Coreless brushless direct current motor

A technology of brushed DC motors and hollow cups, applied in electromechanical devices, electrical components, electric components, etc., can solve the problem of low motor torque coefficient, high speed, and the inability to develop high torque density and power density hollow cup brushless DC motors, etc. problem, to achieve the effect of high power and torque density, high efficiency, and improved space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

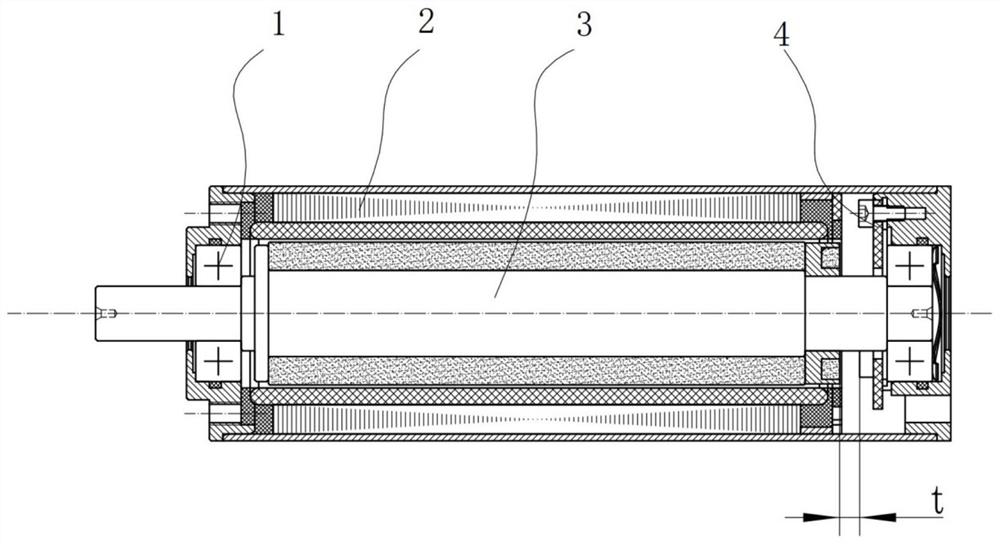

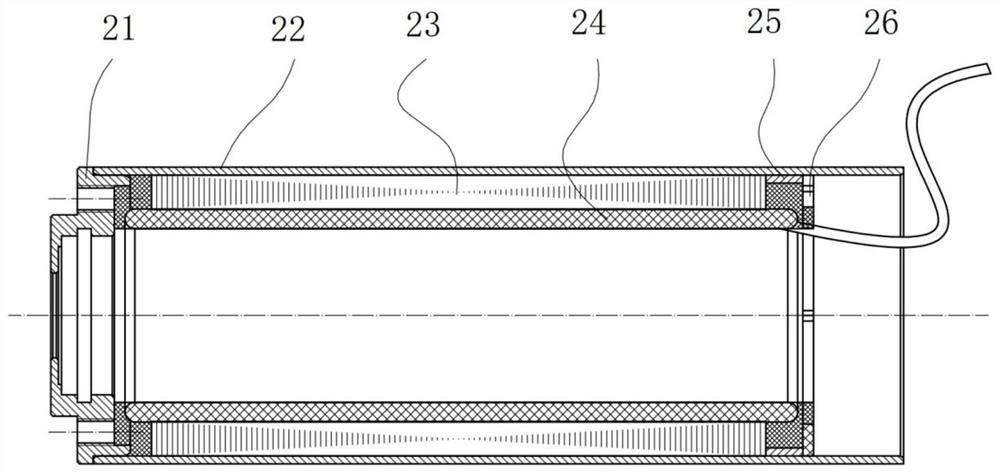

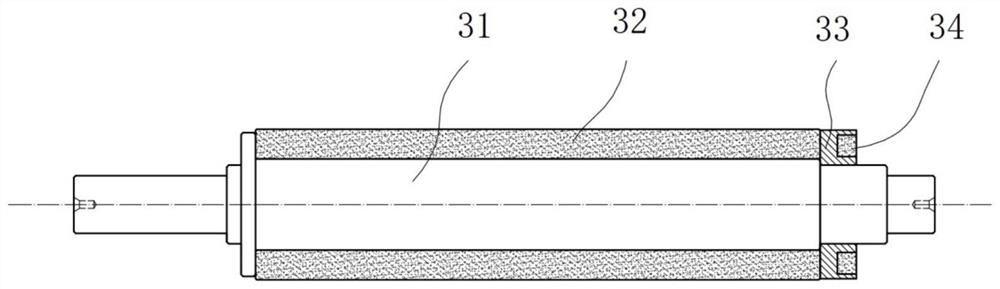

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the examples are only specific elaborations of the present invention, the purpose of which is to allow those skilled in the art to better understand the technical solution of the present invention, and should not be regarded as limiting the present invention. Structures that are not described in detail are processed and connected using traditional structures.

[0042]It should also be noted that, in the case of no conflict, the implementation manners and features in the implementation manners in this solution can be combined with each other. The descriptions in this scheme refer to "center", "length", "width", "thickness", "upper", "lower", "front", "back", "left", "right", The orientations or positional relationships indicated by "vertical", "horizontal", "top", "bottom", "inner", "outer", etc. are based on the orientati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com