Patents

Literature

1157 results about "Sodium hypochlorite solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium Hypochlorite is a chemical compound with the formula NaOCl. Sodium hypochlorite solution, commonly known as bleach is frequently used as a disinfectant and as a bleaching agent.

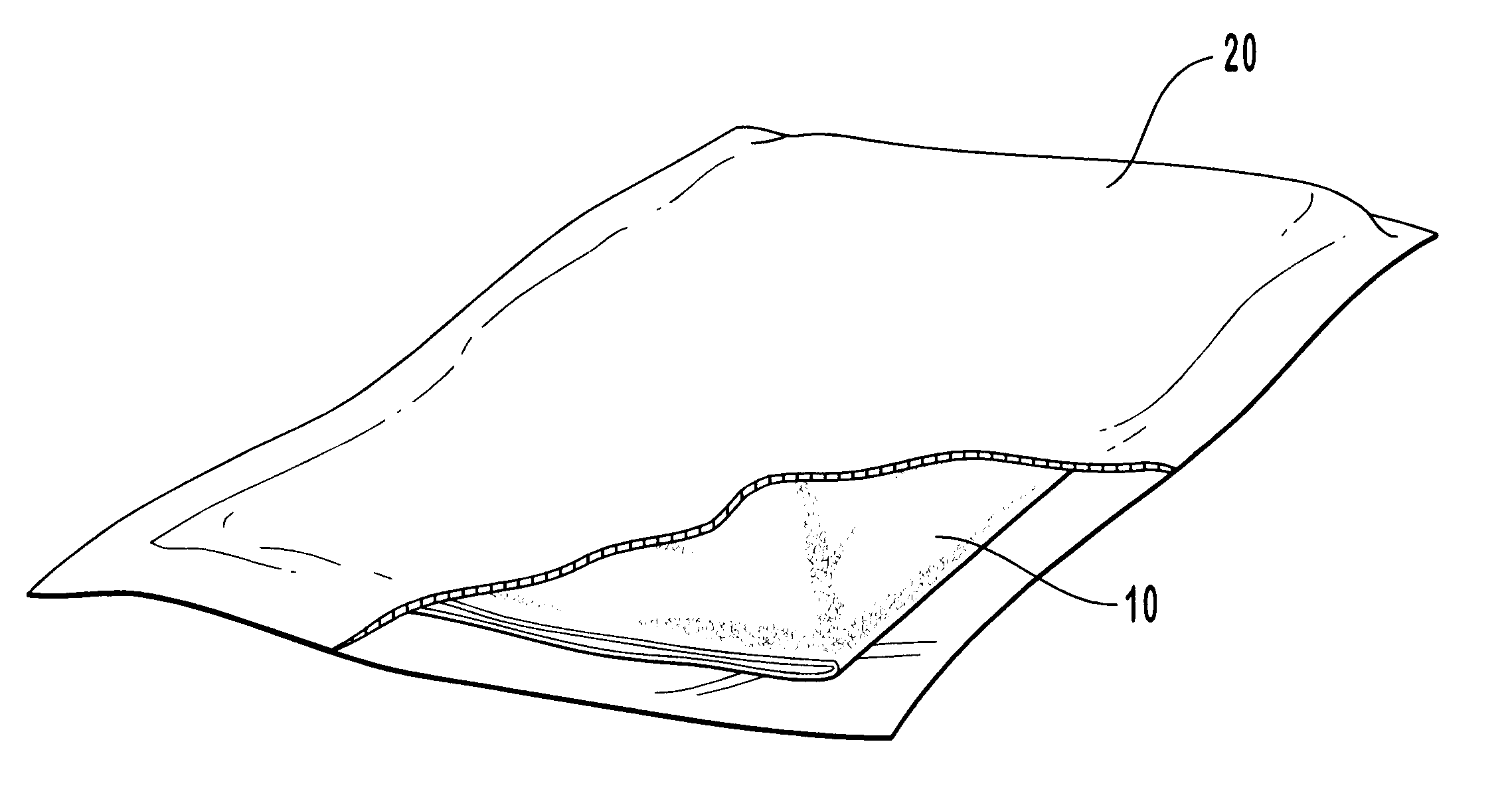

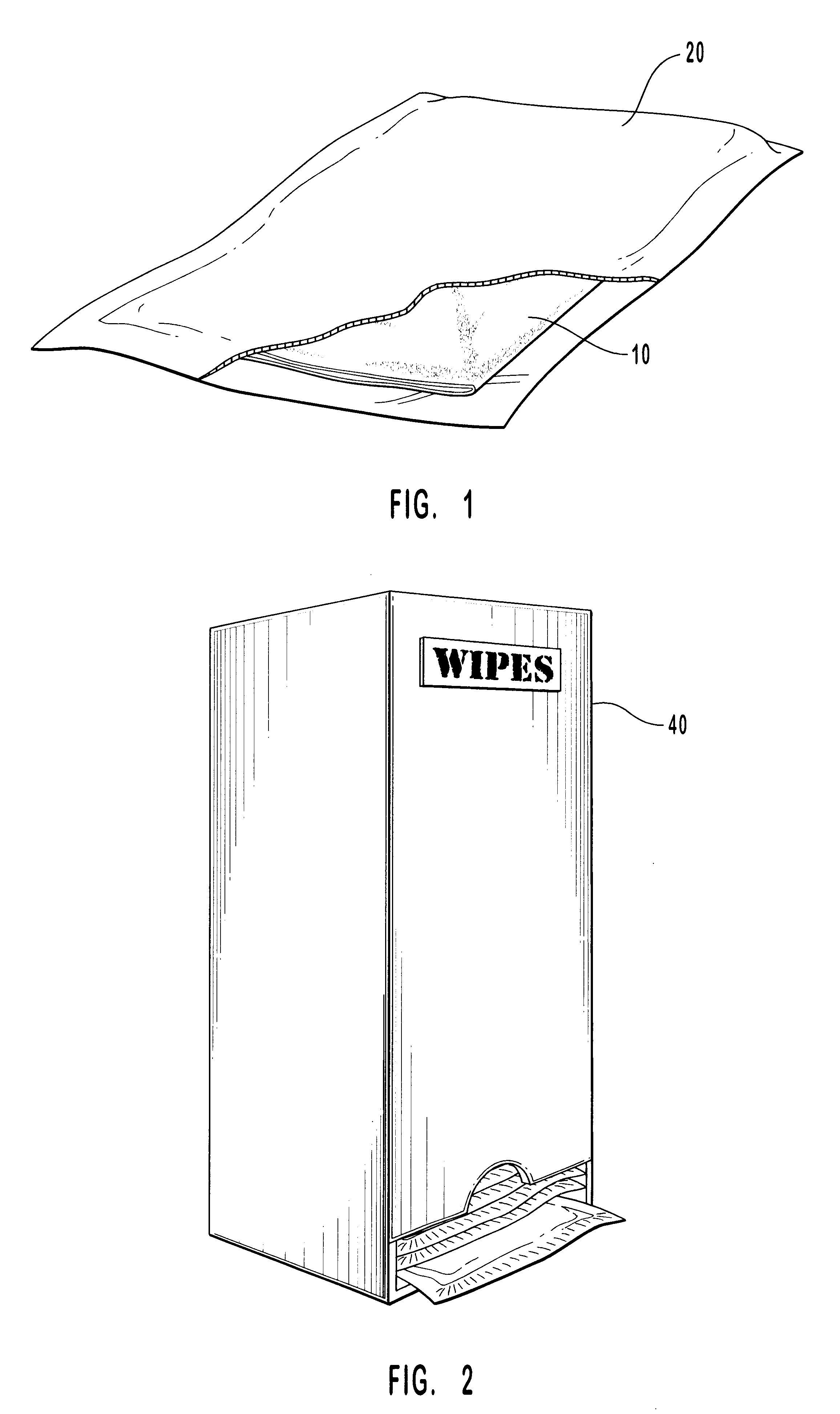

Topical, non-cytotoxic, antimicrobial hydrogel with thixotropic properties

InactiveUS6333054B1Reduce apparent viscosityImprove distributionElectrolysis componentsInorganic active ingredientsCytotoxicitySodium hypochlorite solution

A thixotropic, non-cytotoxic, topical hydrogel that contains a proven safe and effective, broad spectrum, antimicrobial agent based on a unique electrolytically derived sodium hypochlorite solution.

Owner:AMUCHINA

Process for removing oil from solid materials recovered from a well bore

InactiveUS6846420B2Low costLower oil levelHollow article cleaningFluid removalSodium hypochlorite solutionResidual oil

The present invention provides a process and an additive package for removing oil from solid material recovered from a well bore, e.g., drill cuttings and produced sand. In this process, the solid material is passed from the well bore to a separation zone. An aqueous acidic solution containing a polymer substituted with an amino group is introduced to the separation zone containing the solid material along with a halogenating agent and optionally one or more surfactants. The polymer, halogenating agent, and optional surfactant constitute the additive package. The polymer substituted with an amino group is preferably chitosan, and the halogenating agent is preferably a sodium hypochlorite solution. The mixture formed in the separation zone is agitated to cause a product of a reaction between the polymer and the halogenating agent to contact the solid material and remove residual oil therefrom.

Owner:HALLIBURTON ENERGY SERVICES INC

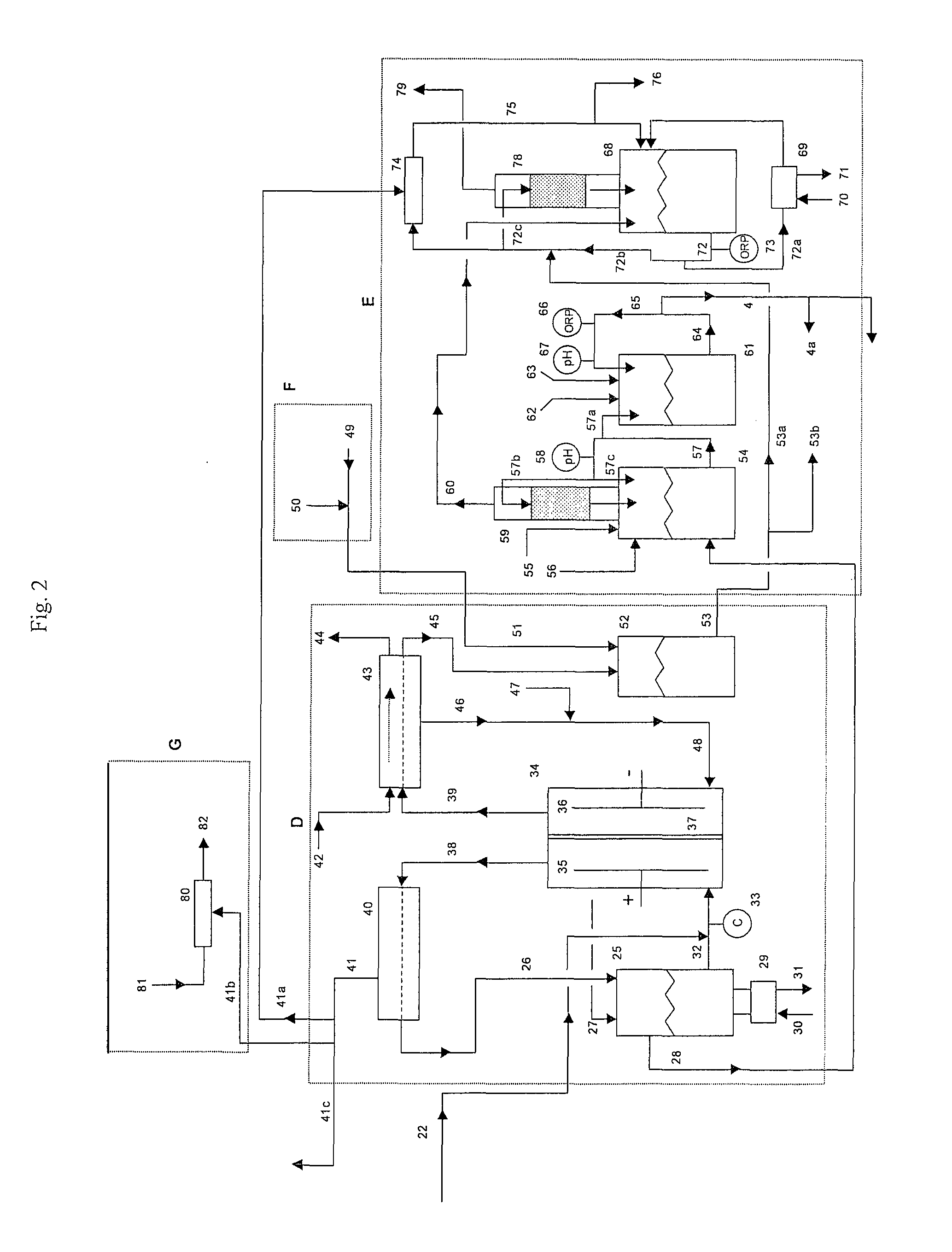

Process for the on-site production of chlorine and high strength sodium hypochlorite

ActiveUS20070251831A1Reduce hardnessGuaranteed uptimeCellsPhotography auxillary processesElectrolysisBleach

The present invention relates to a novel economical on-site electrochemical based membrane cell based process with the capability of producing high strength sodium hypochlorite and / or elemental chlorine gas in any ratio as required by the needs of a water or wastewater treatment plant. The system is compact and modular, using membrane cell based electrolyzers and utilizing novel process modifications and sensors to allow for the unattended control and safe operation of the process. The process allows the operator to produce elemental chlorine gas and sodium hypochlorite in any product ratio, such that 5% to 100% of the total chlorine produced by the process can be converted to high strength bleach. The process has the flexibility to produce stable high quality, low to high strength sodium hypochlorite solutions in concentrations ranging from about 2 to 15% trade as NaOCl.

Owner:ELECTROLYTIC TECH CORP

Sodium hypochlorite gel composition

A gel composition including a sodium hypochlorite solution; at least one viscosity-enhancing agent; and at least one electrolyte is disclosed. Methods of making the composition, methods of disinfecting, and methods of treating are also disclosed.

Owner:ROGOZINSKI WALLACE J

Disinfectants to eradicate viral diseases such as HIV and Hepatitis

InactiveUS6387384B1Efficient killingEffective distributionBiocideDead animal preservationViral diseaseDisinfectant

The present invention is directed to sodium hypochlorite solutions, solids, sprays, gels, powders and bandages to sanitize or disinfect against the harmful effects of diseases such as HIV or hepatitis.

Owner:PROBERT DAVID D +1

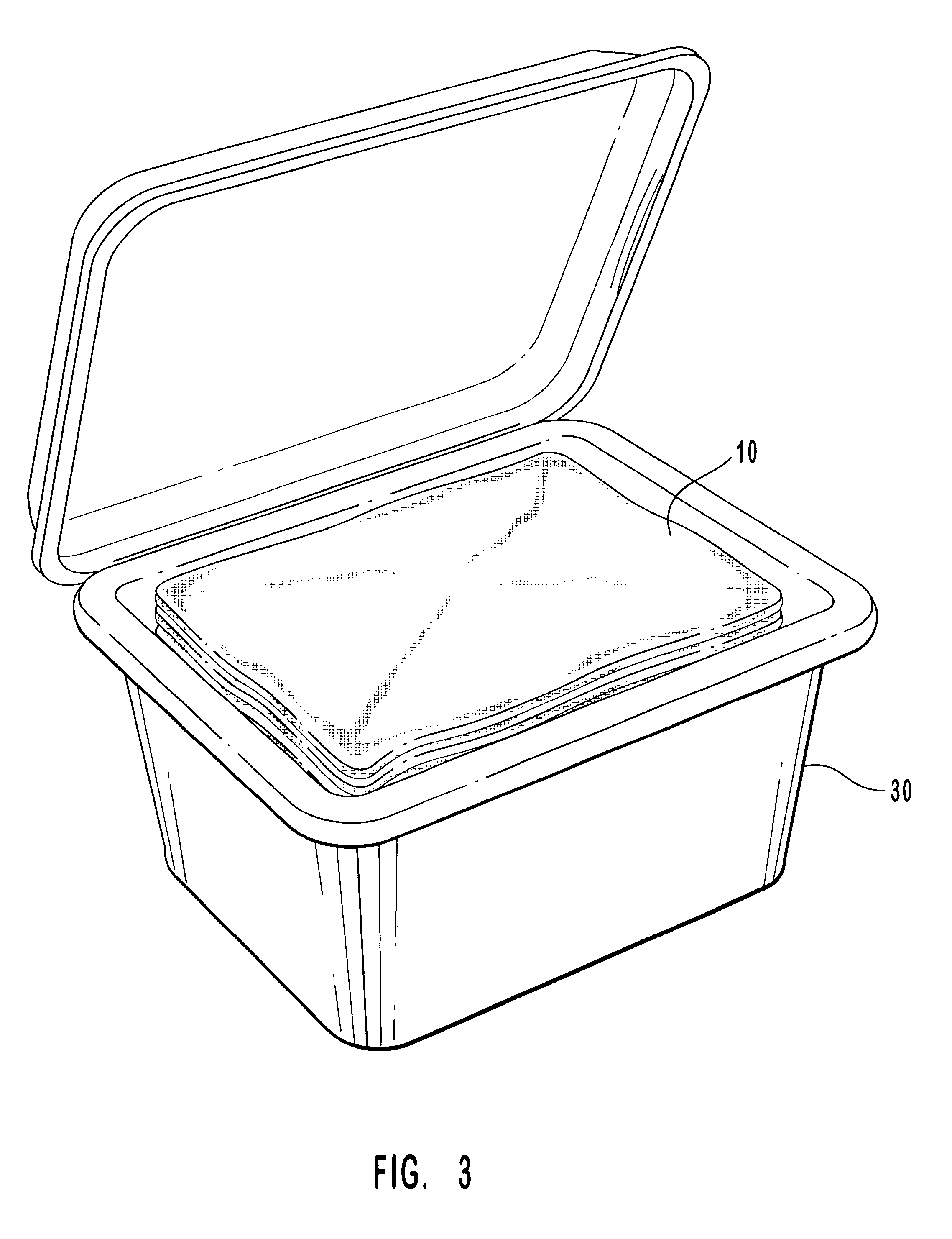

Aluminum electrolysis cell waste cell lining processing method based on chemical precipitation and redox reaction

ActiveCN105327933AReduce processing costsIncrease productivitySolid waste disposalProcessing costFire resistance

The invention discloses an aluminum electrolysis cell waste cell lining processing method based on chemical precipitation and redox reaction. A waste cell lining is crushed and ground to reach the granularity of 1-10 mm and then input into an oxidation reaction pool; a sodium hypochlorite solution is added according to the proportion 1.2-2.0 times of the theoretical value, the alkalescent pH value is controlled to be 7.0-8.5, dangerous element cyanide has a redox reaction with the sodium hypochlorite solution and then is removed, and the reaction time is 0.5-1.0 h; an anti-corrosion sieve is used for filtering out residues after the redox reaction and the residues are put into a precipitation reaction pool; whitewash with the concentration 0.8-1.0 time of the saturation concentration value is added into the precipitation reaction pool, and the residues are soaked for 1.0-1.5 h, are combined with fluoride for reaction and then generate indissolvable CaF2; the anti-corrosion sieve carries out filtering after the precipitation reaction, and obtained filtrate can serve as raw materials for the sodium carbonate industry and aluminum oxide industry; the filtered-out final residues are harmless and can serve as raw materials used for road construction, buildings, cement, fire resistance and other industries. The aluminum electrolysis cell waste cell lining processing method based on chemical precipitation and redox reaction is simple and convenient to implement, low in processing cost and high in production efficiency and does not need an incinerator or other combustion equipment.

Owner:内蒙古泓旺铝业有限责任公司

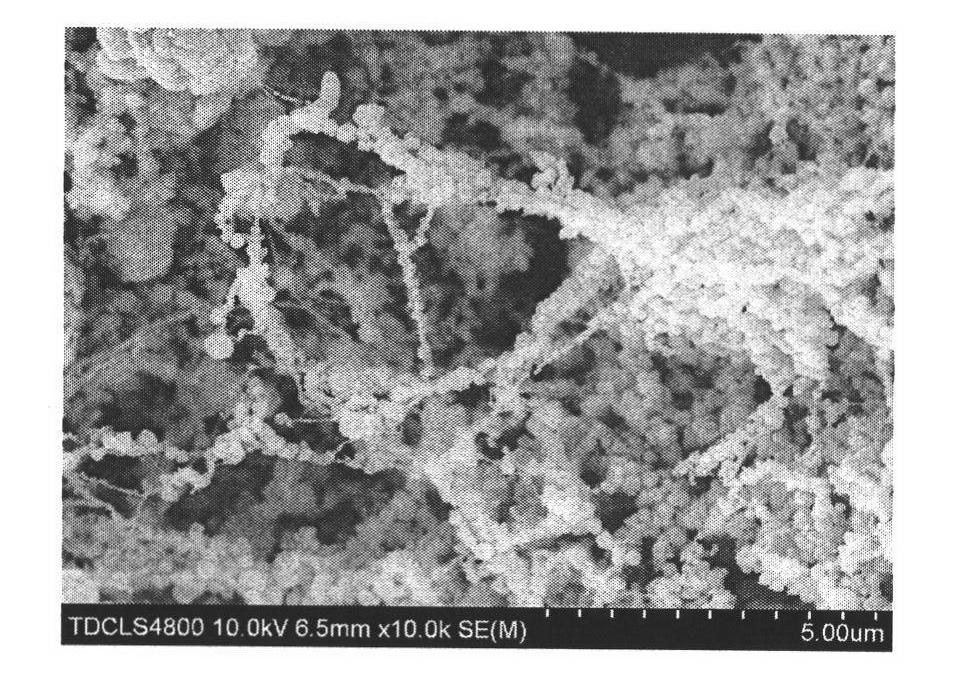

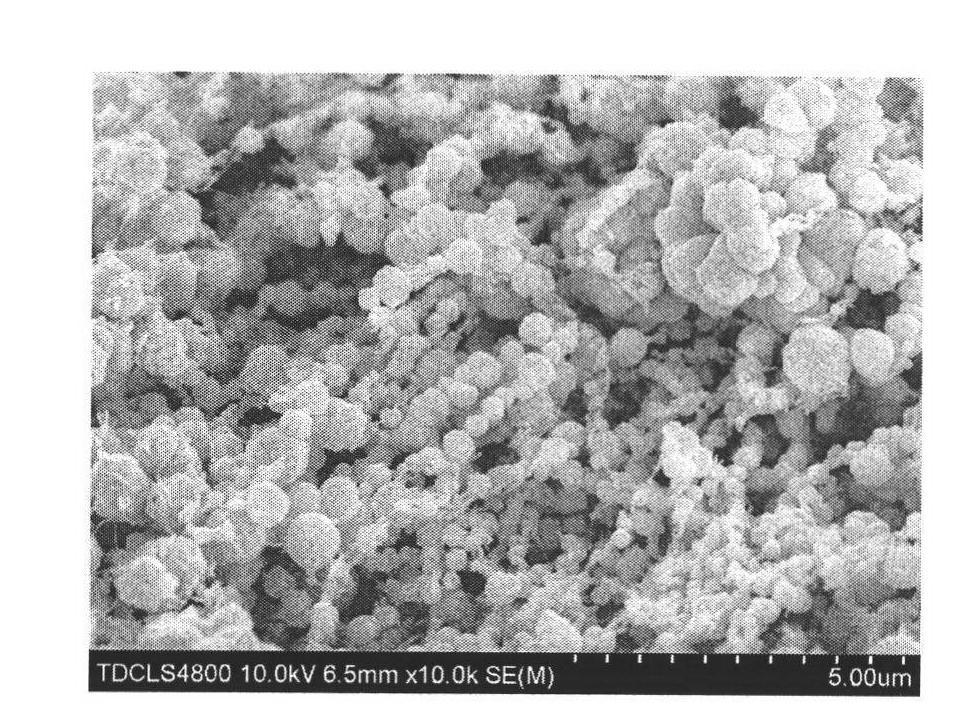

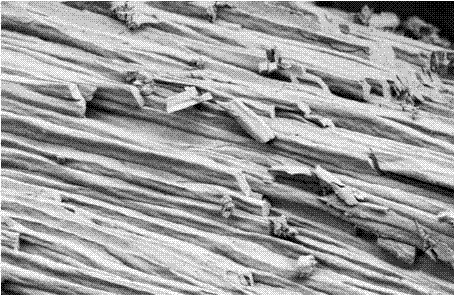

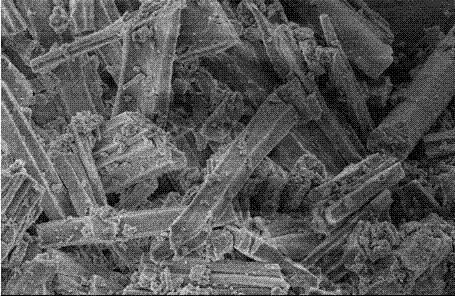

Preparation method of nano-cellulose

The invention discloses a preparation method of nano-cellulose, comprising the following steps of: firstly, swelling the raw material cellulose by aqueous alkali, soaking for a while, centrifugally separating out cellulose, and washing by deionized water till the filter liquor is neutral; dispersing the separated cellulose in water, adding sodium bromide, 2, 2, 6, 6-tetramethyl piperidine-1-oxide and sodium hypochlorite solution, carrying out an oxidation reaction under sonic oscillation, centrifugally separating after reaction, and carrying out freeze drying treatment on suspension liquid to obtain the nano-cellulose powder. Compared with the prior art, the preparation method is incompact in cellulose structure, can enlarge the unit cell distance, and can improve the reaction accessibility after the raw material cellulose is pretreated, so that the oxidation reaction efficiency can be improved, and the product yield can be obviously improved; the oxidation reaction conditions are mild, and are easy to control, and the product quality can not be influenced due to the fact that only a small quantity of sodium chloride and minute quantity of oxidizing agent are mixed in a reaction system after the reaction; and the sonic oscillation is adopted in the process of reaction, so that the oxidation reaction speed can be accelerated, and the reaction time can be obviously shortened.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

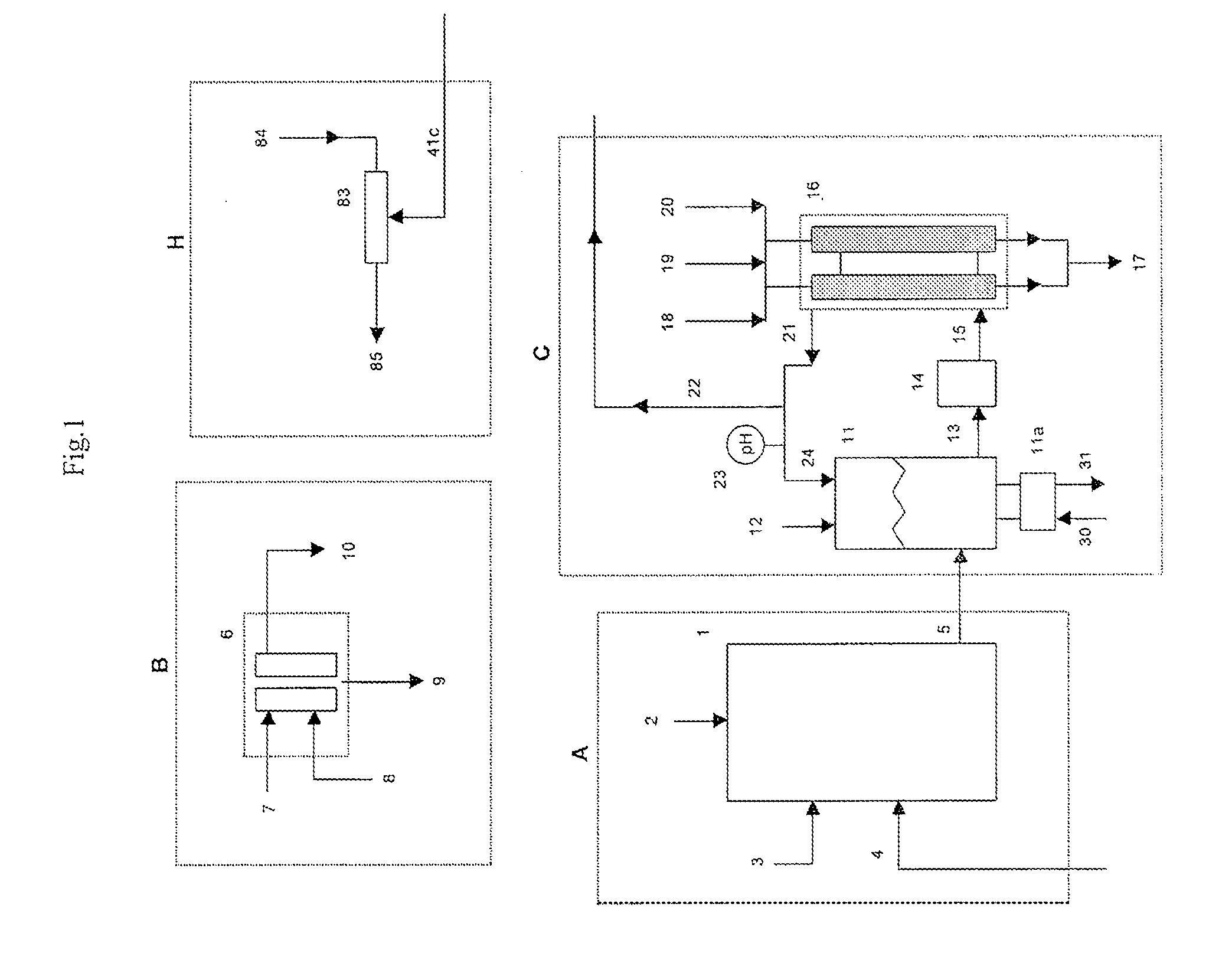

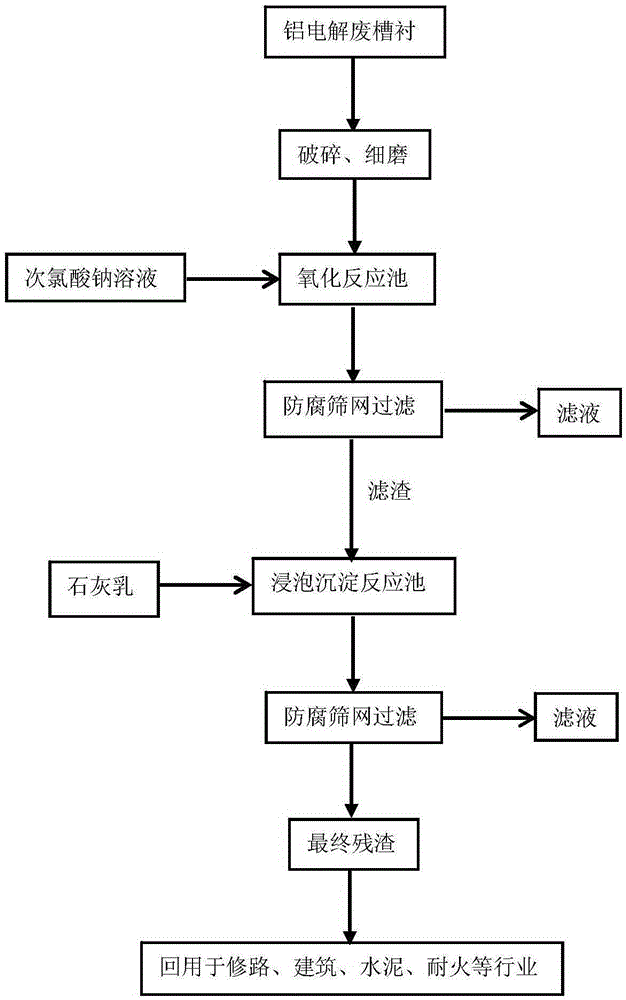

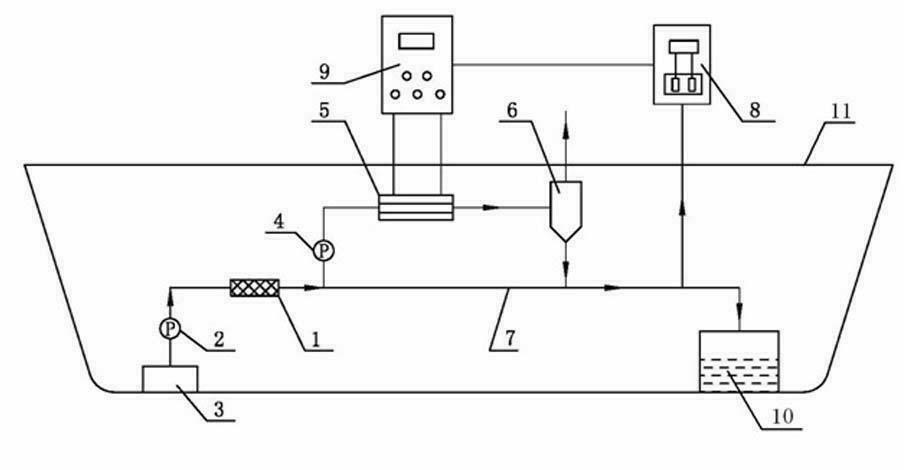

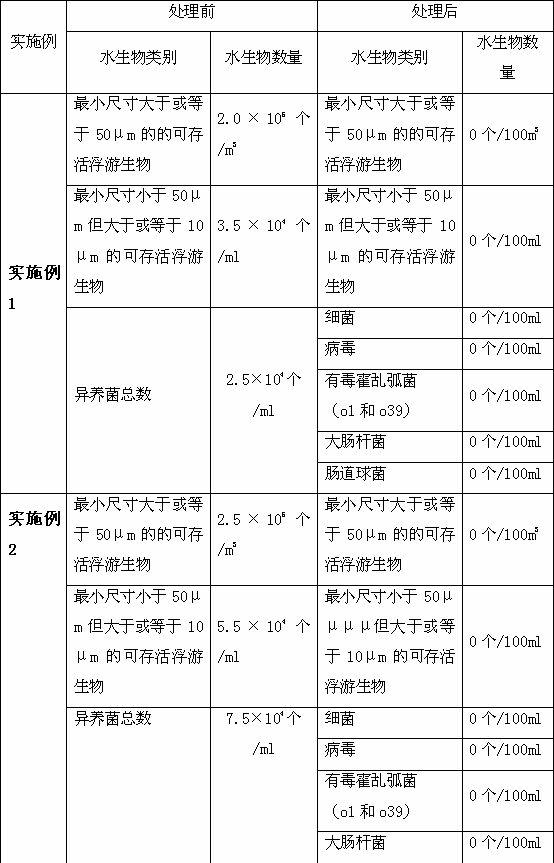

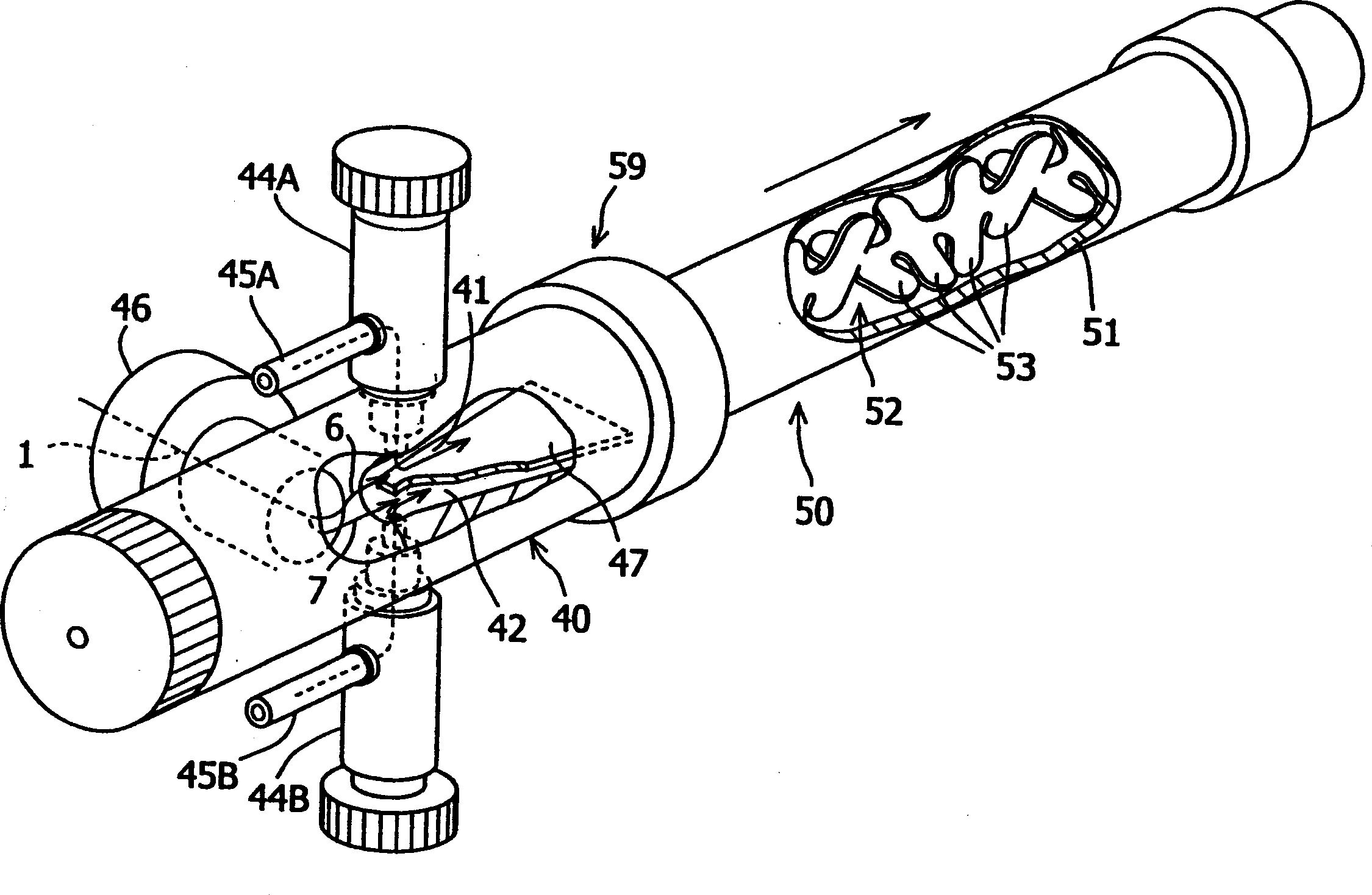

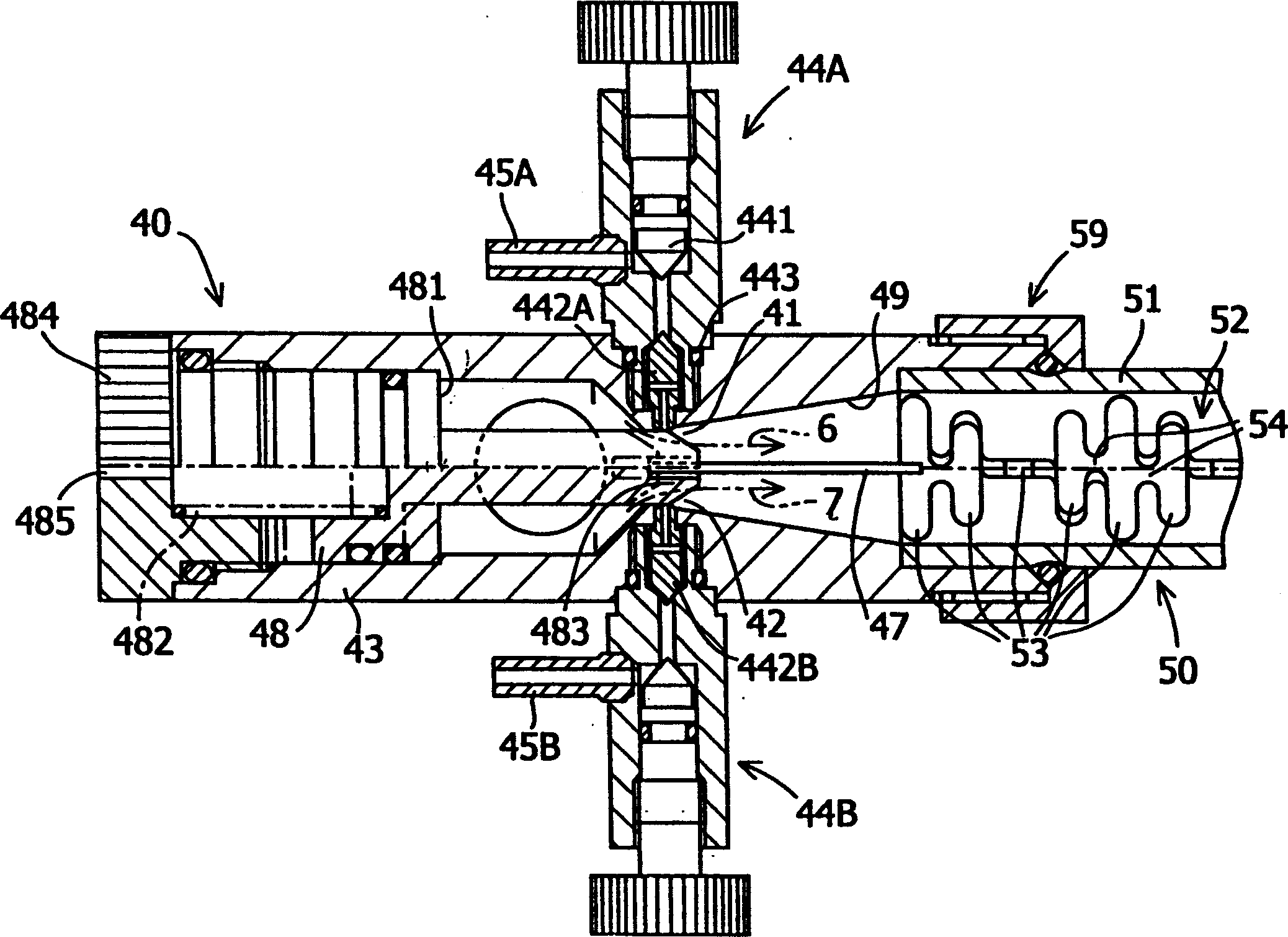

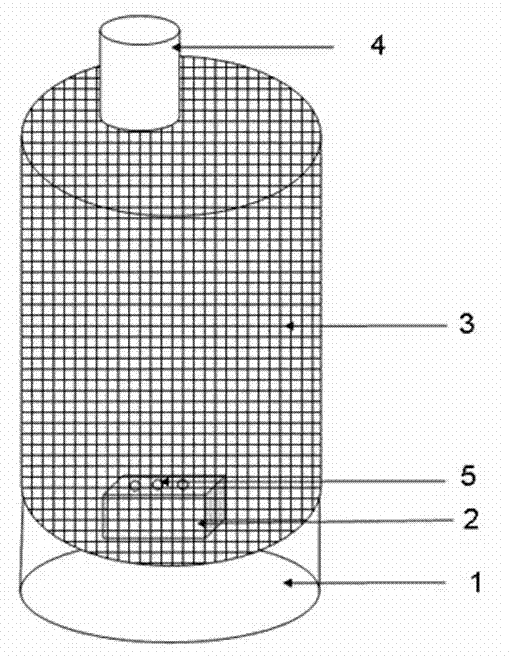

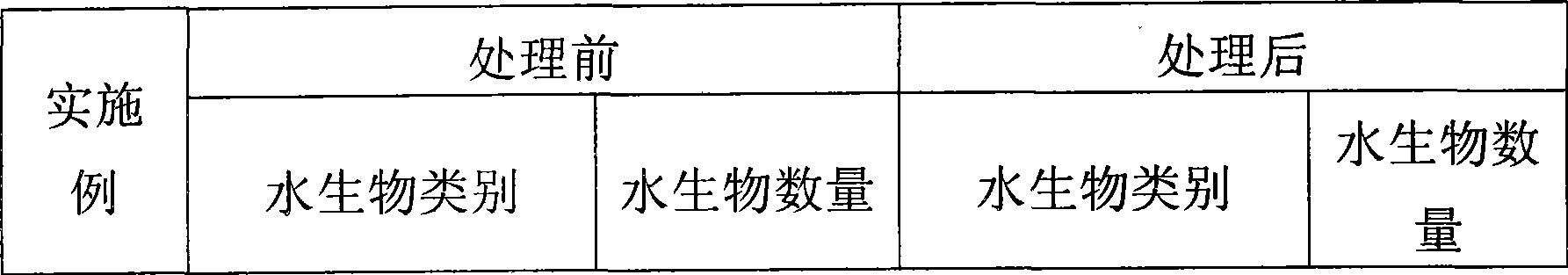

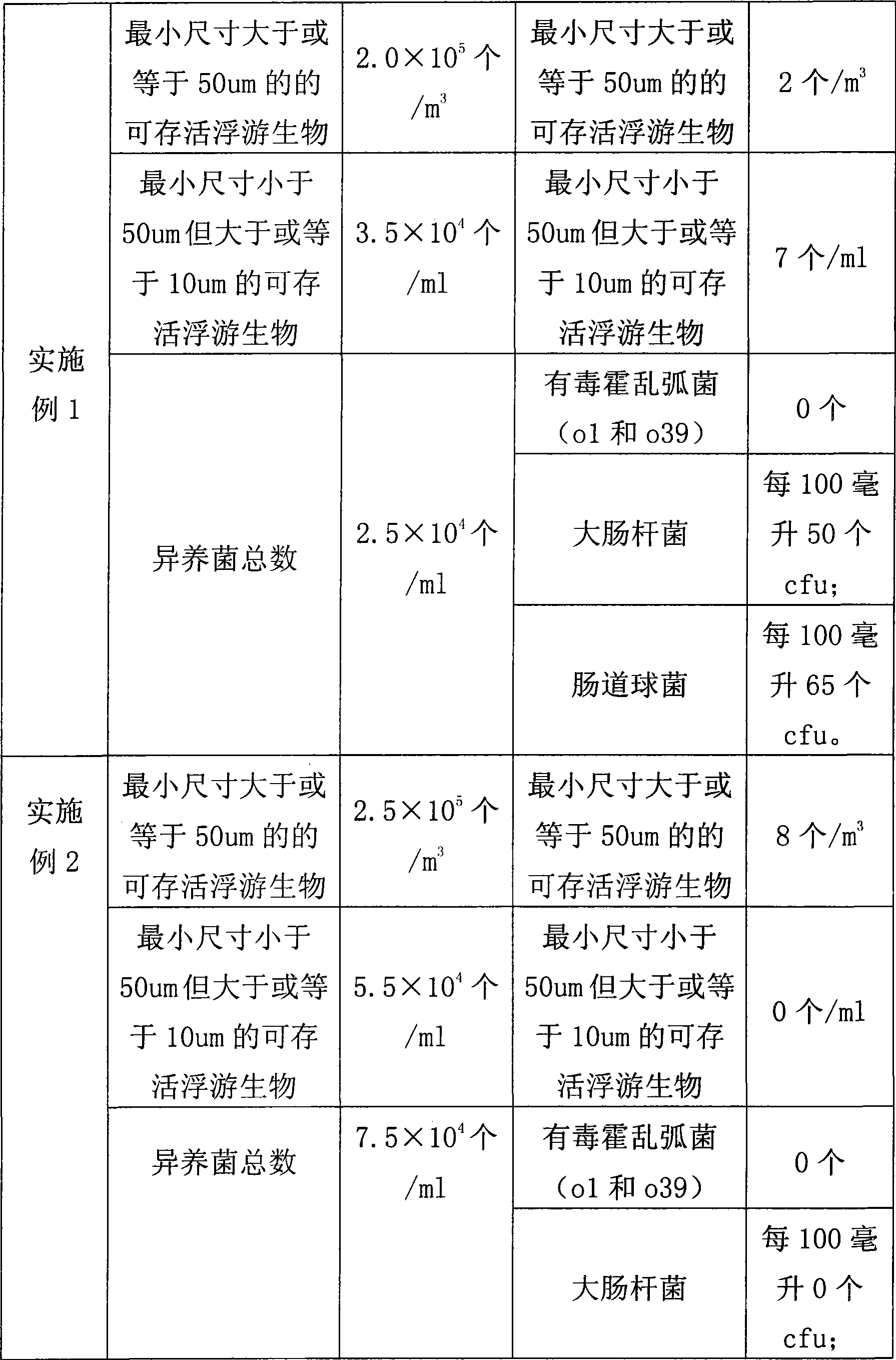

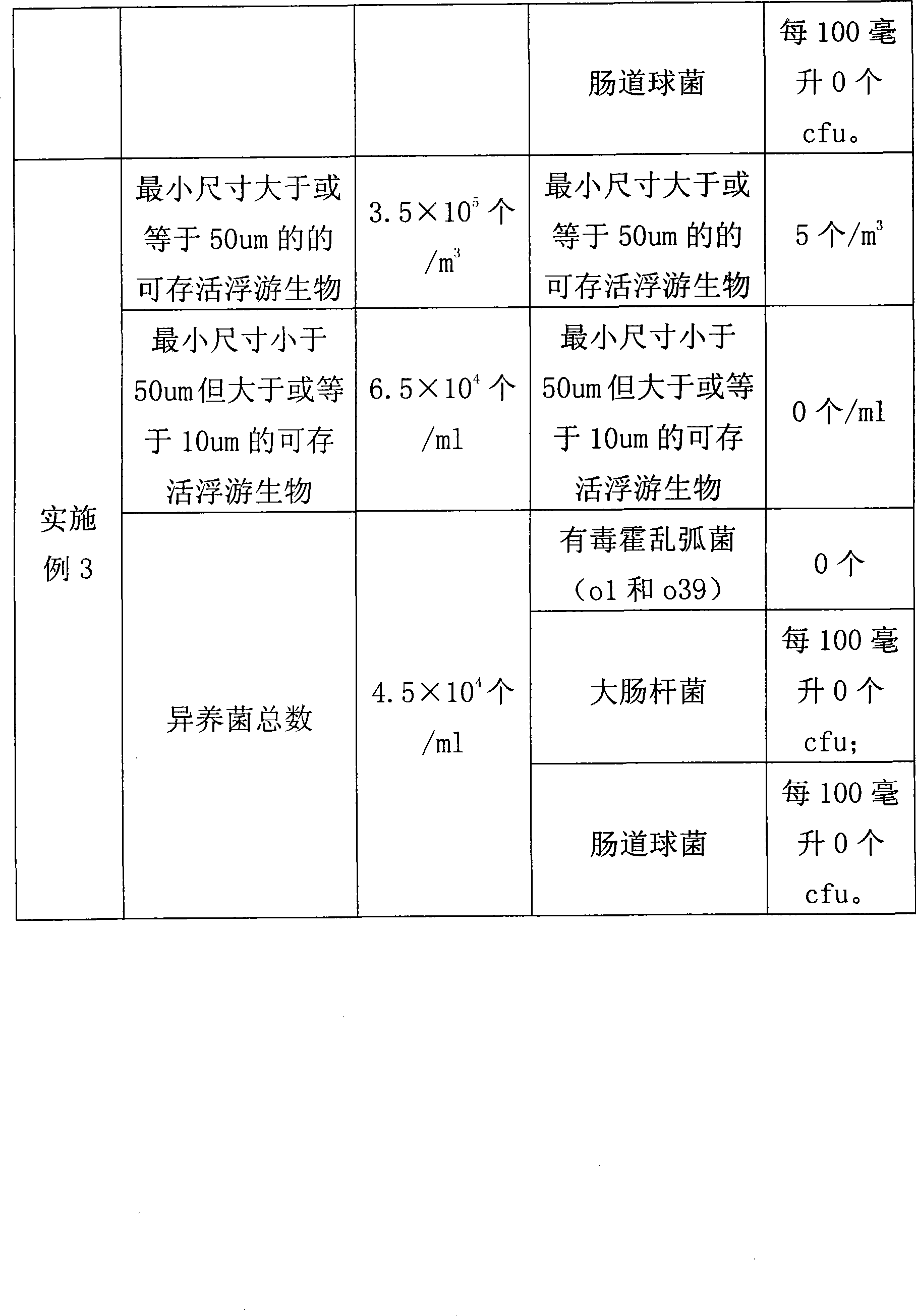

High-efficiency treatment method of ballast water in ship

InactiveCN102515400AReduce generationSimple process routeAuxillariesMultistage water/sewage treatmentSuspended particlesElectrolysis

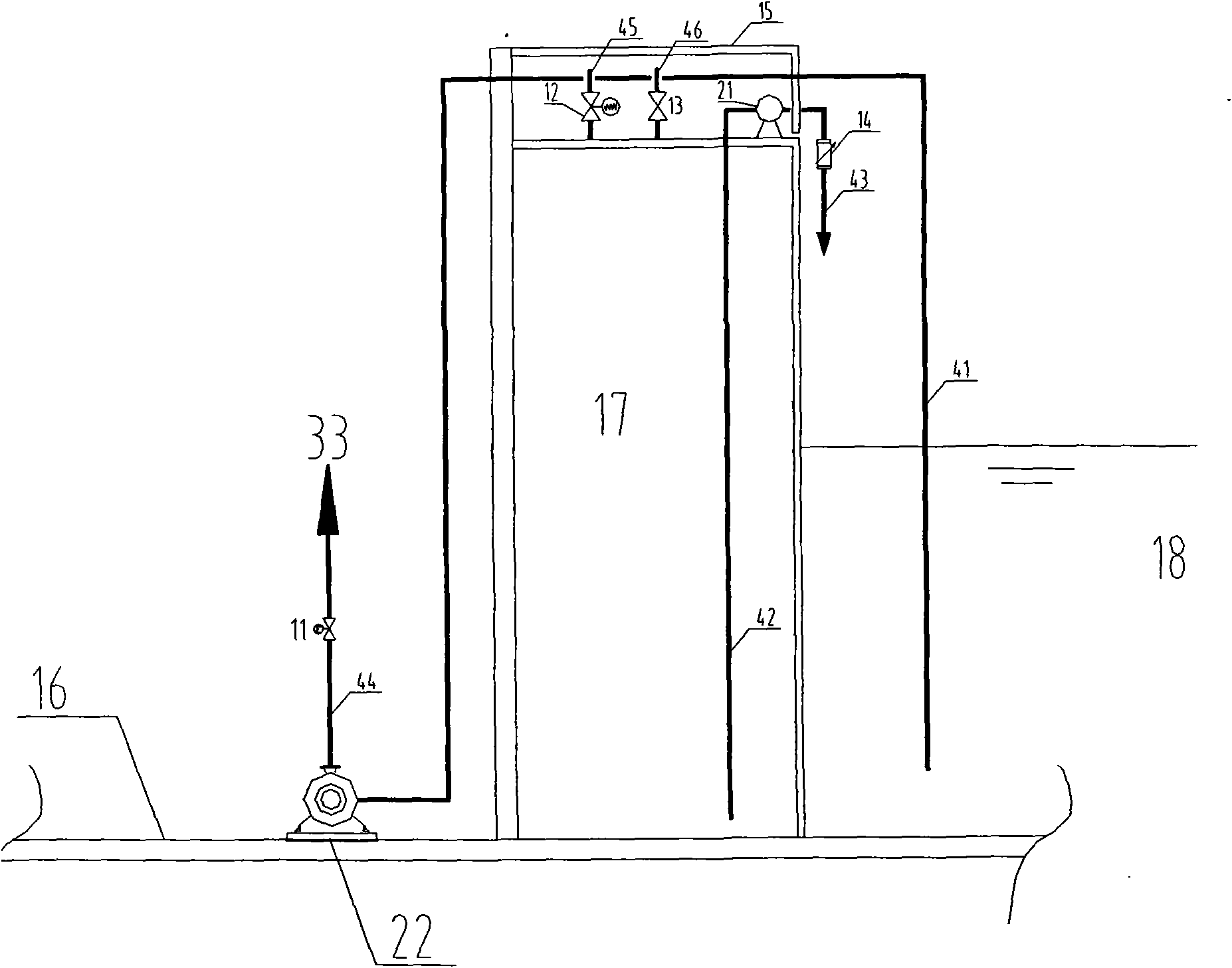

The invention discloses a high-efficiency treatment method of ballast water in a ship and a device adopting the high-efficiency treatment method. The high-efficiency treatment method of ballast water in a ship comprises the following steps of 1, removing planktonts and suspended particles in ballast water by a high-efficiency filter, wherein the removed planktonts and the suspended particles have sizes of above 30 to 40 micrometers; 2, based on a branch electrolysis-based inactivation treatment technology, electrolyzing a part of seawater passing through an electrolysis unit into chlorine and hydrogen by the electrolysis unit, wherein the chlorine is fast dissolved in seawater to form sodium hypochlorite, and 3, feeding back the high-concentration sodium hypochlorite solution obtained by the step 2 to a ballast water feeding header pipe so that residual harmful aquatic organisms in the ballast water are killed. The high-efficiency treatment method of ballast water in a ship has the advantages that a technology of high efficiency filtration and branch electrolysis-based inactivation treatment and the equipment suitable for the technology are adopted; a technical flow is simple; a system volume is small; compared with the existing system, the device adopting the high-efficiency treatment method has a floor space reduced by above 30%; because of the utilization of branch electrolysis, a hydrogen generation amount is low so that hydrogen can be removed completely; a potential safety hazard is eliminated; installation is convenient; and safety and reliability are high.

Owner:SUNRUI MARINE ENVIRONMENT ENG

Method for preparing cuprous oxide/ bacterial cellulose nano composite material

InactiveCN102121038AMaintain nanostructureOvercoming the disadvantages of difficult recyclingMaterial nanotechnologyCopper oxides/halidesGas detectorHydroquinone Compound

The invention relates to a method for preparing a cuprous oxide / bacterial cellulose nano composite material. The preparing method comprises the following steps of: obliquely inoculating acetobacter xylinum strains into culture solution, and culturing the strains to obtain a bacterial cellulose gel film; performing surface activation treatment on the bacterial cellulose gel film in sulfuric acid solution and sodium hypochlorite solution respectively; and sequentially soaking the surface activated bacterial cellulose gel film into Cu(NO3)2 solution and hydroquinone solution to perform reduction reaction to obtain the cuprous oxide / bacterial cellulose nano composite material. The method has the advantages that: the preparation process is simple; and the prepared composite material keeps the nano structure of cuprous oxide particles, simultaneously has good strength performance, and has wide application prospect on the aspects of electrode devices, catalysts, gas sensitive sensors and the like.

Owner:TIANJIN UNIV

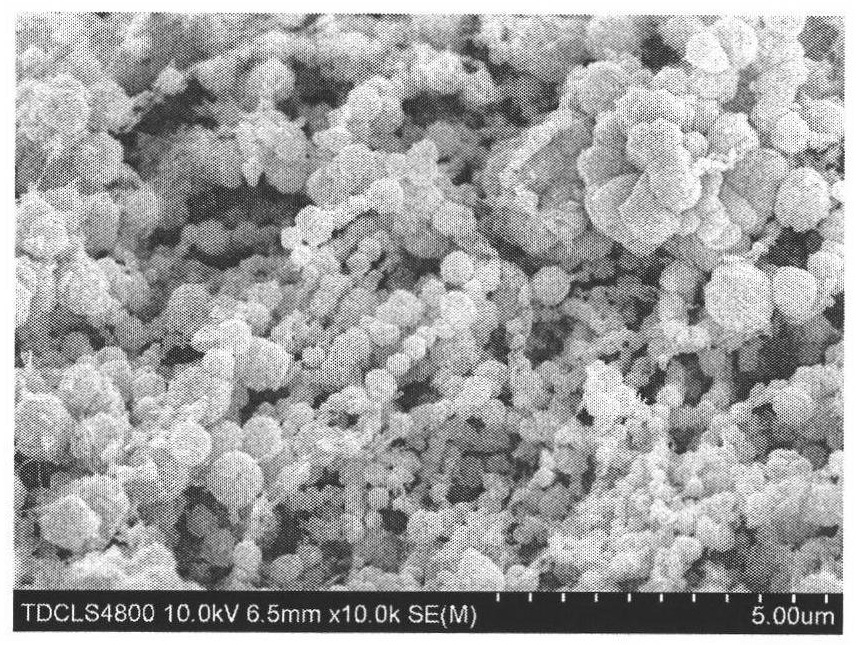

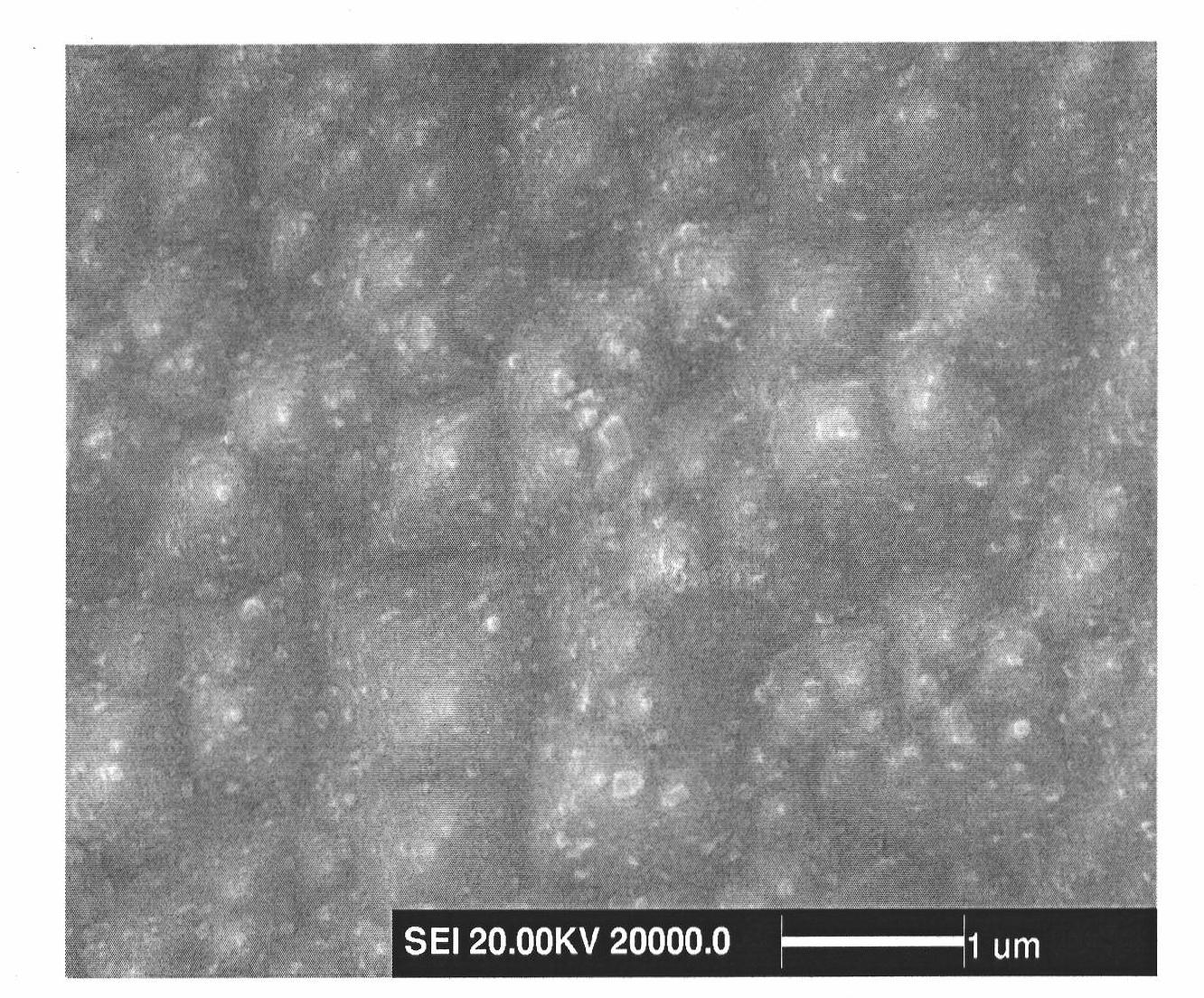

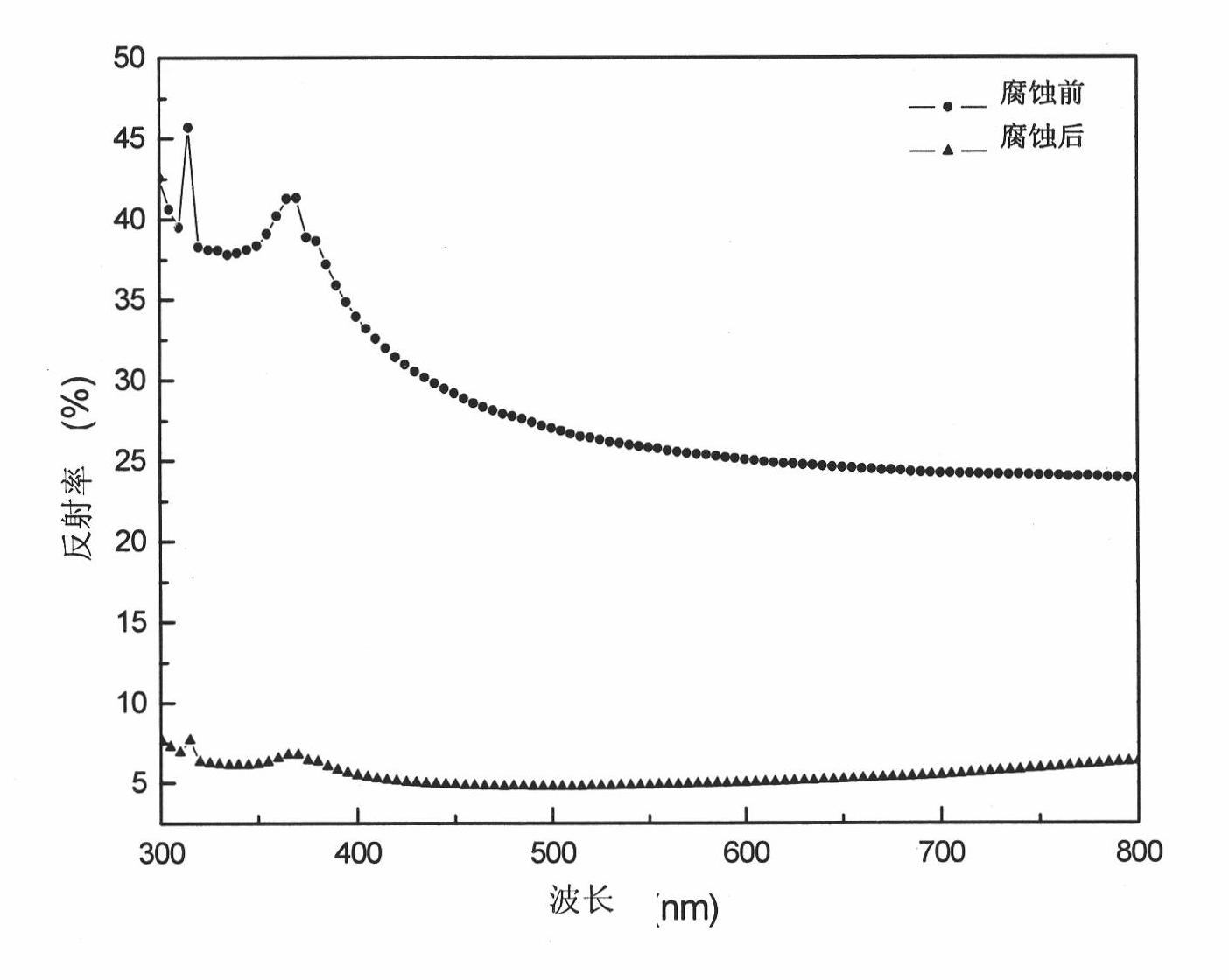

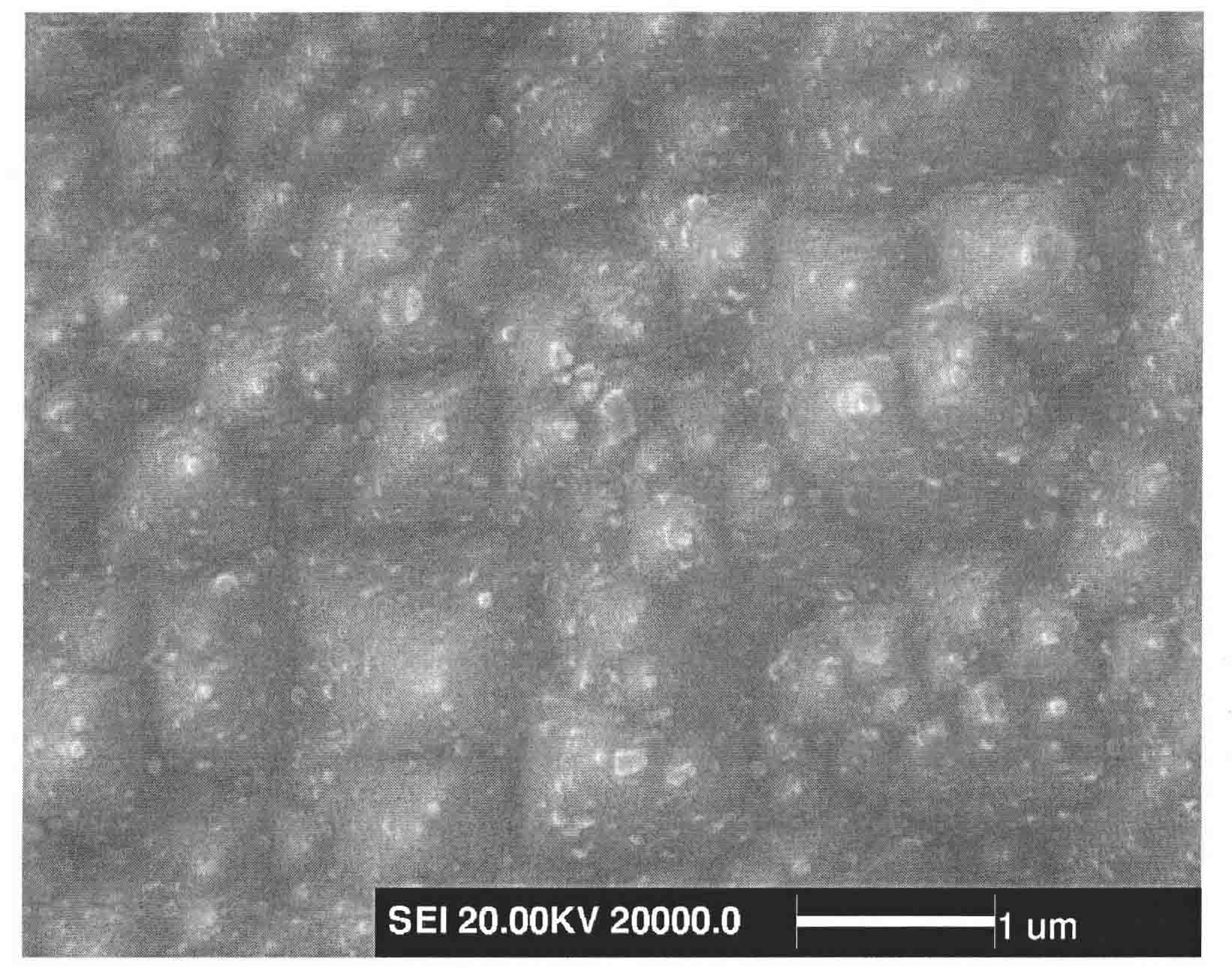

Preparation method of hydrophobic light trapping structure on silicon surface

ActiveCN102102227AImprove anti-reflection effectImprove efficiencyAfter-treatment detailsFinal product manufactureEtchingTrapping

The invention discloses a preparation method of a hydrophobic light trapping structure on silicon surface, belonging to the technical field of the solar cell. The method adopts the silicon wafer (100) or (111) and comprises the following steps: using hot sodium hypochlorite solution and HF to clean and obtain a clean silicon surface; corroding single crystal silicon with alkaline corrosive agent to form the texture with pyramid-shaped surface, or performing catalytic etching with precious metal nanoparticles, namely plating silver on the surface of the silicon wafer through the silver mirror reaction and soaking the silicon wafer plated with silver in acidic corrosive agent; and obtaining the light trapping structure of the antireflection layer. By adopting the light trapping structure, the emissivity can be reduced to 5% in the visible wave band from 380nm to 780nm. By adopting the method of the invention, the technological process of the precious metal nanoparticle plating can be simplified, the characteristics of normal-temperature wet etching can be maintained and the silicon surface can have higher antireflection effect. In addition, the contact angle of the surface of the silicon wafer (100) is up to 110 degrees, the silicon wafer has super hydrophobicity and the new technical means is provided for increasing the efficiencies of the silicon and silicon film solar cells.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

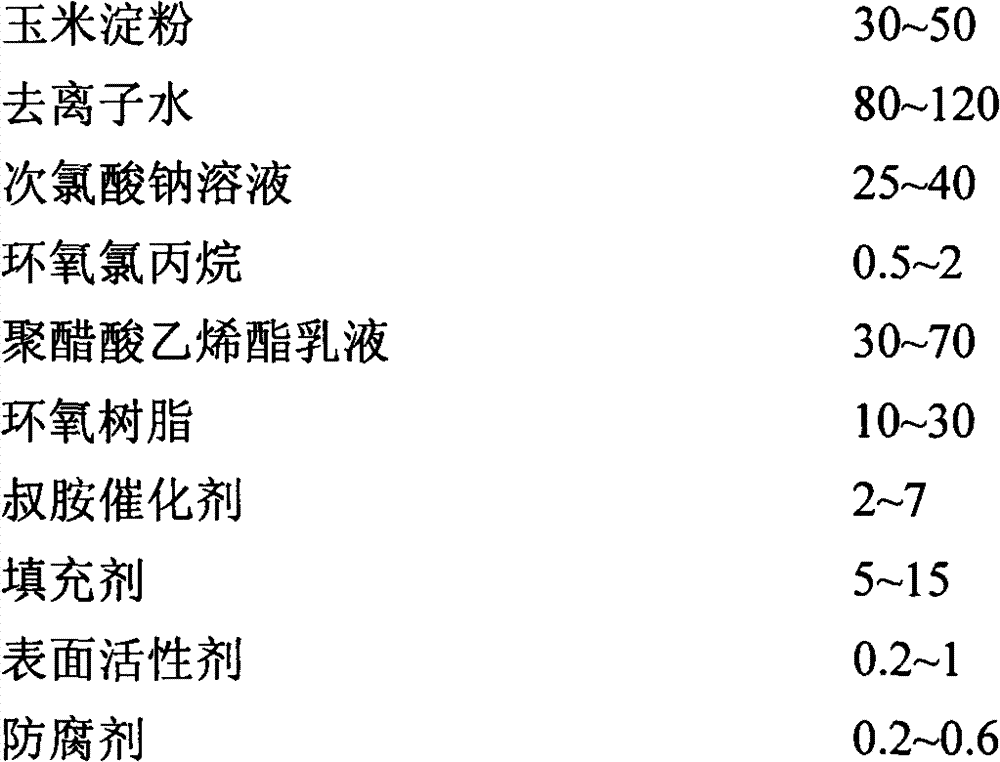

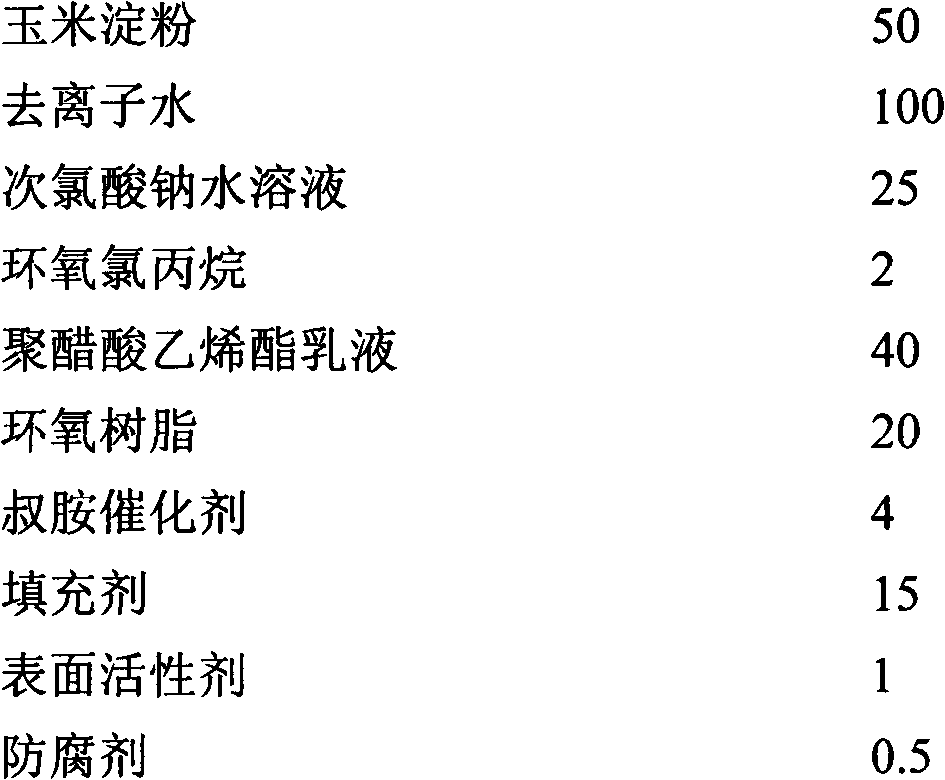

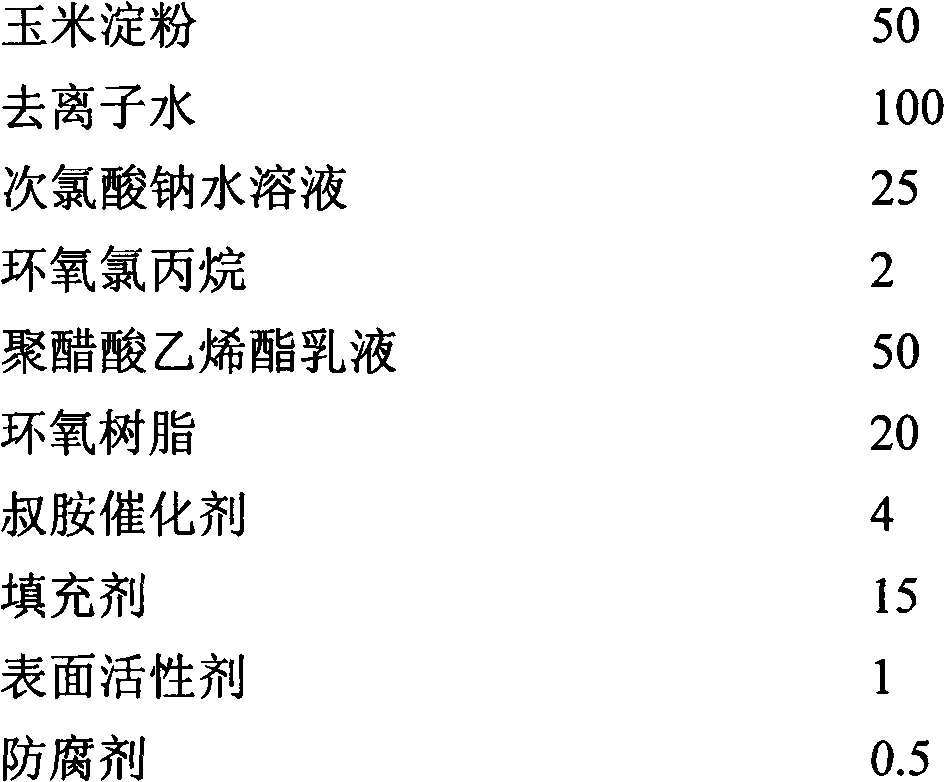

Modified starch adhesive and method for preparing same

InactiveCN102732186AGood compatibilityRaw materials are cheap and easy to getMonocarboxylic acid ester polymer adhesivesStarch derivtive adhesivesEpoxyAdhesive

The invention discloses a modified starch adhesive and a method for preparing the same. The modified starch adhesive comprises the following components by weight: 30-50 parts of corn starch, 80-120 parts of deionized water, 25-40 parts of sodium hypochlorite solution, 0.5-2 parts of epichlorohydrin, 30-70 parts of polyvinyl acetate emulsion, 10-30 parts of epoxy resin, 2-7 parts of tertiary amine catalyst, 5-15 parts of filler, 0.2-1 part of surfactant, and 0.2-0.6 part of preservative, wherein the sodium hypochlorite solution serves as the oxidant, the polyvinyl acetate emulsion serves as the high-cohesive-energy reinforcement component, and the epoxy resin servers as the water-tolerant modified component. The method for preparing the modified starch adhesive comprises the following steps: mixing the oxidized starch emulsion prepared in advance, the polyvinyl acetate emulsion and the epoxy resin according to proportion uniformly, adding the catalyst, the filler and the preservative, and stirring quickly and uniformly. The modified starch adhesive disclosed by the invention has the advantages of high shear strength, high water-tolerant shear strength, moderate viscosity, good liquidity, moderate primary drying time, low cost and excellent integrated performance.

Owner:EAST CHINA UNIV OF SCI & TECH

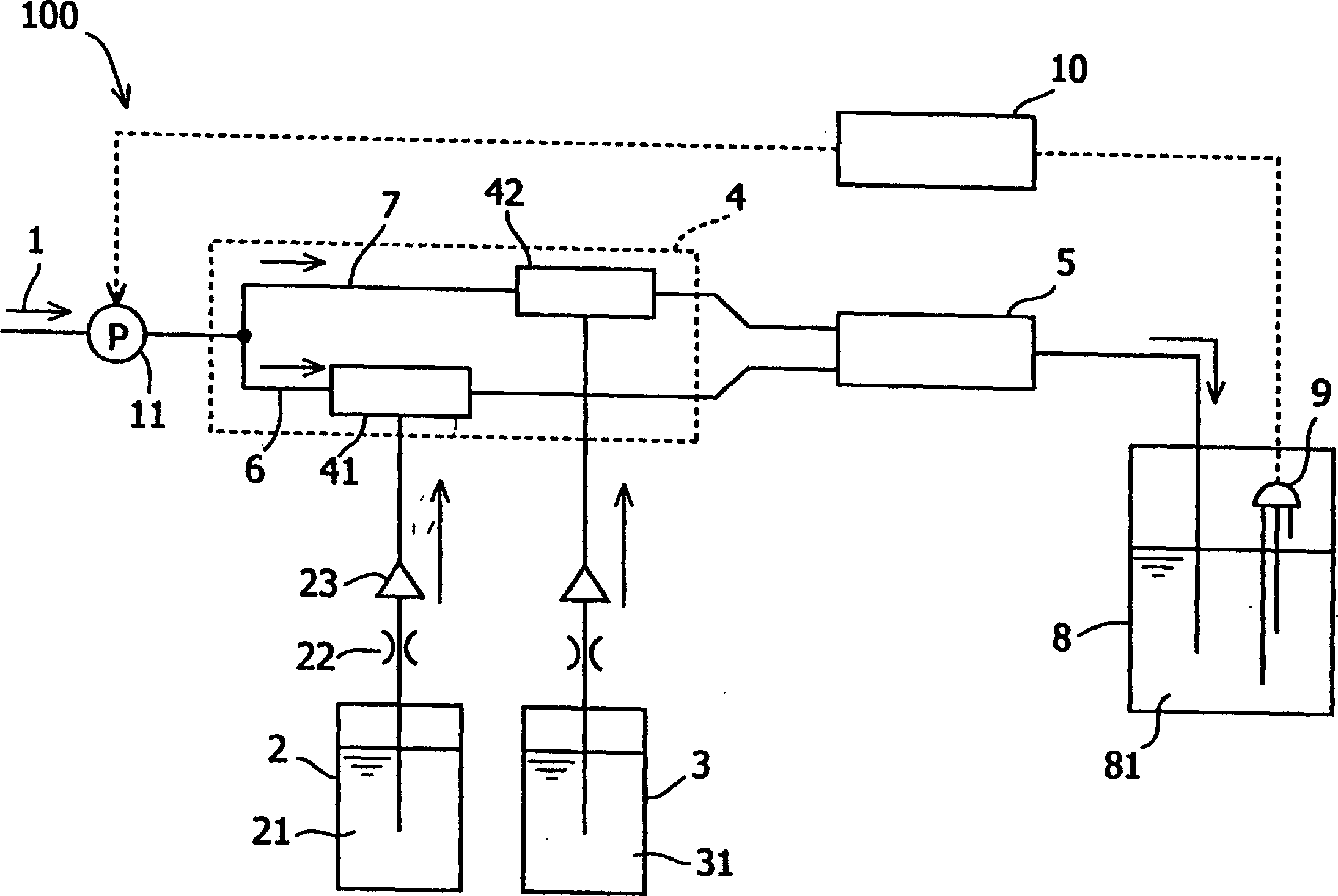

Apparatus for producing sterilized water

InactiveCN1652825AStable pressureStable feed operationFlow mixersMixing methodsChlorine dioxideEnvironmental engineering

An embodiment of an apparatus for producing a sterilized water wherein each of an aqueous acid solution (21) and a chlorine-containing aqueous solution (31) is diluted with raw water (1) in a device (4) for inclusion, and then the resultant solutions are mixed in a mixer (5). The apparatus for producing a sterilized water can be used for satisfactorily exhibiting the sterilization ability of a chlorine-containing aqueous solution such as a sodium hypochlorite solution, a chlorine dioxide solution and a mixture thereof, while suppressing the generation of a chlorine gas, and for producing a desired sterilized water through suitably mixing water, an aqueous acid solution and a chlorine-containing aqueous solution at satisfactorily controlled concentrations.

Owner:FAMILY LIFE

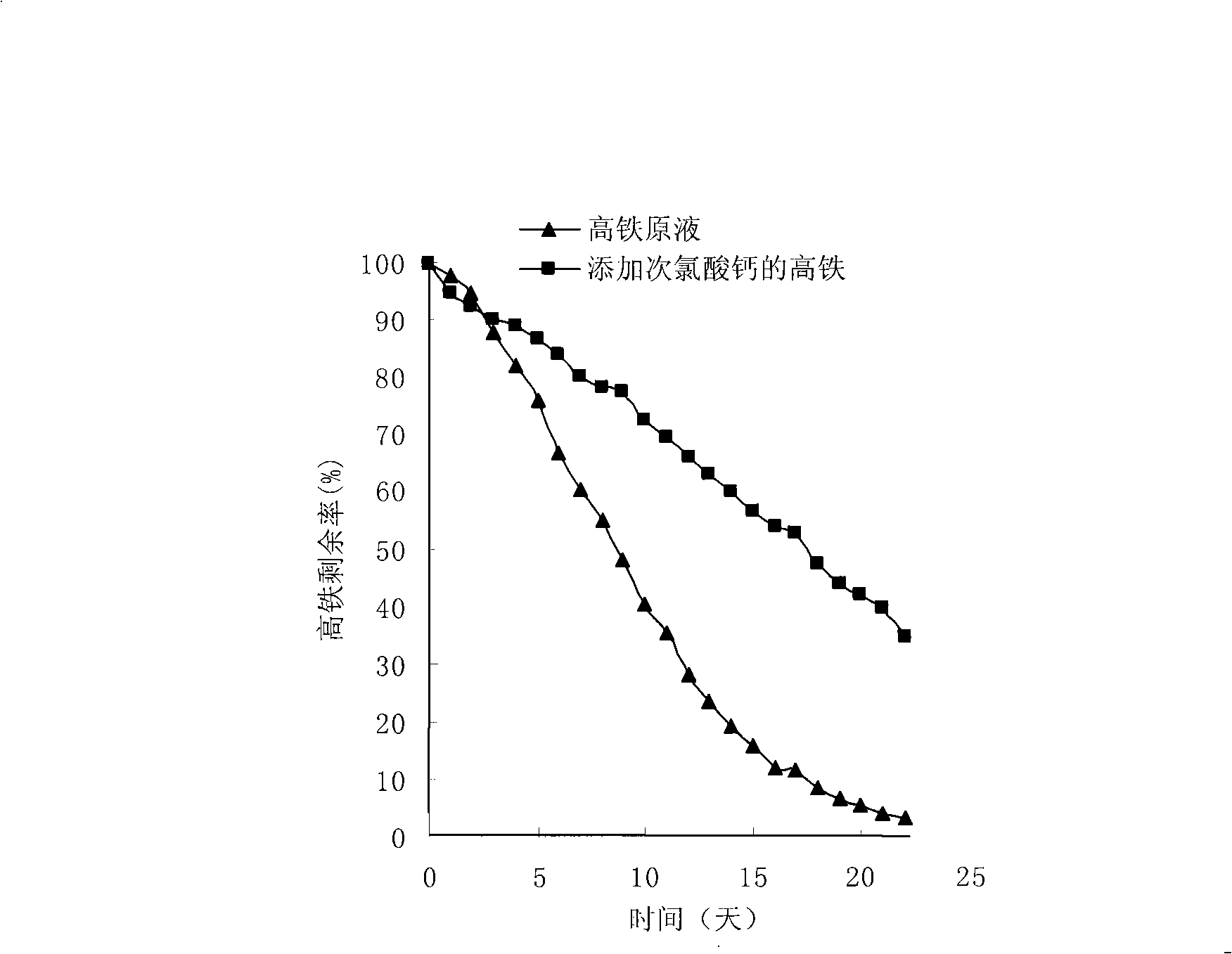

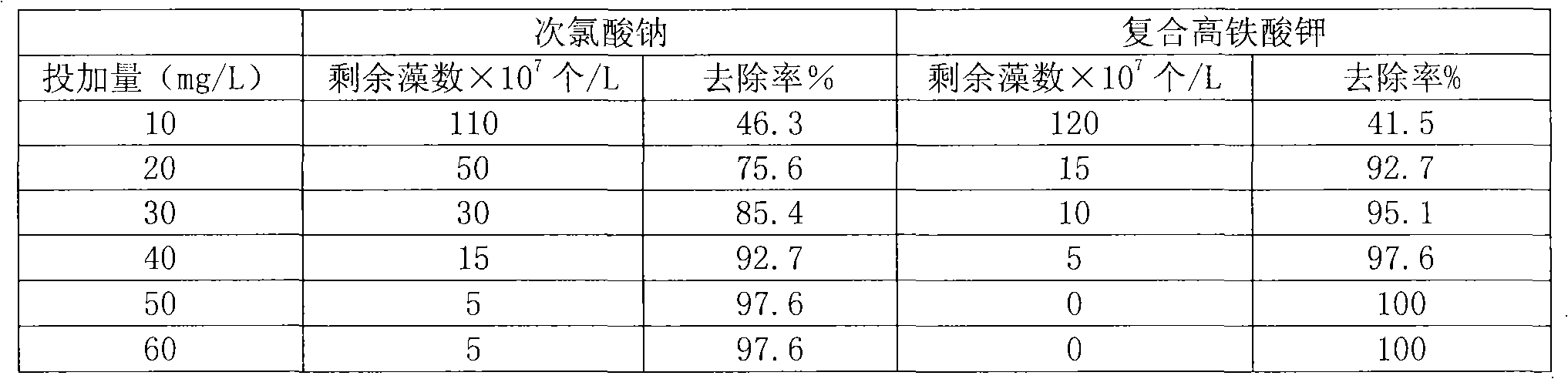

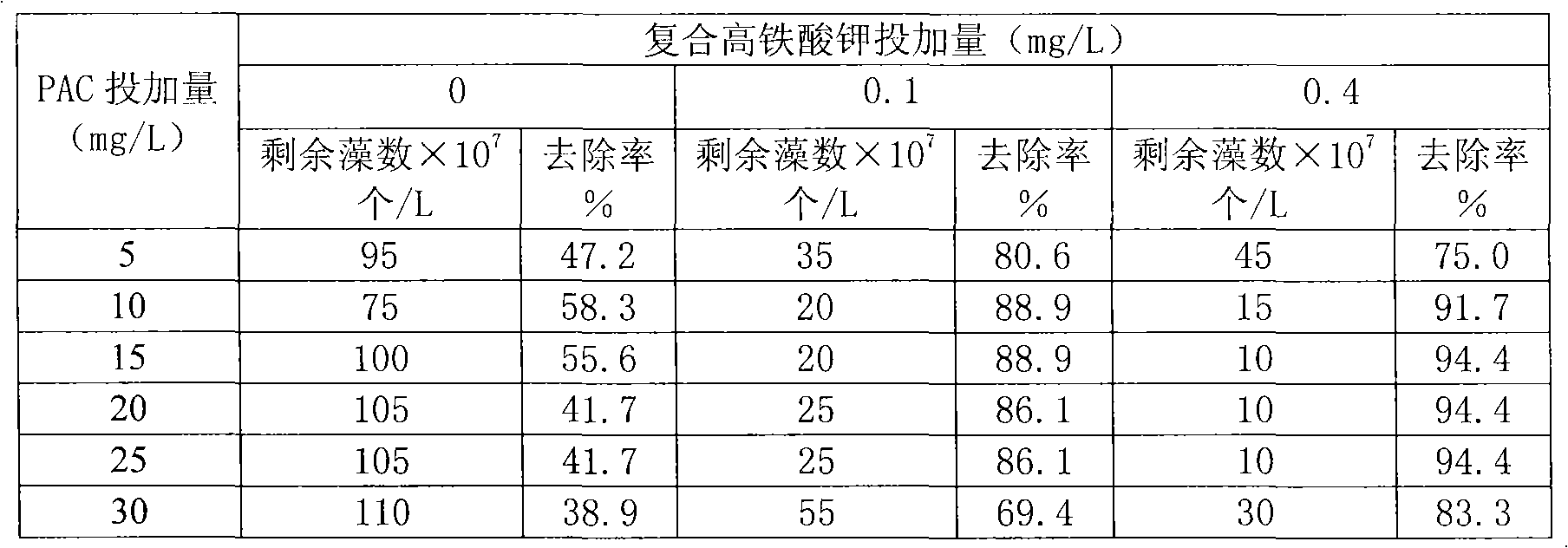

Method for preparing steady composite potassium ferrate solution

InactiveCN101318707AImprove stabilityLong storage timeIron compoundsWater/sewage treatment using germicide/oligodynamic-processChemical industryFiltration

The invention relates to a method for preparing a composite potassium ferrate solution, which belongs to the chemistry and chemical industry and water treatment agent preparation process technical field. The method comprises the following preparation processes that: firstly, a sodium hypochlorite solution reacts with sodium hydroxide, a white salt substance is generated first and is subject to pumping filtration, then ferric nitrate is added according to a molar mass ratio of sodium hypochlorite to ferric nitrate being equal to between 1.5 and 2.0 to 1, the reaction temperature is between 20 and 45 DEG C, and the pumping filtration is performed after 1.5 to 2.0 hours of reaction; and then a filtrate is added with a saturated potassium hydroxide solution to ensure that the filtrate is transformed into a potassium ferrate solution. Then 0.06 to 0.16mol / L of calcium hypochlorite is added, the reaction temperature is controlled to between 10 and 30 DEG C, the reaction time is between 10 and 30 minutes, and finally the composite potassium ferrate solution with good stability is produced. The composite potassium ferrate solution prepared by the method has good stability, long preservation time, difficult decrease of high iron content, and easiness for industrialized production. The product can be widely used for purification treatment of algae-laden water, city domestic sewage and so on.

Owner:SHANGHAI UNIV

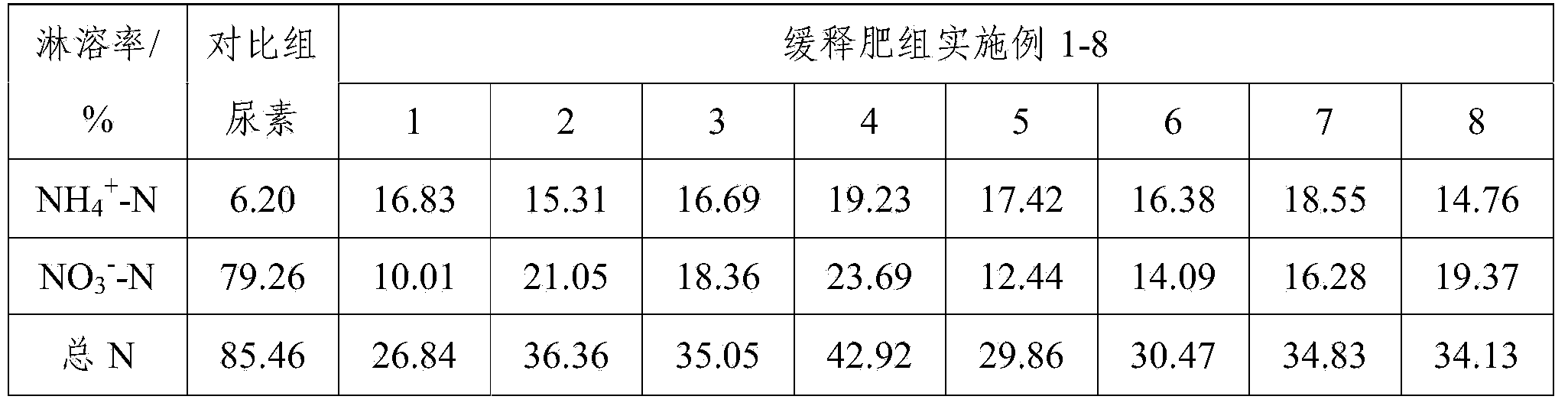

Charcoal-base polyaspartic acid slow-release urea as well as preparation method and application thereof

ActiveCN103804075ASolving Recycling ProblemsEmission reductionFertilizer mixturesField experimentDecomposition

The invention provides charcoal-base polyaspartic acid slow-release urea. The preparation method comprises the steps of 1) charring agricultural waste which is taken as a biomass raw material at 400-600 DEG C to obtain porous charcoal particles; 2) carrying out a reaction between urea and formaldehyde to obtain a modified urea solution; 3) adding polyaspartic acid and derivative thereof to the modified urea solution; 4) soaking the charcoal particles in the mixing solution obtained from the step 3) for 3-10 hours, and drying the soaked charcoal particles; 5) implementing a reaction between starch and a sodium hypochlorite solution to obtain an oxidized starch solution which serves as a binder; and 6) adding the dried charcoal particles to the binder, pelleting and drying to obtain the charcoal-base polyaspartic acid slow-release urea. The preparation method disclosed by the invention is low in cost, and can relieve conversion from NH4+-N to NO3--N, inhibit rapid decomposition and loss of the urea, prolong fertilizer efficiency, improve nitrogen use efficiency and relieve non-point source pollution; results of field experiments show that the slow-release urea product disclosed by the invention can effectively increase both production and income, and can achieve a yield-increasing effect under a circumstance of reducing application of fertilizer.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

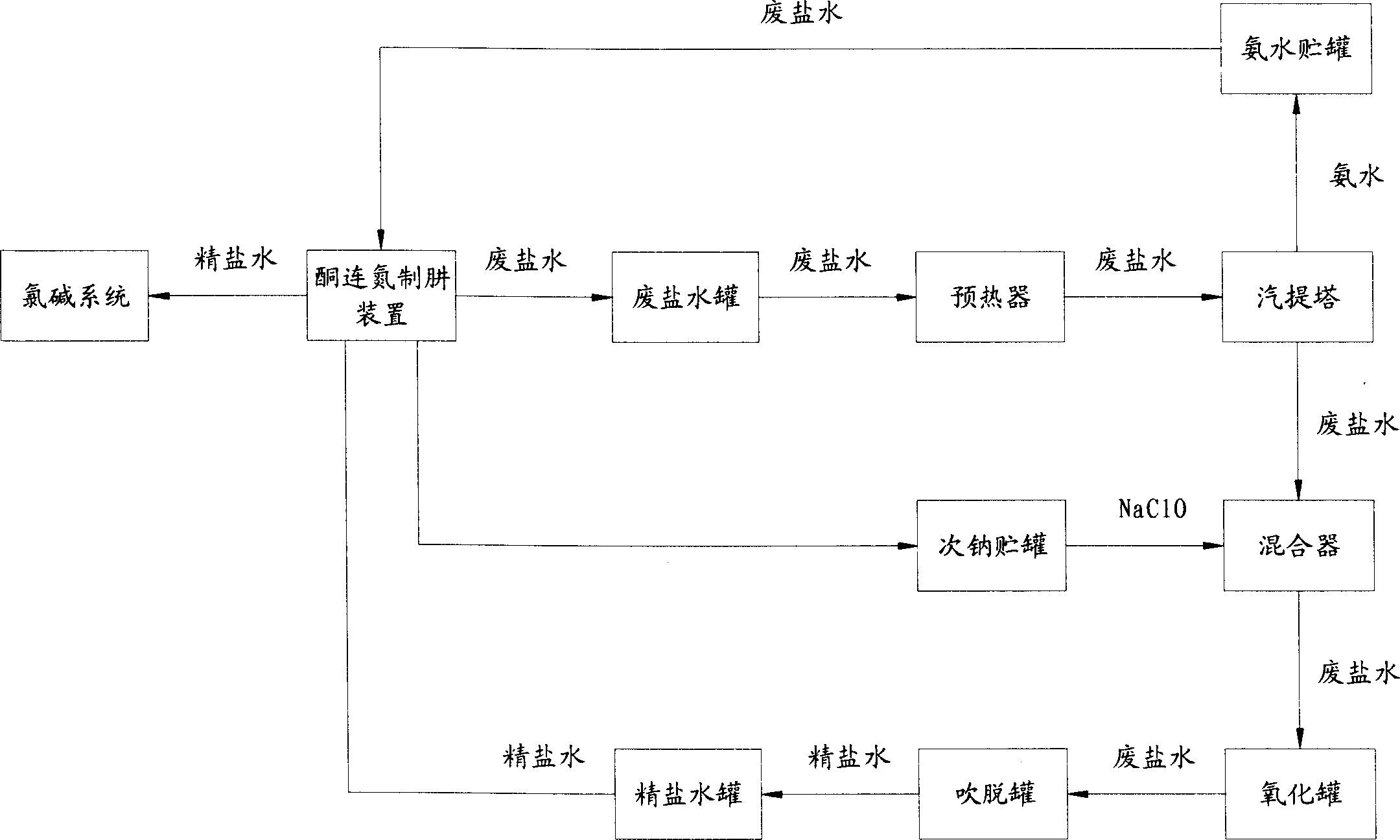

Process for treating hydrazine hydrate waste salt water by ketone linking nitrogen method

ActiveCN1792825ANo emissionsMake full use of resourcesNature of treatment waterWater/sewage treatment by heatingHydrazine compoundKetone

A process for treating the rejected saline generated in preparing hydrazine hydrate from ammonia, sodium hypochlorite and acetone includes such steps as high-pressure and ¿Ctemp hydrolyzing of ketazine in rejected saline, using rectifying tower to collect resultant acetone and ammonia, adding sodium hypochlorite solution, redox reaction between resultant hydrazine hydrate and residual acetone and ammonia to generate sodium chloride, water, N2 and chloromethane, and stirring and blowing with compressed air to carry the gas products away. The removed impurities can be reclaimed.

Owner:YIBIN TIANYUAN GRP CO LTD +1

Process of making frozen light pickled seasoning vegetable

InactiveCN1887114ALighten the original amountAvoid infectionFood preservationFood preparationSodium hypochlorite solutionProduct processing

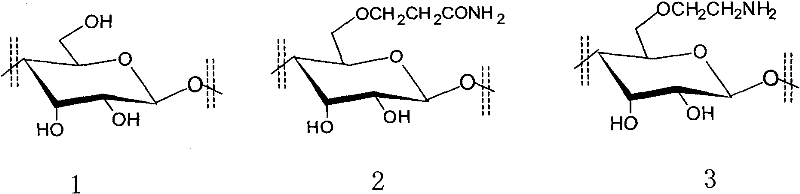

The process of making frozen lightly pickled and seasoned vegetable belongs to the field of deep agricultural product processing technology. The process includes the steps of: soaking fresh vegetable material in 150-250 ppm sodium hypochlorite solution for 6-10 min to sterilize; twice low salt short period pickling; soaking inside seasoning liquid containing trehalose in 5-6 % at the temperature of -4 to 0 deg.c; vacuum packing; quick freezing and maintaining at -18 deg.c. The frozen lightly pickled and seasoned vegetable has the mouth feeling and color of natural vegetable maintained.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD

Method for preparing regenerated cellulose spherical aerogel modified through carboxylation

InactiveCN103570967AImprove permeabilityAvoid gatheringOther chemical processesChemical recyclingFreeze-dryingSolvent

The invention relates to a method for preparing regenerated cellulose spherical aerogel modified through carboxylation, which aims at the problem of poor adsorptive property of the cellulose aerogel prepared by the existing methods. The method comprises steps of firstly, mixing sodium hydroxide, urea and deionized water, then adding into a cellulose raw material, preparing a cellulose solution, adding the cellulose solution into a regeneration solution for solidifying, washing and obtaining spherical hydrogel; and secondly, dissolving TEMPO (tetramethyl-piperidin-1-oxyl) and sodium bromide into deionized water, adding the spherical hydrogel, then adding a sodium hypochlorite solution, regulating pH value of a system through a sodium hydroxide solution, steeping, exchanging the collected solid phase objects sequentially through absolute ethyl alcohol and a tertiary butanol solvent, then cooling, finally, freeze drying so as to finish preparing the cellulose spherical aerogel. The largest capacity of the obtained spherical aerogel in adsorbing metal ions Cu<2+> reaches 0.55m mol / g, and the adsorptive property is good.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Method for preparing metal lithium by electrolyzing molten salt

ActiveCN101760759ASolve the problem of artificial lithium productionQuality improvementLithium chloridePotassium

The invention relates to a method for preparing metal lithium by electrolyzing molten salt. The steps of the method are as follows: (1) lithium chloride and potassium chloride are respectively dried; (2) the dried lithium chloride and the dried potassium chloride are heated in an electrolytic tank until to be completely melted after being uniformly mixed according to the weight ratio of 0.8 to 1.3:1; (3) when the temperature of an electrolyte is stabilized within 415 to 450 DEG C, cooling water is added to the electrolytic tank to form a stable crusting layer on the tank wall; (4) DC electricity is supplied for electrolyzing, and a magnetic pump and a blower are started at the same time to circulate alkaline solution in a tail gas recycling system reactor; (5) after the electrolyzing is carried out for 0.5 to 2h, the liquid metal lithium generated by a cathode is guided out after being collected and is then ingot-cast under the protection of inert gases; meanwhile, chlorine generated by an anode is discharged, is absorbed by the alkaline solution after being cooled to the room temperature, so as to obtain sodium hypochlorite solution. By utilizing the buoyancy of the electrolyte to the metal lithium, the method in the invention can automatically guide lithium out of the electrolytic tank, so as to solve the problem of manual lithium discharging, thereby improving the purity of the metal lithium to higher than 99.0%.

Owner:合肥山河锂盐新能源科技有限公司

Preparation method of macromolecular sterilization fibre with grafted antibacterial monomer on its surface

InactiveCN1400355AImprove hydrophilicityImprove the bactericidal effectFibre treatmentCellulose fiberNitrogen gas

The preparation method of macromolecular sterilization fibre whose surface is grafted by antibacterial monomer belongs to the field of sewage treatment technology, and includes the following steps: firstly, adding quaternary ammonium salt, halogenated amine and macromolecular fibre in the reactor, then adding reaction solvent, charging nitrogen gas into the reactor and discharging air, adding initiating agent to make reaction, after reaction using lots of solvent to stir and flush, filtering and drying, extracting the grafted collulose fibre by using aqueous solution of acetone, and soaking the grafted cellulose fibre in sodium hypochlorite, taking out fibre and drying at room temp. Said invention macromolecular sterilization fibre is a macromolecular treatment agent, not only can be usedfor treating water, but also can be used as medical gauze, artificial skin and shell fabric.

Owner:TSINGHUA UNIV

Method for feeding lepidopteron

InactiveCN103960204APrevent escapeImprove hatchabilityChemicalsAnimal husbandryAnimal scienceDisinfectant

The invention discloses a method for feeding lepidopteron. In the feeding process, a tray type net cage is used as a main feeding tool. The method comprises steps of collecting eggs, sterilizing, hatching larvae from the eggs, feeding the larvae, feeding pupas, feeding imagoes and the like, wherein gauze or plastic ropes are used as an oviposition substrate for collecting the eggs; the eggs are sterilized by using a formaldehyde solution with the volume concentration of 3-4%; the eggs are hatched and fed in an illumination incubator; the larvae are sterilized by using a sodium hypochlorite solution with the volume concentration of 8-12%; pupas feather in the tray type net cage; the feathering imagoes are continuously fed in the net cage and the eggs are collected and sterilized. The tray type net cage is simple and convenient to operate, the insects are effectively prevented from escaping and the cleaning can be carried out at any time; in the feeding process, eggs and larvae are disinfected by using different disinfectants, the disinfection effect is thorough and gentle, the bacteria are effectively prevented from mass propagation, and the hatchability of the eggs, the feathering rate of pupa are also improved, the hatchability of the eggs can be 95-96%, and the feathering rate of pupa can be 98%.

Owner:QINGDAO AGRI UNIV

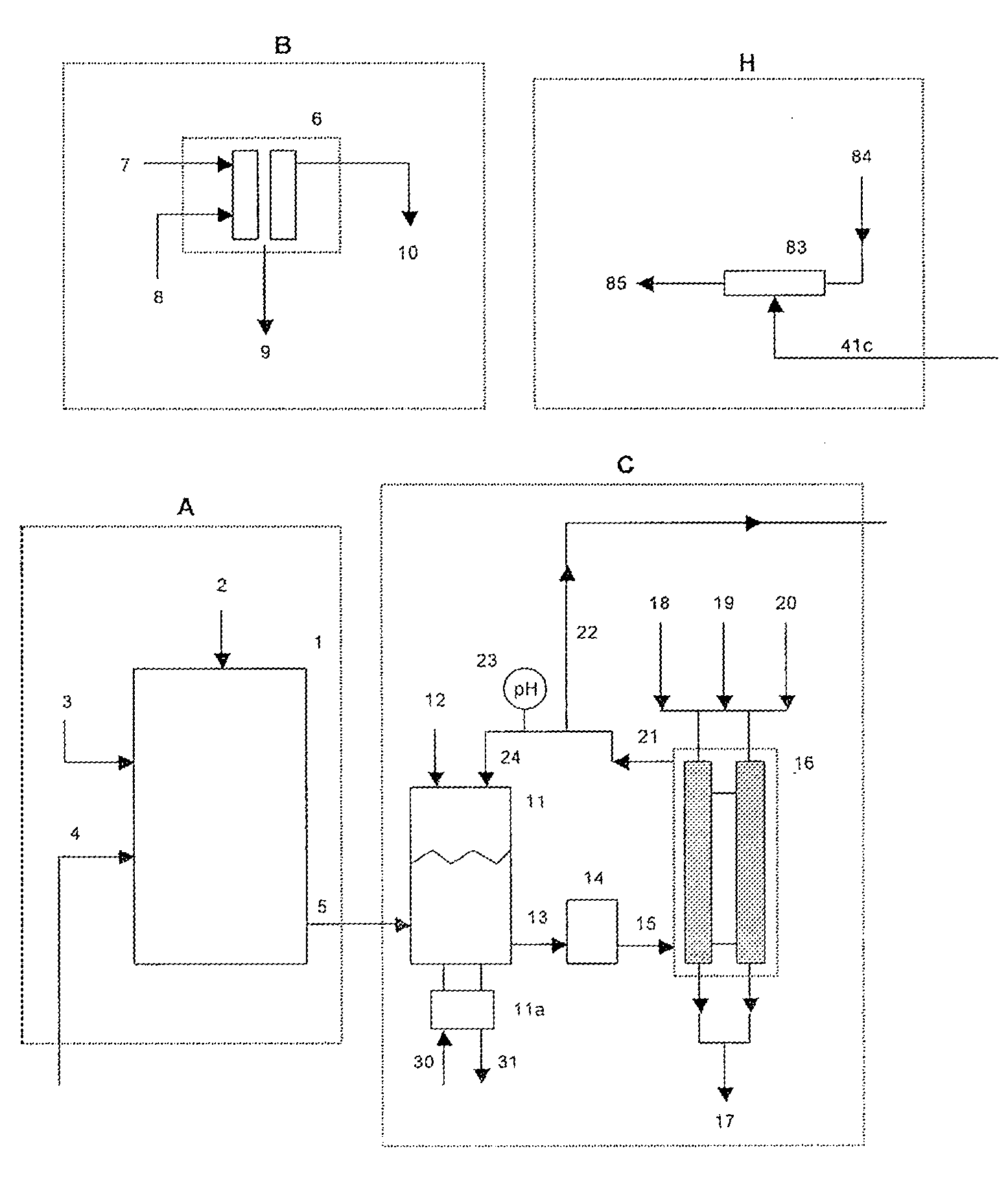

Composite cruising ballast water treatment process

InactiveCN101428919AAddressing Spread ContaminationSolve off-site hazardsElectrolysis componentsWater/sewage treatmentSuspended particlesElectrolysis

The invention belongs to the technical field of ballast water treatment in the shipping process, and relates to a composite ship ballast water treatment method. The method comprises two steps of high-efficiency filtration and inactivation treatment by a reinjection electrolysis process; the high-efficiency filtration is to serially connect a filter to an output port, through which the ballast water is loaded into a ship ballast tank, of a ballast pump to remove pelagic organisms and suspended particles; the rated flow of the filter is the same as the flow of the ballast water; the inactivation treatment by the reinjection electrolysis method is that when the ballast water is loaded, a booster pump is used to extract partial ballast water from a water inlet manifold at an outlet end of the filter to flow through an electrolytic tank, and chloride ions are oxidized on a positive electrode of the electrolytic tank to generate chlorine to be dissolved in the ballast water to generate sodium hypochlorite; and the sodium hypochlorite solution is reinjected into the water inlet manifold by the booster pump to be mixed evenly to ensure that the concentration of the sodium hypochlorite realizes the killing to residual harmful aquatic organisms. The method has the advantages of simple process route, reliable principle, and good treatment effect.

Owner:SUNRUI MARINE ENVIRONMENT ENG

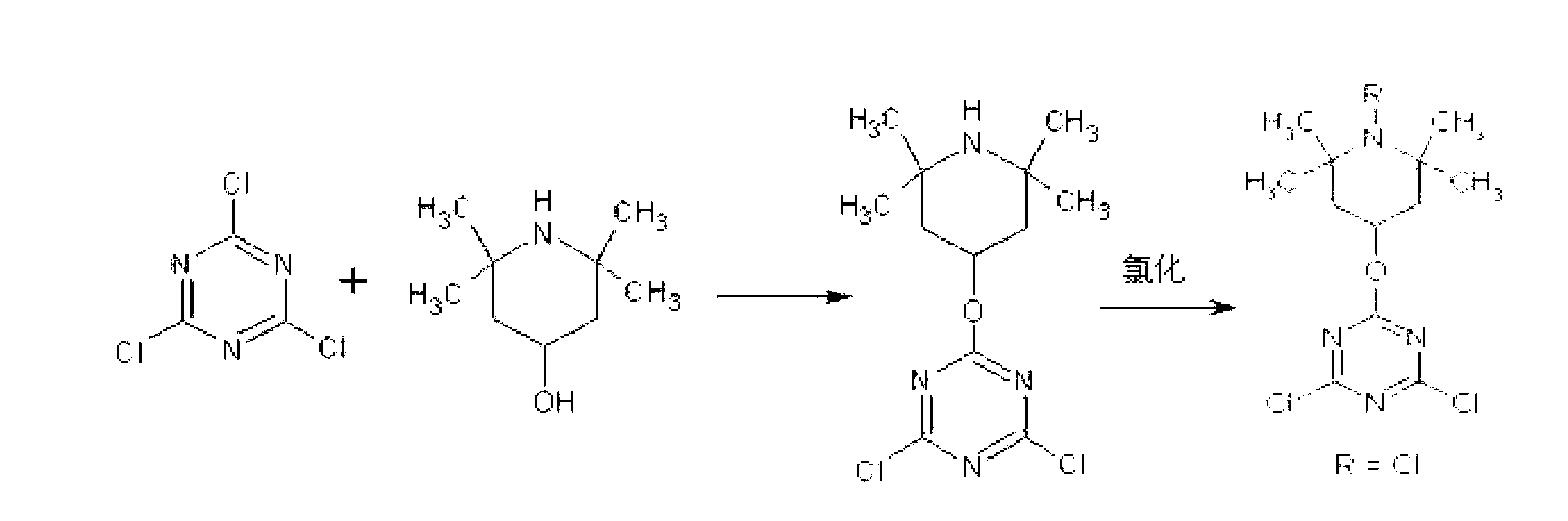

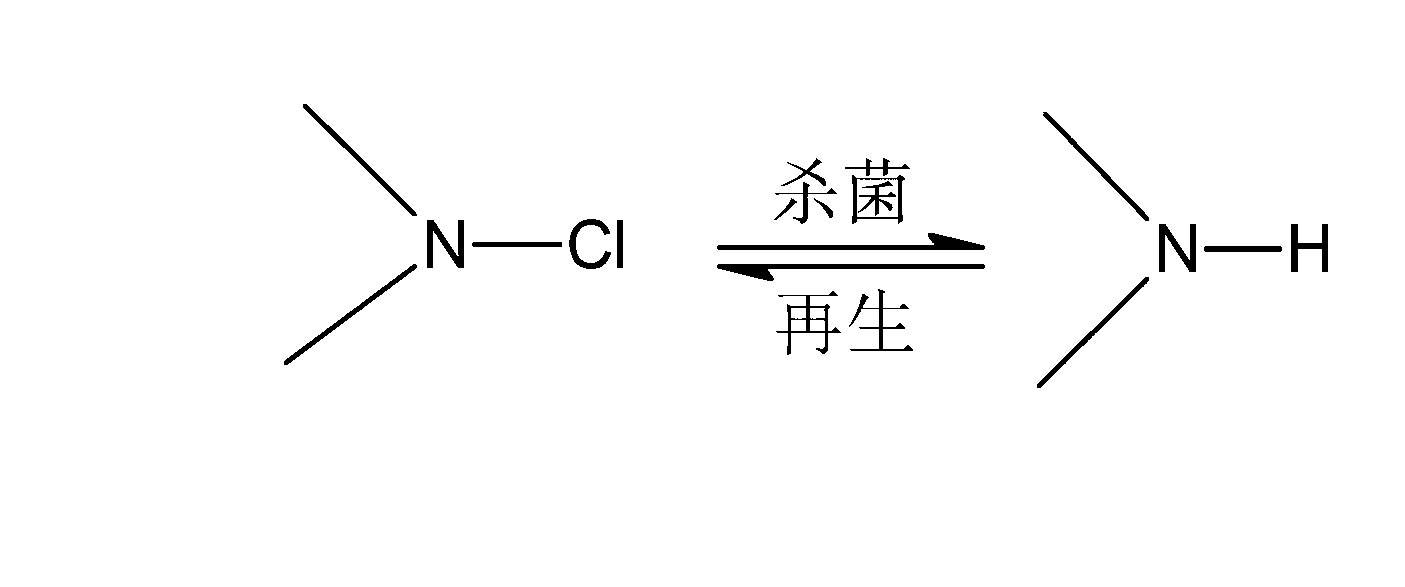

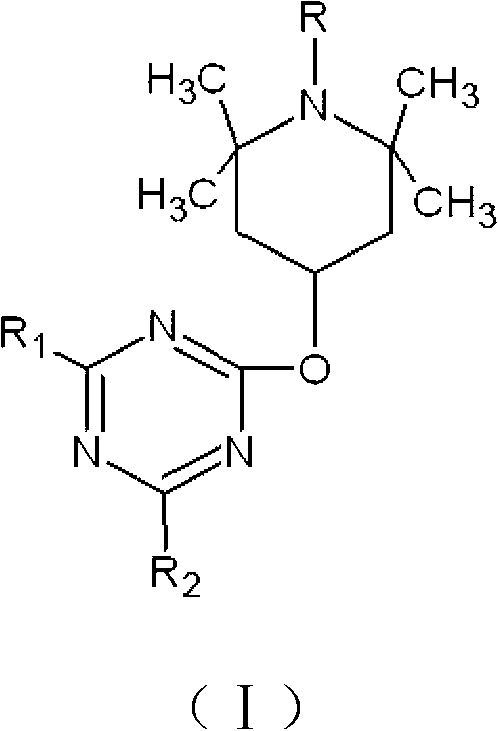

Halamine antibacterial agent, its preparation method and application

ActiveCN102797150ALow priceShort reaction timeOrganic chemistryFibre treatmentReaction temperatureAntibacterial agent

The invention provides a halamine antibacterial agent, its preparation method and application. The halamine antibacterial agent is a compound with a structure shown in formula (I). The preparation method consists of: in the presence of an acid-binding agent, taking cyanuric chloride or cyanuric fluoride or their derivative, and 2, 2, 6, 6-tetramethyl-4-piperidinol as synthesis raw materials to prepare a halamine antibacterial agent precursor with a structure shown in formula (II), and then reacting the precursor with a sodium hypochlorite solution to prepare a halamine antibacterial agent finished product. The halamine antibacterial agent can be applied in textile antibacterial finishing. Specifically, a textile to be treated is dipped in a finishing solution containing the halamine antibacterial agent precursor and a metal salt catalyst for finishing, and finally a halogenation reaction is carried out so as to obtain an antibacterial textile. The method provided in the invention for preparation of the halamine antibacterial agent has the advantages of low cost, simple process, low reaction temperature, no toxicity or pollution, and is in line with the requirements of ecological textile antibacterial finishing. According to the invention, the application process has the characteristics of simple operation and low reaction energy consumption, and antibacterial textiles with good antibacterial properties can be prepared.

Owner:JIANGNAN UNIV

Chemical cleaning method of hollow fiber membrane and device thereof

InactiveCN101829505AGuaranteed fluxImprove stabilitySemi-permeable membranesFiberHollow fibre membrane

The invention discloses a chemical cleaning method of a hollow fiber membrane, comprising the following steps of: (1) preparing a composite chemical cleaning agent with the active chlorine concentration of 10-13%; and (2) back washing the hollow fiber membrane on line by adopting the compounded composite chemical cleaning agent. The invention also discloses a chemical cleaning device of the hollow fiber membrane, which is provided with a composite chemical cleaning agent storage tank and a back washing system comprising a back washing pump; and the upper part of the storage tank is provided with a filling pipe, an electromagnetic valve and an air release valve. The invention can effectively keep the membrane flux of a membrane bioreactor and is matched with the running characteristic of a membrane bioreactor process. The invention solves the problems of large impact on microorganisms in a system, high labor intensity caused by needing to hang a membrane assembly out for cleaning and the like, and difficult running management, can integrate a membrane assembly cleaning system and the membrane bioreactor to improve the control level of automation. By adding a surfactant and regulating the pH value of the system to be greater than 13, the stability of a sodium hypochlorite solution can be improved.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

Salt-free dyeing method of vinyl sulphone type reactive dye for cotton fiber

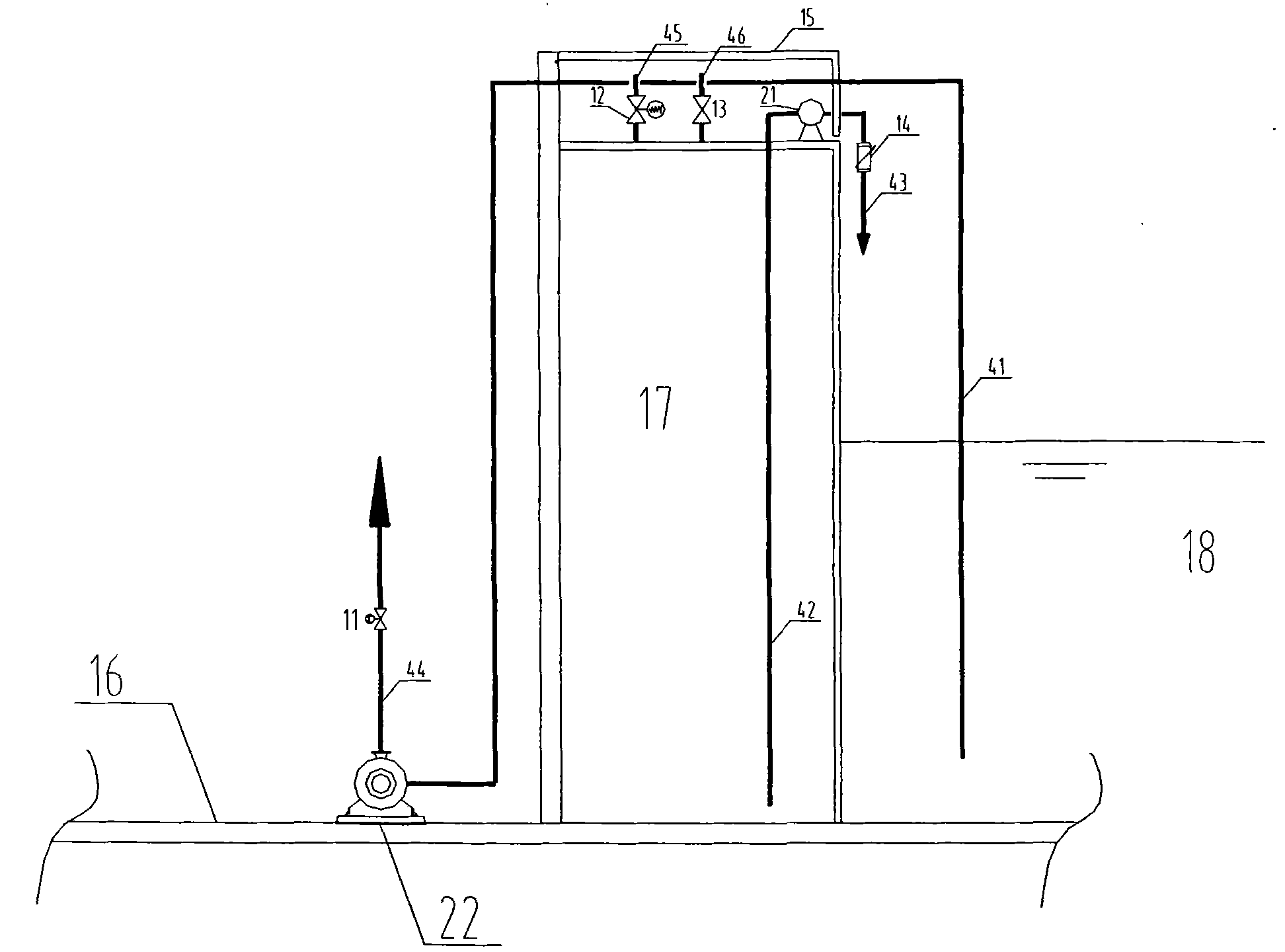

The invention relates to a salt-free dyeing method of vinyl sulphone type reactive dye for cotton fiber, mainly comprising the steps of modifying cotton fiber, dyeing the cotton fiber and the like. The modifying treatment is realized by the steps of: soaking and rolling the cotton fiber by a solution containing acrylamide respectively for two times, and then soaking in a sodium hypochlorite solution to perform Hoffman degradation. The modified cotton fiber is dyed by the vinyl sulphone type reactive dye under a salt-free condition; and therefore, the dyeing rate and the color fixing rate of the dye are improved. By use of the salt-free dyeing method, the content of inorganic salts in dyeing wastewater is reduced, benefit is brought for environment protection, a cotton fiber modifying process can be combined with a chlorine blanching process, the production process is simple and the application prospect is wide.

Owner:QINGDAO UNIV

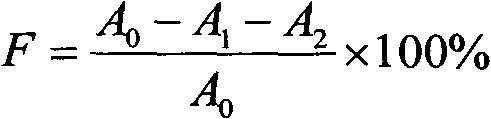

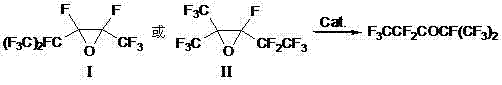

Preparation process of perfluoro-2-methyl-3-pentanone

ActiveCN103787854AHigh selectivityHigh yieldPreparation from heterocyclic compoundsGas phaseReaction rate

The invention discloses a preparation process of perfluoro-2-methyl-3-pentanone, belonging to the technical field of preparation methods of perfluoroketone compounds in the field of organofluorine chemistry. The perfluoro-2-methyl-3-pentanone is obtained by performing an epoxidation reaction and a catalytic isomerization reaction on perfluoro-2-methyl-pentene serving as a raw material in sequence. The preparation process comprises the following steps: I, in a continuous liquid phase epoxidation reaction, mixing a corresponding proportion of aprotic polar solvent into a sodium hypochlorite solution to promote the reaction, increase the raw material conversion ratio and increase the reaction rate at least by 2-3 percent, wherein the step is characterized by easiness and convenience in operation, low equipment requirement and high reaction equipment efficiency; II, performing a continuous gas phase catalytic reaction, wherein the application of a solvent is effectively avoided, the cost and environmental pollution are lowered, the problems of the need of separating the solvent from a product in post-treatment, difficulty in recycling and treating the solvent and a catalyst, and the like are solved, and the product can be refined and purified more easily. The preparation process has the advantages of high process automation degree, easiness and convenience in operation, high product purity and high reaction equipment efficiency, and is suitable for industrial application.

Owner:浙江诺亚氟化工有限公司

Preparation method of prismatic biological calcium carbonate

InactiveCN103571235AWide variety of sourcesImprove surface activityPigment treatment with organosilicon compoundsPigment physical treatmentPotassium hydroxideMechanical property

The invention discloses a preparation method of prismatic biological calcium carbonate. The preparation method comprises the following steps: washing shells to remove residues, soaking the shells in a sodium hydroxide solution, a potassium hydroxide solution or a sodium hypochlorite solution and washing the shells to remove stratum corneum; soaking the samples without the stratum corneum in a sodium hydroxide solution or a potassium hydroxide solution for 30-180 minutes, and washing the samples in a roller for separating prismatic layers of the shells from nacreous layers of the shells, thus obtaining the prismatic layers of the shells; mixing powder obtained by grinding the prismatic layers of the shells with water and a grinding aid and stirring the mixture at high speed to prepare pulp; grinding the prepared pulp and performing dehydration, washing and re-dehydration to obtain filter cakes; adding water to the washed filter cakes to prepare pulp and adding a surfactant in the stirring process; drying surface modified shell prismatic biological calcium carbonate and then breaking the dried surface modified shell prismatic biological calcium carbonate apart, thus obtaining the finished product. The shell prismatic biological calcium carbonate has natural oleophylic hydrophobicity and excellent mechanical property, has good compatibility with matrixes and is uniformly distributed in the matrixes.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

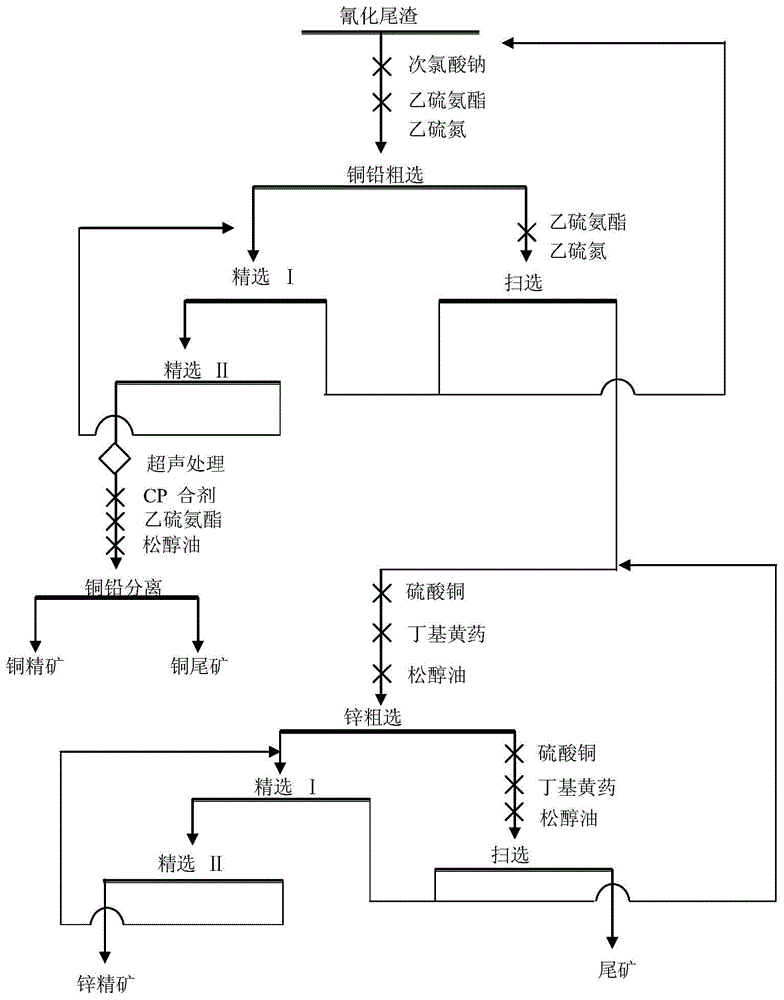

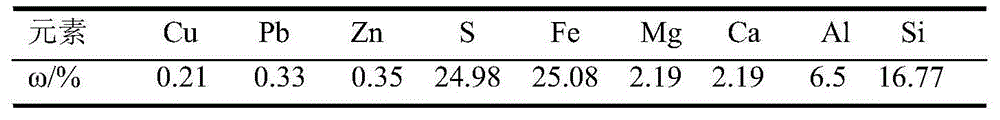

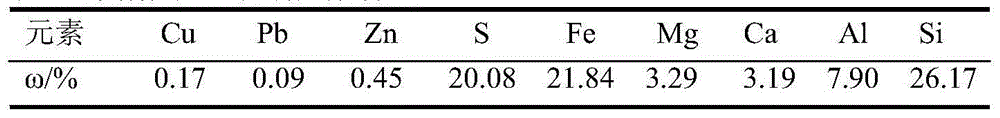

Method for recovering low-grade copper-zinc mineral from cyanidation tailings

The invention discloses a method for recovering low-grade copper-zinc mineral from cyanidation tailings. The method comprises the following specific process steps: (1) adding water into the cyanidation tailings for mixing slurry; (2) adding a sodium hypochlorite solution into pulp, and stirring; (3) adding diethyl dithiocarbamate and ethionine ester as collecting agents, and stirring; (4) performing bulk flotation on copper-lead mineral by performing roughing once, concentration twice and scavenging once to obtain copper-lead mixed concentrate and copper-lead flotation tailings; (5) performing ultrasonic oscillation on slurry-mixed copper-lead mixed concentrate, dehydrating the copper-lead mixed concentrate subjected to ultrasonic oscillation to obtain a filter cake, mixing slurry once again, adding a CP mixture as a conditioning agent, adding ethionine ester as a collecting agent, and adding terpenic oil as a foaming agent for flotation to obtain qualified copper concentrate and copper flotation tailings; (6) performing slurry mixing on the copper-lead flotation tailings, adding copper sulfate for activating zinc mineral, adding sodium butyl xanthogenate as a collecting agent, and adding terpenic oil as a foaming agent for floatation to obtain zinc concentrate and zinc flotation tailings.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

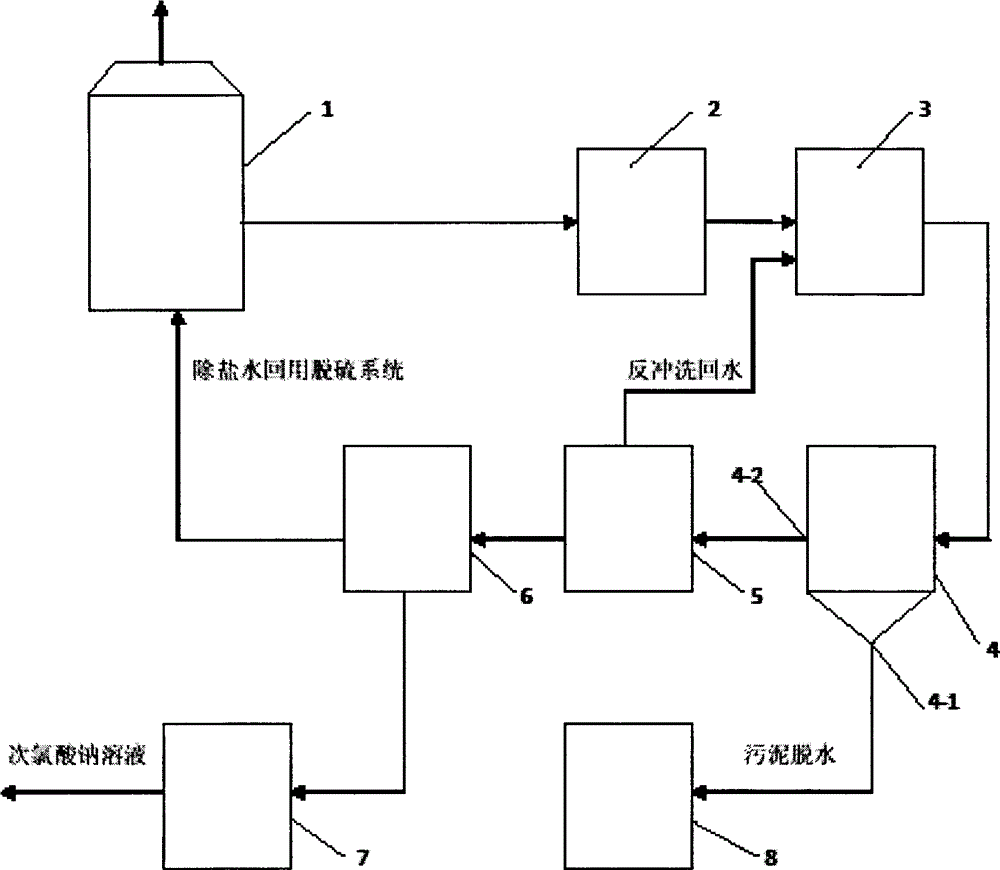

Wet desulphurization wastewater recycling method and apparatus thereof

InactiveCN105314773AAchieve softeningAchieve recyclingElectrolysis componentsMultistage water/sewage treatmentFlocculationUltrafiltration

The invention discloses a wet desulphurization wastewater recycling method and an apparatus thereof. Collected desulphurization wastewater from a gypsum dehydration device enters a flocculation reactor and is pretreated, the desulphurization wastewater is neutralized, flocculated, softened and clarified, and sludge is sent to a sludge treatment device and is dehydrated; separated clarified water undergoes two-stage ultrafiltration, nanofiltration and reverse osmosis desalting, and desalted water returns to a desulphurization system or other water systems. Desalted concentrated water is a high concentrate salt (NaCl) solution, and the high concentrate salt (NaCl) solution goes through a sodium hypochlorite generator to directly electrolyze salt-containing water in order to prepare a sodium hypochlorite solution, and the sodium hypochlorite solution can be used for sterilizing and disinfecting water to realize effective utilization, changing of wastes into valuables and recycling of the desulphurization wastewater, realize complete recycling of the desulphurization wastewater and realize resource recycling. Further, the method has the advantages of no influences on other systems in a power plant, strong practicality, low investment, realization of resource recycling, and wide popularization and use values.

Owner:王辛平

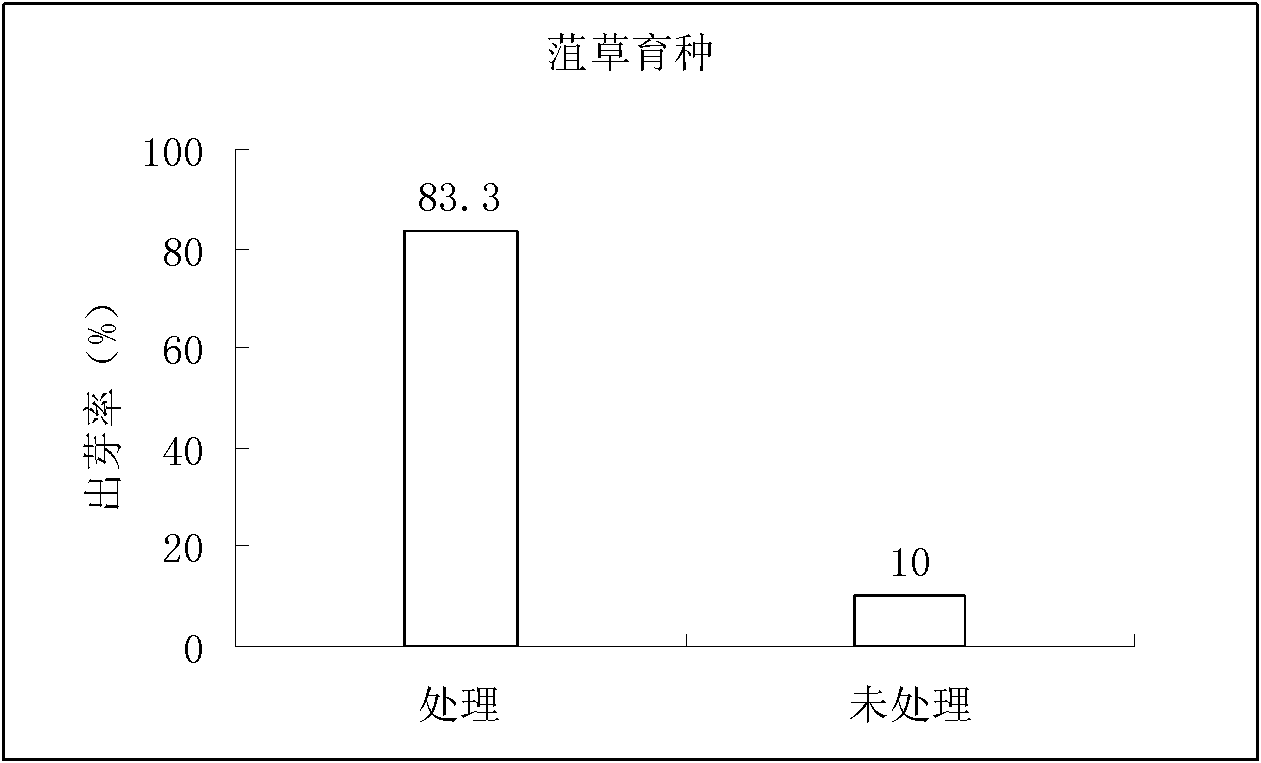

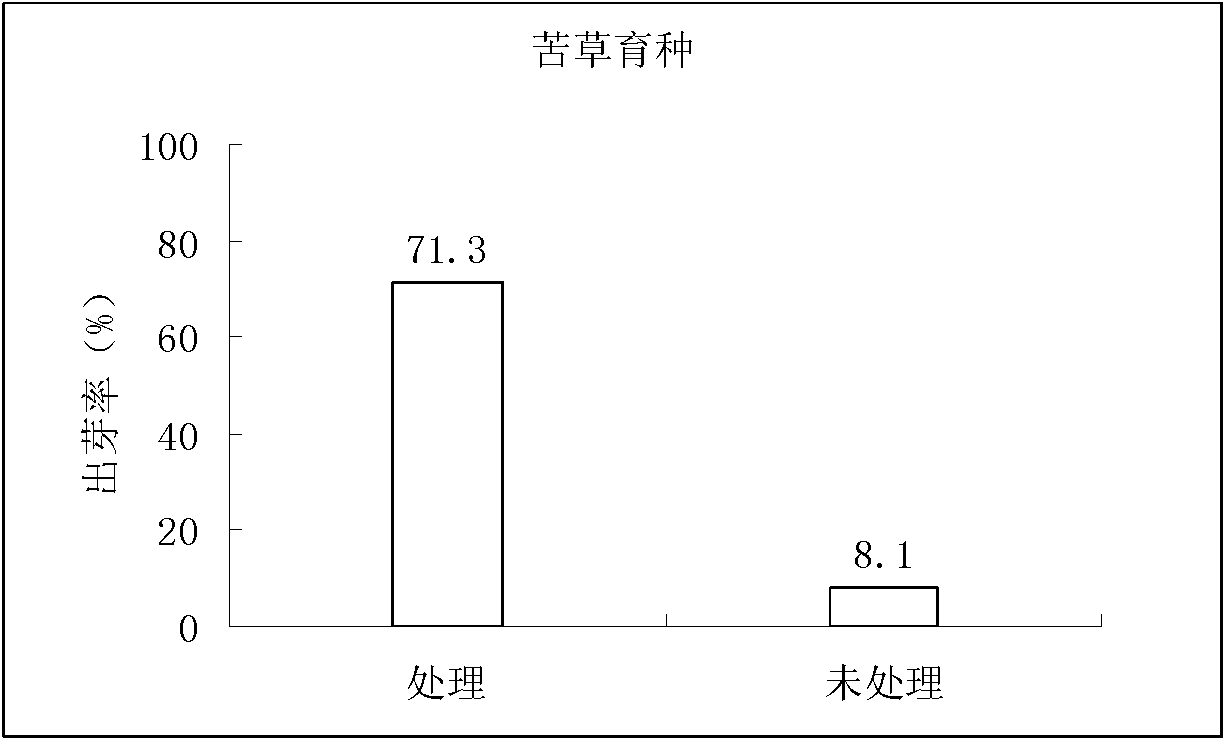

Method for culturing submerged plant seeds

ActiveCN102172154APromote germinationPhysiological process promotionSeed immunisationHorticultureApomixisPlant hormone

The invention relates to a method for culturing submerged plant seeds. The method comprises the following steps: A, soaking the submerged plant seeds produced by apomixia in 0.01-1wt% of dimethoate or sodium hypochlorite solution for 1-6 hours, washing the soaked submerged plant seeds with clear water, naturally drying the soaked submerged plant seeds in the air; B, standing the submerged plant seeds at 20-25 DEG C for 1-3 days, storing at 1-5 DEG C for 1-2 days, and preserving at 30-40 DEG C for 12-36 hours; C, soaking the submerged plant seeds in solution containing plant hormone, trace elements and inorganic salt for 12-24 hours; and D, burying the submerged plant seeds in a matrix by a depth of 3-5cm, and then putting the matrix in which the submerged plant seeds are buried at the bottom of river or lake water. The matrix comprises humus, sediment at the bottom of river and lake, bank soil, clay and sand. The submerged plant seeds bred by the method have high germination rate and environmental adaptability.

Owner:江河水利开发中心有限责任公司

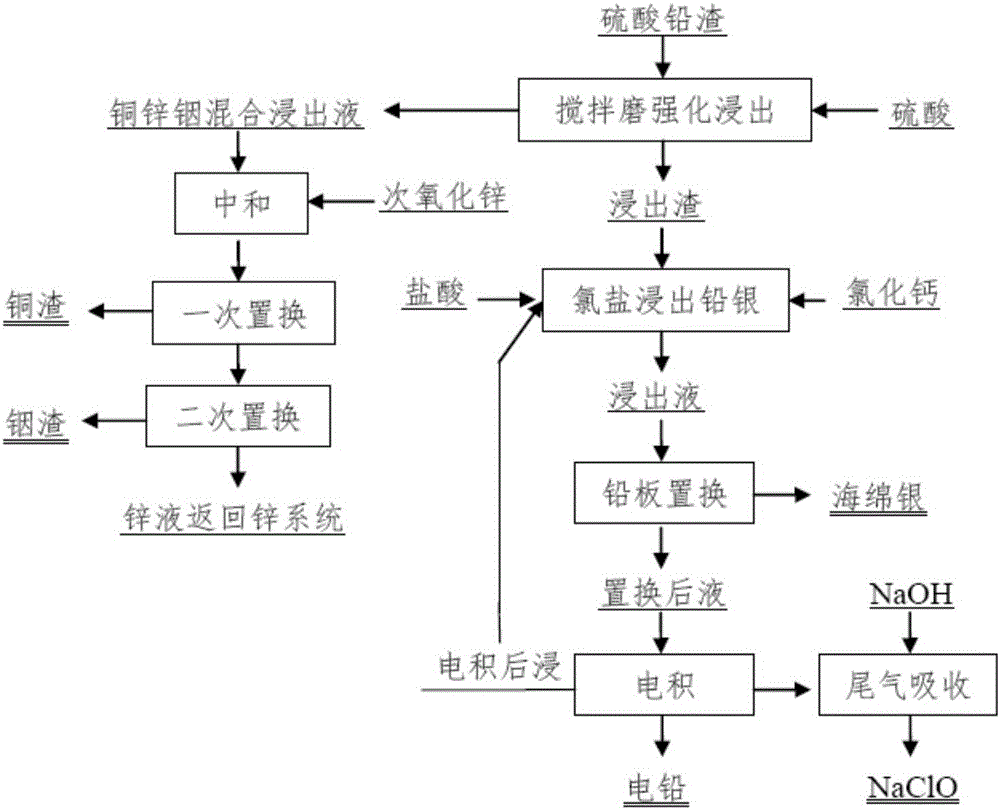

Method of comprehensively recycling valuable metal from lead sulfate slag

ActiveCN105907974ASimple processReduce investmentPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention provides a method of comprehensively recycling valuable metal from lead sulfate slag and belongs to the technical field of hydrometallurgy. The method comprises the following steps: feeding lead sulfate slag in a stirred mill, adding sulfuric acid for intensifying leaching, leaching the copper, zinc and indium, feeding the leached copper, zinc and indium in solution, adjusting the pH of the solution with zinc hypoxide, replacing copper and indium sequentially from the solution with zinc powder to obtain slag rich in copper and indium, returning to the copper and indium recycling process, after sulfuric acid leaching, obtaining the leached slag rich in lead and silver, adding calcium chloride solution and a small amount of hydrochloric acid in the leached slag to leach the lead and silver, feeding the lead and silver in the solution, replacing silver in the lixivium with a metallic lead plate to obtain crude silver powder, adopting the electrodeposition technology in silver replacement-post solution to produce electric lead, during the electrodeposition process, generating sodium hypochlorite solution after absorbing chlorine generated on the anode by NaOH, and returning to the lead and silver leaching process by regarding silver electrodeposition-post solution as a leaching agent. The method has the characteristics of short technological processes, few working procedures and low energy consumption and cost and meets the environmental protection requirements of clean production.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com