Sodium hypochlorite disinfectant generator

A sodium hypochlorite and disinfectant technology, applied in the direction of cells, electrolysis process, electrode shape/type, etc., can solve the problems of slow production speed of sodium hypochlorite disinfectant, production environment impact, no chlorine gas treatment, etc., achieve fast manufacturing speed and simplified operation steps , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

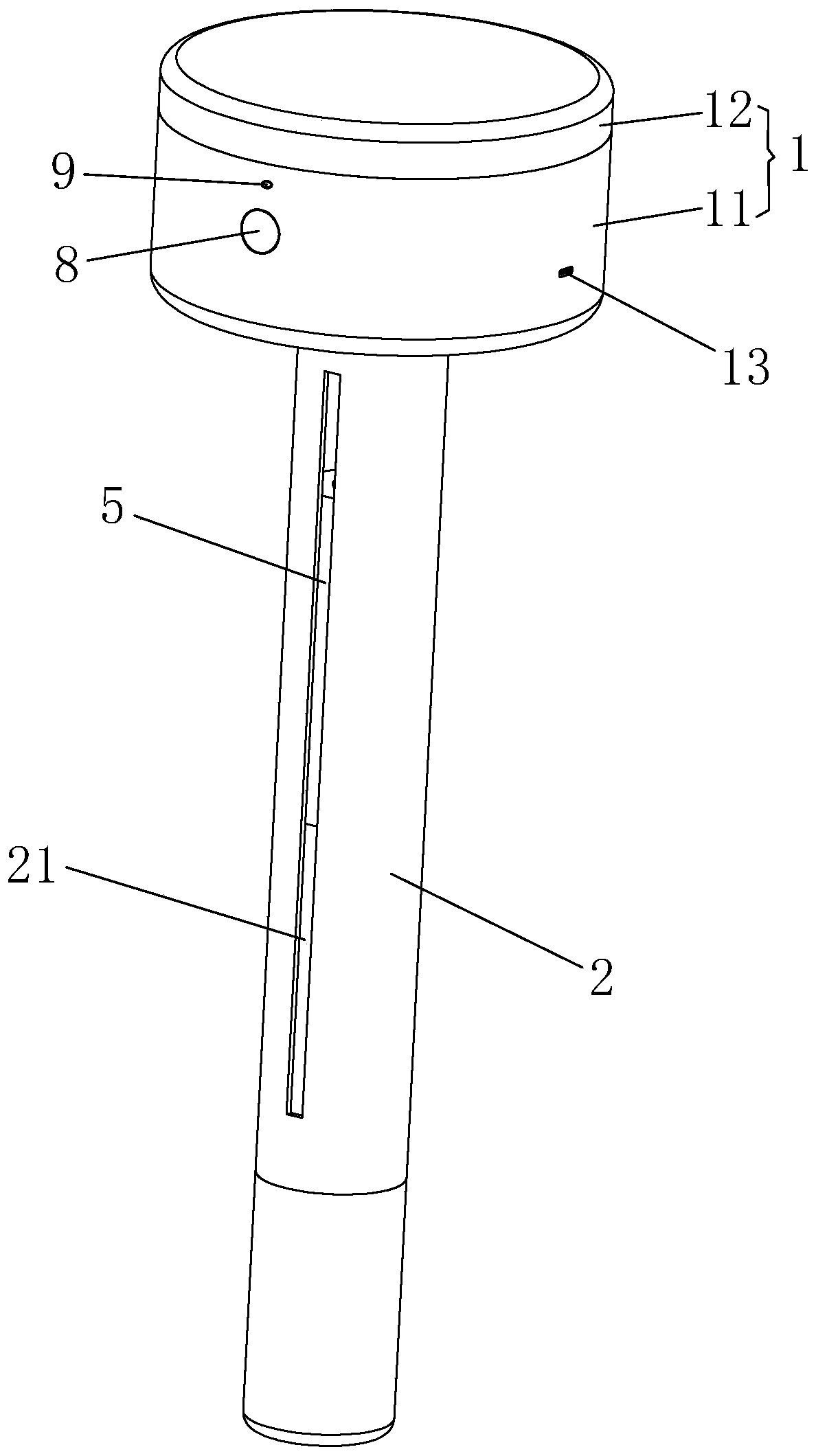

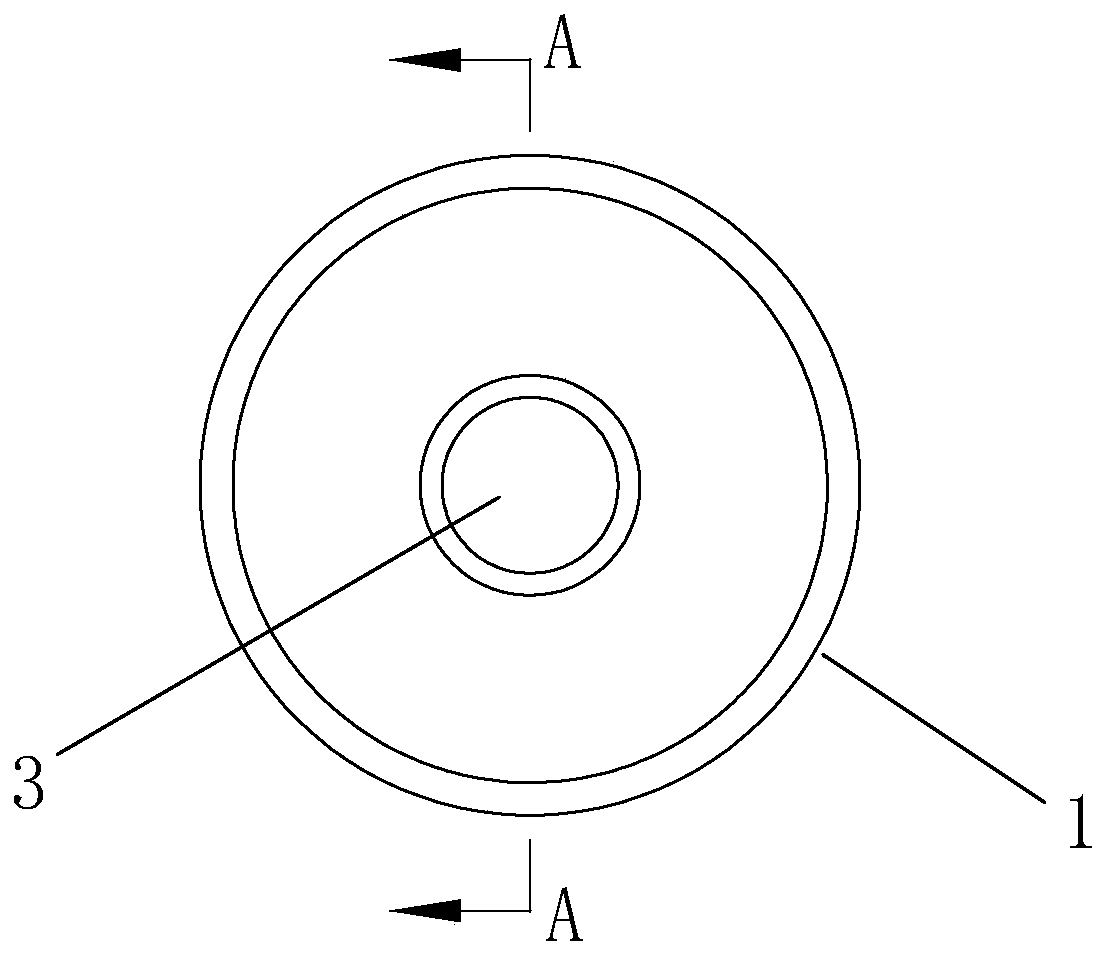

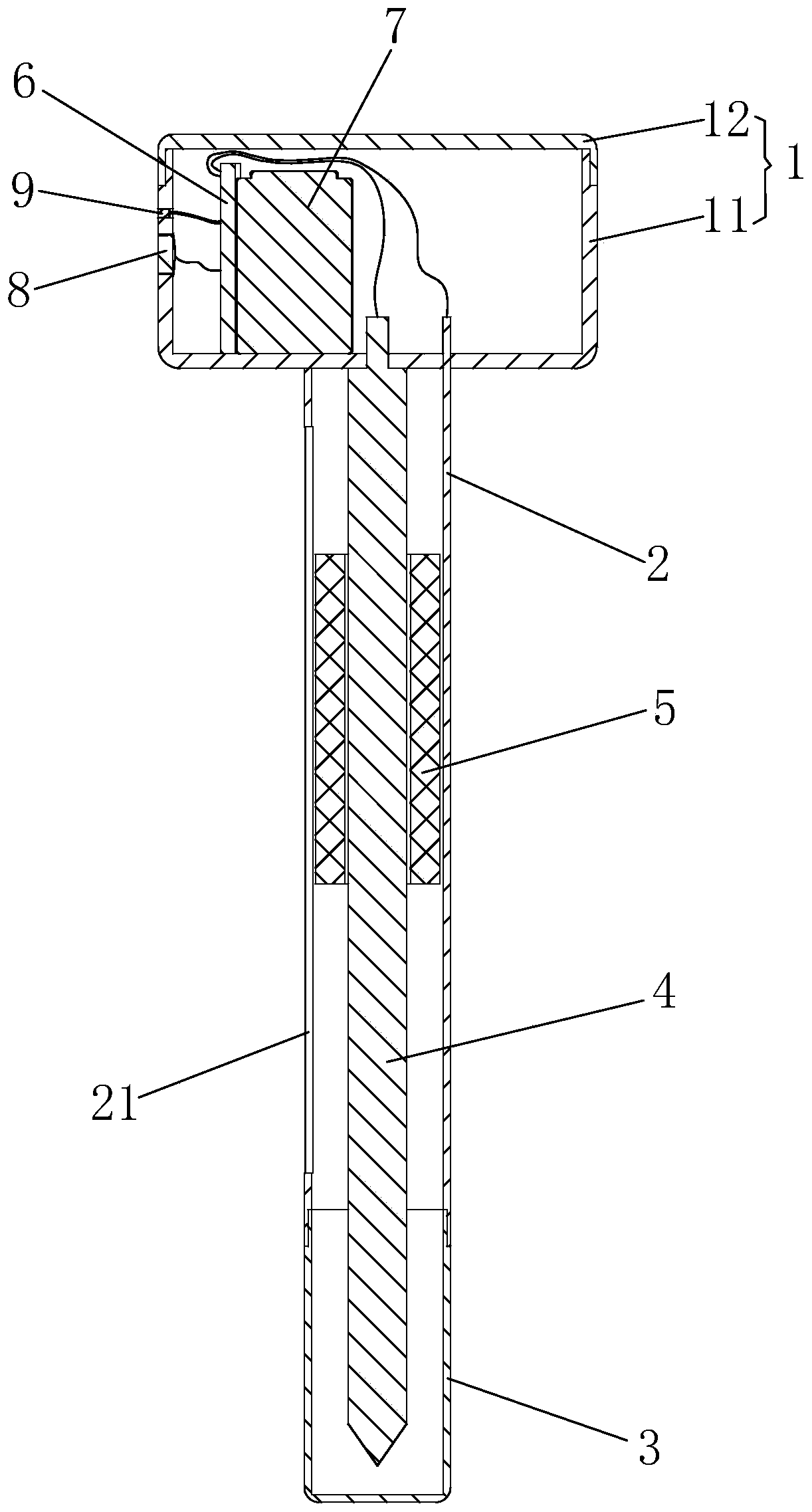

[0035] Embodiment one, Figure 1 to Figure 3 Shown, a kind of sodium hypochlorite disinfectant generator comprises a supporting shell 1, one end of a tubular body 2 is connected on the supporting shell 1, and the other end of the tubular body 2 is connected with a bucket body 3 containing sodium chloride, The outer peripheral surface of the tubular body 2 is provided with a through hole 21 communicating with its inner hole, and a rod-shaped electrode 4 is fixedly connected to the support shell 1, and the rod-shaped electrode 4 is located in the middle of the inner hole of the tubular body 2; the tubular body 2 becomes an electrode, When the tubular body 2 and the barrel body 3 equipped with sodium chloride 10 are extended into the water together, the rod-shaped electrode 4 and the tubular body 2 are electrolyzed by power supply;

[0036] The tubular body 2 is connected to the barrel body 3 by screwing; one end of the tubular body 2 is fixedly connected to the supporting shell ...

Embodiment 2

[0044] Embodiment two, Figure 5 to Figure 7 As shown, a sodium hypochlorite disinfectant generator is different from Embodiment 1 in that a storage chamber 14 is provided on the side of the support housing 1 close to the tubular body 2, and the storage chamber 14 communicates with the tubular body. The inner hole of the body 2 and the outside of the tubular body 2, the material storage chamber 14 is equipped with a material 15 for absorbing chlorine gas. The chlorine-absorbing material 15 can be selected from activated carbon, diatomaceous earth, alkali and other substances, so that a small amount of chlorine generated during the electrolysis process can be absorbed by the chlorine-absorbing material 15, further reducing the impact on the operating environment.

Embodiment 3

[0045] Embodiment three, Figure 8 to Figure 10 As shown, a sodium hypochlorite disinfectant generator is different from Embodiment 1 in that: when the barrel body 3 is a transparent body, the barrel body 3 is screwed by a section of pipe body 31 and a transparent barrel body 32 As a result, the section of the tubular body 31 is screwed to the tubular body 2 , and only one rod-shaped electrode 4 is fixedly connected to the supporting shell 1 , and the section of the tubular body 31 is connected to the tubular body 2 to form an electrode.

[0046] The lower shell 11 is also provided with a supporting surface 111 for placing the generator, and the supporting surface 111 is a plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com