Modular primary permanent magnet bilateral switched reluctance linear motor

A technology of switched reluctance and linear motors, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low thrust density, limited application, large thrust fluctuations, etc., and achieve reduced thrust fluctuations, high power density, and elimination of Effect of Thrust Harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

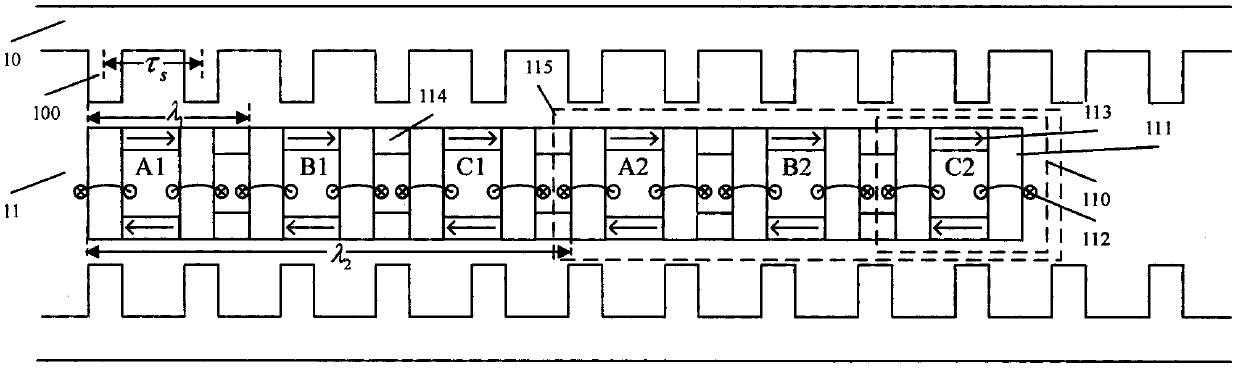

[0047] A modular primary permanent magnet bilateral switched reluctance linear motor of the present invention is shown in figure 1 , including a primary 11 and a secondary 10, and an air gap exists between the primary 11 and the secondary 10. The secondary 10 is composed of a secondary module 100, the primary 11 is composed of a primary module 110, and each of the primary modules 110 includes two magnetic permeable blocks 111, an armature winding 112, and a wire between the magnetic permeable blocks 111. Permanent magnets 113 distributed up and down. The armature windings 112 in the same primary module 110 have opposite winding directions and belong to the same phase; the permanent magnets 113 are magnetized horizontally, and the magnetization directions of the permanent magnets 113 corresponding to adjacent primary modules 110 are the same, and belong to the same primary module 110 The magnetization directions of the corresponding permanent magnets 113 up and down are opposi...

Embodiment 2

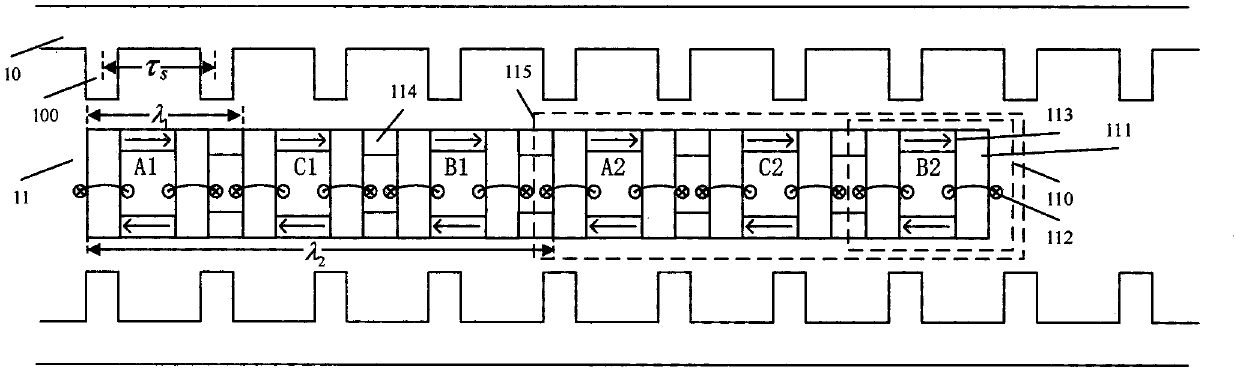

[0053] Another step ratio of a modular primary permanent magnet bilateral switched reluctance linear motor of the present invention, see figure 2 , including a primary 11 and a secondary 10, and an air gap exists between the primary 11 and the secondary 10. The secondary 10 is composed of a secondary module 100, the primary 11 is composed of a primary module 110, and each of the primary modules 110 includes two magnetic permeable blocks 111, an armature winding 112, and a wire between the magnetic permeable blocks 111. Permanent magnets 113 distributed up and down. The armature windings 112 in the same primary module 110 have opposite winding directions and belong to the same phase; the permanent magnets 113 are magnetized horizontally, and the magnetization directions of the permanent magnets 113 corresponding to adjacent primary modules 110 are the same, and belong to the same primary module 110 The magnetization directions of the corresponding permanent magnets 113 up and...

Embodiment 3

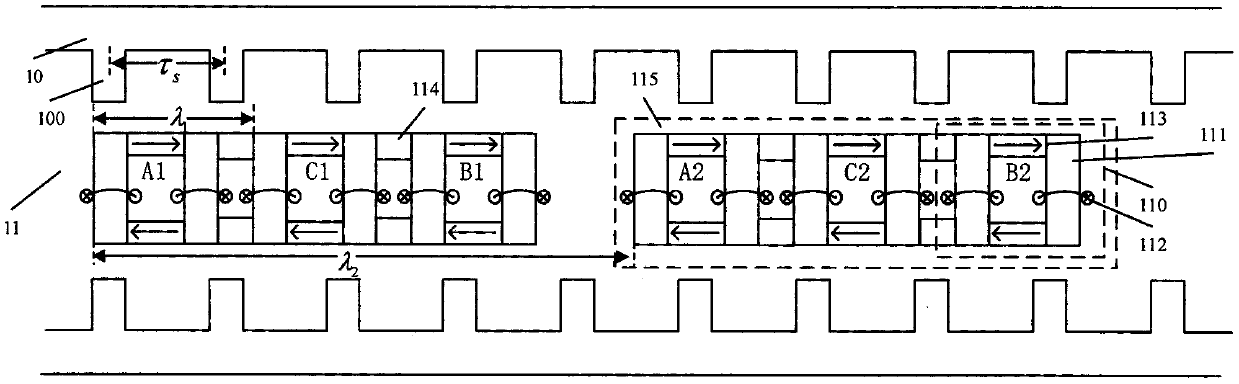

[0059] A modular primary permanent magnet bilateral switched reluctance linear motor of the present invention, see image 3 , is a motor with a complementary structure, including a primary 11 and a secondary 10, and there is an air gap between the primary 11 and the secondary 10. The secondary 10 is composed of a secondary module 100, the primary 11 is composed of a primary module 110, and each of the primary modules 110 includes two magnetic permeable blocks 111, an armature winding 112, and a wire between the magnetic permeable blocks 111. Permanent magnets 113 distributed up and down. The armature windings 112 in the same primary module 110 have opposite winding directions and belong to the same phase; the permanent magnets 113 are magnetized horizontally, and the magnetization directions of the permanent magnets 113 corresponding to adjacent primary modules 110 are the same, and belong to the same primary module 110 The magnetization directions of the corresponding perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com