Technical method for electrolytic aluminium under 3.5 V cell voltage

A process method and technology for electrolysis of aluminum, applied in the process field of electrolysis of aluminum under the voltage of 3.5V cell, can solve the problems of high voltage and high energy consumption of the electrolysis cell, reduce the pole distance and avoid the aggravation of the secondary oxidation reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

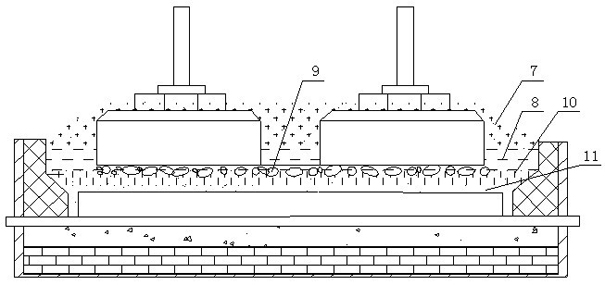

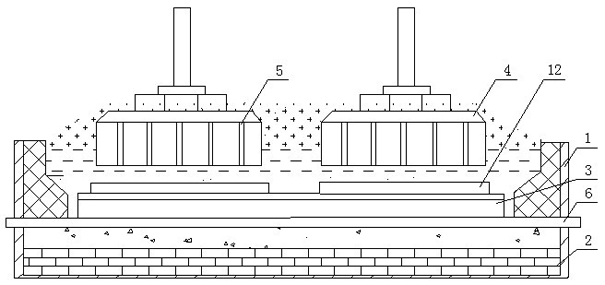

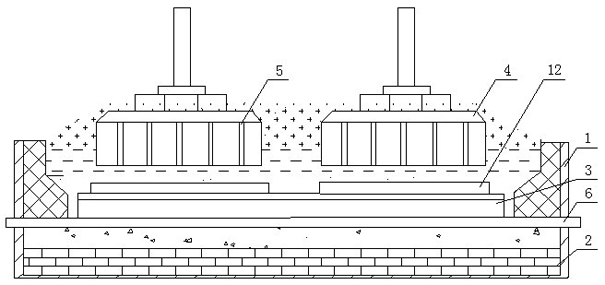

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] Such as figure 2 Shown, a kind of process method of electrolytic aluminum under 3.5V tank voltage, its steps are as follows:

[0025] 1) The cathode 3 is installed at the bottom of the electrolytic cell, the upper surface of the cathode 3 is provided with at least one raised cathode beam 12, the width of the cathode beam 12 is 15cm, 18cm, 20cm or 25cm, and the height is 10cm, 12cm, 13cm or 15cm;

[0026] 2) Install the anode 4 on the upper part of the electrolytic cell. The anode 4 is an anode carbon block with 8 to 13 air guide holes, preferably 12. The air guide holes 5 are arranged in the vertical direction and are large Lower small tapered hole;

[0027] 3) Inject 950°C molten electrolyte into the electrolytic cell, and make both cathode 3 and anode 4 contact with the electrolyte solution;

[0028] 4) Dissolve solid alumina ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com