Patents

Literature

60results about How to "Reduce pole distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature molten salt system for aluminum electrolysis and method for carrying out aluminum electrolysis by same

The invention relates to the field of molten salt electrolysis of nonferrous metal metallurgy and provides a novel molten salt electrolyte system which can be applied to the aluminum electrolysis industry. The molten salt as an electrolyte system of aluminum electrolysis can greatly reduce the electrolysis temperature, and the electrolyte system also presents a favorable dissolving performance onAl2O3 in the process of electrolysis. The novel molten salt electrolyte system comprises ternary or multivariant salt, such as KF, KCl, NaF, NaCl, AlF3, MgF2, CaF2, LiF, BaF2, Al2O3, and the like. Theelectrolyte system has a lower primary crystal temperature and the favorable dissolving performance on the Al2O3. The problems of low Al2O3 solubility and low dissolving speed brought by reducing theelectrolyte primary crystal temperature through reducing the NaF / AlF3 ratio in a sodium cryolite system are solved. In addition, the low-temperature electrolyte system is particularly suitable for adopting an inert anode of metal ceramics or metal alloy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

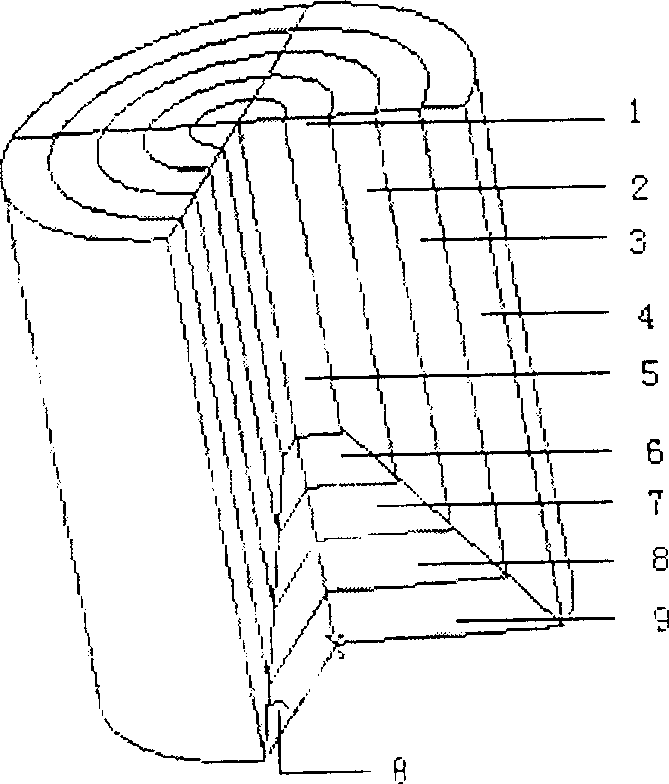

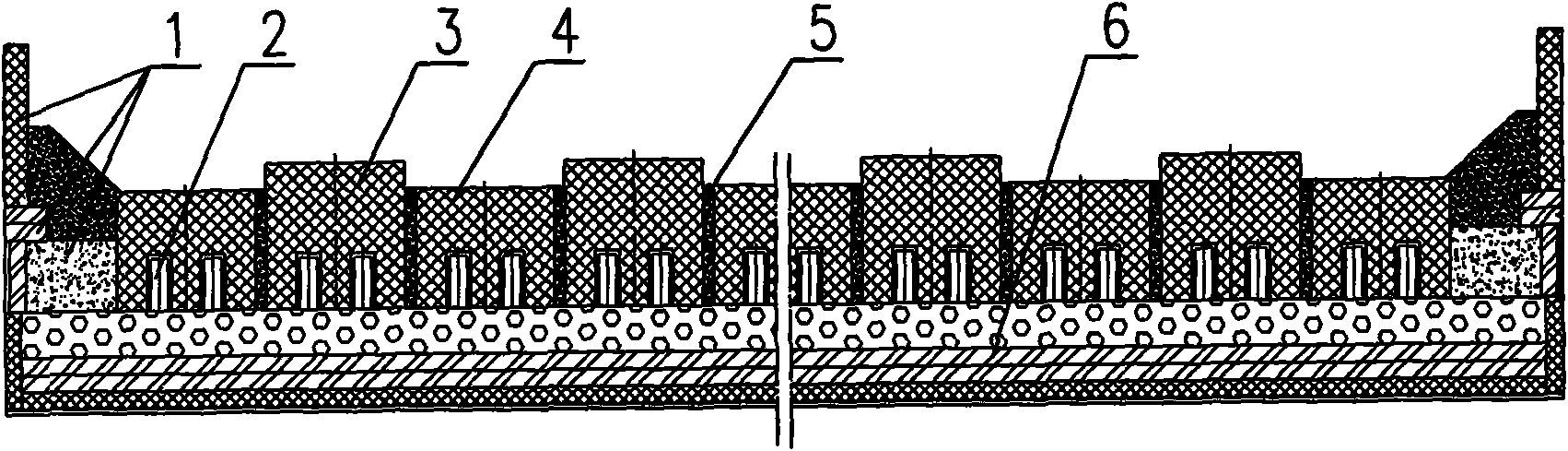

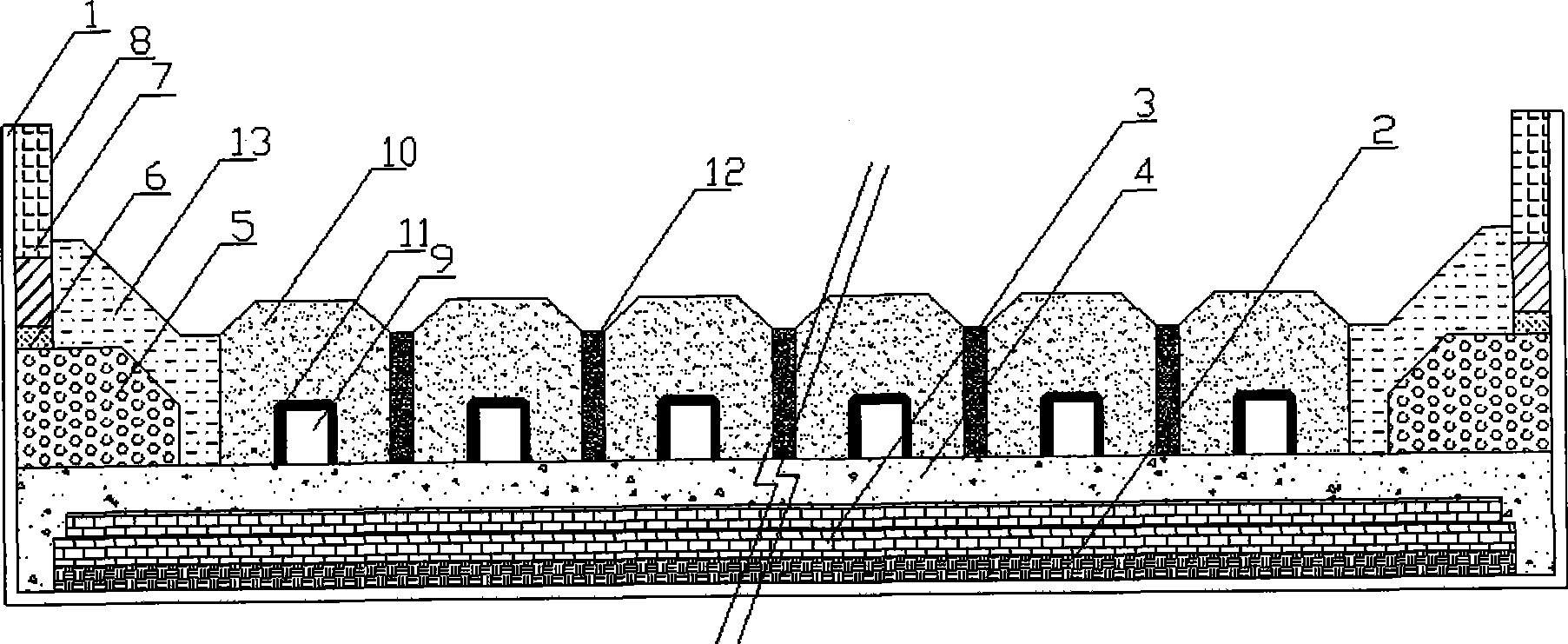

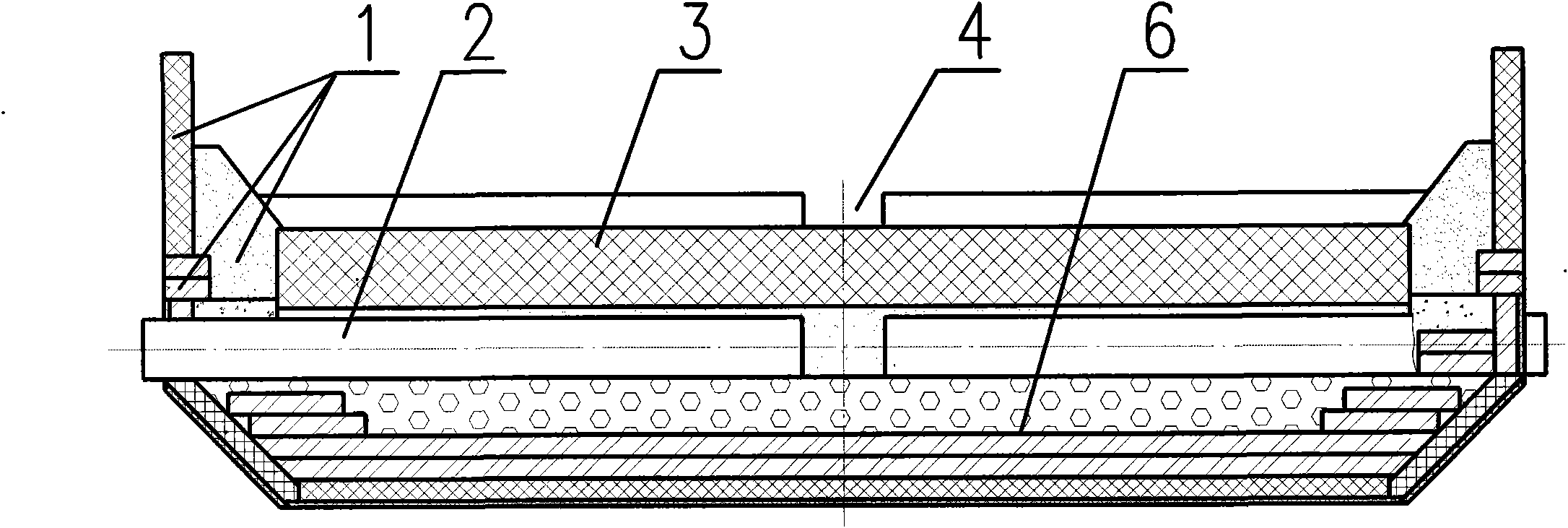

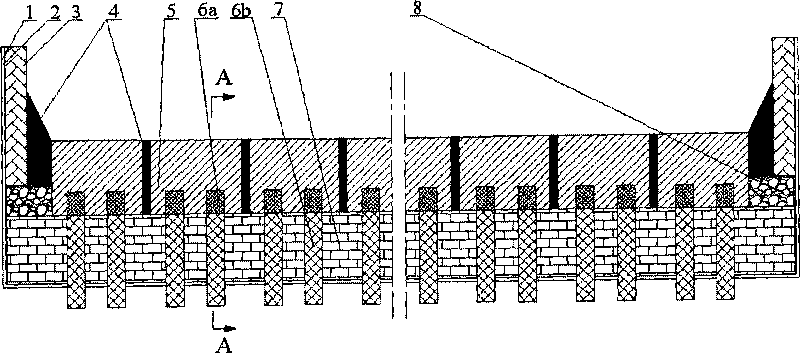

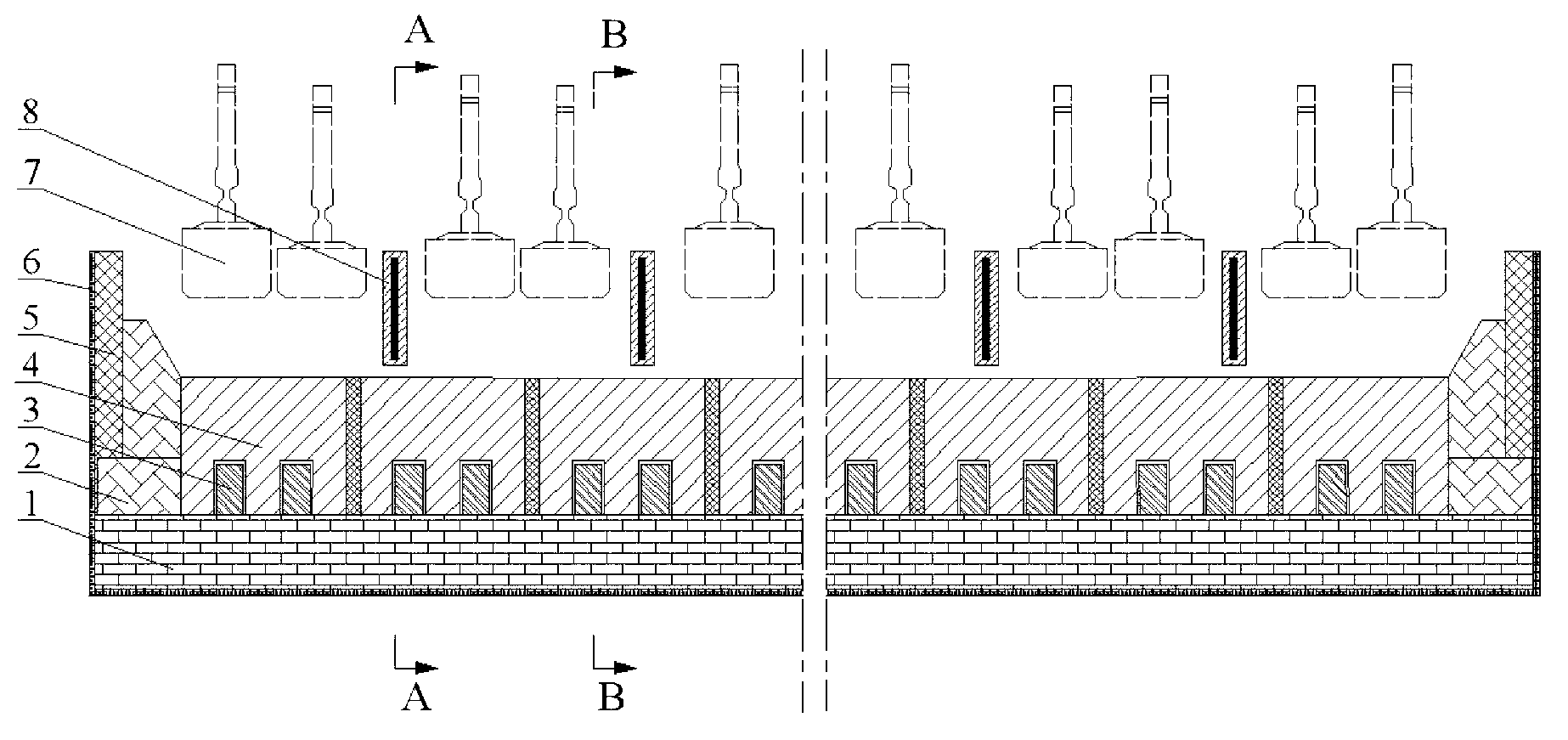

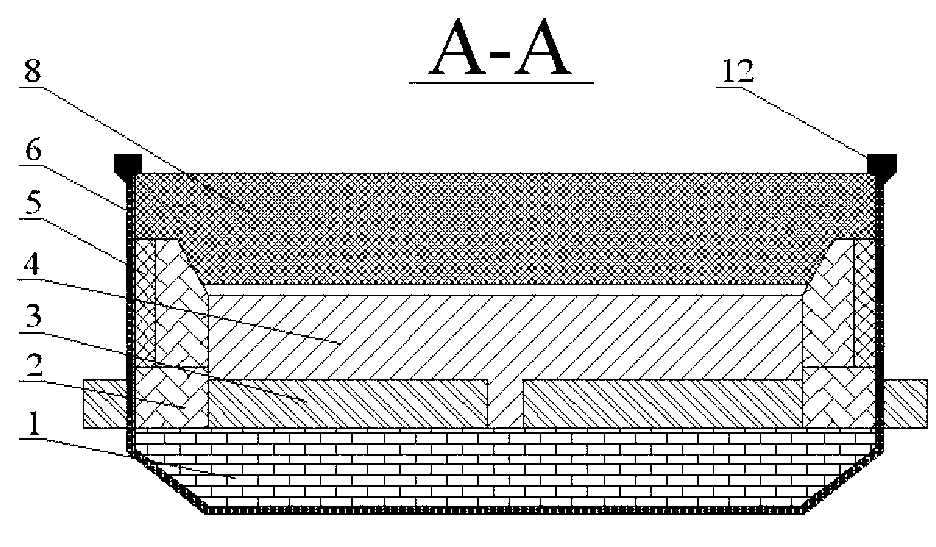

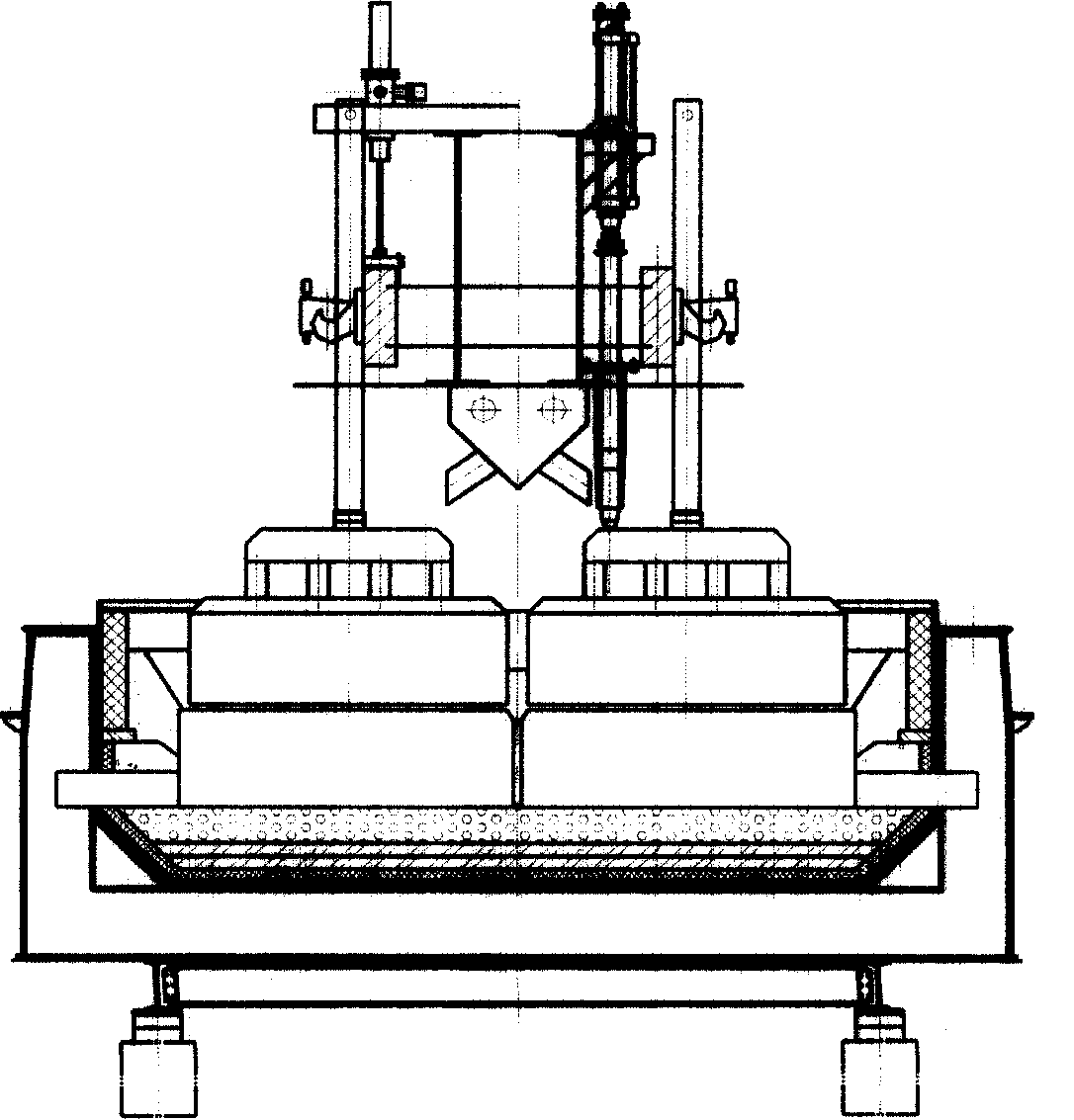

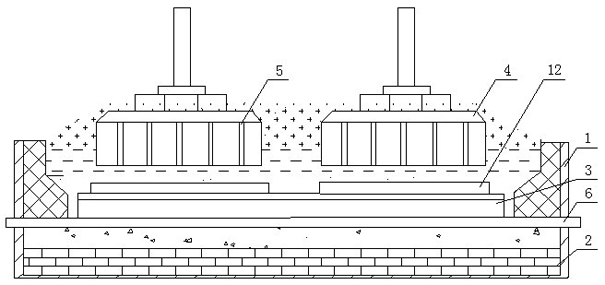

Novel cathode structured aluminum cell with longitudinal and transversal wave damping functions

The invention relates to a novel cathode structure aluminum electrolysis bath with longitudinal and transverse wave decreasing functions, which comprises an electrolysis bath shell, an electrolysis bath lining, a fire-resisting material, a cathode carbon block, a lining carbon brick, carbon tamping paste, fire-resisting concrete, and a cathode carbon bar. The cathode structure aluminum electrolysis bath is characterized in that the top surface of the cathode carbon block is provided with more than one raised structures each of which is connected with the cathode carbon block integrally, and the arranging mode of each raised structure is to be parallel to the axial direction of the cathode carbon block, vertical to the axial direction of the cathode block, or adopt a mixed mode of the two. The novel cathode structure aluminum electrolysis bath with the longitudinal and the transverse wave decreasing functions can slow down the flow speed of cathode aluminum fluid in the transverse direction and the longitudinal direction in the electrolysis bath and reduce the fluctuation height of the aluminum fluid surface in the transverse direction and the longitudinal direction, improve the stability of the aluminum fluid surface of aluminum, reduce the solution loss of the aluminum, reduce the electric energy consumption for aluminum electrolysis production, and prolong the service life of the novel cathode structure electrolysis bath.

Owner:SHENYANG BEIYE METALLURGIGAL TECH CO LTD

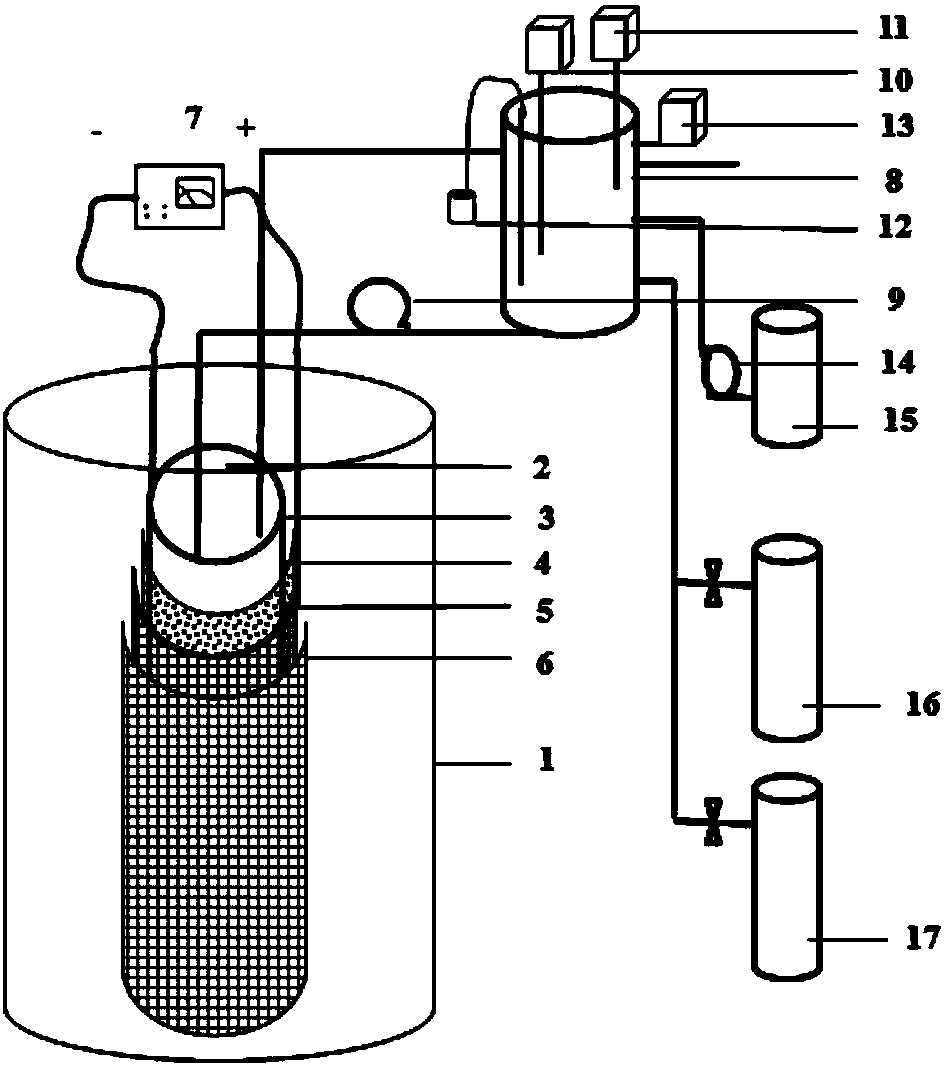

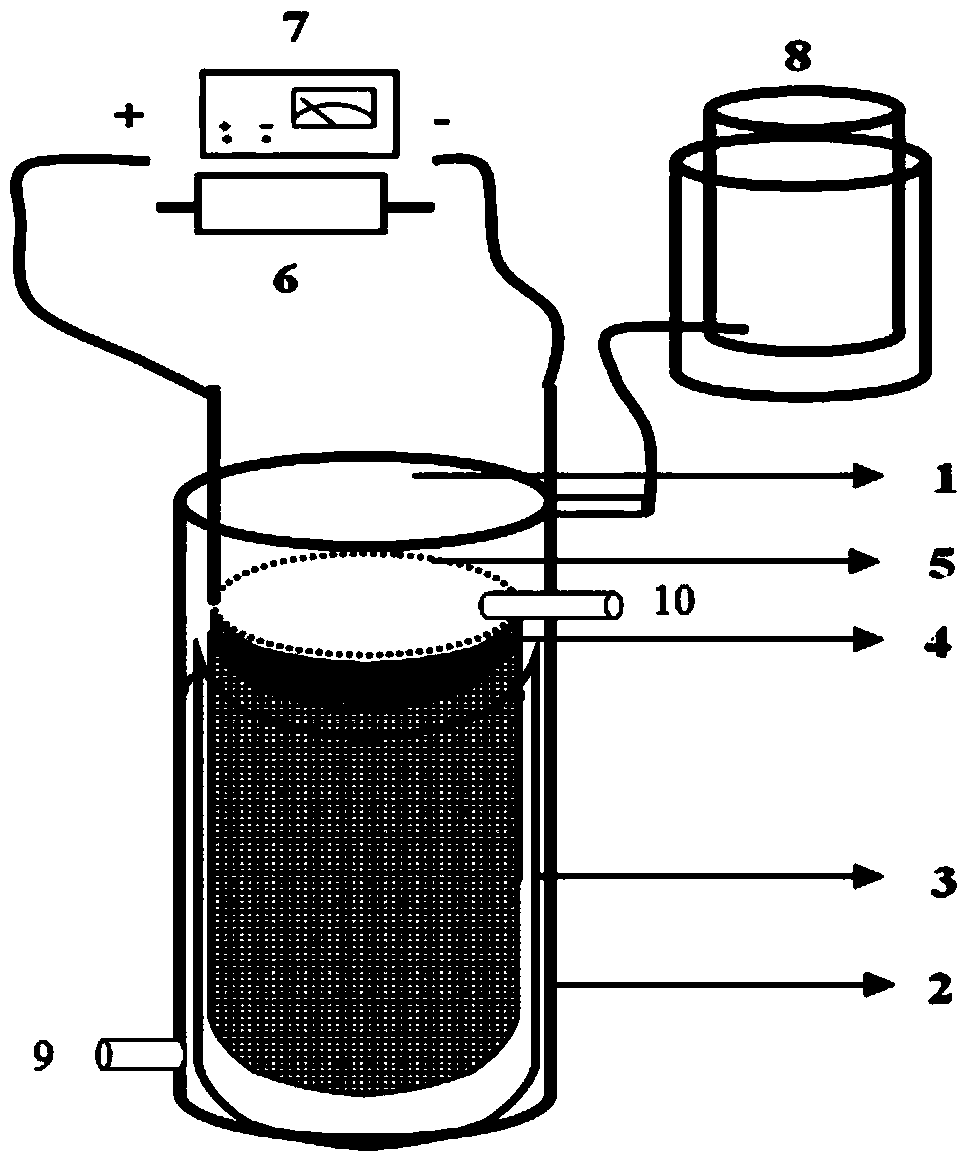

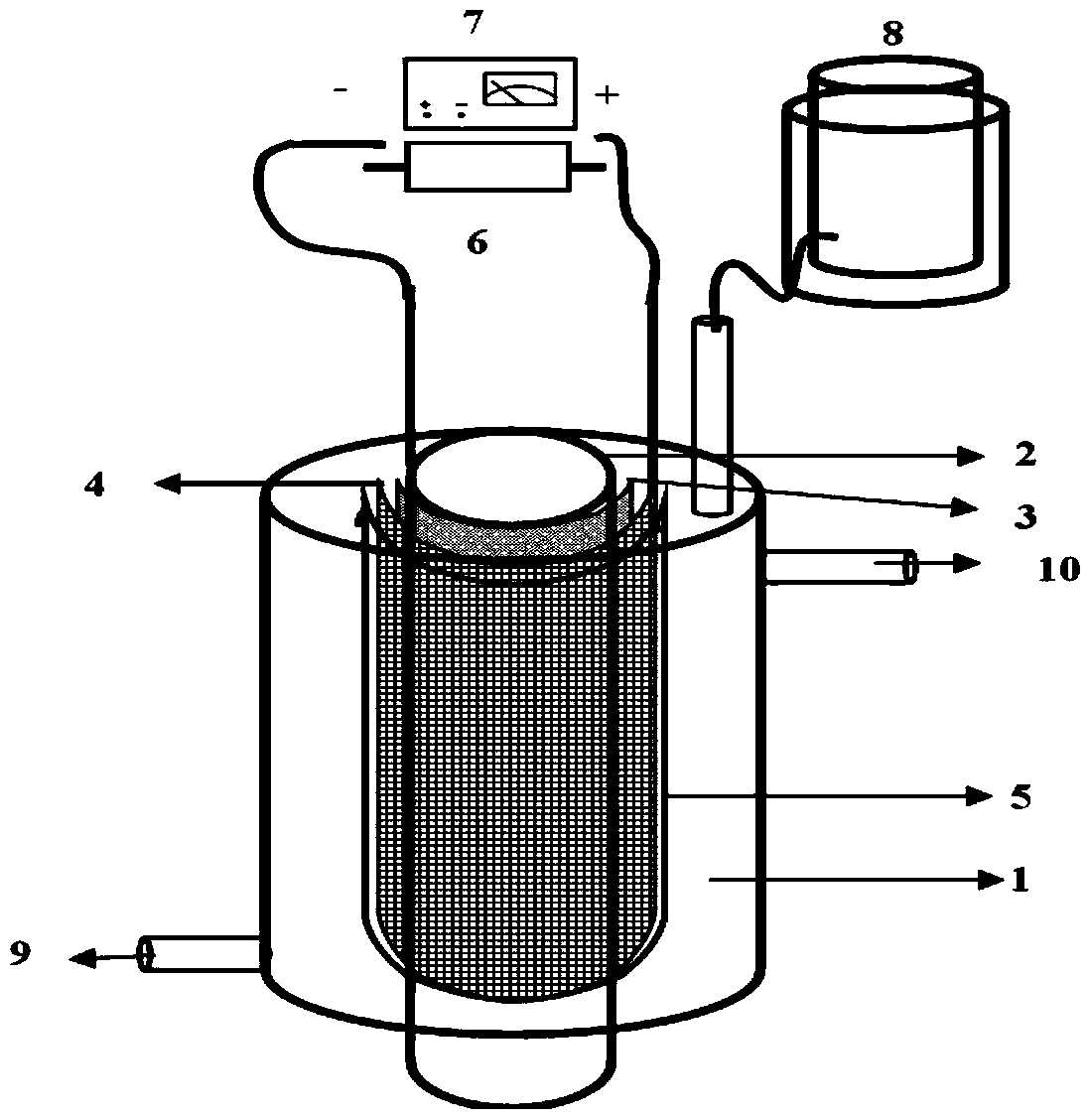

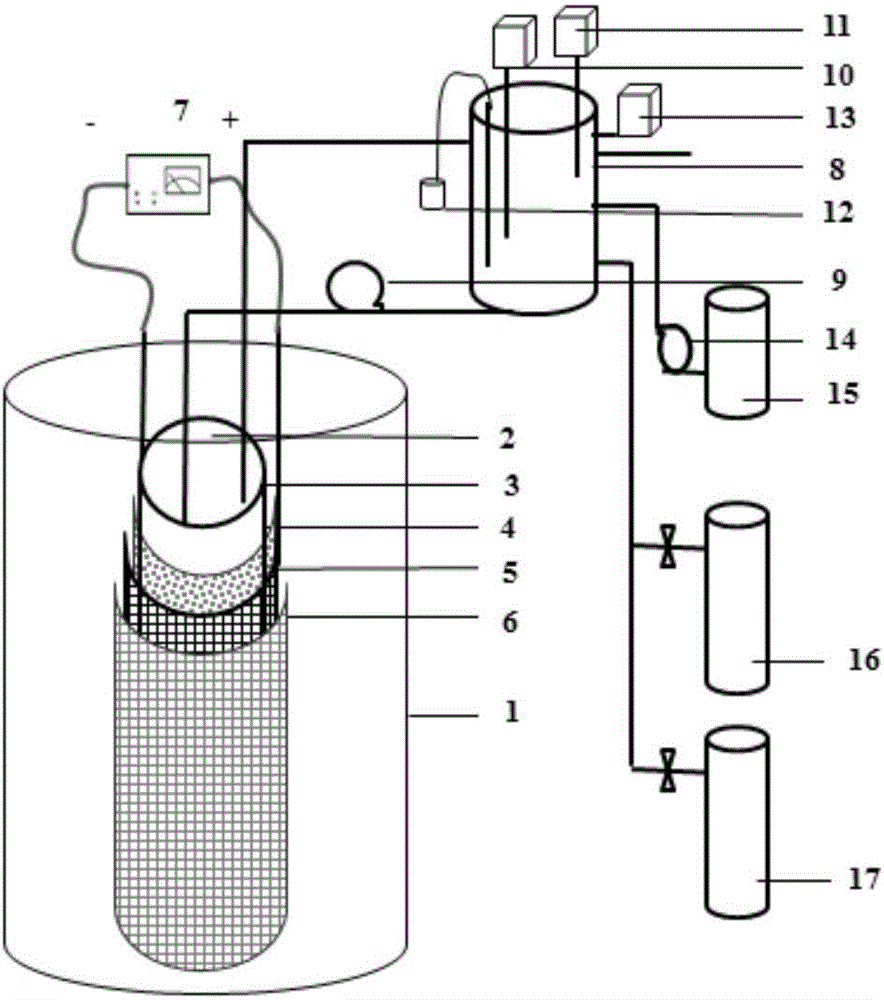

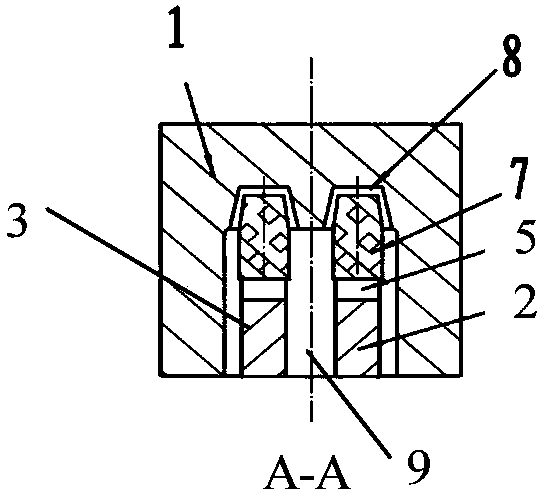

Embedded bioelectricity synthesis system and method

ActiveCN103881905AImplement resourcesAvoid consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsOrganic chemicalsProcess engineering

The invention relates to an embedded bioelectricity synthesis system, which mainly comprises an anaerobic oxidation reactor, a bioelectric synthesis reactor, a culture solution circulation control system, a power supply and an external circuit; the bioelectric synthesis reactor is composed, from the inside to the outside, of a conductive reactor wall, a diaphragm and an anode, and the conductive reactor wall is also a cathode of the reactor; and the culture solution circulation control system is used for controlling and adjusting pH, temperature, CO2 concentration and the like of the culture solution. Through the system disclosed by the invention, the anaerobic oxidation and biosynthetic reduction of the waste and waster water are coupled by applying electrical potential, after waste inside the anaerobic oxidation reactor and the electron generated by anaerobic oxidation of wastewater are transferred to the conductive reactor wall as the cathode, electron streams penetrate through the reactor wall and are transferred to the microbial flora in the bioelectric synthesis reactor and CO2 is reduced and synthesized into organic chemicals after electrons are obtained by the microbial flora,.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Ceramet material with gradient function for electrolyzing Al

The present invention relates to aluminum electrolysis, and is especially inert ceramet anode. The ceramet material has structure of at least two layers and is rod shaped, plate shaped or cup shaped. The ceramic phase is spinelle type composite oxide; and the metal phase is made of Cu, Ni, Co, Fe, Ag, Pt, Au and other metal or their binary or multiple-element alloy. The composite material with gradient function has excellent comprehensive performance under electrolysis, and the anode of the composite material needs no frequent replacement. Using the composite material of the present invention can alter the electrolytic bath structure, raise production efficiency, lower aluminum ingot producing cost, improve environment, and reduce power consumption.

Owner:CENT SOUTH UNIV +1

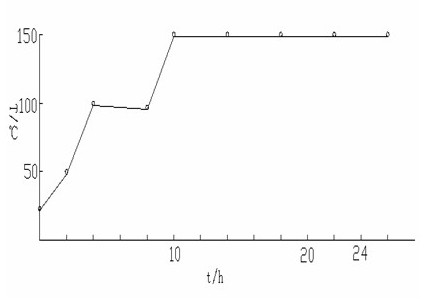

Electrolytic cathode containing titanium boride-carbon coating, and preparation method thereof

The invention discloses an electrolytic cathode containing a titanium boride-carbon coating, and a preparation method thereof. The electrolytic cathode is characterized in that: a coating is coated on the surface of the electrolytic cathode, wherein the coating comprises components of, by mass: 20 to 22% of TiB2, 15 to 20% of epoxy resin, 24 to 27% of diethylene triamine, 0.3 to 0.8% of carbon fiber, and balance of graphite powder. The preparation method of the aluminum electrolytic cathode comprises steps that: the materials are sufficiently mixed and uniformly coated on the surface of the electrolytic cathode; the coating is heated from normal temperature to 150 DEG C, such that the coating is cured, and the electrolytic cathode containing the titanium boride-carbon coating is obtained.According to the invention, good wettability of aluminum liquid and the electrolytic cathode is utilized, such that aluminum oxide deposition is not easy to be left on the surface of the electrolyticcathode. Therefore, deposition or crusting is not easy to occur, current is uniformly distributed, disturbance of magnetic fields to the aluminum liquid is reduced, current efficiency is improved, energy consumption is reduced, the service life of an electrolyte tank is prolonged, and aluminum liquid level and polar pitch can be appropriately reduced. With the electrolytic cathode provided by theinvention, an average working voltage and a secondary reaction probability of the aluminum electrolyte tank are reduced, aluminum electrolytic production is improved, and the quality of aluminum products is improved.

Owner:YUNNAN RUNXIN ALUMINUM

Composite alloy inert anode for aluminum electrolysis and aluminum electrolysis method utilizing same

ActiveCN101824631AChange performanceImprove physical and chemical propertiesTectorial membraneRare-earth element

The invention relates to a composite alloy inert anode for aluminum electrolysis. The composition of the matrix of the composite alloy inert anode for aluminum electrolysis is (x)A(y)B, wherein X is the content of A in percentage by weight, y is the content of B in percentage by weight, X is 40-100%, and y is 0-60%; A consists of one or multiple elements of Cu, Ni, Fe, Co, Al, Mn, W, Cr, Ti, Sn and Zn; and B consists of one or multiple elements of Mo, Pd, Ag, Cd, Au, Pt, Sb, Mg, Ir, Bi, Pb, Si, N, C and rare-earth. A compact protective film is coated on the matrix, and is an oxide film and or a permeator. The composite alloy inert anode is adopted in the process of electrolysis, thus solving the problems of poor conductivity and thermal shock stability of ceramic anodes; the composite alloy inert anode has better corrosion resistance as compared with a single alloy anode; and in addition, the composite alloy inert anode is especially suitable for being applied in a low-temperature aluminum electrolysis system and can also be applied in the field of fusion-electrolysis metallurgy of rare earth, Mg and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method of TiB2/C gradient cathode material for aluminum electrolytic bath

InactiveCN101608321AImproved working characteristics of the working faceImprove working characteristicsContinuous mixingMaterials science

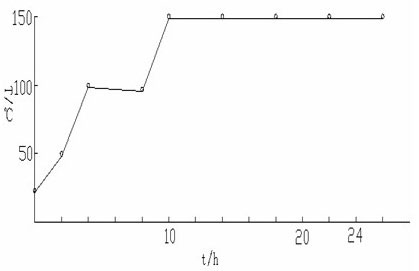

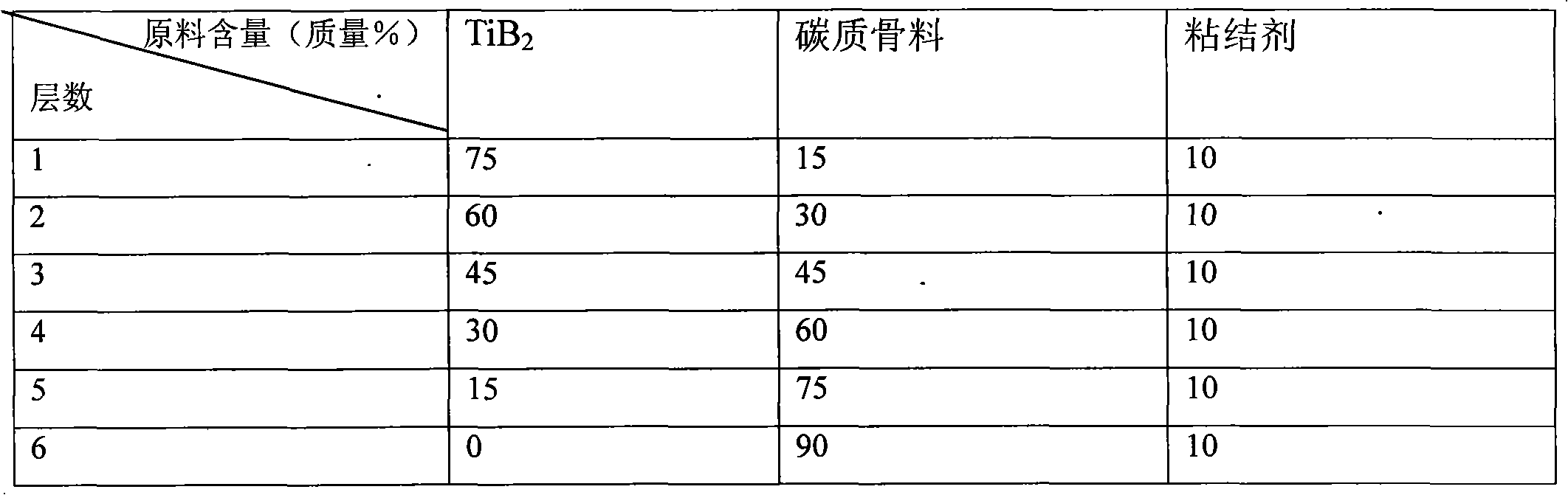

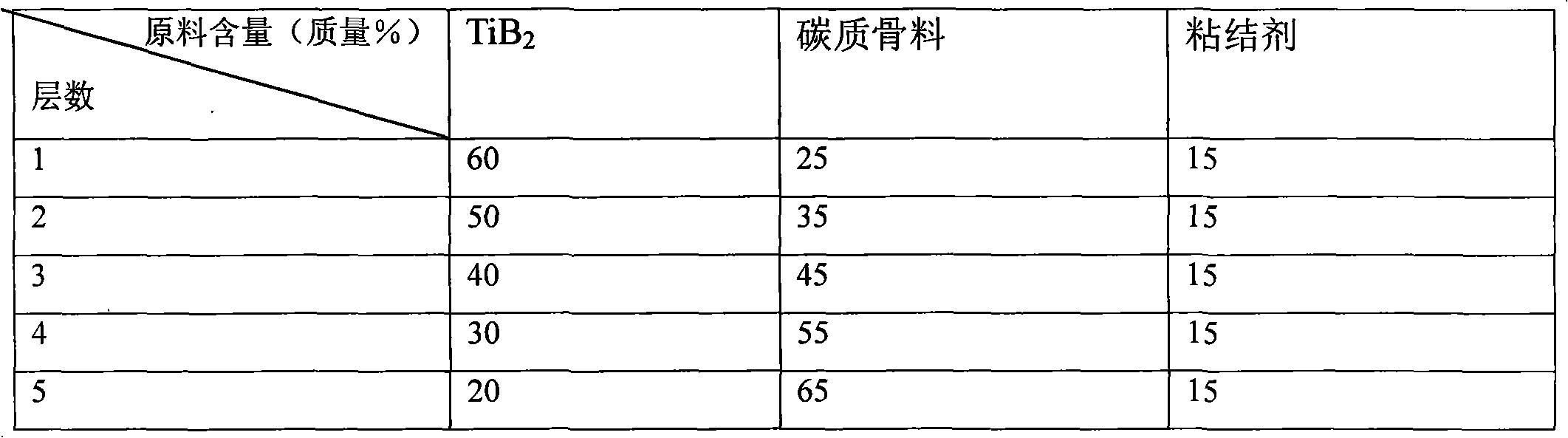

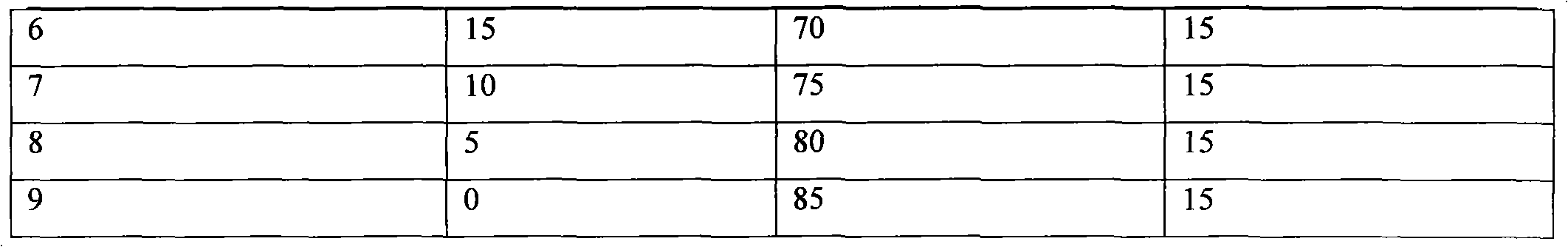

The invention relates to a preparation method of TiB2 / C gradient cathode material for an aluminum electrolytic bath, which belongs to the technical field of electrolytic aluminum. The adopted raw materials comprise TiB2, carbon aggregate and cementing agent. The procedure is continuous dosing, continuous mixing and paving and adopts the sequence as follows: the content of the TiB2 in each layer sequentially increases and changes from a bottom layer to a surface layer, and the content of the carbon aggregate sequentially reduces and changes; or the content of the TiB2 sequentially reduces and changes, and the content of the carbon aggregate sequentially increases and changes; the materials paved layer by layer are hot-pressed and sintered, and then are naturally cooled to the room temperature so as to obtain the product. Because micro components of the materials prepared by the invention sequentially change, the invention can better solve the problems of easy coating shedding and the like caused by thermal mismatching of carbon and TiB2; meanwhile, the cathode material has strong sodium corrosion resistance, can remarkably improve the current efficiency of the electrolytic bath, and prolongs the service life of the electrolytic bath.

Owner:NORTHEASTERN UNIV

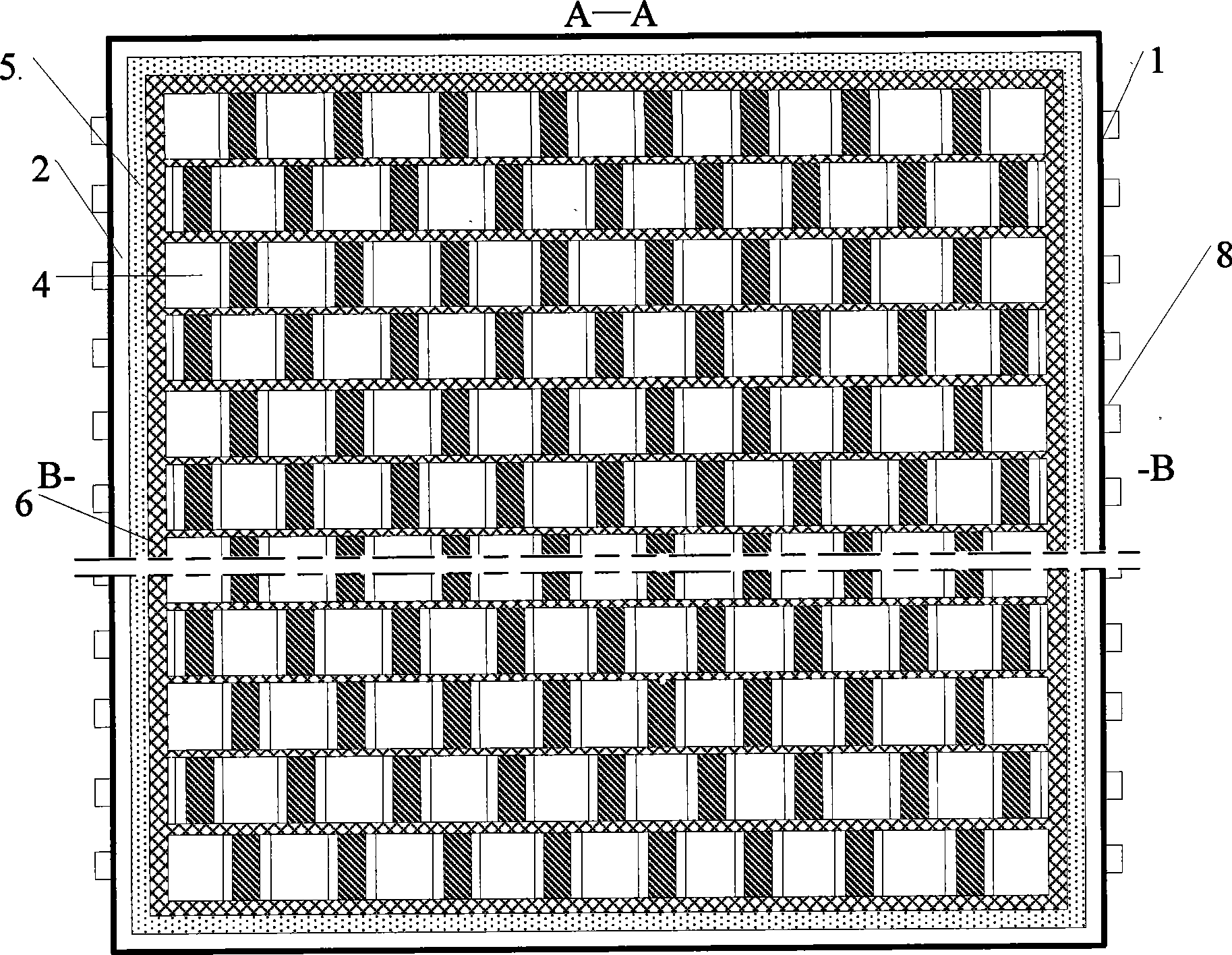

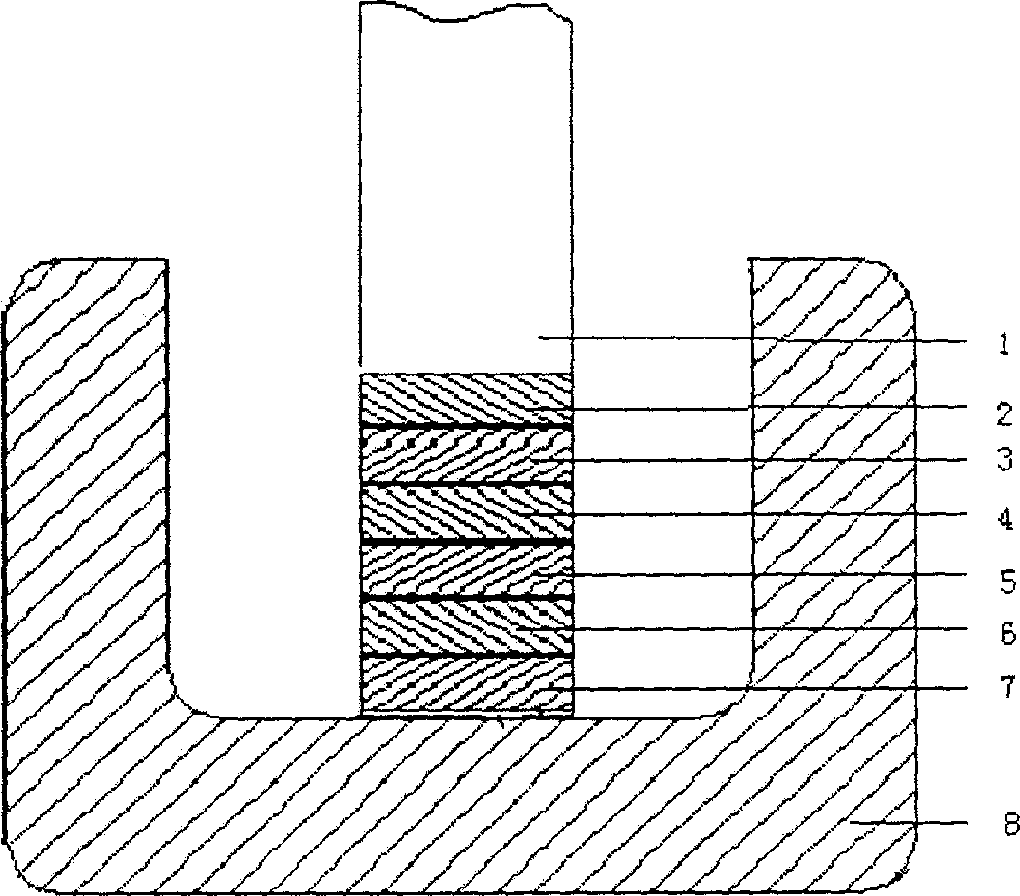

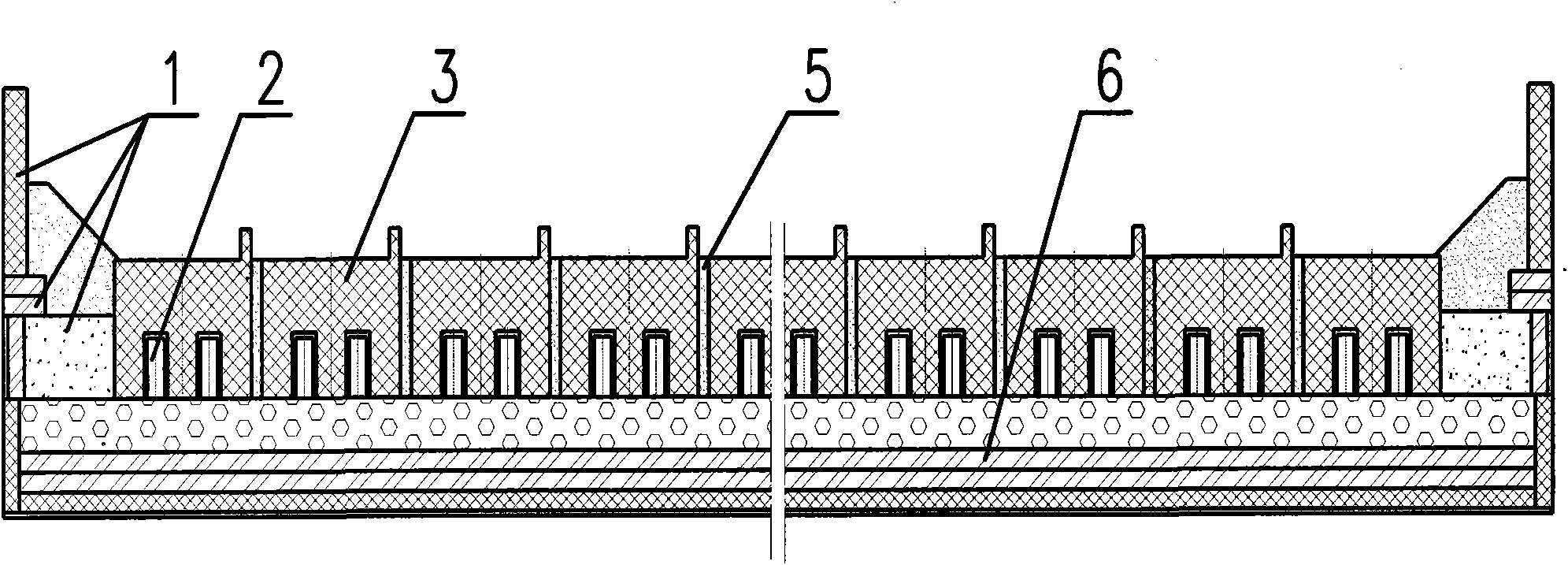

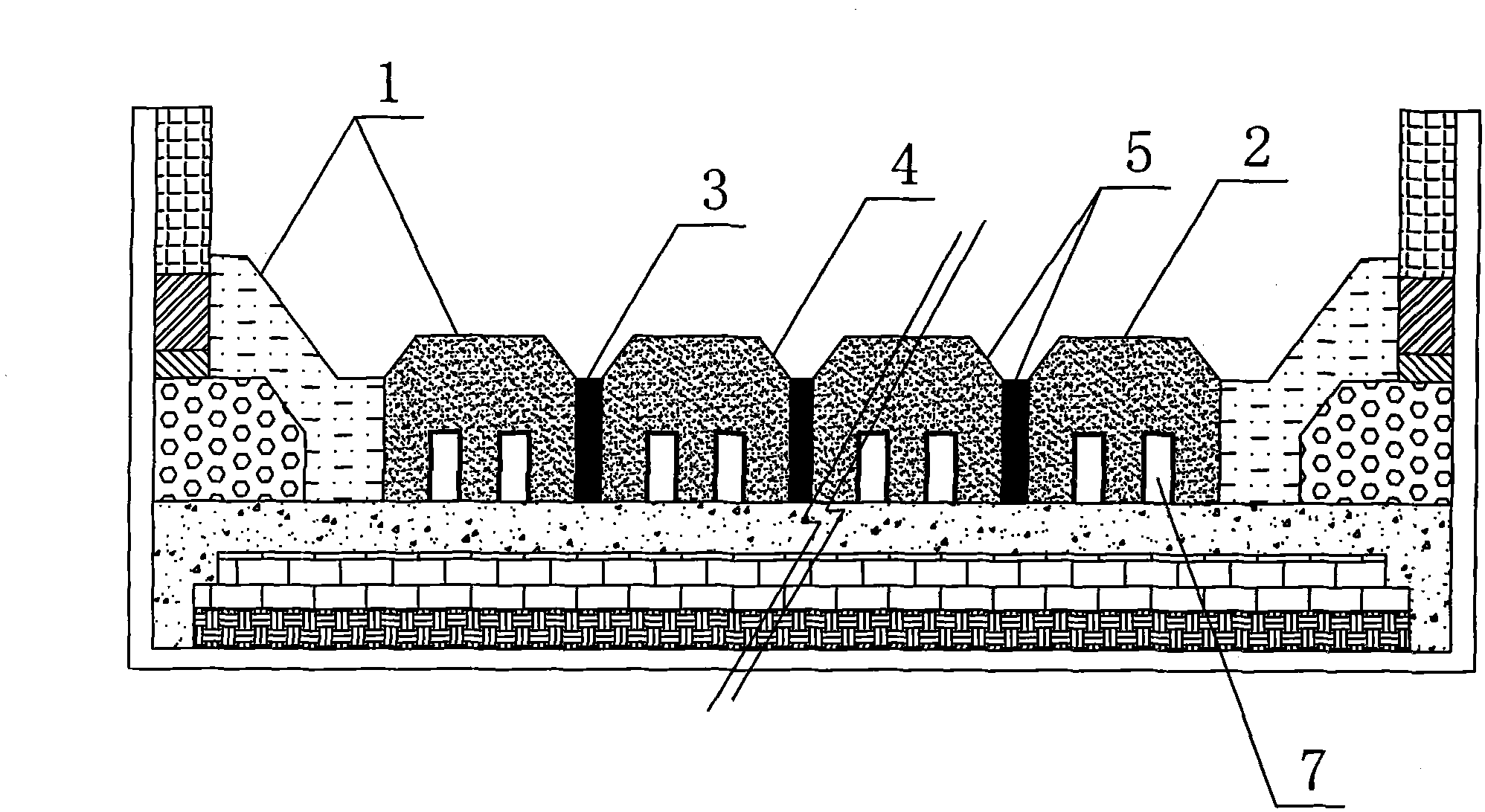

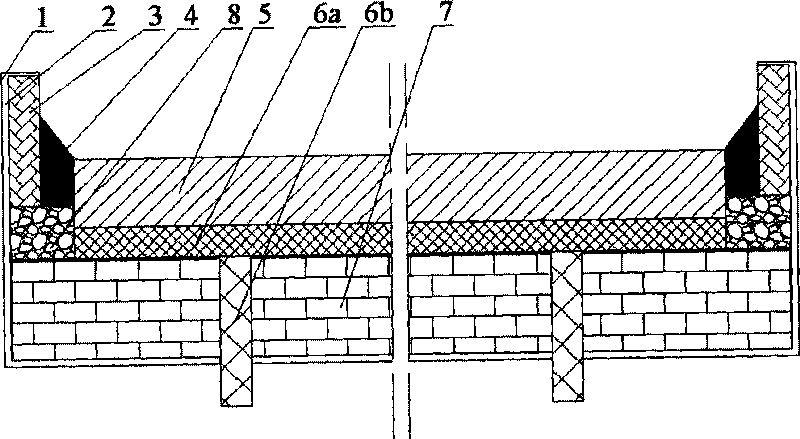

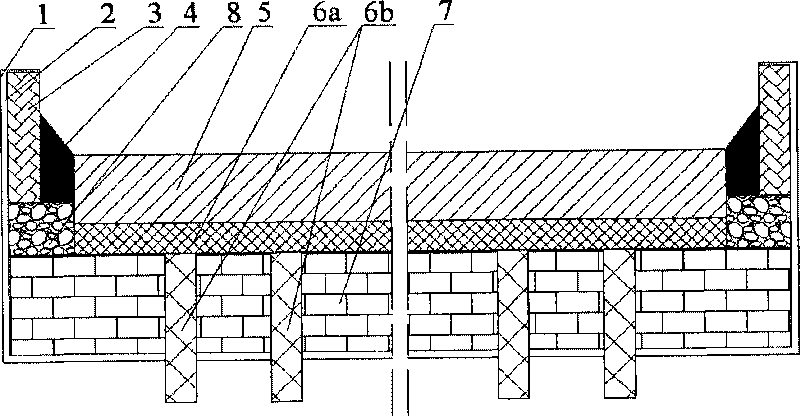

Cathode structure of aluminium cell

The invention discloses a cathode structure of an aluminium cell, which belongs to the technical field of aluminium cells and comprises a cell shell and a lining, wherein the lining comprises a cathode carbon block, a lateral lining, a bottom lining and a tamping paste. The invention is characterized in that the cathode carbon block in the same aluminium cell is formed by arranging high cathode carbon blocks and low cathode carbon blocks, thereby enabling the upper surface of the cathode to be rugged; a cathode steel bar is horizontally arranged on the bottom of the cathode carbon block and passes through out of the lateral of the aluminium cell. Consequently, aluminium liquid is divided into a plurality of small aluminium ponds, thereby effectively restricting the flow and the fluctuation of the aluminium liquid due to the action of an electromagnetic force, improving the stability of the aluminium cell, reducing the height and the polar distance of the aluminium liquid, improving the current efficiency and achieving the goal of energy saving and consumption reducing.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Process of preparing titanium sponge by fusion electrolysis of titanium dioxide

InactiveCN1664173AImprove conductivityImprove the efficiency of electrochemical deoxidationElectrolysisLithium chloride

The invention relates to a method for preparing the titanium sponge through electrolyzing the titania by fused salt. The titania applied in the cathode is formed by roasting 1-3h in the carbon reducing atmosphere and 1200-1300 Deg.c. The cathode has two forms: one is plate-like titania, which is formed through roasting the shaped titania combined with PVA adhensive in high temperature and carbon reducing atmosphere; the second is titania particles, which is formed through roasting the rectangle mesh cathode made up of non-corrosive steel or metallic titanium netting in high temperature and carbon reducing atmosphere. The electrolyte is the mixing molten salt system of calcii chloridum and lithium chloride, and the anode uses carbite or inert materials. The cathode and anode are arranged vertically, and the electrode surfaces are parallel, and the electrolyser has at least one group of anode-cathode-anode electrode, and it can set many electrodes in one electrolyser. The voltage of the controlling electrolyzer is 2.8-3.2V, the electrolyzing temperature is 850-900 Deg.c. Cleaning the cathode with the dilute hydrochloric acid and drying it, and getting the titanium sponge, which contains oxygen below 600ppm and the current efficiency is between 70-80%.

Owner:UNIV OF SCI & TECH BEIJING

Bioelectrochemistry device and bioelectrochemistry method for extracting reducing energy from waste and wastewater

ActiveCN103811791AImplement resourcesEnergizeTreatment with anaerobic digestion processesBiochemical fuel cellsBiofuel CellsWastewater

The invention relates to a bioelectrochemistry device and a bioelectrochemistry method for extracting reducing energy from waste and wastewater. The device comprises a positive electrode chamber serving as a reactor, a conductor wall, a membrane, a positive electrode, an external circuit and a load or an external power supply, wherein the conductor wall is a negative electrode of the reactor; the negative electrode serving as a reactor main body structure or an independent negative electrode is embedded into the positive electrode chamber. A plurality of the devices can be connected in parallel or in series to form an integrated device, so that the treatment capability is improved. The device can work under a biological fuel battery or biological electrolytic tank mode or alternately runs in the two modes; the pH value of the wastewater is controlled to be 4-9 in a working process.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

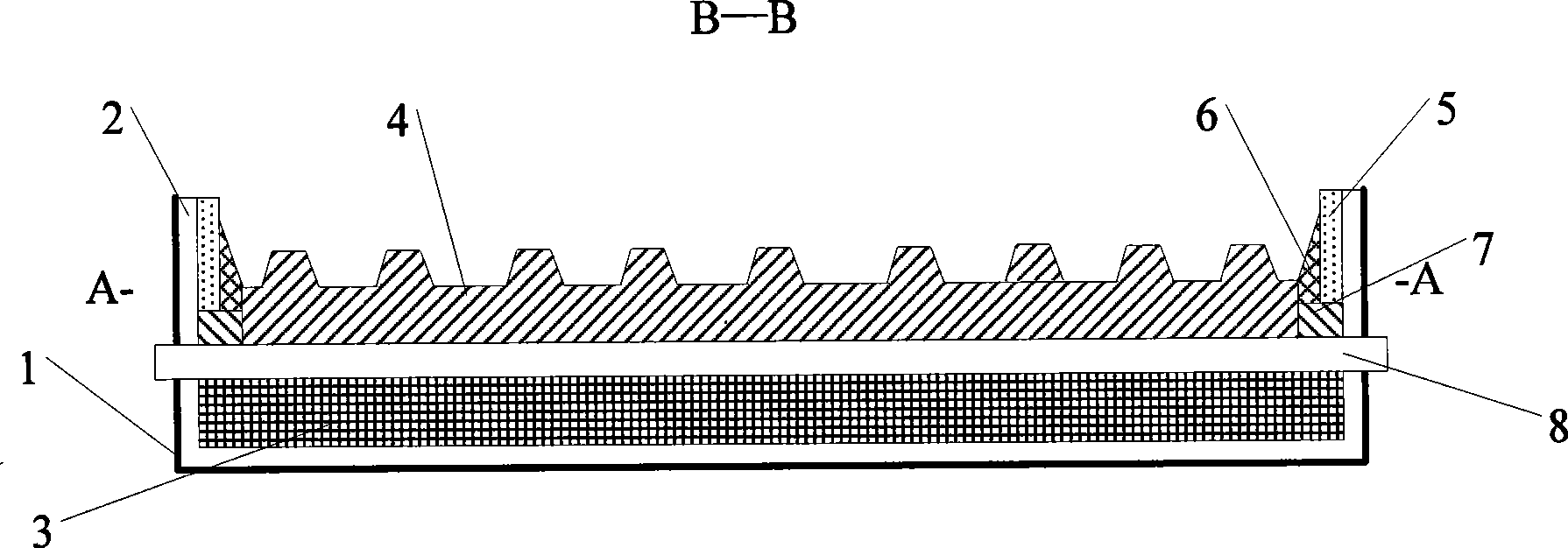

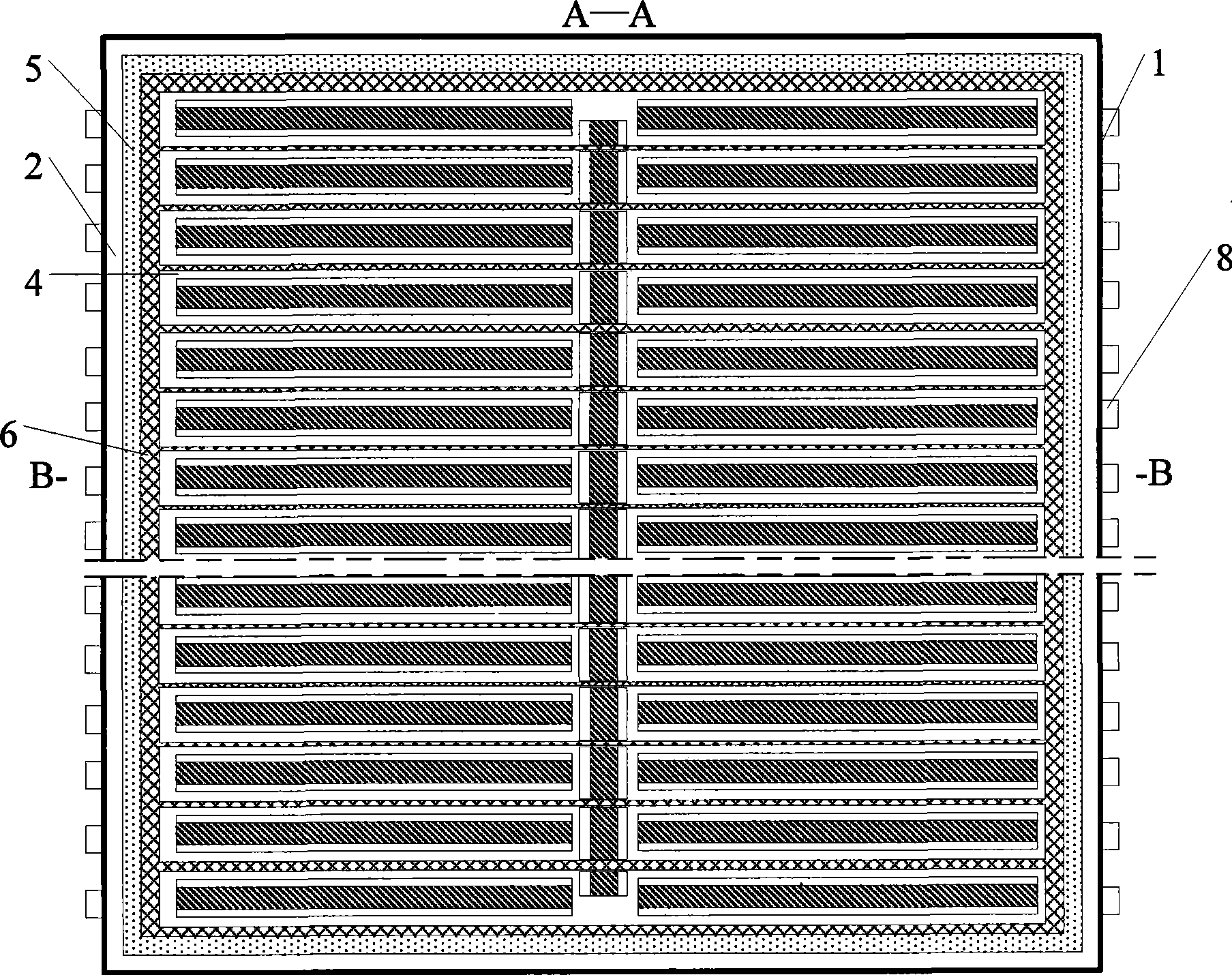

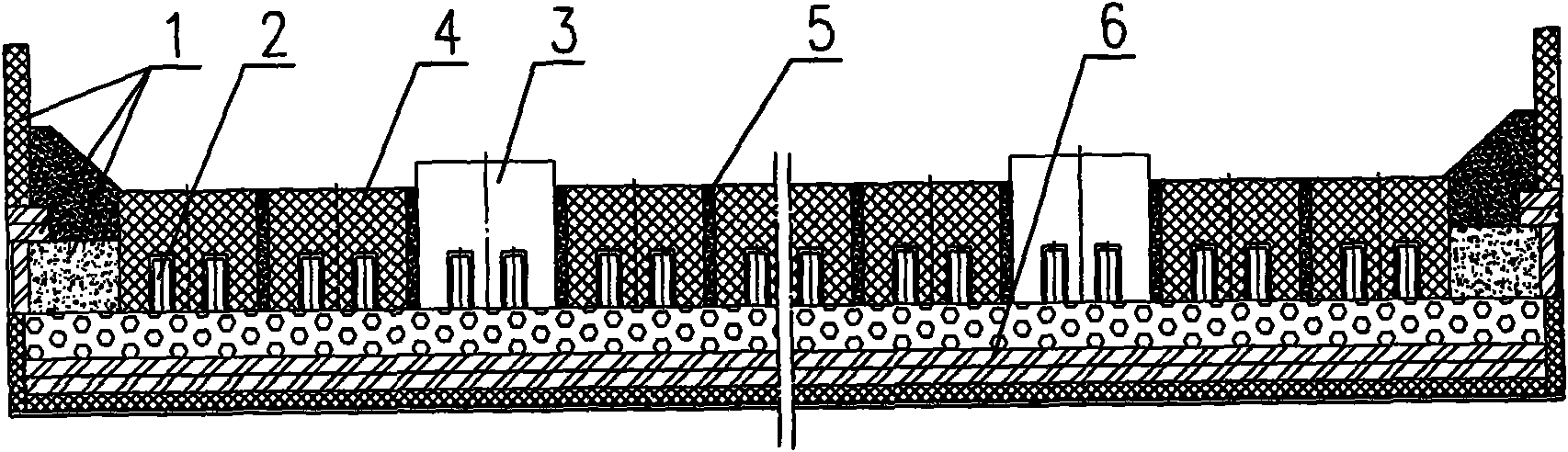

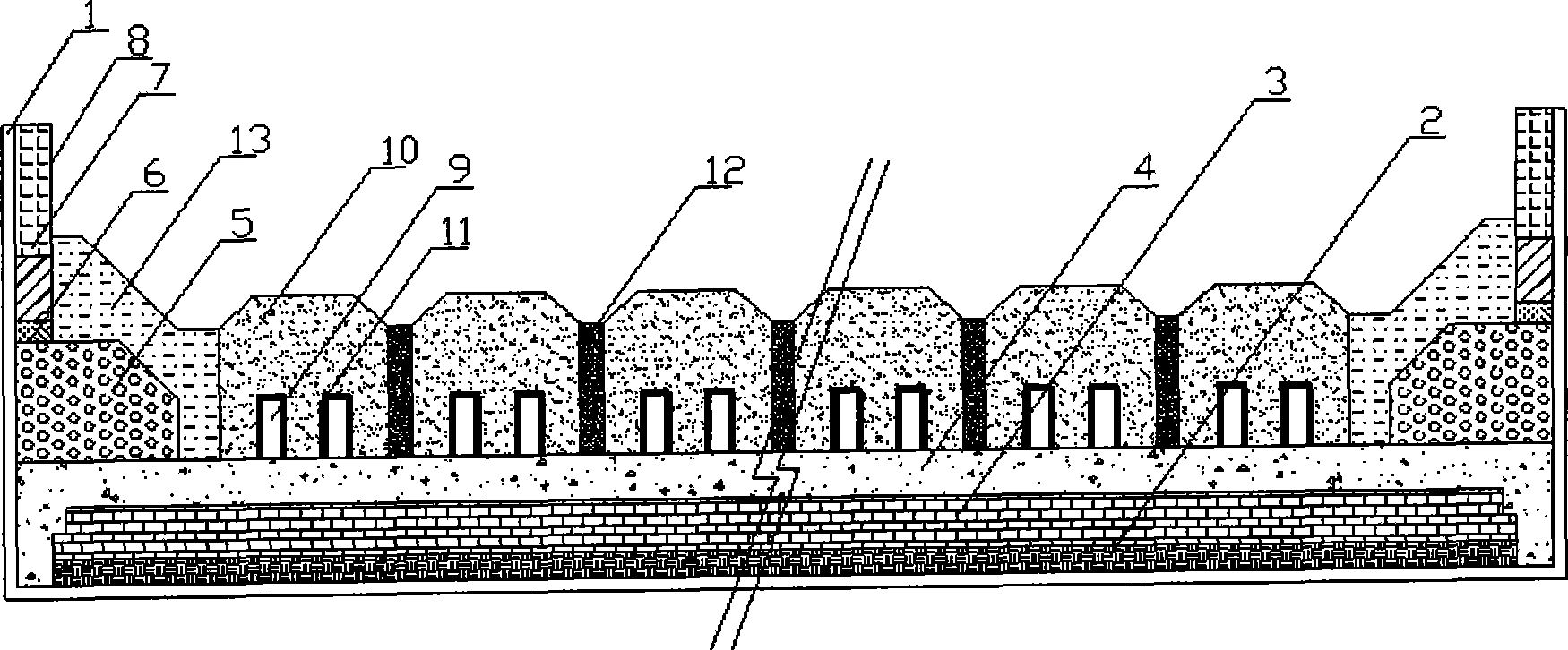

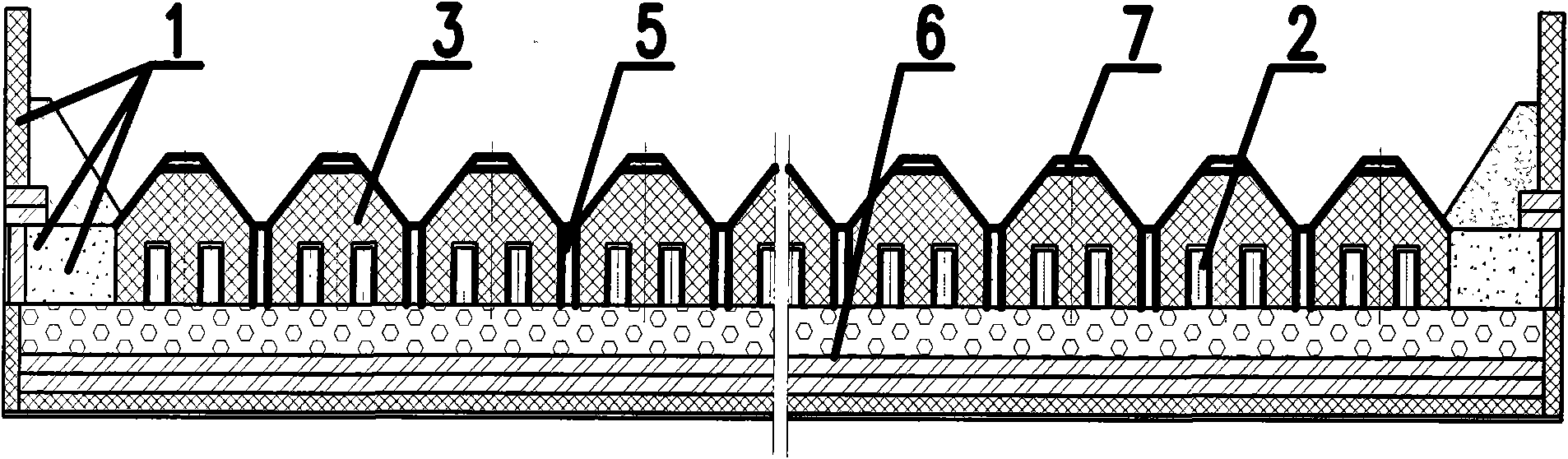

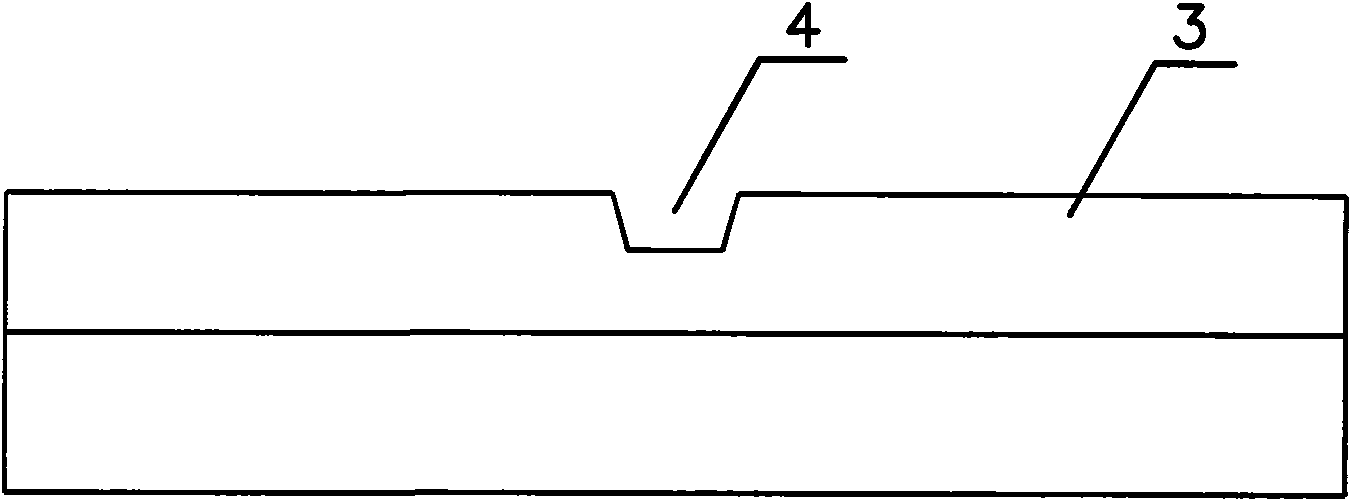

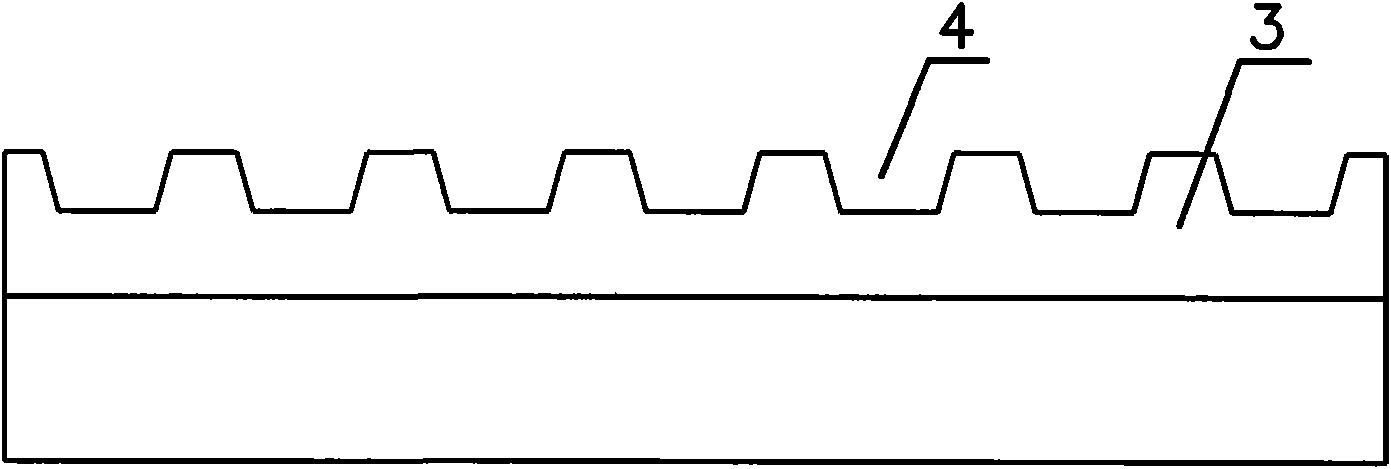

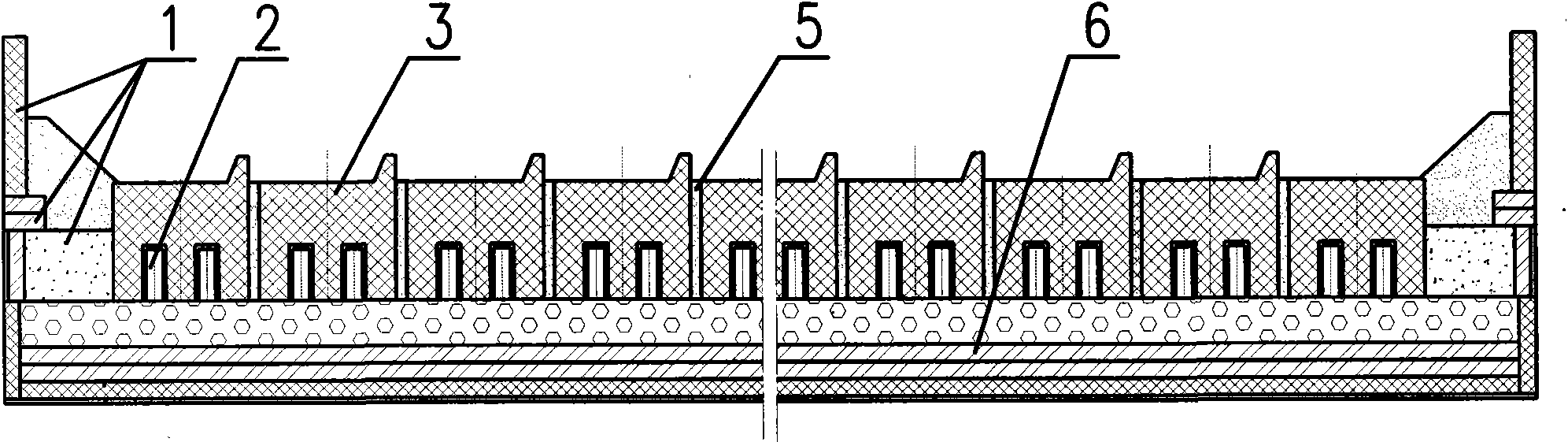

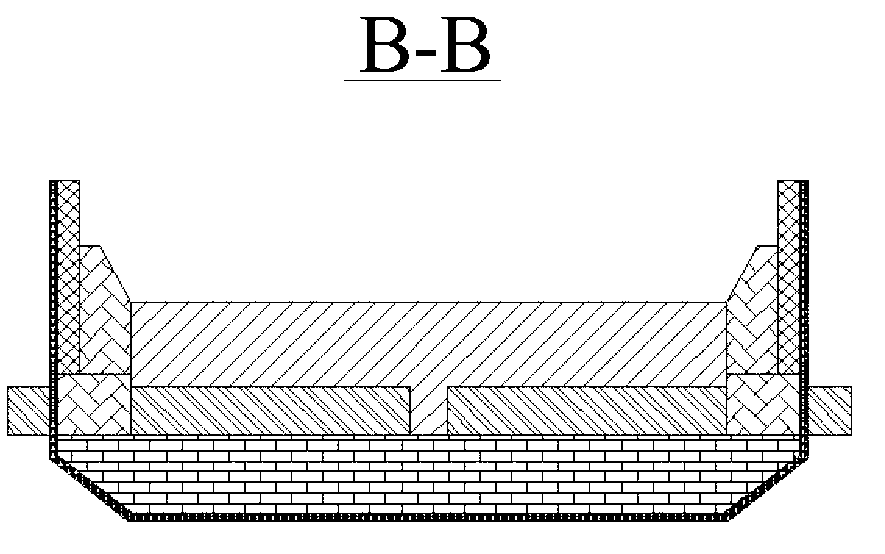

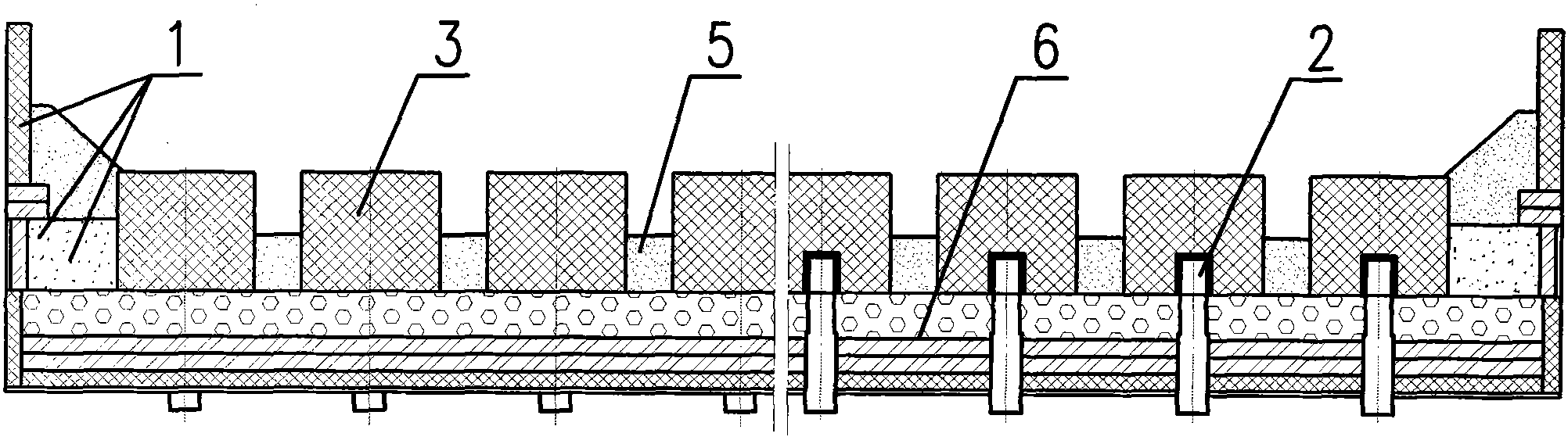

Novel energy-saving aluminum cell with chamfering grooving cathode

The invention relates to a novel energy-saving aluminum electrolytic cell with a chamfered grooved cathode. The aluminum electrolytic cell is characterized in that: a cathode carbon block adopted by the electrolytic cell is a chamfered and grooved novel carbon block; the upper part of the cross section of the carbon block is a trapezoid; the upper surface of the middle part of the longitudinal section of the carbon block is provided with a through rectangular tank; and the whole surface of the cathode on the bottom of the electrolytic cell is in the form of a plurality of dovetail grooves orthogonal with a rectangular groove. The novel energy-saving electrolytic cell can not only bring about evener current density distribution of an aluminum liquid, the cathode carbon block and a steel rod, but also improve the even distribution of a magnetic field, reduces the stress produced by the magnetic action on the aluminum liquid, effectively reduces the flow velocity of the aluminum liquid, changes the flow state of the aluminum liquid, changes the turbulent flow into the laminar flow, reduces the fluctuation of an electrolyte and the aluminum liquid in the cell, and consequently reduces the polar pitch and the pressure fall in the cell and realizes energy conservation and consumption reduction of electrolyzation.

Owner:HUNAN CHUANGYUAN ALUMINUM IND

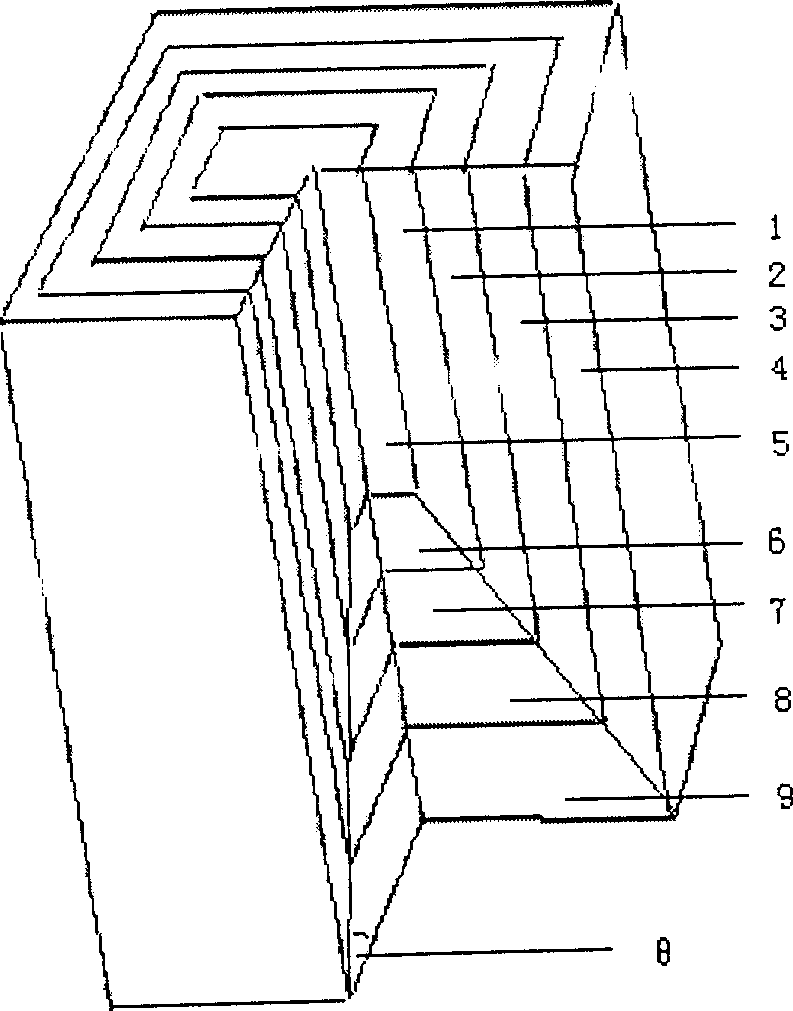

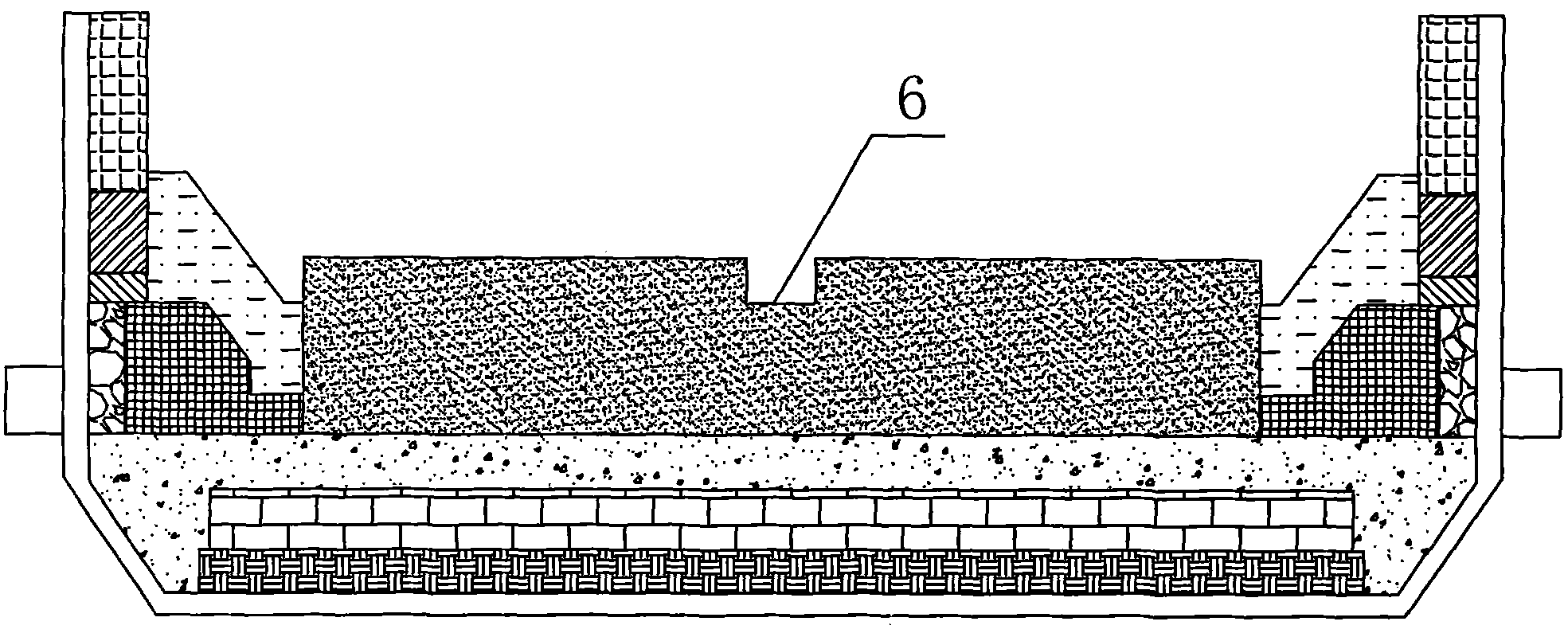

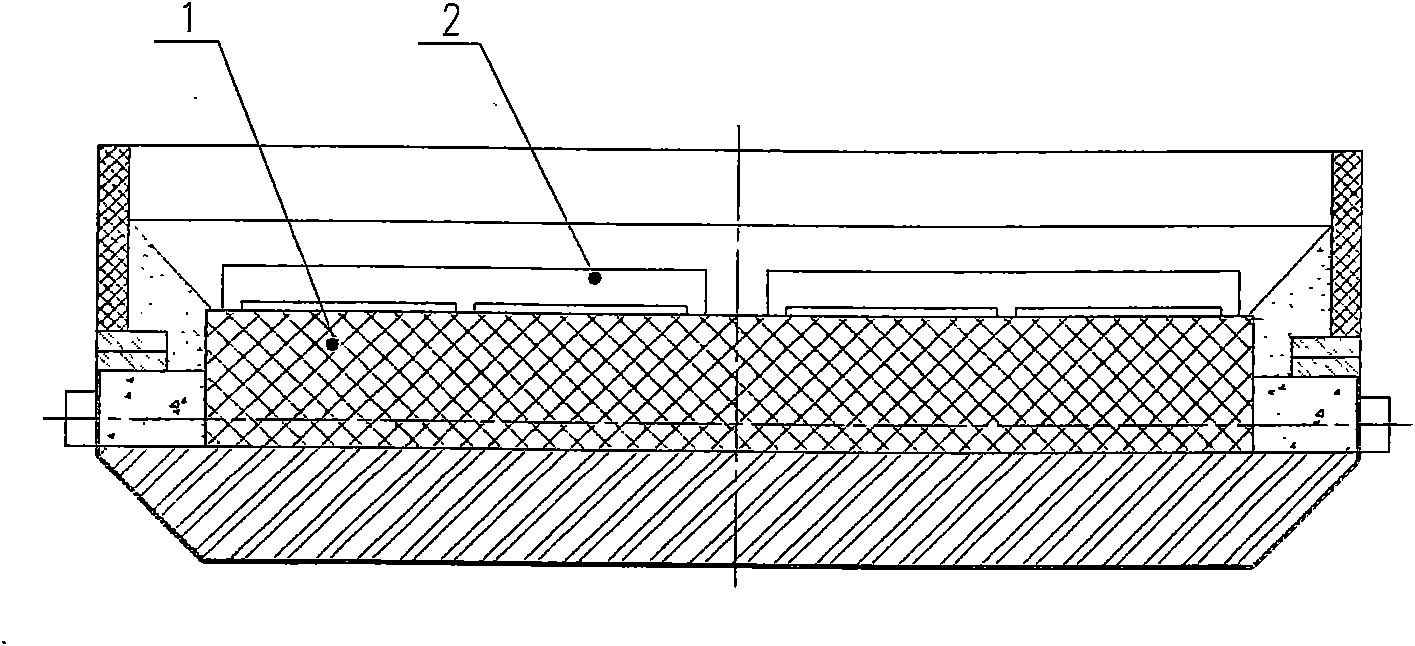

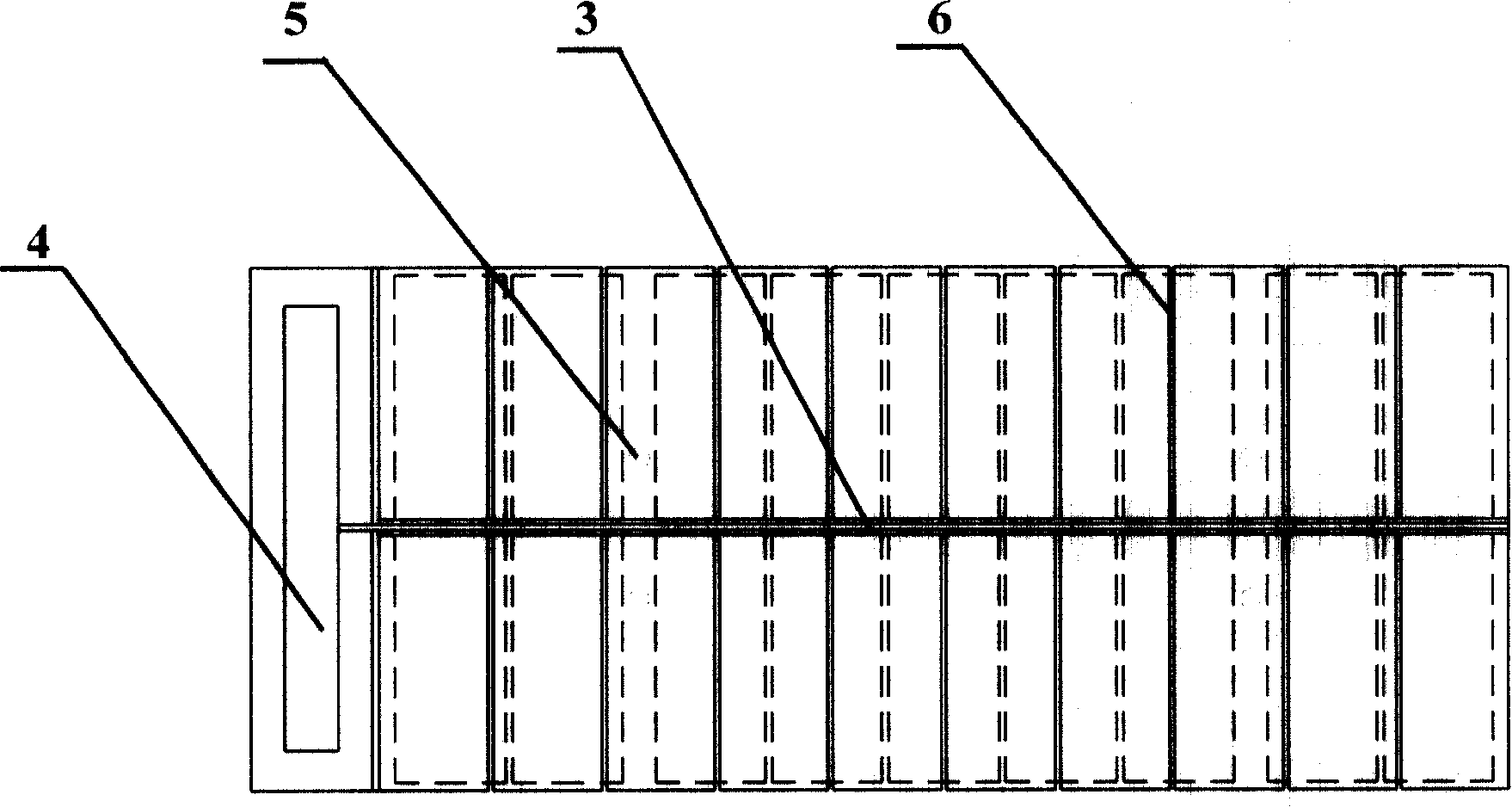

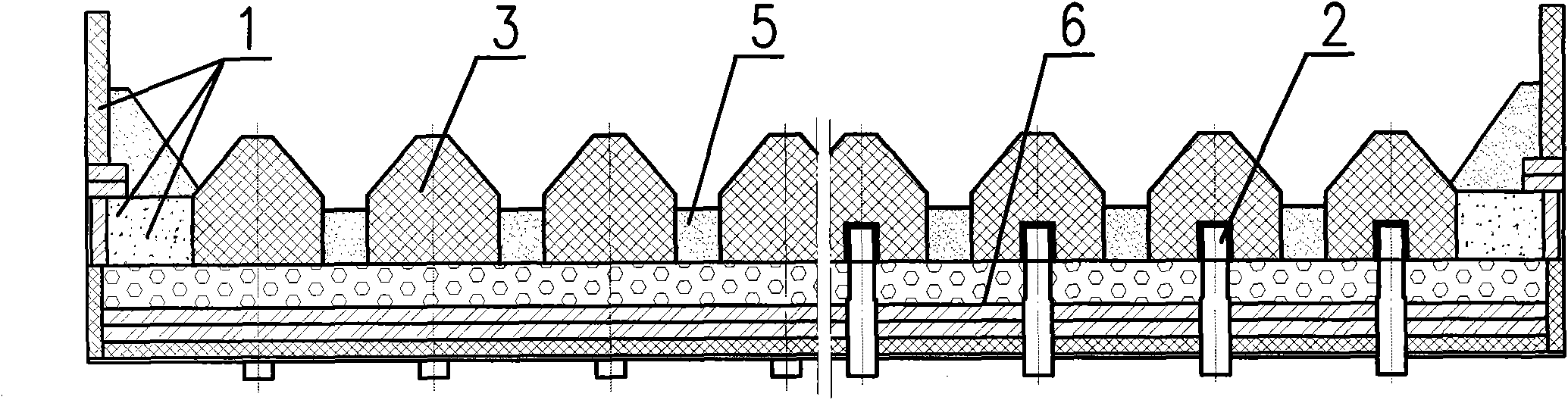

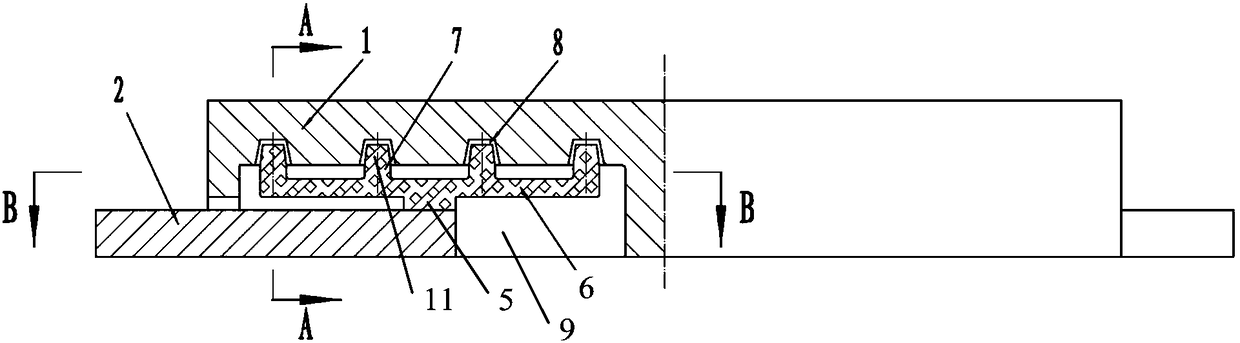

Aluminum electrolytic bath composite cathode carbon block structure

The invention discloses a horizontal electricity-outlet aluminum electrolytic bath cathode structure, and belongs to the technical field of aluminum electrolytic baths. An aluminum electrolytic bath composite cathode carbon block structure comprises a bath shell and a lining; the lining mainly comprises cathode carbon blocks, a side lining and a bottom lining, wherein the upper parts of the sections of the cathode carbon blocks are trapezoidal, while the lower parts are square; the cathode carbon blocks are connected by adopting a binding material; and cathode steel bars are arranged at the bottoms of the cathode carbon blocks and penetrate the electrolytic bath from the lateral part or the bottom. Many grooves are formed on the upper surface of the cathode so as to divide a great liquid aluminum bath into a plurality of areas, effectively constrain the flow and fluctuation of the liquid aluminum due to the action of electromagnetic force, improve the stability of the electrolytic bath, reduce the height and polar distance of the liquid aluminum, improve the current efficiency and fulfill the purposes of energy conservation and consumption reduction.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

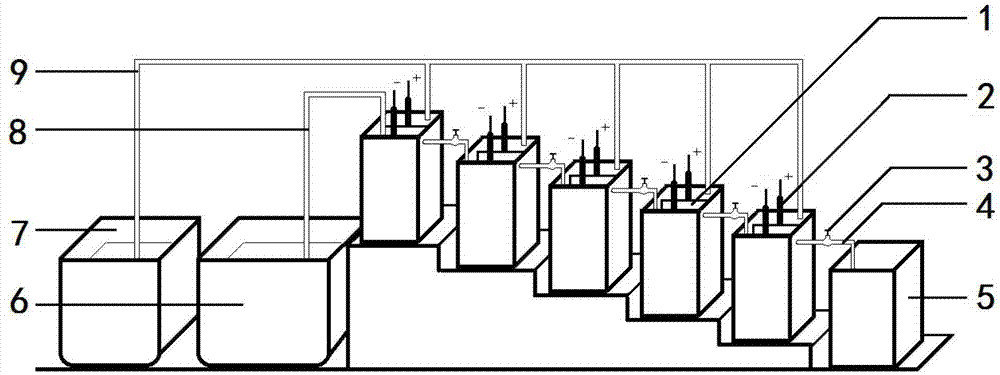

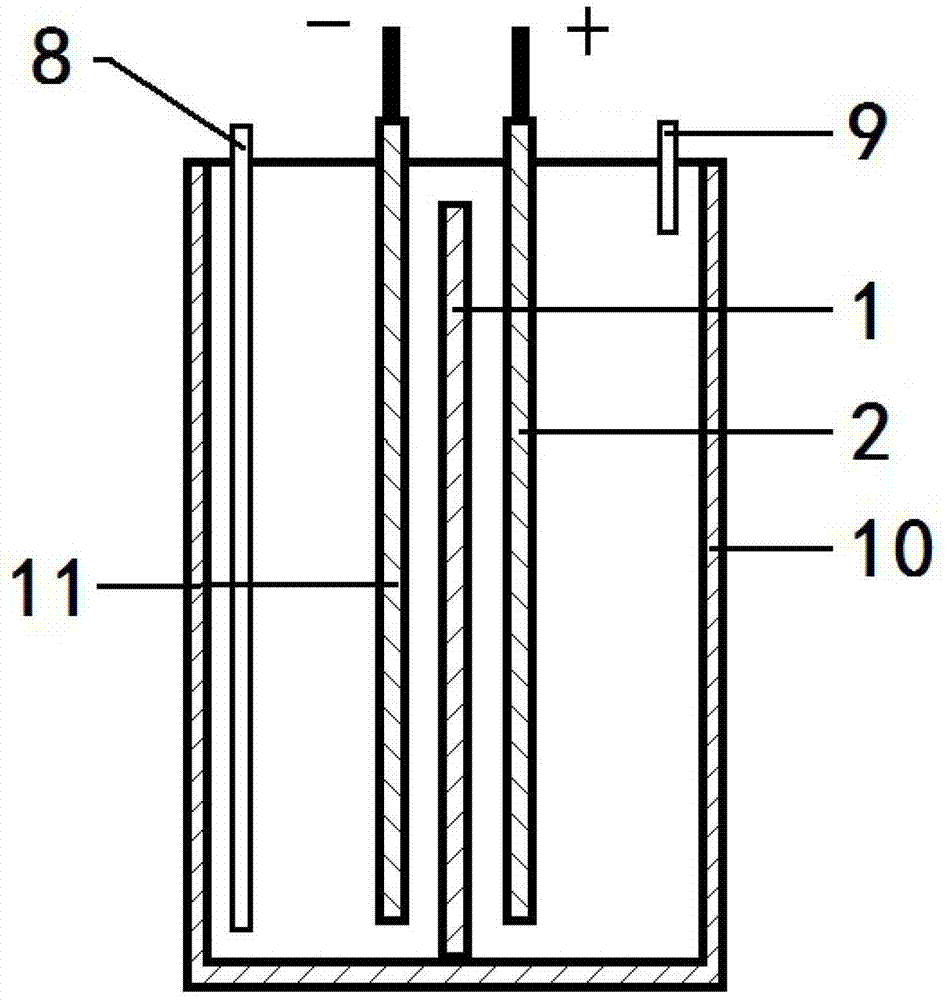

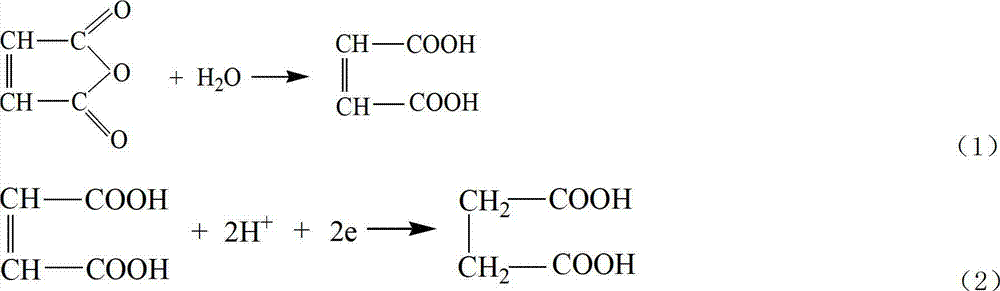

Method for producing butanedioic acid based on serial overflowing method of bipolar membrane electrolytic cell

InactiveCN102899680AMild preparation conditionsReduce pole distanceCellsElectrolytic organic productionChemistryElectrolytic cell

The invention relates to a method for producing butanedioic acid based on a serial overflowing method of a bipolar membrane electrolytic cell. According to the technical scheme, (1) a serial overflowing bipolar membrane electrolytic cell set is composed of a cathode chamber electrolyte raw material cell, an anode chamber electrolyte moisture replenishing cell, monomer electrolytic cells in equal size and a collecting cell, wherein the monomer electrolytic cells are arrayed in a ladder form in turn and the collecting cell is located under the side of the bottom bipolar membrane monomer electrolytic cell, (2) the cathode chamber electrolyte prepared in advance is injected into a cathode chamber of the electrolytic cell according to the arrayed mode of the serial overflowing bipolar membrane electrolytic cell set, and meanwhile, the electrolyte of the anode chamber is fully filled. The electrolysis is started after electrifying and an end product of the butanedioic acid is prepared. According to the method provided by the invention, the preparation condition is mild, the production is performed within the temperature scope of room temperature to 65 DEG C, and the current efficiency is above 90%.

Owner:FUJIAN NORMAL UNIV

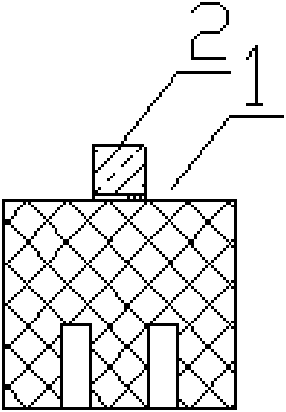

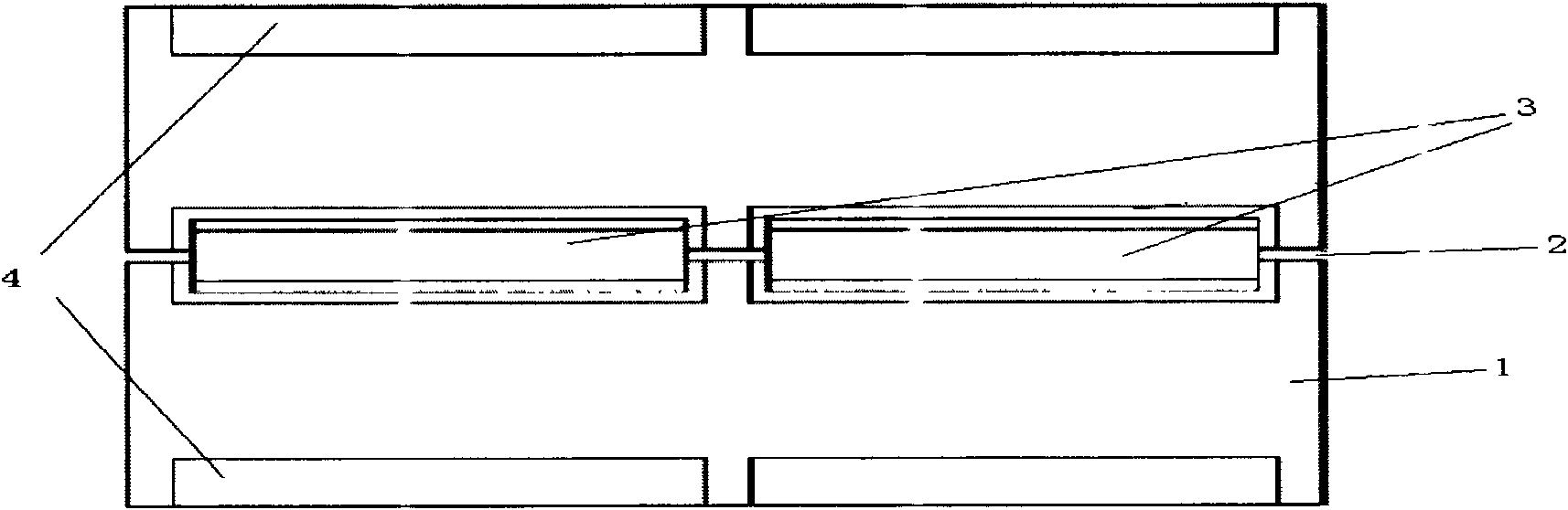

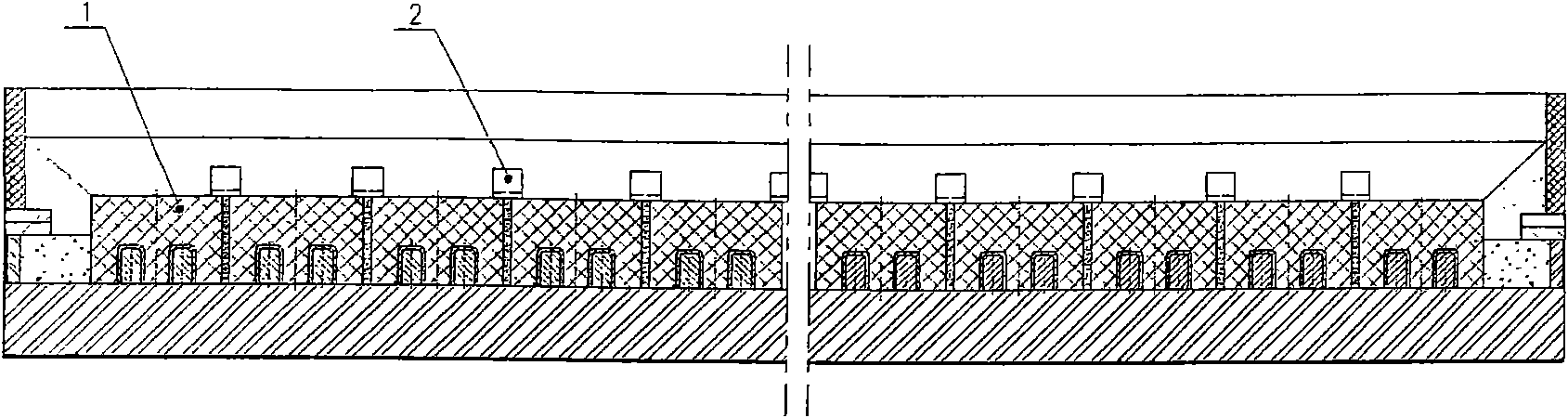

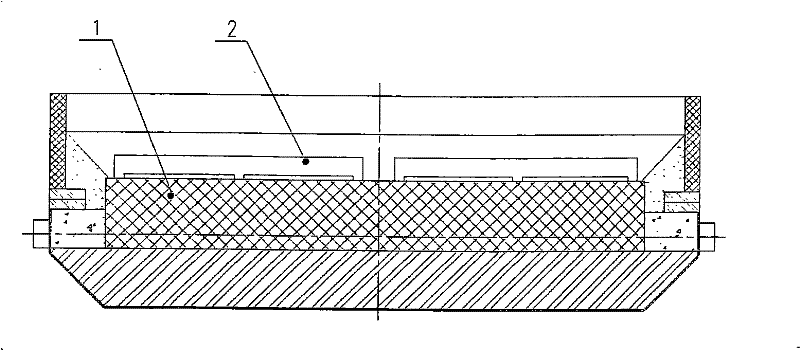

Cathode of aluminum cell

The invention discloses a cathode of an aluminum cell, which comprises cathode carbon blocks (1) arranged at the bottom of the aluminum cell and bulge bands (2) arranged on the cathode carbon blocks (1). The bulge bands (2) are arranged on the surface of the cathode carbon blocks (1) located inside the aluminum cell. The bulge bands (2) are located in the center or edge of the top surface of the cathode carbon blocks (1) or in the break joint of split joint between two cathode carbon blocks (1). The invention can better improve stability of aluminum liquid electrolyte interface in the aluminum cell, effectively reduce polar distance during normal producing and obtain lower aluminum cell working voltage, thereby achieving the effect of energy conservation and consumption reduction.

Owner:GUIYANG AL-MG DESIGN & RES INST

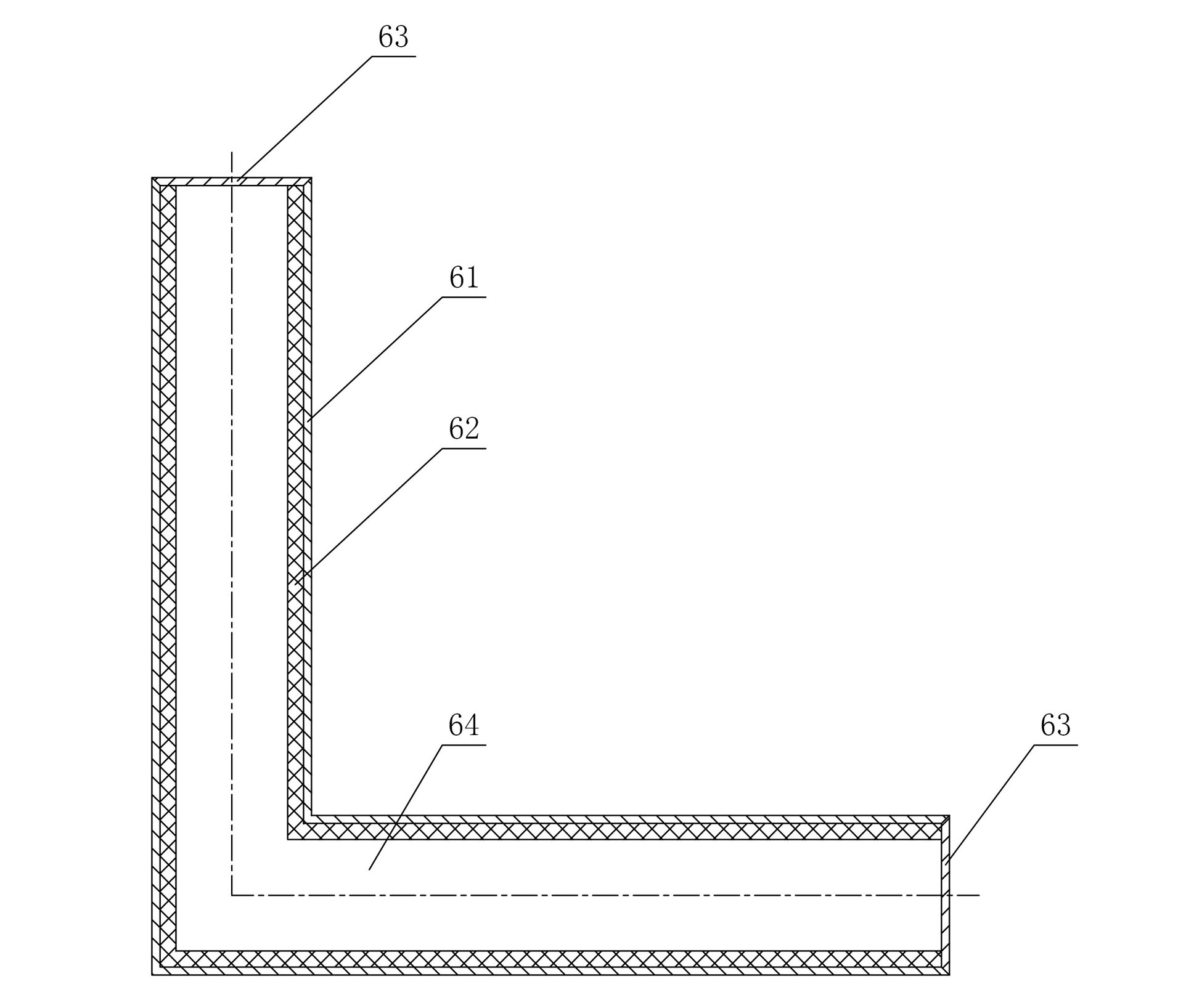

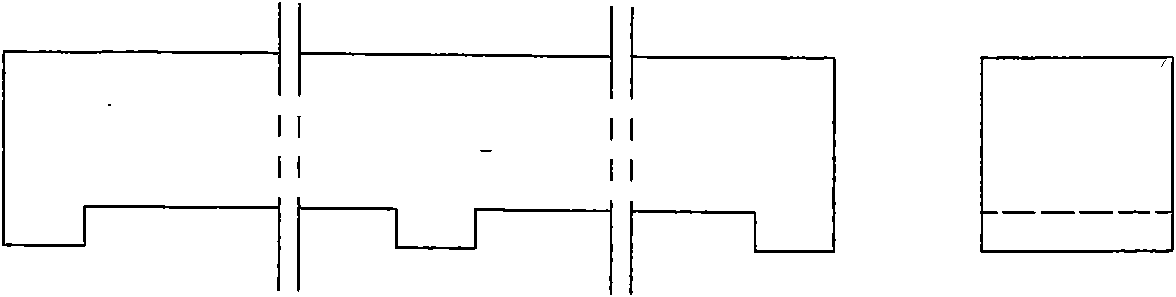

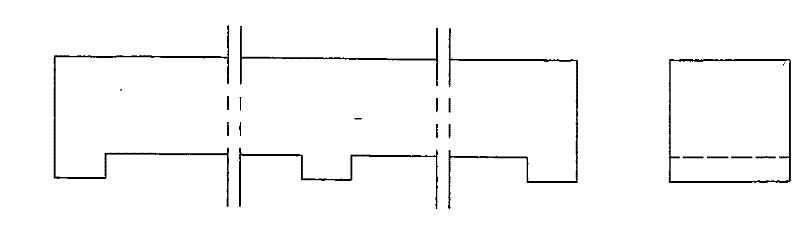

Cathode carbon block structure

The invention belongs to a cathode structure of an aluminum electrolysis bath, which belongs to the technical field of the aluminum electrolysis bath. A cathode carbon block structure comprises a bath case and an inner liner, wherein the inner liner mainly consists of a cathode carbon block, a side inner liner, a bottom inner liner and tamping paste, the cathode carbon block is in an L shape, i.e. one edge of the upper surface of the cathode carbon block is projected so that the upper surface of the cathode carbon block is in the L shape, and a cathode steel rod is horizontally arranged at the bottom of the cathode carbon block and is penetrated out from the side part of the electrolysis bath, or the cathode steel rod is vertically arranged at the bottom of the cathode carbon block and is penetrated out from the bottom of the electrolysis bath. Liquid state aluminum liquid of the invention is divided into a plurality of small aluminum cells by the L-shaped cathode carbon block, the flowing and the fluctuation of the aluminum liquid caused by the electromagnetic force effect are effectively restricted, the stability of the electrolysis bath is improved, the height of the aluminum liquid can be lowered, the polar distance of the aluminum liquid can be shortened, the current efficiency can be improved, and the goal of energy saving can be reached.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Building method of aluminum electrolysis cell

The invention relates to a building method of an aluminum electrolysis cell, which comprises a conventional building method and comprises the following building steps: (1) when cathode blocks of the electrolysis cell are manufactured, symmetrically chamfering the upper end part of each cathode block along the longitudinal direction, and forming a transverse groove at the top of each cathode block; (2) when the cathode blocks are built, reserving a gap of 20-40mm between every two adjacent cathode blocks, and tamping the gap by cathode tamping paste, wherein the opposite chamfers of the adjacent cathode blocks and the cathode tamping paste filled into the gap form a trapezoidal groove, and the depth of the trapezoidal groove is the same as the depth of the transverse groove at the top of each cathode block; and (3) forming one or two longitudinal grooves at the bottom of each cathode block, laying steel bars of corresponding sizes in each longitudinal groove, and tamping the gap between each cathode block and each steel bar by cathode steel bar paste. The aluminum electrolysis cell built by the method can greatly reduce the horizontal current in aluminum liquid to enable the current density of the cathode blocks and the cathode steel bars to be more uniform, thereby greatly prolonging the service life of the electrolysis cell.

Owner:SNTO TECH GRP

Bottom-discharging aluminum cell

InactiveCN101760760ATo achieve the purpose of saving energy and reducing consumptionReduce dissolution lossMagnetic fieldCathode

The invention discloses a bottom-discharging aluminum cell which is provided with a plurality of cathodes. Each cathode comprises a horizontal cathode steel rod and a vertical cathode steel rod or each cathode comprises a horizontal cathode steel rod and one or more vertical cathode steel rod; the horizontal cathode steel rod or a flat cathode steel block and the vertical cathode steel rod form a T-shaped or phi-shape structure. The bottom of the vertical cathode steel rod is connected with a cathode bus of the aluminum cell; the cathode bus of the aluminum cell is partially gathered on the bottom of the aluminum cell and is partially gathered on the end of the aluminum cell. The bottom-discharging aluminum cell uses the specific cathode structure and bus, so the aluminum liquid and the cathode current of the aluminum cell are uniformly distributed, the level current and the vertical magnetic field are small and the stability of the surface aluminum liquid is excellent.

Owner:CENT SOUTH UNIV

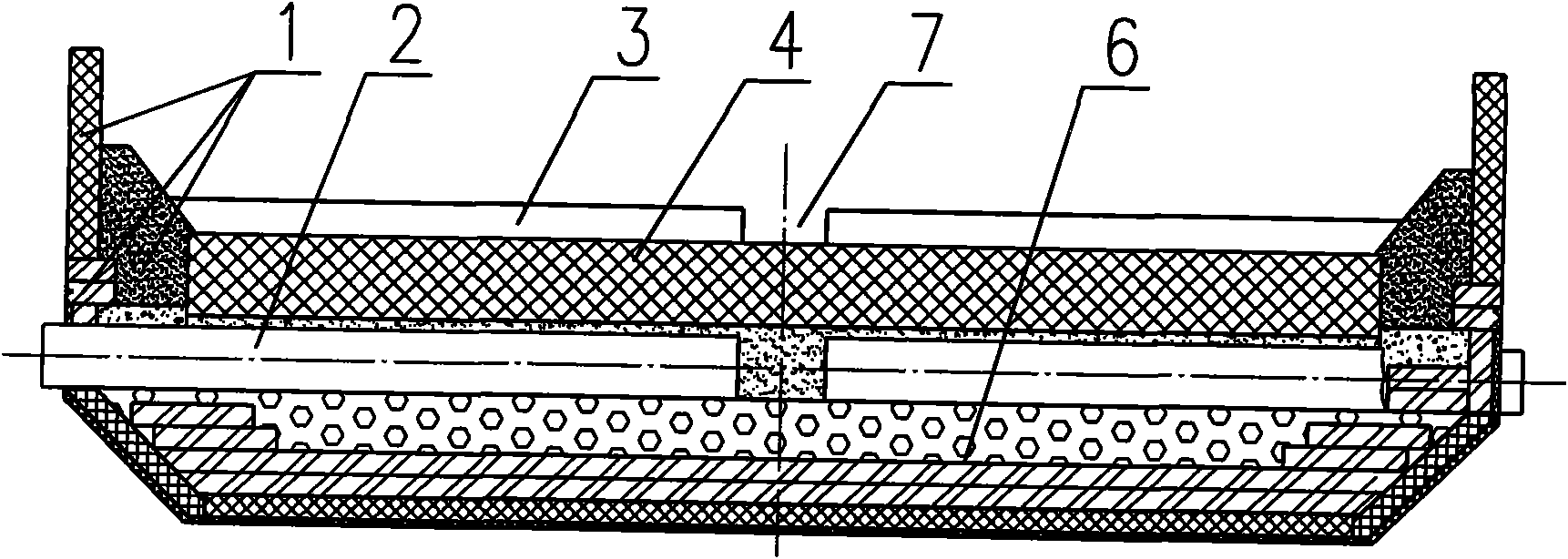

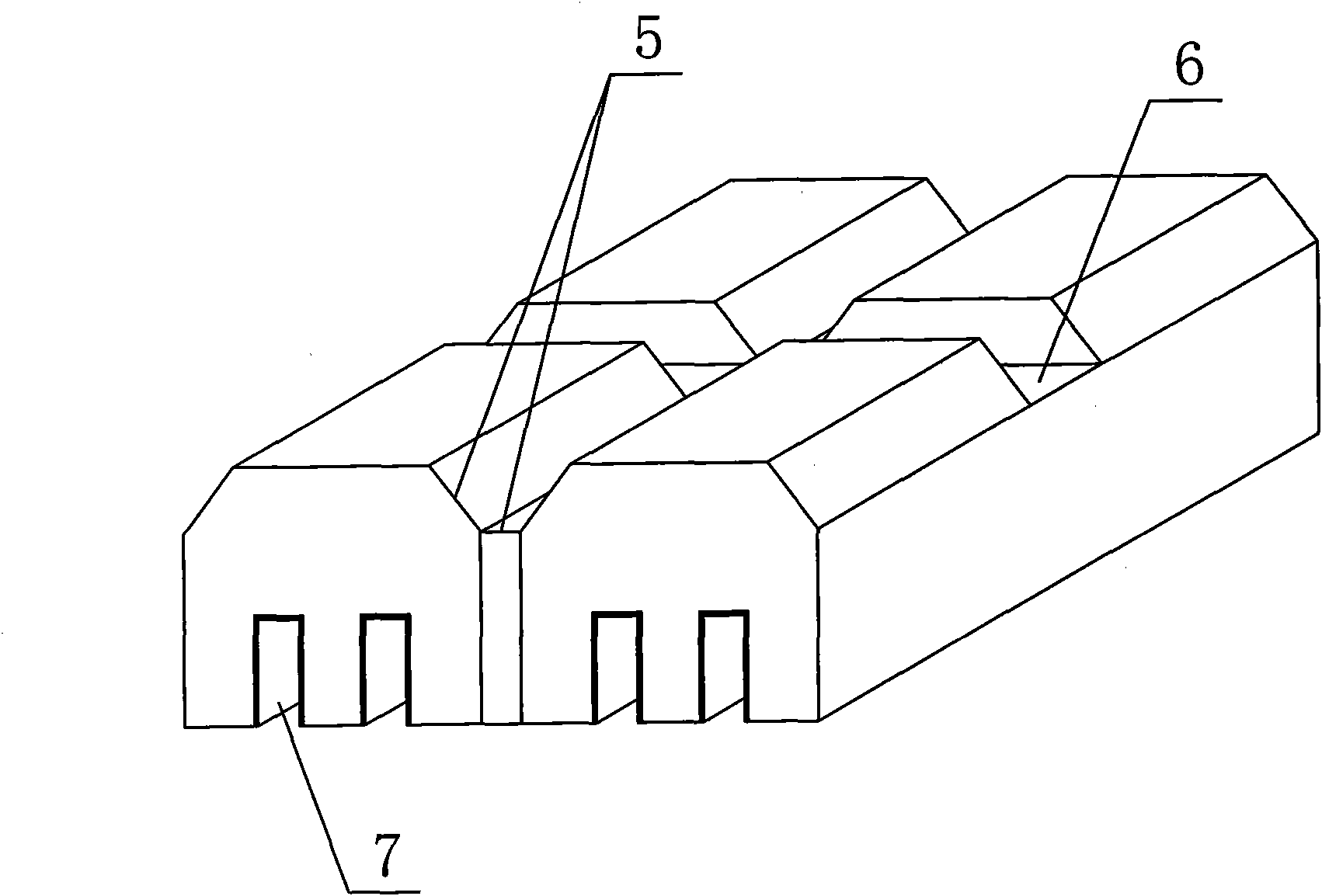

Novel composite graphitized deformed cathode for aluminium electrolysis

A novel composite graphitized deformed cathode for aluminium electrolysis contains main body blocks and a graphitized cathode flow-resisting block, wherein grooves are symmetrically arranged on the longitudinal edges of the main body blocks, and the graphitized cathode flow-resisting block with the different material of the main body blocks is embedded in the two grooves over the two main body blocks. The invention adopts the mode that the flow-resisting block is embedded in the joint split of the two cathode main body blocks over the electrode, thus the electrode distance of the aluminium electrolysis device is reduced, the bath voltage is decreased by about 0.35V-5V, the ton aluminum electricity consumption can be reduced by no less than 1000KWh, and the energy-saving and consumption-reducing effect is obivous. The deformed cathode of the invention can be used to avoid slotting in the middle of each main body block, wherein slotting in the middle of each main body block can reduce the effective thickness of the main body block so as to influence the service life; and by using the deformed cathode, the aim of performing local reinforcement to the joint split of the main body blocks thus prolonging the service life of the electrolytic bath.

Owner:GUANGXI QIANGQIANG CARBON

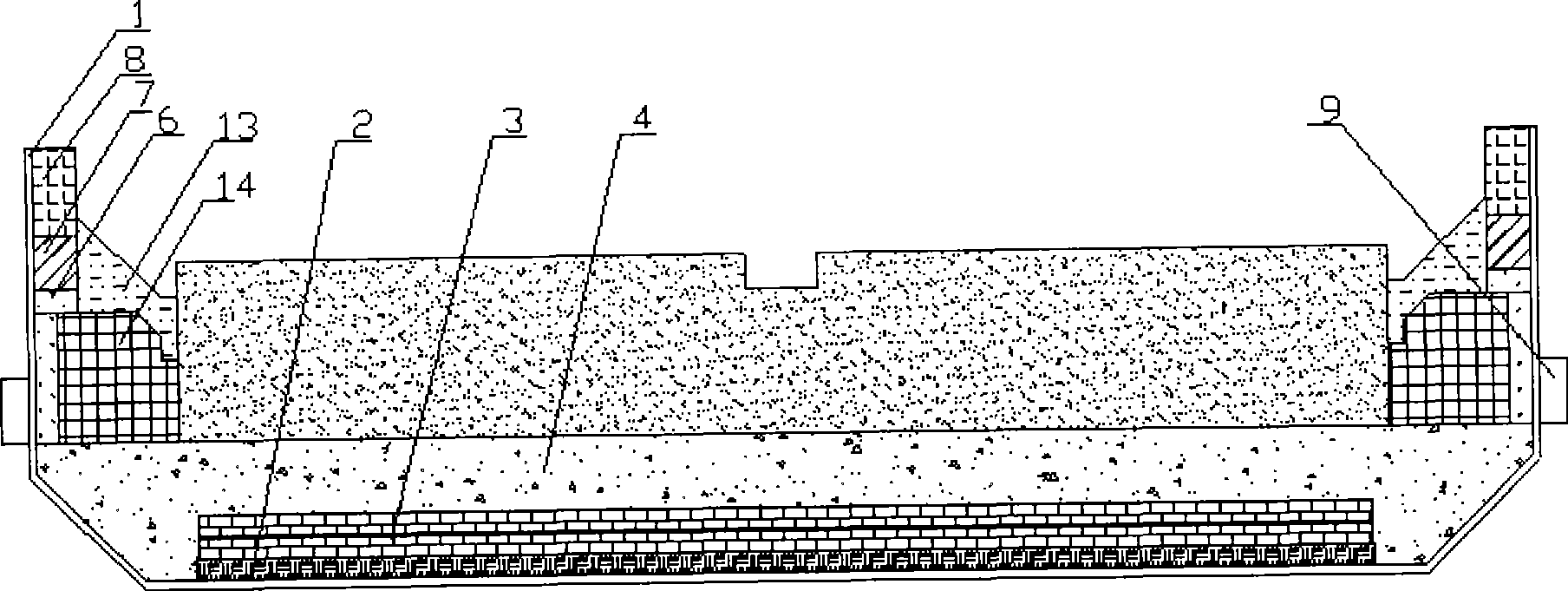

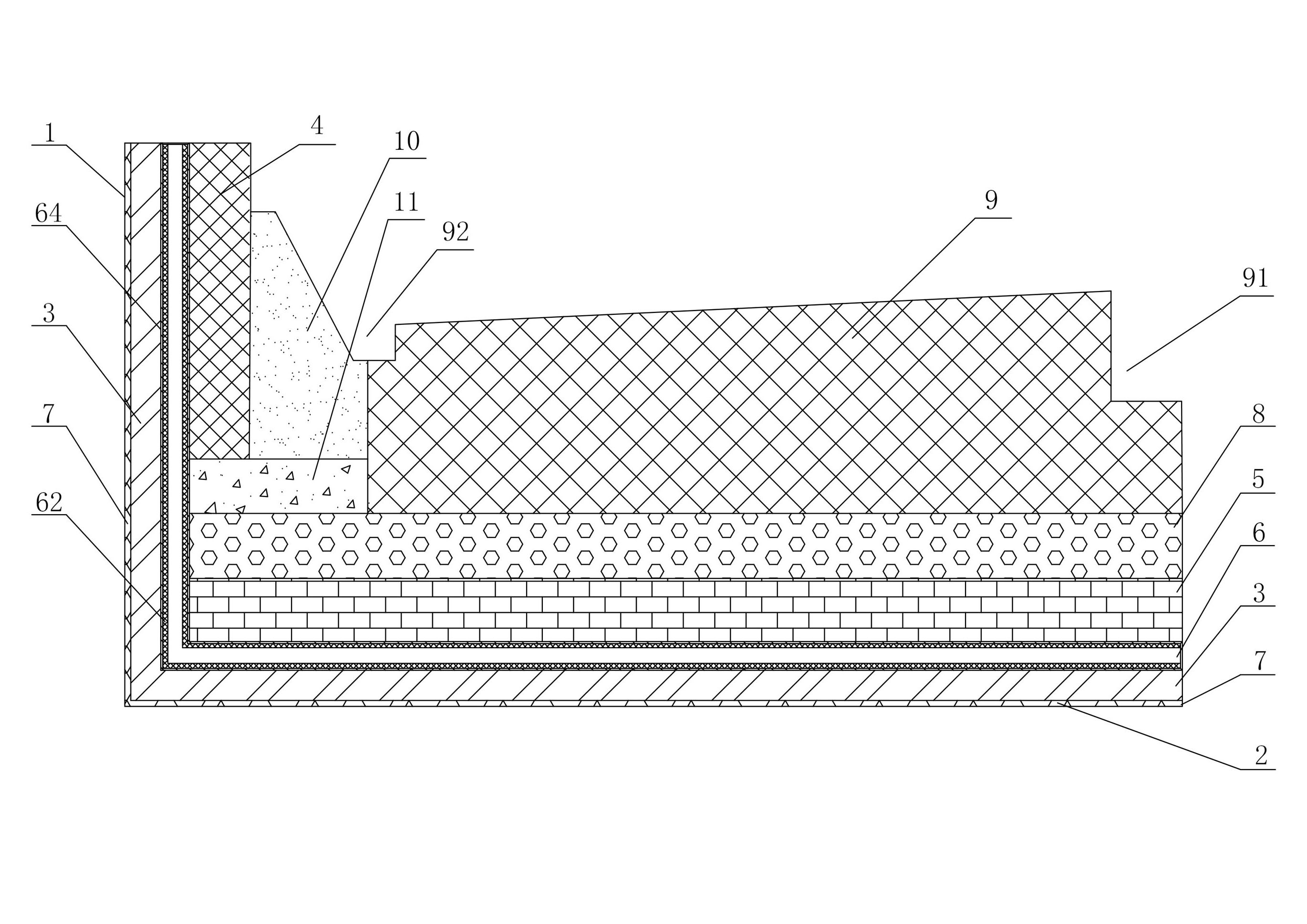

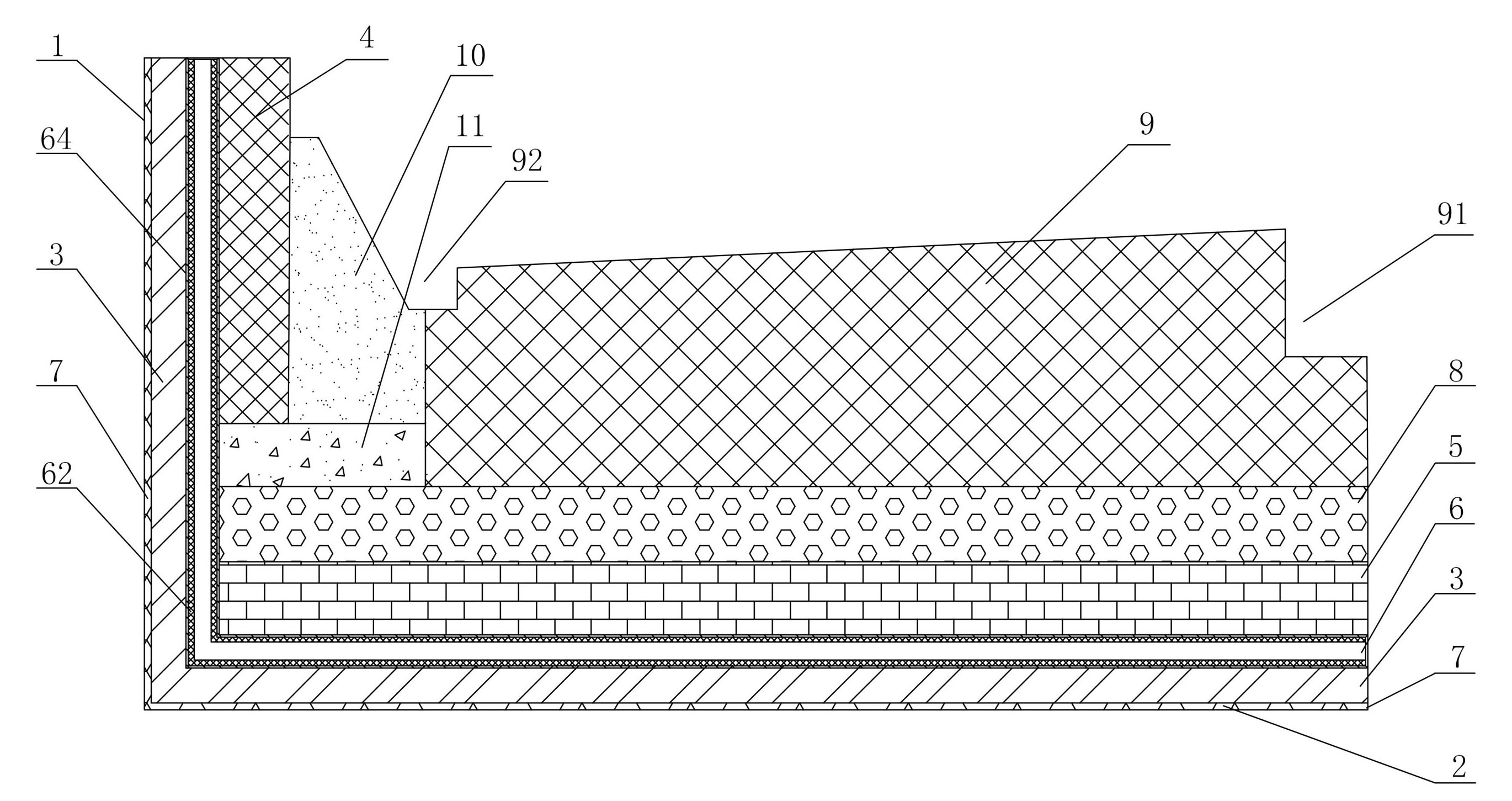

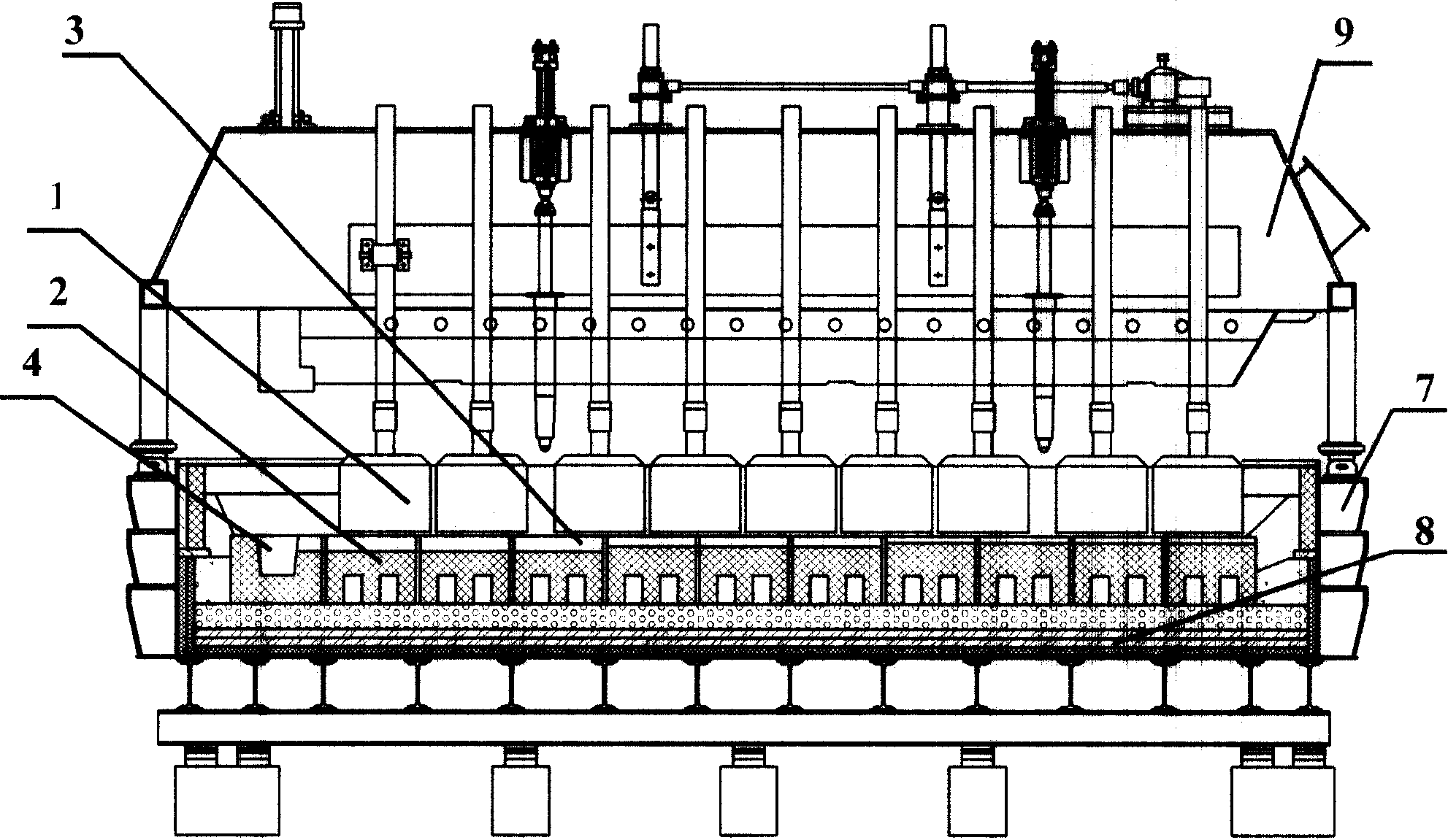

Heat pipe and heat pipe based guide type aluminium electrolysis cell

The invention discloses a heat pipe which comprises a pipe case, a wick and sealed end covers, wherein the pipe case is in an L shape, the wick is covered on the inner wall of the pipe case, the sealed end covers are arranged at the two ends of the pipe case so as to form a sealed pipe cavity, and the sealed pipe cavity is filled with working fluid. The heat pipe has the advantages that the structure is simple, and heat at the side wall of an aluminium electrolysis cell can be conveniently transferred to the bottom of the cell. The invention also discloses a heat pipe based guide type aluminium electrolysis cell which comprises a cell body, wherein the outer side of the cell body is provided with a heat insulation brick layer, the cell body is provided with a side carbon block at the inner side of the side wall, the cell body is provided with a fireproof brick layer at the inner side of the bottom of the cell, a cathode carbon block is arranged above the fireproof brick layer, the middle of the cathode carbon block is provided with a central aluminium accumulation sump, the two sides of the cathode carbon block are connected with the side carbon block by the tamping paste, the joint of the tamping paste and the cathode carbon block is provided with a peripheral aluminium accumulation sump, and the cell body is internally provided with the heat pipe. The aluminium electrolysis cell has the advantages that the radiation loss of the side of the aluminium electrolysis cell can be reduced, the heat utilization ratio of the aluminium electrolysis cell can be improved, and the service life is long.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

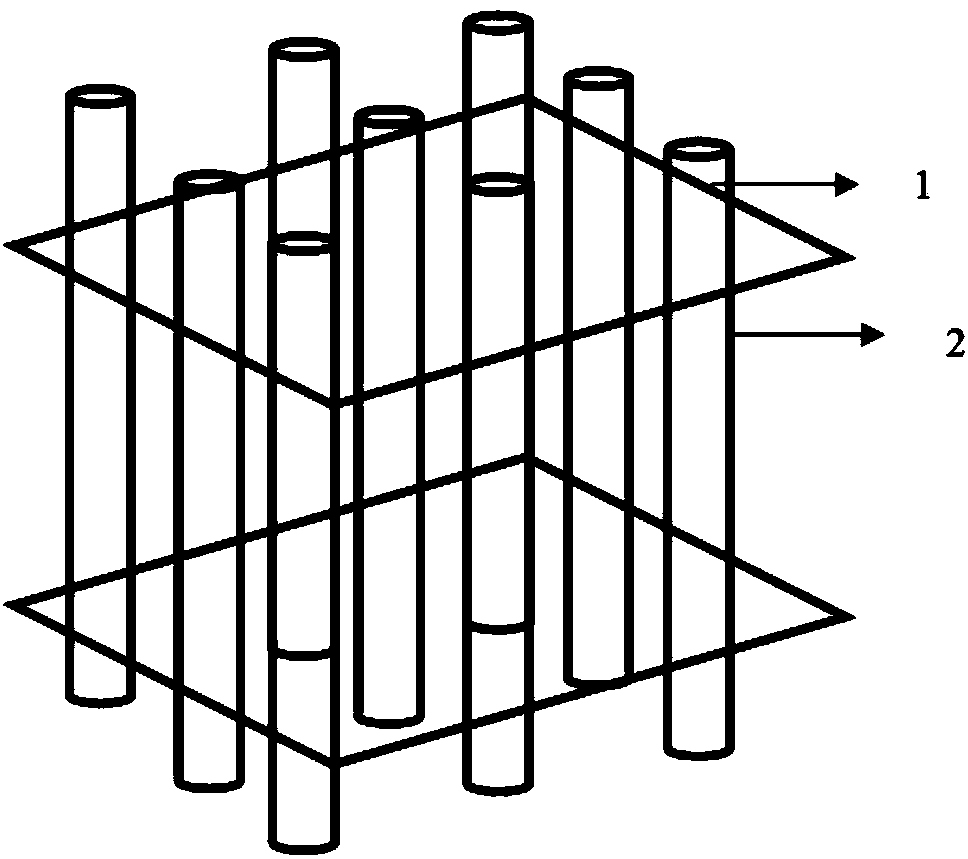

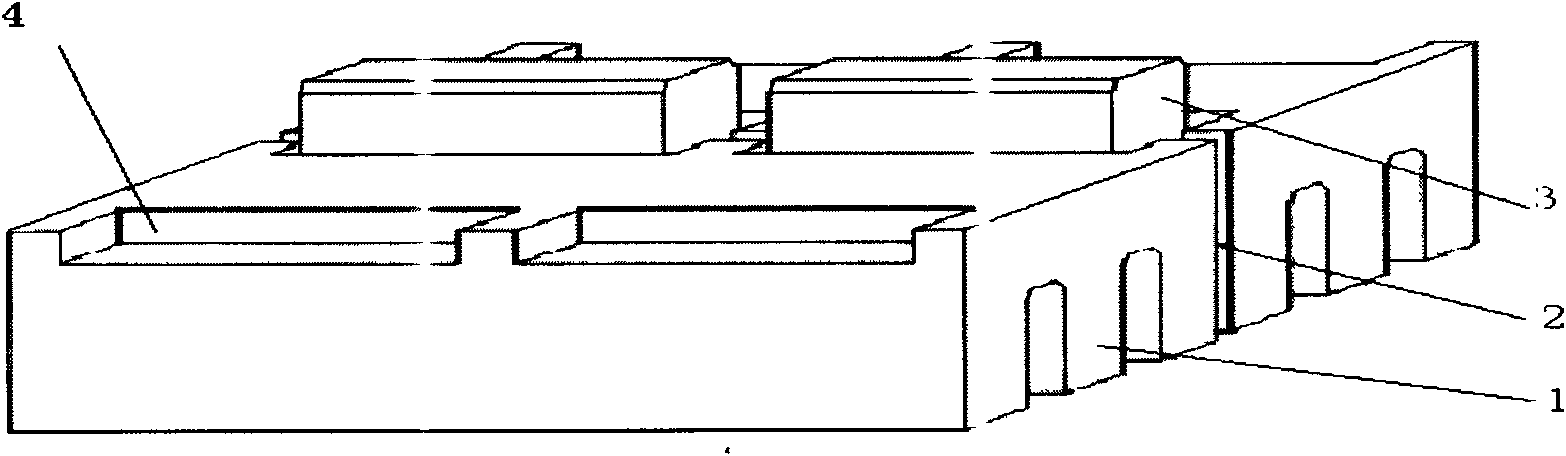

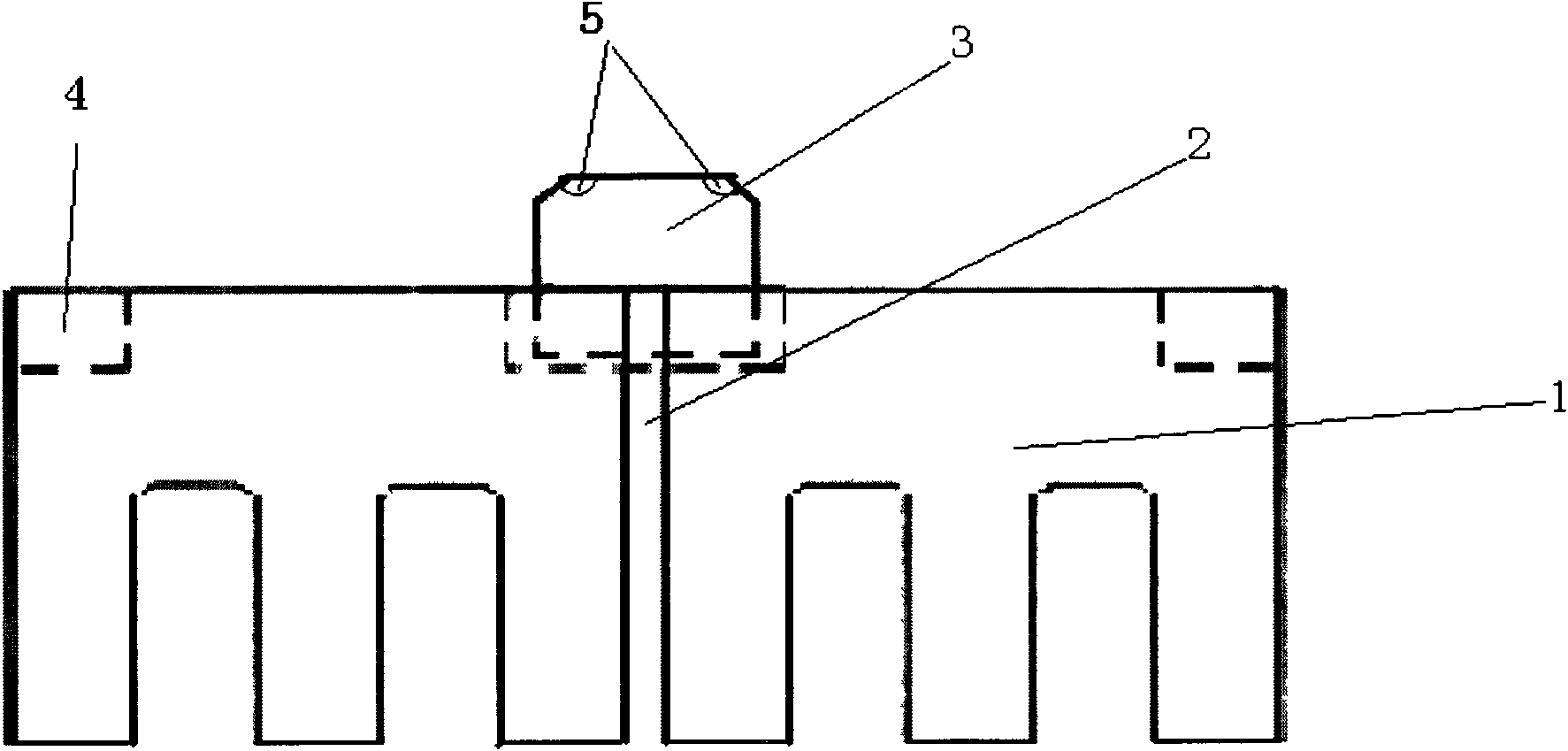

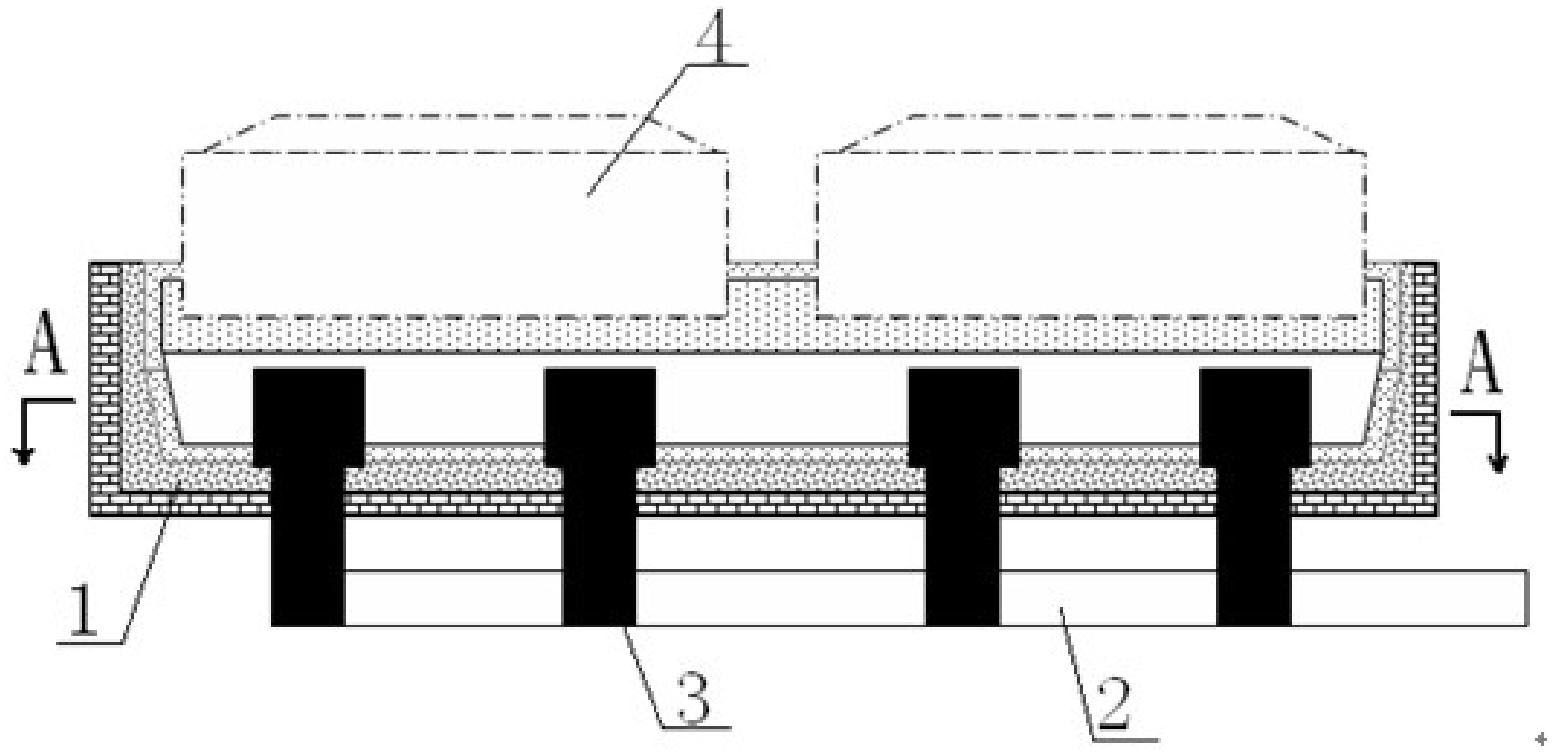

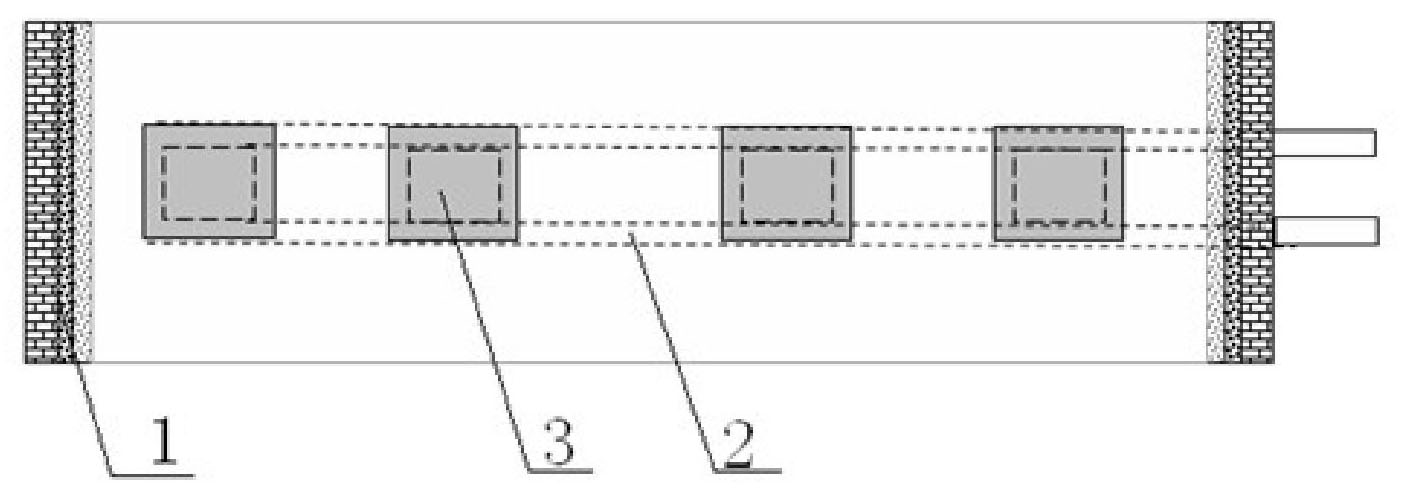

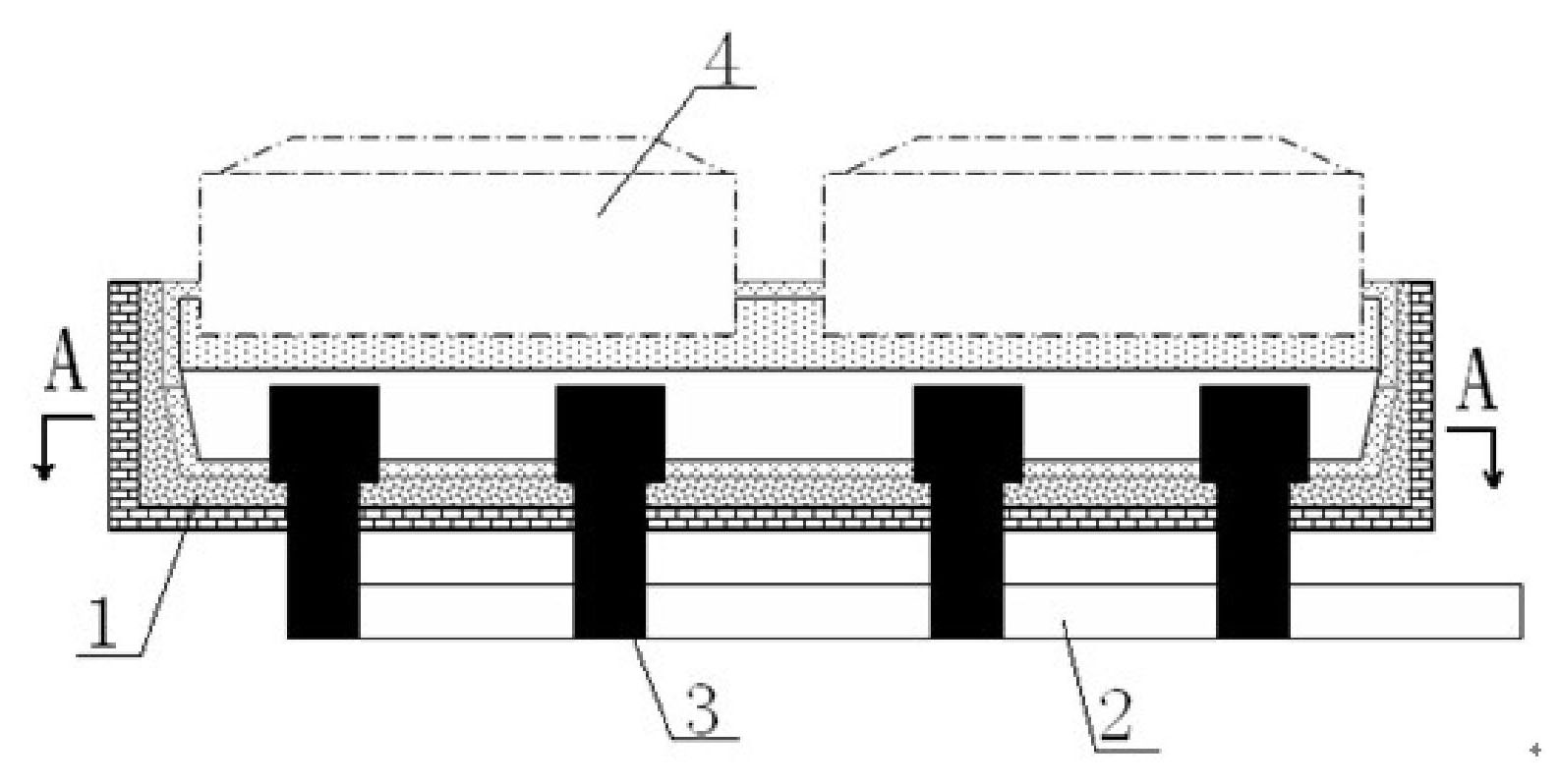

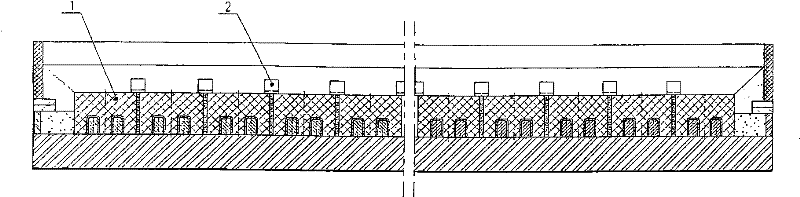

Cell bottom structure of electrolytic cell

The invention discloses a cell bottom structure of an electrolytic cell. The cell bottom structure comprises an electrolytic cell (1) and a cathode bus (2), wherein the bottom of the electrolytic cell (1) is provided with columnar cathode carbon blocks (3) which are perpendicular to the bottom of the electrolytic cell (1); and the lower ends of the columnar cathode carbon blocks (3) are connected with the cathode bus (2). In the cell bottom structure, the column cathode carbon blocks are vertically inserted in the bottom of the electrolytic cell, and the lower ends of the columnar cathode carbon blocks are connected with the cathode bus, so that current which is led in from anode carbon blocks is led out downwards from the columnar cathode carbon blocks through molten aluminum to reduce horizontal current in the molten aluminum; and a cathode which extends into the molten aluminum can effectively reduce fluctuation of the molten aluminum, so that a stable molten aluminum surface is achieved to reduce polar distance between the cathode and an anode and reduce the cell voltage to fulfill the aim of reducing power consumption.

Owner:GUIYANG AL-MG DESIGN & RES INST

An embedded bioelectric synthesis system and method

ActiveCN103881905BImplement resourcesAvoid consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityNuclear engineering

The invention relates to an embedded bioelectricity synthesis system, which mainly comprises an anaerobic oxidation reactor, a bioelectric synthesis reactor, a culture solution circulation control system, a power supply and an external circuit; the bioelectric synthesis reactor is composed, from the inside to the outside, of a conductive reactor wall, a diaphragm and an anode, and the conductive reactor wall is also a cathode of the reactor; and the culture solution circulation control system is used for controlling and adjusting pH, temperature, CO2 concentration and the like of the culture solution. Through the system disclosed by the invention, the anaerobic oxidation and biosynthetic reduction of the waste and waster water are coupled by applying electrical potential, after waste inside the anaerobic oxidation reactor and the electron generated by anaerobic oxidation of wastewater are transferred to the conductive reactor wall as the cathode, electron streams penetrate through the reactor wall and are transferred to the microbial flora in the bioelectric synthesis reactor and CO2 is reduced and synthesized into organic chemicals after electrons are obtained by the microbial flora,.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Energy saving and consumption reduction method of aluminum reduction cell

The invention discloses an energy saving and consumption reduction method of an aluminum reduction cell, which is applicable to the aluminum reduction cell with current intensity higher than 60 kA. The invention comprises a retaining block which is placed on a cathode carbon block, and the retaining block can be one block or a plurality of blocks according to the size of cell capacity. The retaining block can be horizontally placed along the major axis direction or the minor axis direction of the reduction cell, the other parts at the lower part of the retaining block except support legs are opened, the height of the retaining block is not beyond the height of a molten aluminum layer of the reduction cell. In the invention, owning to the existence of the retaining block, the fluctuation in the molten aluminum layer is decreased, the polar distance is reduced, the cell voltage is decreased significantly, and the electric energy efficiency is increased.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

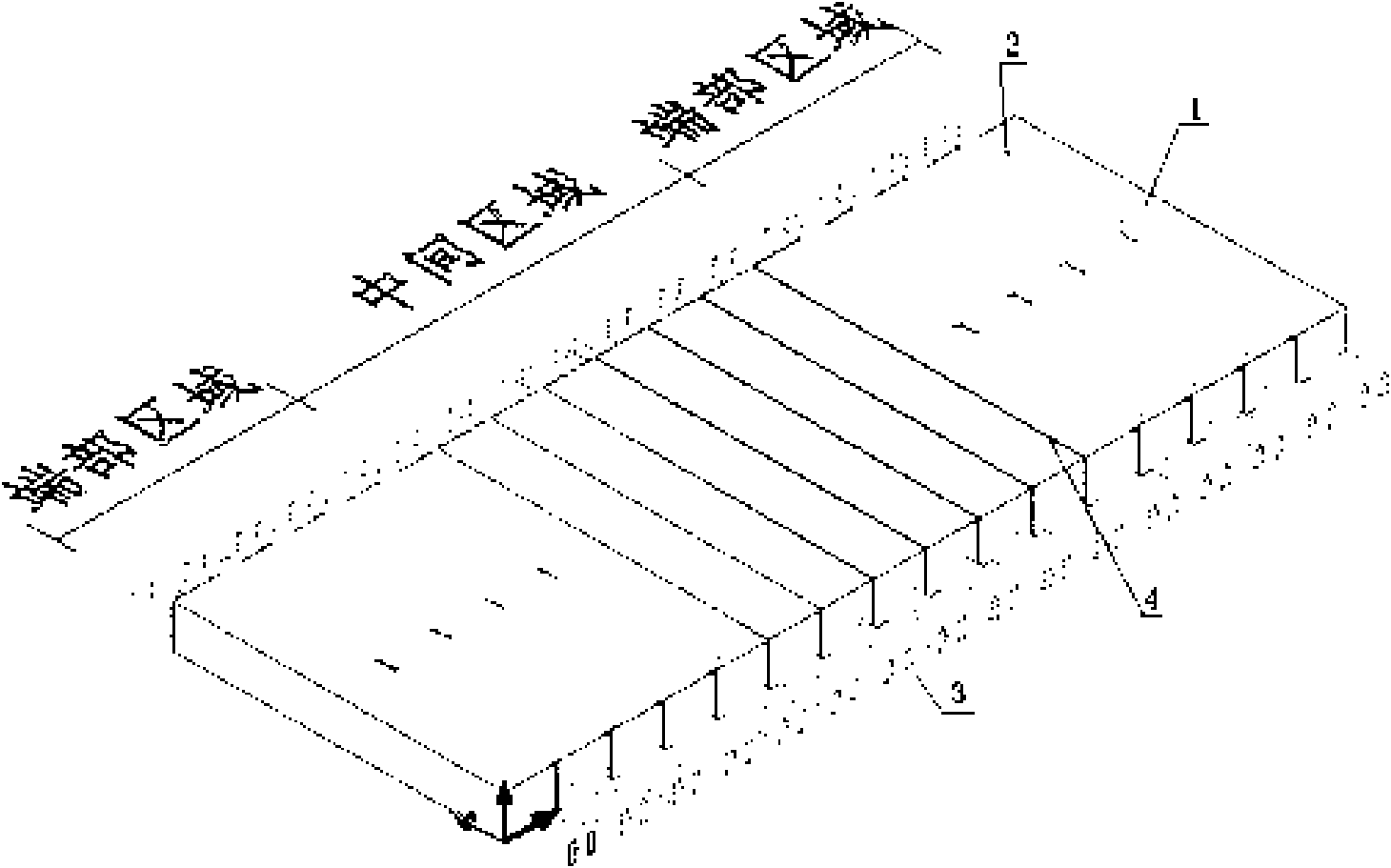

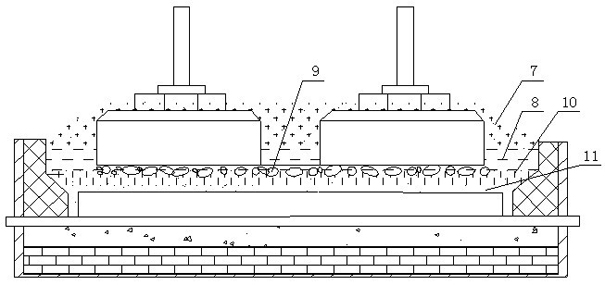

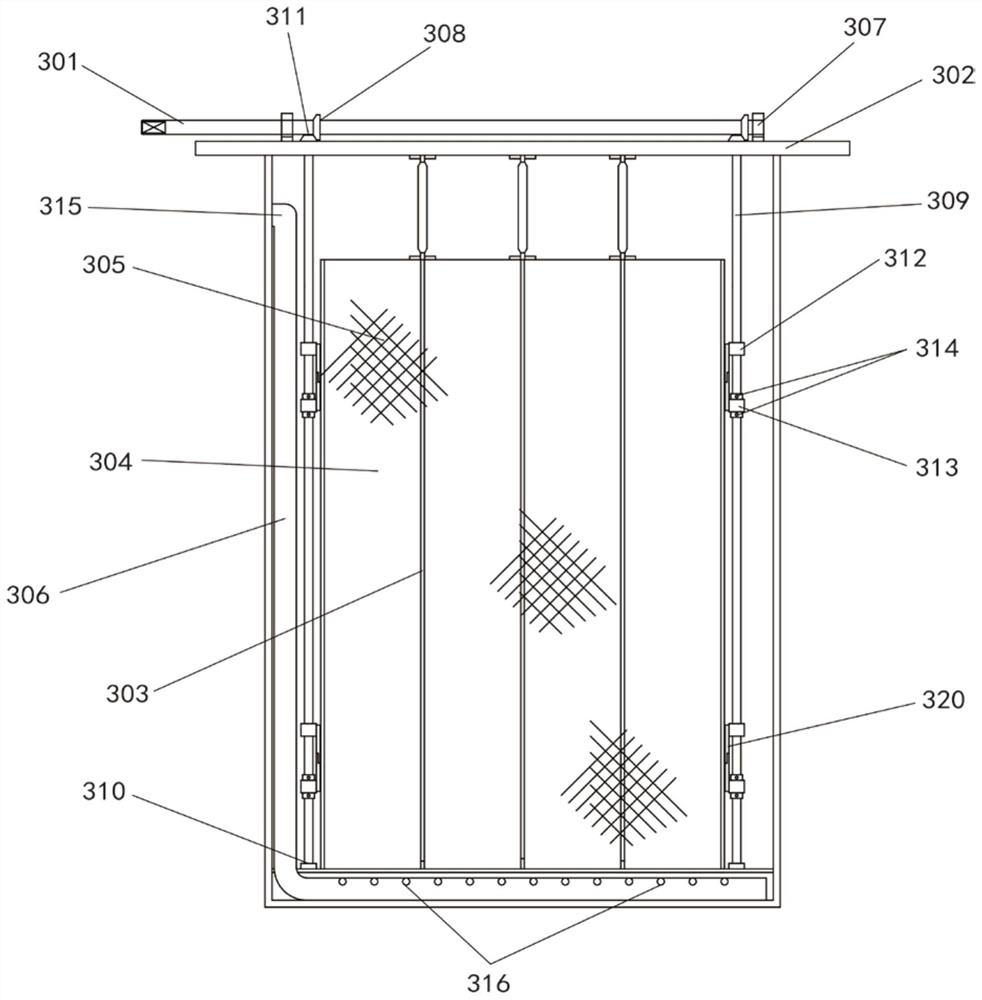

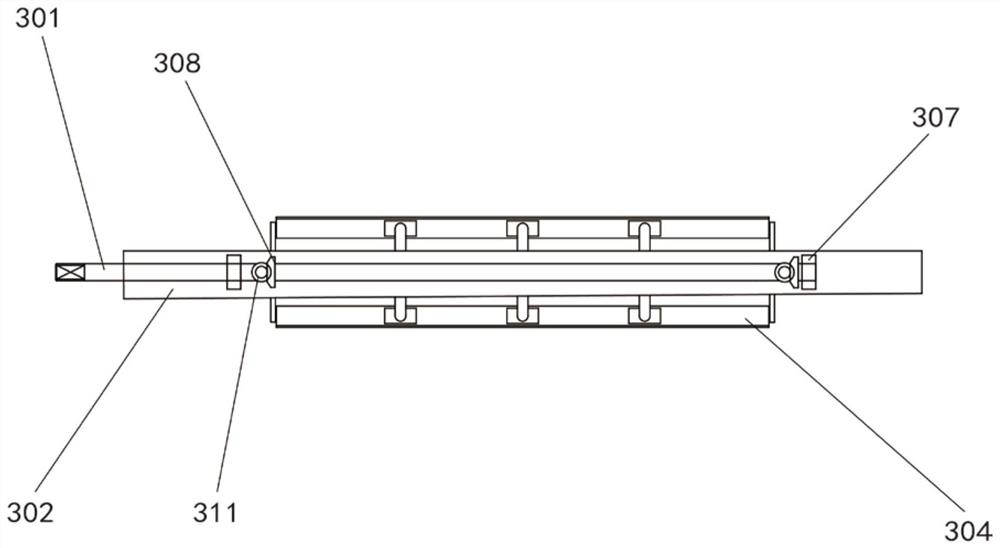

Region electrolysis prebaking aluminum cell

The invention discloses a region electrolysis prebaking aluminum cell which comprises a cathode (4), a side carbon block (5), a cell housing (6) and an anode (7), wherein at least one region segmenting plate (8) is arranged in the longitudinal direction of the cell, is used for segmenting the whole cell melt working region into a plurality of small regions, and is embedded and fixed in the side carbon block (5), an aluminum guide channel is arranged between a body of the region segmenting plate (8) or the region segmenting plate (8) and the cell, and an integral molten aluminum communicating channel is formed through the aluminum guide channel. The region electrolysis prebaking aluminum cell has the advantages of being capable of greatly reducing fluctuation of molten aluminum, being easy to install, replace and maintain, and being low in cost.

Owner:CENT SOUTH UNIV

Aluminum electrolysis bath

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

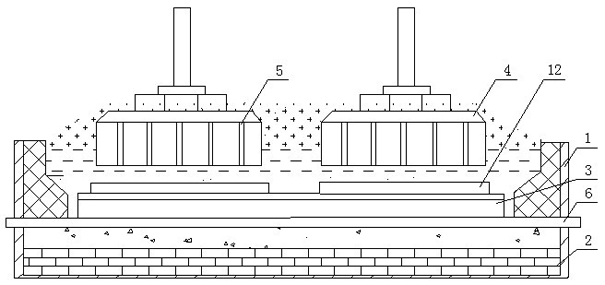

Technical method for electrolytic aluminium under 3.5 V cell voltage

InactiveCN102011146AAvoid secondary oxidation reaction intensificationReduce pole distanceAluminiumCell voltage

The invention provides a technical method for electrolytic aluminium under 3.5 V cell voltage, comprising the following steps: 1) installing at least one raised cathode of a cathode raised beam at the bottom of an electrolytic cell, wherein the width of the cathode raised beam is 15-25cm, and the height of the cathode raised beam is 10-15cm; 2) installing an anode with 8-13 air holes on the upper part of the electrolytic cell, wherein the air holes are arranged along the vertical direction and are tapered holes with bigger upper parts and smaller lower parts; 3) injecting molten electrolytes with the temperature of 950 DEG C in the electrolytic cell, and enabling the cathode and the anode to contact with the electrolyte solution; 4) dissolving sold alumina in the molten electrolytes, and introducing direct current from the anode; and 5) pumping the aluminum solution out of the electrolytic cell via a vacuum ladle, purifying and casting to obtain metallic aluminium. By utilizing the technical method in the invention, the problem of oversized thickness of an electrolytic interlayer in the electrolytic cell is solved, the cell voltage is reduced to 3.3-3.60V, and the current drain index for per ton of electrolytic aluminium is reduced by 1000kwh.

Owner:重庆天泰铝业有限公司

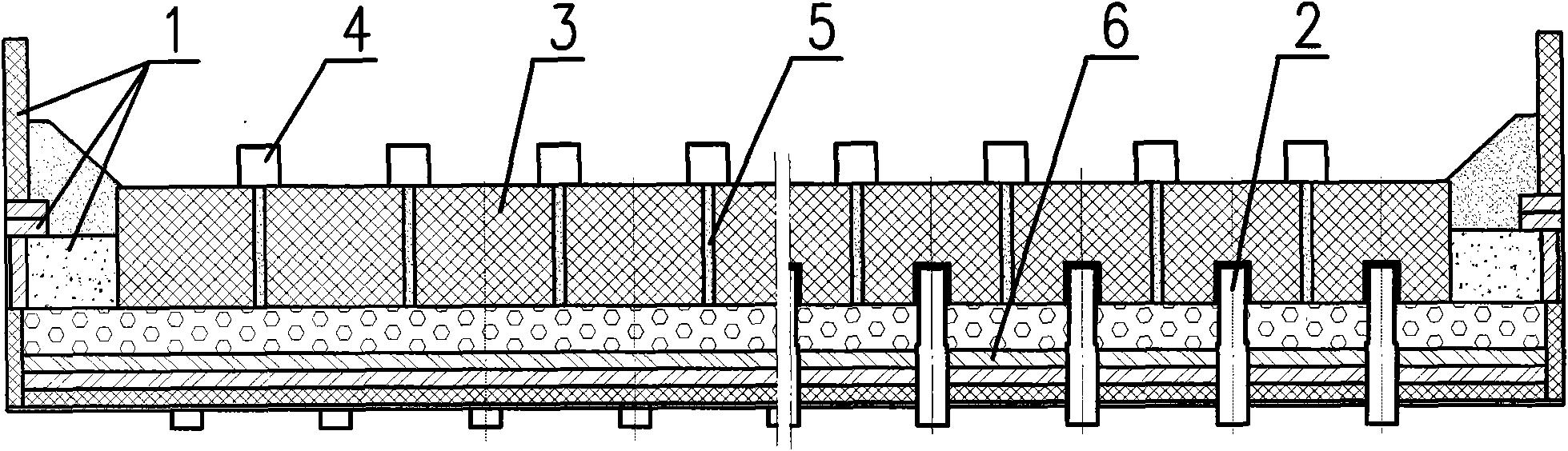

Slot base aluminium electrolysis cell cathode structure

The invention discloses a slot base aluminium electrolysis cell cathode structure, belonging to the technical field of aluminium electrolysis cell. The aluminium electrolysis cell cathode structure comprises a housing and an inner lining. Cathode carbon blocks are connected by a fastening material, the distance among cathode carbon blocks is increased, the height of the fastening material is lower than the height of the cathode carbon blocks, or distance among cathode carbon blocks is not increased, baffle plates are arranged on the upper surface of the cathode carbon blocks, cathode steel bars are vertically arranged at the bottom of the cathode carbon blocks and penetrate through the bottom of the aluminium electrolysis cell. As cathode steel bars are vertically arranged at the bottom of the cathode carbon blocks and penetrate through the bottom of the aluminium electrolysis cell, horizontal current in aluminium liquid is basically removed, stability of the aluminium electrolysis cell is enhanced, cathode conductive path is shortened and cathode drop is lowered. In the invention, a large aluminum pool is divided into a plurality of small sections, so that flow and volatility due to the action of electromagnetic force are restricted, stability of the aluminium electrolysis cell is enhanced, liquid level and polar distance of the aluminum liquid are lowered, current efficiency is enhanced, senseless power consumption is greatly reduced and energy conservation effect is very noticeable.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

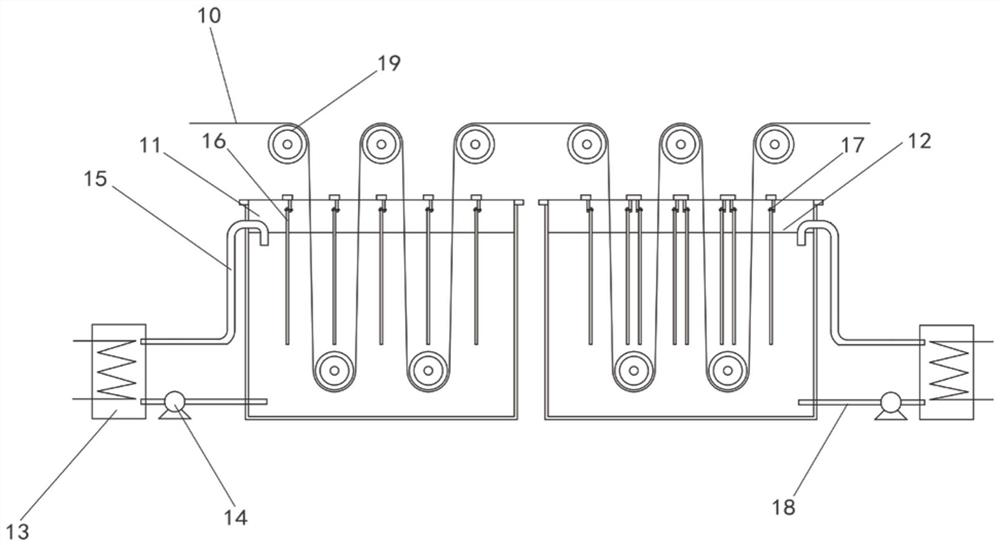

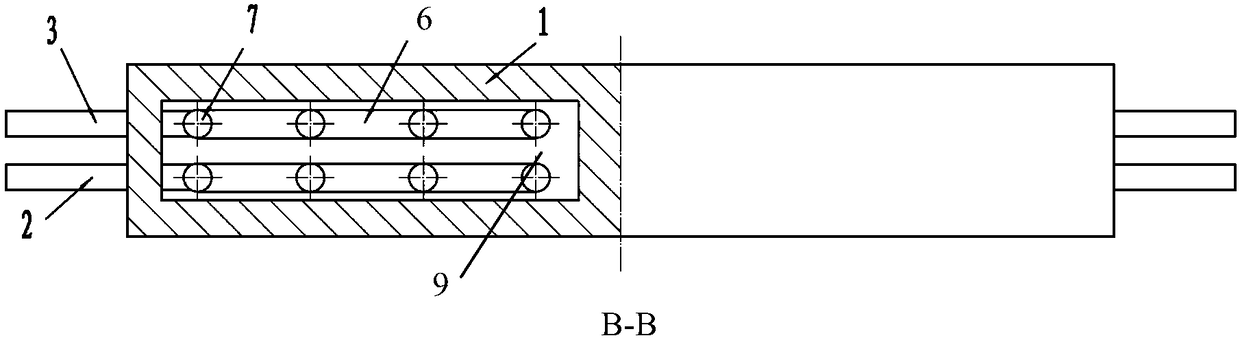

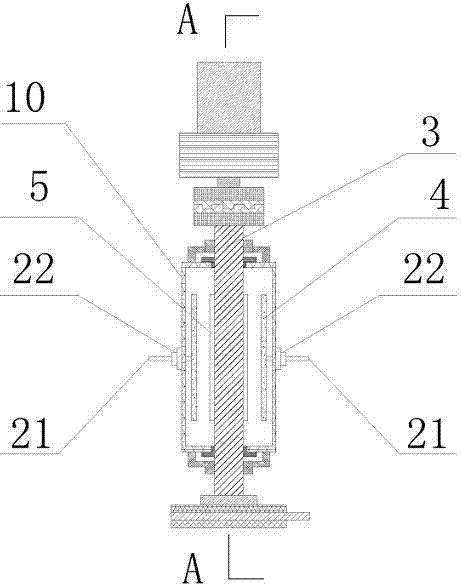

Expanded electrode applied to aluminum foil linkage enabling equipment

ActiveCN112992559APole distance adjustableReduce pole distanceCapacitor manufactureElectrolytic agentCurrent distribution

The invention discloses an expanded electrode applied to aluminum foil linkage enabling equipment. The expansion electrode comprises an electrode outer frame provided with a plurality of metal wires to achieve conduction of an external power source connected with the expanded electrode and the aluminum foil linkage enabling equipment; one or two electrode inner frames arranged on the electrode outer frame, wherein the metal wires extend to the tops of the electrode inner frames; an electrode net welded on the electrode inner frame, connected with the metal frame and used for electrode reaction; a forced circulation distribution pipe arranged on the inner side and the bottom of the electrode outer frame, connected with an electrolyte temperature regulating tank of the aluminum foil linkage enabling equipment through a liquid inlet pipe, and used for guiding electrolyte in the electrolyte temperature regulating tank into the expanded electrode; and an electrode expansion adjusting component arranged on the outer side of the electrode outer frame, respectively connected with the electrode outer frame and the electrode inner frame, and used for realizing expansion and contraction of the expanded electrode. The technical scheme of the invention has the beneficial effects that only the electrode part is redesigned, the original flat plate type electrode is changed into the box type expanded metal screen plate electrode, the electrode distance between the electrodes is adjustable, the electrode distance between the electrodes is reduced, the cell voltage can be reduced, and the electrodes have better current distribution uniformity.

Owner:上海伍源生物科技有限公司

Aluminum cell cathode structure capable of reducing horizontal current and improving current distribution

ActiveCN108396333AUniform current distributionSmall electromagnetic forcePower flowCurrent distribution

The invention discloses an aluminum cell cathode structure capable of reducing horizontal current and improving current distribution. The structure comprises a cathode carbon block and cathode current-conducting rods, one penetrating groove or two coaxial and symmetric long grooves are formed in the bottom face of the cathode carbon block, and grooves are formed in the top face of the cathode carbon block; each cathode current-conducting rod is composed of a rod body, a current conducting claw and claw heads; the current conducting claws are fixedly arranged on the top ends of the rod bodies,three or more claw heads are arranged on each current conducting claw and are located in the grooves, and the positions between the grooves and the claw heads are filled with conductors. According tostructural design, the claw heads can evenly share the current from the cathode carbon block, the current can be more evenly distributed, horizontal current is reduced, the melt interface stability isgood, the groove voltage can be reduced through reducing the electrode distance, and energy consumption reduction is achieved.

Owner:NORTHEASTERN UNIV

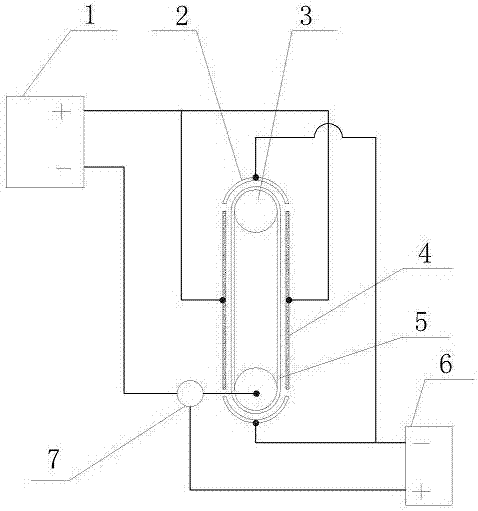

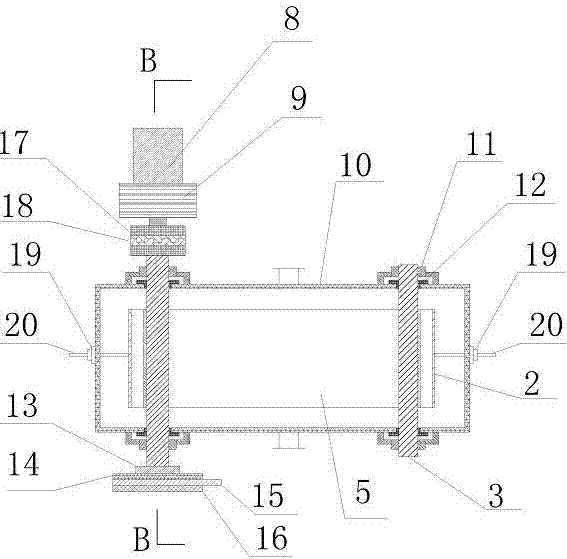

Novel electrolysis device

InactiveCN107059046AReduce electrolysis energy consumptionSmall device footprintCellsElectrode shape/formsElectricityAnode

The invention discloses a novel electrolysis device. The novel electrolysis device mainly comprises a tank body, a rotating device, a rotating powered device, an electrolysis power source and a polarity changing power source, wherein one cathode roller is arranged at each of the two ends in the tank body; a cathode plate strip sleeves the two cathode rollers; anode plates are parallelly placed on the side surfaces of the cathode plate strip; anode conductive bars connected with the anode plates are connected with the anode of the electrolysis power source; the two ends of one of the two cathode rollers are separately connected with the rotating device and the rotating powered device; the rotating powered device is connected with the cathode of the electrolysis power source, is connected with the anode of the polarity changing power source, and is provided with a change-over switch used for switching a current loop; and polarity changing semicircular arc plates connected with the cathode of the polarity changing power source are arranged on the outer edges of the cathode rollers. The novel electrolysis device has the advantages that automatic cleaning is achieved, the cathodes do not scale, electrolytic efficiency is high, pickling facilities are not required, damage of pickling to the polar plates is eliminated, the anodes are not subjected to polarity changing, and service life of the anode plates is prolonged.

Owner:王兆兵

Energy saving and consumption reduction method of aluminum reduction cell

ActiveCN101768759BSmall fluctuationNo need to change the structureUltimate tensile strengthMinor axis

The invention discloses an energy saving and consumption reduction method of an aluminum reduction cell, which is applicable to the aluminum reduction cell with current intensity higher than 60 kA. The invention comprises a retaining block which is placed on a cathode carbon block, and the retaining block can be one block or a plurality of blocks according to the size of cell capacity. The retaining block can be horizontally placed along the major axis direction or the minor axis direction of the reduction cell, the other parts at the lower part of the retaining block except support legs are opened, the height of the retaining block is not beyond the height of a molten aluminum layer of the reduction cell. In the invention, owning to the existence of the retaining block, the fluctuation in the molten aluminum layer is decreased, the polar distance is reduced, the cell voltage is decreased significantly, and the electric energy efficiency is increased.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com