Field Weakening Control Method for Full Speed Range of Permanent Magnet Synchronous Motor

A permanent magnet synchronous motor, speed range technology, applied in motor control, motor generator control, AC motor control and other directions, can solve the problems of inability to calibrate the motor, complex calibration process, etc., to reduce the cost of labor, time, and control accuracy. The effect of high and increasing specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

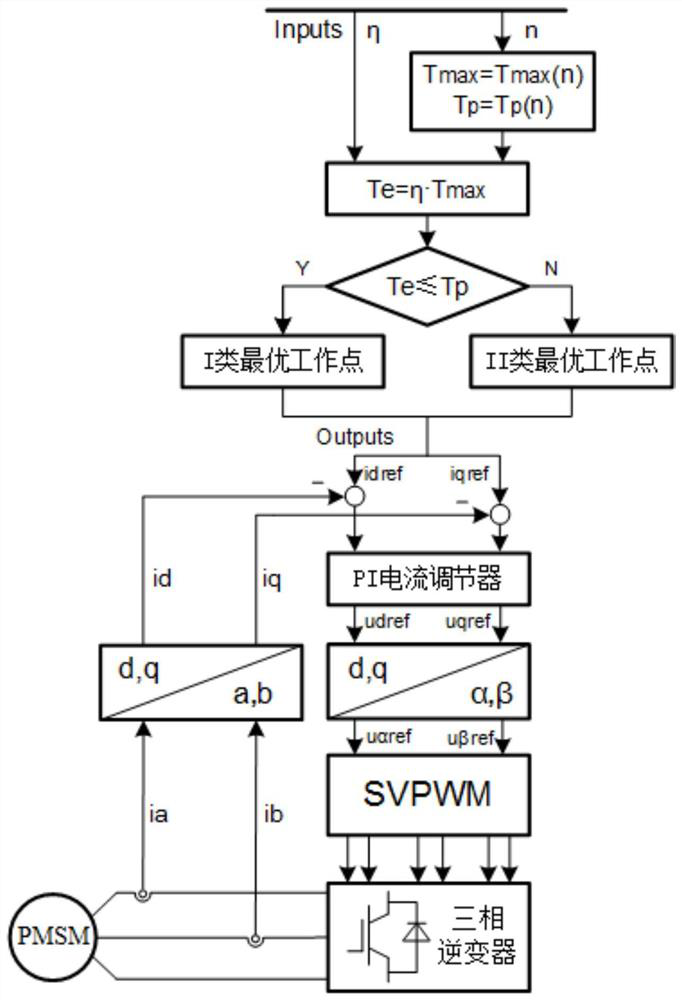

[0042] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0043] attached figure 1It can be seen that, a method for field weakening control of permanent magnet synchronous motors in the full speed range, the calibration obtains the three-dimensional table of the maximum torque-speed characteristic curve of the motor: speed(n)-torque(T max )-current (i d,Tmax );

[0044] Calibrate to obtain the working point on the maximum torque current ratio curve (MTPA), and on this basis, calibrate to obtain the three-dimensional table of the switching torque-speed characteristic curve: speed (n)-torque (T P )-current (i d,Tp );

[0045] Obtain the maximum torque and switching torque that can be output at the current speed;

[0046] Obtain the target output torque in this state;

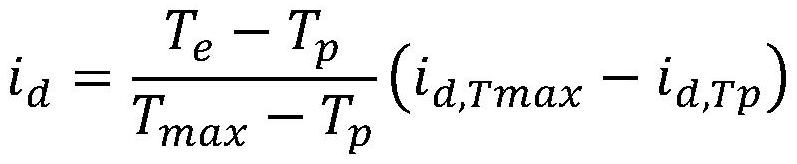

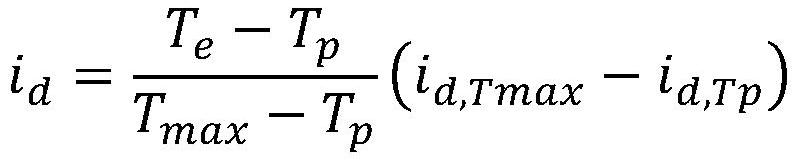

[0047] According to the speed-torque-current table obtained above, the optimal field-weakening operating current in the current state is obtained.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com