Novel electrolysis device

A technology of electrolysis device and power receiving device, which is applied in the direction of electrolysis process, electrolysis components, electrodes, etc. It can solve the problems of affecting the life of the anode, affecting the efficiency of electrolysis, and the peeling off of the anode coating, and achieves simplified pipeline layout, simple operation, The effect of reducing the footprint of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in detail.

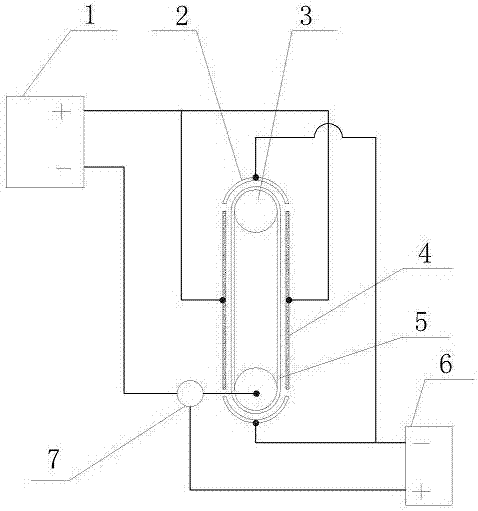

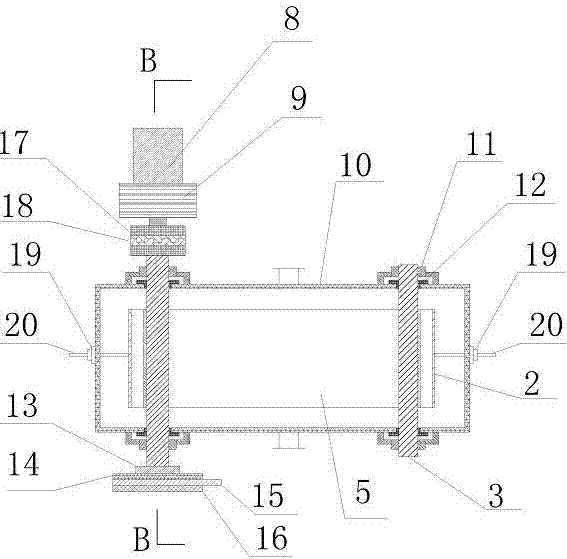

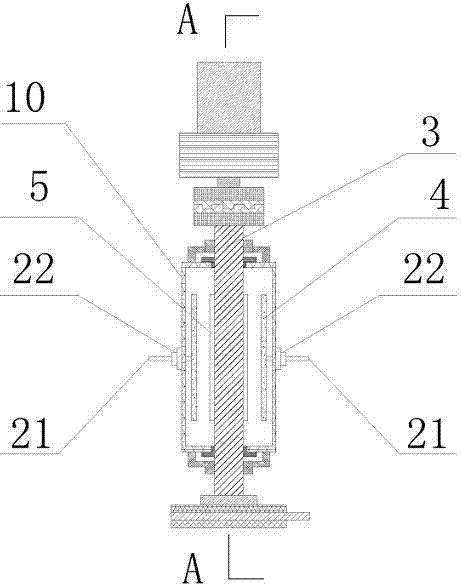

[0027] Such as figure 1 , figure 2 , image 3 A new type of electrolysis device shown mainly includes a tank body 10, a rotating device, a rotating power receiving device, an electrolysis power supply 1, and an inverted pole power supply 6. There is a cathode cylinder 3 at both ends of the tank body 10. A cathode roller 3 is covered with a cathode plate belt 5, the cathode plate belt 5 is connected end to end to form a closed ring belt and is tensioned by two cathode rollers 3, and the two sides of the cathode plate belt 5 are parallel with the anode plate 4, The anode conductive strip 21 connected to the anode plate 4 extends out of the tank body 10 through the seal 22 and is connected to the positive pole of the electrolysis power supply 1, and the two ends of the two cathode cylinders 3 extend out of the tank body 10 through the shaft seal 12 and are connected to the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com