Motor

A motor rotor, trapezoidal technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of unobvious improvement of flat-top wave waveform, increased assembly difficulty, increased amount of magnetic steel, etc., to achieve improvement Effects of air gap magnetic density waveform, increasing reluctance torque component, and reducing harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

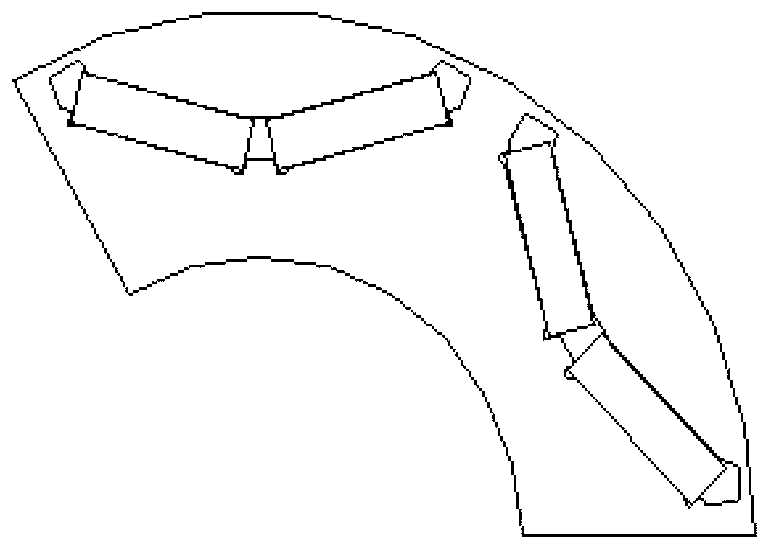

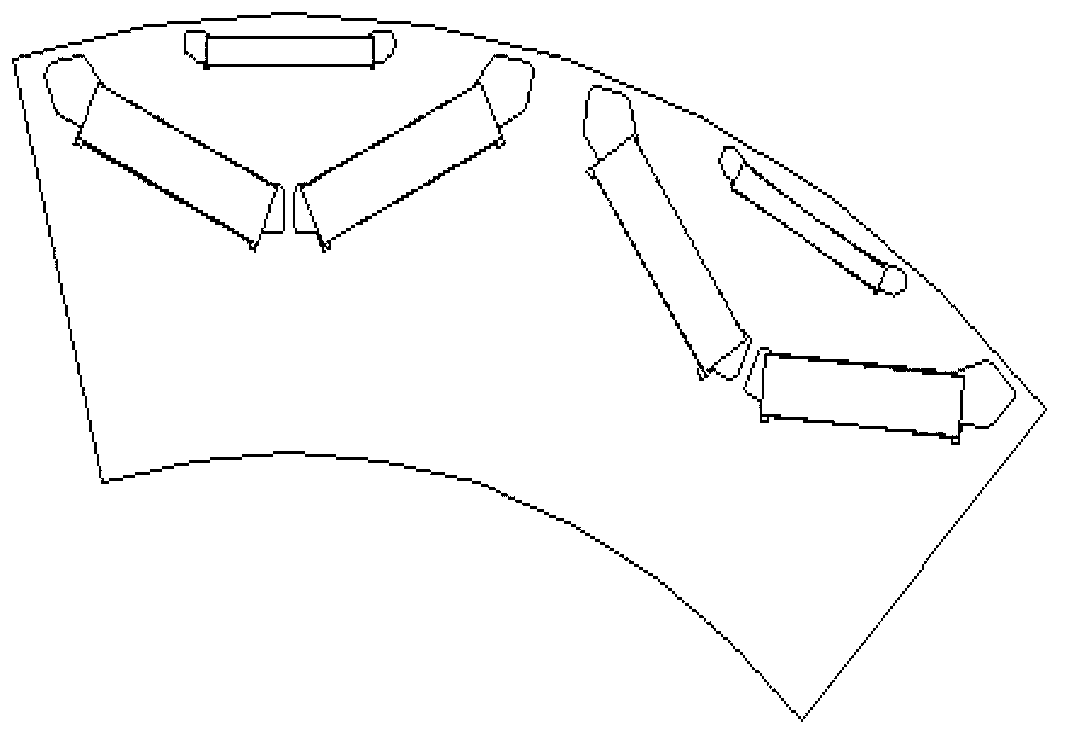

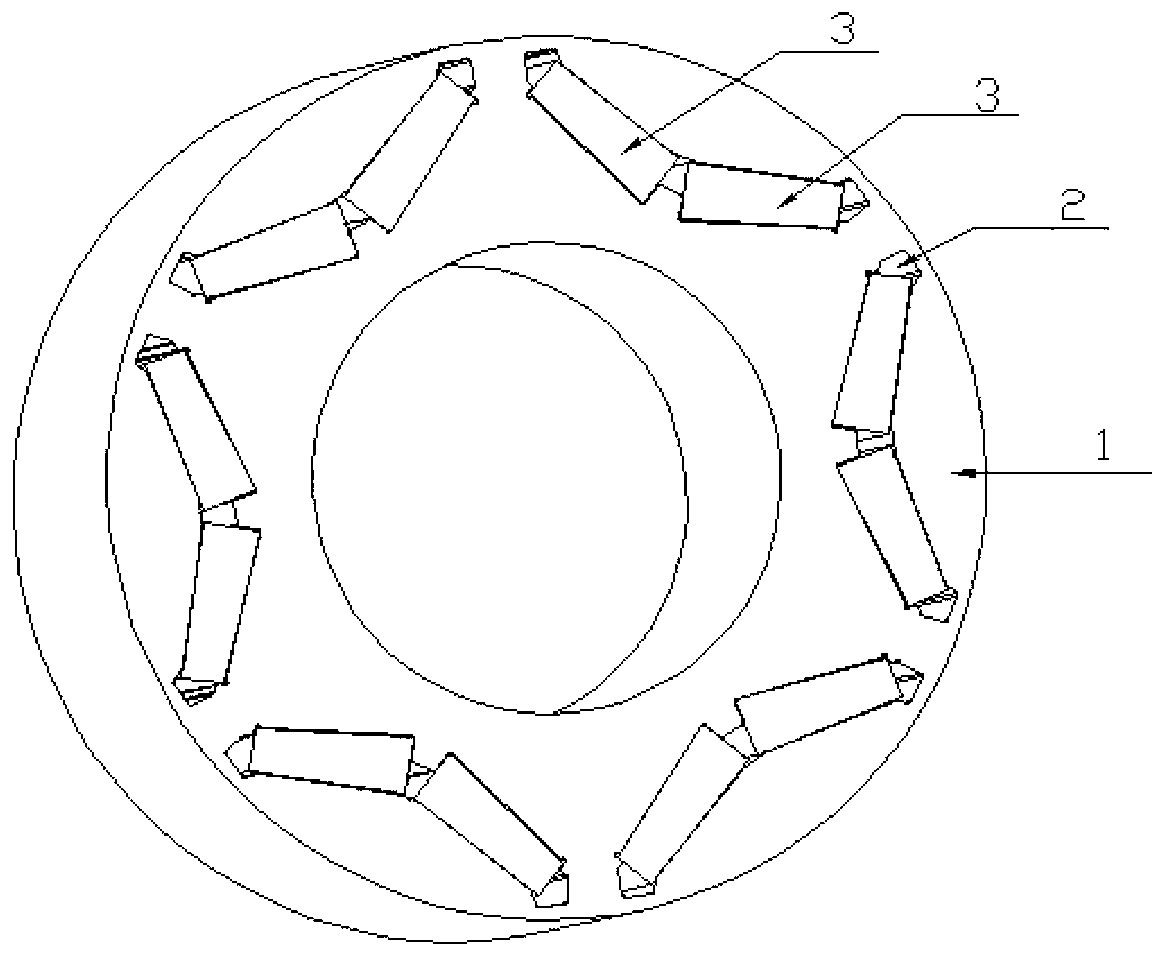

[0014] Such as image 3 The motor rotor of the shown motor includes a rotor core 1, a trapezoidal magnetic steel 3 and a trapezoidal magnetic steel groove 2, and the rotor core 1 is a core formed by stacking rotor punches. The rotor core 1 is evenly distributed with the same trapezoidal magnetic steel grooves 2 axially penetrating, and the adjacent trapezoidal magnetic steel grooves 2 are V-shaped radially symmetrically distributed relative to the rotor core 1, and the angle of the V shape is greater than 0° and less than 180° °, and the V-shaped opening faces the outer circle of the rotor core 1, and the corresponding trapezoidal magnetic steel 3 is embedded in each trapezoidal magnetic steel groove 2 alternately according to N pole and S pole.

[0015] Since the trapezoidal magnetic steel groove 2 and the trapezoidal magnetic steel 3 of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com