Slot base aluminium electrolysis cell cathode structure

A technology of aluminum electrolytic cell and cathode structure, which is applied in the field of aluminum electrolytic cells, can solve the problems of limited space for improving current efficiency, loss of current efficiency, difficulty in achieving energy saving, etc., achieve shortened conductive path, improve power utilization rate, and improve cathode voltage. Reduce the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

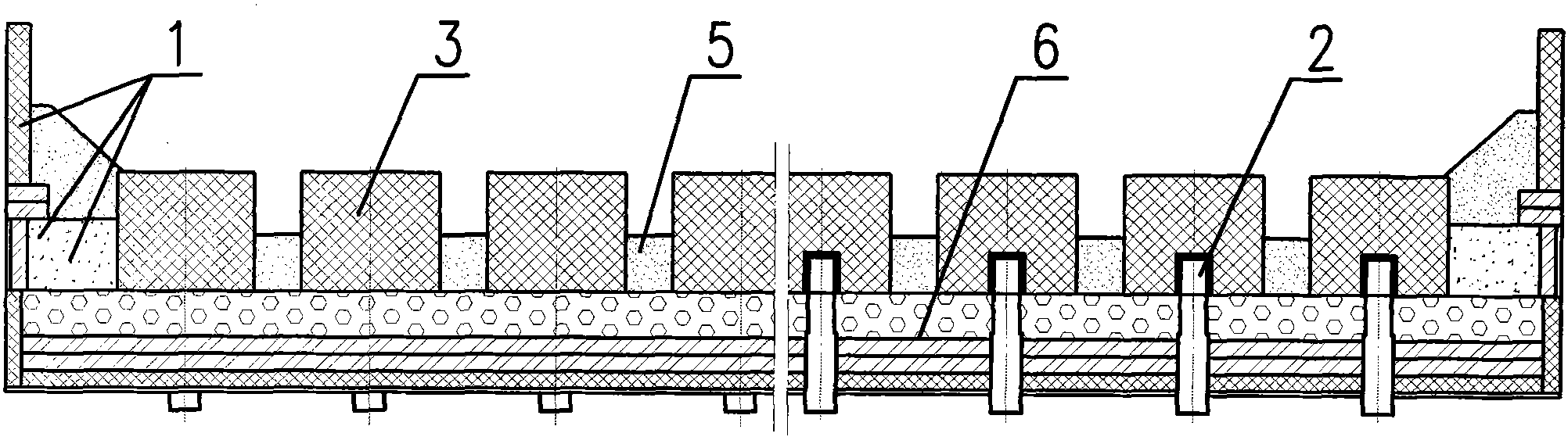

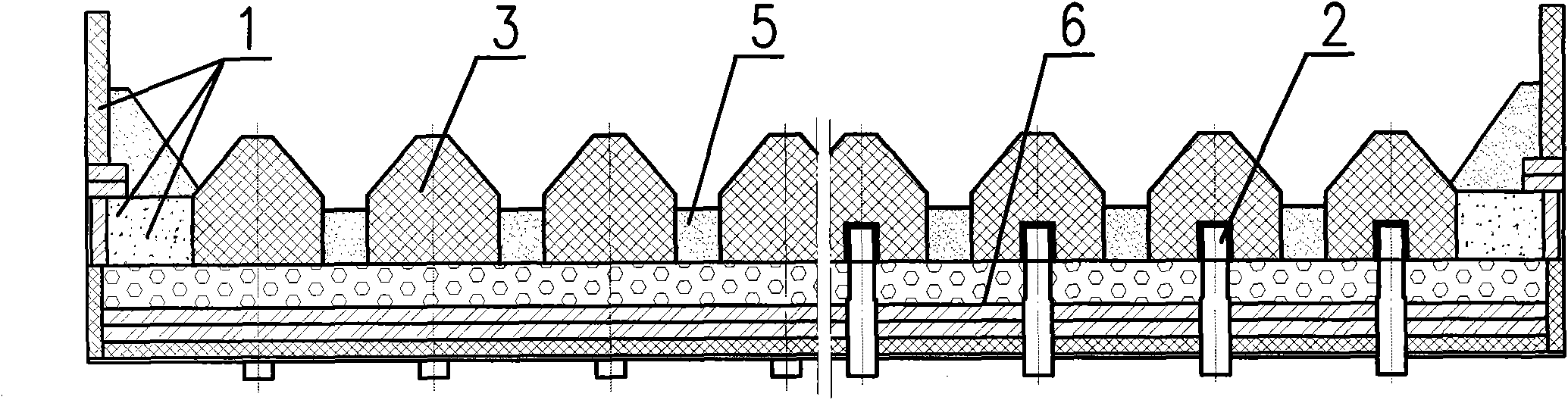

[0041] Figure 1~2 As shown, the cathode structure of the aluminum electrolytic cell is composed of the tank shell, the side lining 1, the cathode carbon block 3, the fixing material 5 between the cathode carbon blocks, and the bottom lining 6. Cathode steel rods 2 are vertically installed at the bottom of cathode carbon block 3, and 2 to 6 cathode steel rods 2 are assembled into one through the bottom lining 6 and out from the bottom of the tank. Carbon paste, magnesia bricks, silicon carbide bricks and other fastening materials 5 are used for connection. The height of the fastening material 5 is 20-450mm lower than the cathode carbon block. The end of the carbon block and the side lining 1 are tamped with castables and surrounding paste. The distance between the cathode carbon blocks 3 is 30-300 mm.

[0042] The end of the cathode carbon block and the side liner 1 are tamped with castables and surrounding paste.

[0043] Cathode steel rods 2 are vertically installed at th...

Embodiment 2

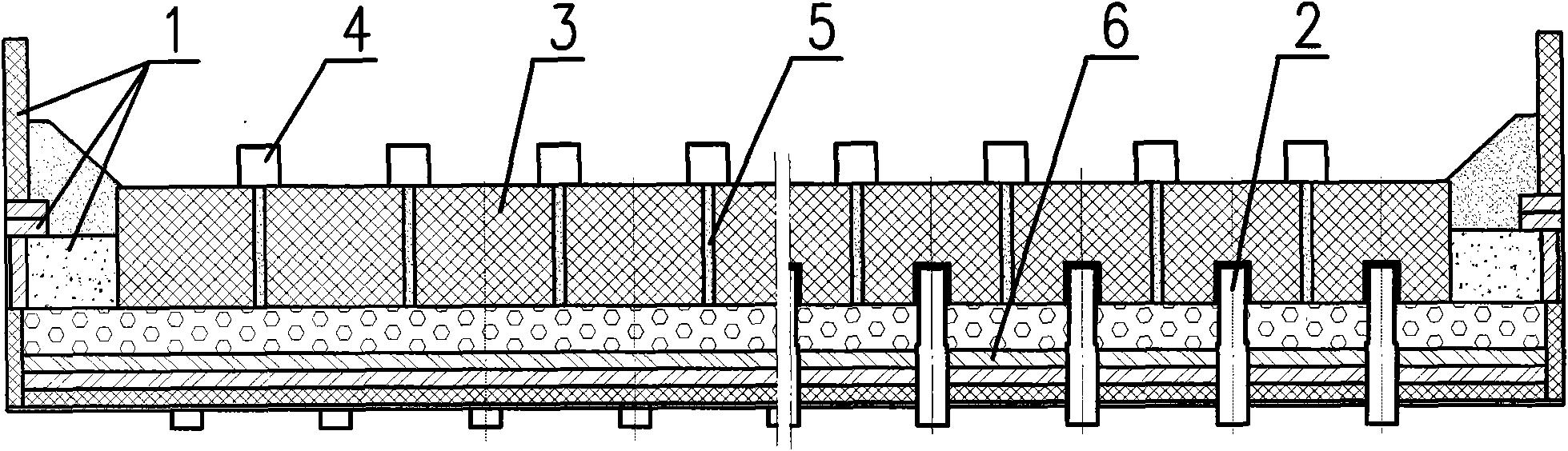

[0045] Figure 3-4As shown, the cathode structure of the aluminum electrolytic cell is composed of a side lining 1, a cathode carbon block 3, a block 4, a fixing material 5 between the cathode carbon blocks, and a bottom lining 6. Cathode steel rods 2 are vertically installed at the bottom of the cathode carbon block, and 2 to 6 cathode steel rods 2 are assembled into one through the bottom liner 6 and come out from the bottom of the tank. The installation of the cathode carbon block 3 is the same as that of the electrolytic cell currently in production. The block 3 is connected by a fastening material 5, the upper surface of the cathode carbon block 3 is a plane, and a block 4 is placed on the upper surface of the cathode carbon block. The block can be placed along the vertical or horizontal direction of the electrolytic cell. Generally, the number of stoppers 4 placed on the surface is 1-100 pieces

[0046] The end of the cathode carbon block and the side liner 1 are tamped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com