High-power density permanent magnet motor

A technology of permanent magnet motor and high density, which is applied in the direction of electrical components, electromechanical devices, electric components, etc. It can solve the problems of large thrust fluctuation, poor sine degree of air gap magnetic density waveform, low motor efficiency and thrust density, etc., and achieve the reduction of thrust Effects of fluctuation and cost, good sinusoidal, reduced secondary weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

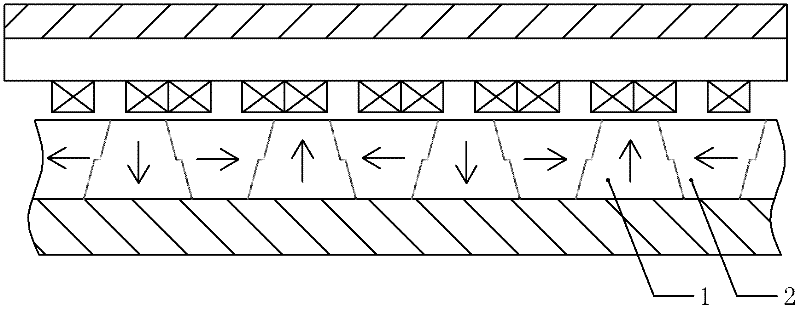

[0021] Embodiment 1: The high force density permanent magnet motor described in this embodiment is a unilateral flat panel motor, the motor includes a primary and a secondary, and an air gap exists between the primary and secondary; the secondary includes a main permanent magnet 1. The auxiliary permanent magnet 2 and the yoke plate. The cross-section of the main permanent magnet 1 is a hexagon or octagon with a left-right symmetrical structure, and the length of the bottom side of the hexagon or octagon near the air gap is smaller than that away from the air gap. The length of the bottom edge of the gap side, each main permanent magnet 1 is magnetized in parallel, and its magnetization direction is perpendicular to the direction of relative motion between the primary and secondary, and the cross section of the auxiliary permanent magnet 2 is a hexagonal or left-right symmetrical structure. Octagonal, the length of the bottom edge near the air gap side of the auxiliary permanen...

specific Embodiment approach 2

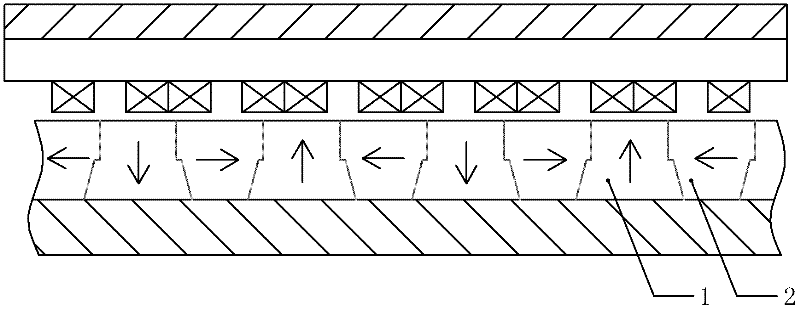

[0023] Specific embodiment two: a kind of high force density permanent magnet motor described in this embodiment is a double-sided flat motor, and the motor includes a primary and a secondary, an air gap between the primary and the secondary; the secondary is Bilateral structure, each side secondary includes main permanent magnet 1, auxiliary permanent magnet 2 and yoke plate, the cross section of main permanent magnet 1 is a hexagonal or octagonal symmetrical structure, and the hexagonal or octagonal The length of the bottom edge near the air gap side is less than the length of the bottom edge far away from the air gap side. Each main permanent magnet 1 is magnetized in parallel, and its magnetization direction is perpendicular to the direction of relative motion between the primary and secondary. The auxiliary permanent magnet 2 The cross section is hexagonal or octagonal with left-right symmetrical structure, the length of the base of the auxiliary permanent magnet 2 near th...

specific Embodiment approach 3

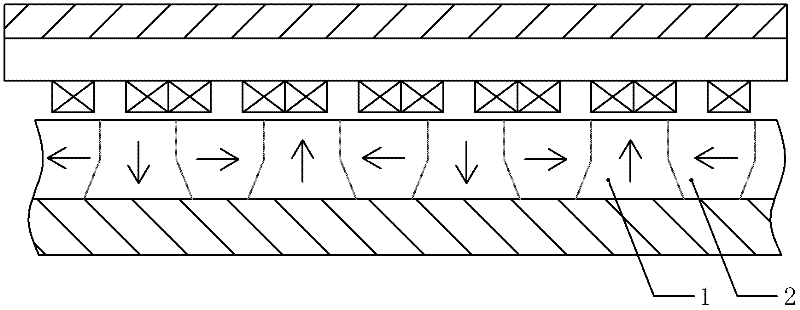

[0025] Specific embodiment three: The high force density permanent magnet motor described in this embodiment is a cylindrical linear motor, the motor includes a primary and a secondary, an air gap exists between the primary and secondary, and the secondary includes a main permanent magnet 1. The auxiliary permanent magnet 2 and the magnetically conductive yoke, the main permanent magnet 1 is annular, and its cross section is a hexagonal or octagonal symmetrical structure, and the hexagonal or octagonal shape is close to the air gap side The length of the bottom edge is less than the length of the bottom edge away from the air gap side, each main permanent magnet 1 is magnetized in parallel, and its magnetization direction is perpendicular to the direction of relative motion between the primary and secondary, and the auxiliary permanent magnet 2 is circular. Its cross section is hexagonal or octagonal with left-right symmetrical structure, and the length of the bottom side near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com