Variable-flow speed-change brushless non-reversing permanent magnet direct-current motor

A DC motor, non-commutation technology, applied in electric components, magnetic circuit rotating parts, magnetic circuit and other directions, can solve the problems of high power consumption, poor motor speed regulation characteristics, high manufacturing cost, etc., to achieve power consumption Small volume, high utilization rate of permanent magnet energy, and fast torque response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

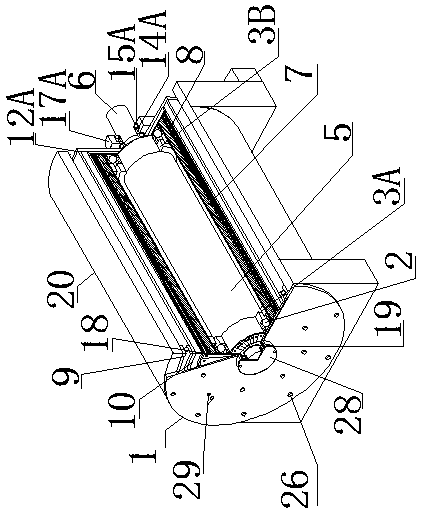

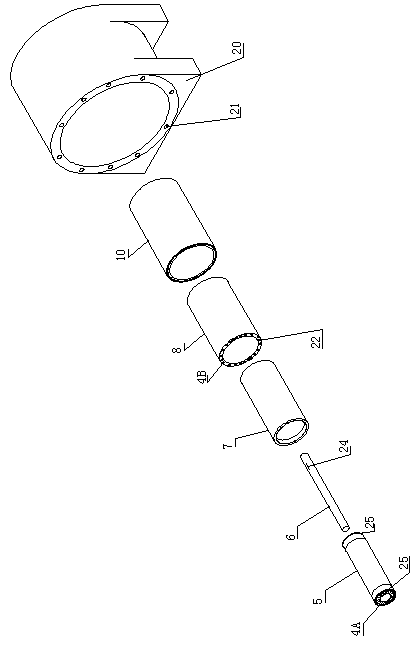

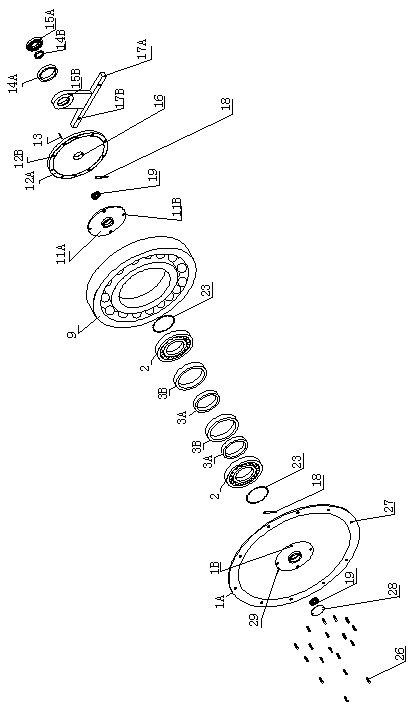

[0043] The present invention is designed according to the force that the energized wire will be subjected to in the magnetic field. The technical parameters of the inner and outer stator turns of the coil of the present invention are listed as columns; the radial diameter of the two ends of the outer stator (8) of the coil is 400mm, and its circumference is 1256mm, 66 wires can be arranged in the axial direction with a 19mm wire, the effective axial length of the wire in the magnetic field is 1000mm, and the wire diameter is 70mm 2 , the diameter of the wedge-shaped copper bar of the stator (5) inside the coil is 70 mm 2 , it only plays the role of conduction current. In order to reduce the resistance loss, its wire diameter can be increased, and the wire diameter of the conductive plate (18) is 70 mm 2 , the length is 100mm, and the magnetic induction of the permanent magnet inner and outer rotors is 0.3 Tesla. The total length of the current passing through the inner and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com