Patents

Literature

337 results about "Air gap flux density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calculation of flux is normally done using just the air gap reluctance alone and ignoring any reluctance in the iron. The flux density in the gap is not quite the same as in the iron due to fringing effect, but this can usually be ignored and the air gap flux density considered equal to the core density.

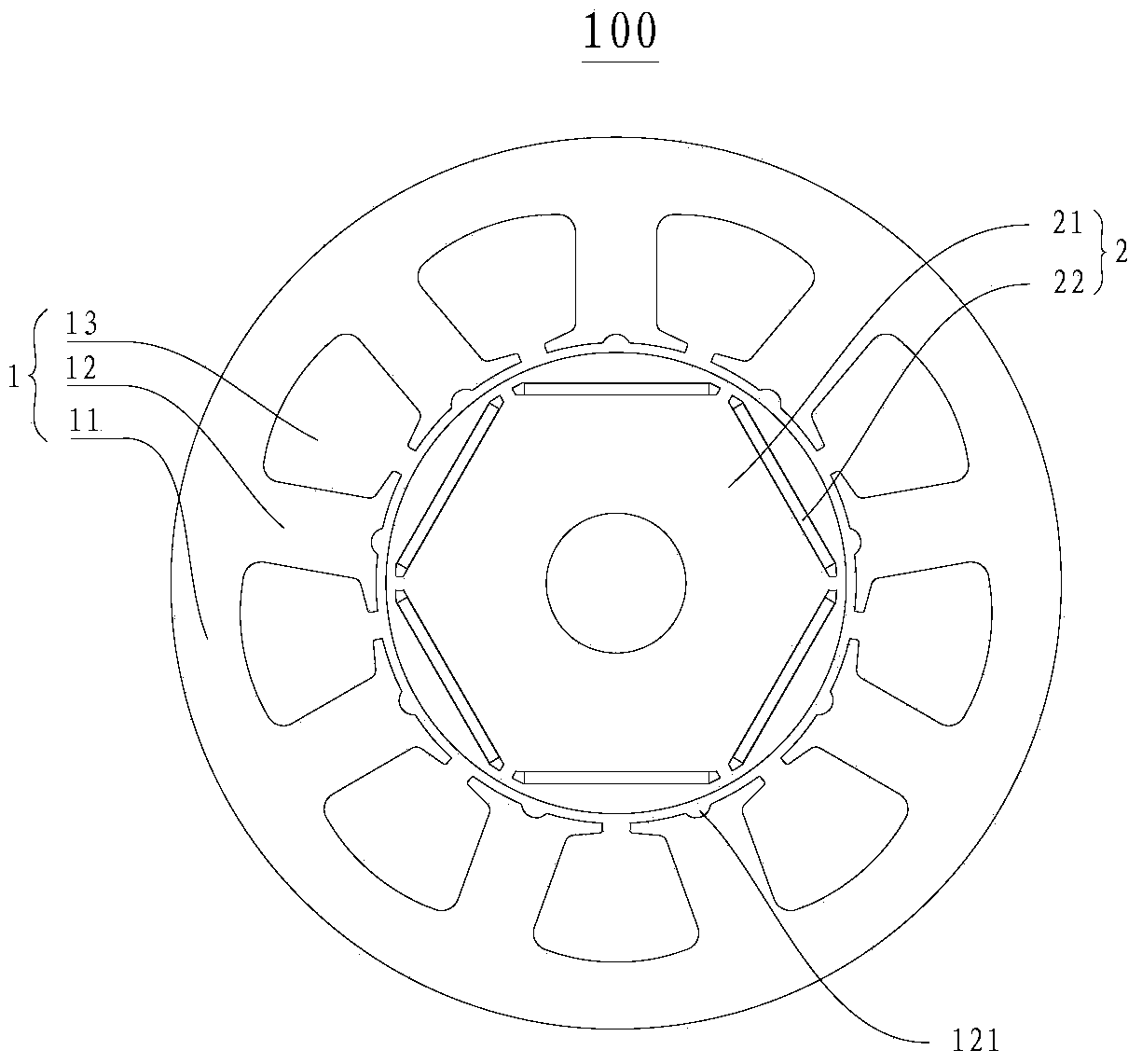

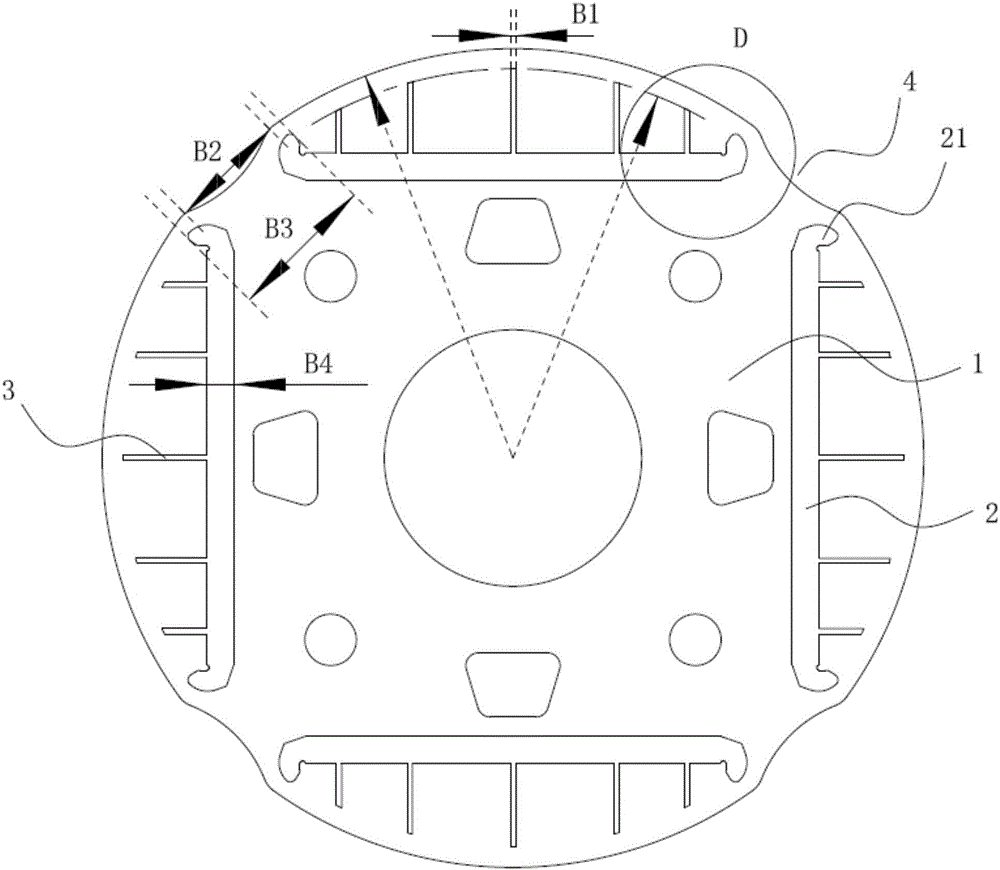

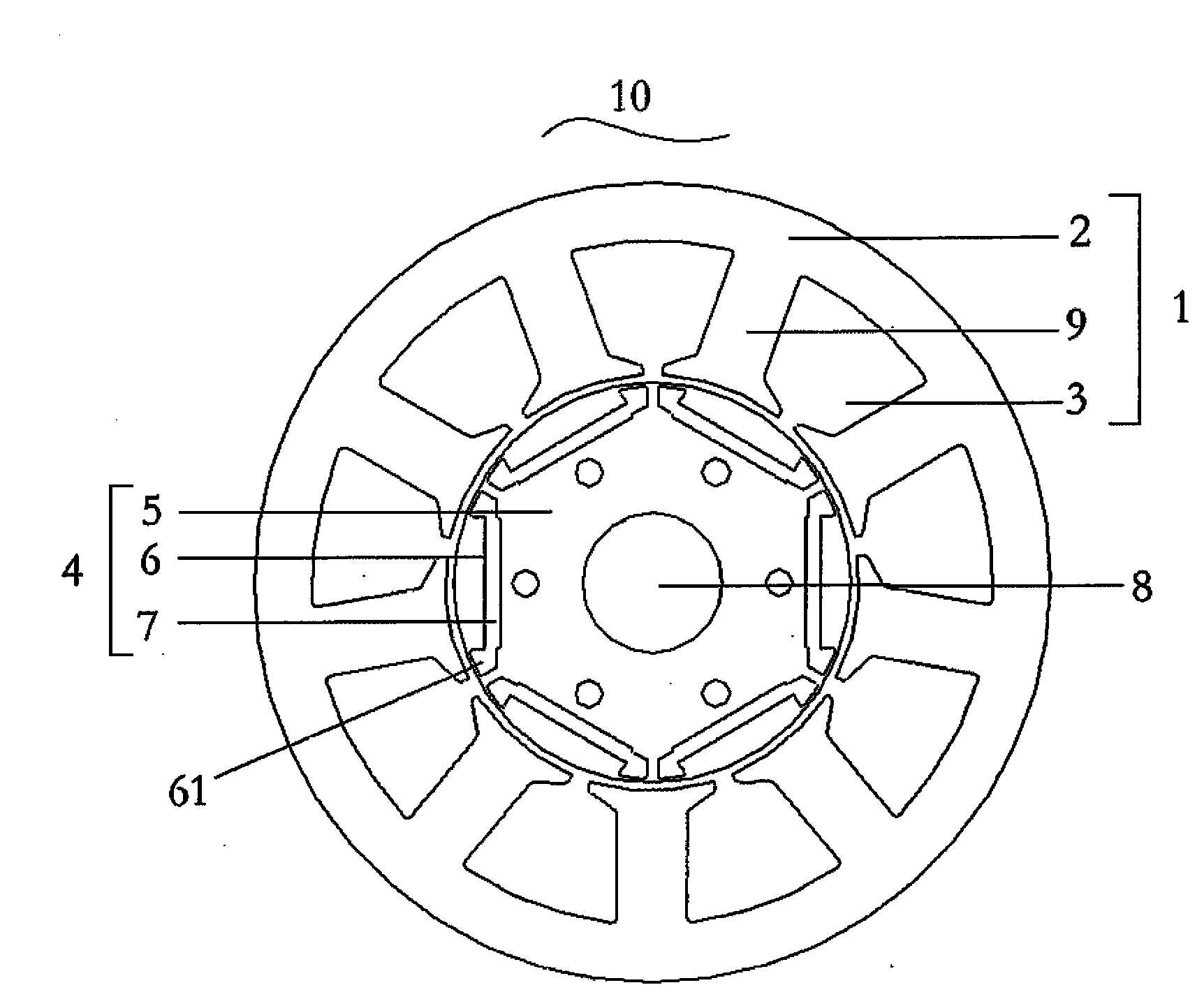

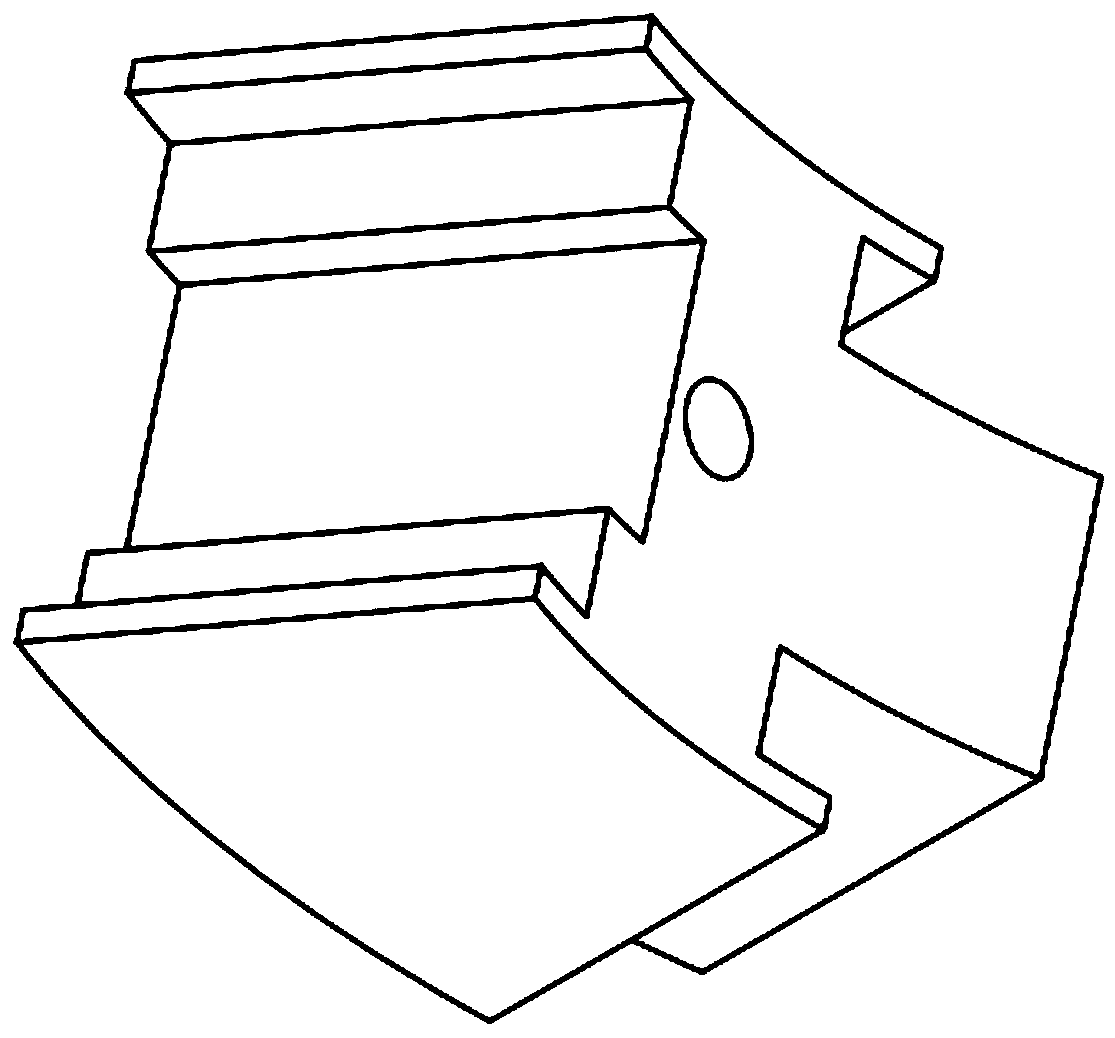

Rotor iron core and permanent magnet synchronous motor with same

ActiveCN105553143AGreat effortHarmonic reductionMagnetic circuit rotating partsSynchronous machinesHarmonicPermanent magnet synchronous motor

The invention provides a rotor iron core and a permanent magnet synchronous motor with the same. The rotor iron core comprises an iron core body, wherein grooves are formed on the peripheral wall of the iron core body in an axial direction of the iron core body; the grooves comprise a first groove and a second groove which are communicated mutually; and a depth of the first groove in a radial direction of the iron core body is greater than that of the second groove in the radial direction of the iron core body. At the position of the first groove, an air gap is the largest, magnetic resistance is high, an air gap flux density is small, and an applied moment fluctuation with a stator tooth socket is reduced; the first groove and the second groove have different depths; by transition of the second groove, a fundamental wave magnetic field is increased and is closer to sine; a torque of the tooth socket is reduced, so that a motor output is increased, a harmonic wave is reduced, and an electromagnetic force and operation vibration voice of the motor are reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

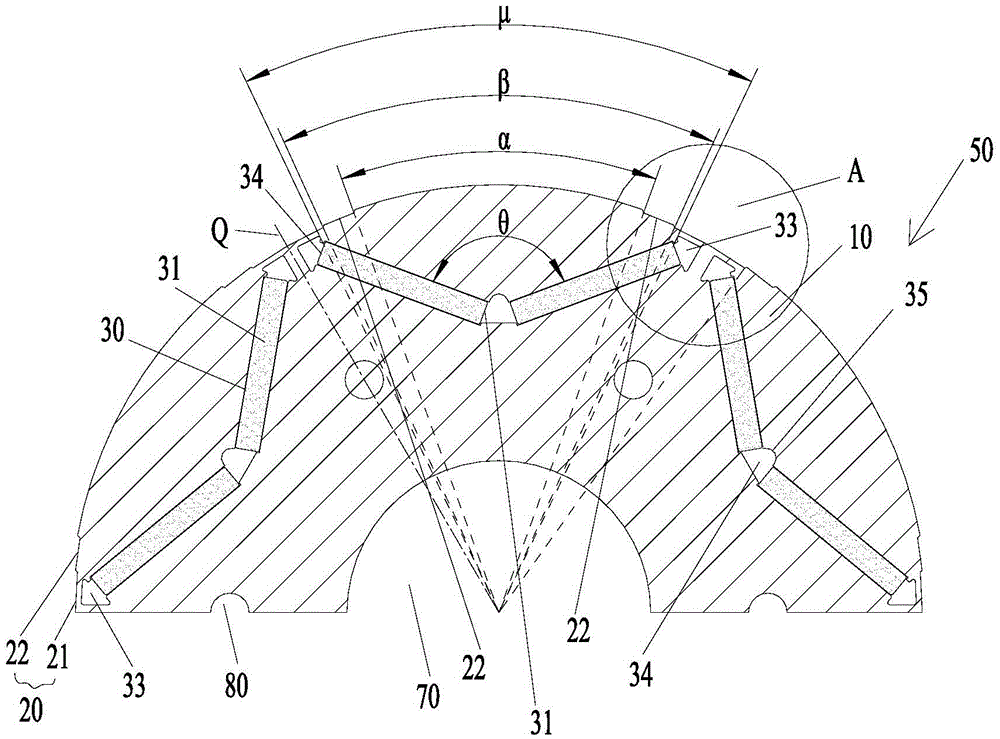

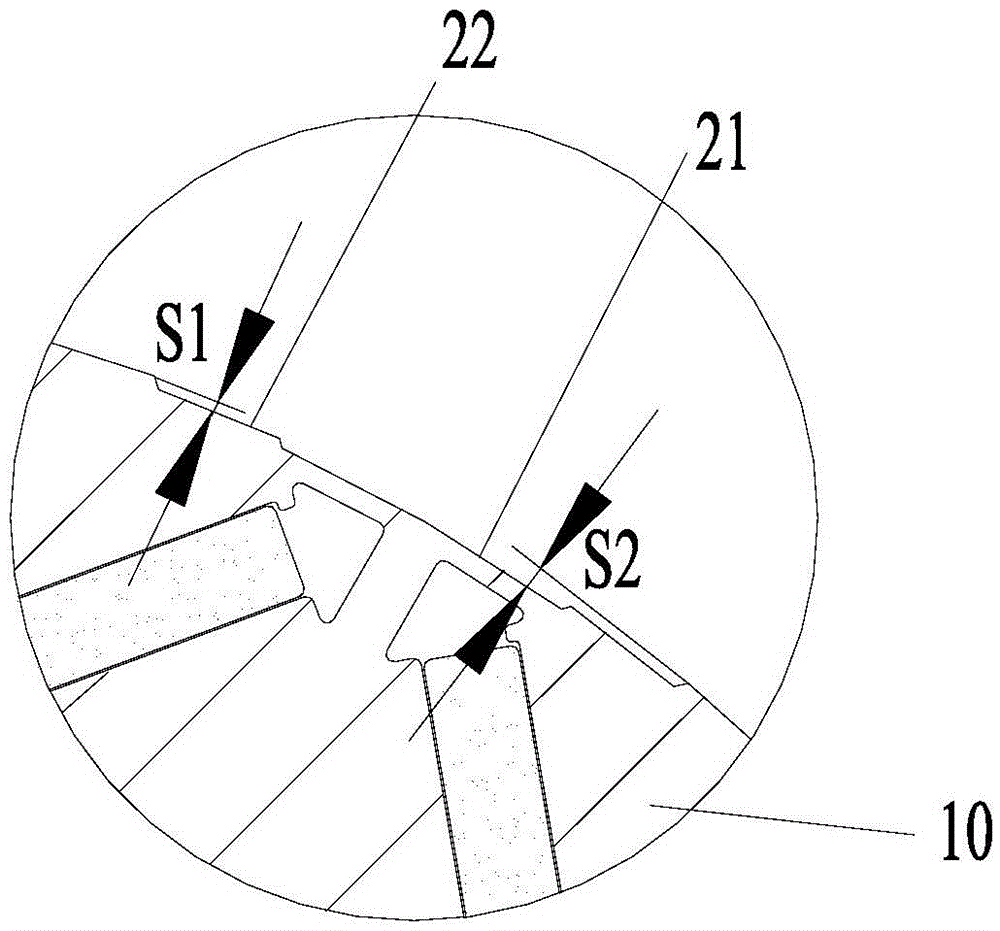

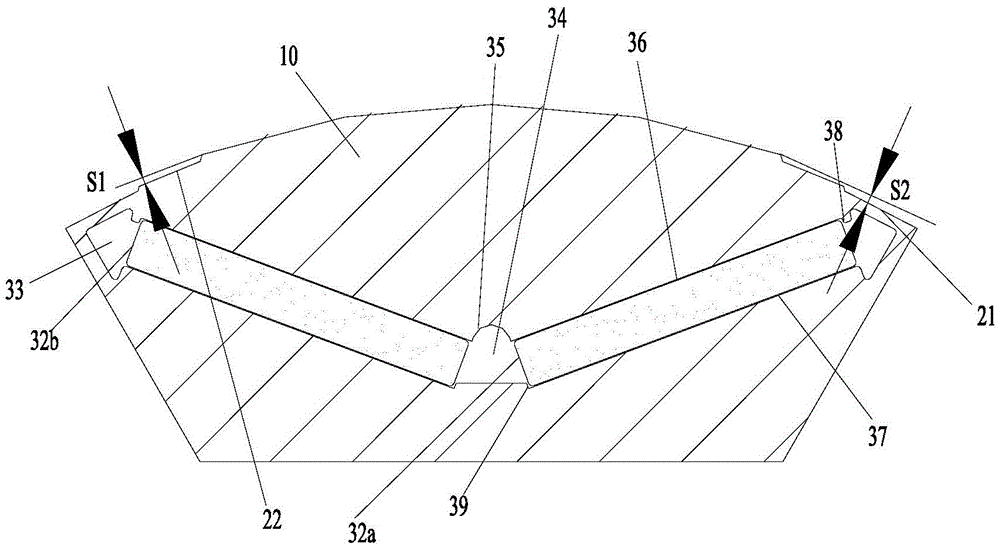

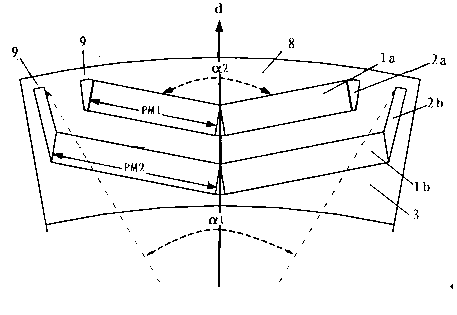

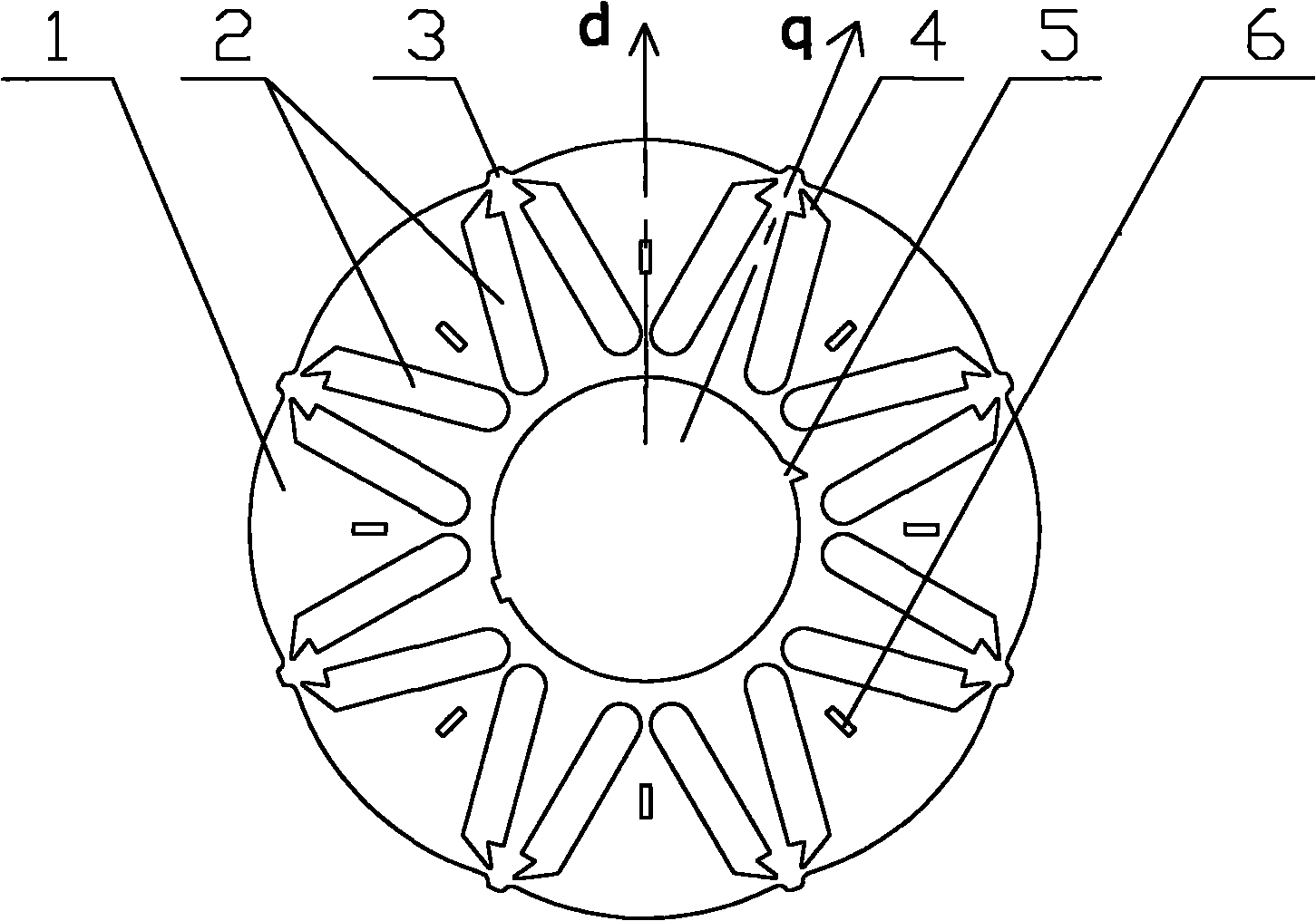

Double-layer V-shaped built-in permanent magnet motor rotor for electric automobile

InactiveCN103280904AImproved air gap magnetic field waveformImprove resultant torque rippleSynchronous machine detailsMagnetic circuit rotating partsConstant powerMagnet

The invention relates to a double-layer V-shaped built-in permanent magnet motor rotor for an electric automobile. Multiple groups of permanent magnet slots which are radially arranged in an inner layer and an outer layer are uniformly arranged on the iron core of the rotor at intervals along the circumferential direction; one or more V-shaped magnetized stripy magnetic steel is embedded in each permanent magnet slot. By virtue of the optimization of structures such as the angle of polar arc of inner-layer V-shaped magnetic steel, the included angle of outer-layer V-shaped magnetic steel, the width proportion of the inner-layer magnetic steel to the outer-layer V-shaped magnetic steel and the included angle of the outer-layer forcipated permanent magnet slot and the outer-layer magnetic steel, the air-gap flux density waveform is more approximate to the sinusoidal distribution, the harmonic component is reduced, the air-gap field waveform of the motor is improved, the fundamental wave frequency of spline torque fluctuation is improved, the spline fundamental wave and the ultraharmonics torque amplitude value are reduced, the torque fluctuation caused by splines is reduced, and the synthesis torque fluctuation of the motor is greatly reduced; and meanwhile, the reluctance torque is obviously increased, the salient pole rate and flux weakening speed expanding capability of the motor are improved, a constant-power speed range wider than that of a surface-mounted permanent magnet motor can be obtained, and the driving requirement of electric and hybrid automobiles can be met.

Owner:苏州和鑫电气股份有限公司

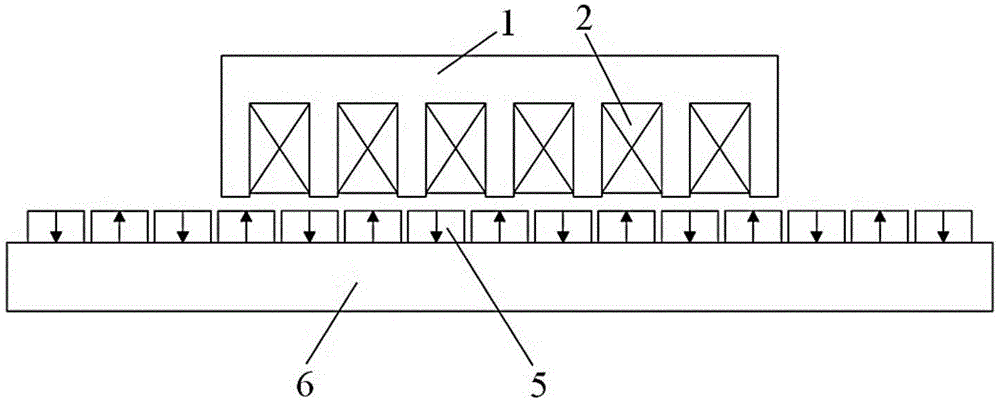

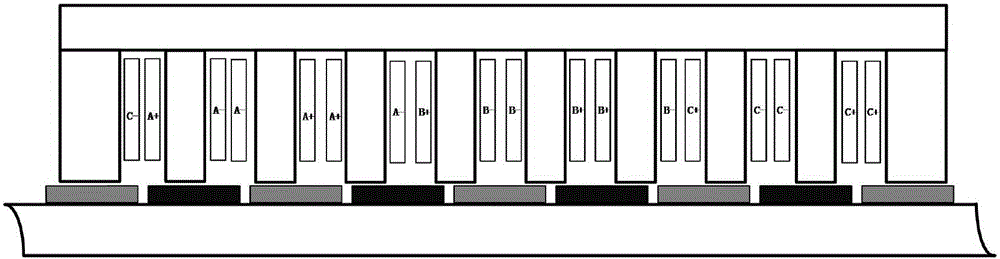

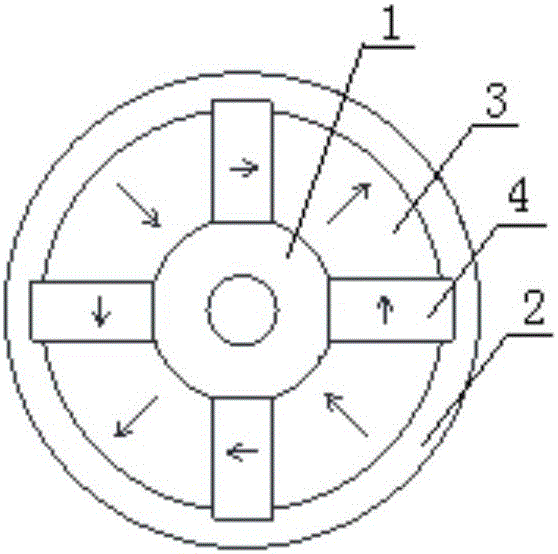

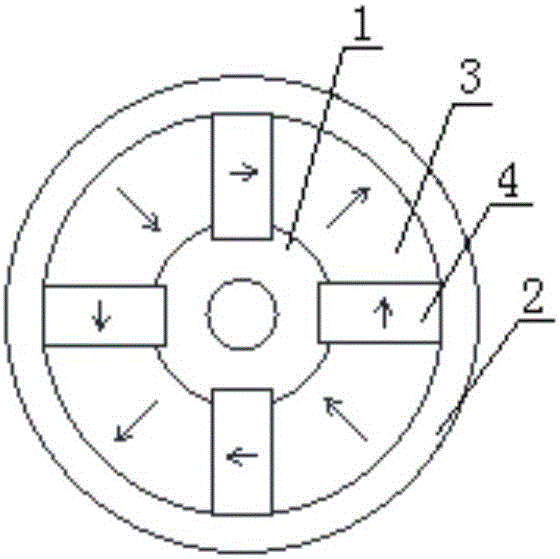

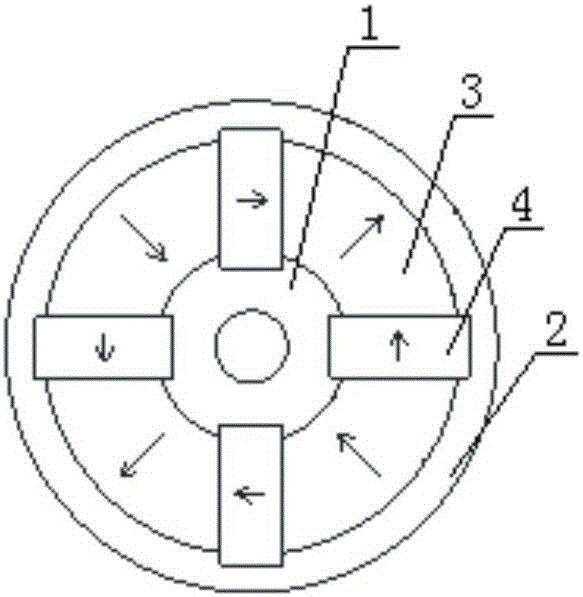

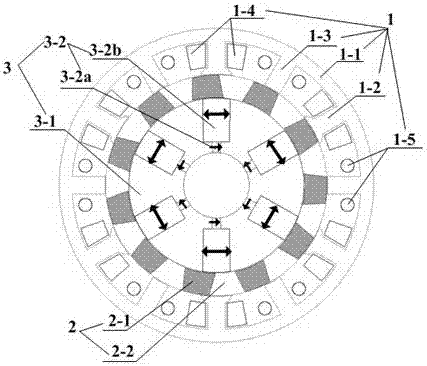

Magnetic-concentrating-type consequent-pole cursor permanent magnet motor and application thereof

ActiveCN106374718AIncrease air gap flux densityImproved Air Gap Ability to Transfer Electromagnetic PowerPropulsion systemsPower factorElectric machine

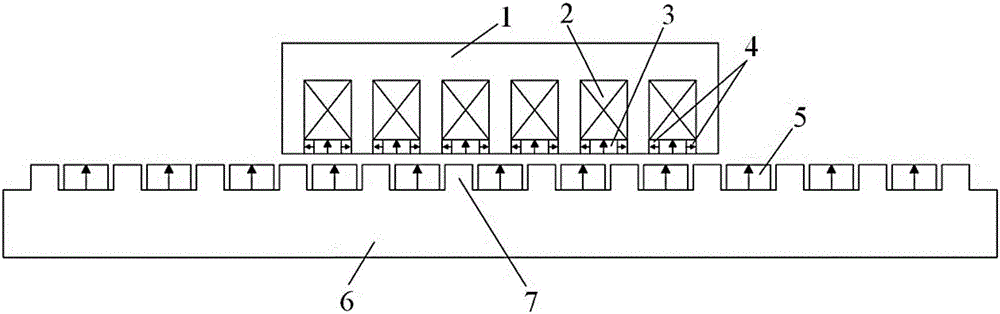

The invention discloses a magnetic-concentrating-type consequent-pole cursor permanent magnet motor, which comprises a primary core and a secondary core, wherein a plurality of open slots are formed in the primary core; armature windings are arranged in the open slots of the primary core; the secondary core and the primary core are arranged at an interval and can oppositely move; Halbach permanent magnets are arranged in notches of the open slots of the primary core, thereby forming a Halbach (Halbach) permanent magnet array; a plurality of open slots which are arranged at intervals are formed in the surface, relative to the primary core, of the secondary core and permanent magnets are arranged in the open slots, thereby forming an excitation permanent magnet array; and the magnetization direction of the Halbach permanent magnet array is matched with that of the excitation permanent magnet array. Through comprehensive application of a consequent-pole structure and a Halbach array, the air-gap flux density of the motor is significantly strengthened, the air-gap electromagnetic power transmission capacity of the motor is improved, the electromagnetic properties of the counter electromotive force, the thrust density, the power factor and the like of the motor are improved, and reduction of the volume of the motor, improvement of the acceleration performance of the motor and reduction of the capacity of a frequency converter are facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH

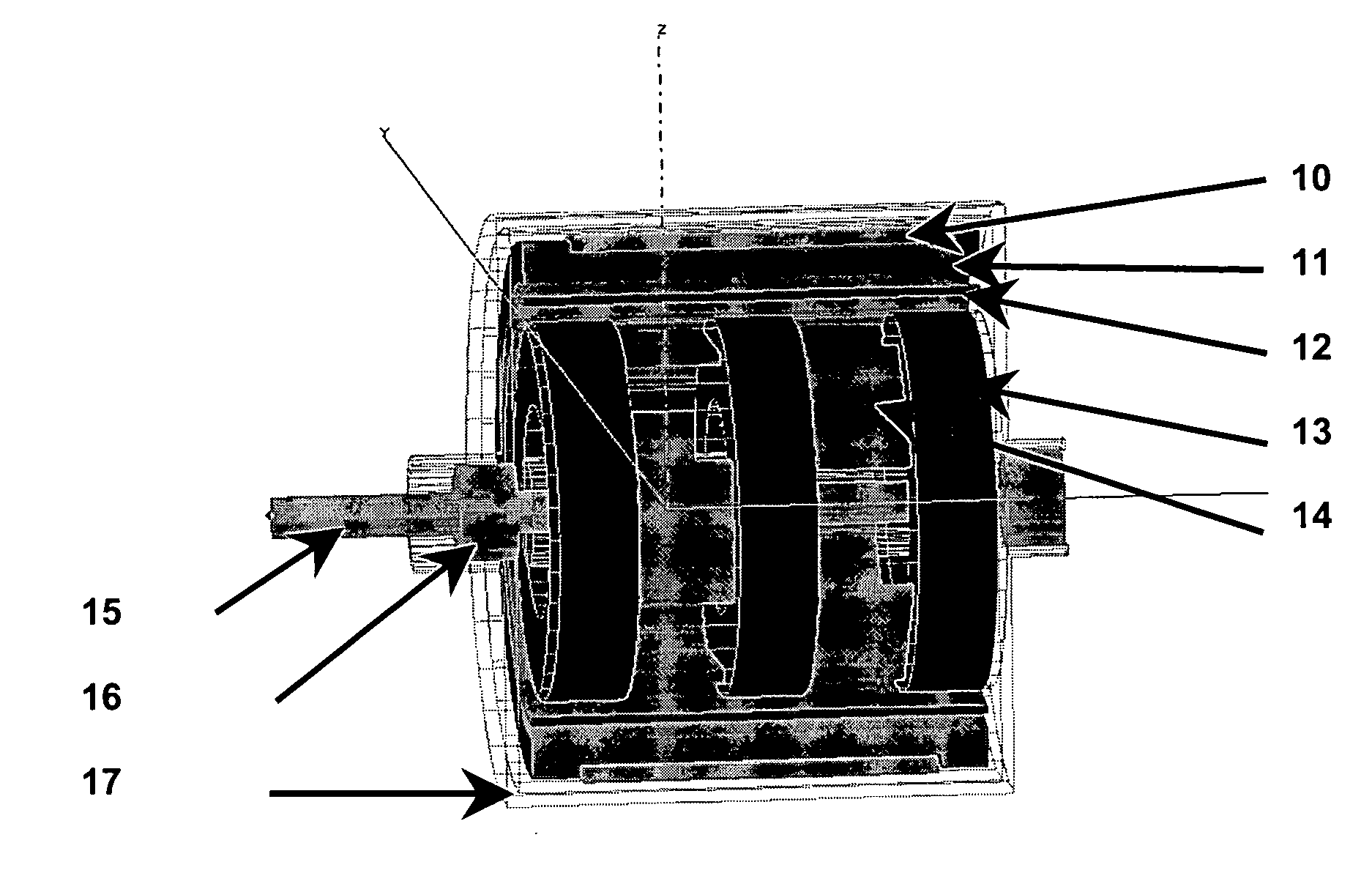

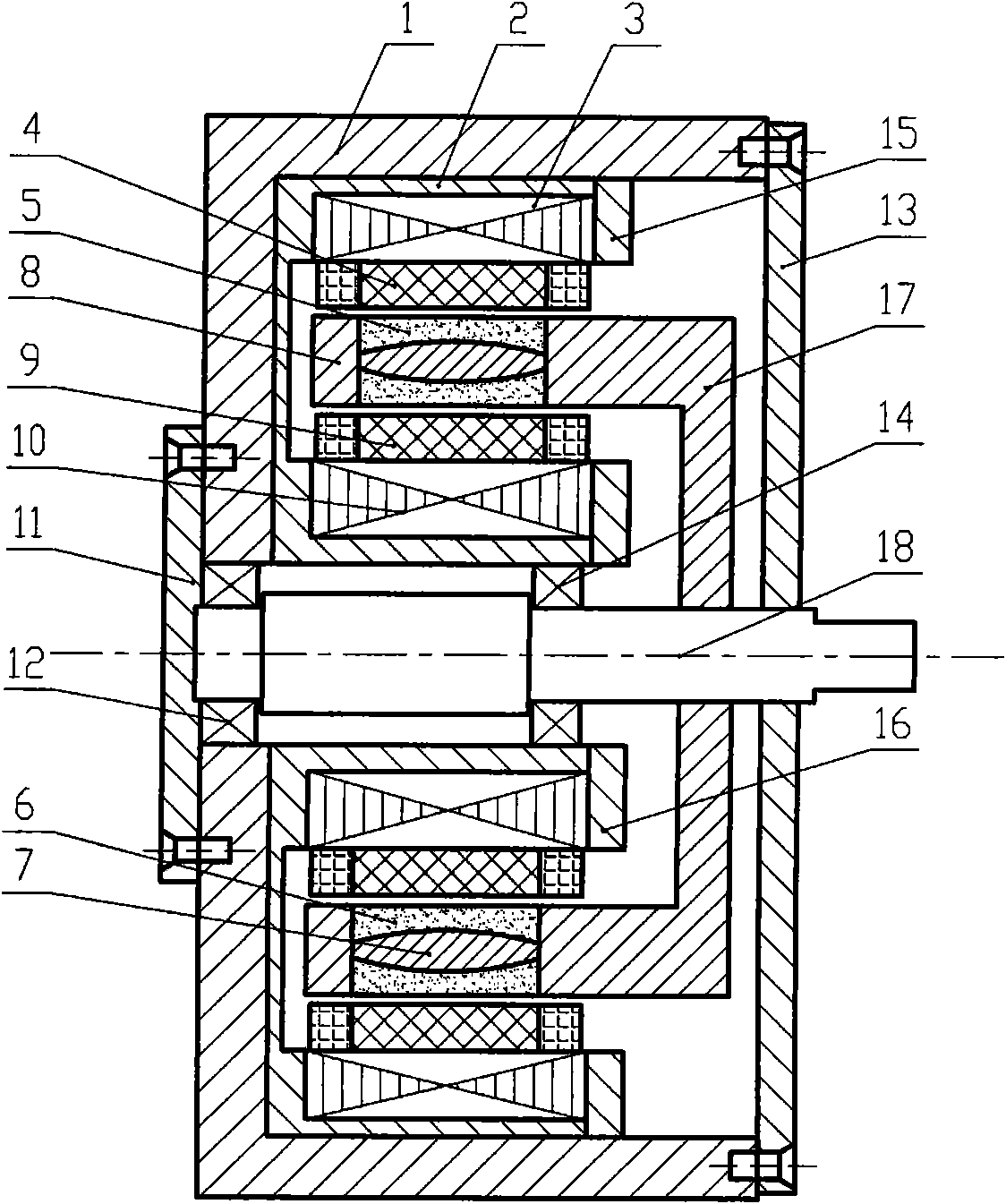

Multi-pattern high temperature superconducting motor using flux trapping and concentration

InactiveUS20070052304A1Increase flux densityMore powerSynchronous machinesCooling/ventillation arrangementSynchronous motorSuperconducting electric machine

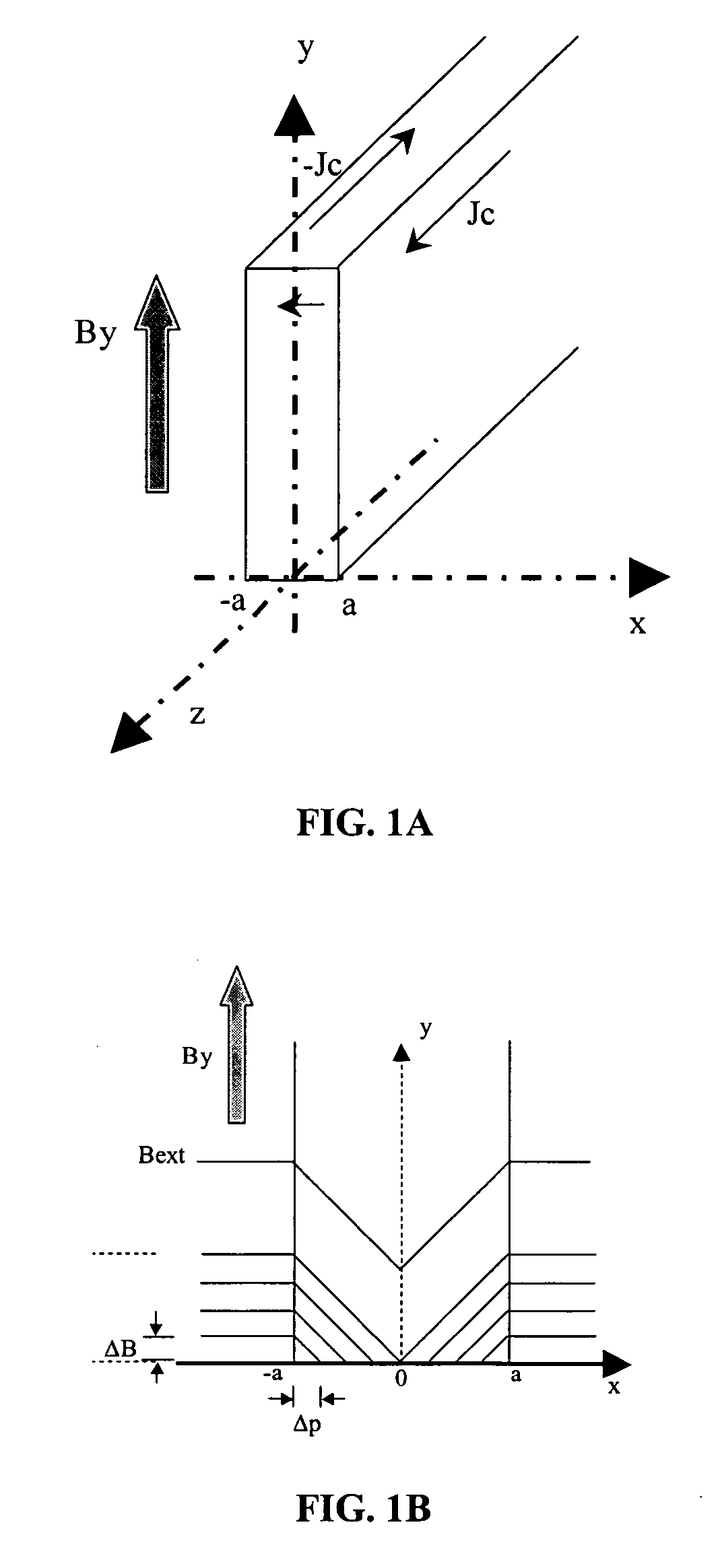

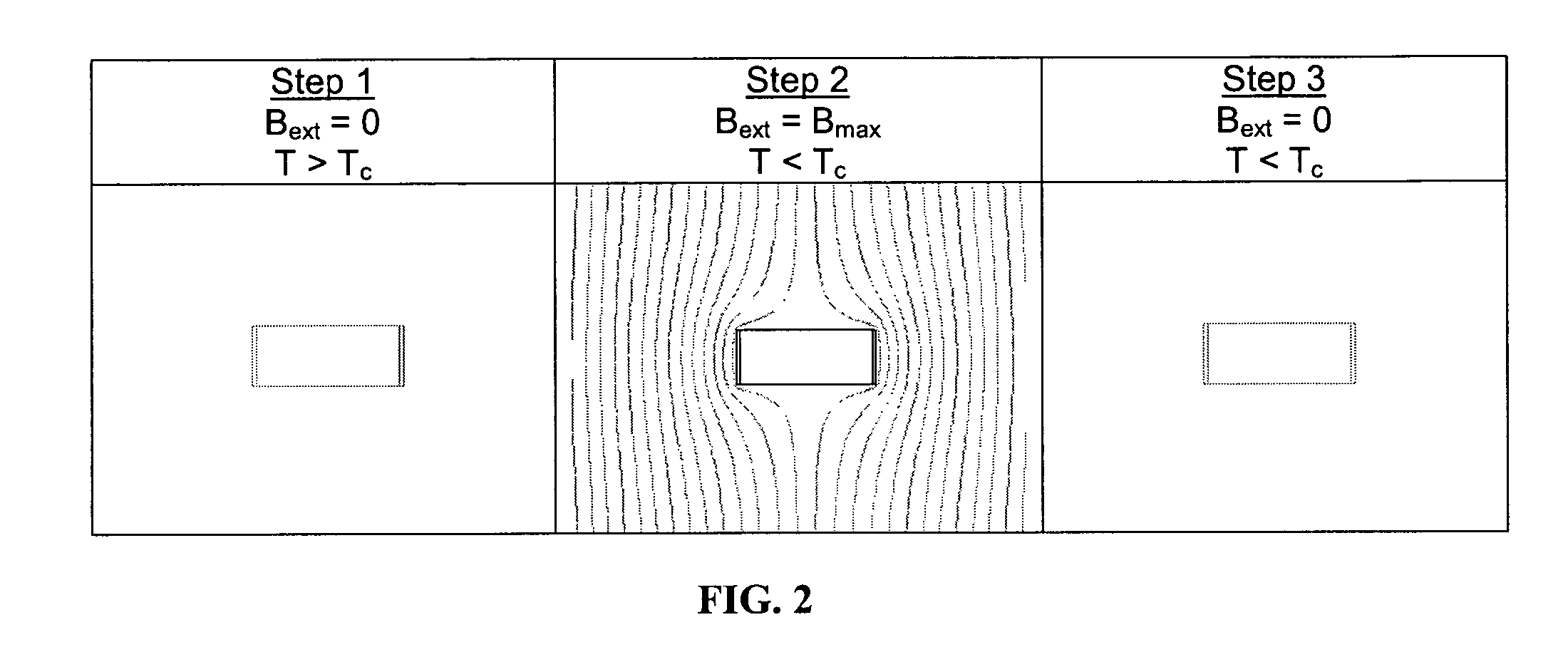

A high temperature superconducting synchronous motor having an inductor topology that increases the air gap flux density in direct relation to motor power density by trapping flux and concentrating it in the air gap to obtain more power in the same volume or smaller volume for the same power, and whose geometry enables the induction motor to be lighter than superconducting motors without the inductor topology, the motor being positioned in a housing, and the motor comprising: a) stator means having an armature winding to provide a stator field; b) rotor means positioned within the stator field and on which is disposed at least two polygon shaped ring or coil means along the same axis to provide separated and spaced apart relationship field solenoids; c) at least three high temperature superconducting plate means disposed in alternating relationship between the ring or coil means to hold the ring or coil means together to trap magnetic field and shape flux lines; and d) cooling means to cool the superconducting in the rotor to a temperature below the critical temperature of the superconducting plate means.

Owner:MASSON PHILIPPE +1

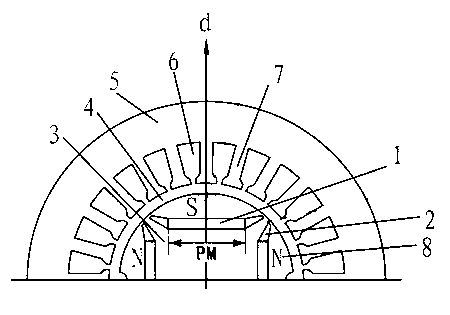

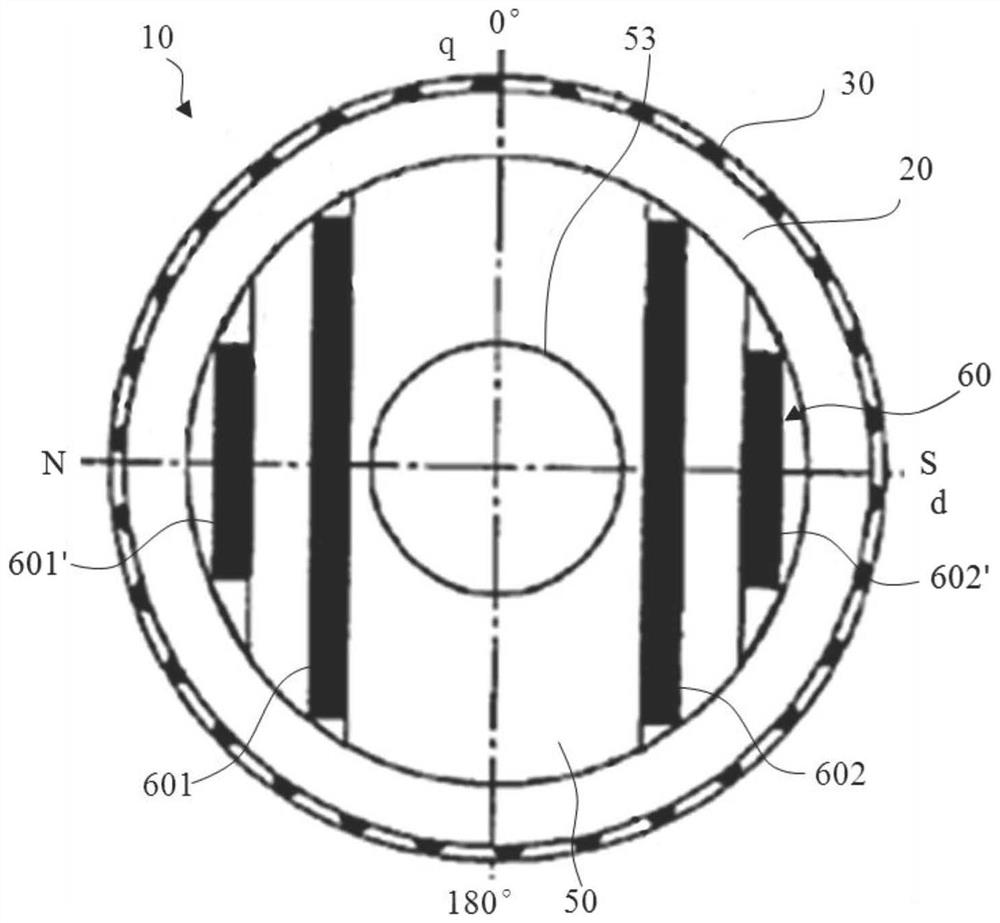

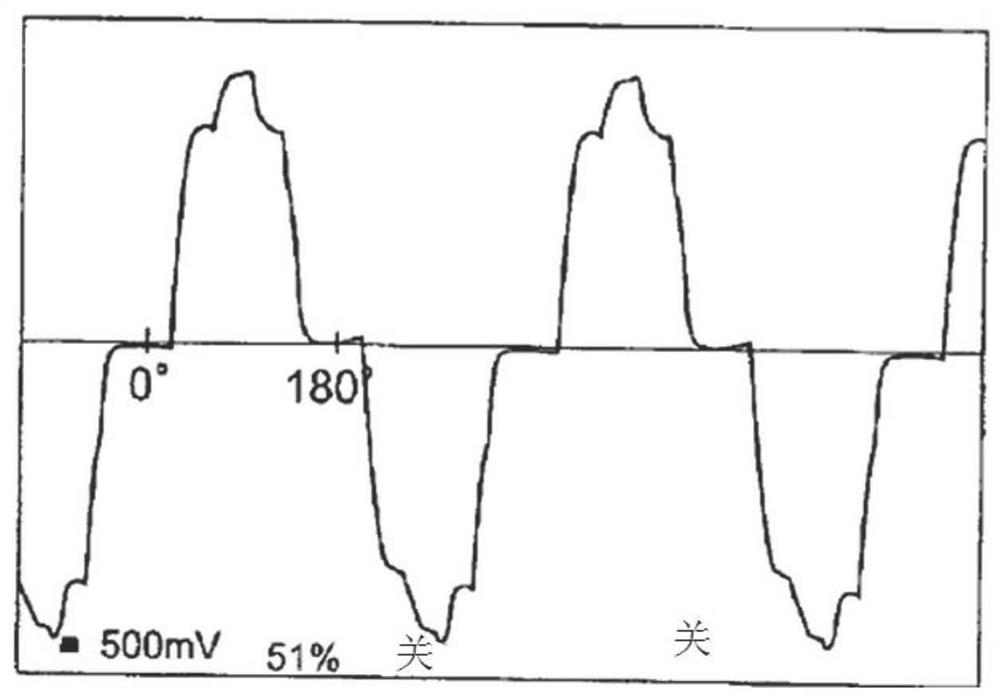

Permanent magnet synchronous motor

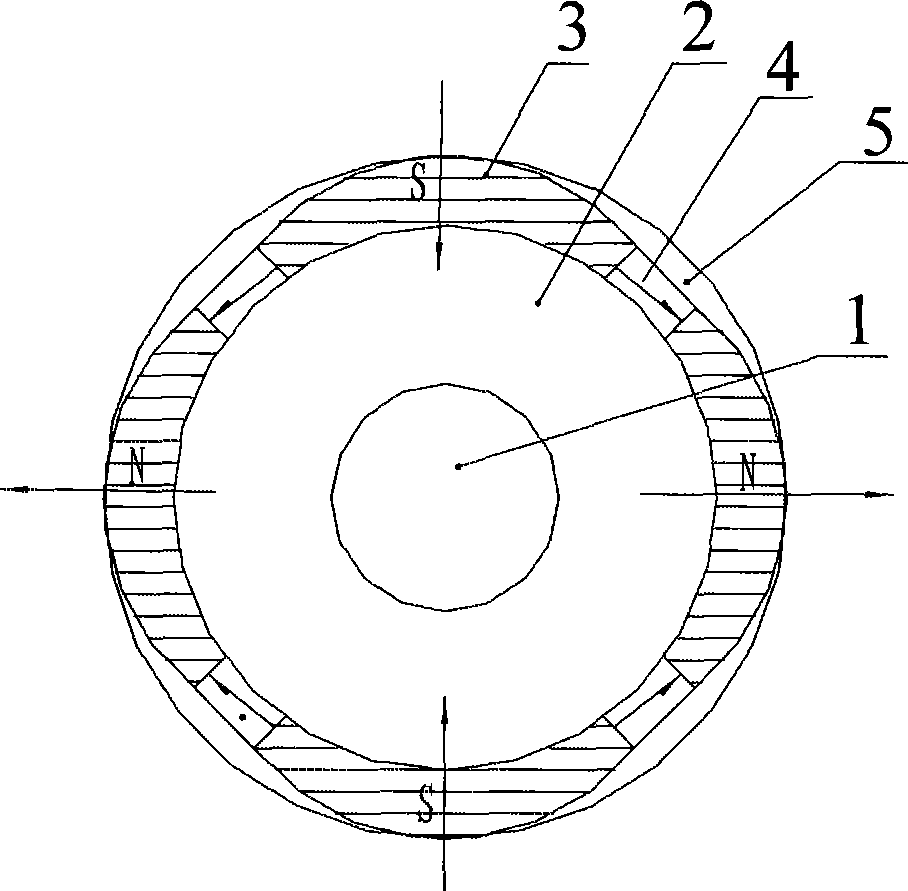

InactiveCN102420475AReduce cogging torqueEasy to manufacture and assembleMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorMagnetic poles

A purpose of the present invention is providing a permanent magnet synchronous motor rotor structure which has high air gap flux density and is easy to generate back electromotive force with a sine wave. In a permanent magnet synchronous motor, a circumferential surface of the rotor is uniformly provided with a plurality of magnetic steel grooves which are independently enclosed and do not contact mutually. Every two magnetic steel grooves are arranged to form a V shape, an opening of the V shape faces excircle of the rotor, and a tip of the V shape faces a rotor center. Each magnetic steel groove is provided with magnetic steel. In each group of V-shaped magnetic steel grooves, two magnetic steel facing the excircle of the rotor core have a same magnetic pole, and magnetic poles of magnetic steel facing the excircle of the rotor core in two adjacent groups of V-shaped magnetic steel grooves are opposite with the magnetic pole of the two magnetic steel. The excircle of the rotor goes down toward the center with depth delta and smooth transition at a crossing position of axes, which means that air gap width at the crossing position is less than air gap width at a straight axis position by delta. Through improving the rotor, the permanent magnet synchronous motor rotor has high mechanical strength and a large salient pole ratio, and weakened magnetism speed expansion is facilitated.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

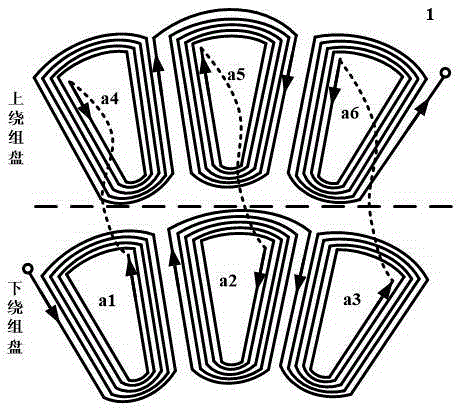

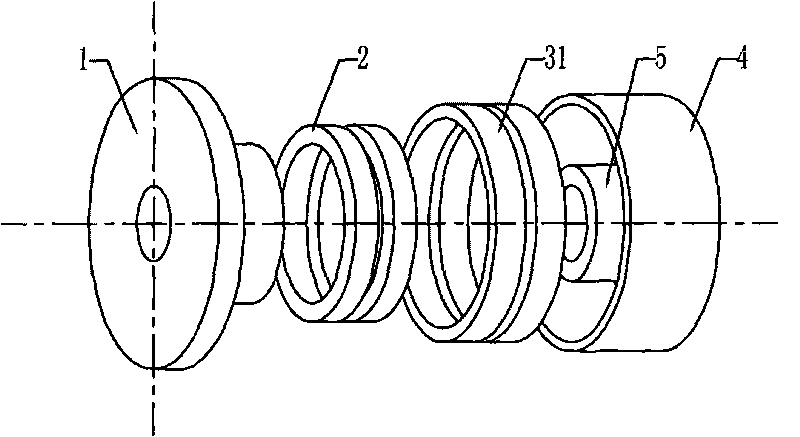

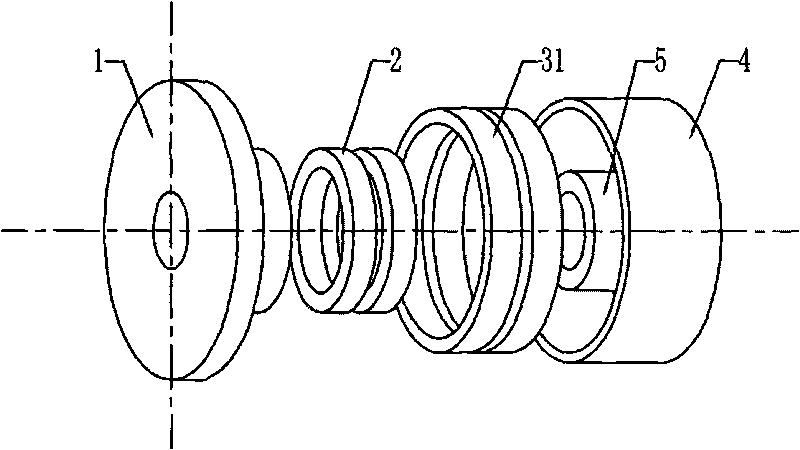

Axial flux motor of stator iron-core-free Halbach permanent magnet array

ActiveCN105305749AImprove structural strengthAchieve coolingMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorMolecular materials

The invention discloses an axial flux motor of a stator iron-core-free Halbach permanent magnet array. The motor includes two permanent magnet rotors, the rotors are mounted on a rotating shaft in the manner that permanent magnets of the rotors face each other, and a circular ring made of a high-molecular material is mounted between the rotors; radial guide grooves are regularly arranged in the circumferential directions of the front and back sides of the circular ring, and used for mount a stator winding coil with excitation lines; each permanent magnet rotor is composed of a magnetic conductive yoke of the rotor and a segmented permanent magnet mounted in the yoke; and 12 permanent magnets whose magnetizing directions are different from one another are mounted under each pair of poles, the axial magnetizing direction of the first permanent magnet is 0 degree, the difference between the magnetizing directions of the adjacent permanent magnets is 30 degree, and, thus, the Halbach array is realized, and the content of harmonic waves of air-gap flux density is greatly reduced. The axial flux motor has the advantages of high air-gap flux density sine degree, low winding loss, high structural intensity of the stator, good heat radiation effect, and high power / volume ratio.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

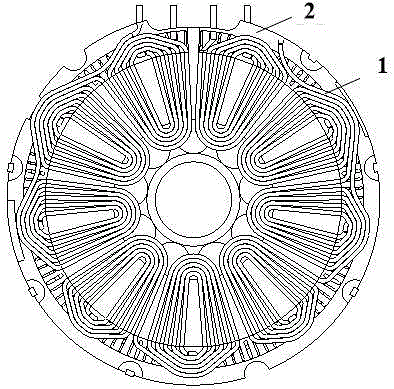

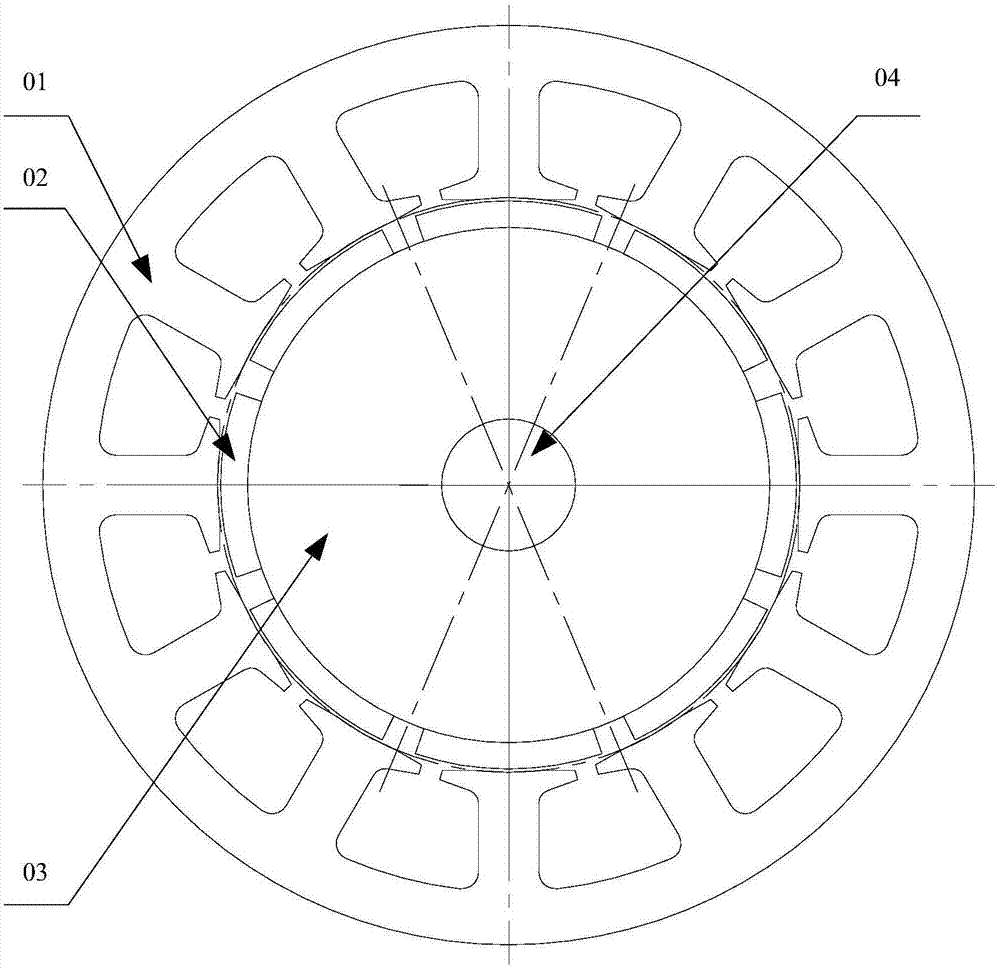

Motor for compressor and compressor with motor

InactiveCN103746473AImprove electromagnetic noiseReduce radial magnetic pullMagnetic circuit rotating partsMagnetic circuit stationary partsHarmonicElectric machine

The invention discloses a motor for a compressor and the compressor with the motor. The motor comprises a stator and a rotor, wherein the stator comprises a stator core; the stator core comprises tooth parts and a yoke part; a slot part is defined between any two adjacent tooth parts; an auxiliary slot is formed in the middle part of the inner lateral surface of each tooth part; the rotor is arranged on the inner side of the stator. According to the motor for the compressor, the order where air-gap flux density harmonics appear can be reduced, so that radial magnetic pull to the stator is reduced, and the electromagnetic noise of the motor is improved.

Owner:GUANGDONG MEIZHI PRECISION MFG

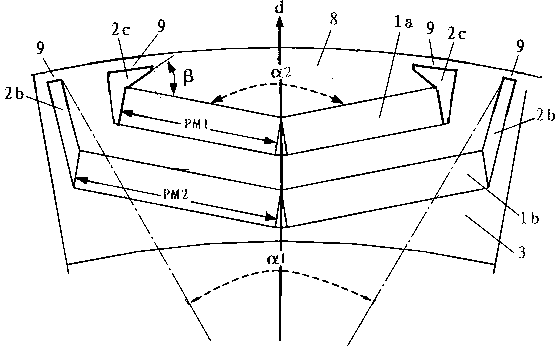

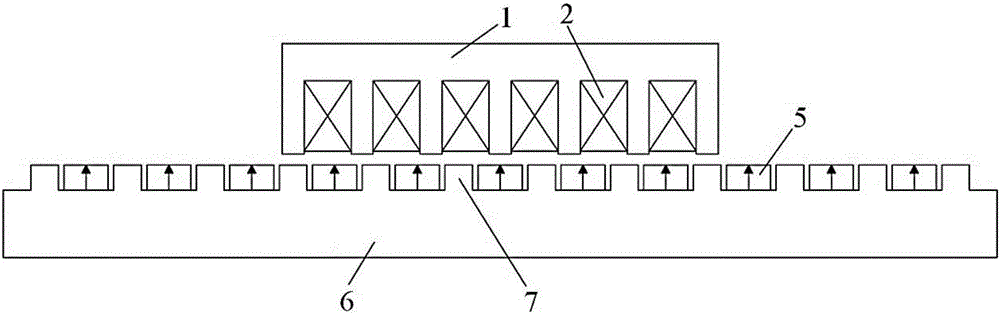

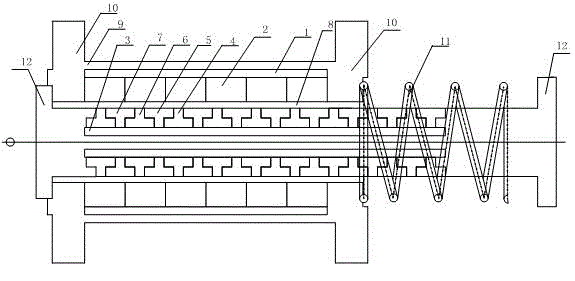

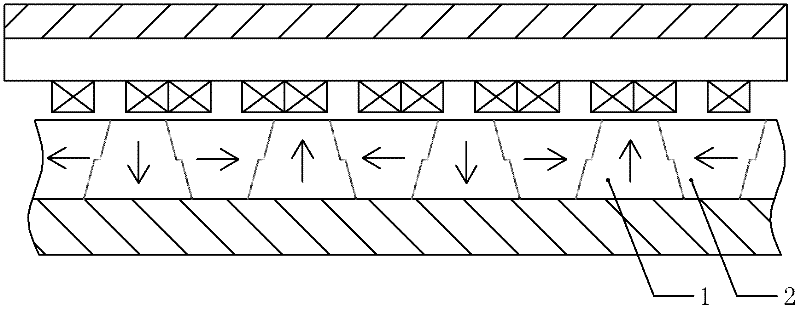

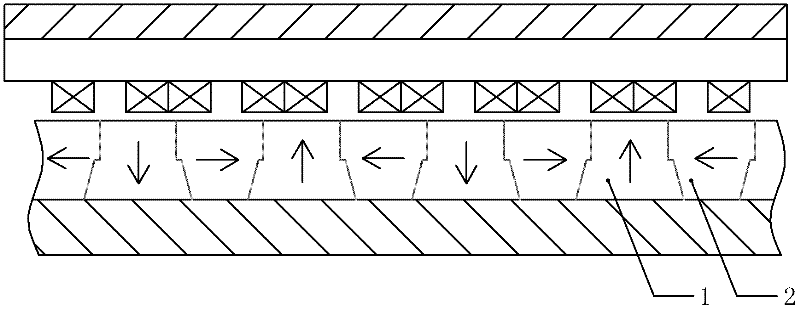

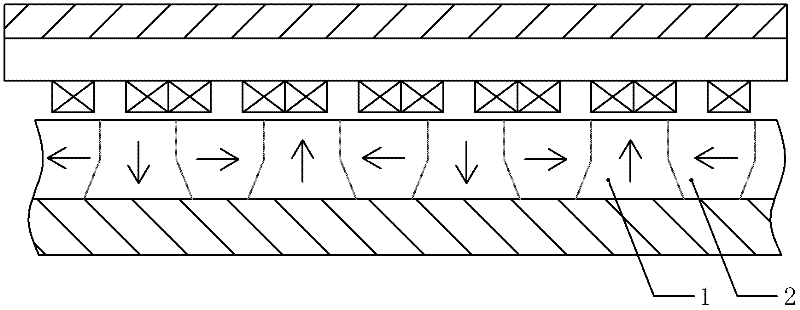

Built-in permanent magnet dual-side flat plate type linear motor

ActiveCN101741214AIncrease effective lengthIncrease magnetic densityPropulsion systemsSurface mountingPermanent magnet linear motor

The invention relates to a built-in permanent magnet dual-side flat plate type linear motor, which belongs to the technical field of motors, and solves the problems of low air gap flux density and low thrust density of the conventional surface-mount permanent magnet dual-side flat plate type linear motor. A secondary pole of the built-in permanent magnet dual-side flat plate linear motor comprises two flat plate type excitation components, a primary pole is positioned between the two flat plate type excitation components of the secondary pole, each secondary iron core is provided with a plurality of pairs of grooves on the air gap side, each permanent magnet is closely matched with the groove in which the permanent magnet is positioned, and two permanent magnets of each pair of grooves and the iron core between the grooves form a magnetic pole; on the lognitudinal cross section of the flat plate type excitation components, the cross section of each groove is a parallelogram, the groove bottoms of the two grooves of each pair of grooves are close to each other and form a V-shape, and the range of the included angle Theta of two adjacent sides of the two grooves in each pair of grooves is not less than 30 degrees and not more than 150 degrees; and the magnetizing direction of each permanent magnet is vertical to the bevel edge of the parallelogram, the magnetizing directions of the two permanent magnet in each magnetic pole are in the same direction or in the opposite directions, and the polarities of the adjacent two magnetic poles are opposite. The invention is a linear motor.

Owner:HARBIN INST OF TECH

Rotating electrical machine and its manufacturing method

InactiveCN102013744ALarge amplitudeSmall size and high outputMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetizationElectrical polarity

This invention provides a rotating electrical machine which increases more easily an amplitude of a fundamental wave component in a gap magnetic flux density and realizes a small size high output. The rotating electrical machine including a rotor that has an even number of first permanent magnets aligned in a circumferential direction of the rotor, second permanent magnets of a number equal to that of the first permanent magnets, provided respectively between the stator and circumferential ends of the first permanent magnets adjacent to each other in the circumferential direction, and core pieces of a number equal to that of the first permanent magnets, provided respectively between the second permanent magnets adjacent to each other in the circumferential direction. Each of the first permanent magnets has a direction of magnetization in parallel with a radial direction of the rotor, the directions of magnetization of the first permanent magnets adjacent to each other in the circumferential direction are opposite to each other, each of the second permanent magnets has a direction of magnetization perpendicular to the radial direction, the directions of magnetization of the second permanent magnets adjacent to each other in the circumferential direction are opposite to each other, and the first permanent magnet and the two second permanent magnets which are adjacent to the core piece have magnetic poles identical to one another on ends facing the core piece.

Owner:YASKAWA DENKI KK

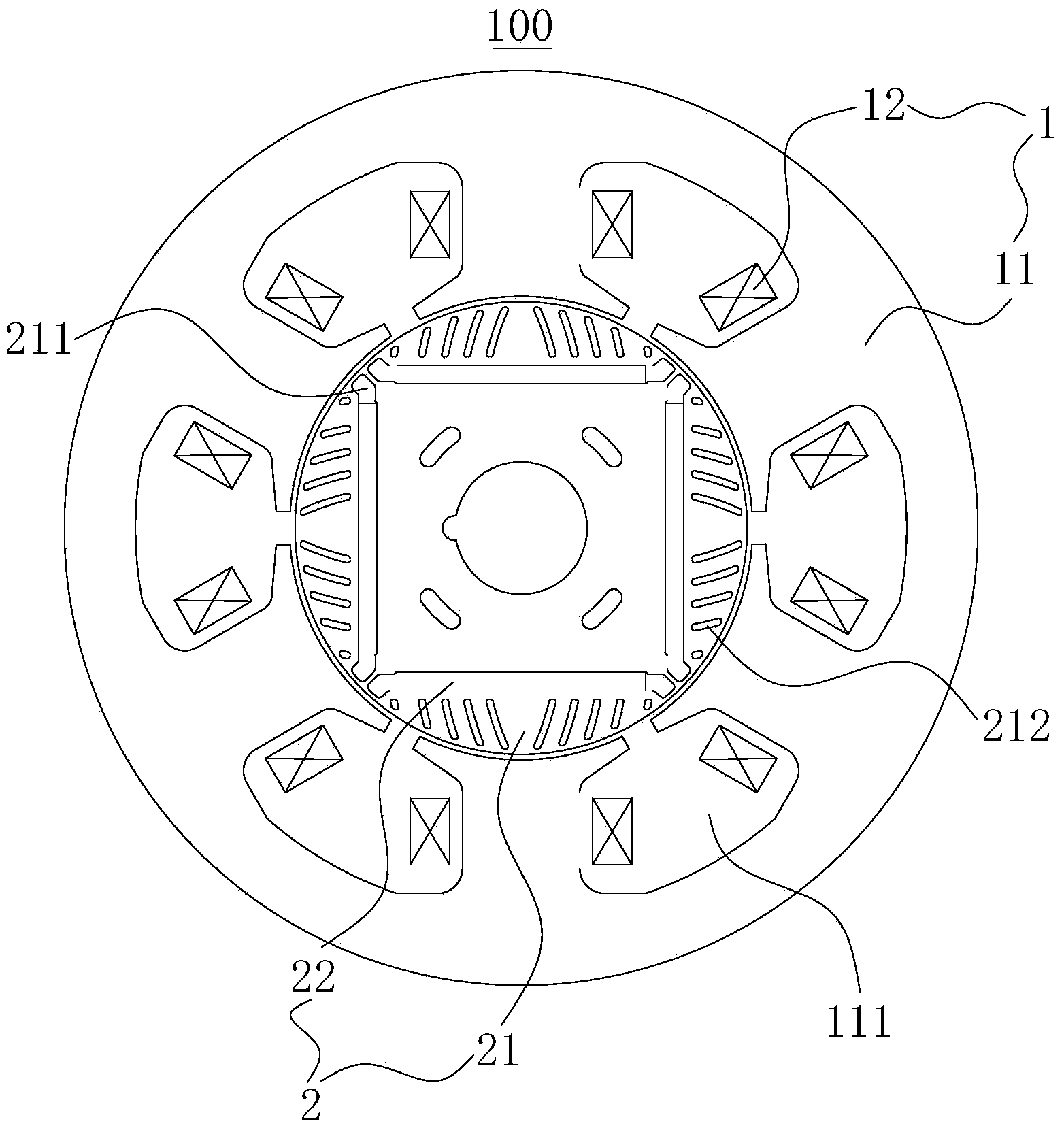

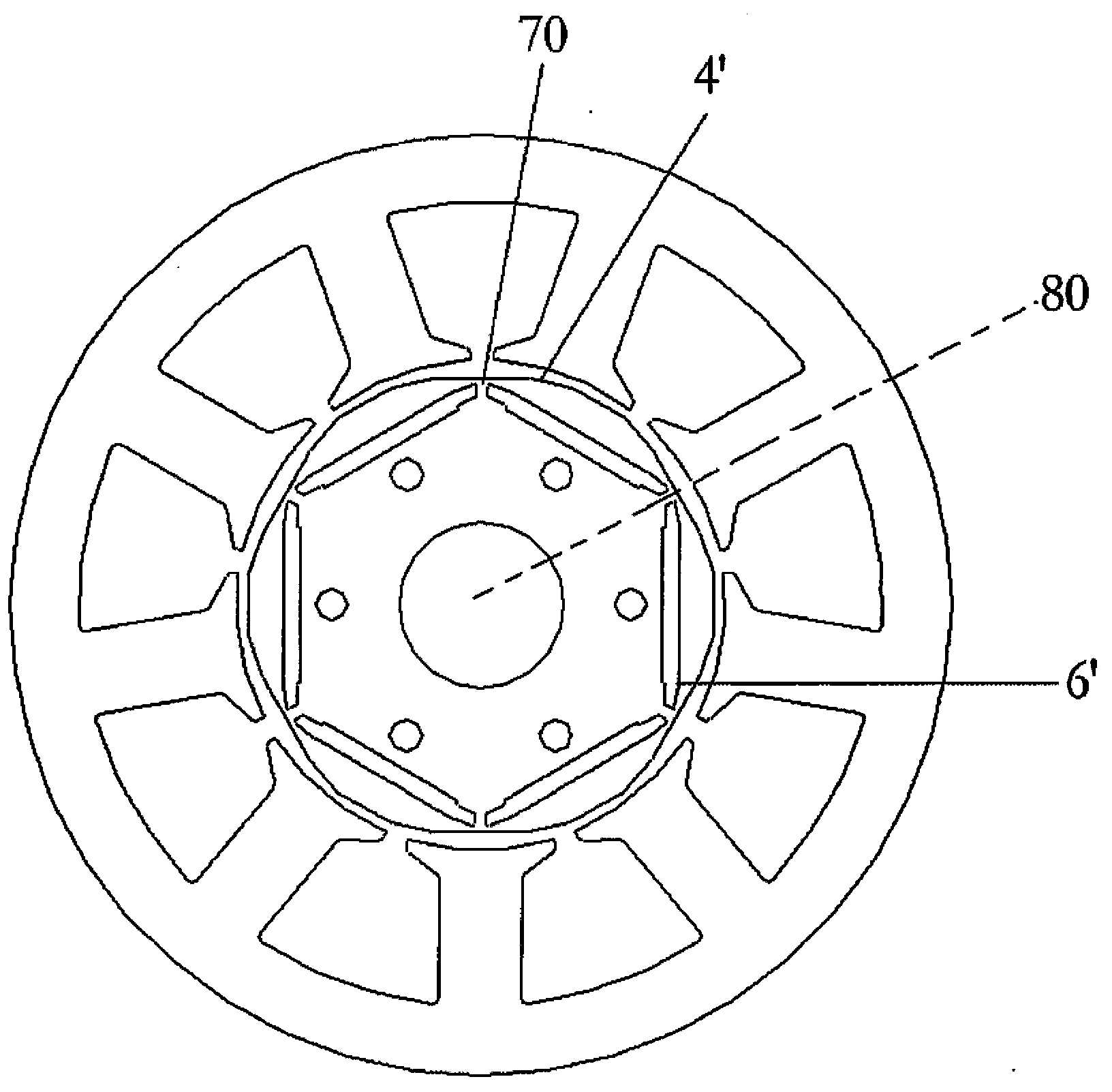

Permanent magnet synchronous motor and compressor provided with same

ActiveCN104269986AImprove electromagnetic noiseIncrease output powerMagnetic circuit rotating partsPiston pumpsRotor magnetsLoad torque

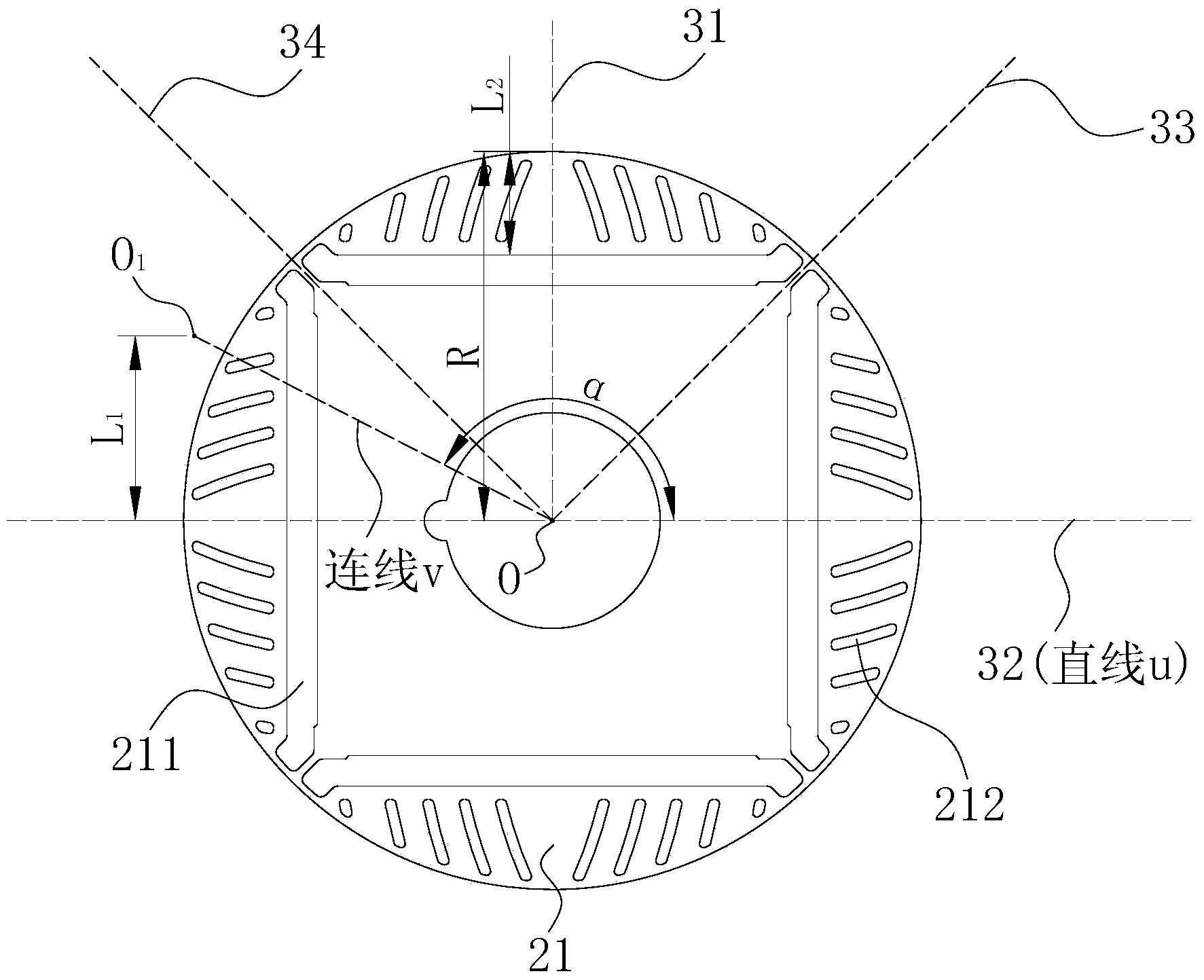

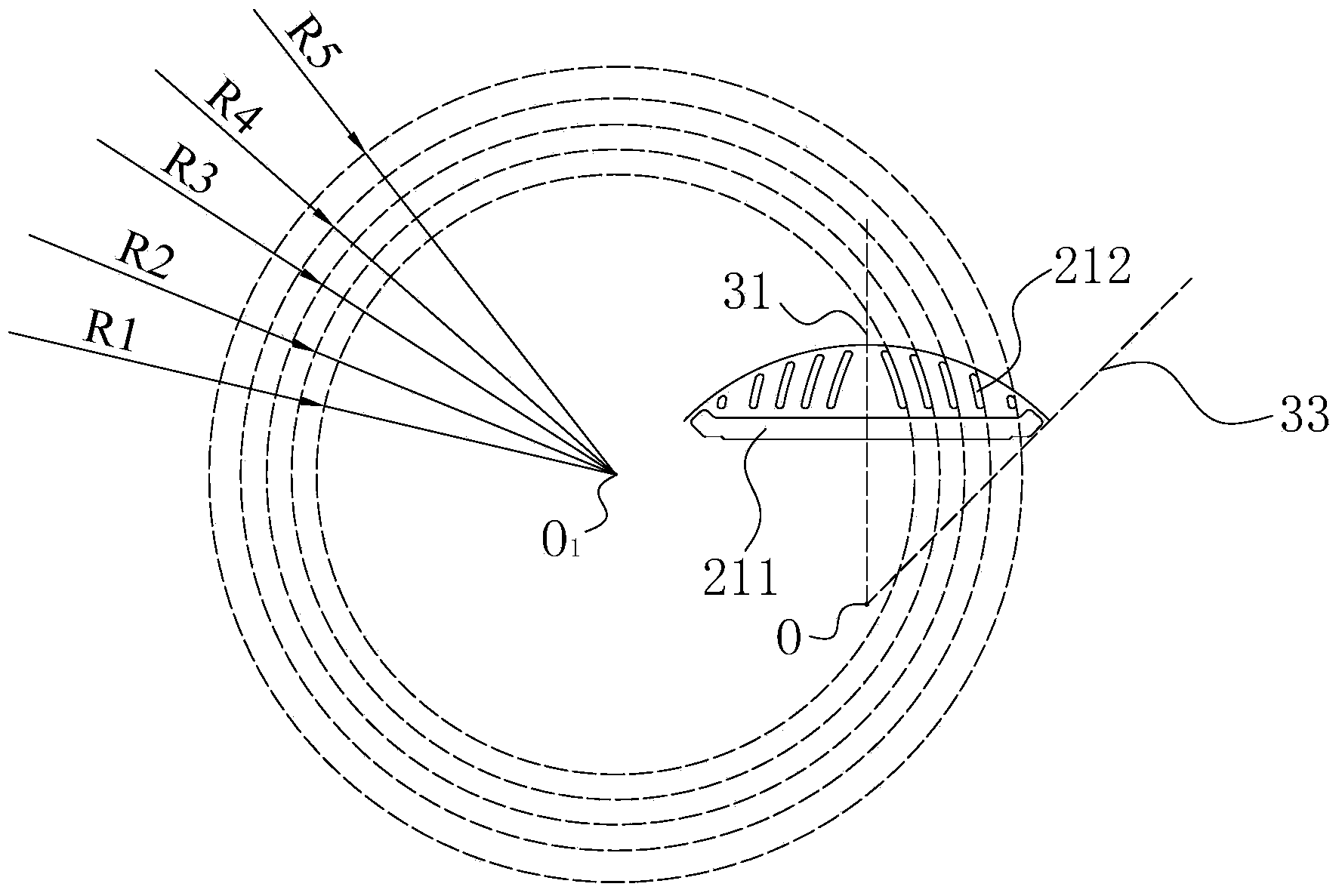

The invention discloses a permanent magnet synchronous motor and a compressor provided with the same. The permanent magnet synchronous motor comprises a stator and a rotor. The rotor comprises a rotor iron core and a plurality of rotor magnets. The rotor iron core is provided with a plurality of placing grooves. The multiple rotor magnets are arranged in the multiple placing grooves. A plurality of slits are formed in the rotor iron core and located between the corresponding placing grooves and the outer peripheral wall of the rotor iron core. The slits between a first shaft d and a first shaft q are distributed in a concentric circle with a point O1 as the circle center, the vertical distance L1 between the point O1 and a straight line u meets the formula: L1<=R-L2 / 2, a connecting line of the point O1 and the center O of the rotor is defined as a connecting line v with the center O of the rotor as a fixed point, and an included angle alpha of the connecting line v and a second shaft d meets the formula: alpha>=270 degrees / P. According to the permanent magnet synchronous motor, air gap flux density and counter potential waveforms are improved, the cogging torque amplitude and load torque fluctuations are reduced, radial electromagnetic force is reduced easily, and therefore electromagnetic noise of the motor is reduced.

Owner:GUANGDONG MEIZHI COMPRESSOR

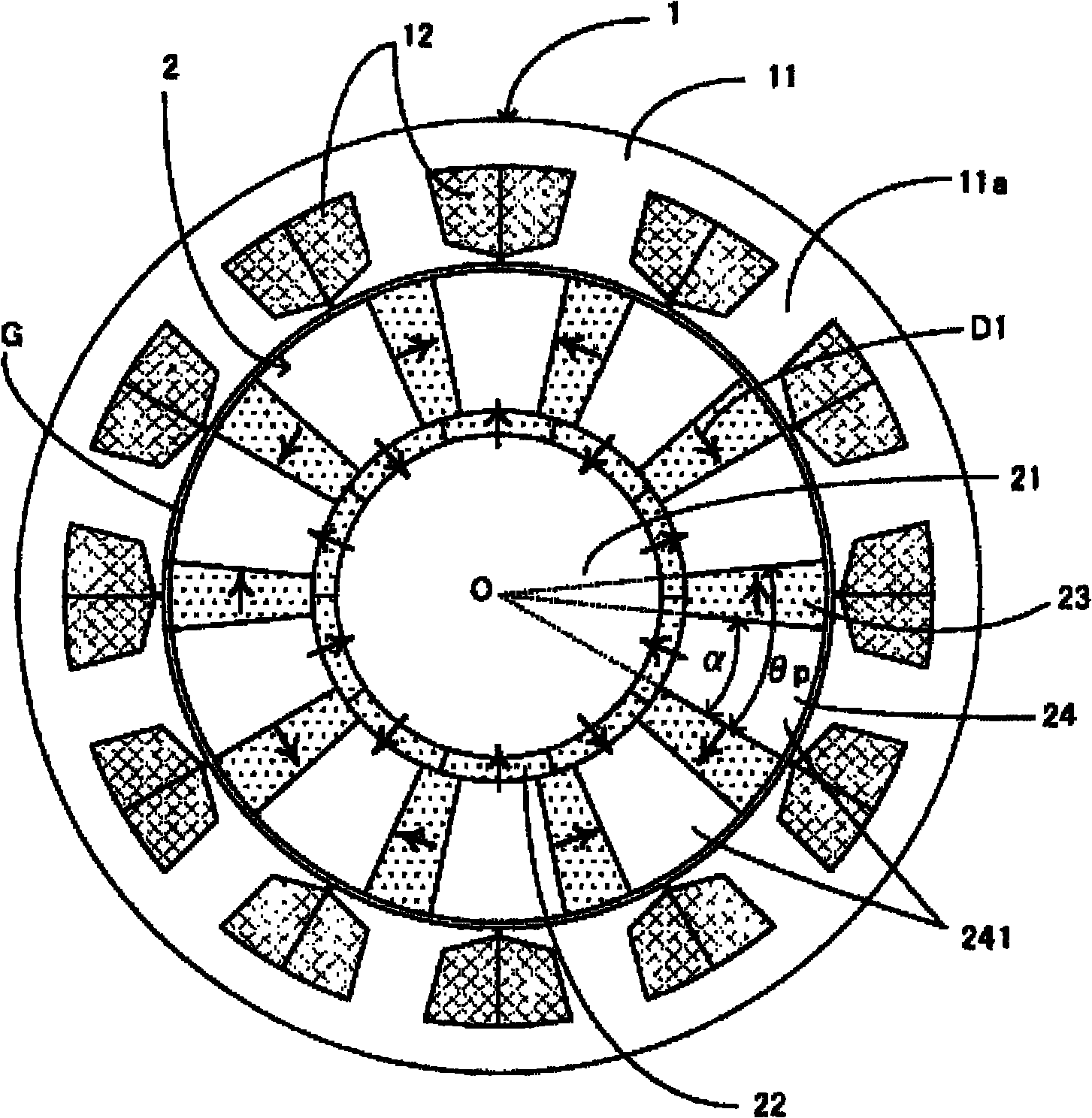

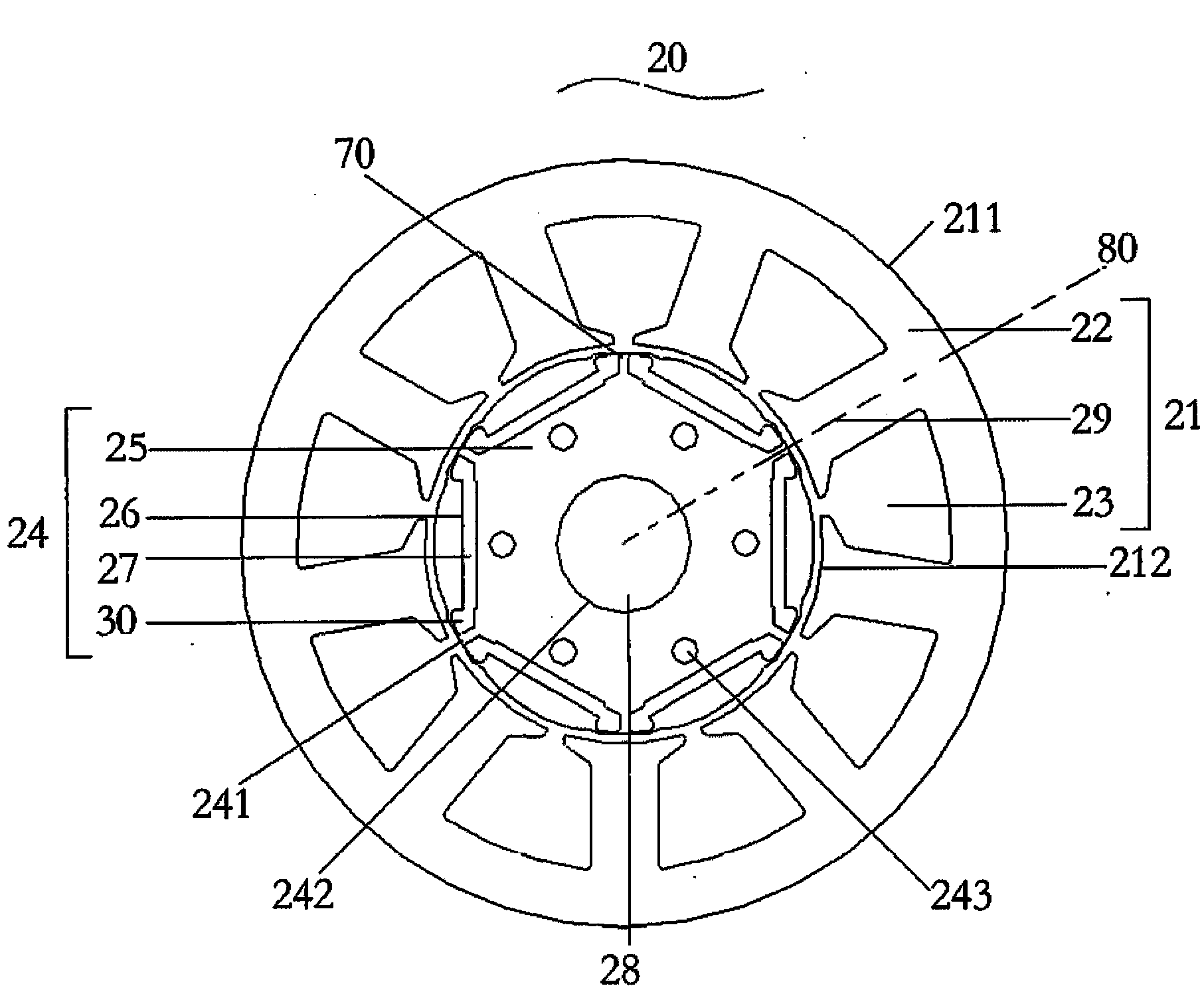

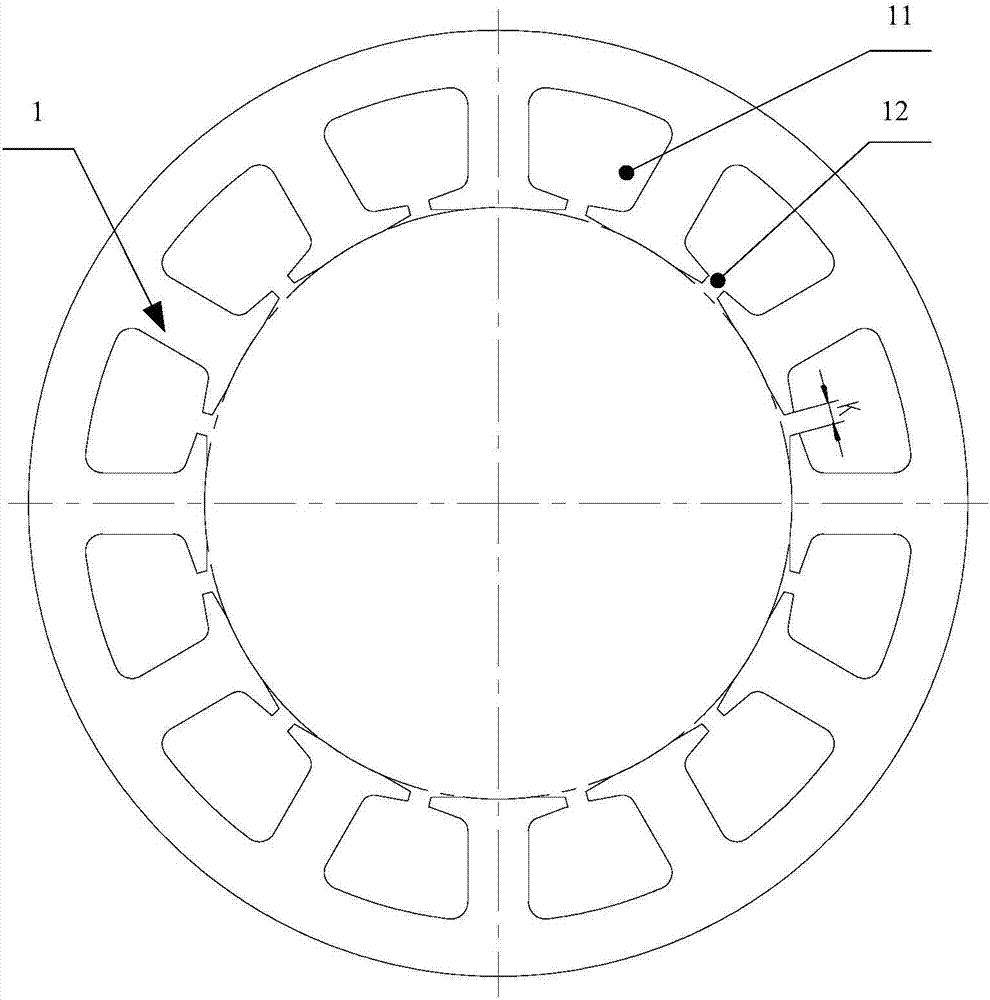

Rotor of permanent magnet synchronous motor and motor

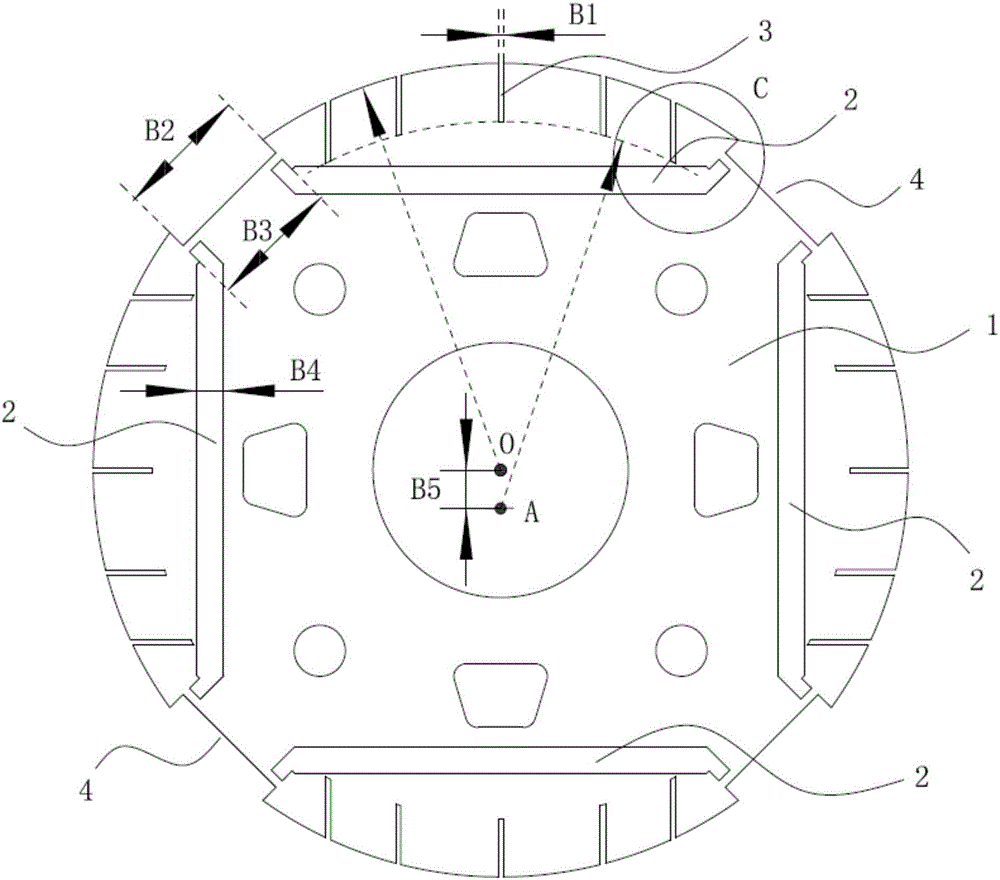

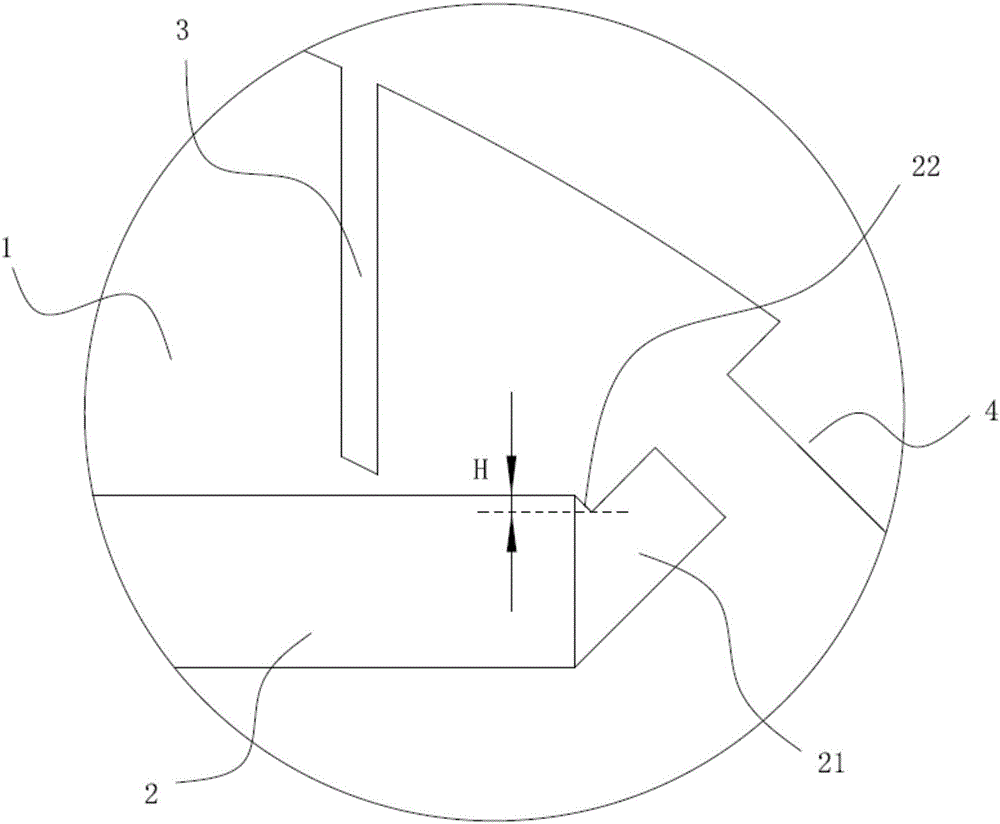

ActiveCN106340982AReduce electromagnetic noiseSolve the problem of a large number of harmonics in the air gapMagnetic circuit rotating partsSynchronous machine detailsHarmonicPermanent magnet synchronous motor

The invention discloses a rotor of a permanent magnet synchronous motor (PMSM) and a motor, belongs to the technical field of motors and solves the problem that a conventional device has a lot of higher harmonic magnetic fields. The rotor of the PMSM has a plurality of magnetic steel grooves uniformly distributed in the circumferential direction of a rotor body, permanent magnets are inserted in the magnetic steel grooves, and the adjacent permanent magnets are opposite in polarity. A plurality of slits are arranged in the outer edge of the rotor body at positions corresponding to the magnetic steel grooves, the slits communicate with an air gap between a stator and the rotor, and the inner ends of the slits are on the same arc line; or, a plurality of slits are arranged in the outer edge of the rotor body at the positions corresponding to the magnet steel grooves, the slits communicate with the magnet steel grooves, and the outer ends of the slits are located on the same arc line. The rotor of the PMSM and the motor solve the problem that lots of harmonics exist in the air gap between the inner side wall of the stator and the outer side wall of the rotor, reduce the electromagnetic noise of the motor and ensure air-gap flux density and sinusoidal features.

Owner:GREE ELECTRIC APPLIANCES INC

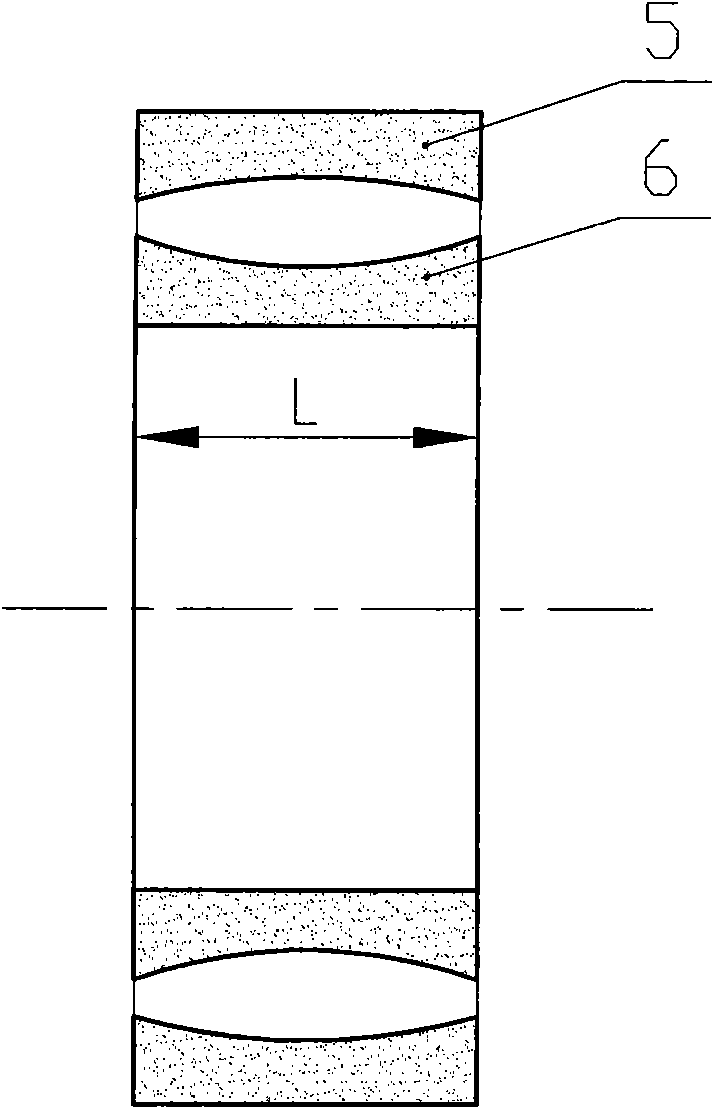

Rotor for asynchronous starting permanent magnet motor, and asynchronous starting permanent magnet motor

PendingCN112186921AHigh torqueImprove efficiencyMagnetic circuit rotating partsSynchronous machinesElectric machinePermanent magnet motor

The invention relates to a rotorfor asynchronous starting a permanent magnet motor, and an asynchronous starting permanent magnet motor. The rotor comprises a rotating shaft, an iron core and a squirrel cage, the rotating shaft penetrates through the center of the iron core, the squirrel cage is arranged on the periphery of the iron core, at least two poles of permanent magnets are embedded in theiron core, each pole permanent magnet is provided with at least two layers in the radial direction so as to at least comprise a first-layer permanent magnet and a second-layer permanent magnet, and the second-layer permanent magnet is arranged on the outer side, away from the center o of the rotating shaft, of the first-layer permanent magnet. In a cross section of the rotor, a total length L2 ofthe second layer of permanent magnets is in a range of 40% to 100% of a total length L1 of the first layer of permanent magnets. The waveform of the air gap flux density of the asynchronous startingpermanent magnet motor comprising the rotor is closer to the ideal sine wave efficiency, and the efficiency and the performance of the motor are improved.

Owner:EMERSON CLIMATE TECH (SUZHOU) CO LTD

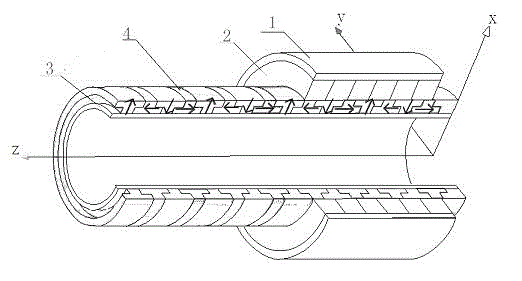

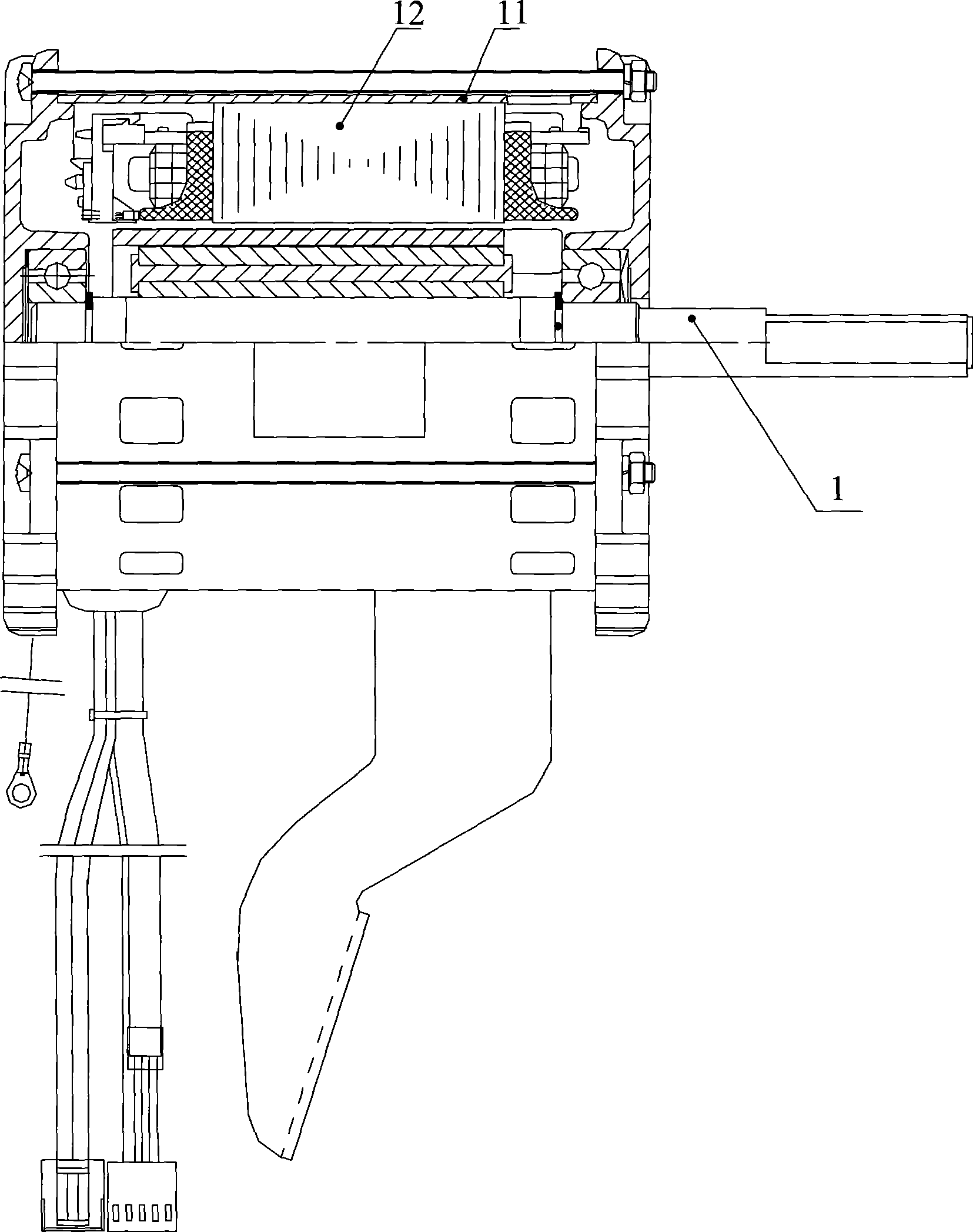

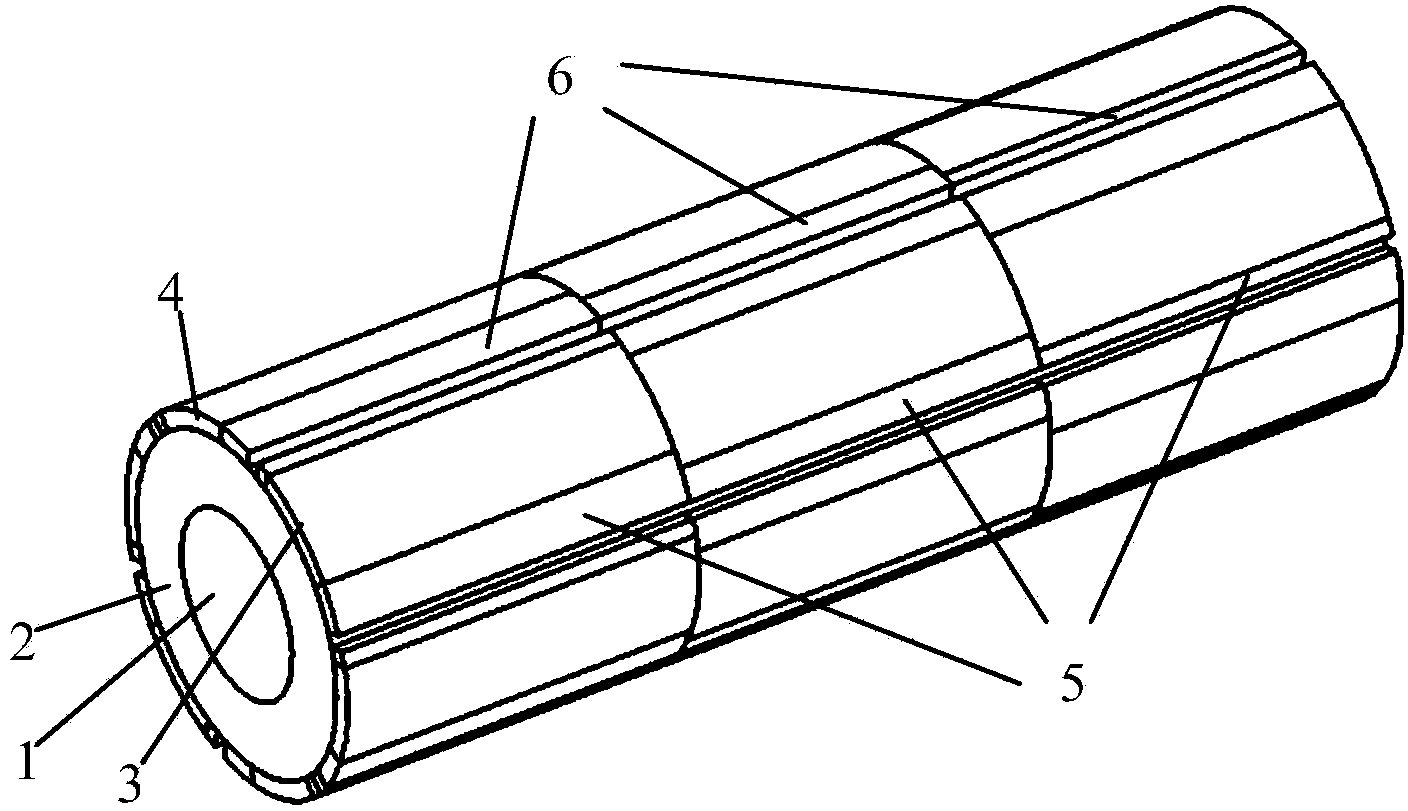

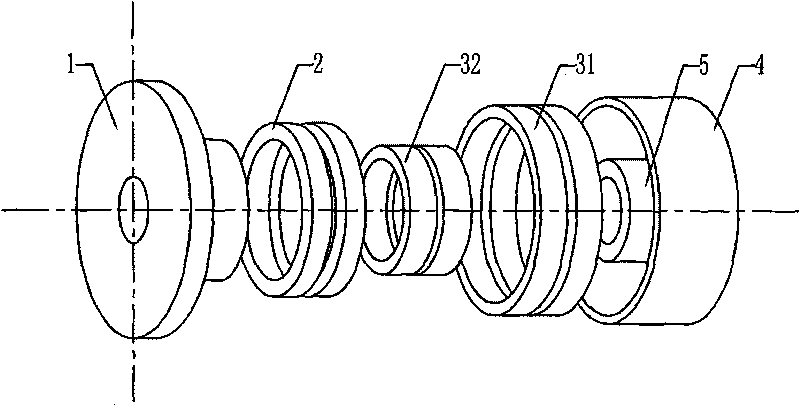

Cylindrical magnetic-pole combined linear generator

ActiveCN104467343AIncrease profitThe magnitude of the electromotive force is largeDynamo-electric machinesPower qualityMagnetic poles

The invention discloses a cylindrical magnetic-pole combined linear generator which comprises a stator structure and a rotor structure. The stator structure comprises a stator iron core and a stator winding, wherein the stator iron core is connected with the stator winding in a gapless and sleeving mode. The rotor structure comprises a rotor iron core and a permanent magnet ring assembly. The permanent magnet ring assembly is pasted to the periphery of the rotor shaft iron core through a surface pasting type structure. The stator structure and the rotor structure are arranged at an interval. The rotor structure is located in the stator structure. Both the stator structure and the rotor structure are of a cylindrical structure. The stator iron core is of a slotless structure. The cylindrical magnetic-pole combined linear generator is small in jitter degree, good in air gap magnetic flux density sine performance, high in output electric energy quality, and especially suitable for being used in direct-drive power generation systems under the sea conditions of small waves near the coast and islands.

Owner:浙江万果科技有限公司

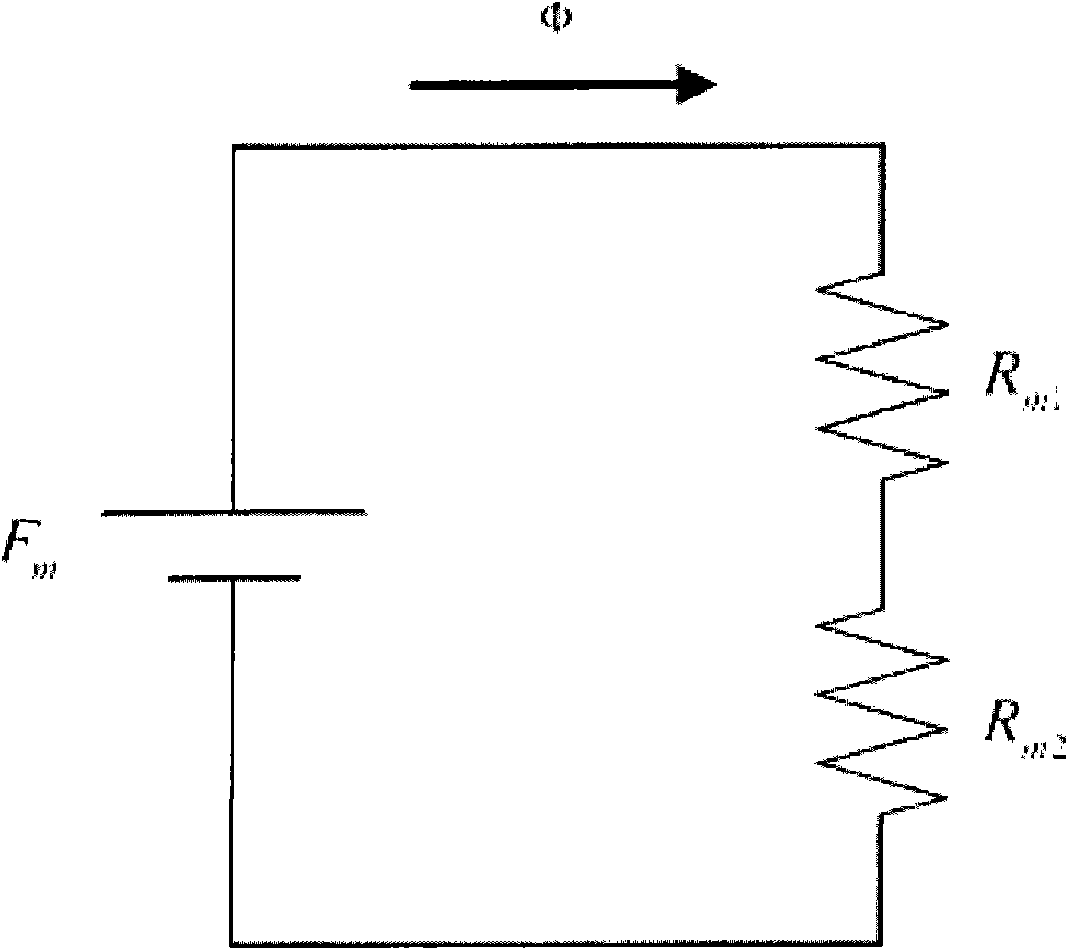

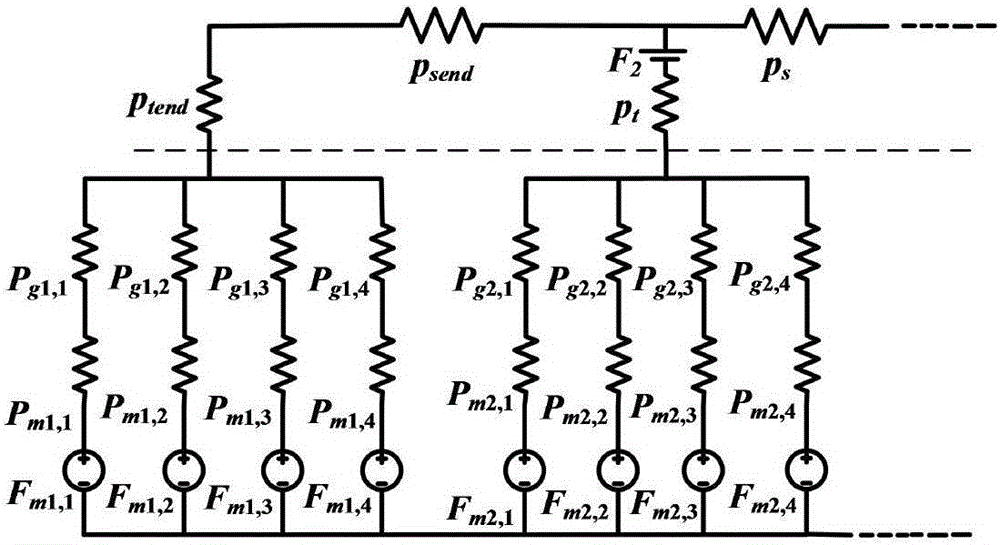

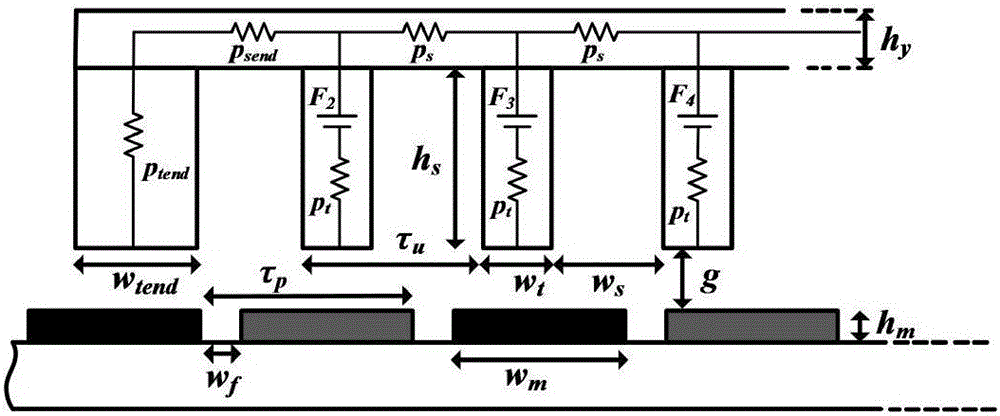

Permanent magnet synchronous linear motor modeling and characteristic analyzing method based on equivalent magnetic circuit method

InactiveCN105787158AGuaranteed accuracyGeometric CADSpecial data processing applicationsPermanent magnet synchronous motorConductor Coil

The invention relates to a permanent magnet synchronous linear motor modeling and characteristic analyzing method based on an equivalent magnetic circuit method. The method comprises following steps of dividing a permanent magnet synchronous linear motor equivalent magnetic circuit method analyzing model into two parts, wherein a linear motor primary forms a first part, and an air gap and a motor secondary form a second part; ignoring the saturation of an iron core, solving the permeance of the first part and magnetomotive force parameters generated by an armature winding; equally dividing the magnetic circuit in each space width entering into each primary tooth into four branches except the end part of the motor; obtaining the distribution of the air gap flux density of the motor at any moment; and solving the magnetic linkage of the motor, the counter electromotive force of an armature and the magnetic resistance of the motor. According to the method, under the premise of ensuring the model precision, the model is simple and practicable.

Owner:TIANJIN UNIV

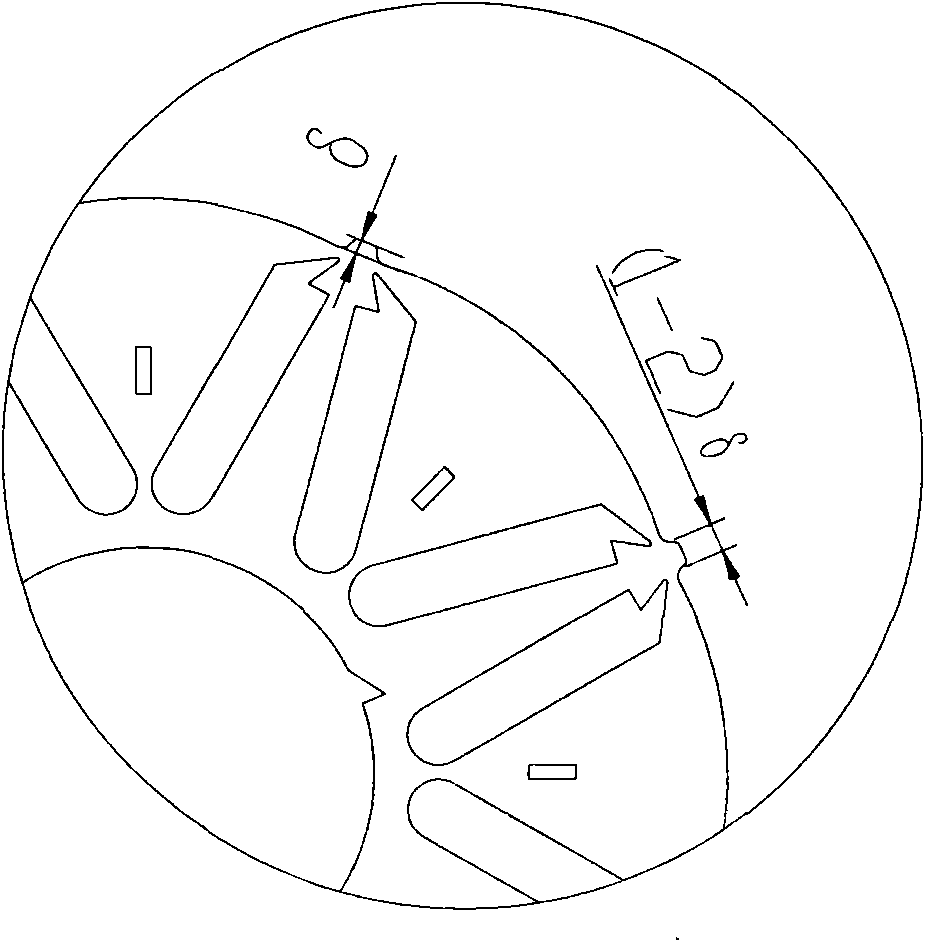

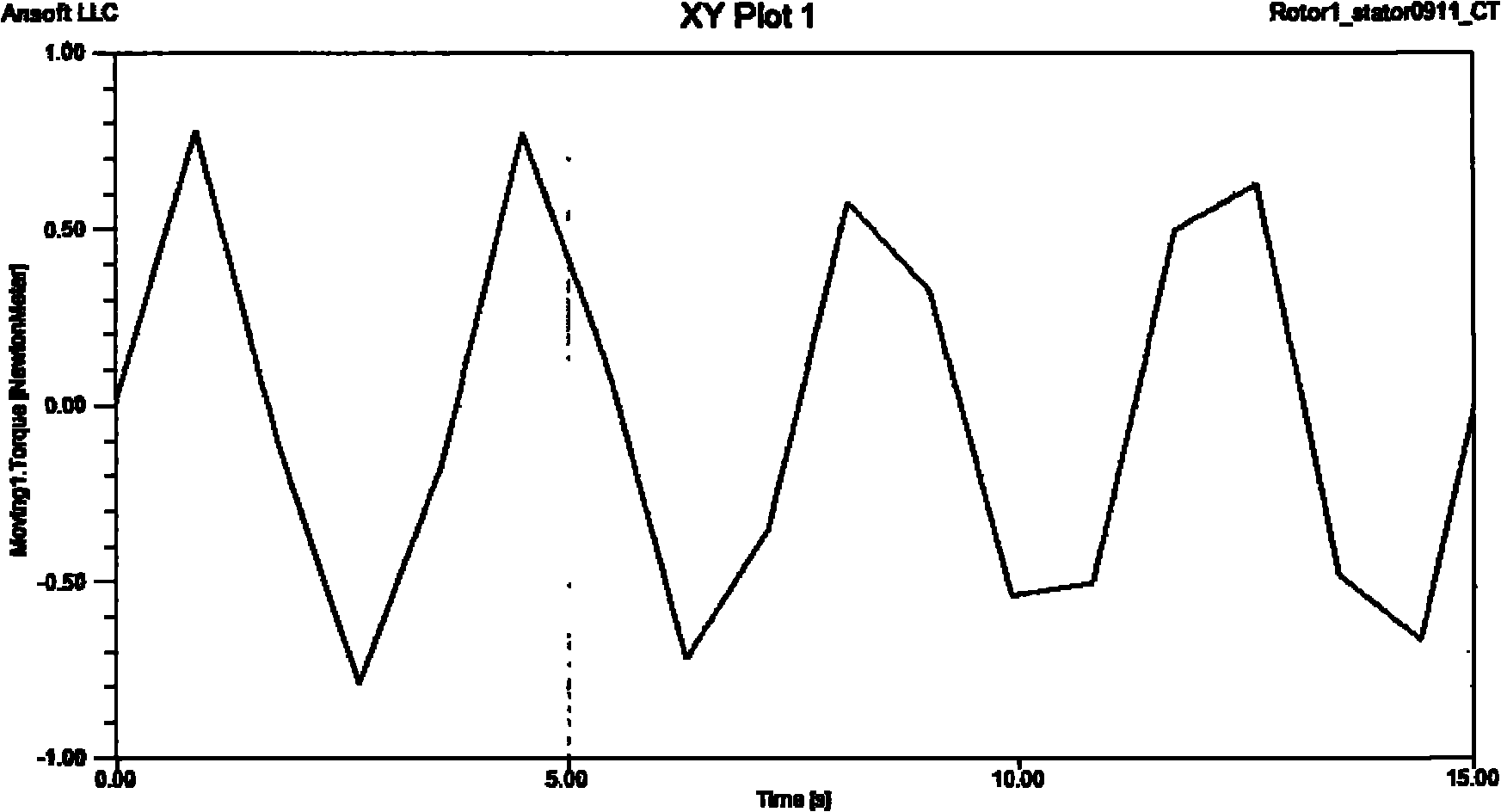

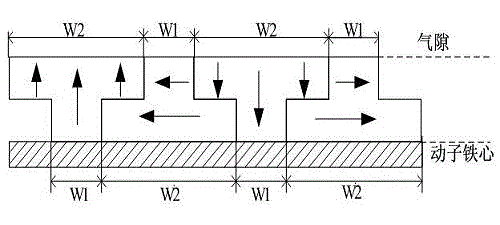

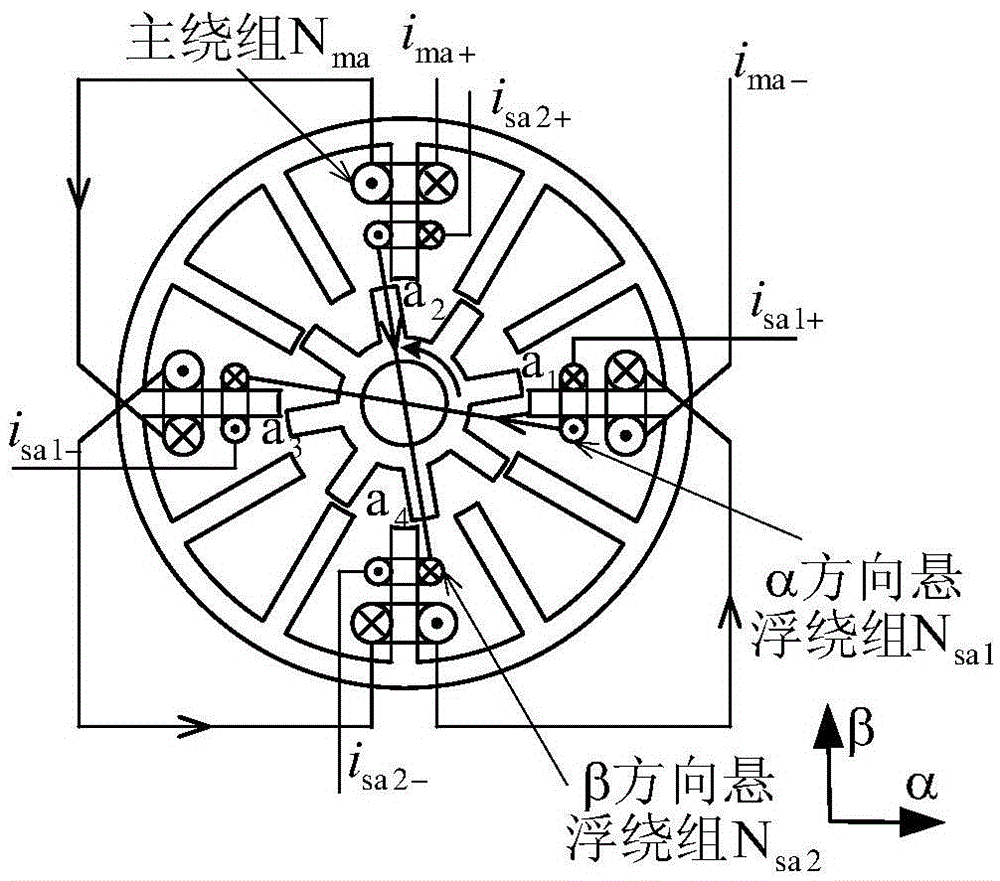

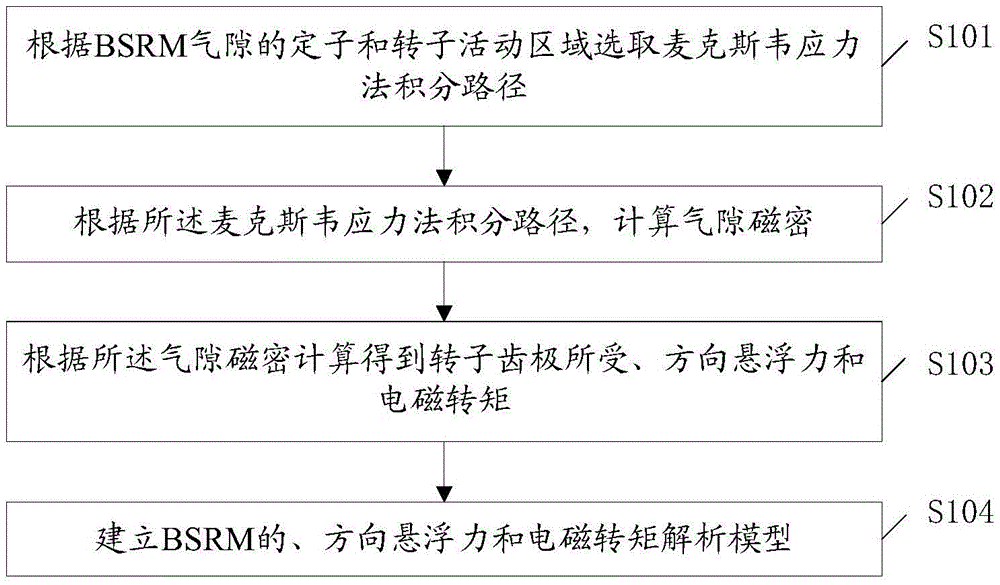

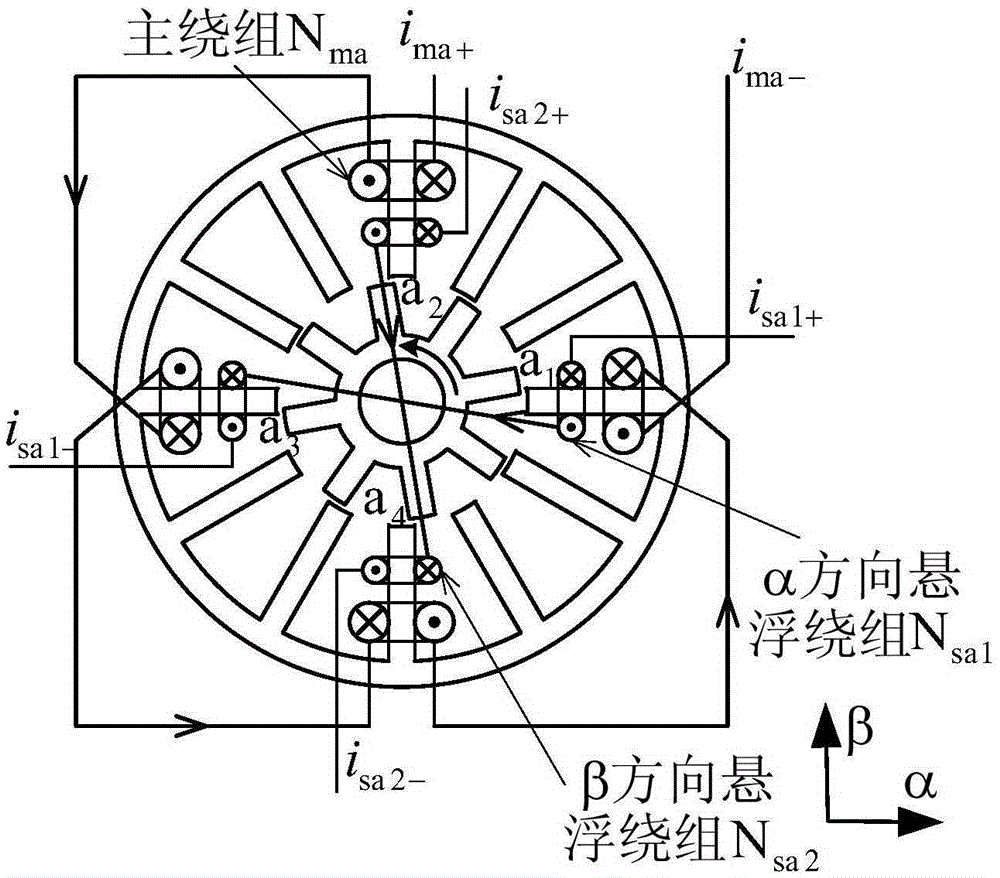

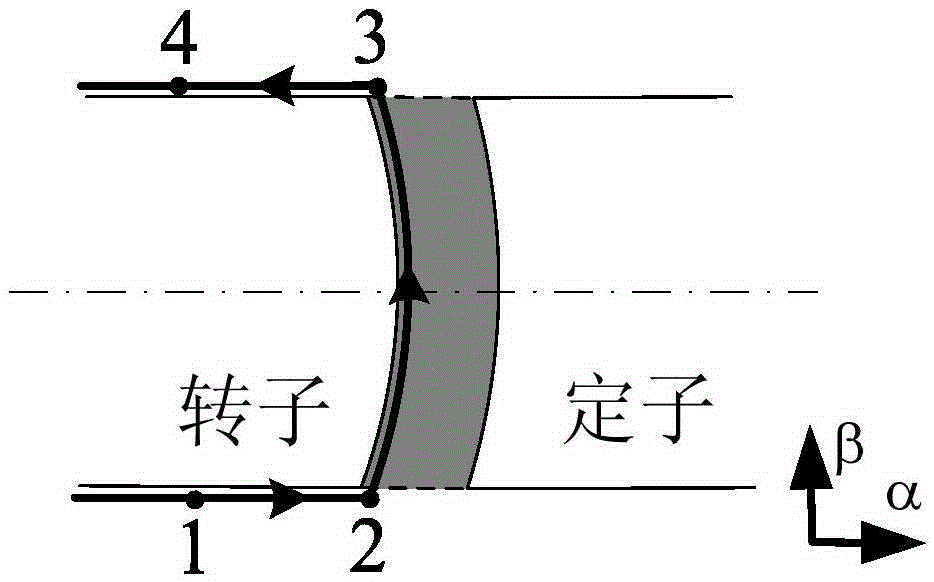

BSRM (Bearingless Switched Reluctance Motor) analytical modeling method based on Maxwell stress method

ActiveCN105549419AEnable accurate modelingImprove modeling accuracySimulator controlLevitationAir gap flux density

The invention discloses a BSRM (Bearingless Switched Reluctance Motor) analytical modeling method based on a Maxwell stress method. The method comprises steps: according to a stator and rotor action zone in a BSRM air gap, a Maxwell stress method integral path is selected; according to the Maxwell stress method integral path, air gap flux density is calculated; according to the air gap flux density, levitation forces and electromagnetic torques applied to a rotor tooth pole in an alpha direction and in a beta direction can be calculated and obtained; and alpha and beta-direction levitation force and electromagnetic torque analytical models for the BSRM are built. The BSRM analytical modeling is realized, and the modeling precision is high.

Owner:HOHAI UNIV

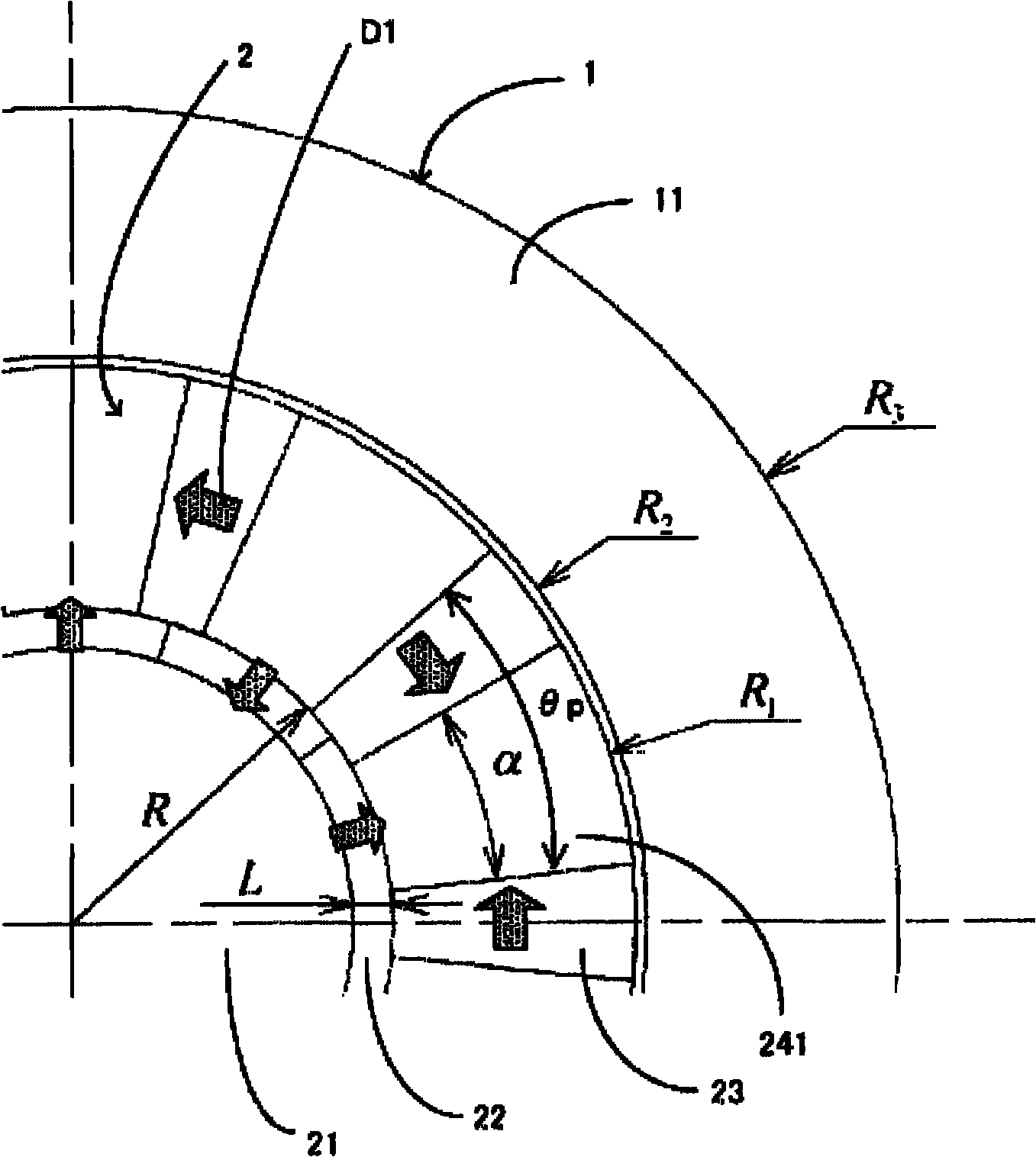

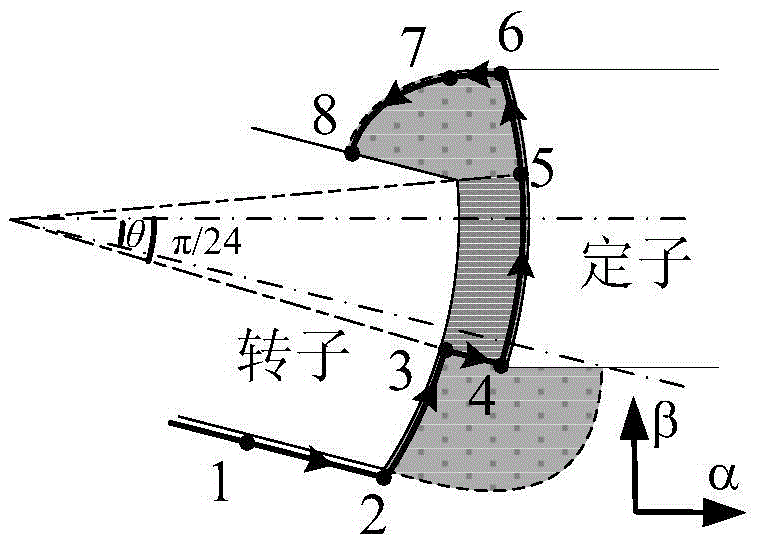

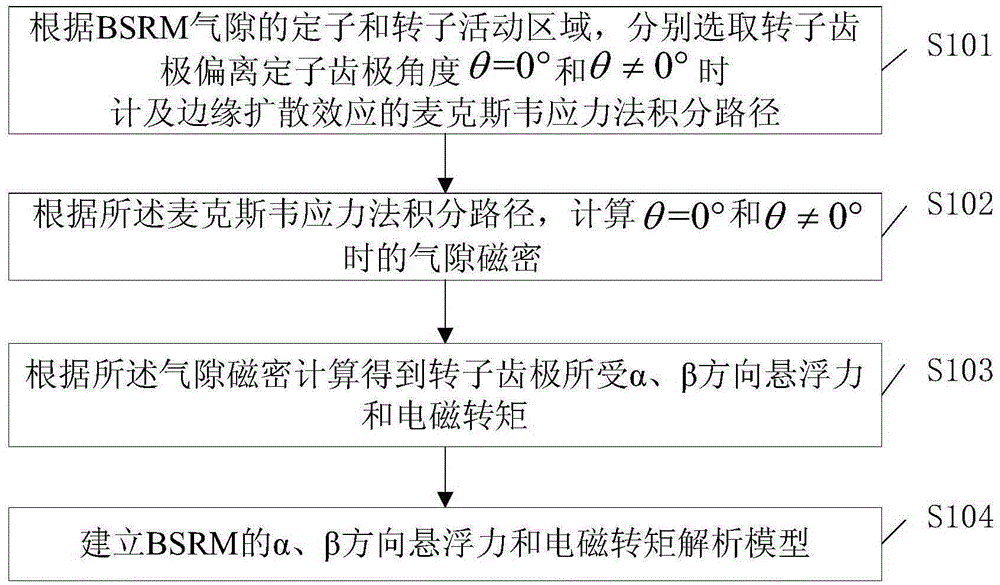

BSRM modeling method considering edge diffusion effect

ActiveCN105373014AEnable accurate modelingImprove modeling accuracySimulator controlLevitationModel method

The invention relates to a BSRM modeling method considering the edge diffusion effect. The method includes the following steps that: Maxwell stress method integral paths considering the edge diffusion effect are selected respectively according to a stator movement region and a rotor movement region of a BSRM air gap when an angle theta by which rotor tooth poles deviate from stator tooth poles is equal to 0 degree and when the theta is not equal to 0 degree; based on the Maxwell stress method integral paths, air gap flux densities when theta is equal to 0 degree and when the theta is not equal to 0 degree are calculated; alpha-direction levitation forces and beta-direction levitation forces which are borne by the rotor tooth poles, and electromagnetic torques can be obtained through calculation according to the air gap flux densities; and an alpha-direction and beta-direction levitation force and electromagnetic torque analytical model of a BSRM is established. With the BSRM modeling method adopted, BSRM analytical modeling is realized, and the edge diffusion effect is considered, and therefore, modeling accuracy is high.

Owner:HOHAI UNIV

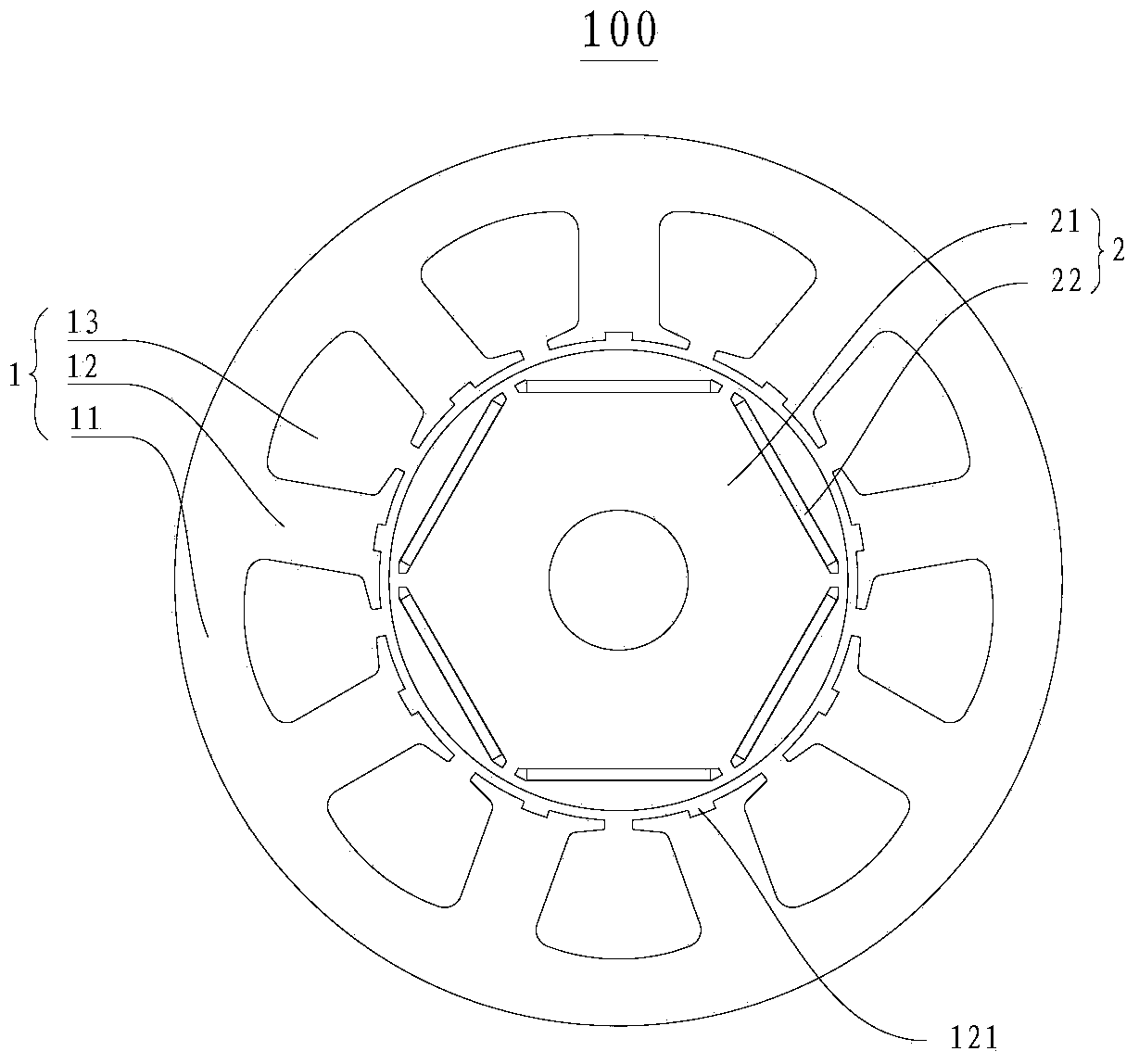

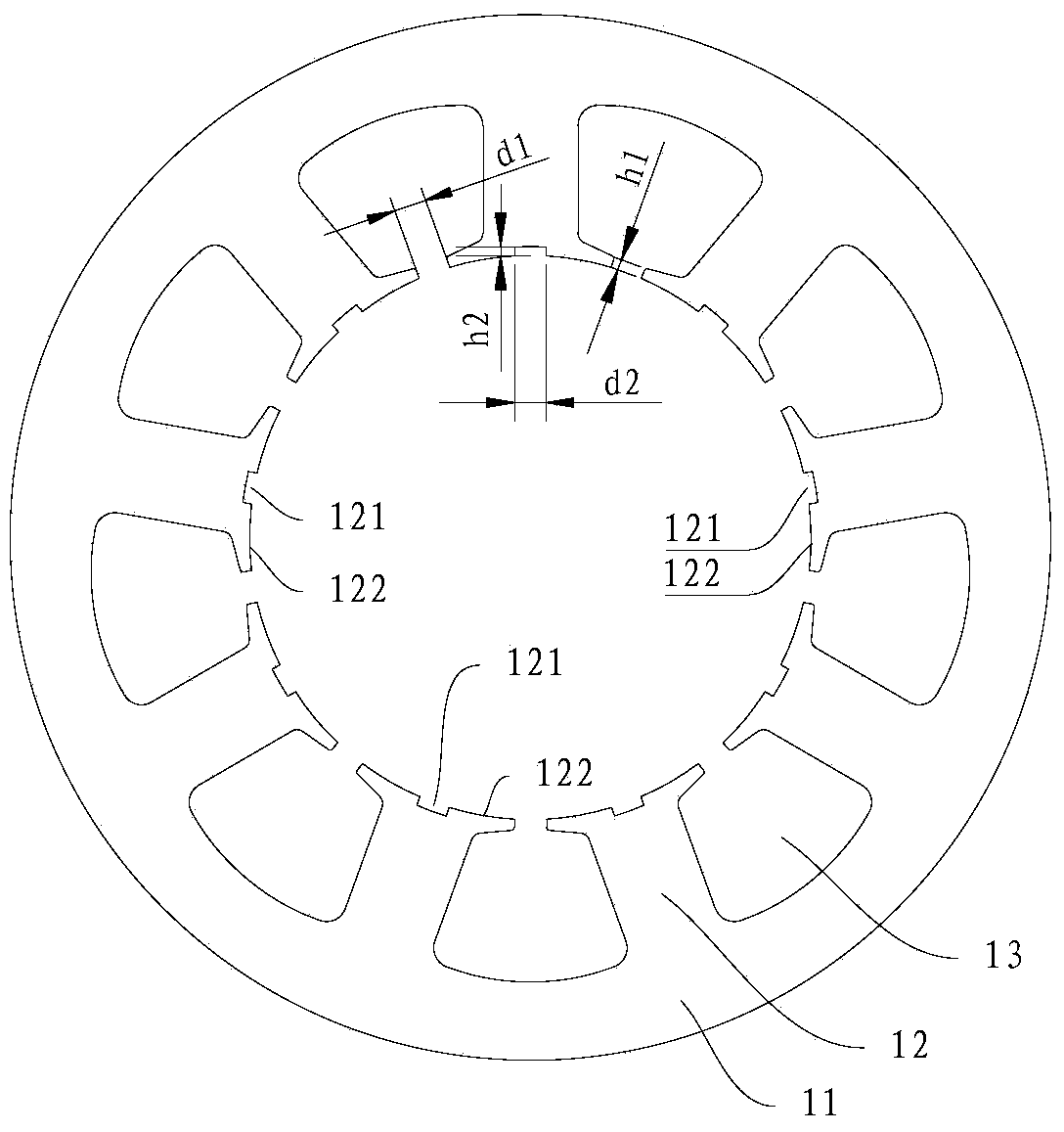

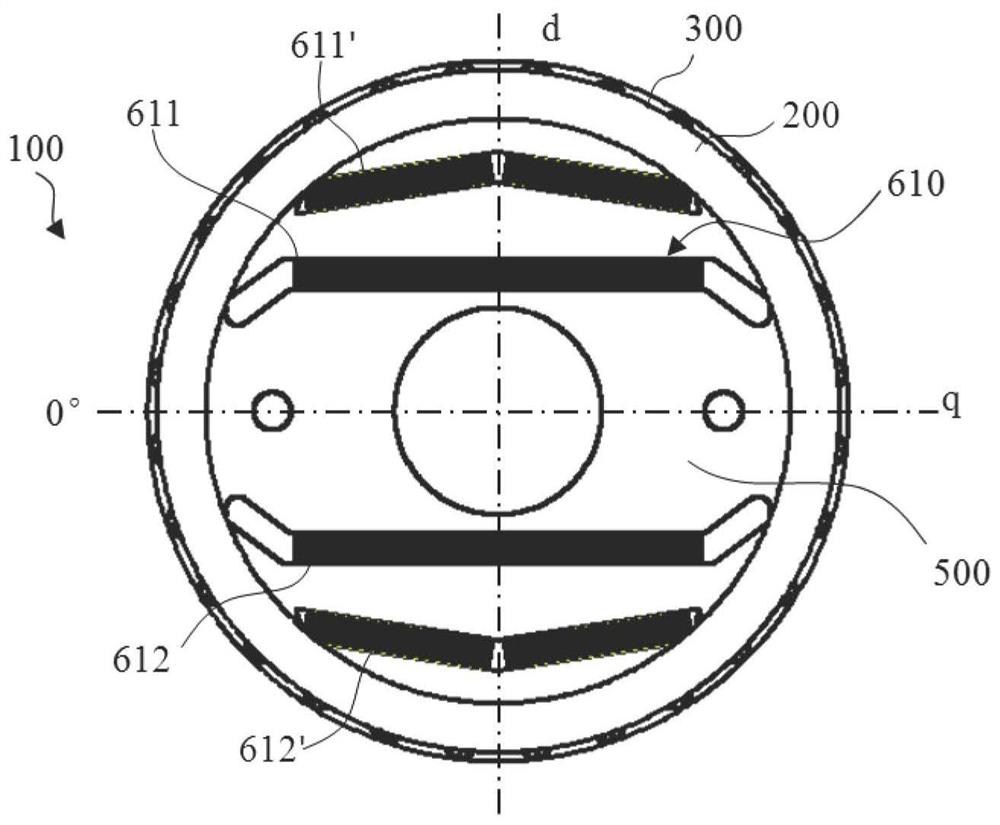

Rotor, built-in permanent magnet motor and compressor

ActiveCN104300710AIncrease inductanceMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet motorAir gap flux density

The present invention provides a rotor, a built-in permanent magnet motor and a compressor. The rotor is used in the built-in permanent magnet motor and includes a rotor core; multiple permanent magnetsinstalled inside the rotor core at intervals; multiple air tanksarranged to be adjacent to the end portion fo the permanent magnet and close to the outer periphery of the rotor; multiple dents, each dent being arranged on the outer periphery of the rotor and making air gap flux density between the outer periphery of rotor and inner circumference of the stator of built-in permanent magnet motor being close to the sine curve.

Owner:DANFOSS (TIANJIN) CO LTD

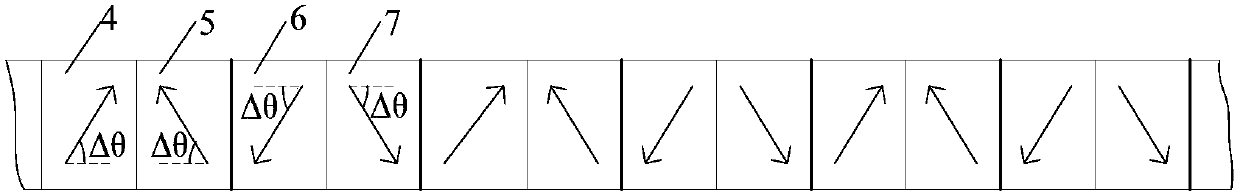

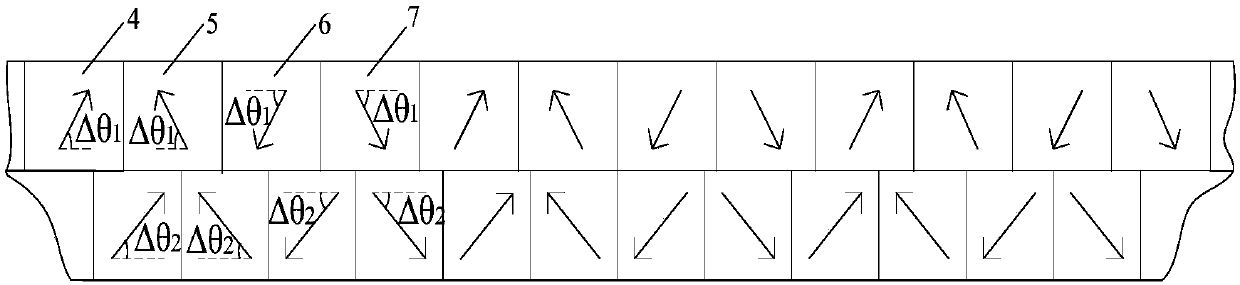

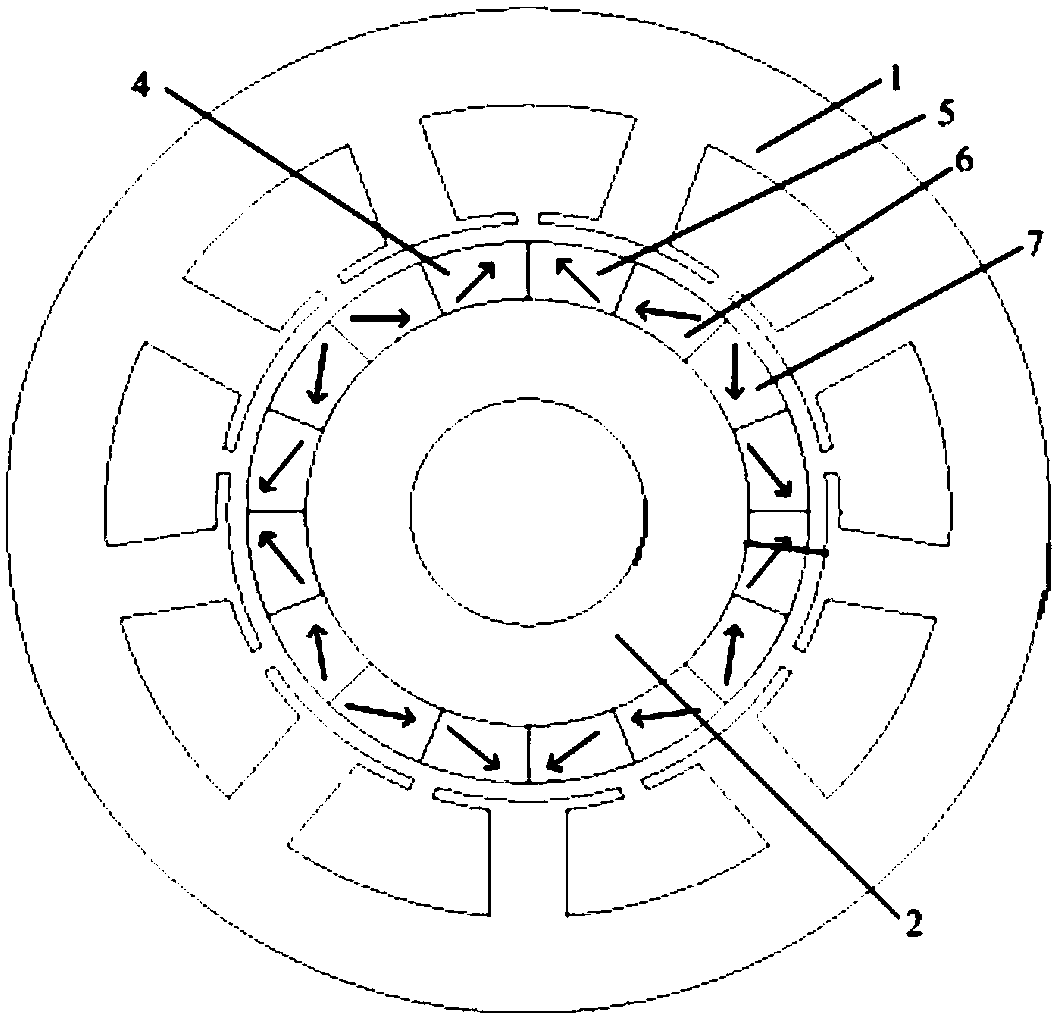

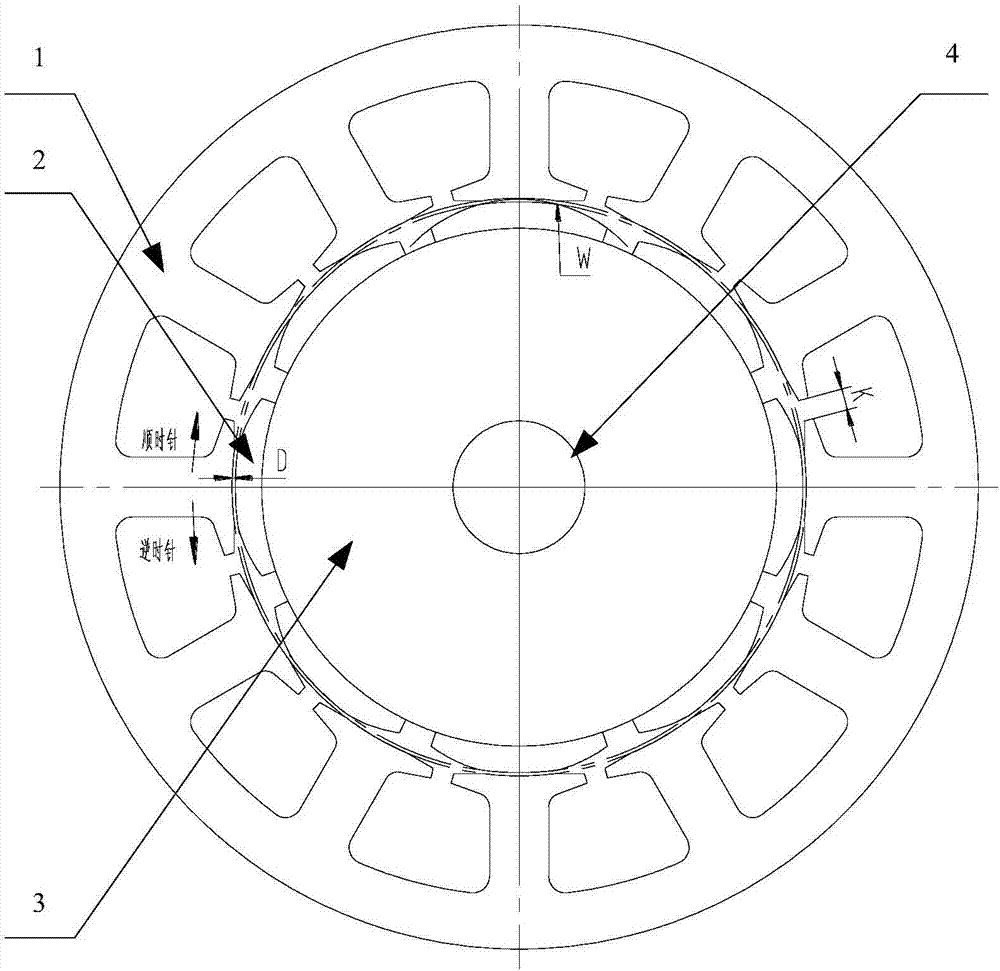

Two-section Halbach permanent magnet motor with optimal magnetization angle

ActiveCN107634631AReduce harmonic componentsRaise the amplitude valueMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetizationTorque density

The invention discloses a two-section Halbach permanent magnet motor with an optimal magnetization angle, which is characterized in that the optimal magnetization angle of a first permanent magnet section of the N-pole is an included angle of a magnetization direction and a clockwise circumference tangential direction; the optimal magnetization angle of a second permanent magnet section of the N-pole is an included angle between the magnetization direction and an anticlockwise circumference tangential direction; the optimal magnetization angle of a first permanent magnet section of the S-poleis an included angle between the magnetization direction and the anticlockwise circumference tangential direction; and the optimal magnetization angle of a second permanent magnet section of the S-pole is an included angle between the magnetization direction and the clockwise circumference tangential direction, and a rotor is matched with a corresponding stator to form a two-section Halbach permanent magnet motor with an optimal magnetization angle. The two-section Halbach permanent magnet motor can improve the radial air gap flux density fundamental wave amplitude and reduce a harmonic component of the air gap flux density, thereby being capable of outputting the torque at the same volume and cost. Therefore, the torque density and the power density of the kind of motors can be improved,and the scheme is also applicable to motor without a rotor core and external rotor motors.

Owner:HEFEI UNIV OF TECH

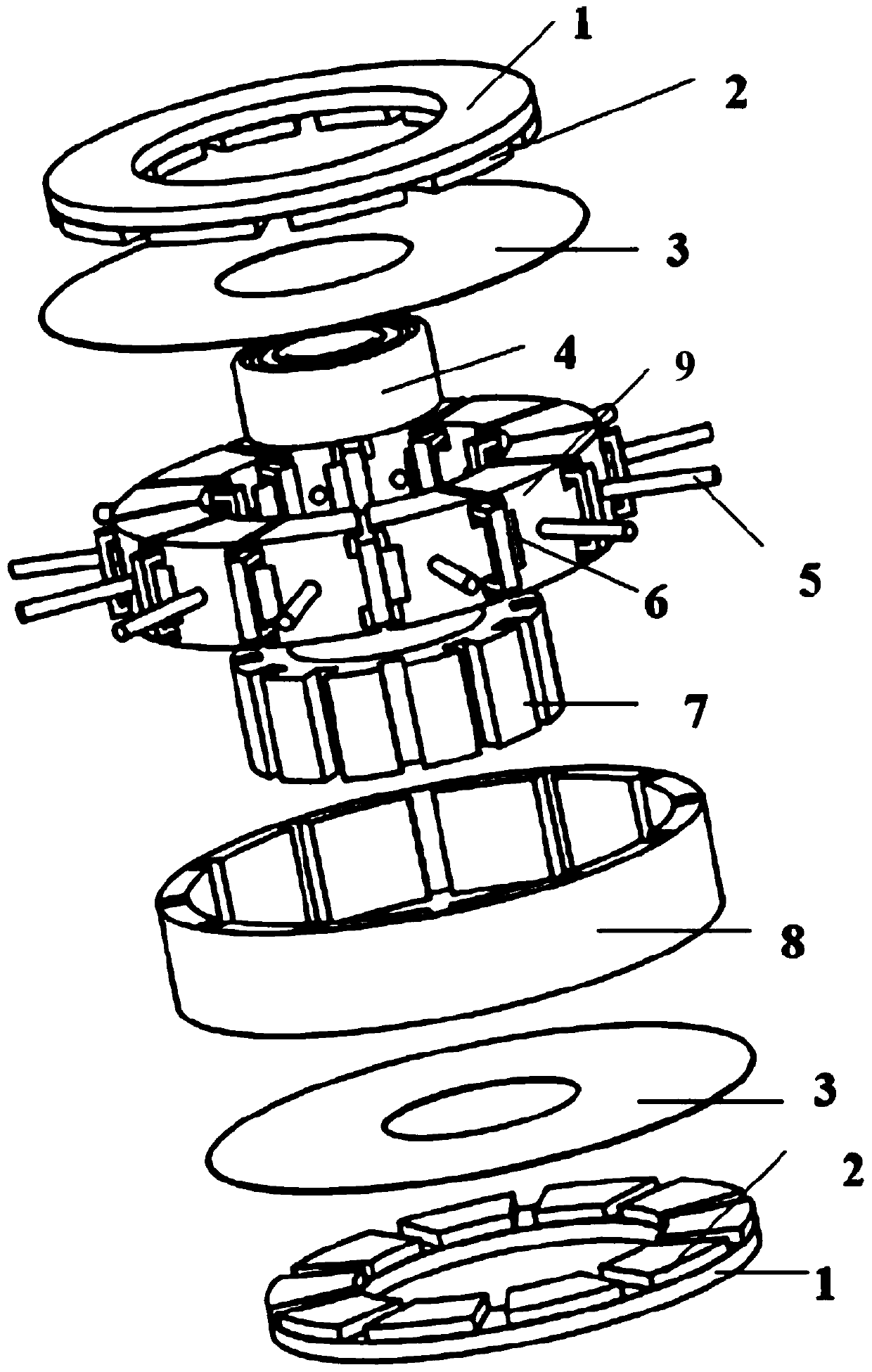

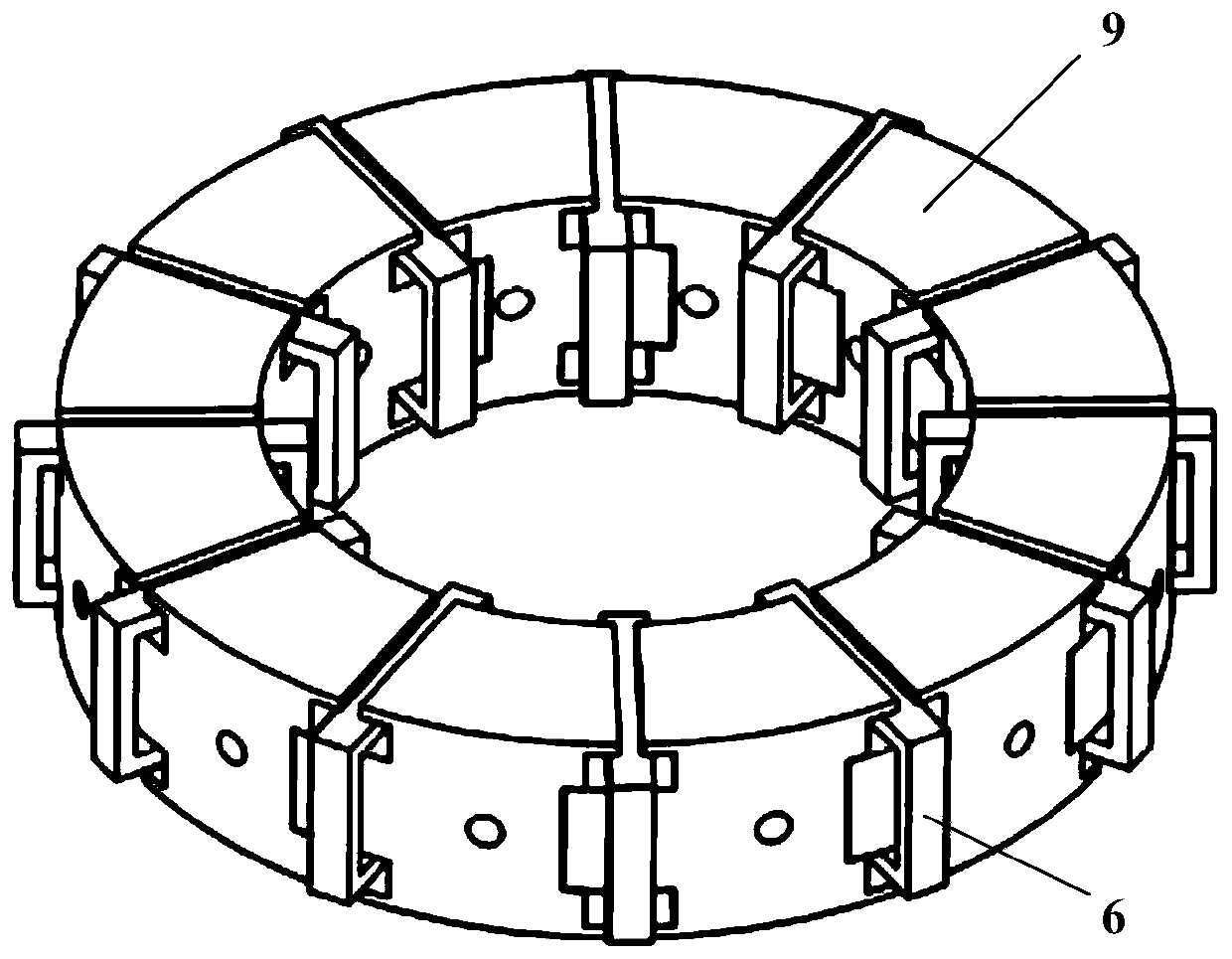

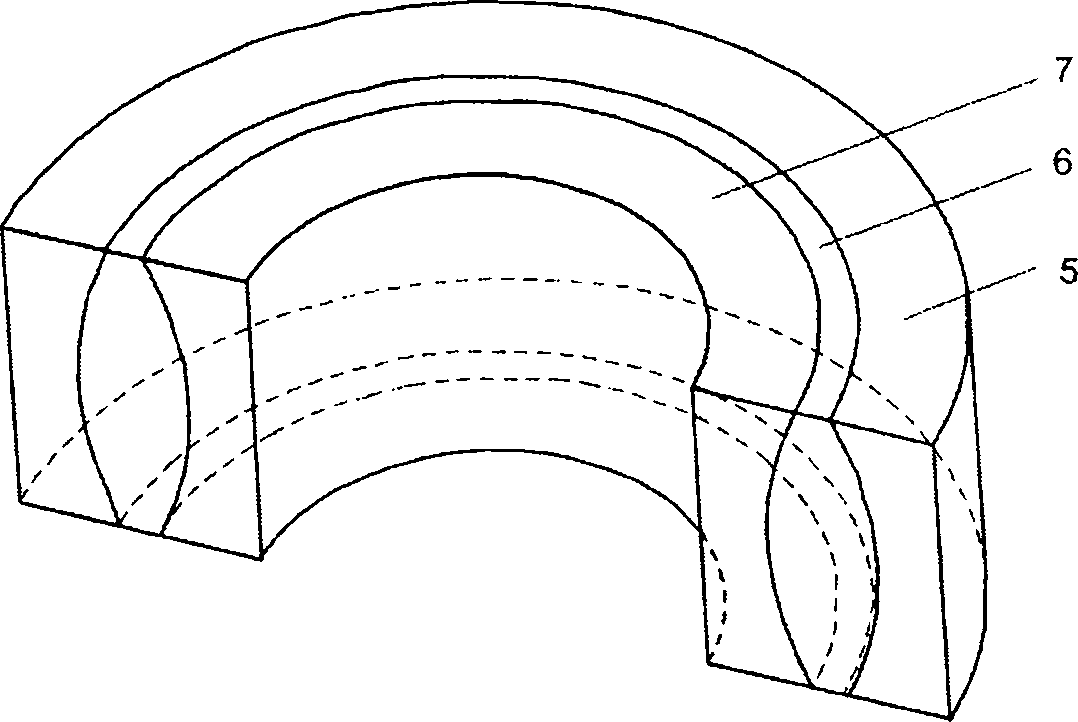

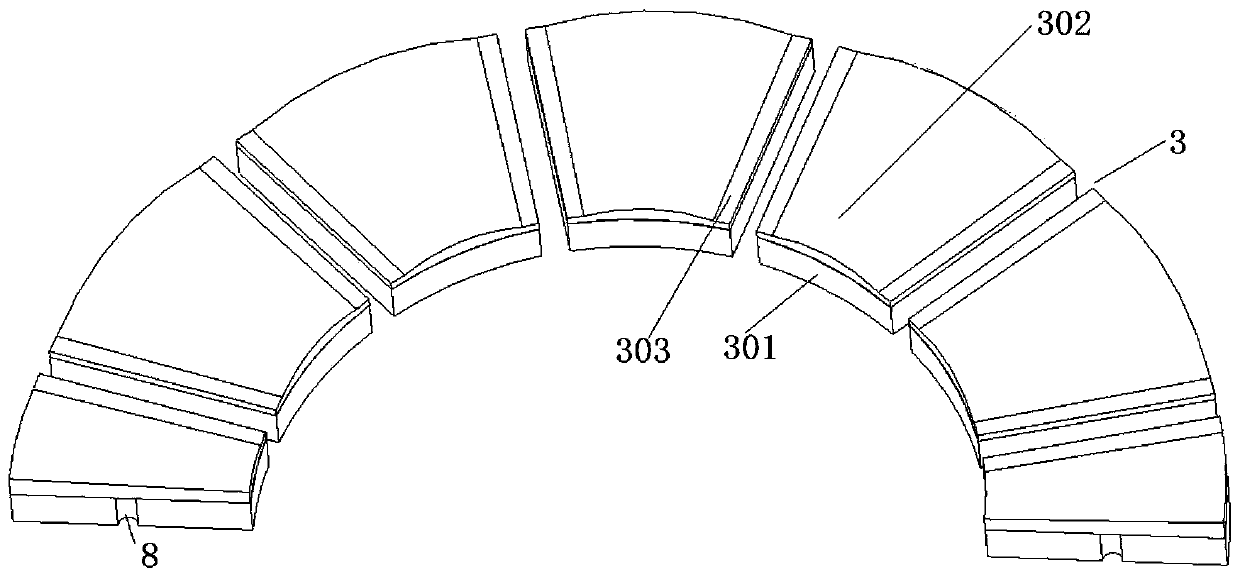

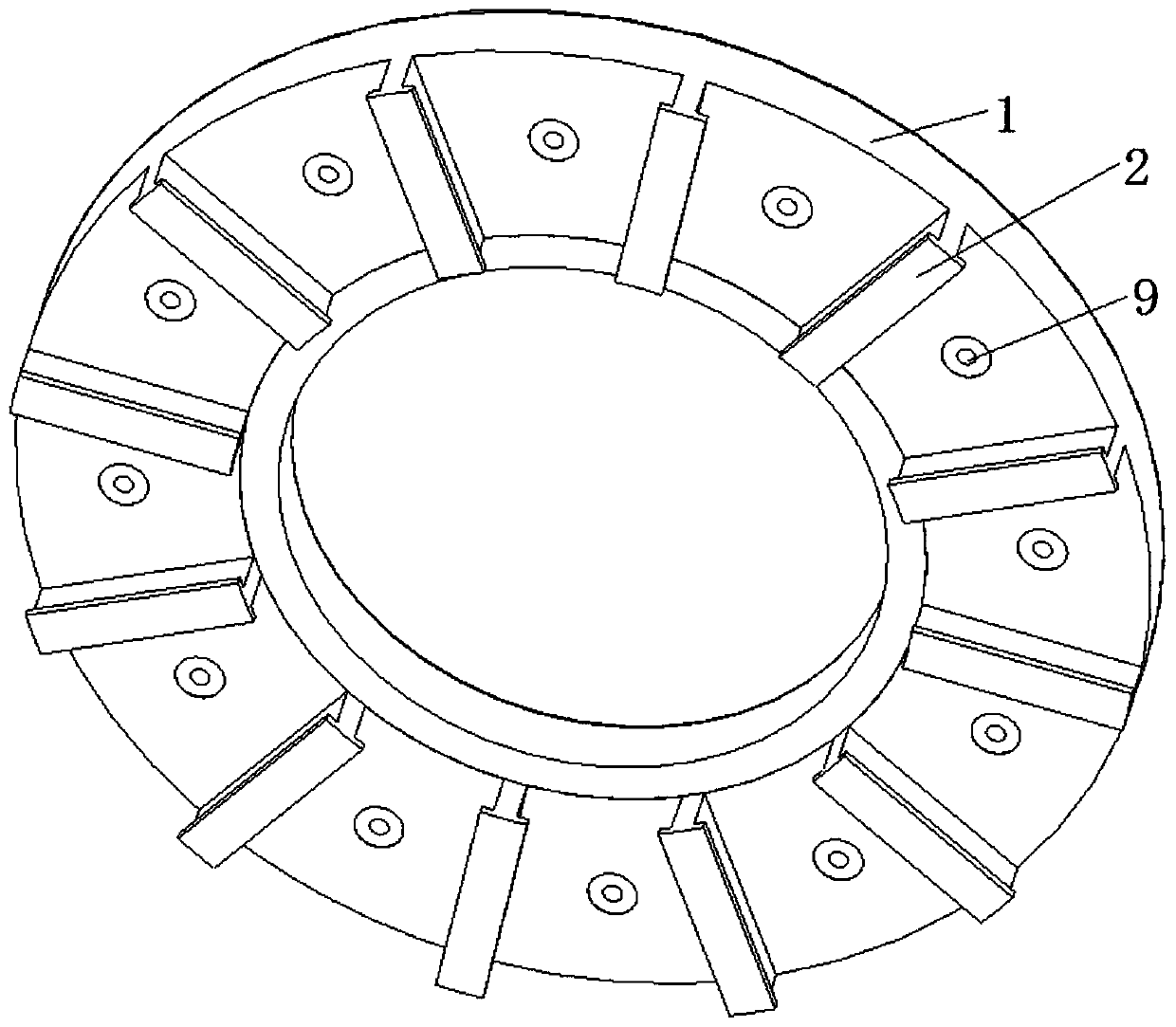

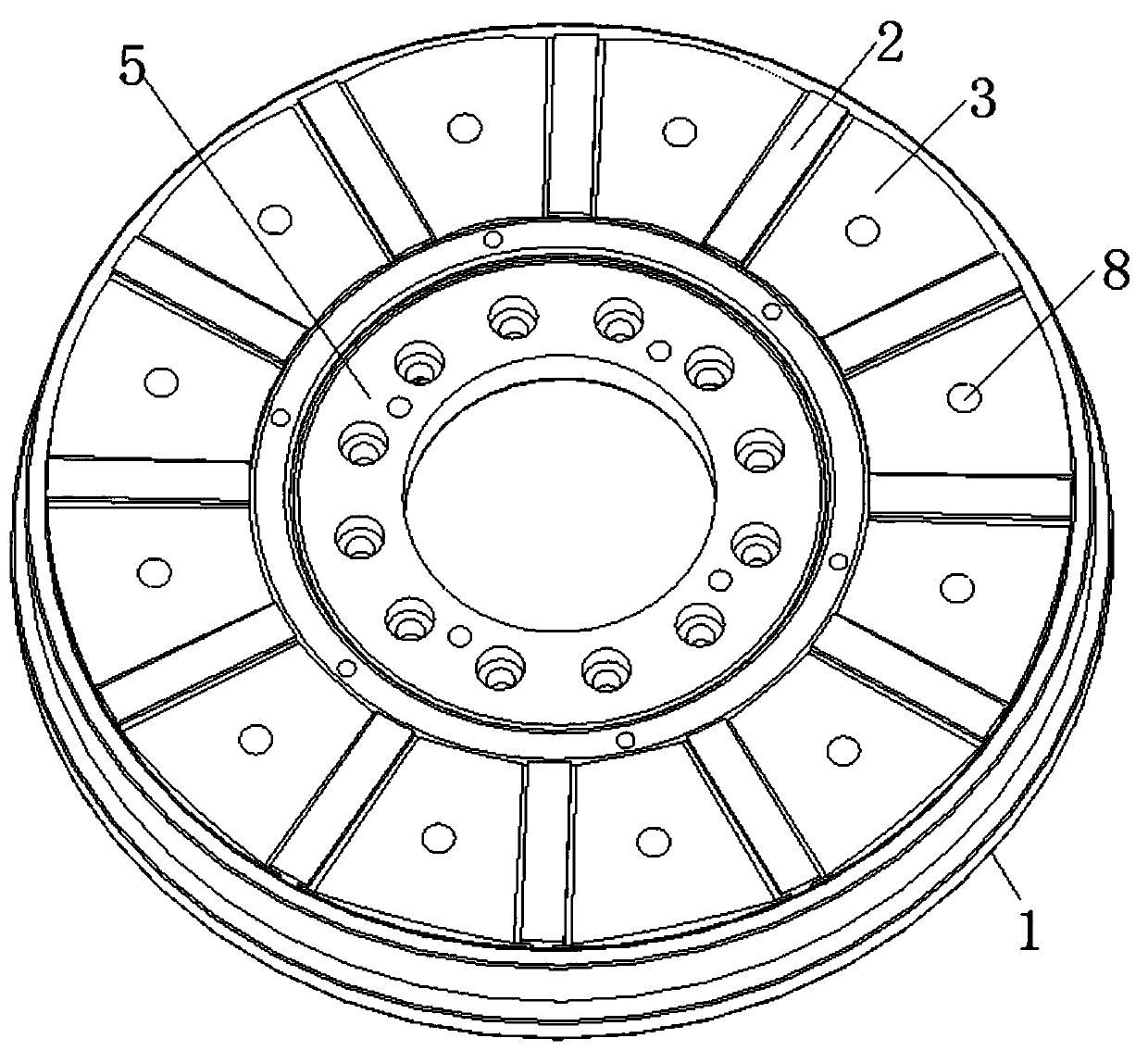

Modular axial flux permanent magnet motor

InactiveCN110611379AReduce stressHigh mechanical strengthWindingsMagnetic circuit rotating partsFlywheel energy storageCooling effect

The invention discloses a modular axial flux permanent magnet motor. The motor comprises a stator, double rotors and a bearing. The stator comprises a stator iron core, a stator winding, stator iron core fixing pins and a stator sealing plate. The stator iron core adopts a modular structure, the stator winding is wound on a yoke part of the stator iron core, and the stator iron core fixing pins radially penetrate through the stator iron core and are fixed on a fixed ring. The stator sealing plate is used for sealing stator cooling oil to improve the cooling effect. The rotors comprise rotor back yokes and rotor permanent magnets which are symmetrically installed on two sides of the stator, the rotor permanent magnets are fixed to the rotor back yokes, and inner circumferences of the rotorback yokes are fixed to the bearing. Equal air gaps are kept between the double rotors and the stator to generate a magnetic field. The modular axial flux permanent magnet motor has the advantages ofhigh air gap flux density, high stator structural strength, high torque density and good cooling effect and is suitable for being applied to electric propulsion, wind power generation and high-speed flywheel energy storage occasions.

Owner:NANJING UNIV OF SCI & TECH

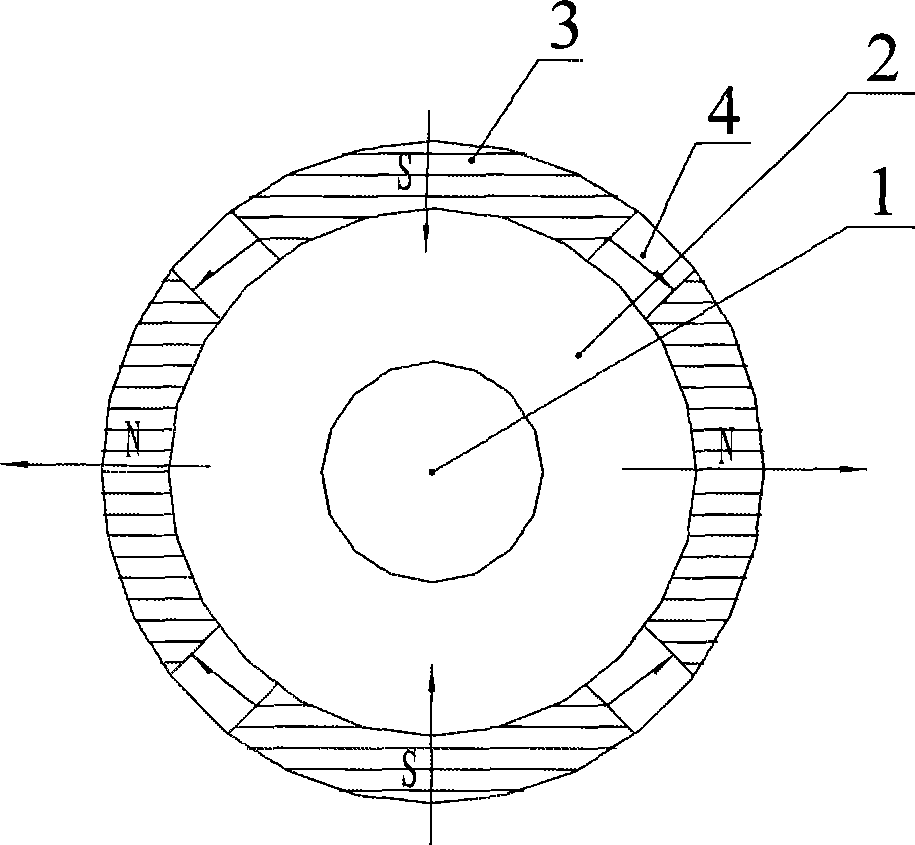

Surface-mounted motor, surface-mounted motor rotor and stator

ActiveCN107276272AChanging the air gap lengthReduce vibration and noiseMagnetic circuit rotating partsMagnetic circuit stationary partsSurface mountingElectric machine

The invention discloses a surface-mounted motor, a surface-mounted motor rotor and a stator. The magnetic steel (2) of the surface-mounted motor rotor is provided with an external side surface facing the stator (1). The two sides of the external side surface are provided with trimming structures which are symmetrically arranged along the center line. According to the surface-mounted motor rotor, the two sides of the external side surface are provided with the trimming structures which are symmetrically arranged along the center line so that the air gap length of all the positions along the internal circumferential surface of the stator of the motor can be changed, then the air gap magnetic field can be improved, the air gap flux density and the counter-electromotive force waveform sine degree can be enhanced, the harmonic proportion can be reduced and thus the torque ripple can be reduced and the motor vibration noise can be effectively reduced. The stator and the surface-mounted motor have the same technical effects with those of the surface-mounted motor rotor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Rotor of high-speed Halbach-type permanent magnet motor

InactiveCN105790468AImprove power densityImprove dynamic response performanceMagnetic circuit rotating partsPermanent magnet motorAir gap flux density

The invention provides a rotor of a high-speed Halbach-type permanent magnet motor. The rotor comprises a Halbach-type permanent magnet structure, a rotor shaft and a rotor sheath, wherein the Halbach-type permanent magnet structure comprises strip-shaped rectangular permanent magnets and strip-shaped arc permanent magnets; the external surfaces of the strip-shaped arc permanent magnets are arc-shaped; the strip-shaped rectangular permanent magnets and the strip-shaped arc permanent magnets are arranged in the peripheral direction of the rotor shaft at intervals; the rotor sheath is arranged outside the strip-shaped rectangular permanent magnets and the strip-shaped arc permanent magnets; the adjacent strip-shaped rectangular permanent magnets and strip-shaped arc permanent magnets are directly laminated; and a groove corresponding to the strip-shaped rectangular permanent magnets or the strip-shaped arc permanent magnets is formed in the rotor shaft or the rotor sheath. Due to the structural design of the rotor, the numerical value of the air-gap flux density of the rotor is improved; the sine degree of the waveform is enhanced; the power density of the motor is improved; the flux density of a rotating shaft yoke is reduced; the hollow rotating shaft provides a cooling channel for the rotor; and the dynamic response ability of the rotor is improved.

Owner:HARBIN INST OF TECH

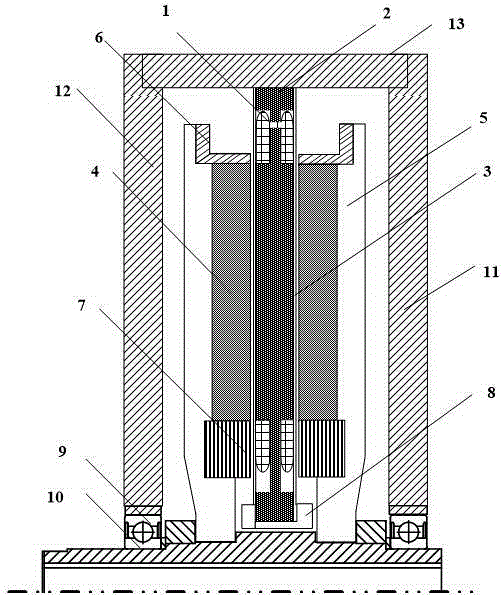

Permanent magnet brushless moment motor with double stators

InactiveCN102035322AMake up for the large equivalent air gapMake up for the serious defect of magnetic flux leakage at the endMagnetic circuit rotating partsMagnetic circuit stationary partsAxial distributionAir gap flux density

The invention discloses a permanent magnet brushless moment motor with double stators, mainly comprising a rotor shaft, an inner stator core, an inner stator cup, an outer stator core, an outer stator cup, a rotor core, rotor inner magnetic steel and rotor outer magnetic steel, wherein the rotor inner magnetic steel and the rotor outer magnetic steel are in a structure with a thin middle part and two thick ends along the axial direction; the rotor inner magnetic steel, the rotor outer magnetic steel and the rotor core jointly form a rotor assembly arranged between the inner stator cup and the outer stator cup; the inner stator cup and the outer stator cup are respectively fixedly connected with the inner stator core and the outer stator core; and the inner stator core and the outer stator core are connected to a main case through sleeves. The unequal thickness design of the rotor inner magnetic steel and the rotor outer magnetic steel in the invention compensates the influence of brow leakage on axial air gap flux density distribution and ensures the uniform axial distribution of the air gap flux density; coils of an inner stator winding and an outer stator winding jointly form the coils of a motor winding, the serial connection turn number of windings of each phase is increased to ensure that the moment coefficient of a motor becomes large, thereby increasing the moment density and reducing the volume of the motor.

Owner:BEIHANG UNIV

Low noise fast response permanent magnet DC brushless motor for constant wind control

InactiveCN101459370AImprove qualityReduce torque fluctuationMagnetic circuit rotating partsMagnetic circuit stationary partsLow noiseBrushless motors

The invention provides a low noise fast response permanent magnet direct current brushless motor for controlling constant air volume, which comprises a shell, a stator and a rotor in the shell, wherein the stator comprises a stator iron core and a stator winding which are fixed on the inner wall of the shell, the rotor comprises a main shaft and a rotor iron core, the external circumferential direction of the rotor iron core is evenly fixed with rotor magnetic poles which comprise radial magnetized magnetic steel and tangential magnetized magnetic steel, the radial magnetized magnetic steel is a main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is a side magnetic pole. Or, the inner circumferential direction of the rotor iron core is evenly embedded with built-in radial magnetized rectangular strip magnetic steel which is the main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is the side magnetic pole. The low noise fast response permanent magnet direct current brushless motor gathers magnetic through two ways of radial and tangential direction, thereby observably increasing the air gap flux density, greatly reducing the mechanical time constant, increasing fast response, controlling the constant air volume in a high performance, which leads a motor to steadily operate in high efficiency, saving energy, low fluctuation, low noise, frequent starting and rapid response, and the low noise fast response permanent magnet direct current brushless motor can achieve the miniaturization and lightening of the motor.

Owner:苏州和鑫电气股份有限公司

Disc type motor rotor with pole shoe composite magnetic pole structure

PendingCN111355323AGood magnetic conductivityEasy to processMagnetic circuit rotating partsMagnetic polesElectric machinery

The invention discloses a disc type motor rotor with a pole shoe composite magnetic pole structure, and relates to the field of motors. The disc type motor rotor comprises a rotor supporting disc, a hole is formed in the center of the rotor supporting disc, and a groove is formed in the surface of one side of the rotor supporting disc and used for installing a rotor core and composite magnetic poles; the rotor iron core is of an annular structure, is arranged at the bottom of the groove and is tightly attached to the rotor supporting disc, T-shaped baffles distributed in the radial direction are arranged on a surface of a side, away from the rotor supporting disc, of the rotor iron core, and the T-shaped baffles divide the rotor iron core into a plurality of fan-shaped spaces at equal intervals along the circumference; the composite magnetic poles are arranged in the fan-shaped spaces on the rotor iron core; the composite magnetic poles comprise permanent magnets and pole shoes, and the pole shoes made of composite soft magnetic materials are installed on the surface of the permanent magnet. The radians of the pole shoes on the surface of the permanent magnet can be adjusted, sinewave air gap flux density is generated, the output torque of a motor is smooth, the pole shoes can protect the permanent magnets against field loss under the action of a demagnetization field, the field weakening capacity of the motor is improved, and the motor is easy to machine and suitable for batch production.

Owner:仪坤动力科技(上海)有限公司

Mixed asymmetric permanent magnet rotor

InactiveCN104167844AReduce manufacturing costAvoid noiseMagnetic circuit rotating partsPermanent magnet rotorAir gap flux density

The invention discloses a mixed asymmetric permanent magnet rotor which aims at solving the problems that material cost is excessively high, and torque ripples need to be reduced. The rotor comprises a rotating shaft, a rotor core and a permanent magnet. The permanent magnet is pasted to the surface of the rotor core in a sectional-type-structure mode and is of a spliced structure made of neodymium iron boron materials and ferrite materials, each pole of the permanent magnet is formed by three permanent magnet bodies, the middle of the permanent magnet is made of the neodymium iron boron materials, and the two ends of the permanent magnet are made of the ferrite materials. When the rotor rotates, air gap flux density is in a step shape which is closer to the sine wave, and the torque ripples are effectively reduced. The mixed asymmetric permanent magnet rotor is mainly used for a linear rotating converter, shaking and losses of the converter can be lowered with the rotor serving as a rotating part, and meanwhile the stability of the converter is improved.

Owner:SOUTHEAST UNIV

High-power density permanent magnet motor

InactiveCN102594086AReduce thrust fluctuationLow costMagnetic circuit rotating partsPropulsion systemsWave shapeRelative motion

The invention relates to a high-power density permanent magnet motor, belonging to the field of motors, solving a problem of poor sine degree of an air gap flux density waveform in a conventional motor. The cross section of each main permanent magnet body in a linear electric motor secondary unit is in a shape of bilaterally symmetric hexagon or octagon, the bottom edge of the hexagon or octagon, close to an air gap side is shorter than the bottom edge far away from the air gap side, the main permanent magnet bodies are magnetized in parallel in a direction vertical to relative motion direction of a primary unit and the secondary unit, auxiliary permanent magnet bodies are magnetized in parallel in the relative motion direction of the primary unit and the secondary unit, and the main permanent magnet bodies and the auxiliary permanent magnet bodies are alternately and closely arranged and fixed on the air gap side of a conductive magnetic yoke. According to the high-power density permanent magnet motor disclosed by the invention, the cross section of each main permanent magnet body in the linear electric motor secondary unit is in the shape of radially symmetric octagon, and the length of the edge of the octagon at the air gap side is smaller than the length of the edge far away from the air gap side; the main permanent magnet bodies are magnetized radially or in parallel, and the auxiliary permanent magnet bodies are magnetized tangentially; and the main permanent magnet bodies and the auxiliary permanent magnet bodies are alternately and closely arranged in the circumferential direction and fixed on the surface of the air gap side of a rotor yoke drum.

Owner:HARBIN INST OF TECH

Less-rare-earth multi-excitation-source double-stator flux-switching memory motor

InactiveCN106911237AAchieve separationSolve mutual problemsMagnetic circuit rotating partsMagnetic circuit stationary partsRare earthEngineering

The invention discloses a less-rare-earth multi-excitation-source double-stator flux-switching memory motor, which belongs to the technical field of motor body design and operating principles. Coaxial outer stators, rotors and inner stators are sleeved together in turns from outside to inside to compose the memory motor, wherein a radial air gap exists between the outer stators and the rotors, the rotors and the inner stators, the outer stators are composed of armature core teeth, fault-tolerant teeth and stator yokes, and the rotors are composed of a rotor support, a magnetic silicon steel block and a magnetic insulation block, and meanwhile, the inner stators are composed of the inner stator core and a combined permanent-magnet cell block. The double-stator structure of the motor realizes the separation of armature winding and permanent magnet and solves the problem that multiple excitation sources inside the traditional flux-switching permanent magnet motors restrain each other, thereby easily increasing motor power density and torque density. The memory motor maintains high air-gap flux density and ensures of the motor power density and the torque density, meanwhile, the consumption of rare-earth permanent-magnetic materials is effectively lowered. On the other side, the memory motor can realize flexible adjustment of a motor air-gap field and expand the range of speed operation.

Owner:YANGZHOU UNIV

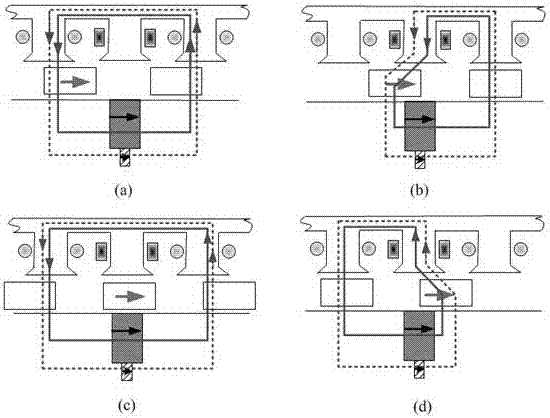

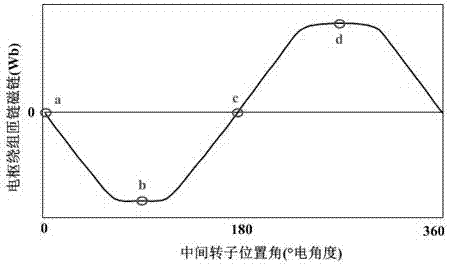

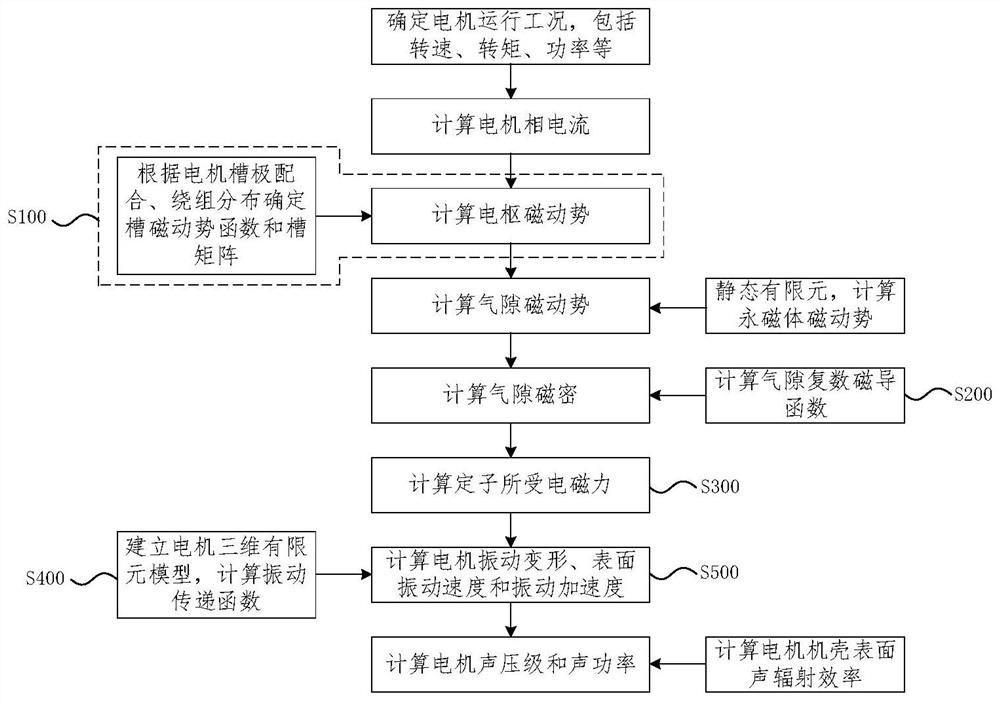

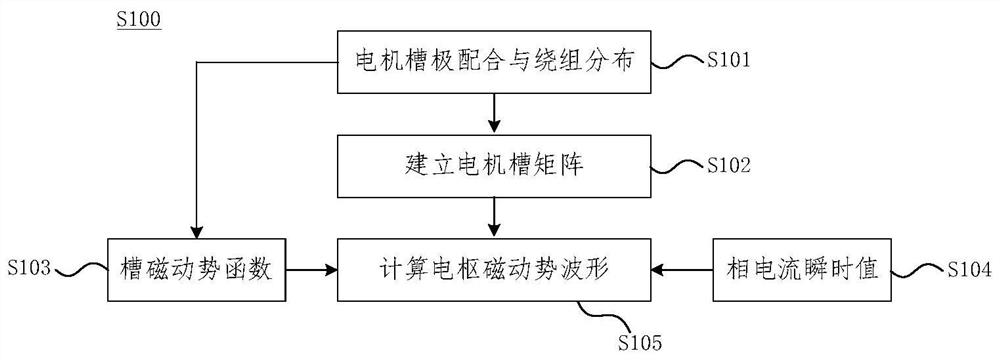

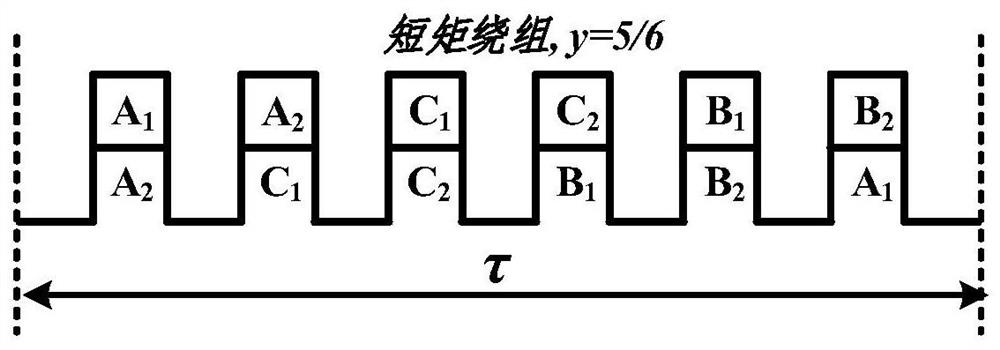

Motor electromagnetic force and electromagnetic vibration noise analysis method and system

PendingCN112906145ARapid assessmentQuick analysisGeometric CADDesign optimisation/simulationElement modelVibration acceleration

The invention discloses a motor electromagnetic force and electromagnetic vibration noise analysis method and system, and the method comprises the following steps: S100: determining the operation condition of a motor, obtaining the phase current of the motor at any moment, and determining a slot magnetomotive force function and a slot matrix of the motor, and the armature magnetomotive force of the motor at any moment; s200, establishing a static finite element model of the motor, and analyzing the magnetomotive force of a permanent magnet of the motor and the complex air gap permeability functions of a stator and a rotor of the motor; s300, obtaining the air gap flux density of the motor, and obtaining the electromagnetic force borne by each stator tooth of the motor; s400, establishing a three-dimensional structure finite element model of the motor, and analyzing a vibration transfer function of the motor; and S500, calculating the vibration speed and the vibration acceleration of the motor under the excitation of any electromagnetic force, and obtaining the sound pressure level and the sound power radiated by the motor based on the vibration speed and the vibration acceleration. According to the invention, the electromagnetic force and the electromagnetic vibration noise of the motor under various working conditions can be quickly evaluated and analyzed, and the calculation and optimization efficiency of the vibration noise of the motor is greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

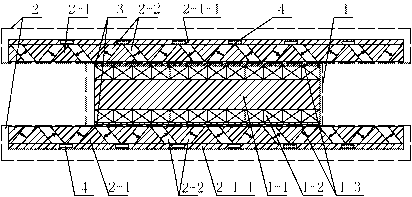

Short magnetic circuit structural cylindrical DC linear electric motor

InactiveCN101741217AIncrease output thrustGood dynamic responseMagnetic circuit shape/form/constructionPropulsion systemsElectric machineAir gap flux density

The invention provides a short magnetic circuit structural cylindrical DC linear electric motor, relating to electric motor field and solving the problems that the existing electric motor has long magnetic circuit, low air gap magnetic density, large use amount of magnetic core and heavy electric motor, and that the dynamical property of the electric motor is poor due to large mass of rotor when needing dynamic secondary level. The two coils of the primary level in the invention are mutually connected in series and have opposite winding directions; the two coils are fixed on a winding supporting seat along the axial direction; the external magnetic guide yoke and the internal magnetic guide yoke in the secondary level are toroidal magnetic guide yokes; the permanent magnets in the secondary level are three toroidal permanent magnets; the permanent magnets are closely fit on the internal wall of the toroidal external magnetic guide yoke along the axial direction; the three permanent magnets are charged with magnetism sequentially along external radial direction, axial direction and internal radial direction; the permanent magnets and the primary level form external air gap; and the primary level and the internal magnetic guide yoke form internal air gap. The invention shortens the route of the magnetic flow of the permanent magnets, reduces secondary level mass and magnetic-leakage of the linear electric motor, enhances air gap magnetic density and improves the thrust output and dynamic response of the electric motor.

Owner:HARBIN INST OF TECH

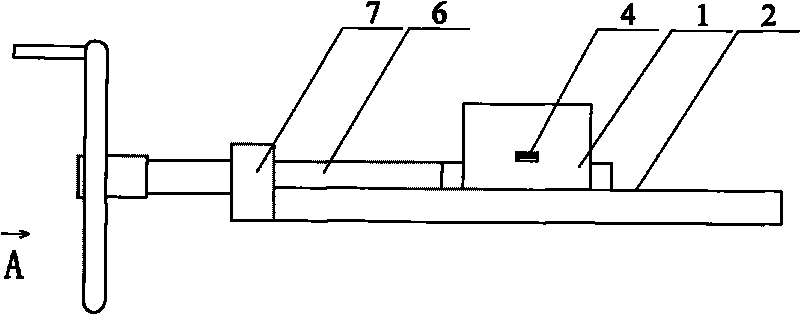

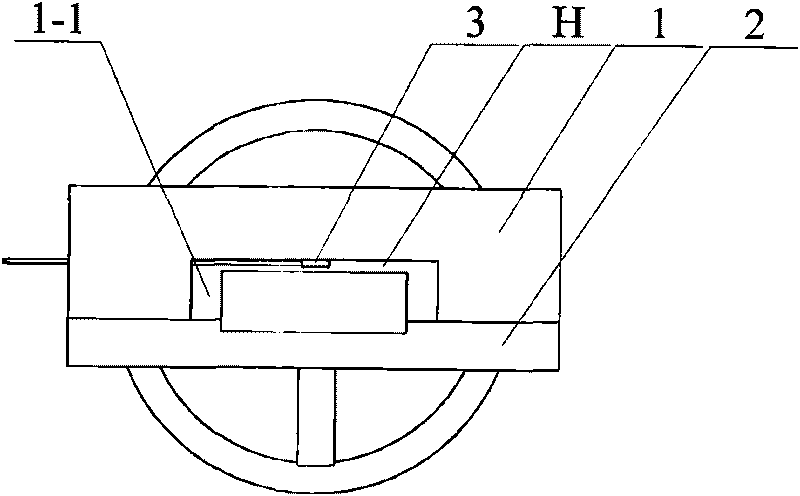

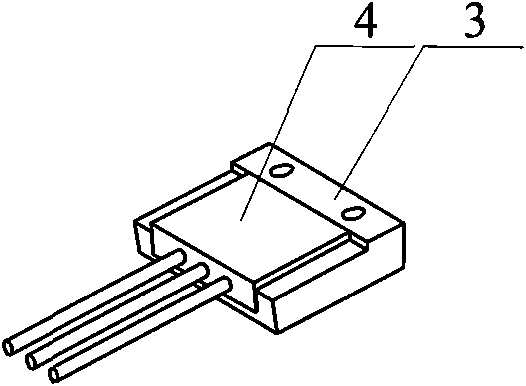

Device for measuring flux density value of practical air gap field of magnetic steel in electric appliance

ActiveCN101699310ARealize closed magnetic circuit testChange section shapeMagnetic property measurementsElectric machineAir gap flux density

The invention discloses a device for measuring flux density value of practical air gap field of magnetic steel in electric appliance, relating to the field of magnetic property measurement. The device is used for solving the problem that when the measured magnetic steel is measured under the condition of a magnetic open circuit, a measuring result can not truly and quantificationally reflect the flux density value of the measured magnetic steel in the air gap field. In the invention, the middle part of a member for constructing the air gap field is provided with a channel, the size of the channel adapts to the size of the measured magnetic steel, an air gap is remained between the upper side wall in the channel and the upper end surface of the measured magnetic steel, the size of the air gap is consistent with the size of the air gap of the measured magnetic steel in the electric appliance, a magnetic sensor is arranged in the air gap between the measured magnetic steel and a closed magnetic loop, and the magnetic induction intensity of the magnetic sensor is worked out by a magnetic induction intensity detector. The device is used for measuring the air gap flux density value of the measured magnetic steel under the condition of the closed magnetic loop when the electric appliance is produced, and moreover, the arrangement of the magnetic steel in an electric motor or an electric appliance is optimized according to test data, thereby improving the property of the electric motor or the electric appliance.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com