Method and apparatus for cleaning containers to be sealed and containing a filler from oxygen gas

a technology of oxygen gas and filler, which is applied in the direction of packaging, packaging protection, packaging under special atmospheric conditions, etc., can solve the problem of very time-consuming process and achieve the effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

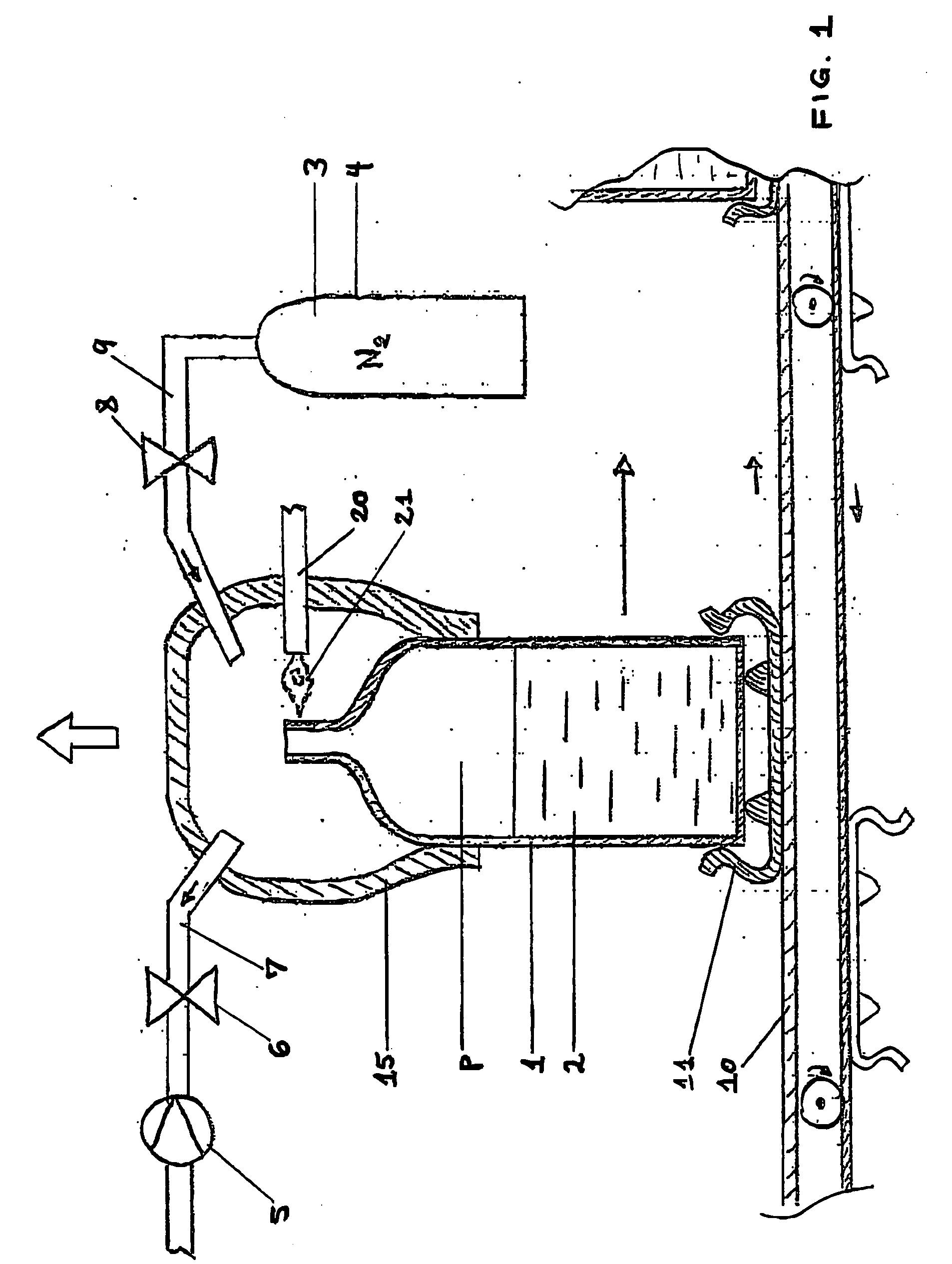

[0106]FIG. 1 shows a schematic cross-section of a detail of an apparatus for cleaning filled containers. A container 1 containing a liquid filler 2, e.g., an aqueous solution of a drug, which is sensitive to oxidation, is helt in a holder 11 of a conveyor 11. The small arrows indicate the directions of movement of container 1 and conveyor 10. On top of the container a temporary seal 15 has been placed, e.g., a cap with rubber lips. Through a gas line 7, in which a valve 6 is arranged, gas, typically ambient gas, contained in the container 1, can be removed from the container 1 by means of a pump 5. By means of this evacuation, a pressure p in the container 1 is reduced to about 50 mbar. Thereupon, Nitrogen gas 3 from a gas cylinder 4 is filled into the container via a gas line 9 in which a valve 8 is arranged. Either then the container 1 is sealed by means of a sealing apparatus 20 having a flame 21 (sealing by melting), or the container 1 is sealed after another evacuation of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com