Direct torque control method suitable for multi-motor system

A direct torque control, multi-motor technology, applied in motor generator control, electronic commutation motor control, multiple motor speed adjustment, etc., can solve problems such as large torque fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

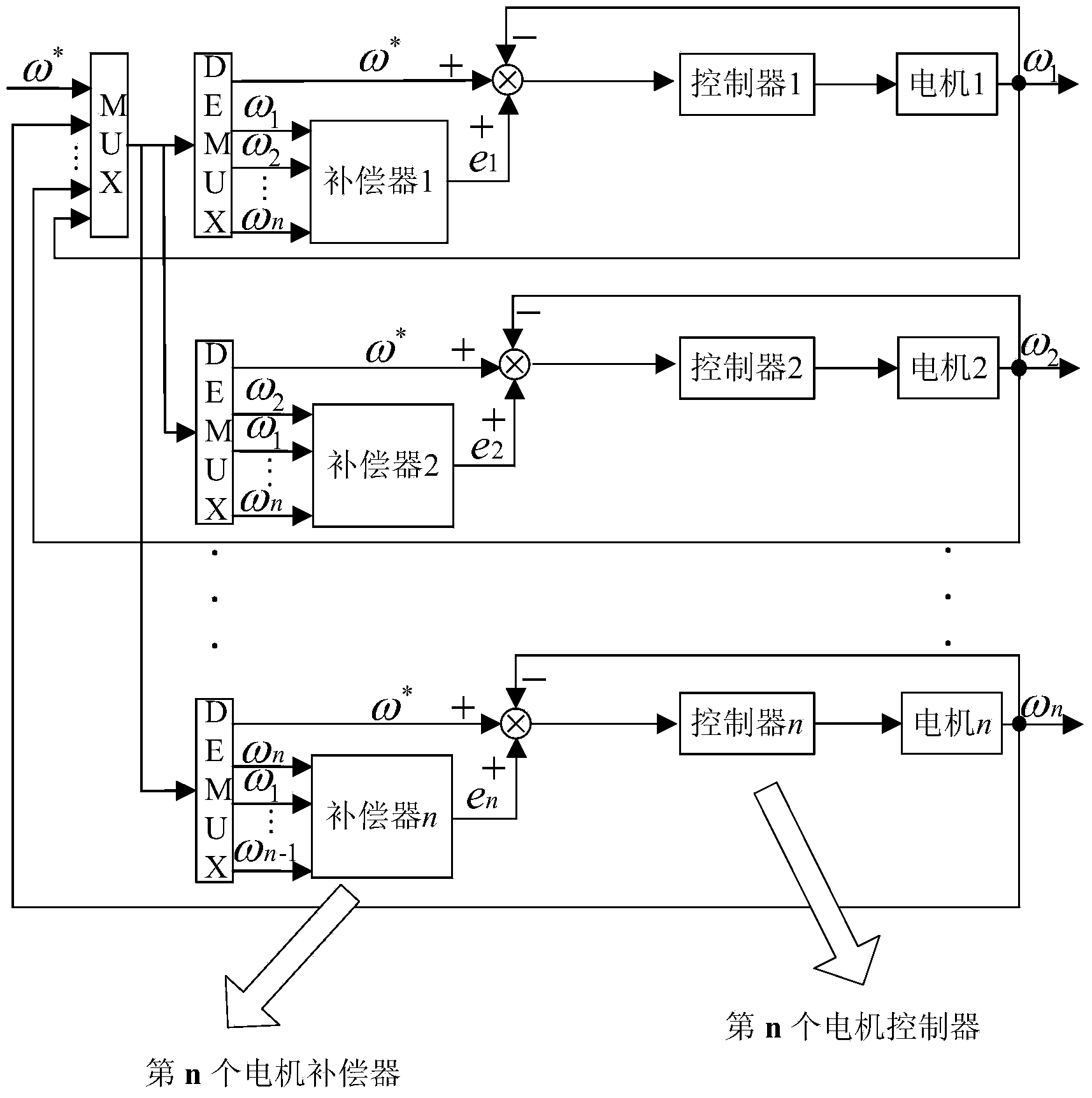

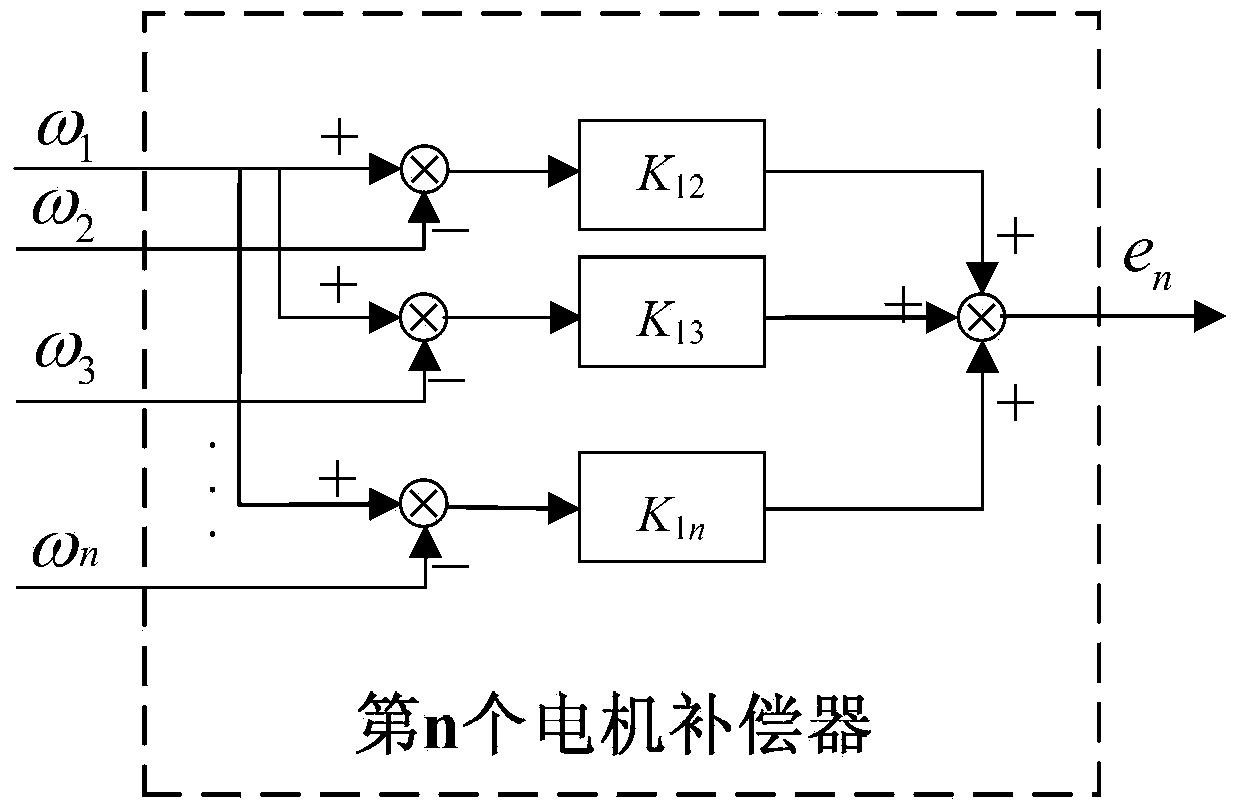

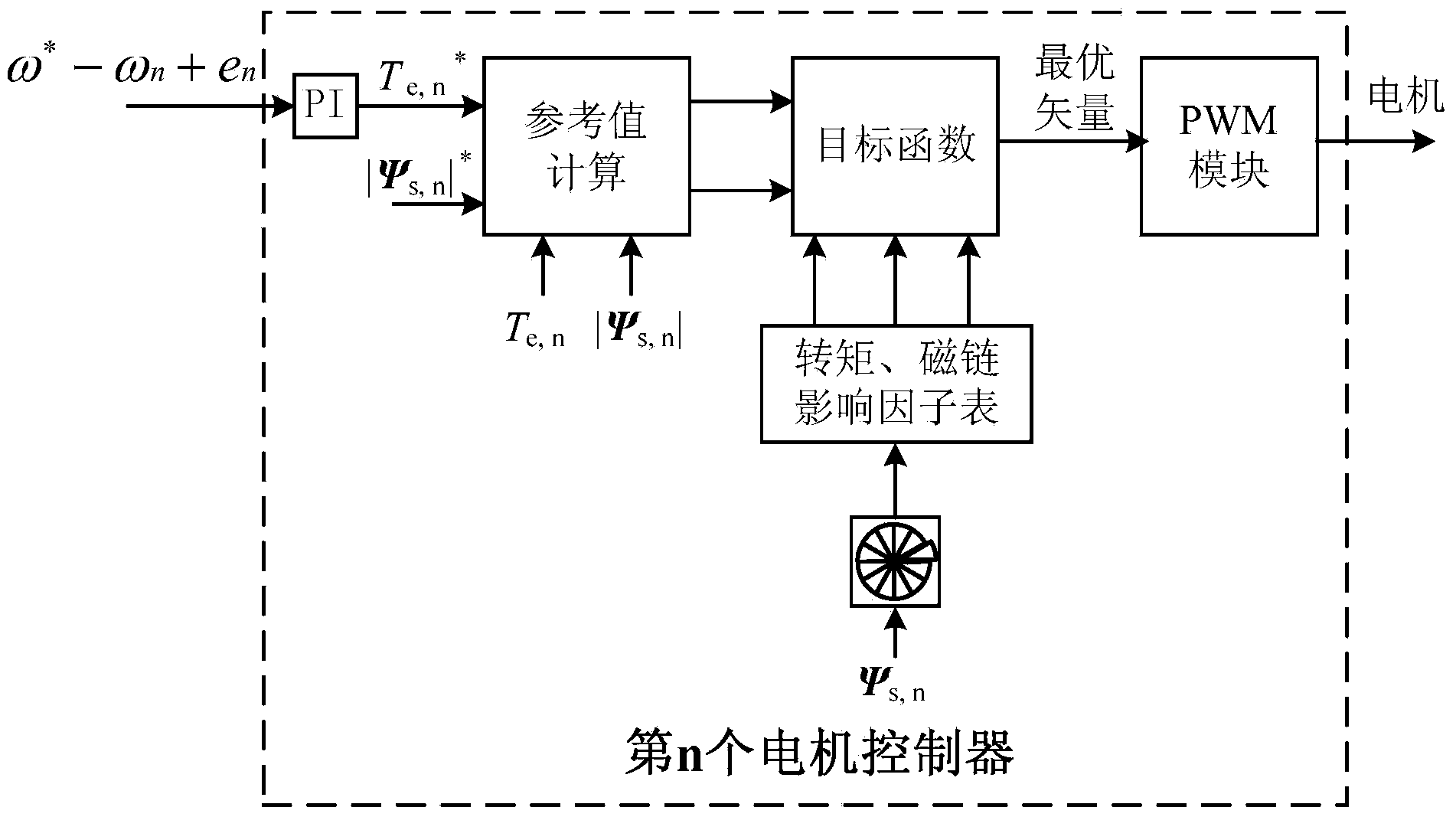

[0034] The invention is applicable to a multi-motor cooperative control system. The present invention will be described in further detail below in conjunction with specific examples and accompanying drawings. Picture 1-1 It is a schematic diagram of the direct torque control strategy of the multi-motor system in the present invention. The direct torque control method applicable to the multi-motor system of the present invention comprises the following steps:

[0035] Step 1. Generate the control reference signal of a single motor through the deviation coupling controller of the multi-motor system:

[0036] In a multi-motor (motor number n greater than or equal to 3) speed synchronous control system, the structure diagram of the deviation coupling control method is as follows Picture 1-1 shown. Picture 1-1 In the process, the actual speed and the given speed of each motor at each moment are all sent to the multiplexer MUX, and the splitter DEMUX is used to separate the given...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com