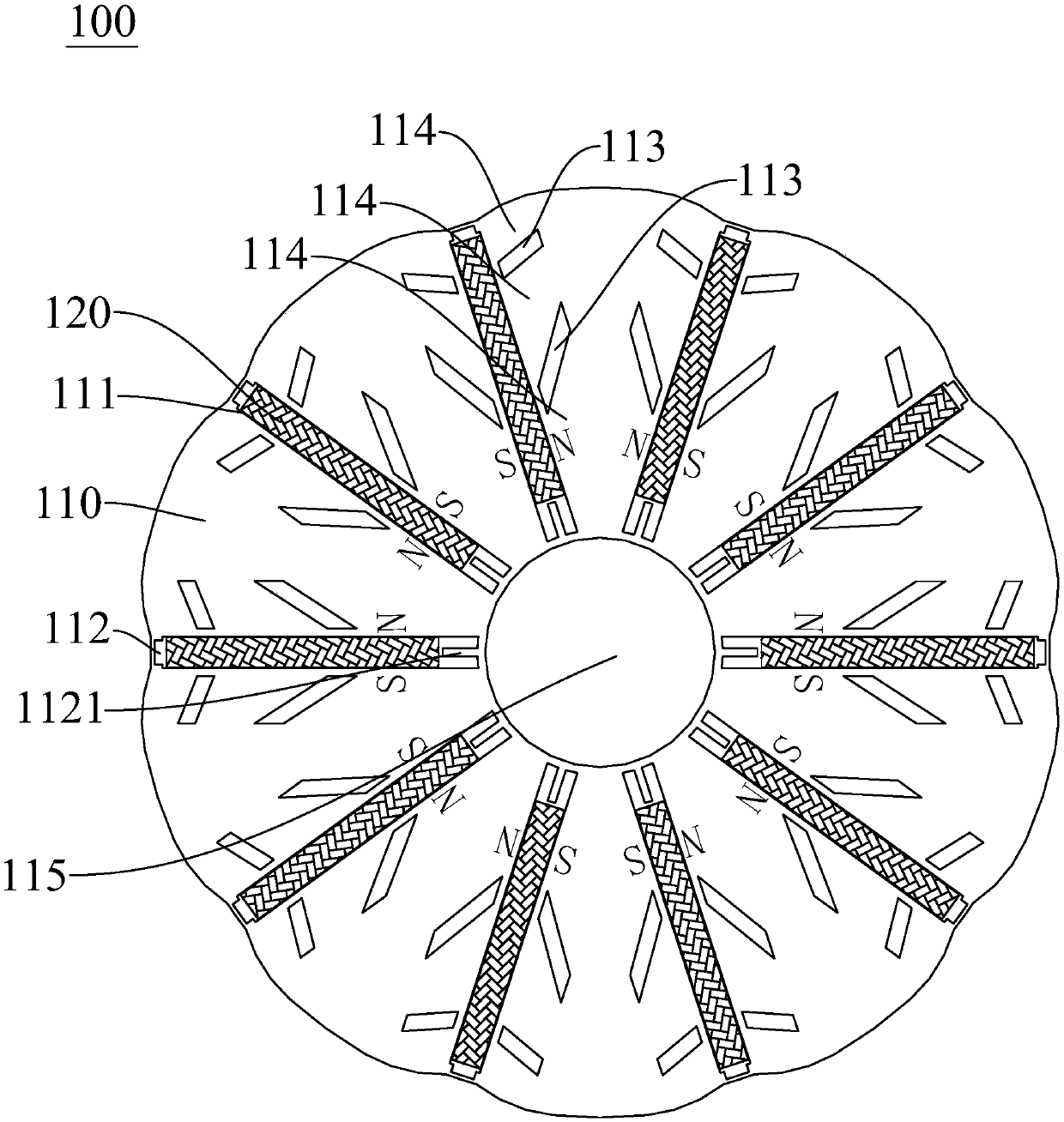

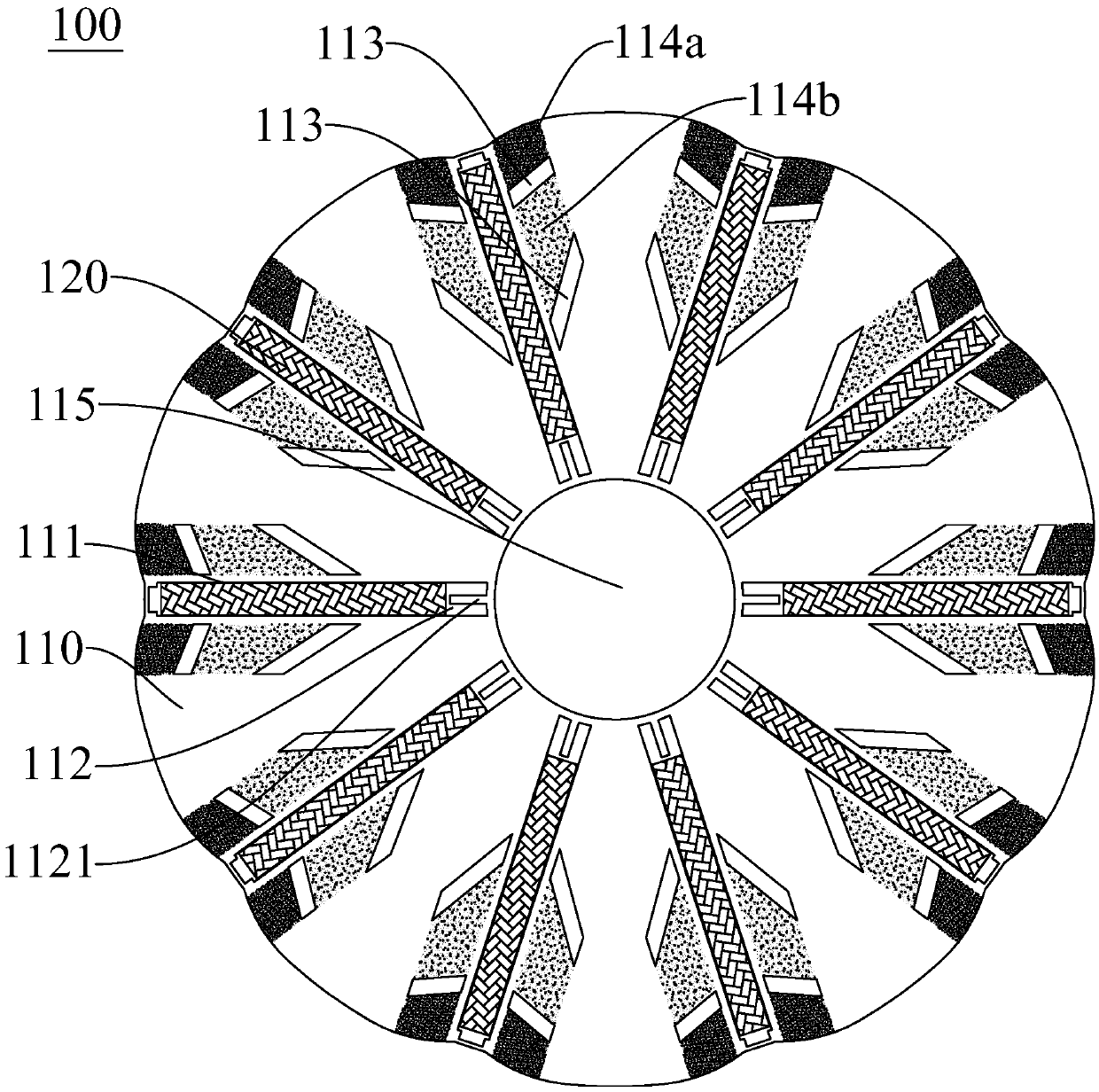

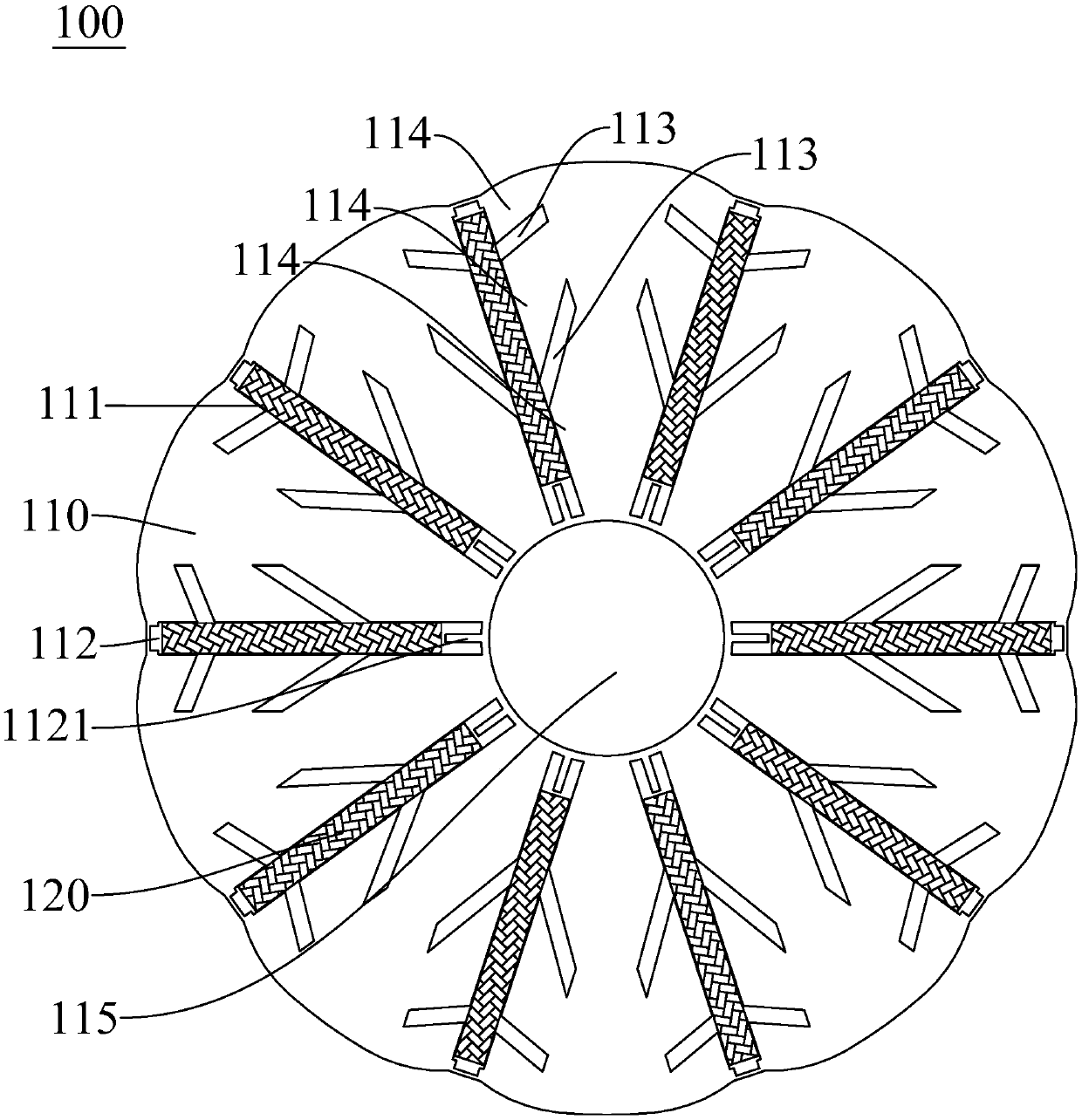

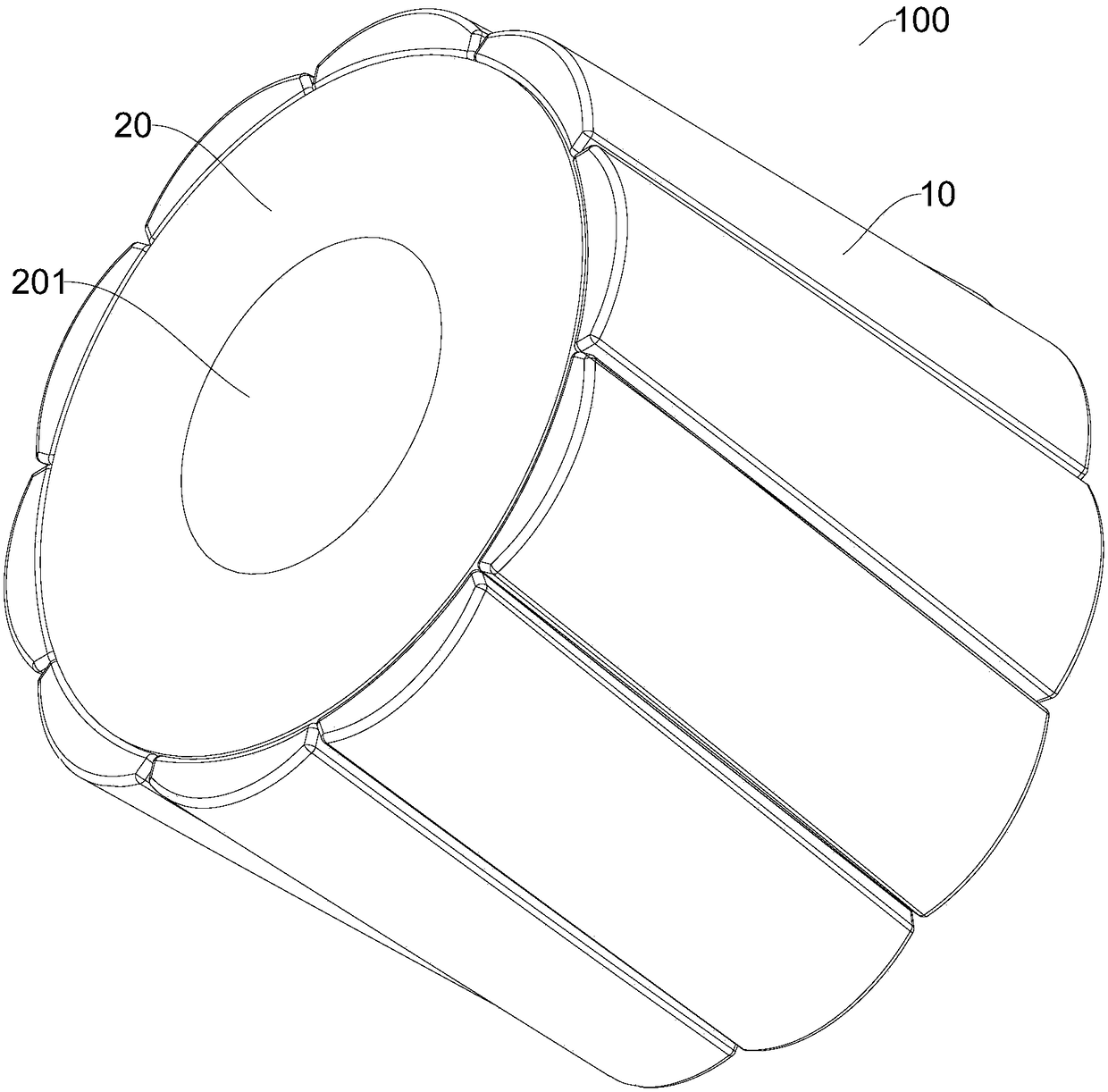

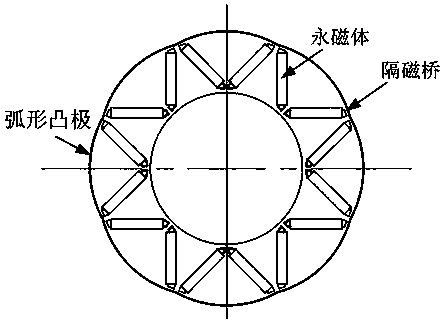

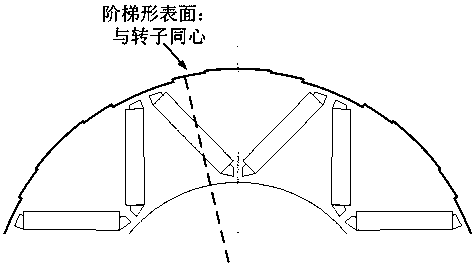

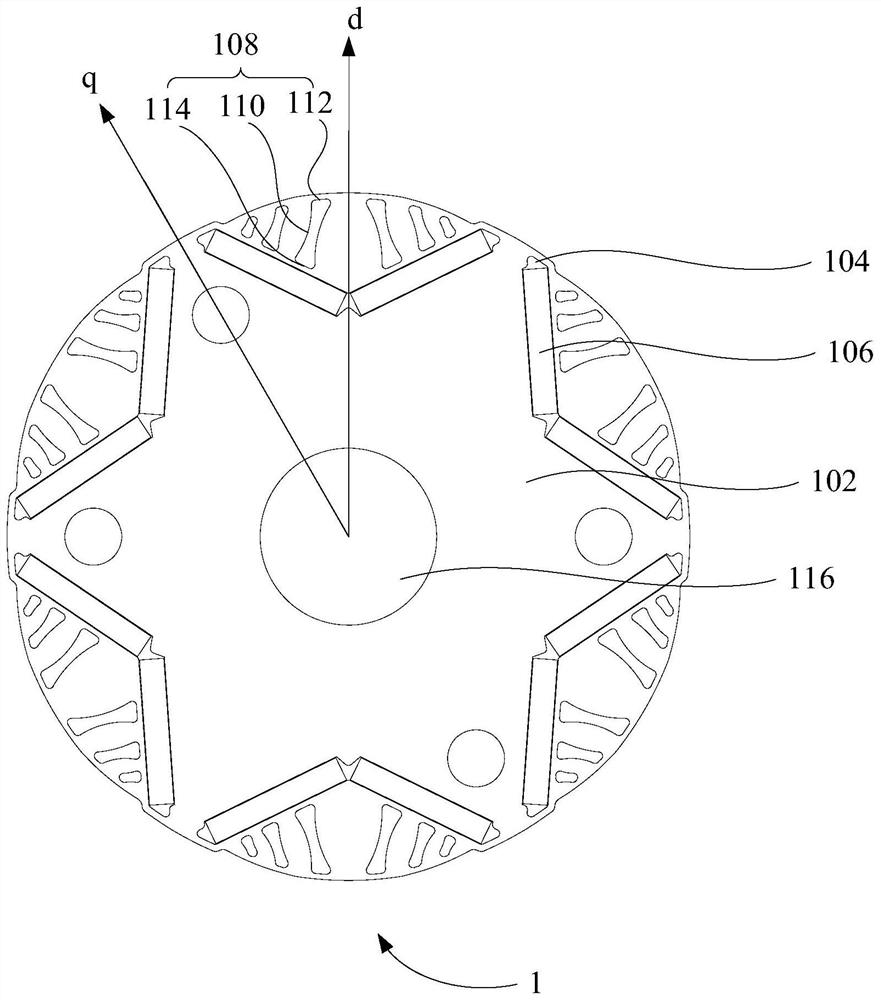

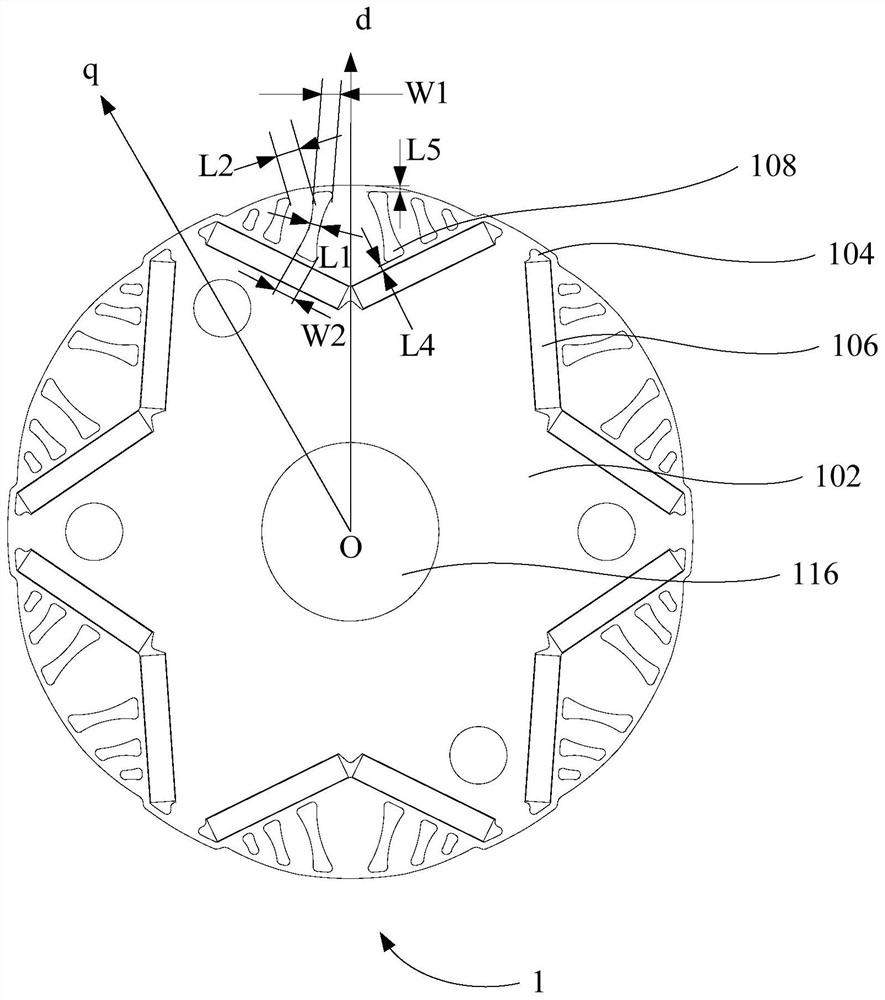

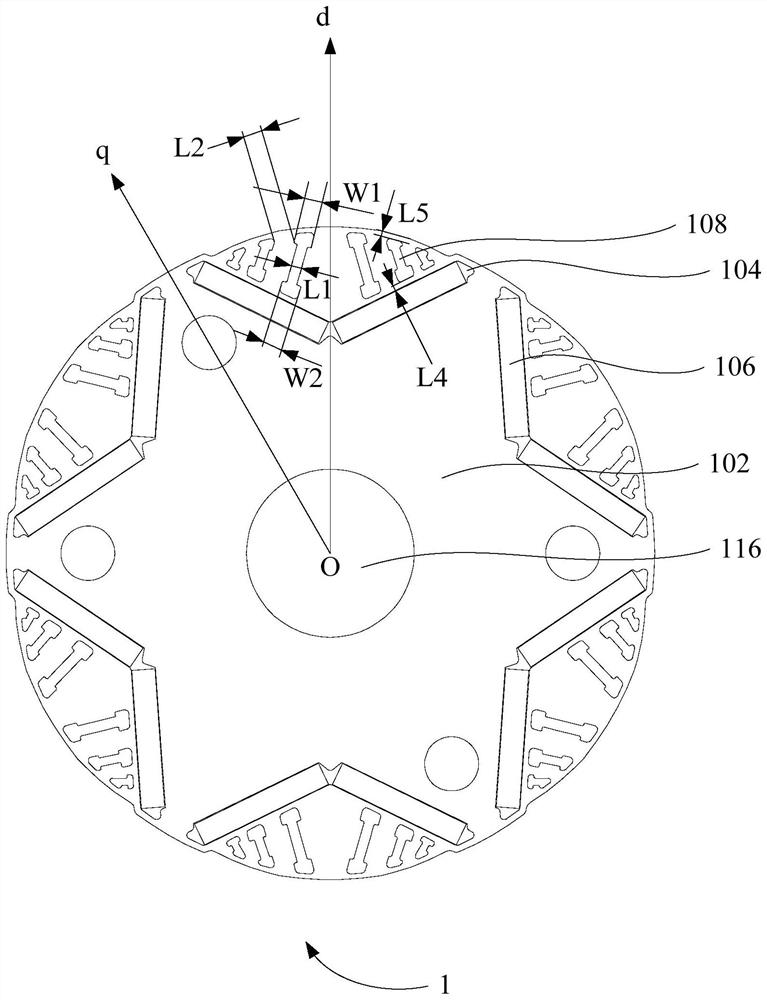

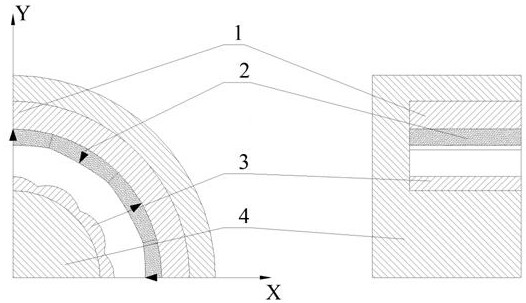

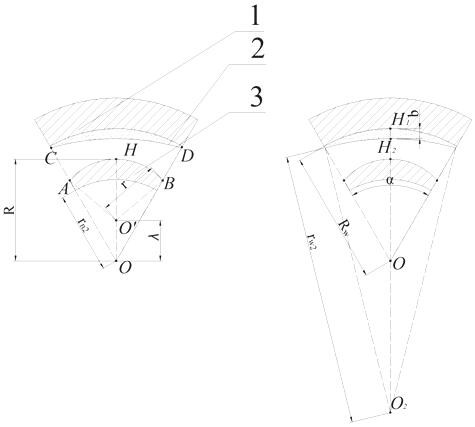

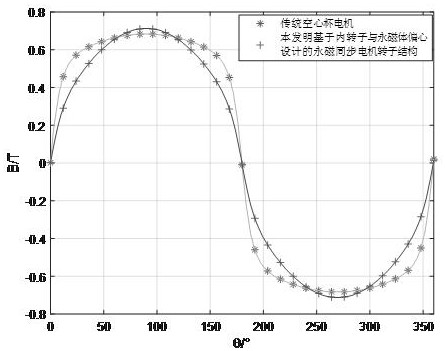

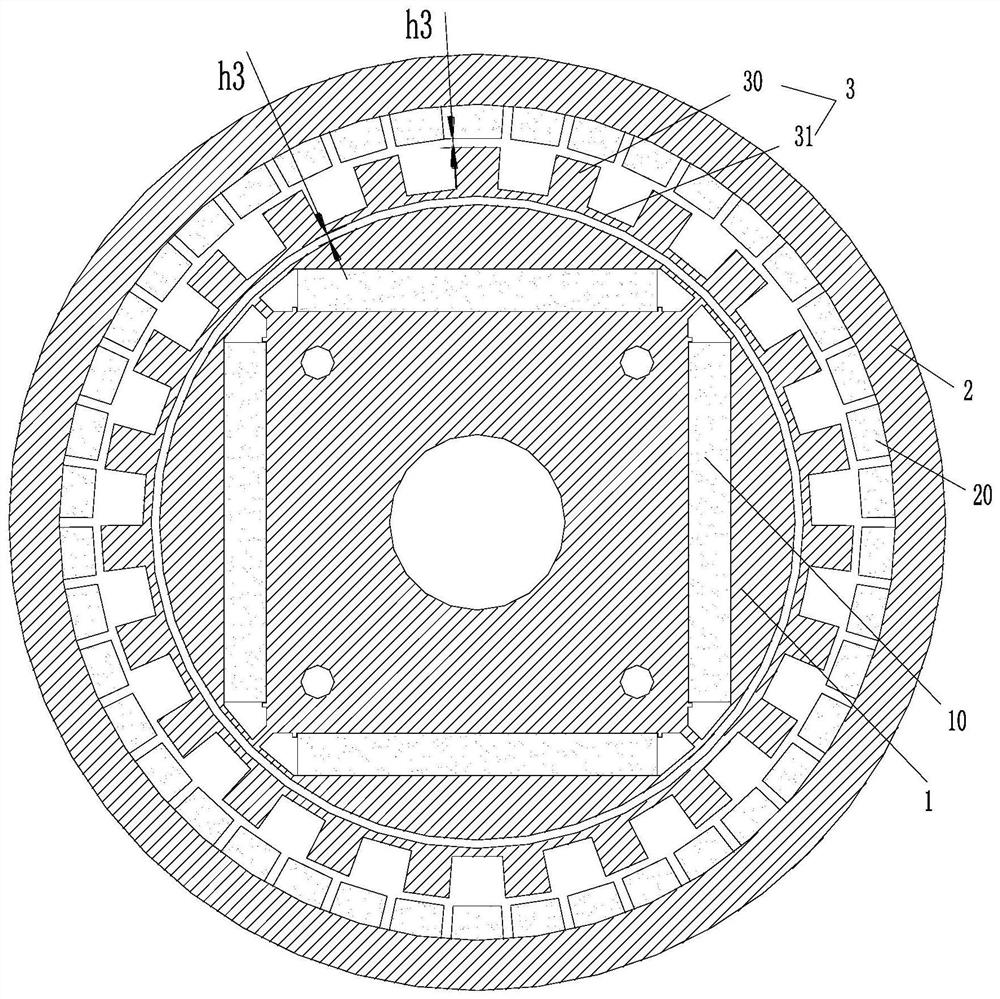

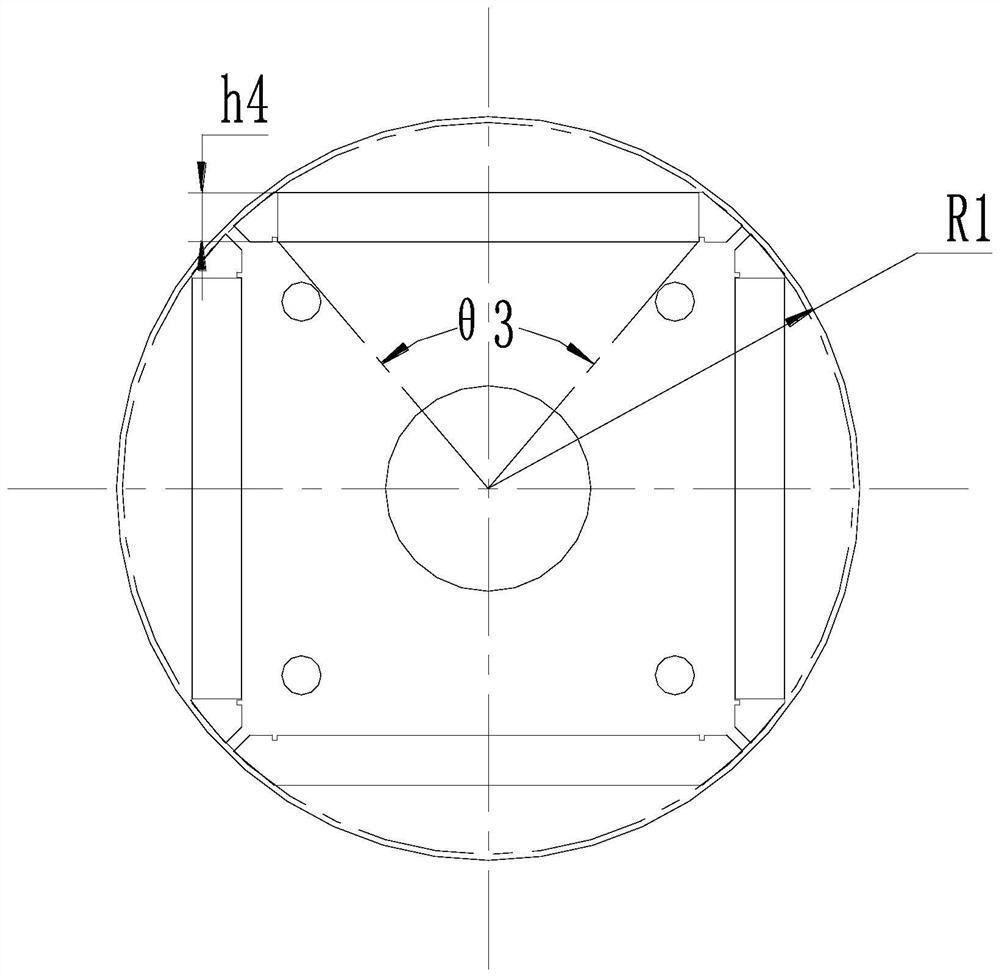

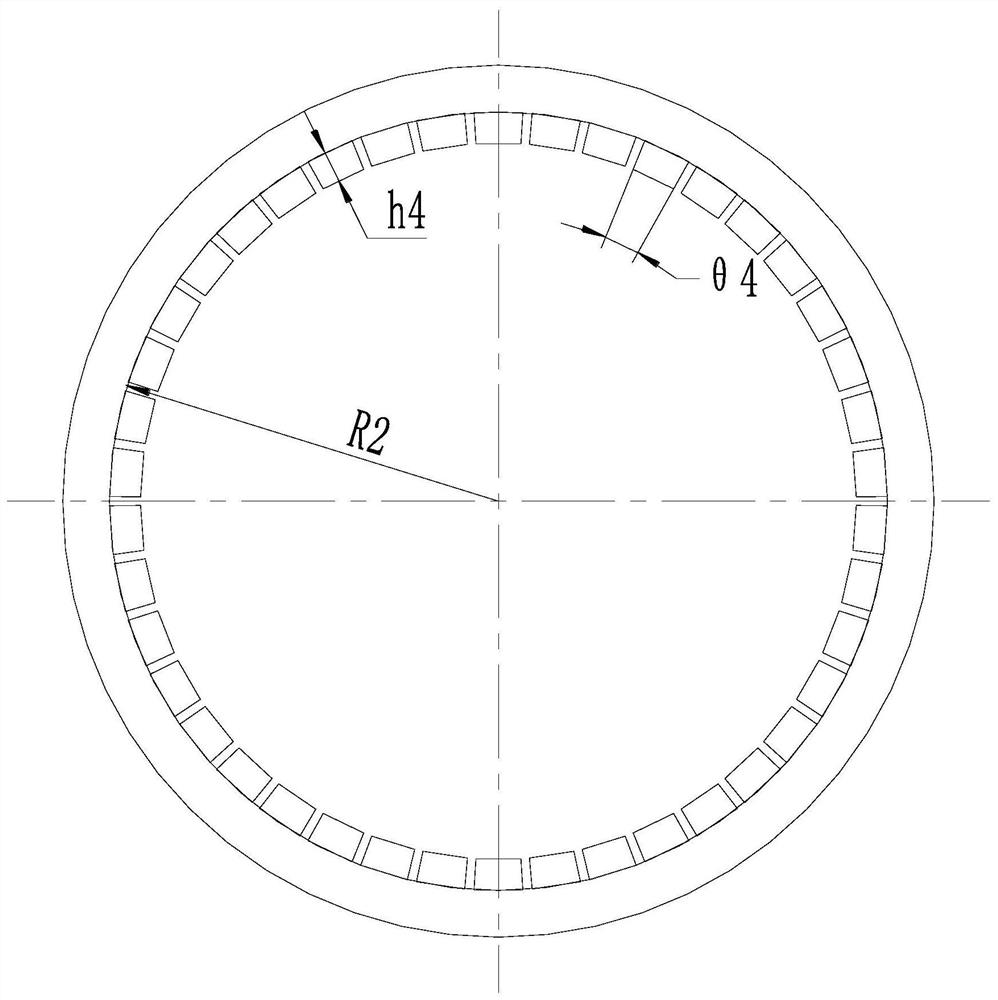

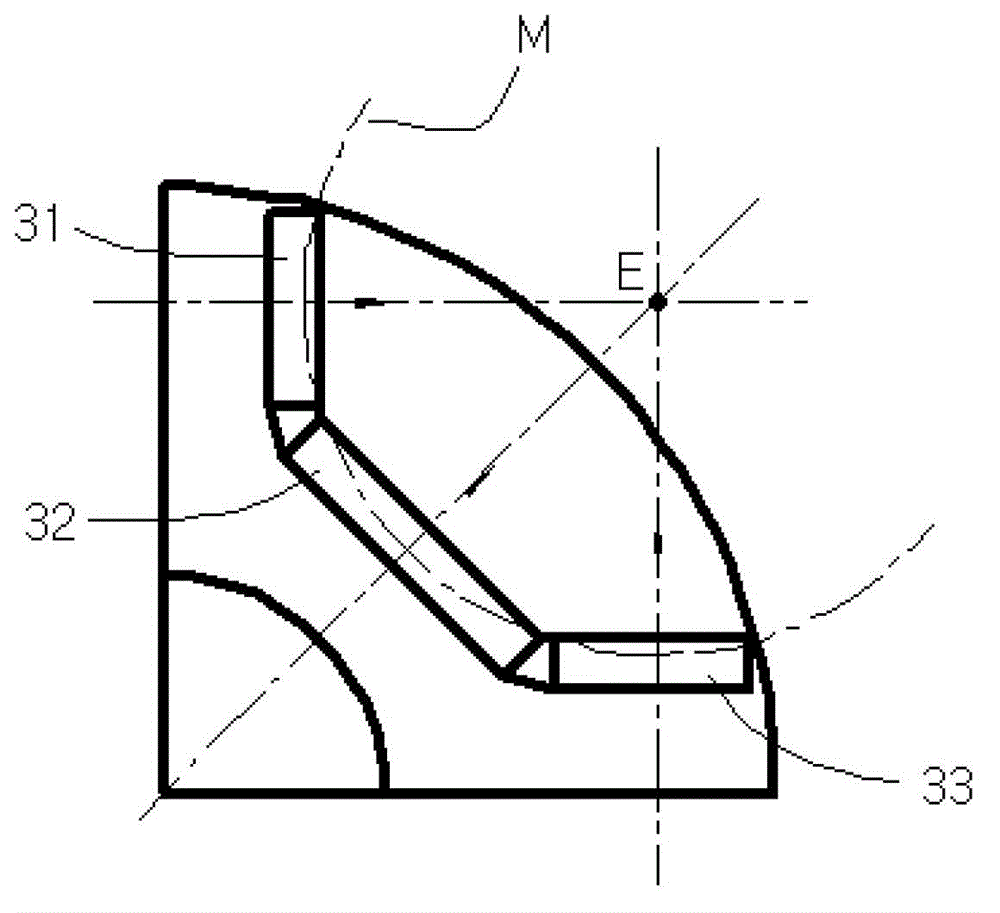

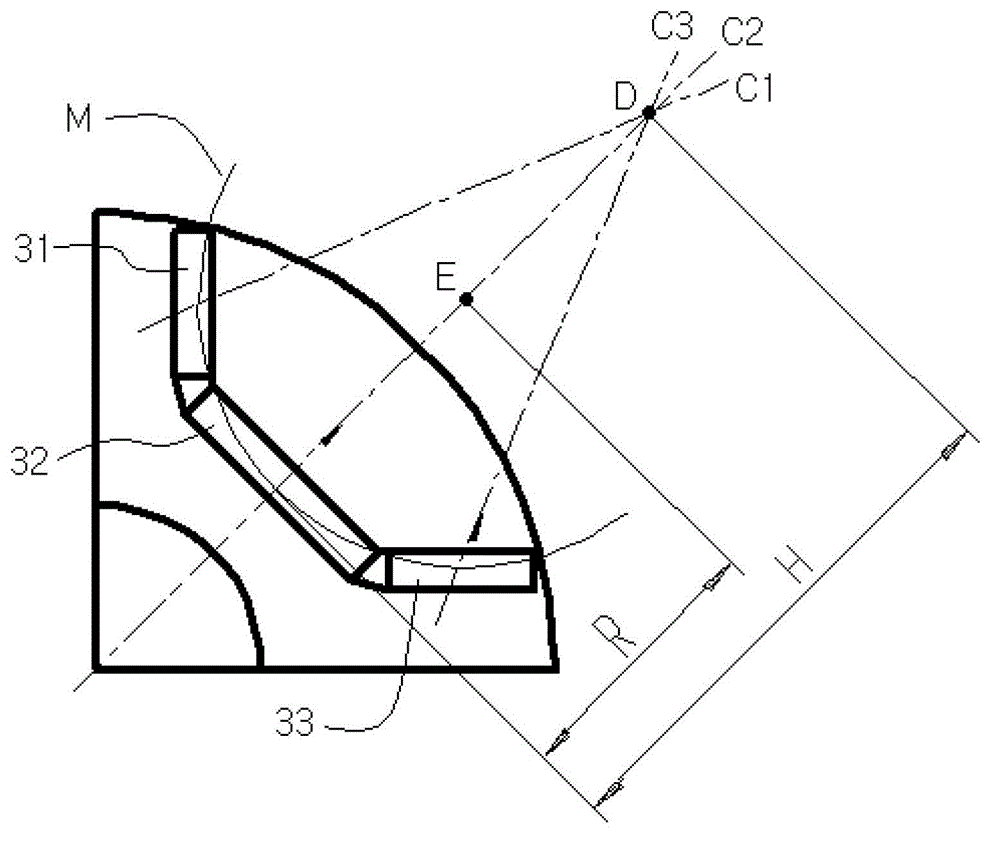

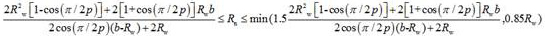

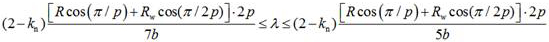

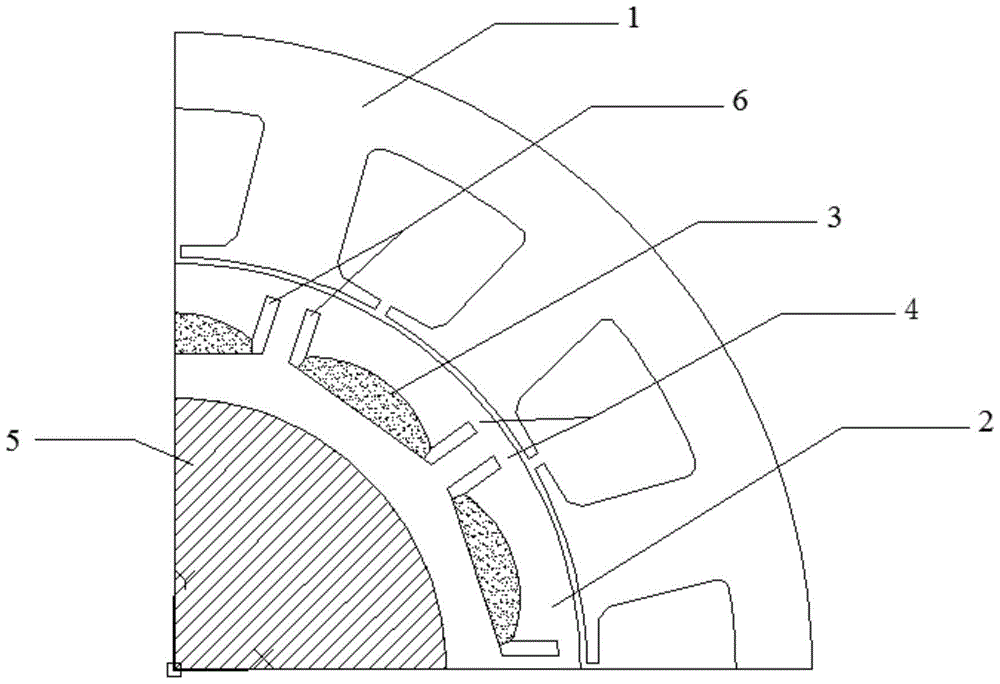

Rotor structure and design method of a permanent magnet assisted synchronous reluctance motor

ActiveCN110048530BIncrease sineImprove air gap flux density waveformMagnetic circuit rotating partsMagnetic barrierSynchronous reluctance motor

The invention belongs to the technical field of permanent magnet motors and relates to a rotor structure of a permanent magnet auxiliary synchronous reluctance motor and a design method. The rotor structure comprises a rotating shaft, a rotor iron core and a permanent magnet block; the rotor iron core is provided with a central hole, and the rotary shaft penetrates through the central hole of therotor iron core and is fixedly connected with the rotor iron core; the rotor iron core is evenly divided into an even number of poles, and at least two layers of U-shaped magnetic barriers are arranged in each pole. The distance between the circle center O1 of an outer circle formed by the U-shaped magnetic barriers in each pole and the circle center O2 of the outer circle of the rotor iron core is h, and h is larger than 0; and a magnetic pole center line formed by the U-shaped magnetic barriers in each pole passes through the circle center O1 and the circle center O2. Therefore, a non-uniform air gap and non-equal-width magnetic bridge rotor structure is constructed. According to the rotor structure and the design method in the invention, the sine degree of air gap flux density in the motor is improved, the air gap flux density waveform is optimized, the problem of torque ripple of the permanent magnet auxiliary synchronous reluctance motor is solved, the torque ripple is obviously reduced, and the motor can be guaranteed to run more stably and efficiently in an electric transmission system.

Owner:DALIAN UNIV OF TECH

Motor

InactiveCN103269136AIncrease the reluctance torque componentReduce torque fluctuationMagnetic circuit rotating partsMagnetic reluctanceControl theory

The invention relates to the technical field of a motor, and aims at providing the motor. The motor comprises a motor rotor. The motor rotor comprises a rotor iron core, trapezoid magnetic steel and trapezoid magnetic steel grooves. At least two same trapezoid magnetic steel grooves which are penetrated in the axial direction are formed in the rotor iron core. The adjacent trapezoid magnetic steel grooves which are symmetrically distributed in the radial direction corresponding to the rotor iron core are of a V shape, an opening of the V shape is towards an outer circle of the rotor iron core, the corresponding trapezoid magnetic steel is embedded in the trapezoid magnetic steel grooves in an alternating mode according to an N pole and an S pole. The magnetic steel grooves and the magnetic steel of the motor rotor are trapezoid, magnetic circuits and magnetic reluctance of a direct-axis (d-axis) evenly change in the peripheral direction, on the basis of preserving a number of advantages of the V-shaped magnetic steel, air-gap magnetic flux density waveforms are improved, the number of harmonic waves is reduced, magnetic reluctance torque weight of the motor is increased, and torque ripple of the motor is reduced.

Owner:HANGZHOU DEWOS ELECTRIC TECHNOLOGY CO LTD

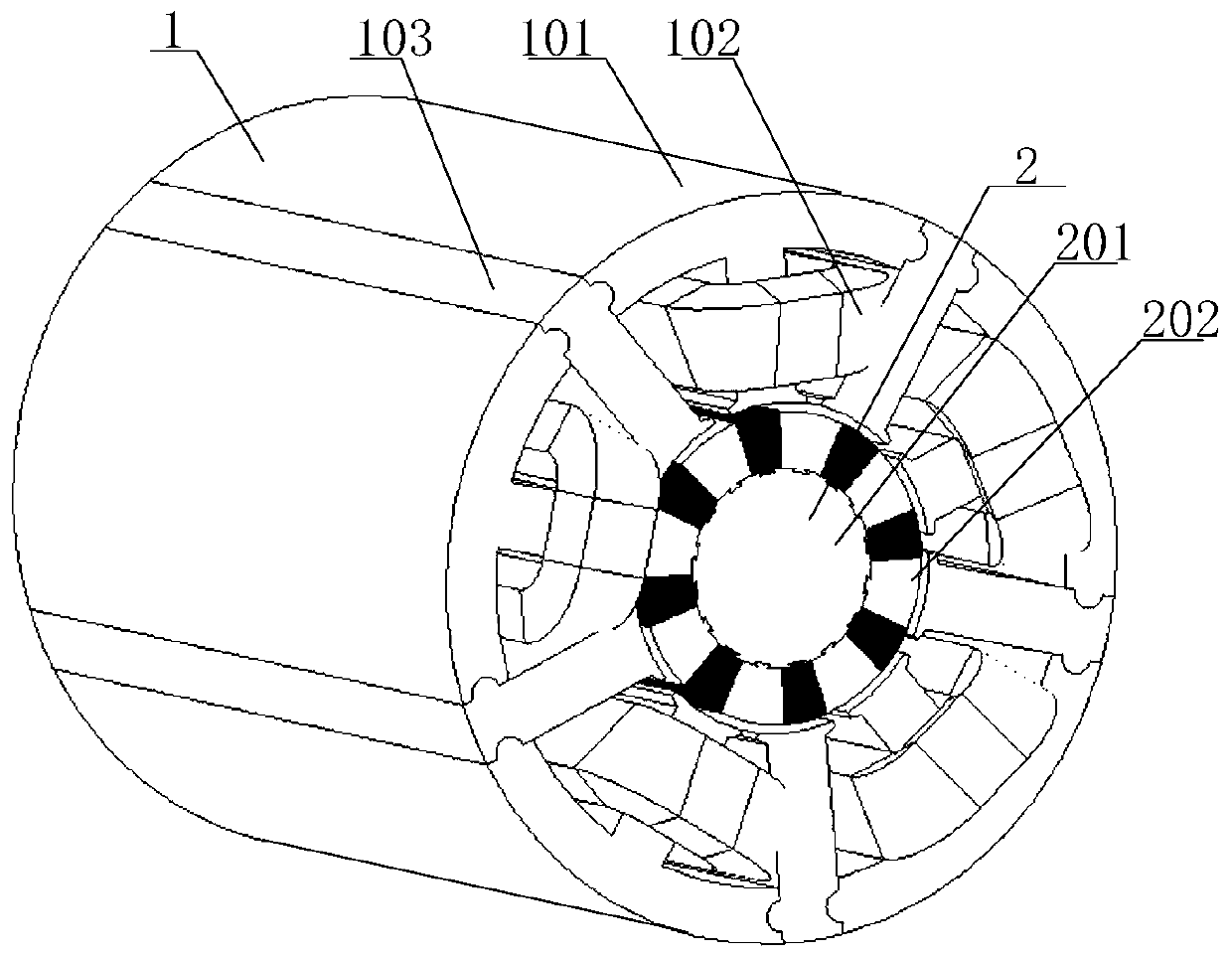

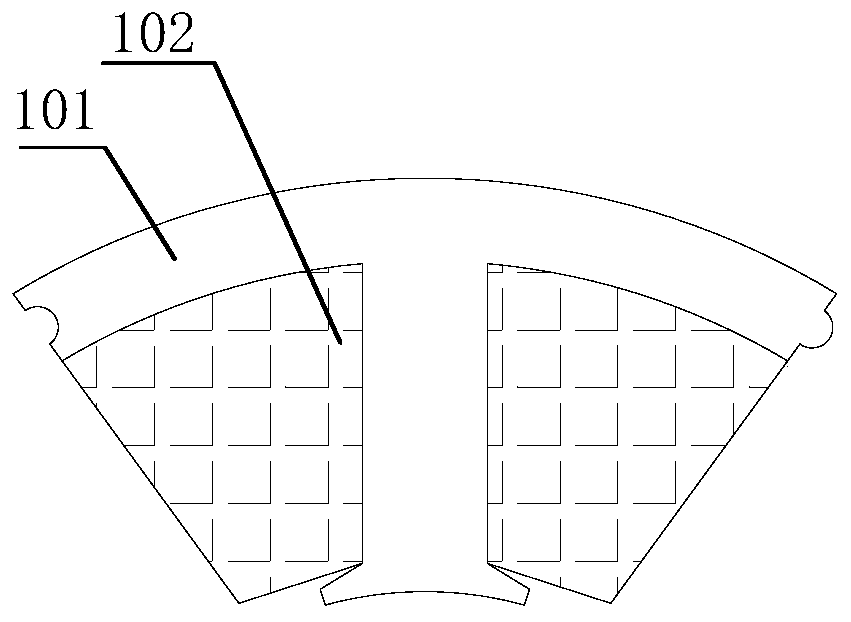

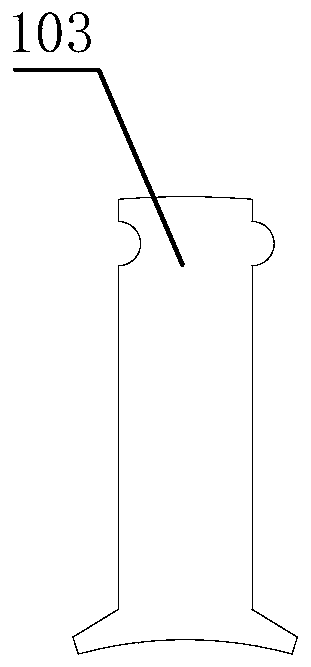

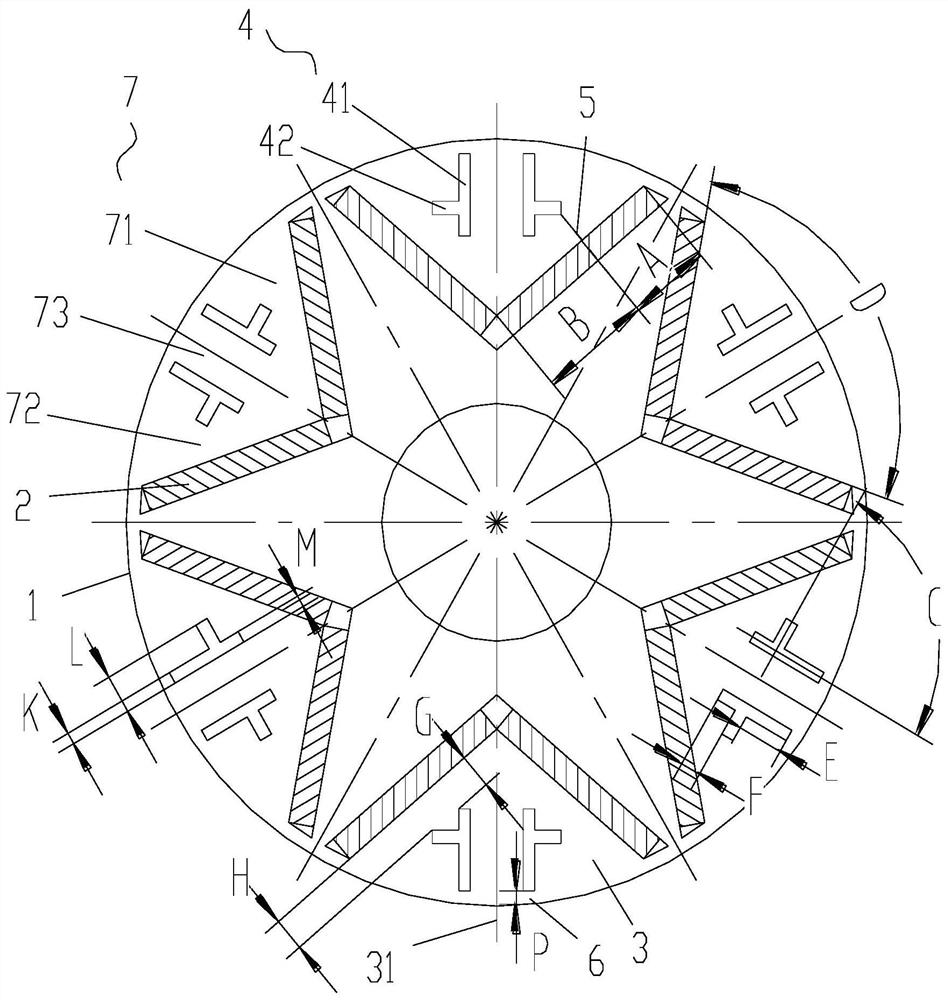

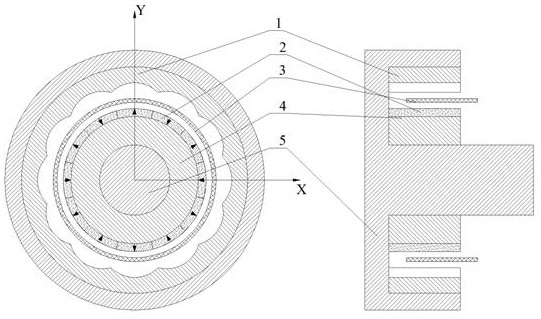

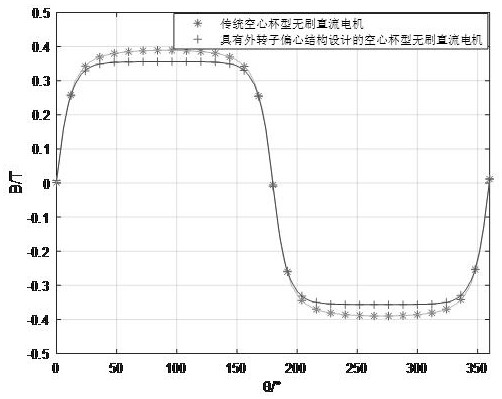

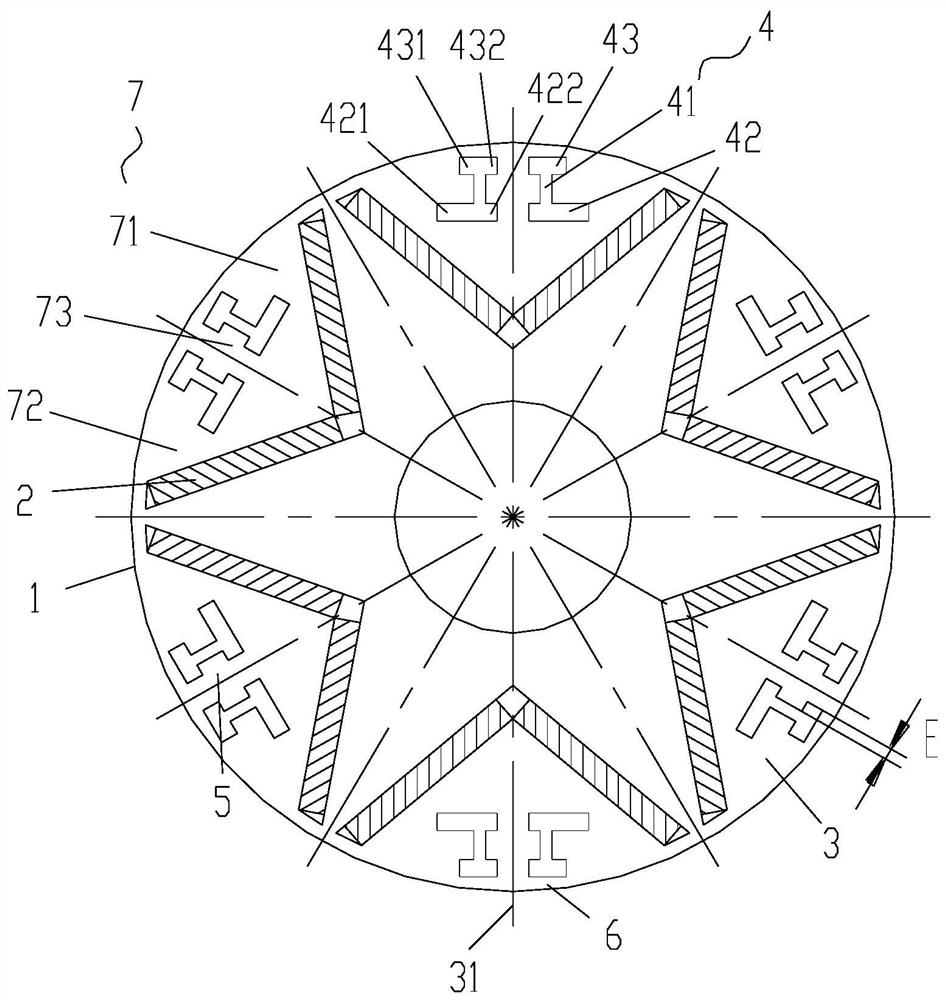

Hollow cup structure motor with sunflower-shaped inner rotor

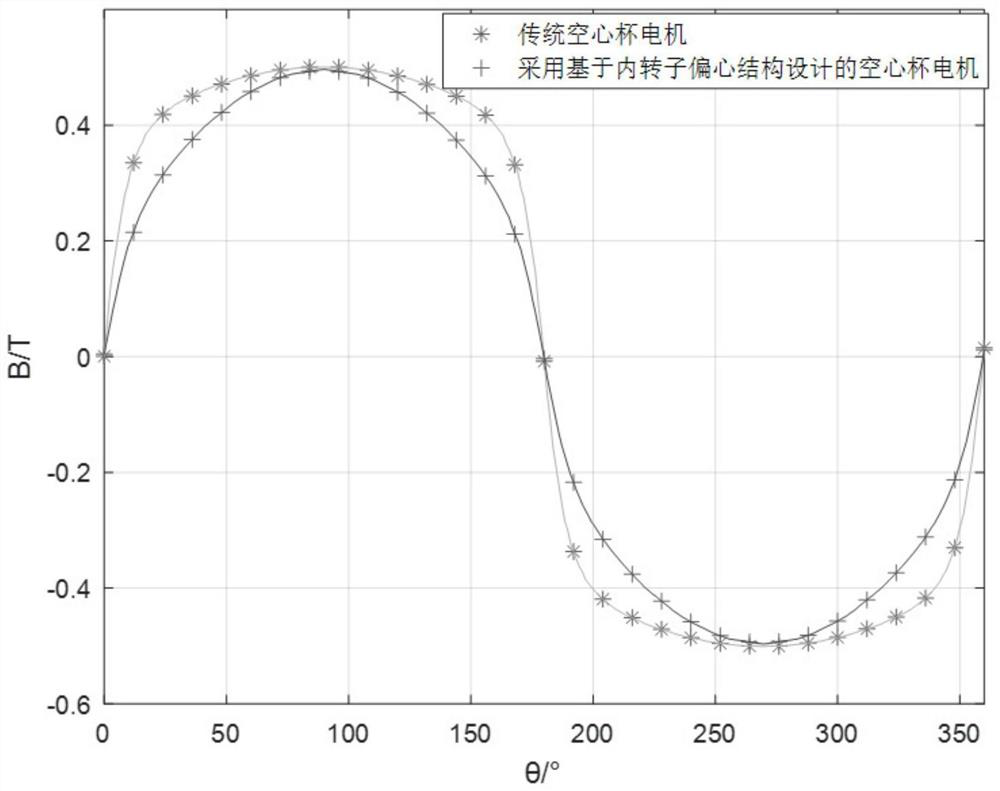

ActiveCN113098162AImprove air gap flux density waveformImprove performanceMagnetic circuit rotating partsElectric machinesElectric machineClassical mechanics

The invention relates to the technical field of motors, and especially relates to a hollow cup structure motor with a sunflower-shaped inner rotor. The coreless structure motor with the sunflower-shaped inner rotor comprises an outer rotor iron core, a plurality of permanent magnets, an eccentric inner rotor iron core and a rotor shaft. Along the radial cross section of the rotor shaft, the external contour of the eccentric inner rotor core comprises a plurality of eccentric arcs protruding towards the permanent magnets, the number of the eccentric arcs is consistent with that of the permanent magnets, and the eccentric arcs are in one-to-one correspondence with the permanent magnets. The two end points of the eccentric arc are located on the connecting line of the two side edges of the corresponding permanent magnet and the center of the rotor shaft, and the circle center of the eccentric arc is located on the connecting line of the middle point of the arc edge of the corresponding permanent magnet and the center of the rotor shaft, so that the air-gap flux density waveform of the motor is improved, the harmonic content in an air-gap magnetic field is reduced, and the air-gap magnetic field approaches sine waves, therefore, the back electromotive force waveform of the coreless motor is improved, the torque pulsation is reduced, and the performance of the motor is improved.

Owner:BEIHANG UNIV +1

Multi-phase permanent magnet fault-tolerant servo motor

InactiveCN111030329AIncrease electromagnetic loadImprove winding processMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePermanent magnet motor

The invention relates to the technical field of permanent magnet motors, and discloses a multi-phase permanent magnet fault-tolerant servo motor. The motor comprises a modular stator, a special-shapedarray coreless rotor and a casing. The outer circle surface of the modular stator is fixed on the inner circle surface of the casing. The special-shaped array coreless rotor is arranged in the modular stator, a preset air gap is formed between the special-shaped array coreless rotor and the modular stator, the modular stator is provided with Q grooves used for arranging Q stator submodules, and Qis an even number; the special-shaped array coreless rotor comprises a rotating shaft and p-pole permanent magnets, each pole permanent magnet is of a structure of a plurality of special-shaped arraymagnetizing permanent magnets, the p-pole permanent magnets are connected with the rotating shaft in a dovetail groove mode, and p is a positive integer. Therefore, the problems of low reliability, no fault-tolerant capability, slow dynamic response, low power density and the like of a conventional servo motor can be solved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Rotor of permanent magnet motor, permanent magnet motor and compressor

PendingCN110768421AImprove air gap flux density waveformImprove noiseMagnetic circuit rotating partsElectric machineryPermanent magnet motor

The invention discloses a rotor of a permanent magnet motor, the permanent magnet motor and a compressor. The rotor includes a rotor iron core and a plurality of permanent magnets. The rotor iron coreis provided with a center hole and a plurality of magnet slots. The plurality of magnet slots are arranged in the circumferential direction of the center hole. Each of the magnet slots extends in theradial direction of the center hole. Portions, located at the two ends of each of the permanent magnets in the radial direction, of each of the magnet slots form first magnetic isolation slots. The rotor iron core is provided with a second magnetic isolation slot on at least one side of each of the magnet slots in the circumferential direction. Each second magnetic isolation slot separates a single-sided area where the second magnetic isolation slot is located into a plurality of magnetic field pathways distributed in the radial direction. In two magnetic field pathways adjacent in the radialdirection, the minimum width of the magnetic field pathway located on the outer side in the radial direction is smaller than the minimum width of the magnetic field pathway on the inner side in the radial direction. According to the permanent magnet motor of the embodiment of the invention, the magnetization characteristics of the rotor iron core are improved, and noises of the permanent magnet motor are reduced.

Owner:GUANGDONG MEIZHI COMPRESSOR

Inclined pole magnetic bush for electric machines and electric machine rotor and electric machine having the skewed pole magnetic bush

InactiveCN109217600AImprove air gap flux density waveformSmall torqueMagnetic circuit rotating partsSynchronous machine detailsAxis of symmetryElectric machine

The invention discloses an inclined pole magnetic bush for an electric machine and an electric machine rotor and an electric machine having the same, The oblique pole magnetic tile comprises: a body that extends obliquely with respect to an axial direction of the motor, the axis of symmetry of the radial section of the body intersects and is perpendicular to the central axis of the motor, and theradial outer side edge of the radial section is formed into an arc which is eccentrically disposed with the center of the motor and has a bending radian greater than that of the radial inner side edge. The inclined pole magnetic bush according to the embodiment of the invention can obviously improve the vibration, noise, loss and the like of the motor, and improve the performance of the motor.

Owner:SANHUA AWECO APPLIANCE SYST WUHU CO LTD

Linear and rotary motion converter for V-type magnetic pole

InactiveCN104184302AIncrease profitIncreased torque densityDynamo-electric gearsLinear motionPull force

The invention discloses a linear and rotary motion converter for a V-type magnetic pole. According to the linear and rotary motion converter, linear motion and rotary motion can be mutually converted, and kinetic energy transfer can be achieved. The converter comprises a rotary unit, a linear unit and a magnetism adjusting mechanism. The rotary unit comprises a rotating shaft, a rotor core and a permanent magnet, wherein the permanent magnet is of a segmented V-type structure and is pasted on the surface of the rotor core. The linear unit comprises a mover yoke and a permanent magnet. The magnetism adjusting mechanism is composed of permeable magnetism adjusting iron blocks and fixed between the rotary unit and the linear unit. As the rotary unit is of a novel magnetic pole structure, the torque pulsation of the converter is effectively reduced, jitter and loss of the converter are reduced, and the stability and energy conversion efficiency of the converter are improved. Meanwhile, the V-type magnetic pole is centrosymmetric, so that axial magnetic pulls are mutually offset, the operational reliability of the converter is improved, and the service life of the converter is prolonged.

Owner:SOUTHEAST UNIV

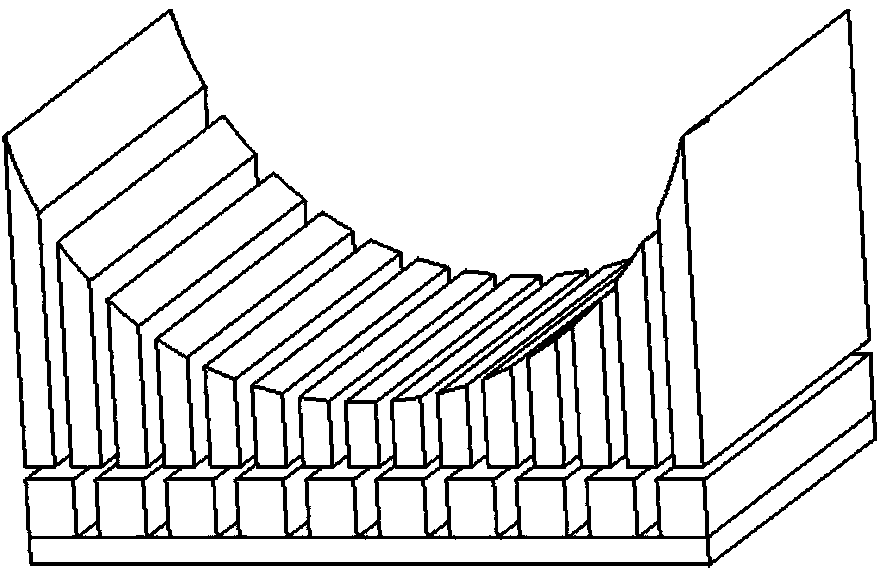

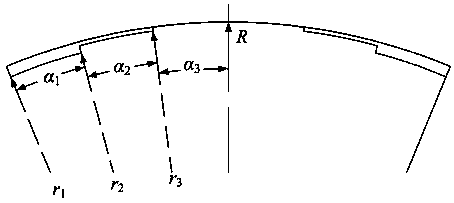

Built-in permanent magnet motor rotor magnetic field improved design method suitable for industrialization

InactiveCN111525758AImprove air gap flux density waveformSmall positioning torqueMagnetic circuitManufacturing stator/rotor bodiesElectric machineMagnetic poles

The invention discloses a built-in permanent magnet motor rotor magnetic field improved design method suitable for industrialization, and the method comprises the following steps: 1, taking one magnetic pole of a rotor as a unit, and determining the number of steps of a stepped concentric arc and the radius of each stepped concentric arc step according to the size of the outer circle of the rotorand the number of the magnetic poles of the rotor; 2, sequentially repeating the step-shaped concentric arc shape determined in the step 1 according to the number of rotor magnetic poles, and salientpole surfaces under all rotor poles are formed; and 3, carrying out sectional processing on the shape of the outer surface of the rotor under each magnetic pole. On the premise of ensuring the outputtorque, the cogging torque of the built-in permanent magnet motor can be effectively reduced, and the industrial technology development of the built-in permanent magnet motor is promoted.

Owner:HARBIN INST OF TECH

Rotor structure, motor and compressor

PendingCN111711291AImproved reluctance distributionReduce coggingMagnetic circuit rotating partsElectric machineryMagnetic poles

The invention mainly aims to provide a rotor structure, a motor and a compressor. The rotor structure comprises a rotor iron core and a plurality of permanent magnets arranged on the rotor iron core so as to form a plurality of magnetic poles on the rotor iron core, wherein the plurality of magnetic poles comprise a plurality of N poles and a plurality of S poles which are alternately arranged along the circumferential direction of the rotor iron core, at least one magnetic pole of the rotor iron core is provided with magnetic isolation holes, the magnetic isolation holes comprise a main holebody and a branch hole, and by using a plane perpendicular to the axis of the rotor iron core as a predetermined plane, the projection of the main hole body on the predetermined plane is strip-shapedand is intersected with the circumferential direction of the rotor iron core along the extension direction of the main hole body, and the projection of the branch hole on the predetermined plane is strip-shaped, and the center line of the extension direction of the projection is connected with the middle portion of the main hole body. By means of the arrangement, the problem that in the prior art,vibration noise of a motor is large is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

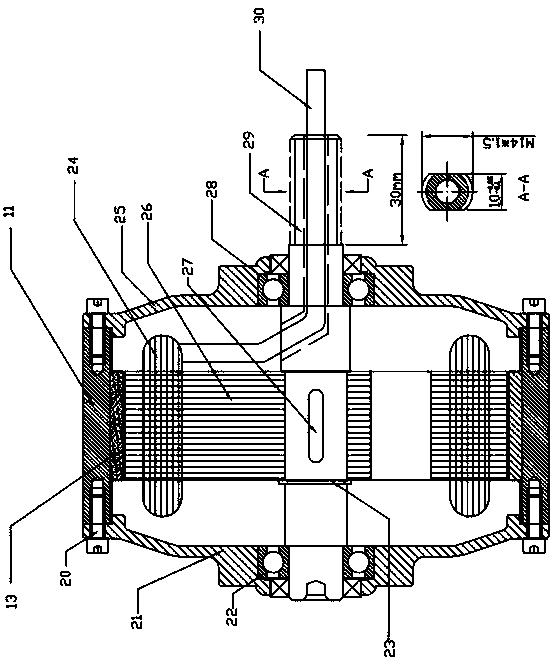

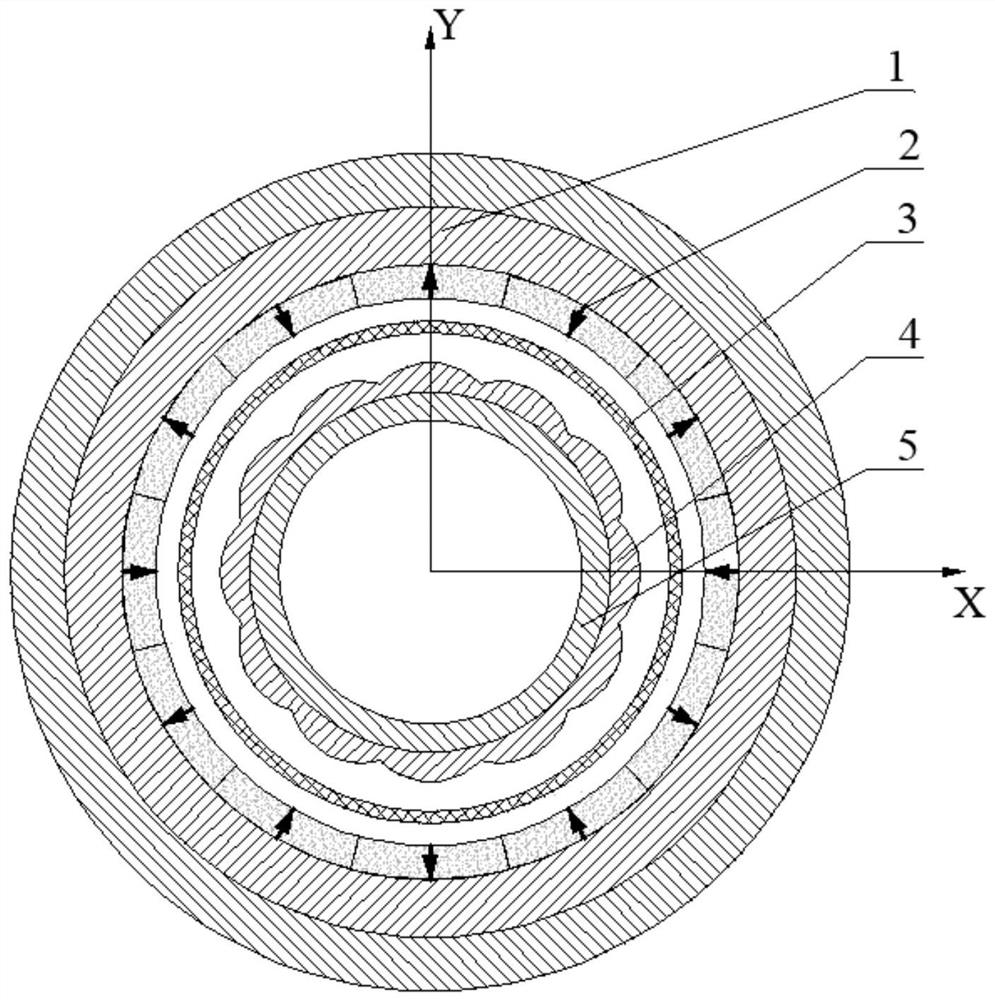

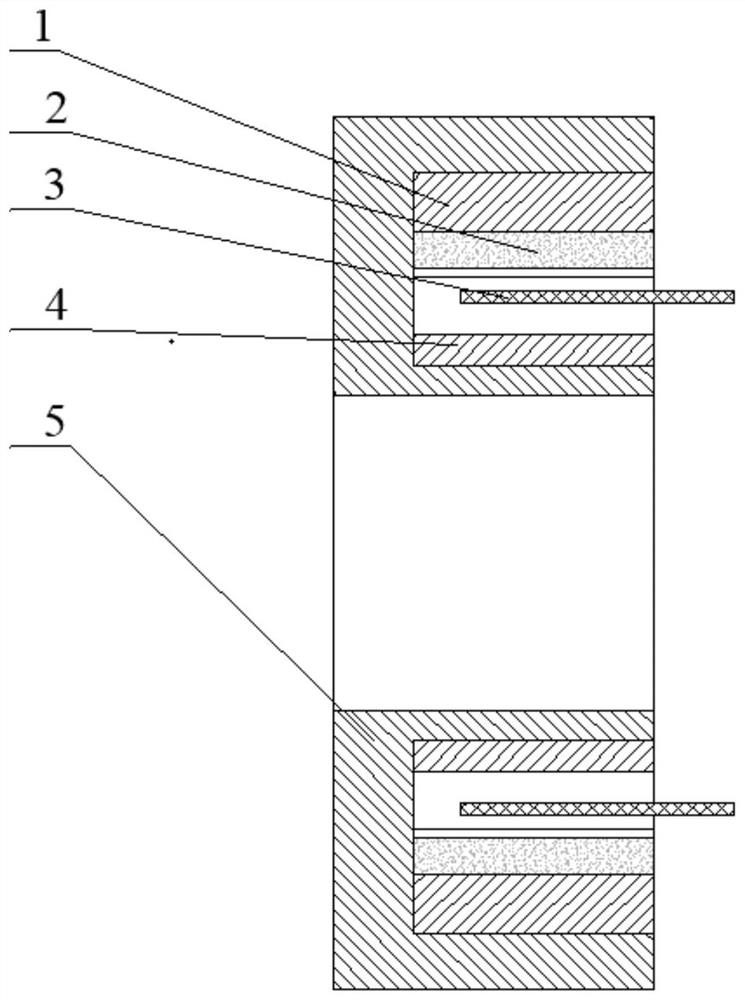

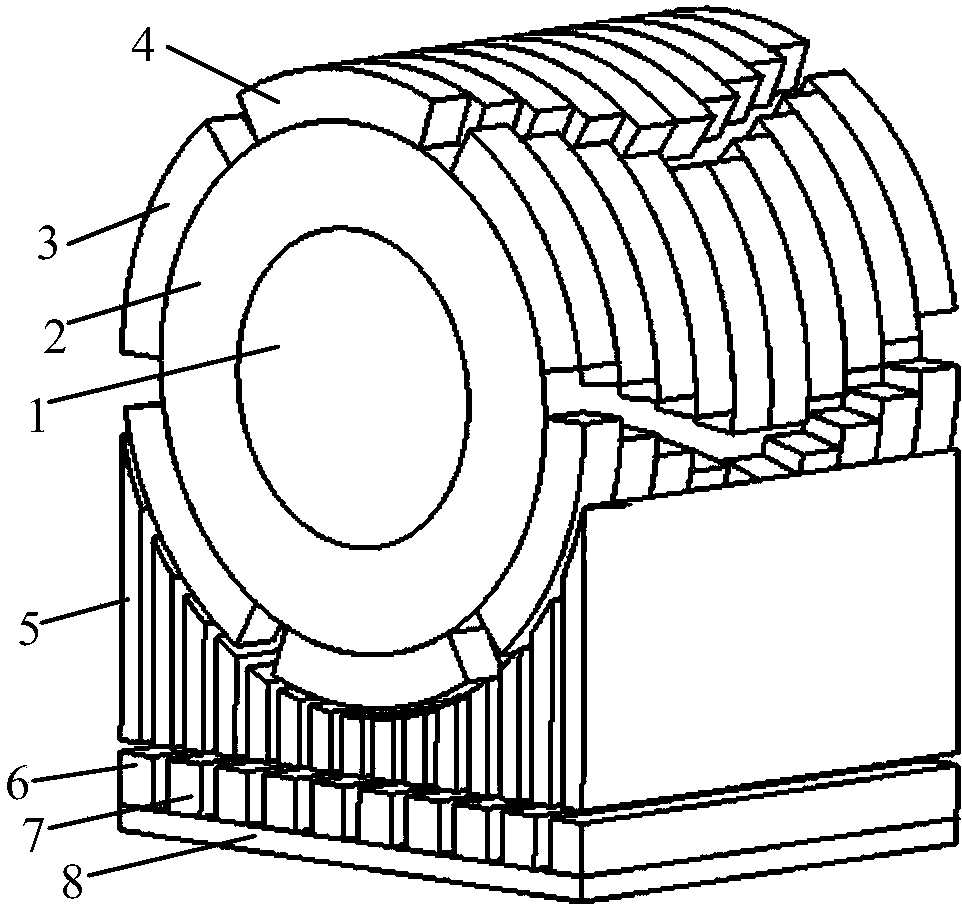

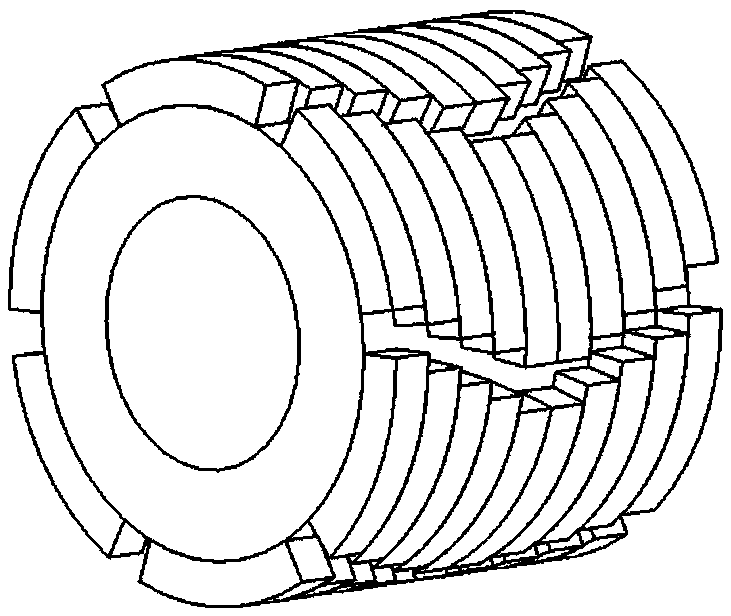

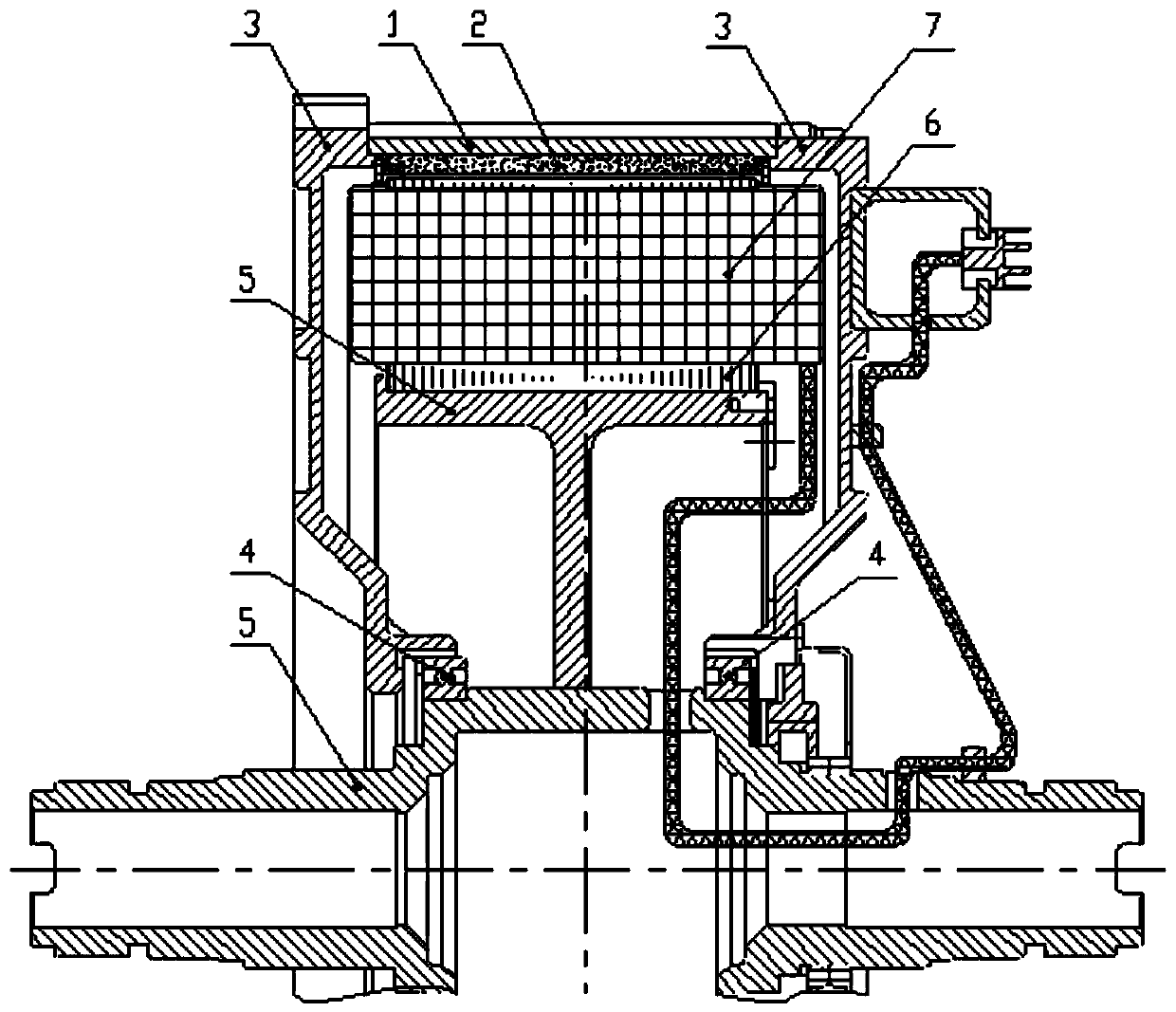

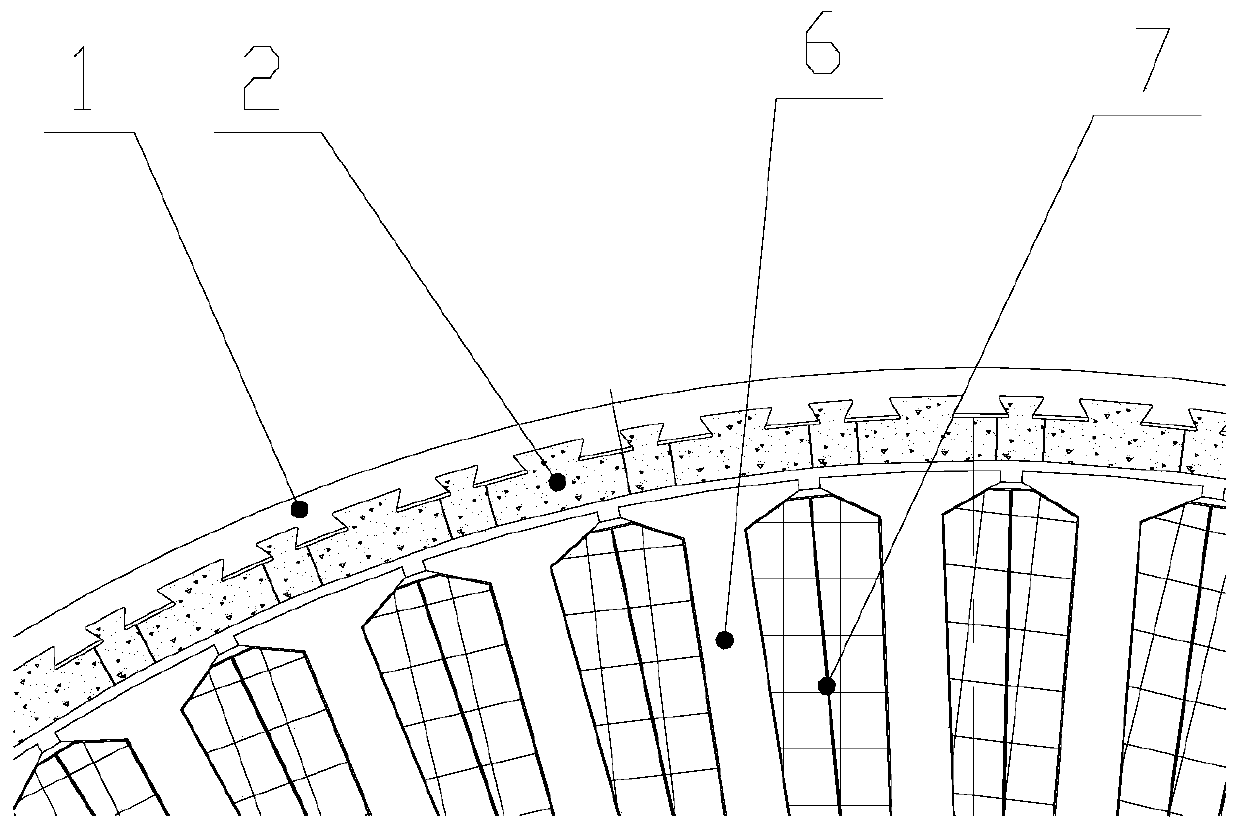

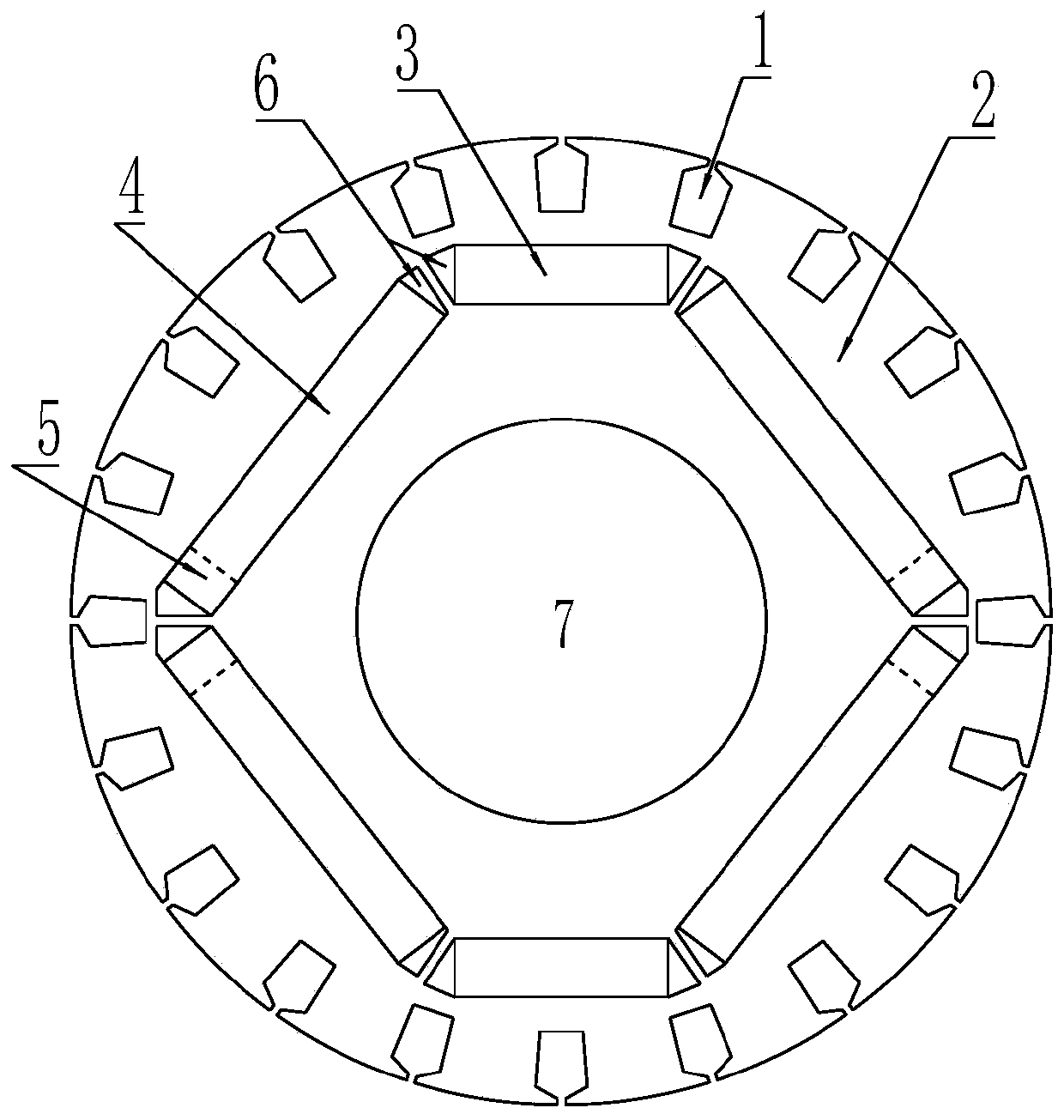

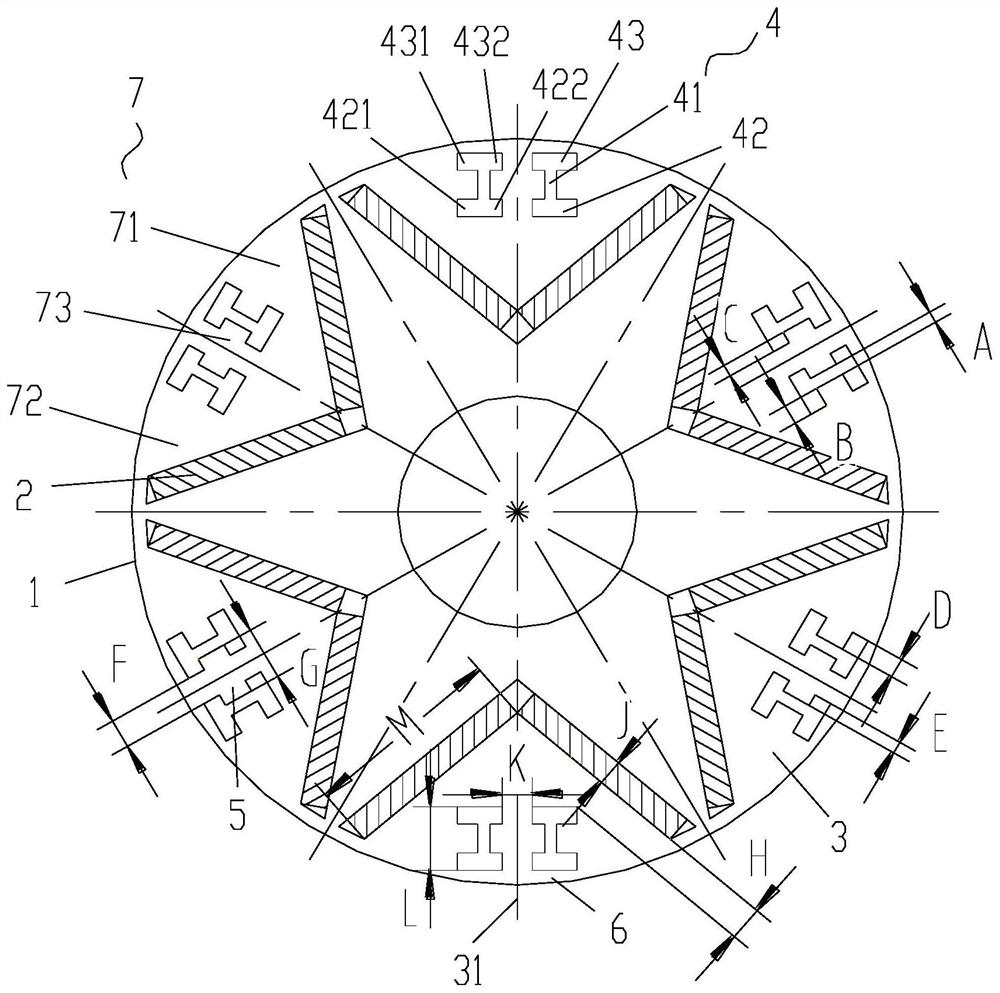

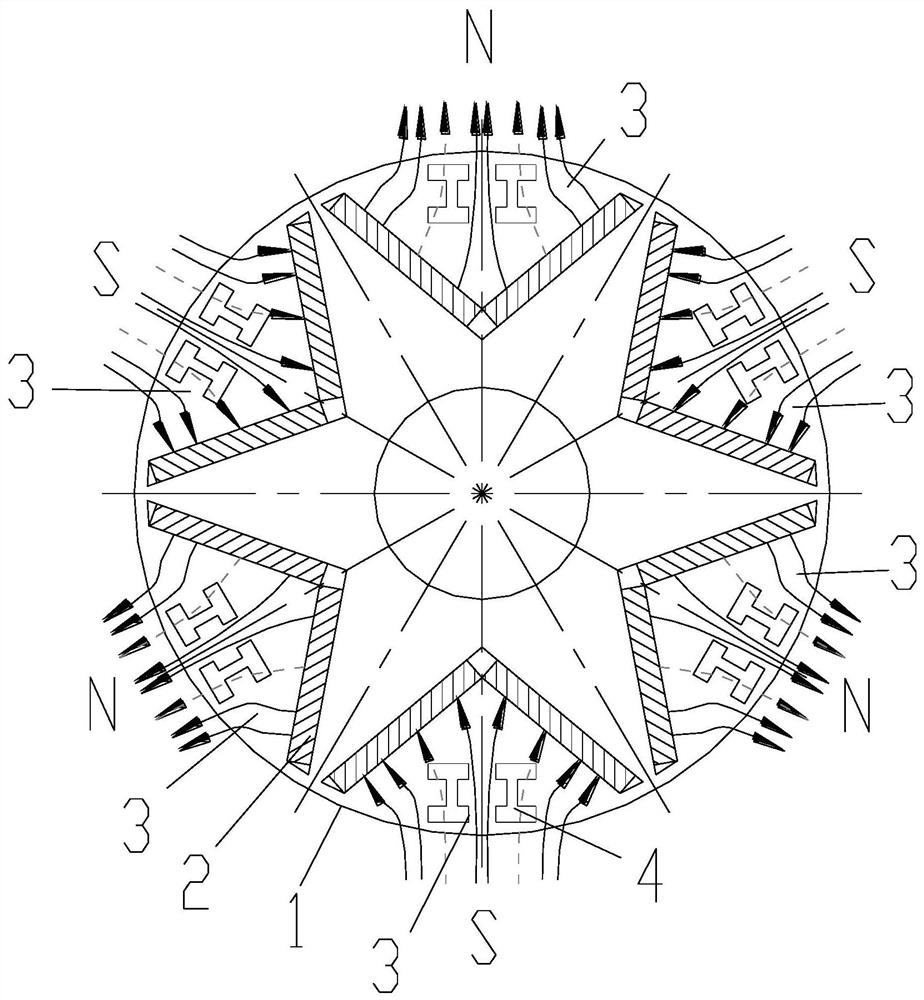

Permanent magnet synchronous motor with limited rotation angle

ActiveCN110474509AGuaranteed reliabilityHigh proportion of lossMagnetic circuit stationary partsMechanical energy handlingPermanent magnet synchronous motorTorque density

A permanent magnet synchronous motor with a limited rotation angle belongs to the technical field of synchronous motors, and comprises a base 1, a permanent magnet 2 and an end cover 3, a bearing 4, arotating shaft 5, an armature core 6 and an armature winding 7; the base 1 is connected with the end cover 3; the permanent magnet 2 is mounted on the inner side of the base 1, and the base 1, the permanent magnet 2 and the end cover 3 integrally form a stator; the rotating shaft 5 is connected with the end cover 3 through the bearing 4; the armature core 6 sleeves the rotating shaft 5; a grooveis formed in the armature core 6, the armature winding 7 is installed in the groove, and the rotating shaft 5, the armature core 6 and the armature winding 7 integrally form a rotor. The armature core6 is located in the permanent magnet 2, and a gap is arranged between the armature core 6 and the permanent magnet 2. The motor is small in size, high in torque density, low in rotating speed and high in efficiency.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

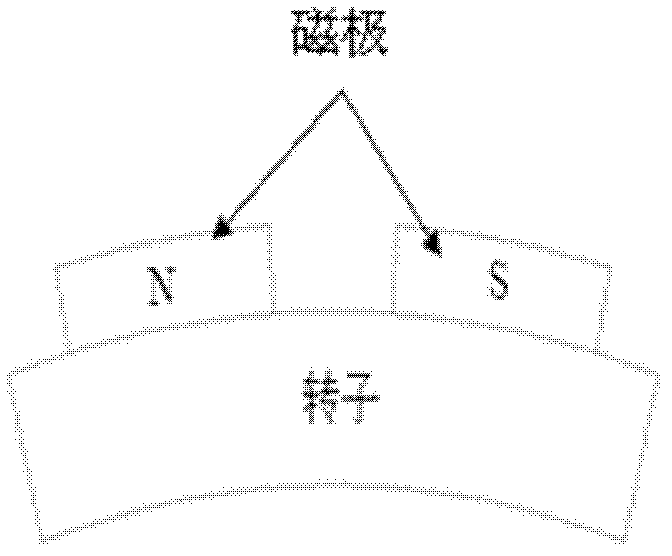

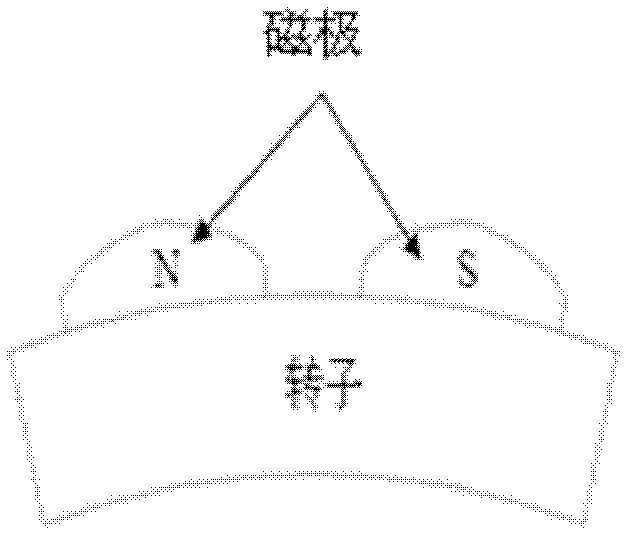

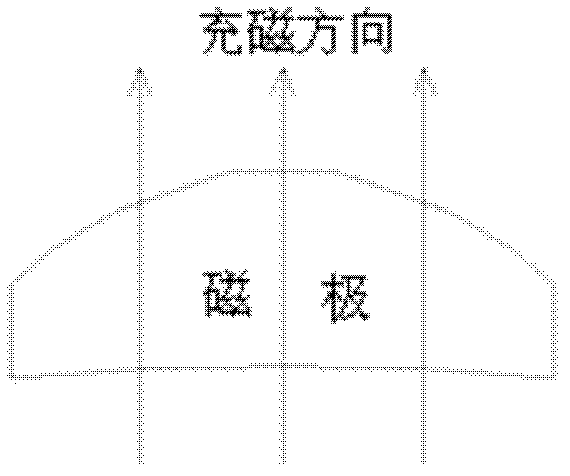

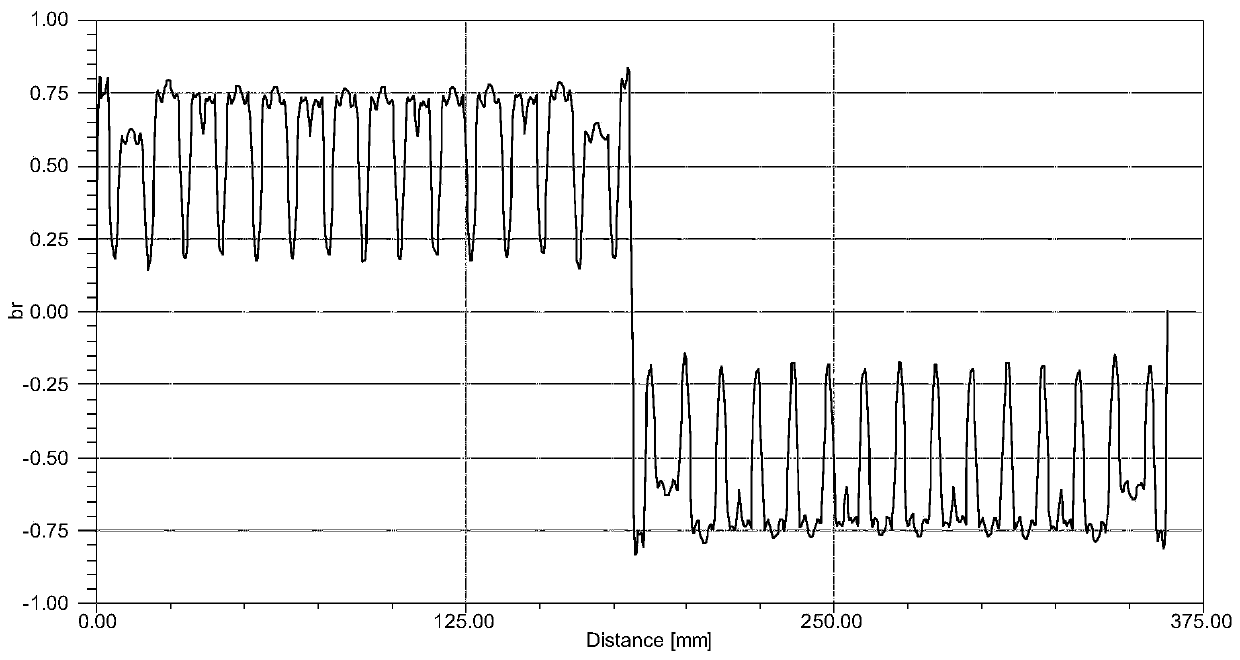

Magnetic pole structure of permanent magnet synchronous direct-driven motor and design method thereof

ActiveCN102545436BGuaranteed uptimeExtend working lifeMagnetic circuit rotating partsMagnetic polesPermanent magnet synchronous motor

The invention relates to a magnetic pole structure of a permanent magnet synchronous direct-driven motor. The magnetic poles are embedded in the circumference of the surface of a rotor in a manner that an N pole and an S pole are alternated, and are opposite to a stator; and a layer of air gap is arranged between the stator and the rotor. The stator comprises an iron core and a winding; and the rotor is of a hollow shaft structure or a solid shaft structure. The magnetic poles of the rotor adopt the magnetic poles with unequal thicknesses, and are uniformly distributed around the surface of the rotor of the motor, so that a no-load magnetic flux density waveform of the air gap is approximate to a sine wave. According to the magnetic pole, a design idea of an inverse problem of an electromagnetic field is adopted, the centers of the magnetic poles with equal thickness are used as a symmetrical axial line, and the thicknesses on two ends of the magnetic poles are gradually reduced, so that an initial scheme of the magnetic poles with unequal thicknesses is obtained. Electromagnetic field software simulation is utilized to obtain the magnetic flux density waveform of the air gap, a fundamental wave and a harmonic component are analyzed, partial size of each magnetic pole is adjusted according to design requirements, and multiple replication is carried out until a design goal is optimized. Due to the adoption of the magnetic pole structure, the vibration and the noise of the permanent magnet synchronous direct-driven motor can be reduced.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Rotor, motor, compressor and refrigeration equipment

ActiveCN112436625AImprove load magnetic densityImprove air gap flux density waveformSynchronous machine detailsMagnetic circuit rotating partsRefrigeration plantClassical mechanics

The invention provides a rotor, a motor, a compressor and refrigeration equipment. The rotor comprises: a rotor core which is provided with an installation groove; a permanent magnet arranged in the mounting groove and forms a magnetic pole; a plurality of slits are arranged on the rotor iron core at one side, far away from the axis of the rotor iron core, of the mounting groove, wherein the minimum distance between two adjacent slits in the plurality of slits is L2, the plurality of slits comprise at least one first slit, the minimum value L1 of the width of the first slit is arranged betweentwo end parts of the first slit along the length direction, and L2 is greater than or equal to 0.5 time L1. According to the rotor provided by the invention, the sizes of the end parts, close to theouter wall of the rotor core, of the first slits and the end parts, close to the mounting grooves, of the first slits are relatively large, the influence of a stator armature magnetic field on a rotormagnetic field is prevented, the mechanical performance of the rotor is improved, the distance between two adjacent slits can be ensured to be within a reasonable range, and flux loss reduction is benefited.

Owner:ANHUI MEIZHI PRECISION MFG

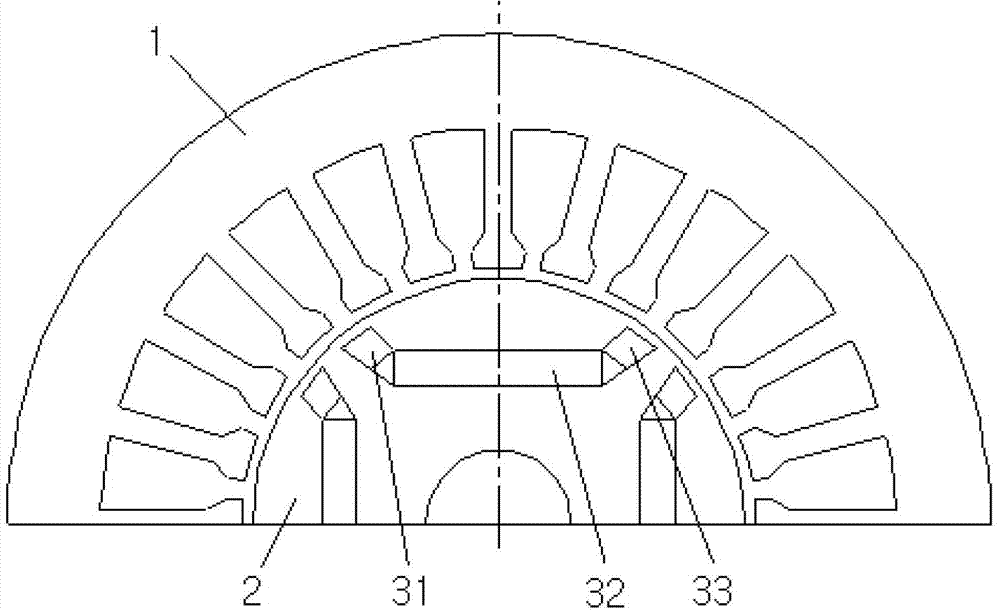

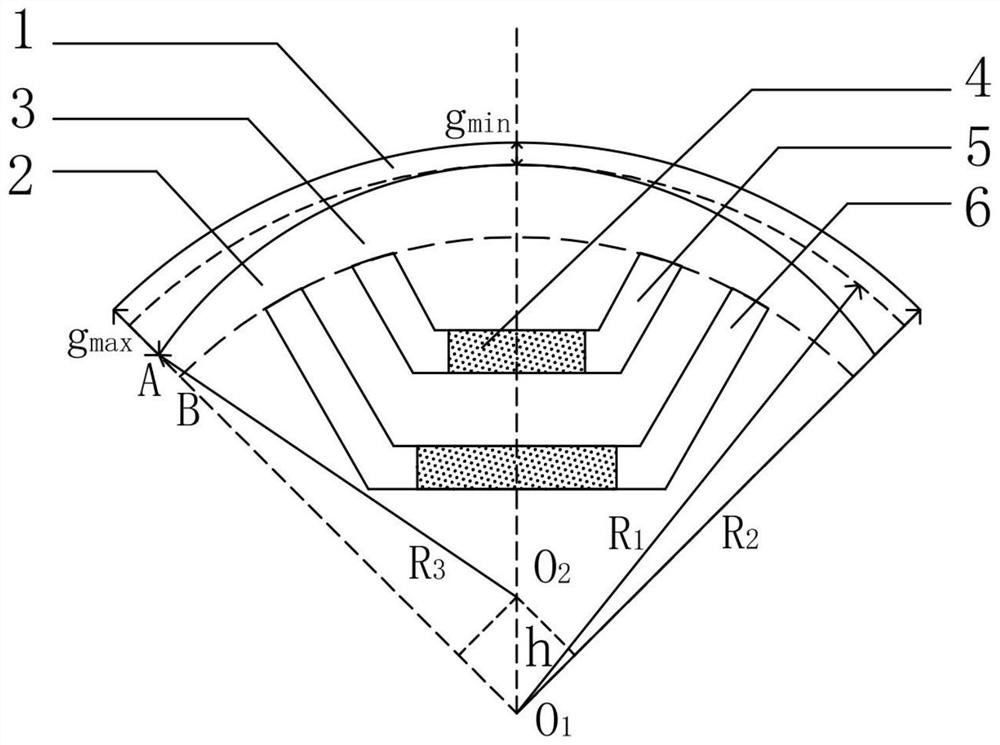

A Rotor Structure for Improving Air Gap Flux Density Waveform of 2-pole Self-starting Permanent Magnet Motor

ActiveCN106558932BIncrease display spaceOvercome the disadvantage of limited rotor spaceMagnetic circuit rotating partsManufacturing stator/rotor bodiesConductive materialsNon magnetic

The invention, which belongs to the technical field of motor fittings, particularly relates to a rotor structure capable of improving a gap flux density waveform of a two-pole self-starting permanent-magnet motor. The rotor structure comprises a rotor iron core having a plurality of mouse case slots and permanent magnets installed in permanent-magnet slots. The permanent magnets under two poles employ three-segment type inverted-U-shaped magnetic circuit structures and each of the permanent magnets includes an intermediate-segment permanent magnet and two segments of side permanent magnets; air slots are formed between the two adjacent segments of permanent magnets; the three segments of permanent magnets are arranged in a left-right symmetric mode relative to the central lines of the intermediate-segment permanent magnets; and end portions, far away from mounting slots of the intermediate-segment permanent magnets, of mounting slots of the two segments of side permanent magnets are non-magnetic-conductive material filling parts. The whole rotor structure is in a left-right-symmetric mode relative to the central lines of the intermediate-segment permanent magnets and the rotor is installed at a rotating shaft. Therefore, the gap flux density waveform of the motor can be optimized. On the basis of sinusoidal processing of the gap flux density waveform of the motor, the harmonic contents in the air-gap field and the stator winding can be reduced, the counter-electromotive-force waveform can be optimized, the motor efficiency can be improved; and the motor torque pulsation can be reduced.

Owner:DANDONG SHANCHUAN ELECTRICAL ENG

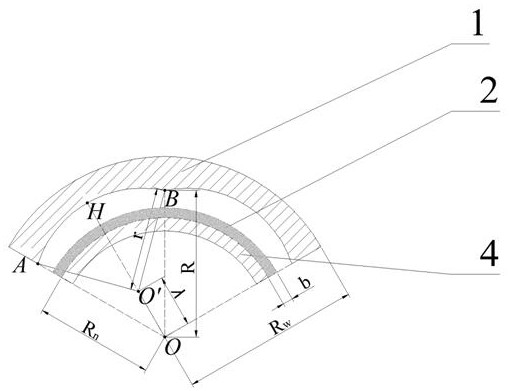

Sine wave rotor based on permanent magnet and inner rotor core eccentric structure design

ActiveCN113541354AImprove air gap flux density waveformImprove performanceSynchronous machine detailsMagnetic circuit rotating partsEngineeringFlywheel

The invention relates to the technical field of generators, and particularly discloses a sine wave rotor based on a permanent magnet and inner rotor iron core eccentric structure design, which comprises an outer rotor iron core, a plurality of eccentric permanent magnets, an inner rotor iron core and a rotor shaft. The plurality of eccentric permanent magnets are alternately arranged along the radial inner side of the outer rotor iron core, every two adjacent eccentric permanent magnets are opposite in magnetizing direction, each eccentric permanent magnet is composed of an arc edge outer contour, an eccentric arc inner contour and two side edges, the inner contour of the inner rotor iron core is circular, the outer contour is composed of a set of eccentric arcs protruding outwards, and an annular air gap is formed between the radial outer side of the inner rotor iron core and the eccentric permanent magnets. The sine wave rotor designed based on the permanent magnet and the inner rotor core eccentric structure is adopted, the air-gap flux density waveform of the energy storage flywheel generator is improved, the harmonic content in an air-gap magnetic field is reduced, the air-gap magnetic field is made to be close to sine waves, the counter electromotive force waveform of the generator is improved, torque pulsation is reduced, and the performance of the energy storage flywheel generator is improved.

Owner:安徽华驰动能科技有限公司

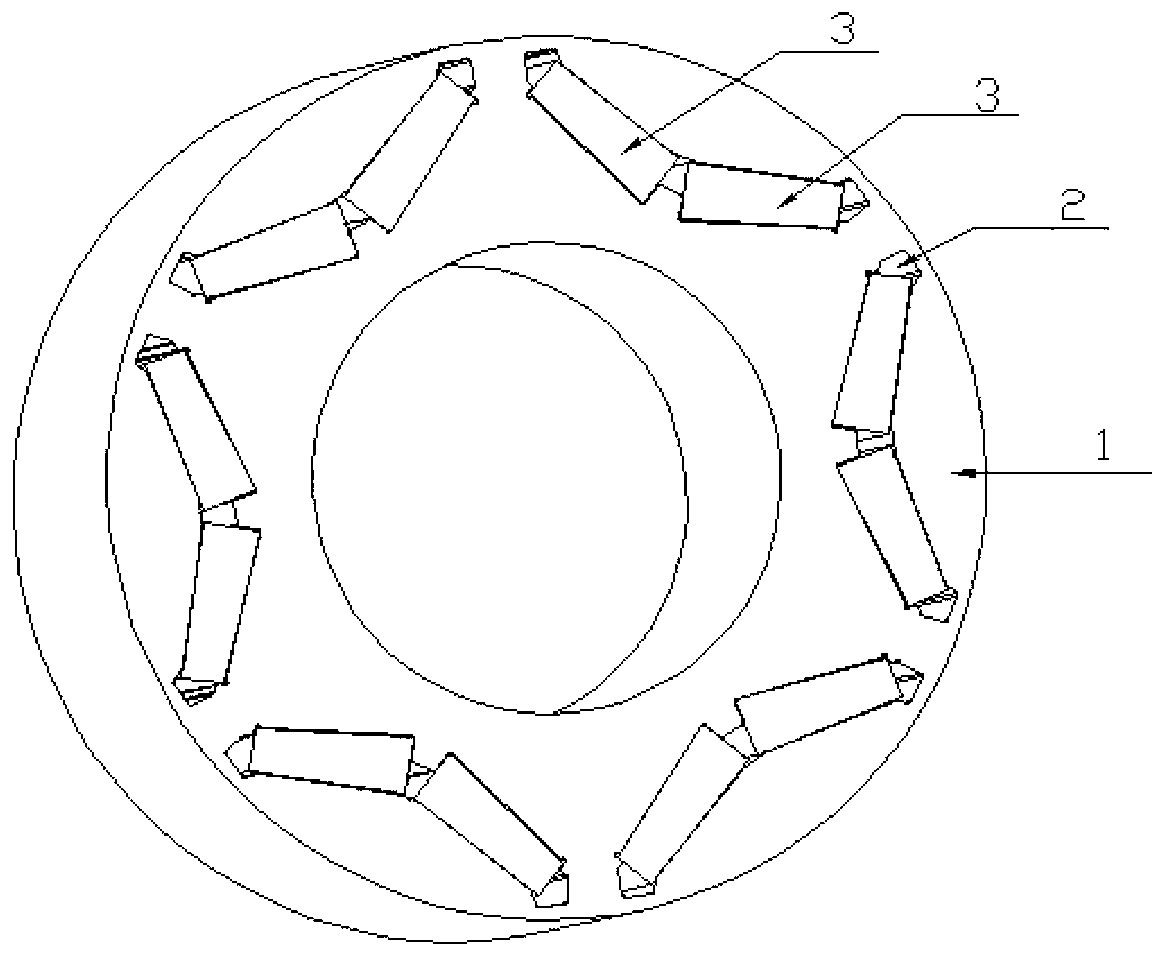

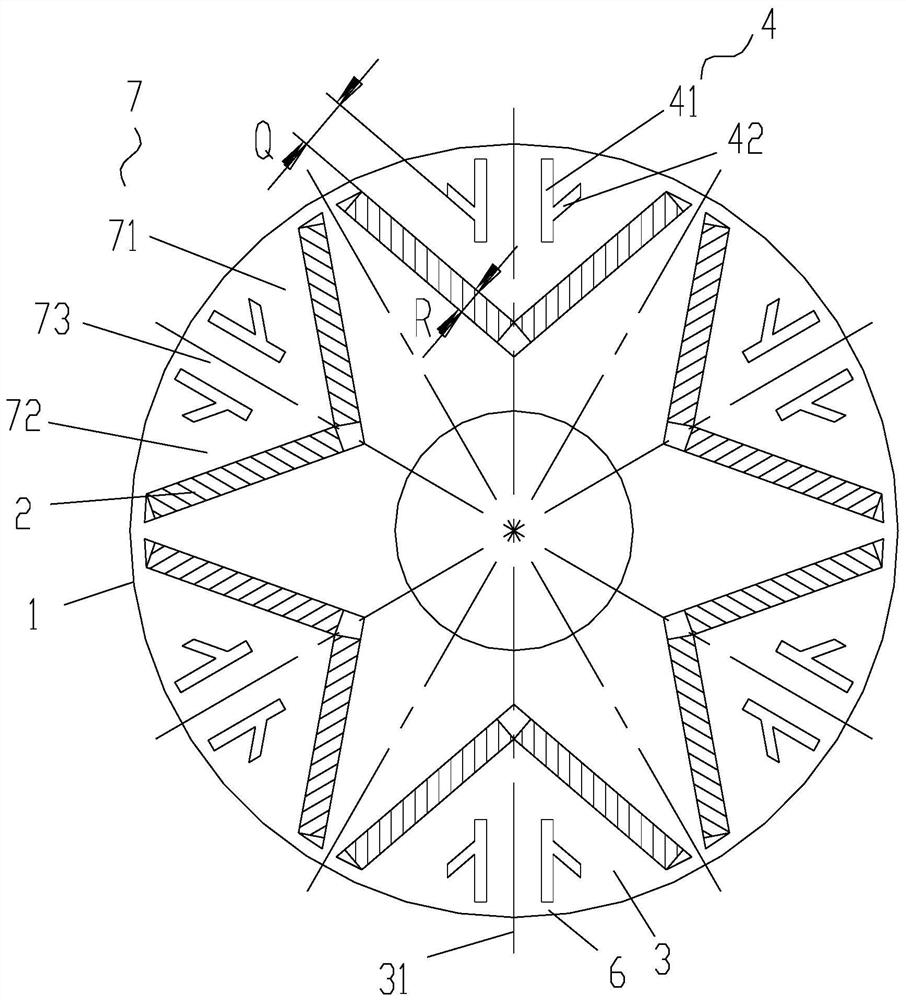

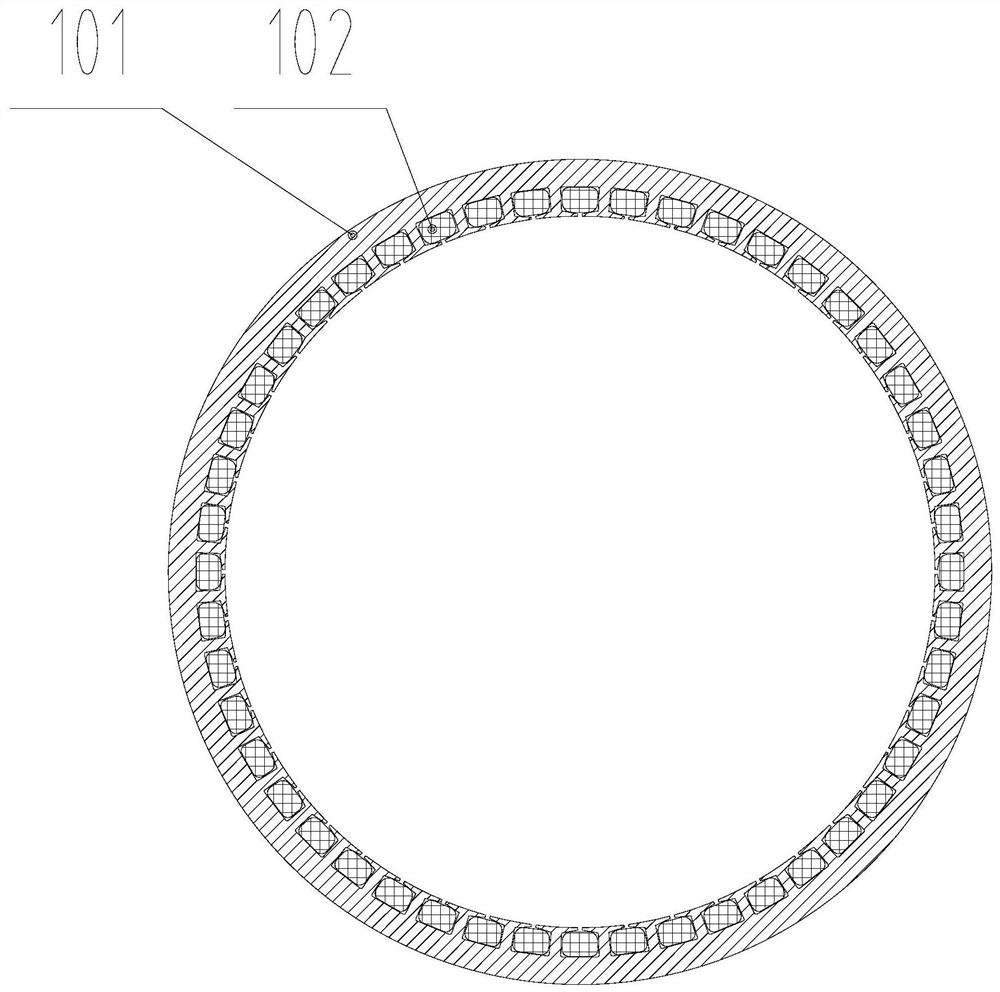

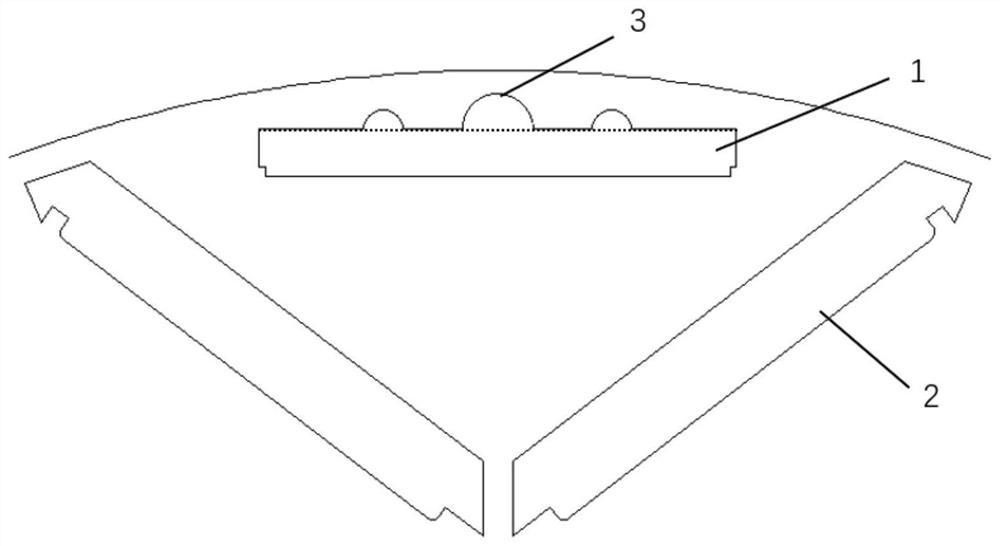

Magnetic gear and compound motor with same

ActiveCN112636562BIncrease torqueImprove work performanceMagnetic circuitPermanent-magnet clutches/brakesGear wheelElectric machinery

The present invention provides a magnetic gear and a composite motor with it, wherein the magnetic gear includes: an inner rotor body, on which a plurality of inner rotor permanent magnets are arranged, and the plurality of inner rotor permanent magnets are arranged along the circumference of the inner rotor body The direction is arranged at intervals; the outer rotor body is provided with a plurality of outer rotor permanent magnets, and the plurality of outer rotor permanent magnets are arranged at intervals along the circumferential direction of the outer rotor body; the modulation ring, the modulation ring includes a plurality of modulation blocks and magnetic bridges , two adjacent modulation blocks are connected by a magnetic bridge; the radial section of the modulation block and the radial section of the magnetic bridge are both fan-shaped, and the center of the fan ring is the center of the modulation ring; the radial section of the modulation block is The corresponding central angle is θ1, and the corresponding central angle of the magnetic bridge is θ2, 0.3<θ1 / θ2<0.96. The present invention solves the problem of large torque fluctuation of the magnetic gear in the prior art, which leads to poor performance of the magnetic gear.

Owner:GREE ELECTRIC APPLIANCES INC

Square wave rotor based on outer rotor iron core eccentric structure design

ActiveCN113541355AImprove air gap flux density waveformImprove performanceMagnetic circuit rotating partsSynchronous machine detailsElectric machineEngineering

The invention relates to the technical field of generators or motors, and particularly discloses a square wave rotor designed based on a outer rotor iron core eccentric structure design. The square wave rotor comprises an outer rotor iron core, permanent magnets, a stator, an inner rotor iron core and a rotor shaft, the radial outer side of the outer rotor iron core is installed at the outer end of the rotor shaft, the radial inner side of the inner rotor iron core is installed at the inner end of the rotor shaft, the permanent magnets are tile-shaped, and the permanent magnets are alternately arranged along the radial outer side of the inner rotor iron core. The magnetizing directions of every two adjacent permanent magnets are opposite, the outer contour of the outer rotor iron core is round, the inner contour of the outer rotor iron core is composed of a plurality of eccentric arcs in the circumferential direction, the number of the eccentric arcs is the same as that of the permanent magnets, and annular air gaps are formed between the radial inner side of the outer rotor iron core and the permanent magnets. After the outer rotor core eccentric structure design is adopted, the air-gap flux density waveform of the motor is effectively improved, and an air-gap magnetic field is close to a square wave, so that the back electromotive force waveform of the motor or a generator is improved, the torque pulsation is reduced, and the motor performance is improved.

Owner:安徽华驰动能科技有限公司

Built-in permanent magnet synchronous motor

ActiveCN103078464BImprove qualityImprove air gap flux density waveformMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsBand shapePermanent magnet synchronous motor

The invention discloses a built-in permanent magnet synchronous motor, relates to the technical field of a motor and aims to solve the technical problem of improving the comprehensive quality of the motor. Multiple permanent magnet slots are axially and symmetrically arranged in a rotor of the motor along the central axis of the rotor at intervals, three permanent magnets distributed in an arc band shape are arranged in each permanent magnet slot, wherein one permanent magnet is a middle steel magnet, and the other two permanent magnets are side steel magnets; the built-in permanent magnet synchronous motor is characterized in that each middle steel magnet adopts the normal magnetization vertical to the surface of the steel magnet, and each two side steel magnets in one slot adopt the non-normal magnetization, so that the arc center of a magnet arrangement arc of each permanent magnet slot is enabled not to coincide with the magnetization orientation point of permanent magnets in the corresponding permanent magnet slot. According to the motor provided by the invention, the comprehensive quality of the motor is greatly improved.

Owner:SHANGHAI TOP MOTOR +2

Rotor structure, motor and compressor

PendingCN111711294AReduce coggingReduce the proportion of back EMF harmonicsMagnetic circuit rotating partsPhysicsEngineering

The invention mainly aims to provide a rotor structure, a motor and a compressor. The rotor structure comprises a rotor iron core and a plurality of permanent magnets arranged on the rotor iron core so as to form a plurality of magnetic poles on the rotor iron core, wherein the plurality of magnetic poles comprise a plurality of N poles and a plurality of S poles which are alternately arranged along the circumferential direction of the rotor iron core, at least one magnetic pole of the rotor iron core is provided with a magnetic isolation hole, the magnetic isolation hole comprises a first hole body part, a second hole body part and a third hole body part which are communicated with one another, the second hole body part and the third hole body part are respectively arranged at two ends ofthe first hole body part along the direction far away from the axis of the rotor iron core, and in the circumferential direction of the rotor iron core, the second hole body part and the third hole body part protrude out of the first hole body part. By means of the arrangement, the problem that in the prior art, vibration noise of a motor is large is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Square-wave rotor based on permanent magnet and inner rotor core eccentric structure design

ActiveCN113541353BImprove air gap flux density waveformImprove performanceSynchronous machine detailsMagnetic circuitElectric machineEngineering

The invention relates to the technical field of motors or generators, and specifically discloses a square-wave rotor designed based on permanent magnets and an eccentric structure of an inner rotor core; it includes an outer rotor core, an eccentric permanent magnet, an inner rotor core, and a rotor shaft, and multiple The permanent magnets are placed alternately along the radial inner side of the outer rotor core. The eccentric permanent magnet is composed of an arc-shaped outer profile, an eccentric arc inner profile and two sides. The inner rotor core has a circular inner profile and a set of eccentric permanent magnets. Composed of circular arcs, an annular air gap is formed between the radially outer side of the inner rotor core and the eccentric permanent magnet; the invention adopts a rotor designed based on the eccentric structure of the permanent magnet and the inner rotor core, so that the radial air gap of the flywheel generator The length of the two sides is not uniform, and the length change of the radial sides of the air gap is more reasonable, which improves the air-gap magnetic density waveform of the flywheel generator, making the air-gap magnetic field close to a square wave, thereby improving the hollow cup flywheel Generator back electromotive force waveform reduces torque ripple.

Owner:安徽华驰动能科技有限公司

A permanent magnet synchronous motor rotor structure with bow-shaped permanent magnets

ActiveCN103929033BReduce vibrationReduce noiseSynchronous machine detailsMagnetic polesPermanent magnet synchronous motor

Owner:NORTHWESTERN POLYTECHNICAL UNIV

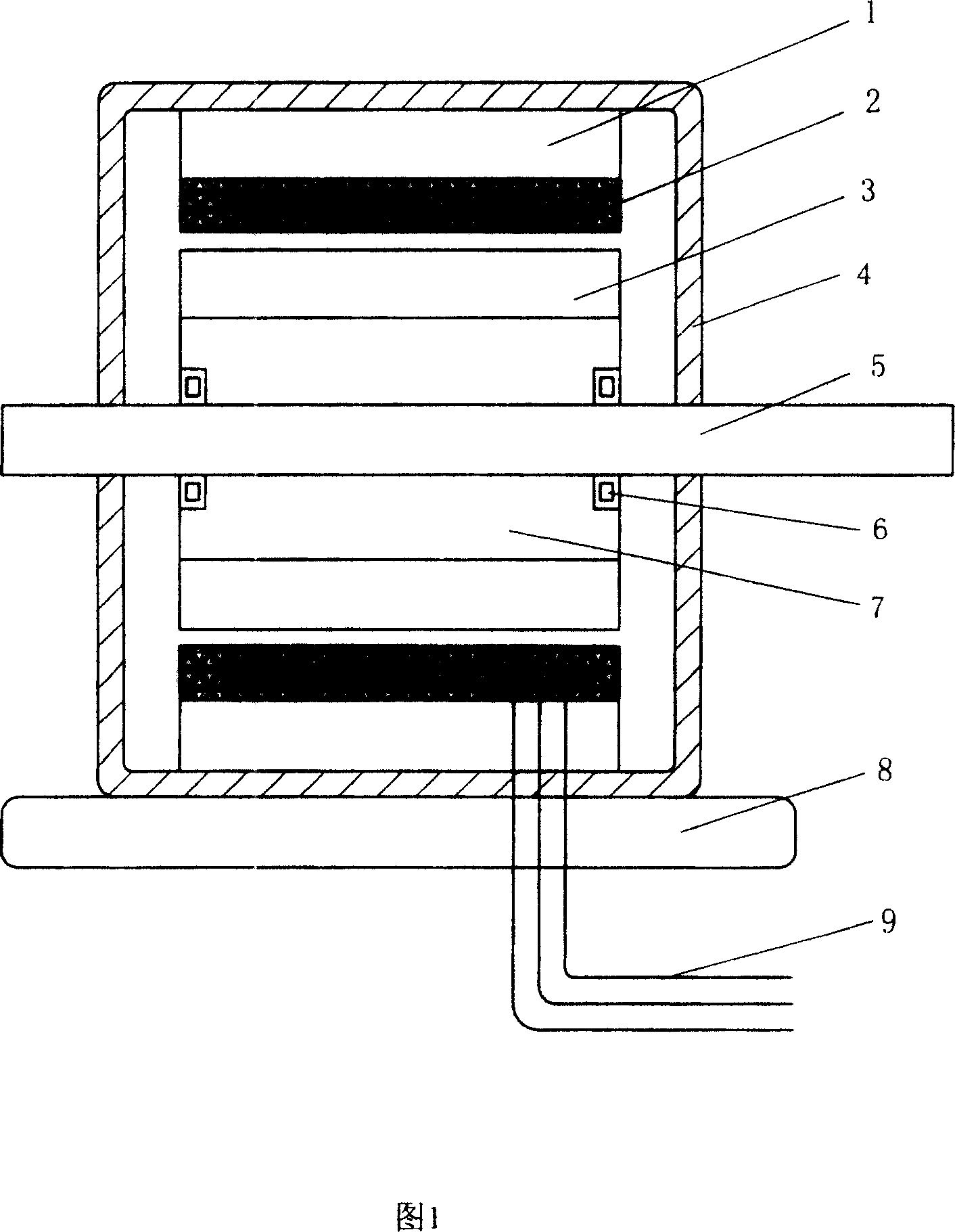

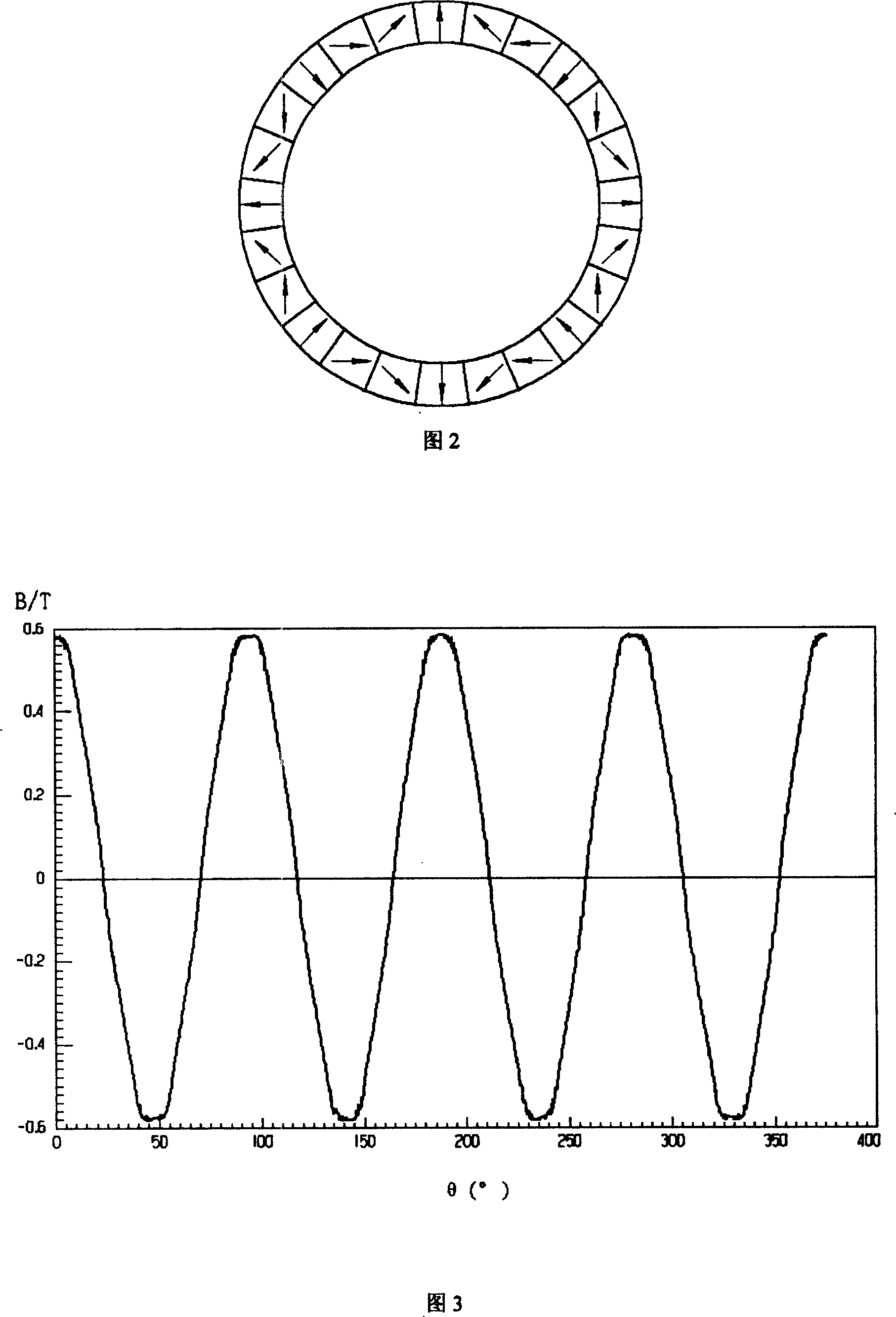

Radial coreless permanent magnet motor

InactiveCN100370684CSimple preparation processImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsHarmonicPower factor

The radial permanent magnet motor without iron core comprises a shell on base, a rotation shaft arranged rotor and stator radially along circular, a bearing to fix the motor rotation shaft on center of shell; wherein, the rotor comprises a frame on shaft and permanent magnet around the frame; the stator comprises a stator yoke with stator coil and stator winding around permanent magnet. His invention has simple structure, high efficiency, little vibration, and no static friction torque; it eliminates iron consumption at root, and decreases greatly the effect of harmonic wave.

Owner:SHENYANG POLYTECHNIC UNIV

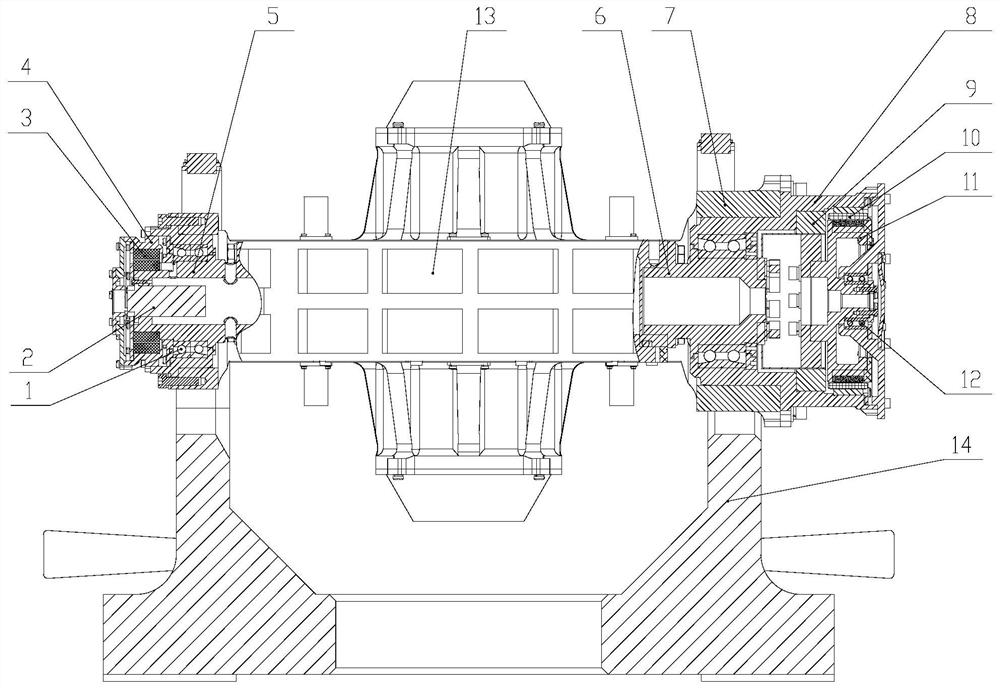

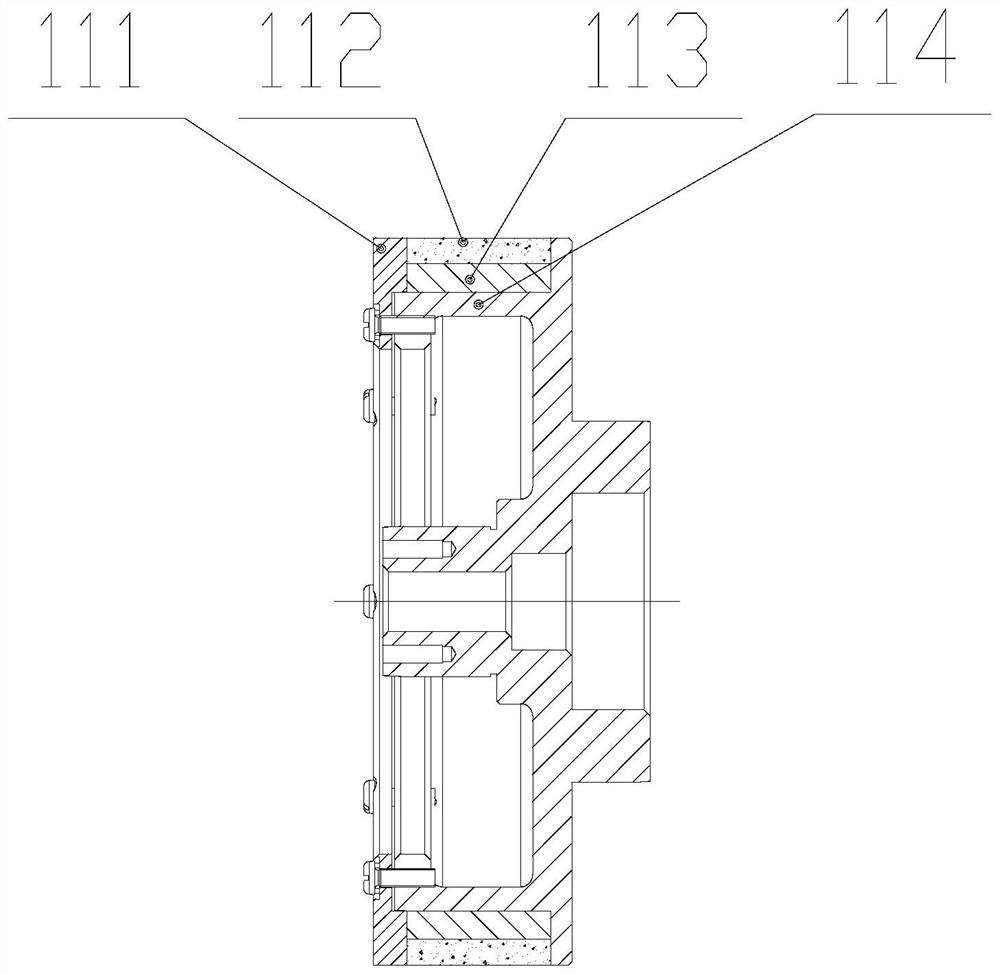

A Frame System for Control Moment Gyroscope

ActiveCN107741746BImprove flux density waveformIncreased torque densityCosmonautic vehiclesCosmonautic partsGyroscopeReduction drive

The invention discloses a frame system for a control moment gyroscope. The frame system can be used as a posture control executing mechanism of large spacecraft like a large satellite and a space station and is composed of a rotary transformer end mechanical bearing, a conducting slide ring, a rotary transformer, a rotary transformer base, a rotary variable shaft, a harmonic shaft, a frame, a motor base, a harmonic reducer, a frame motor stator assembly, a frame motor rotor assembly, a motor end mechanical bearing and the like. A frame core shaft is driven by a frame moment motor to drive a connected gyroscope rotor to rotate to output gyroscope moment, the rotary transformer is in charge of outputting an angular position signal of the frame core shaft to be fed back to a control system ofa moment motor, therefore the moment motor is controlled, an iron core fractional slot structure is adopted by the moment motor to reduce flux leakage, after the moment output by the motor is amplified by the harmonic reducer, the moment is transferred to the gyroscope rotor, and therefore, gyroscope torque is output. The frame system has the advantages that the layout is compact, the size is small, the weight is low, the system noise is small, and the control precision and torque output efficiency of the frame system are high.

Owner:BEIHANG UNIV

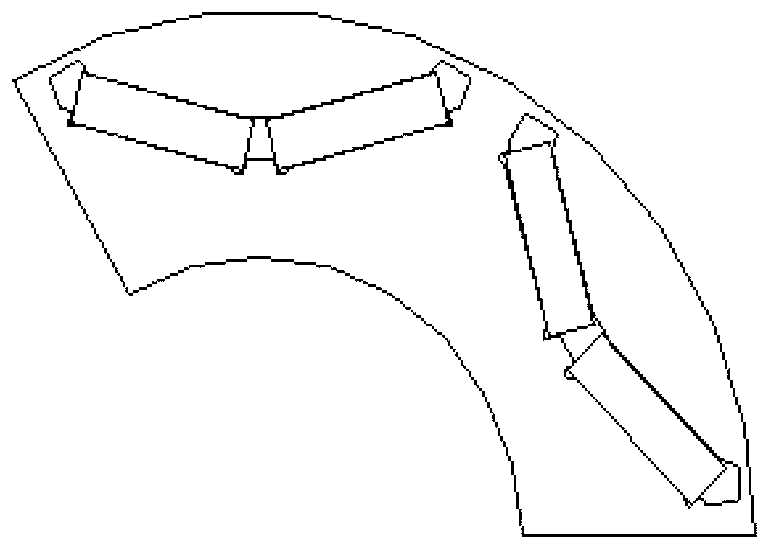

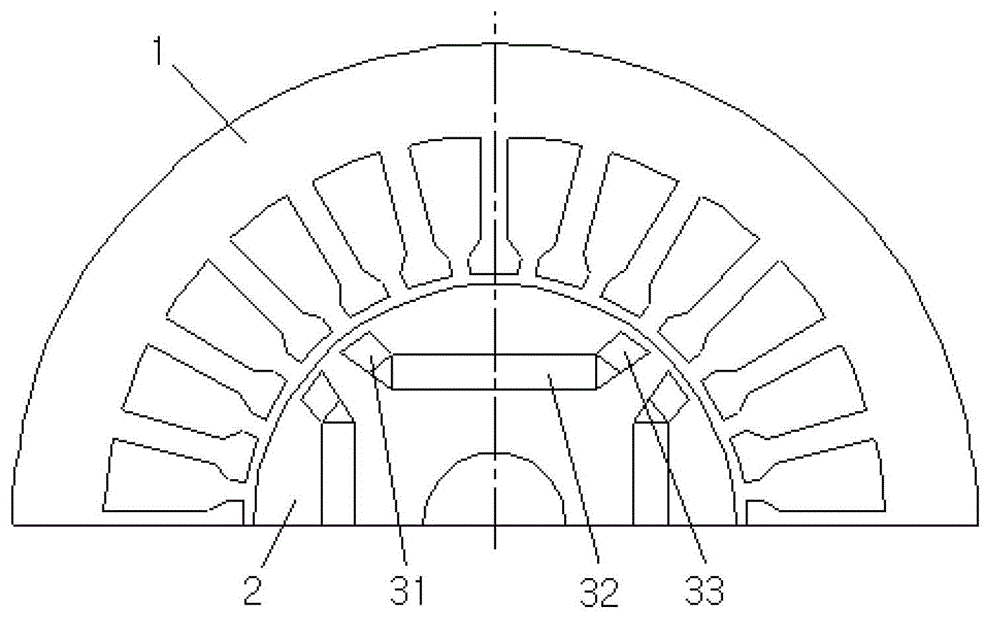

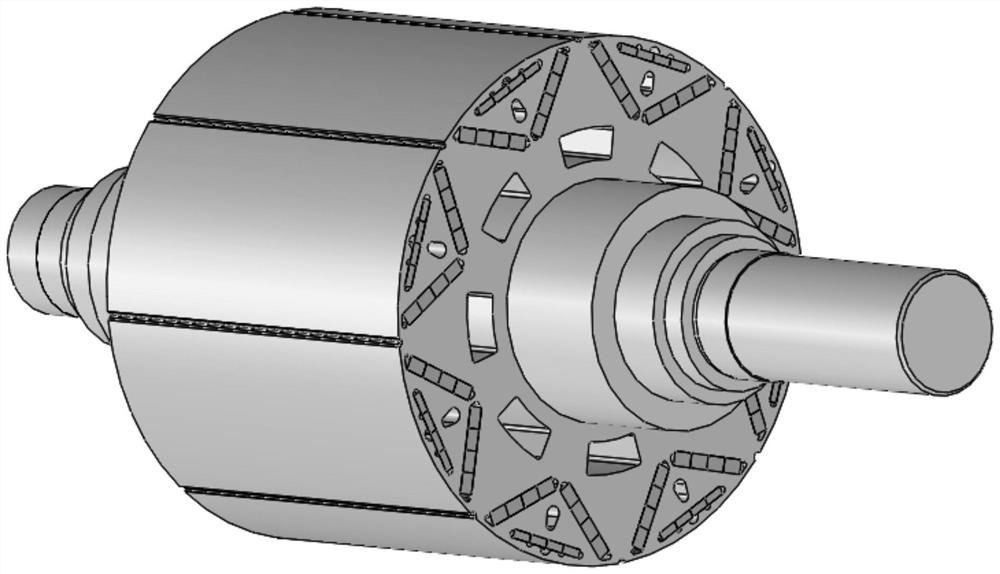

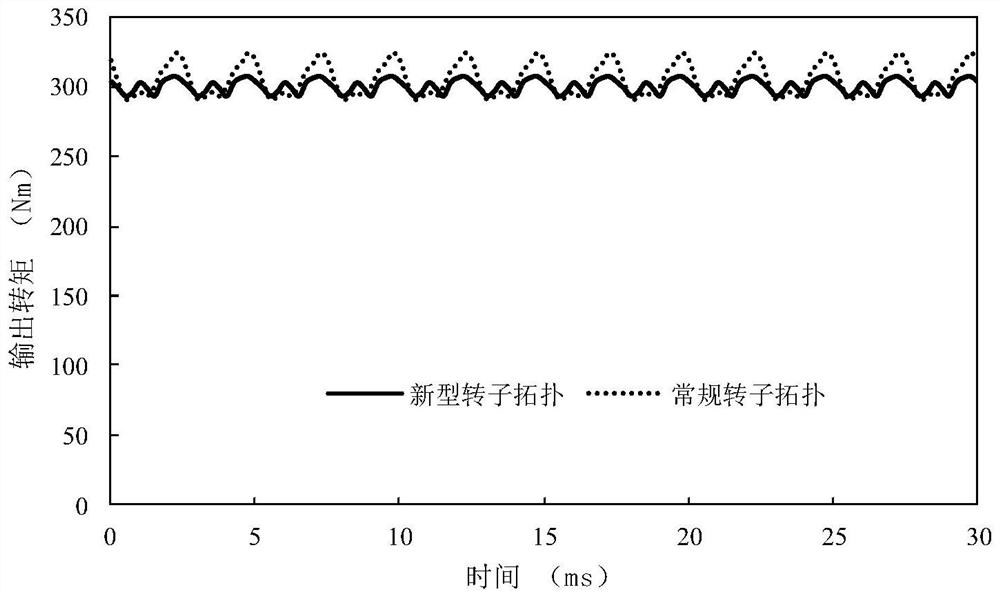

Novel rotor topological structure of built-in permanent magnet synchronous motor

ActiveCN114678980AImprove air gap flux density waveformReduce torque fluctuationSynchronous machine detailsMagnetic circuitMagnetic barrierElectric machine

The invention discloses a novel rotor topological structure of a built-in permanent magnet synchronous motor. At least one iron core structure is arranged, wherein each iron core structure is composed of a linear built-in permanent magnet magnetism isolating magnetic bridge, a V-shaped built-in permanent magnet magnetism isolating magnetic bridge and a semicircular magnetic barrier. Three strip-shaped grooves are formed in the rotor, two of the strip-shaped grooves are each provided with a permanent magnet, the permanent magnets are arranged in a V shape, and a magnetic isolation magnetic bridge of the V-shaped built-in permanent magnets is formed; a permanent magnet is mounted in each of the remaining strip-shaped grooves, so that a linear magnetic isolation magnetic bridge of the built-in permanent magnets is formed; and a plurality of semicircular hole grooves are formed beside the strip-shaped grooves of the magnetic isolation magnetic bridge of the linear built-in permanent magnet to form a magnetic barrier. According to the invention, the air gap flux density waveform of the motor can be improved, the torque ripple under the motor load is reduced, and the rotor mechanical strength of the motor is enhanced.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com