Patents

Literature

81 results about "Whitewash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whitewash, or calcimine, kalsomine, calsomine, or lime paint is a type of paint made from slaked lime (calcium hydroxide, Ca(OH)₂) or chalk calcium carbonate, (CaCO₃), sometimes known as "whiting". Various other additives are sometimes used.

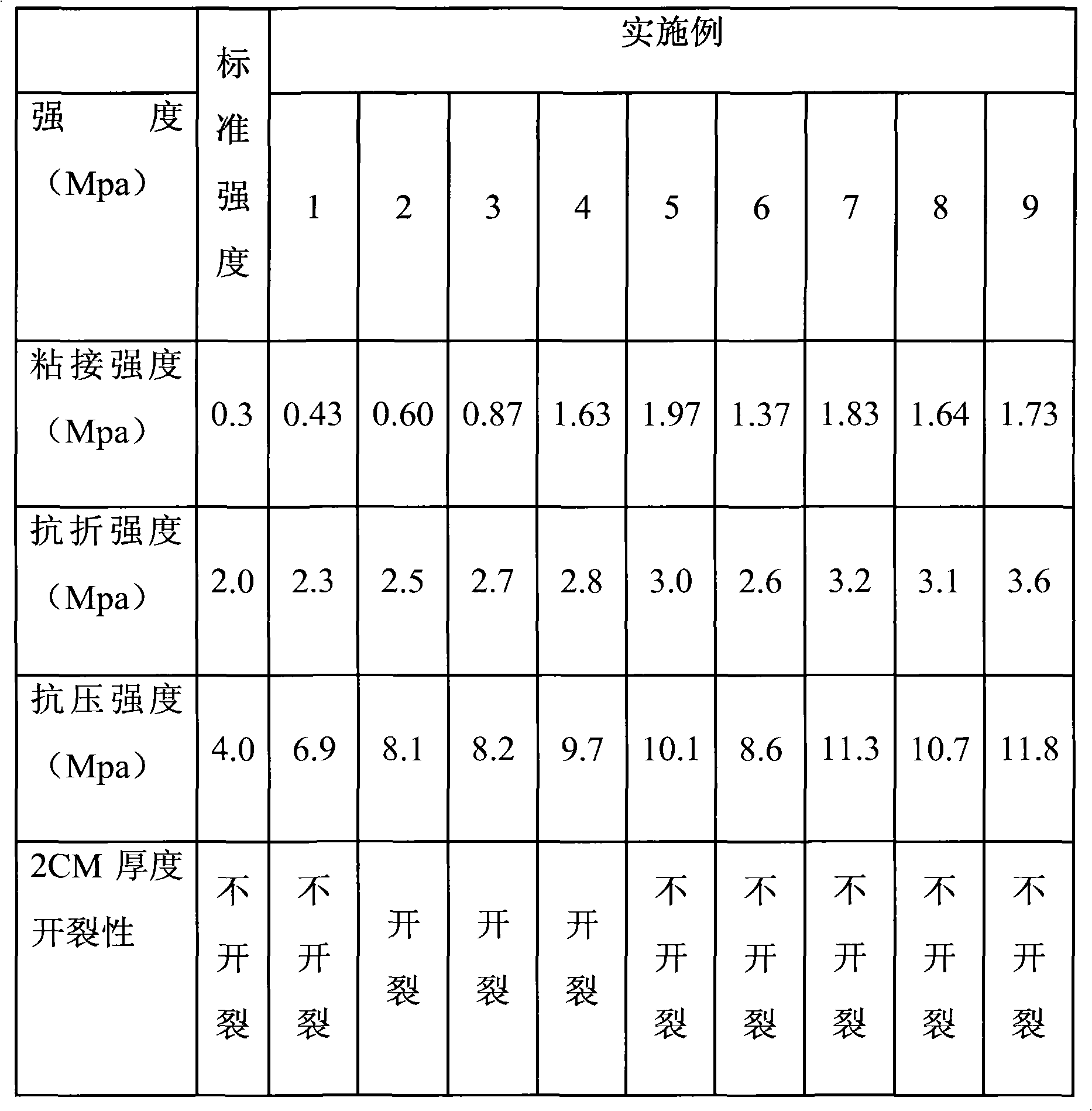

Antibacterial mildew-proof high-strength whitewash mortar

The invention discloses antibacterial mildew-proof high-strength whitewash mortar, which comprises the following components: silicate black cement, flyash, blast furnace slag, building gypsum, quartz sand, a nano antibacterial mildew preventive, a regulator, an inorganic gel, a retarder, an anti-cracking agent and re-dispersible gelatine powder. The nano antibacterial mildew preventive is nano zinc oxide with the fineness of 30nm; the regulator is hydroxypropyl methyl cellulose; the inorganic gel is sodium bentonite; the retarder is a retarder special for polyphosphate gypsum; the anti-cracking agent is lignocellulose; and the re-dispersible gelatine powder is polyvinyl acetate or ethylene resin. The mildew-proof whitewash mortar prepared according to the formula has the advantages of good mildew resistance and water resistance and extremely strong bonding strength; and after the whitewash mortar is prepared into plastering mortar, the brushed base plane has the advantages of no hollowness, no crack, excellent mildew-proof performance, strong adhesive property, high breaking strength and compression strength, and convenient construction simultaneously.

Owner:童捷

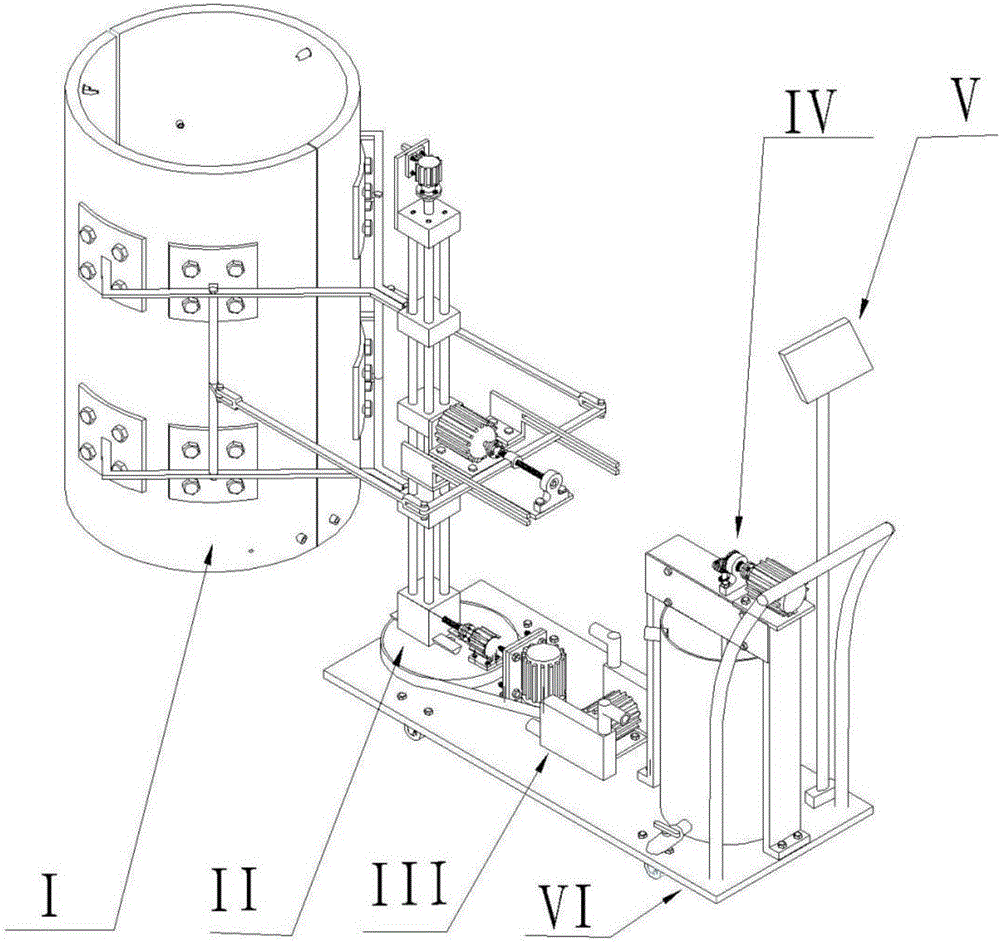

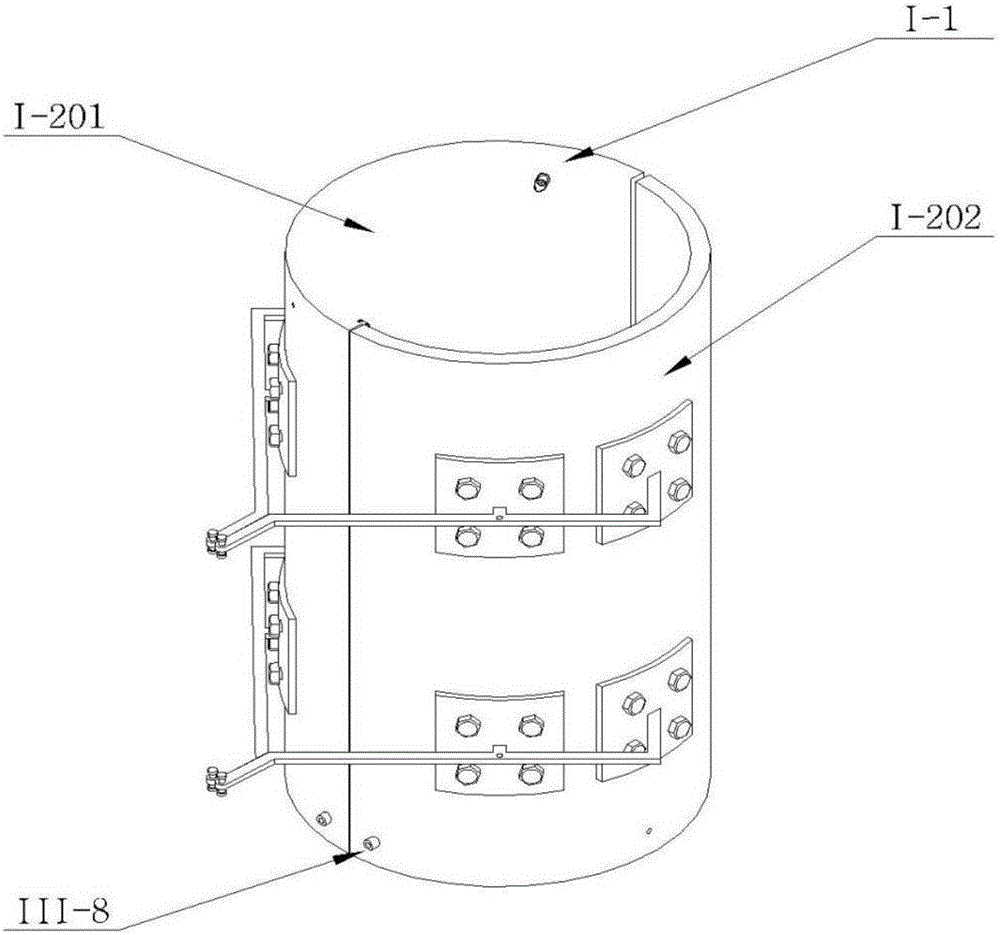

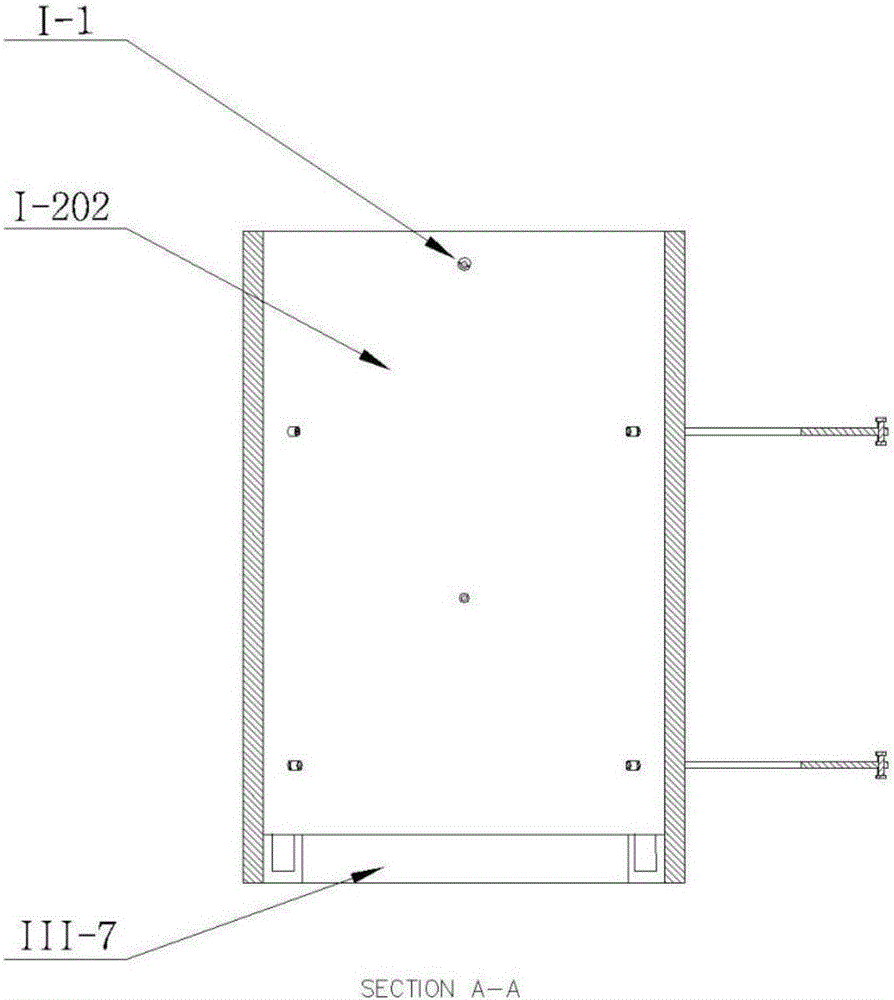

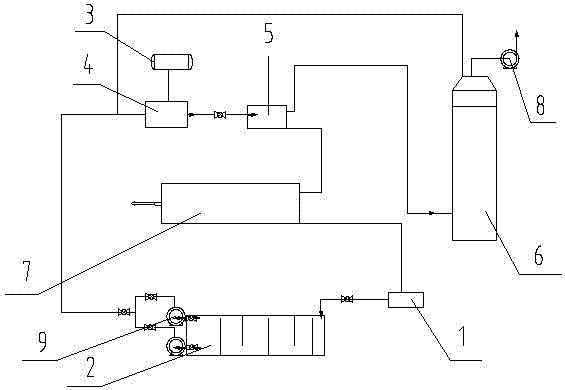

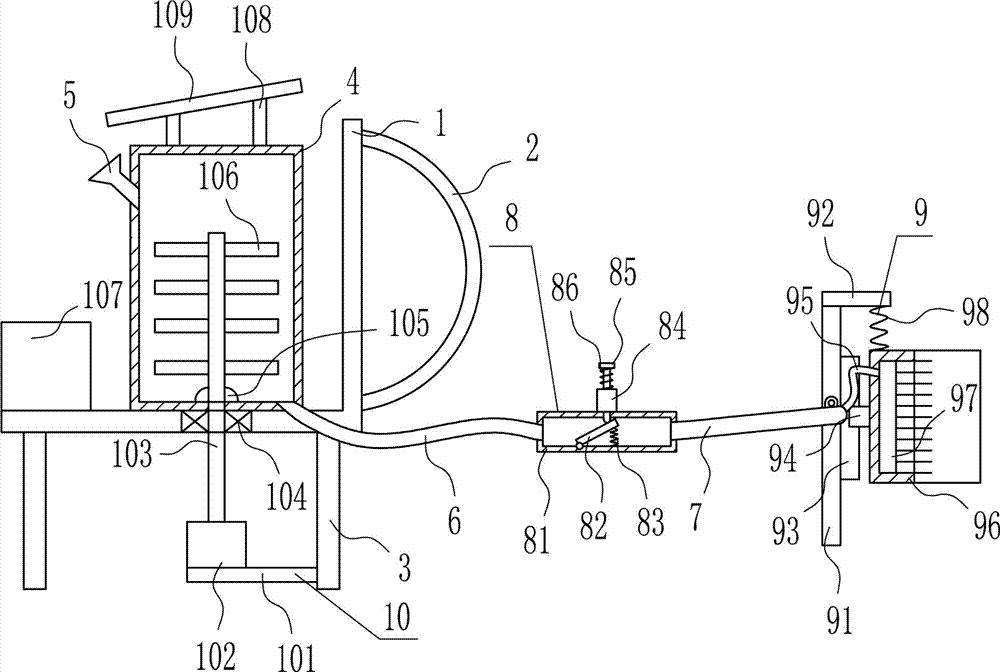

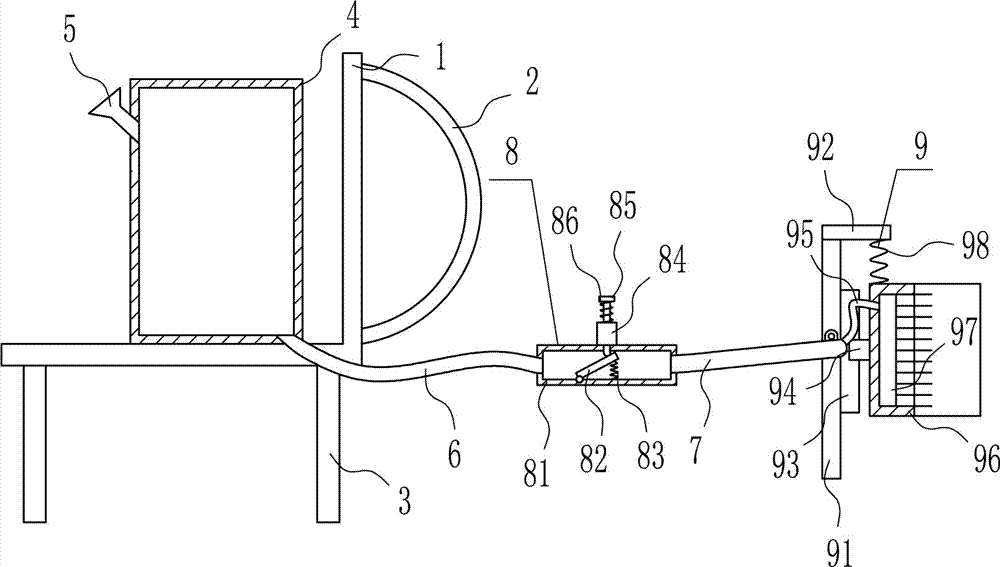

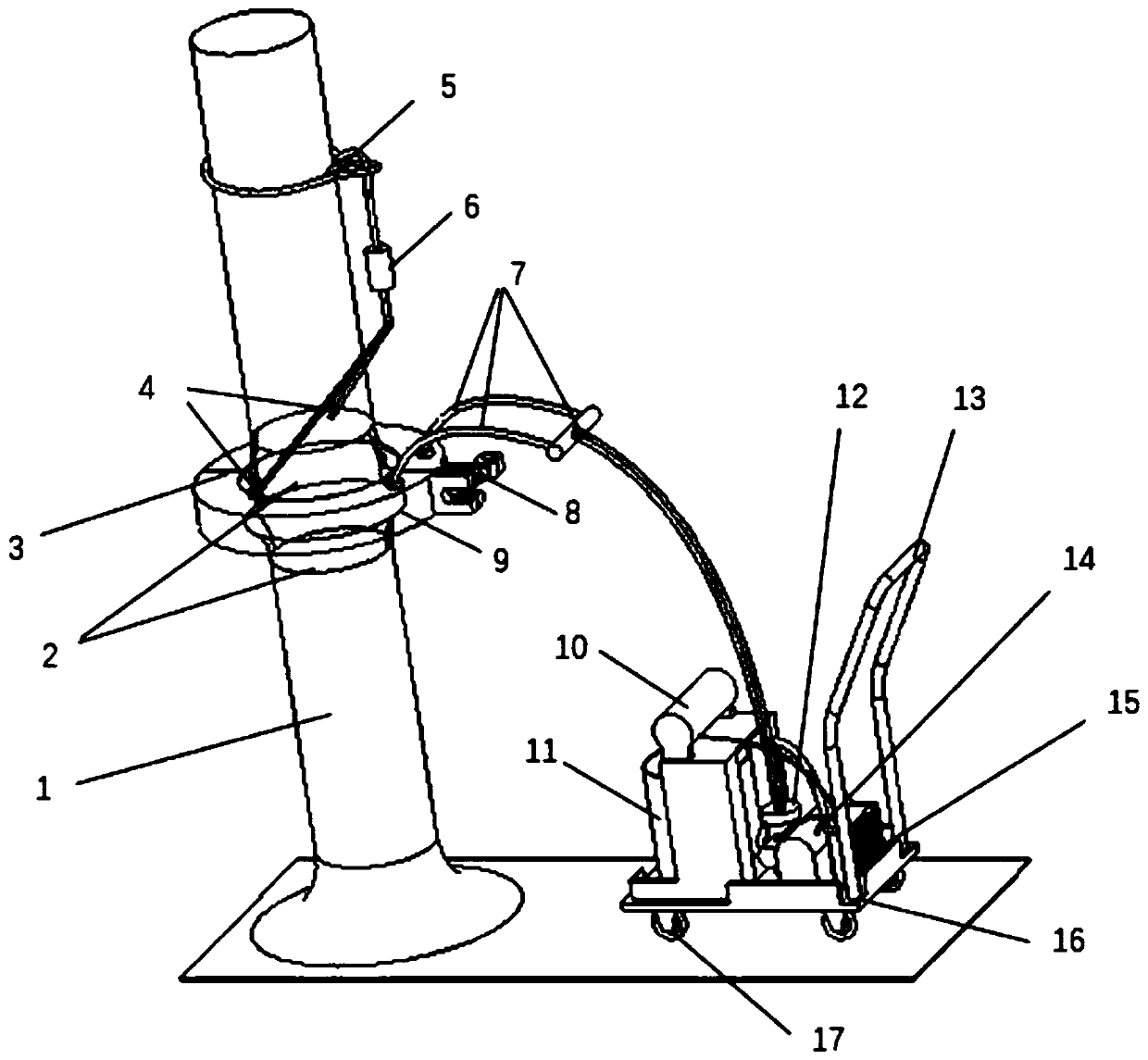

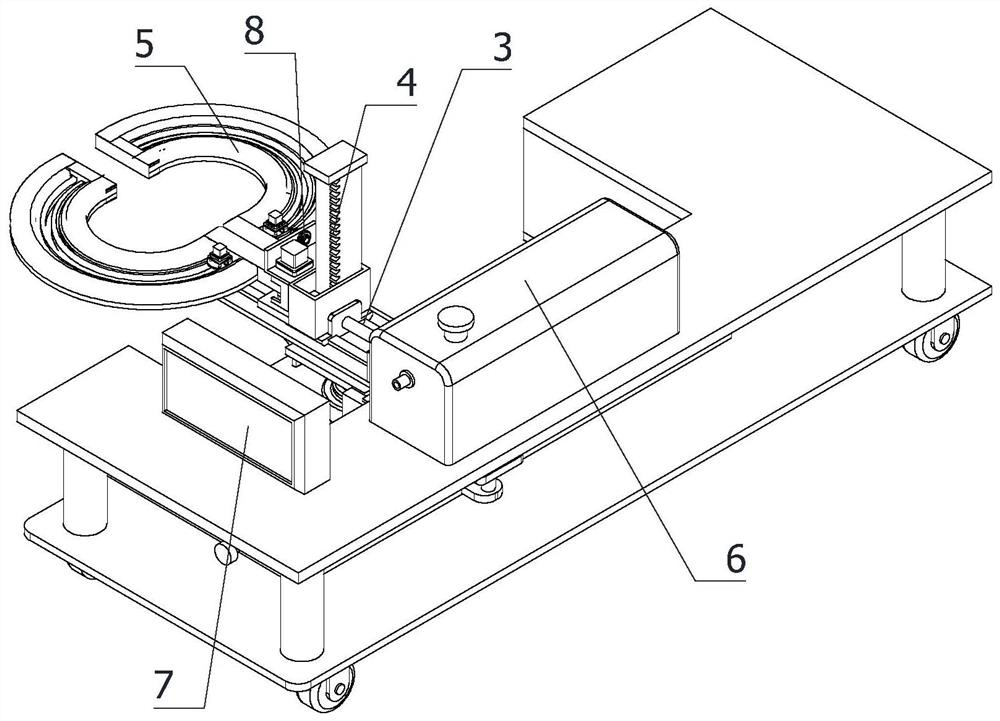

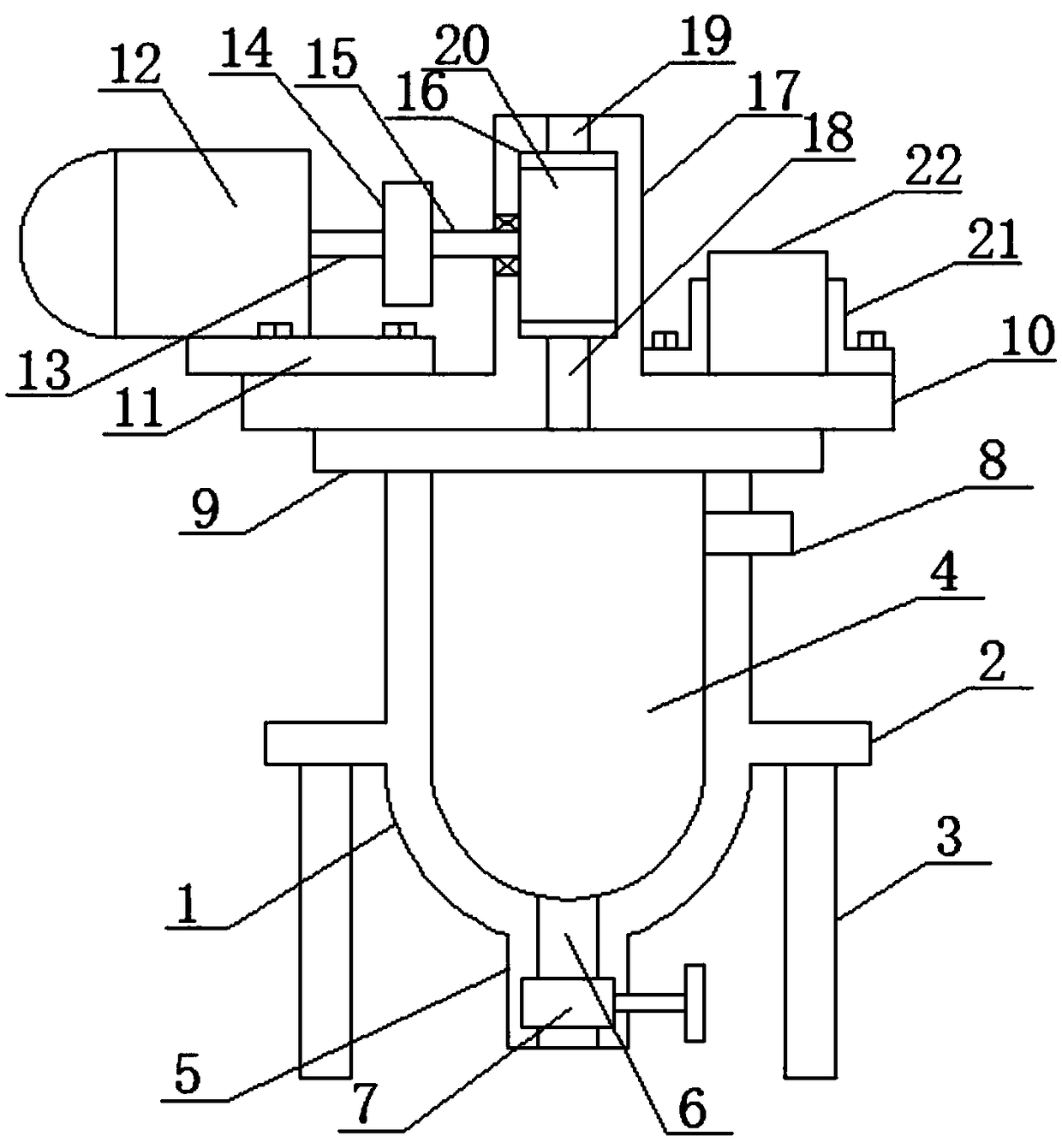

Semi-automatic tree whitewash machine

InactiveCN106733351AIncrease flexibilityAvoid wasteful situationsLiquid spraying apparatusPlant protectionLiquid wasteSprayer

The invention discloses a semi-automatic tree whitewash machine. The problems that in the prior art, pesticide liquid waste is serious, pesticide liquid generates sediment after long-time standing, and operation is complex are solved. During spraying, a stirring part continuously operates, the effect of pesticide liquid is kept, a recycling part automatically recycles surplus pesticide liquid, the production efficiency is greatly improved, labor cost is reduced, land salinization is relieved, and the environment is protected. According to the technical scheme, the semi-automatic tree whitewash machine comprises a spraying mechanism. The spraying mechanism comprises a spraying sleeve, a sprayer head is arranged in the spraying sleeve, and anti-splash shielding devices are arranged at the top end and the bottom end of the spraying sleeve in a matched mode and used for shielding splashing spraying liquid into the spraying sleeve during spraying. The spraying mechanism is connected with a transmission mechanism. The transmission mechanism comprises a rotation driving assembly which drives the spraying mechanism to realize rotation. The spraying mechanism further communicates with a liquid supply and recycling mechanism which provides spraying liquid for the spraying mechanism and meanwhile recycles surplus spraying liquid at the spraying mechanism.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

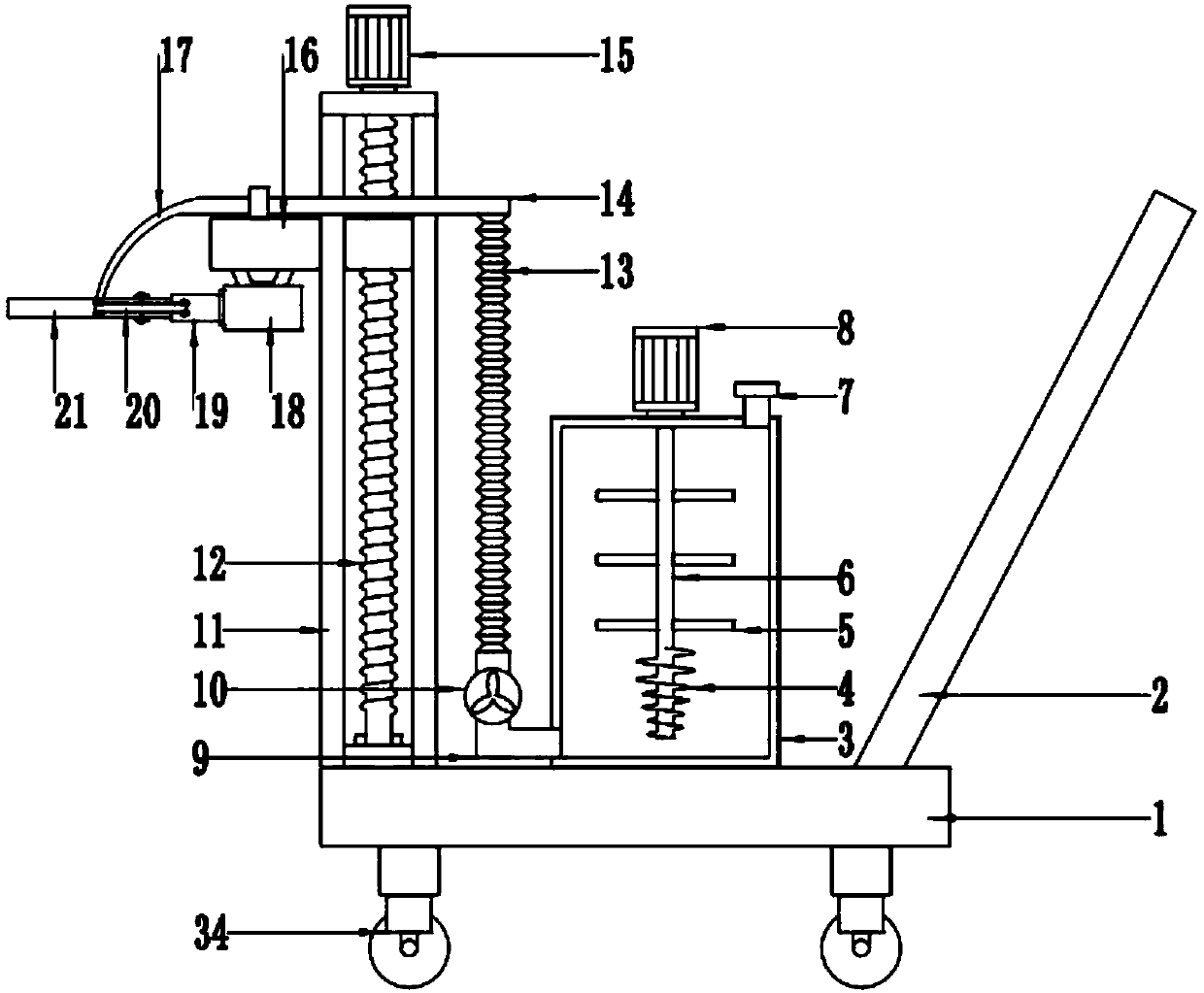

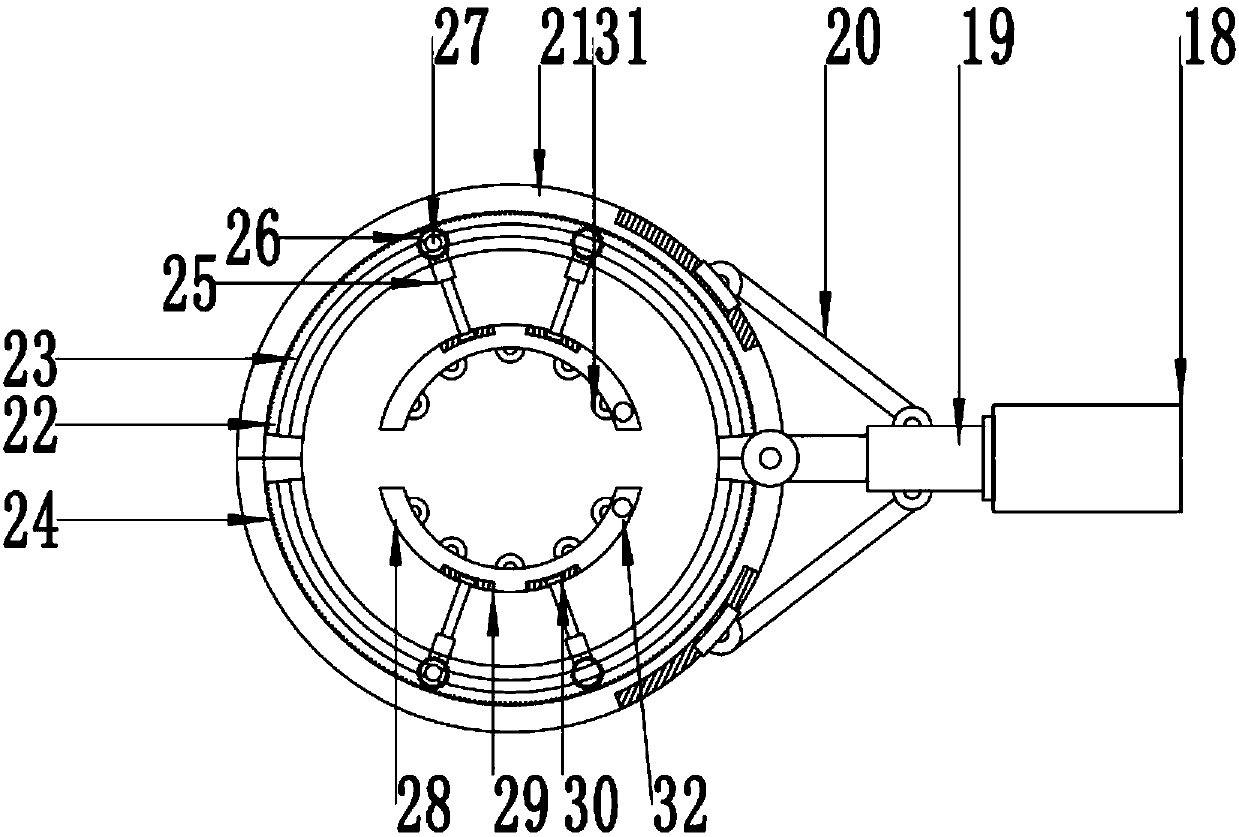

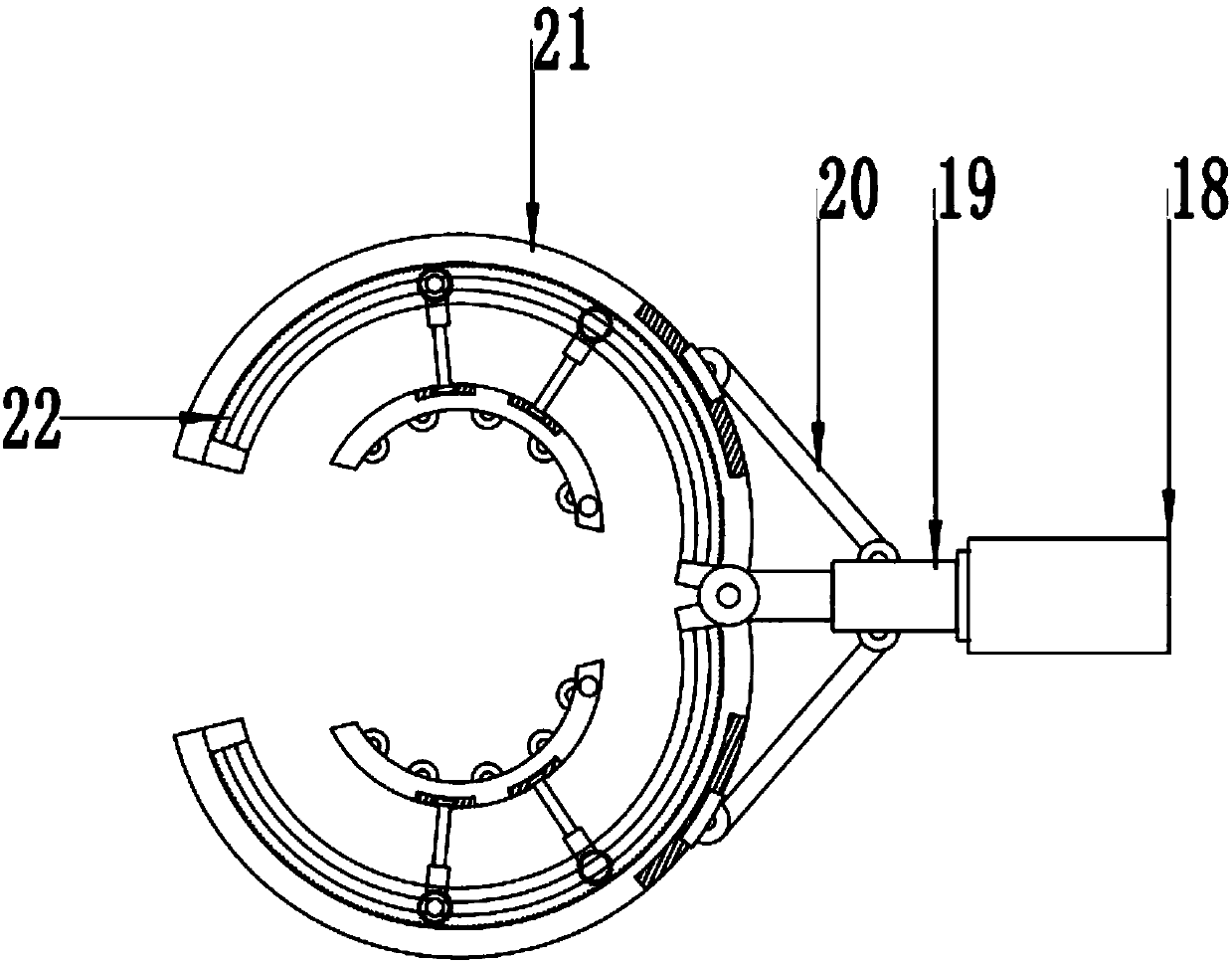

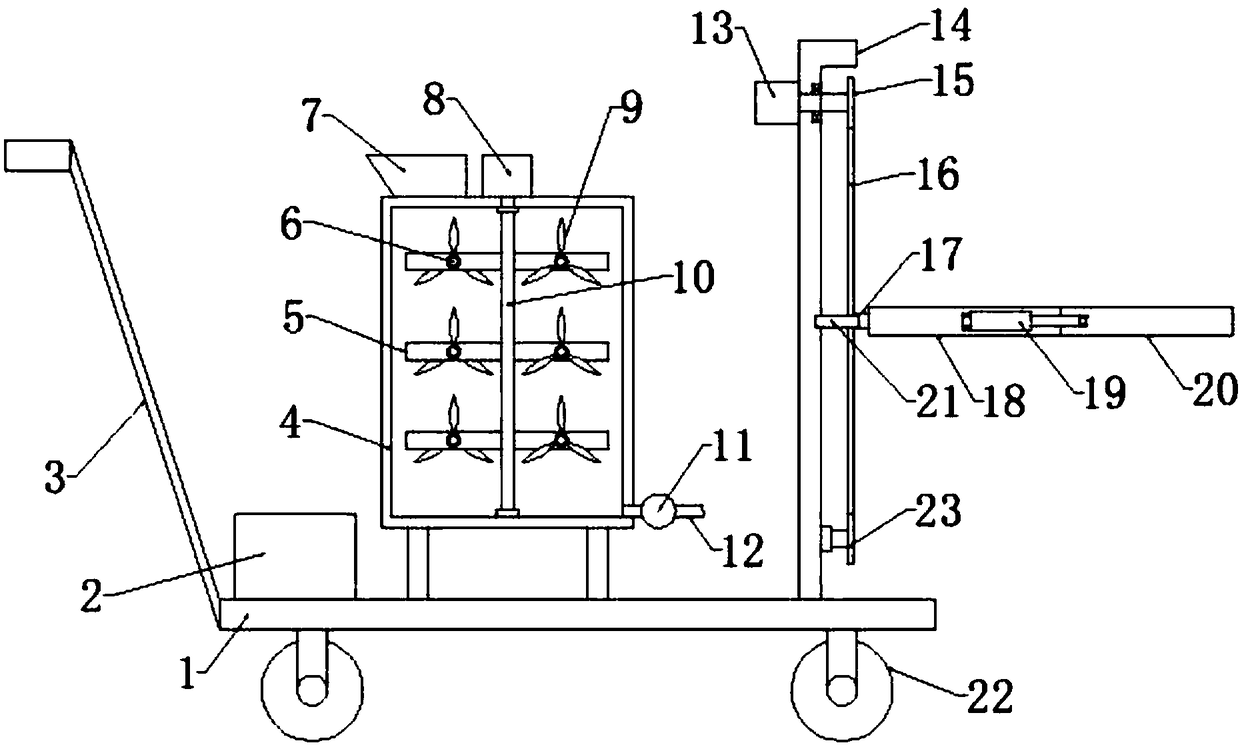

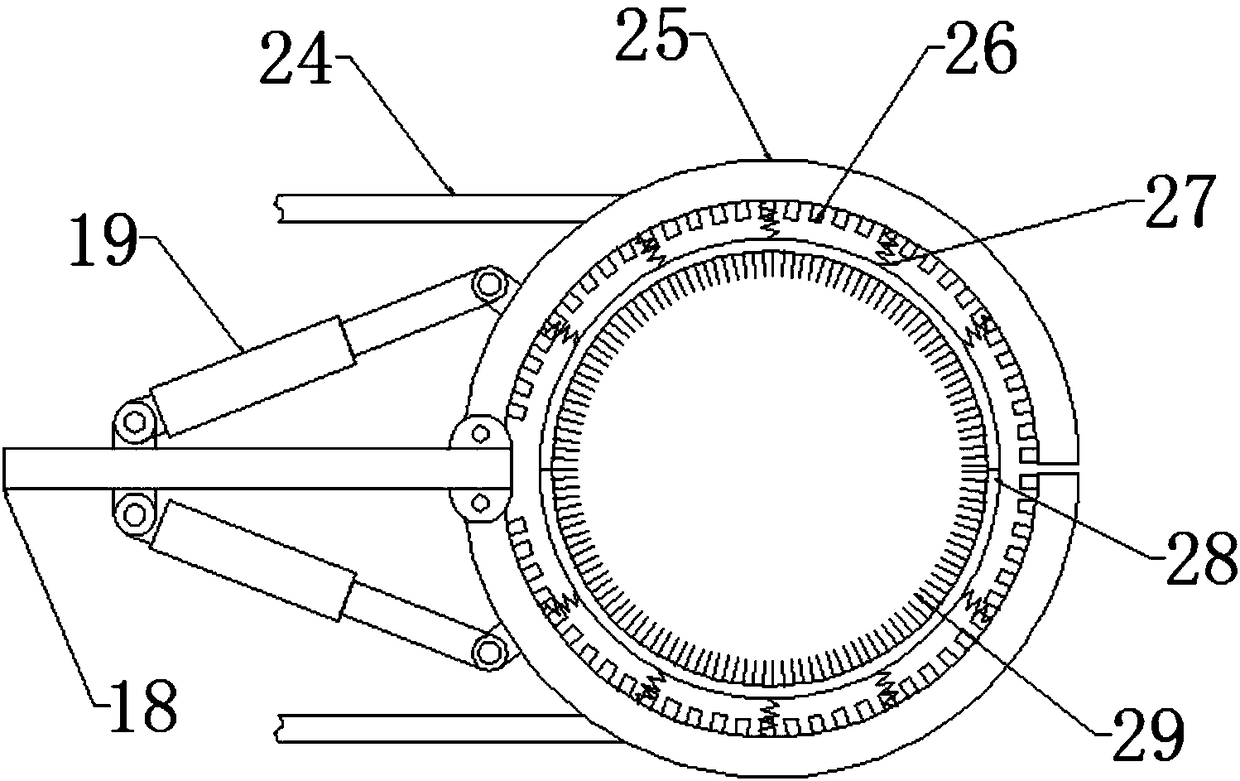

Whitewash device applicable to trees with different diameters

InactiveCN107583813AIncrease whitening perimeterEvenly paintedLiquid surface applicatorsRotary stirring mixersEngineeringWhitewash

The invention discloses a whitewash device applicable to trees with different diameters. The whitewash device comprises a bottom plate, a pushing handle, a material storage mechanism, a lifting mechanism and a paintingbrushing mechanism, wherein the pushing handle is arranged on the bottom plate, and the material storage mechanism is arranged on the left side of the pushing handle; the lifting mechanism is arranged on the left side of the material storage mechanism and comprises a lifting chamber, a threaded rod, a forward and reverse rotating motor A, a moving block and a fixed block; the painting mechanism is arranged on the left side of the lifting mechanism and comprises an electric telescopic rod A, connecting rods, arc plates A, arc plates B, arc chutes, arc racks, electric telescopic rods B, gears, forward and reverse rotating motors B, arc chambers, chutes, sliders, painting rollers, connecting ports and movable blocks. The whitewash device can paint the trees with different diameters white, is widely applied and has good painting effect and high whitewash efficiency.

Owner:SHENZHEN SHENGXIANG INTPROP CO LTD

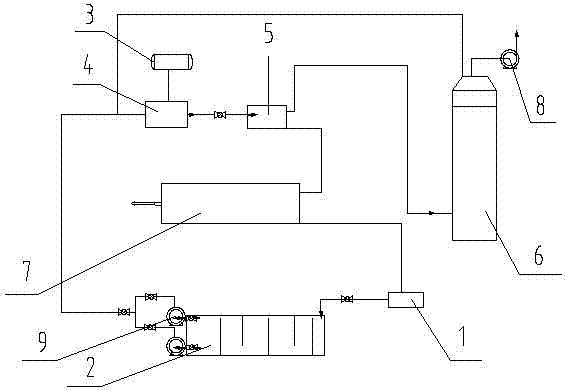

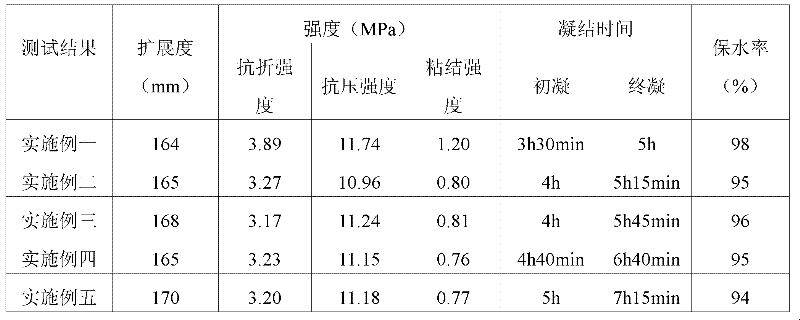

Process for treating organic silicon slurry slag

ActiveCN102180605ATake advantage ofSolve problems such as pollutionSolid waste disposalCement productionSlagSlurry

The invention relates to a process of comprehensively treating waste slag produced from organic silicon, aiming at continuously treating organic silicon slurry slag. In the process, whitewash and the organic silicon slurry slag are utilized for polymerization reaction, various generated pollutants are respectively treated, thus zero emission of gas is achieved, and air pollution is basically free. The process comprises the following specific steps: pumping exterior drainage from a sewage station 1 into a lime pool through a pump so as to dissolve the externally added lime into the whitewash, wherein the pH of the whitewash is more than or equal to 11; pumping the whitewash into a slurry slag treatment reactor through a mortar pump; and then adding nitrogen in a slurry slag tank so as to punch to 0.03MP, thus pressing the slurry slag into the slurry slag treatment reactor for reaction, wherein hydrolyzates can be externally sold, and monomers such as gas and the like can be absorbed though an absorption tower. Compared with the traditional organic silicon slurry slag treatment process, the process in the invention has the advantages that the organic silicon slurry slag is fully utilized, pollution is reduced to the minimum, and the organic silicon slurry slag is continuously treated, thereby achieving zero emission and basically having no air pollution.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

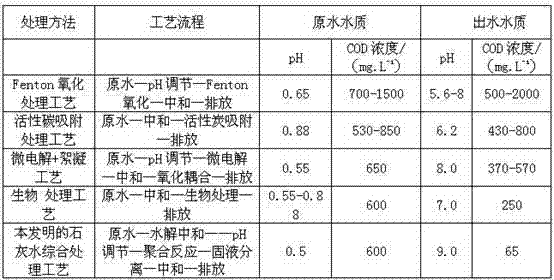

Surface layer whitewash gypsum using dry-process desulfurized ash as raw material and preparation method thereof

The invention relates to a surface layer whitewash gypsum using dry-process desulfurized ash as a raw material and a preparation method thereof. The surface layer whitewash gypsum using dry-process desulfurized ash is prepared from the following components in parts by weight: 40-60 parts of calcined desulfurized gypsum powder, 10-40 parts of dry-process desulfurized ash, 0.5-1 part of gypsum retarder, 0-0.2 part of adhesive, 0-0.2 part of water retention agent and 20-40 parts of filler. The invention develops a surface layer whitewash gypsum with high strength, strong binding power, favorablewater retention property and excellent workability, opens up a new way for producing excellent-property surface layer whitewash gypsum by using waste dry-process desulfurized ash, and fully utilizes desulfurized gypsum, dry-process desulfurized ash and other industrial residues to prepare the novel green energy-saving walling plastering material. The invention not only can reduce the environmental pollution, but also can recycle the waste, thereby reducing the abundant land resources occupied by waste placement and having wide development prospects.

Owner:NANJING UNIV OF TECH

Architectural whitewash device

The invention relates to an architectural whitewash device. The architectural whitewash device comprises a rack, a powder bucket for storing the powder, a pump for driving movement of the powder, a paint roller and a lifting device for driving the painting roller to move up and down. The paint roller comprises a feed pipe with a blind end, two end caps relatively arranged on the blind end of the feed pipe in a sleeving mode, a roller arranged on the two end caps in a sleeving and sealed mode and a coating set connected to the outside of the roller in a sleeving mode. The other end of the feed pipe is connected with the lifting device. A plurality of discharge holes are formed in the feed pipe and between the two end caps. The roller is rotationally connected with the end caps. A plurality of discharge troughs are formed along the circumferential direction on the roller. According to the structure of the architectural whitewash device, the power is saved and the structure is compact. The architectural whitewash device is easy to transfer and operate and has no paint blind zone.

Owner:CHONGQING FENGYUE BUILDING MATERIAL

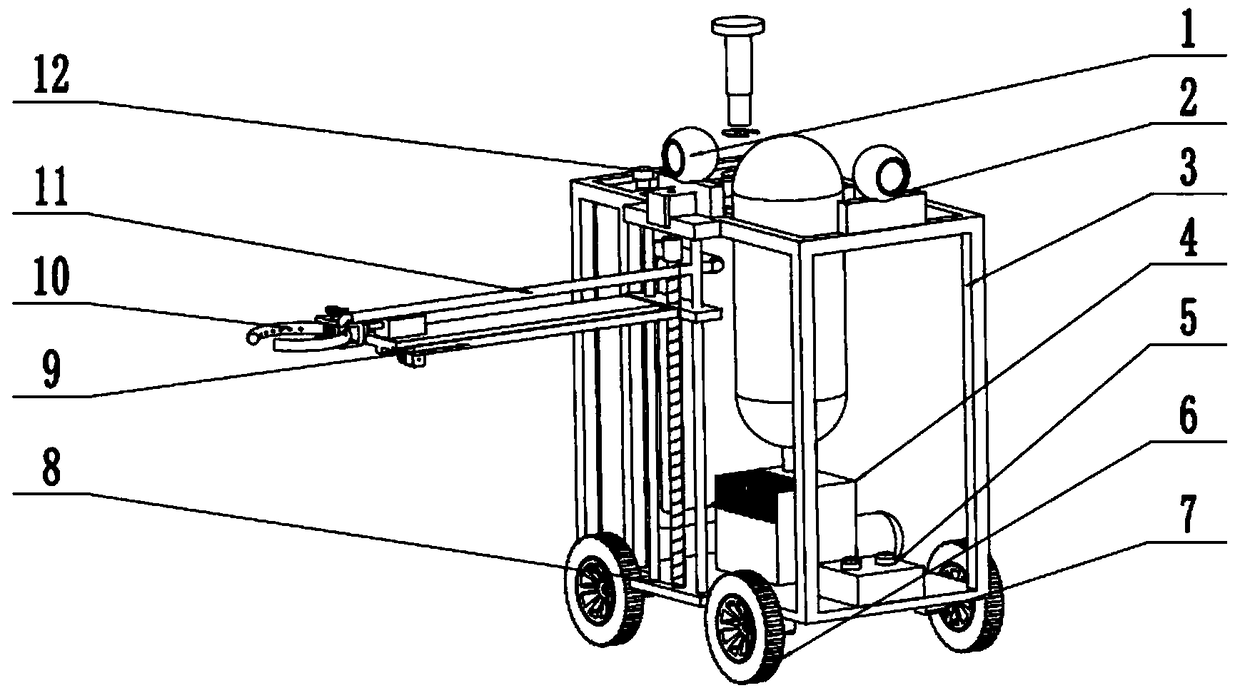

Fully automatic whitening machine for roadside trees

InactiveCN108160384AReduce laborImprove securitySpraying apparatusPlant protectionAir compressionDrive wheel

Provided is a fully automatic whitening machine for roadside trees. The fully automatic whitening machine for roadside trees comprises a spraying regulation and control camera module, a walking regulation and control camera module, a main steel frame assembly, an air compression assembly, a control cabinet, driving wheels, a driving motor, a lifting assembly, a telescopic assembly, a spraying assembly, a connecting pipe and a whitewash solvent tank, wherein the spraying regulation and control camera module is arranged on the main steel frame assembly, the walking regulation and control cameramodule is arranged on the main steel frame assembly, the air compression assembly is arranged on the main steel frame assembly, the control cabinet is arranged on the main steel frame assembly, the driving wheels are arranged on the main steel frame assembly, the driving motor is arranged on the main steel frame assembly, the lifting assembly is arranged on the main steel frame assembly, the telescopic assembly is arranged on the lifting assembly, the spraying assembly is arranged on the telescopic assembly, the connecting pipe is arranged on the spraying assembly, the connecting pipe is arranged on the whitewash solvent tank, the whitewash solvent tank is arranged on the main steel frame assembly. The fully automatic whitening machine for roadside trees can automatically whiten the roadside trees, the labor is reduced, and the security is higher.

Owner:袁超

Planting method for high-quality rice

InactiveCN105309257AImprove qualitySimple structureCalcareous fertilisersAlkali orthophosphate fertiliserRice plantsNonwoven fabric

The invention discloses a planting method for high-quality rice. The method includes the steps of planting broad beans in a rice seedling field, conducting green manuring and wet compositing after broad beans are harvested, applying fermentation chicken manure, conducting exposure, soaking rice seeds in whitewash, then soaking rice seeds in water till sprouting, obtaining soaked rice seeds, smoothing the rice seedling field, conducting irrigation and ridging, draining water to expose ridges, sowing seeds, spreading and shielding seeds and soil, laying nonwoven fabric, removing the nonwoven fabric 4-5 days before seed sowing, applying fermented chicken manure, conducting rice seedling transplanting 2-3 days after water controlling and seedling hardening, keeping the field water level at 3-5 cm during the period from rice seedling transplanting to tillering, applying urea, potassium chloride and calcium superphosphate in a dressing mode, applying composite fertilizer after rice enters the heading stage, spraying biological pesticide, applying urea, potassium chloride and calcium superphosphate in a dressing mode after rice enters the postulation period, cutting off water to make the field dry 7-10 days before rice matures, and conducting harvesting after rice matures. Rice planted through the method is good in quality and high in yield.

Owner:ANHUI MUMAHU AGRI DEV GRP

Method for producing high-strength environment-friendly whitewash gypsum by using desulfurization gypsum

InactiveCN101580372AChanging the particle size distributionHigh particle contentUltimate tensile strengthWhitewash

The invention relates to a method for producing high-strength environment-friendly whitewash gypsum by using desulfurization gypsum. The method comprises the following steps of: firstly, frying the desulfurization gypsum into desulfurization building gypsum with Beta-type semi-hydrated gypsum as the main component, and grinding the desulfurization building gypsum till the specific surface area is 2000-2500cm / g, thus obtaining modified desulfurization building gypsum; and secondly, sequentially doping 0.5-0.6 percent of set retarder and 0.2-0.4 percent of water retention agent into the modified desulfurization building gypsum obtained in the first step according to mass percentage, mixing evenly and then packaging the mixture, thus obtaining the finished product. By grinding and modifying the fried desulfurization building gypsum, the method changes the particle grading distribution of the desulfurization building gypsum and effectively improves the physical properties such as the water retention property, the strength and the like of the whitewash gypsum; the utilization of the muscle protein type gypsum set retarder for adjusting the setting time greatly reduces the strength loss caused by the prolonging of the setting time; and the product obtained according to the method meets environmental protection requirements.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

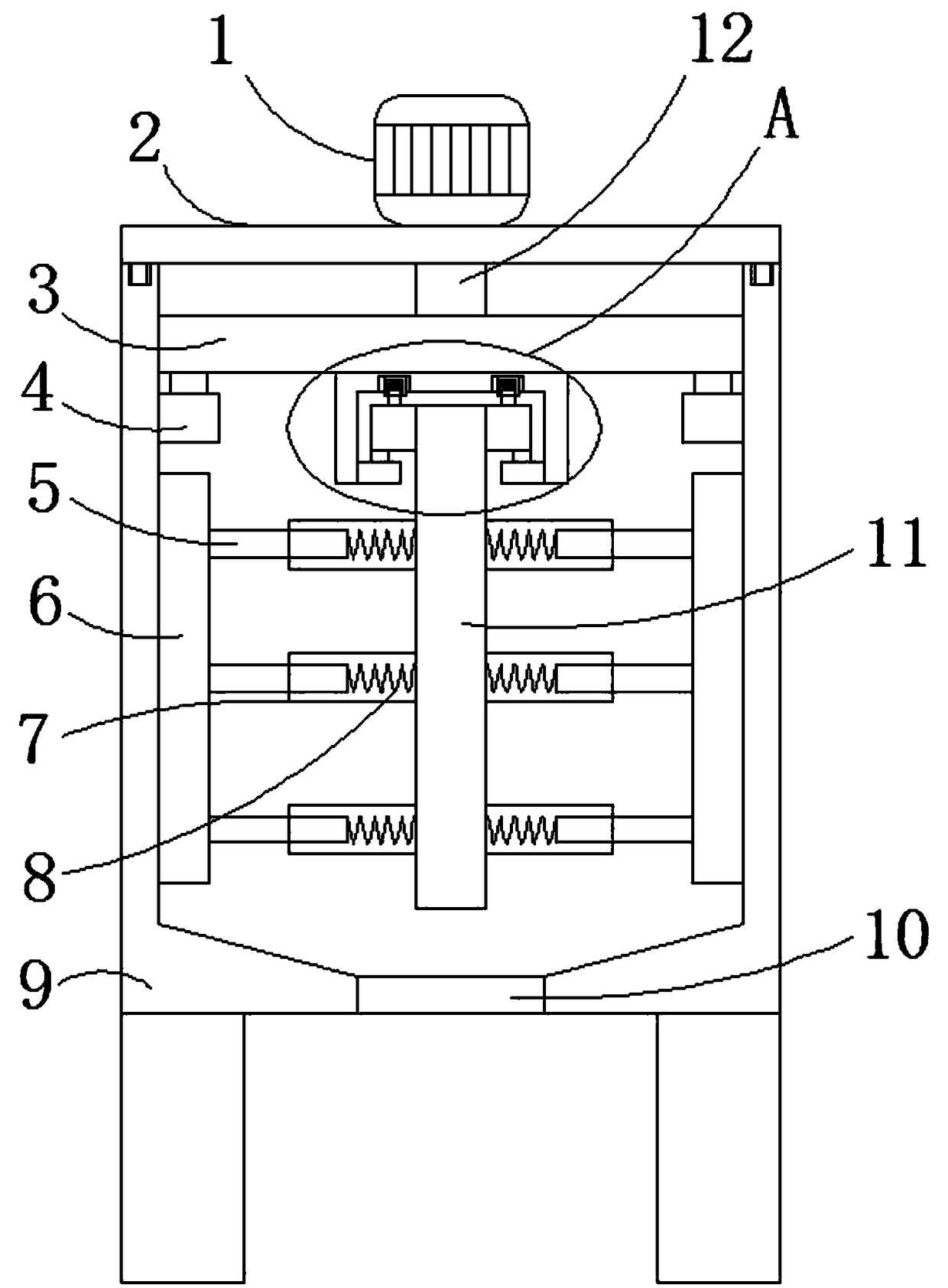

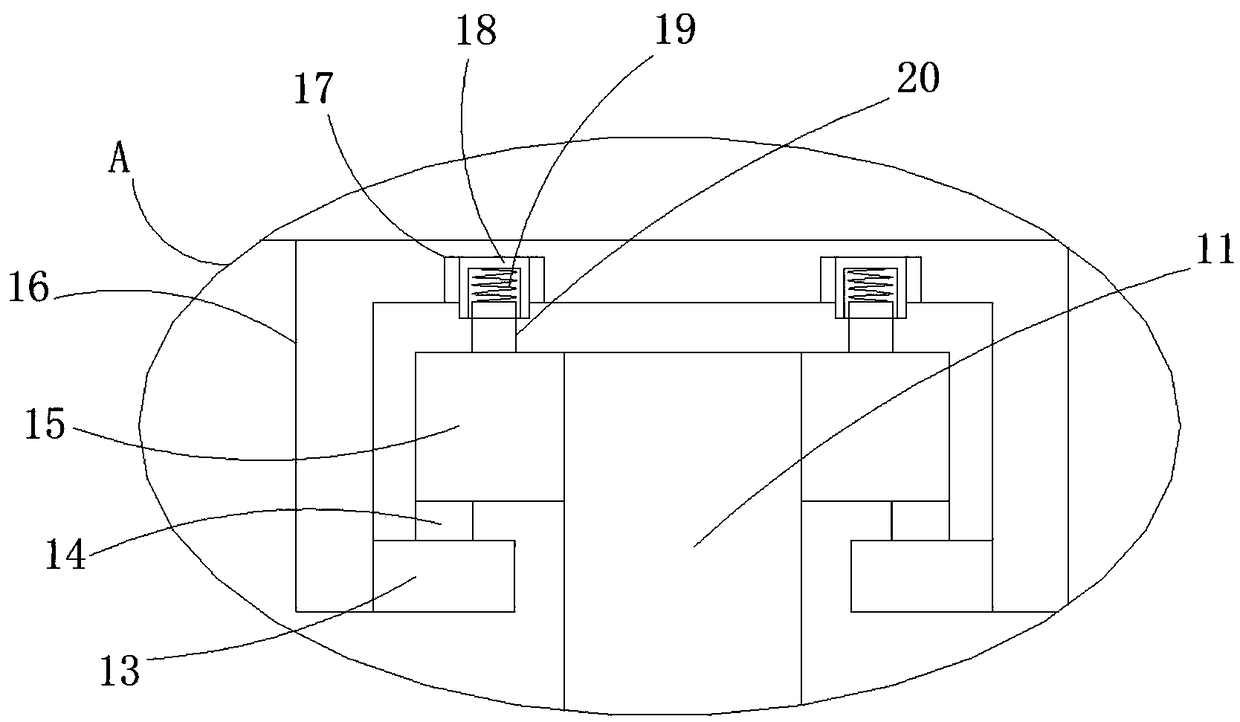

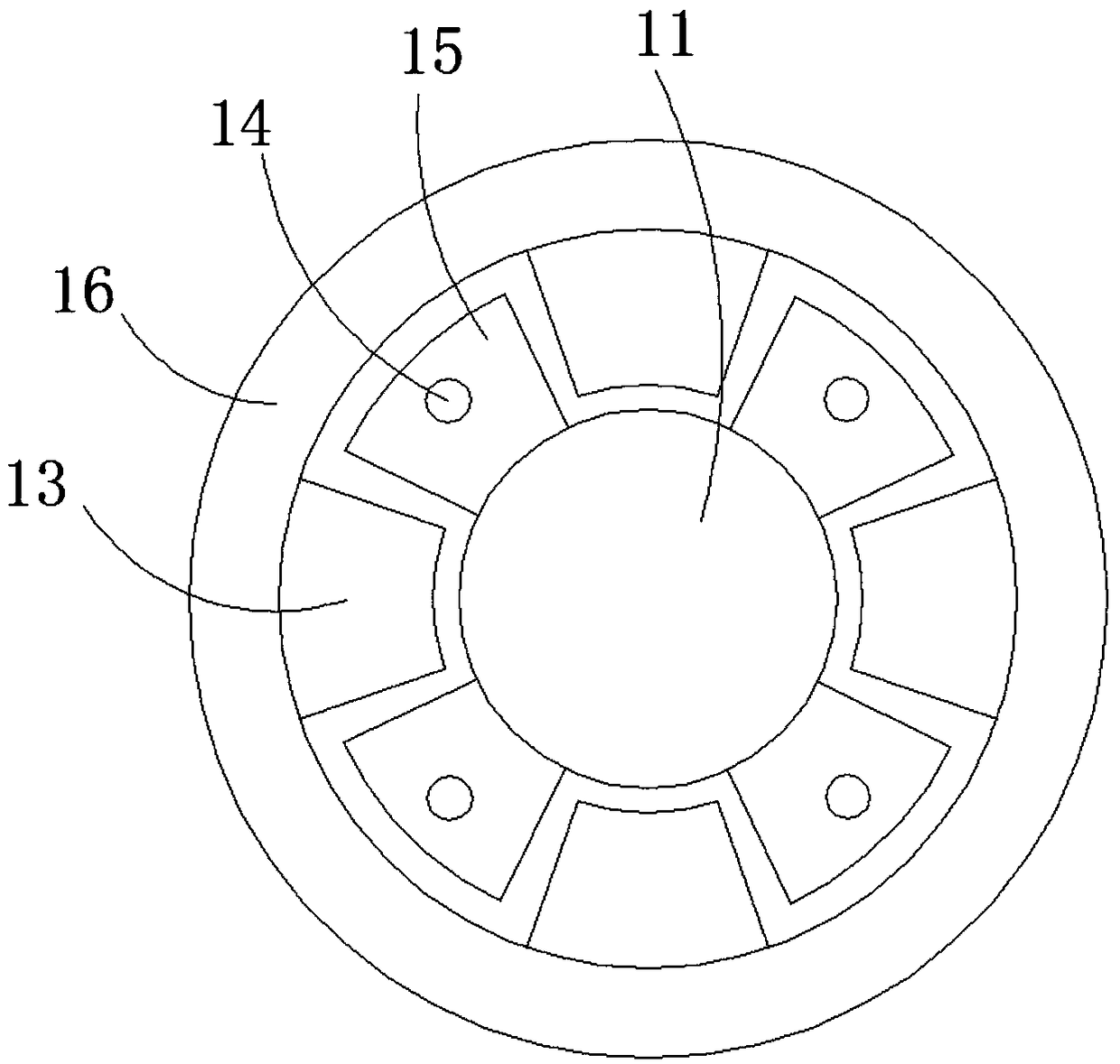

Whitewash coating material stirring apparatus for building construction

InactiveCN109289590AEasy to cleanImprove mix qualityTransportation and packagingRotary stirring mixersElectric machineryEngineering

The invention belongs to the field of whitewash coating material processing, and particularly discloses a whitewash coating material stirring apparatus for building construction. The whitewash coatingmaterial stirring apparatus comprises a stirring box, which is arranged in a hollow cylinder structure, wherein the inner wall of the stirring box is connected to two symmetrically arranged support blocks, a filtering plate is movably placed on the top ends of the support blocks, a horizontal plate is movably arranged along the opening top end of the stirring box, a rotating motor is arranged onthe top end of the horizontal plate by a screw, the output shaft of the rotating motor is vertically connected downward to a rotating rod, and the bottom end of the rotating rod penetrates through thehorizontal plate, and is connected to an installing ring through the filtering plate. According to the present invention, the structure is novel; the installing and disassembling can be rapidly completed, and the integrated design can be avoided, such that the stirring apparatus completing the stirring can be conveniently washed; the coating material attached to the inner wall of the apparatus can be scraped during the stirring operation so as to improve the stirring quality of the whitewash coating material and prolong the service life of the apparatus; and the whitewash coating material stirring apparatus is suitable for promotion.

Owner:安徽家思特涂料有限责任公司

Processing method of kumquat juice

The invention discloses a processing method of kumquat juice. The kumquat juice is prepared by raw material pretreatment, hot ironing, debitterizing, pulping, colloid milling, mixing, homogenizing, degassing, sterilizing, encapsulating and cooling. Compared with the prior art, the processing method conducts debitterizing treatment on kumquat by hot ironing, debitterizing, soaking with whitewash, and adding a little beta-cyclodextrin during a mixing course, and an appropriate amount of traditional Chinese medicine juice, white granulated sugar and lemon juice are compounded, so that the prepared kumquat juice is sour, sweet and palatable in taste, fragrant in flavor and rich in nutrient, has no bitter taste and has health-care effects of clearing heat, reducing fire, moistening a lung and relieving a cough.

Owner:佘延英

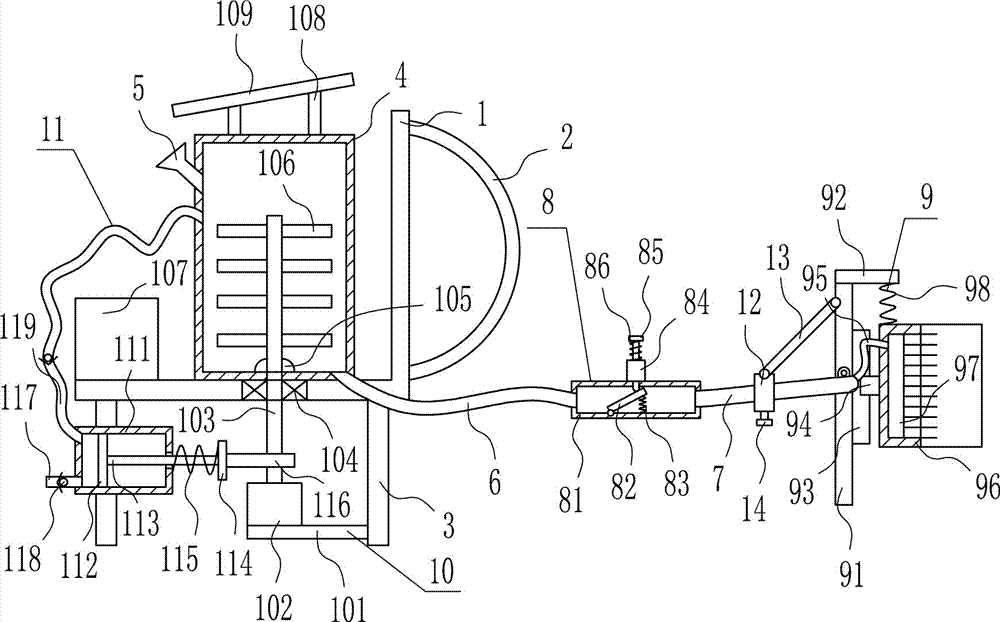

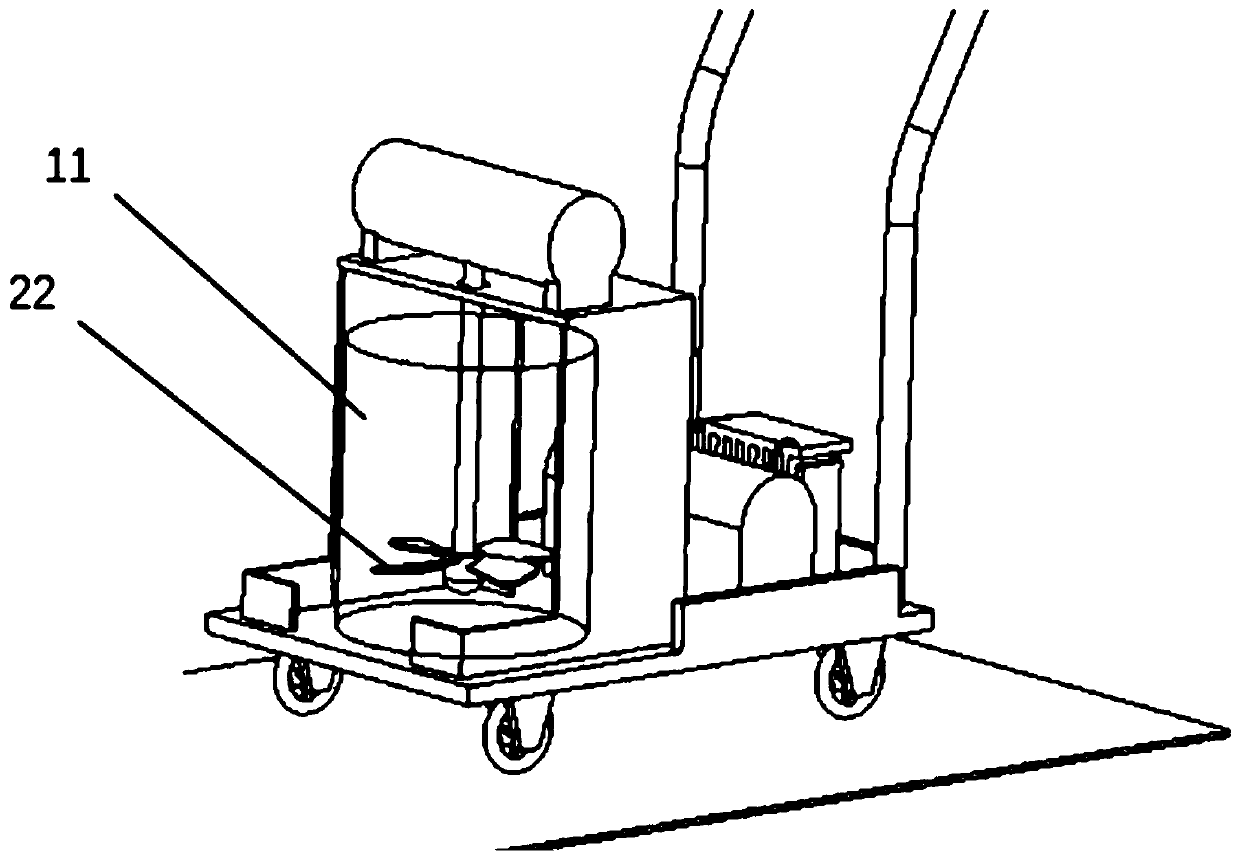

Chain and sprocket wheel trunk whitewashing device

InactiveCN108125380AImprove mixing efficiencyAvoid insufficient and even brushingBrush bodiesRotary stirring mixersPropellerSprocket

The invention discloses a chain and sprocket wheel trunk whitewashing device. The chain and sprocket wheel trunk whitewashing device comprises a baseboard, an L-shaped mounting plate, a first sprocketwheel, a second sprocket wheel, a first motor, a chain, a movable rod, a mounting rod, semicircular whitewashing devices, a whitewash tank, a pressurizing pump, a second motor, a stirring shaft, stirring rods, rotary shafts, spiral propeller blades and stirring supporting rods. Each semicircular whitewashing device comprises a semicircular shell, a semicircular mounting plate, a brush and a nozzle. The mounting rod, an electric push rod and the semicircular whitewashing devices are arranged, trunks can be conveniently and quickly surrounded, and the time and labor are saved; the second motor,the stirring shaft, the stirring rods, the rotary shafts and the propeller blades are arranged, all the parts cooperate with one another to fully stir whitewash, and it is avoided that the whitewashsettles and whitewashing is not uniform; through the cooperation of the first motor, the first sprocket wheel, the second sprocket wheel, the chain and the movable rod, the two semicircular whitewashing devices are driven to constantly move vertically, the trunks are repeatedly and fully whitewashed, and the whitewashing effect is good.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Ointment for treating burn or scald

InactiveCN102846991AGood effectSimple recipeHydroxy compound active ingredientsDermatological disorderVegetable oilWhitewash

The invention discloses an ointment for treating burn or scald. The ointment for treating the burn or the scald comprises the following components by weight percent: a) 40%-60% of vegetable oil, and b) 40%-60% of saturated whitewash. The ointment for treating the burning or the scald is simple in formula, can be prepared when being used and is convenient to use, and the raw materials of the ointment can be obtained easily. The ointment for treating the burn or the scale has the effects of relieving pain, eliminating a swelling, dispersing the red, inhibiting hyperplasia, and removing saprophytic muscle, and is quick in effect taking and good in effect.

Owner:刘海英

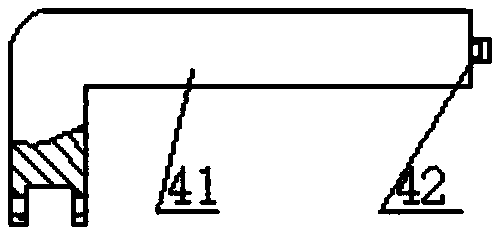

Whitewash spraying equipment for gardens

InactiveCN107999344AAffect the use effectEasy dischargeLiquid surface applicatorsLiquid spraying apparatusTree trunkEngineering

The invention relates to spraying equipment, in particular to whitewash spraying equipment for gardens. The whitewash spraying equipment has the advantages that the time-saving and labor-saving effects can be achieved, the spraying effect is good, whitewash can be spayed and stirred at the same time, and precipitation is not liable to occur. In order to solve the technical problem, the invention provides the whitewash spraying equipment for the gardens. The whitewash spraying equipment comprises an L-shaped plate, a strap and the like; the strap is connected to the right side surface of the L-shaped plate; supporting legs are symmetrically arranged on the left side and the right side of the bottom of the L-shaped plate; a box body is arranged on the right side of the bottom of the L-shapedplate; a feeding hopper is arranged on the upper portion of the left side of the box body and communicates with the interior of the box body; and a discharging pipe is connected to the right side ofthe bottom of the box body. According to the whitewash spraying equipment, the whitewash can be stirred through a stirring device so that the phenomenon that the use effect of the whitewash is influenced due to precipitation of the whitewash can be avoided, the whitewash can be better discharged from the box body into the discharging pipe to be sprayed on tree trunks through a pressurizing device,and therefore the time-saving and labor-saving effects can be achieved, and the spraying effect is good.

Owner:郑瑞文

Environmental protection and energy saving thermal insulation material for building

InactiveCN103755288AImprove thermal performanceGood thermal insulation efficiencyFiberThermal insulation

The invention discloses an environmental protection and energy saving thermal insulation material for building, which is characterized in that the material provided by the invention is produced by mixing and stirring meerschaum, lightweight whitewash gypsum, hydrophobic perlite, aluminous cement, composite fiber (consisting of propylene fiber, wood fiber and fiber brucite), composite adhesive (consisting of methyl hydroxyethyl cellulose ether, starch ether and redispersible emulsion powder), air entraining water reducer, hydrophobic agent and calcium salt of polymethylene amino acid with dry powder appearance. Water is added into the material, after mixing and stirring, the material provided by the invention can be directly plastered to exterior wall, interior wall and roof of house with a certain thickness, and has the advantages of good insulation and heat insulation effects, moistureproof and waterproof, simple construction operation, and reduced additional cost.

Owner:刘季林

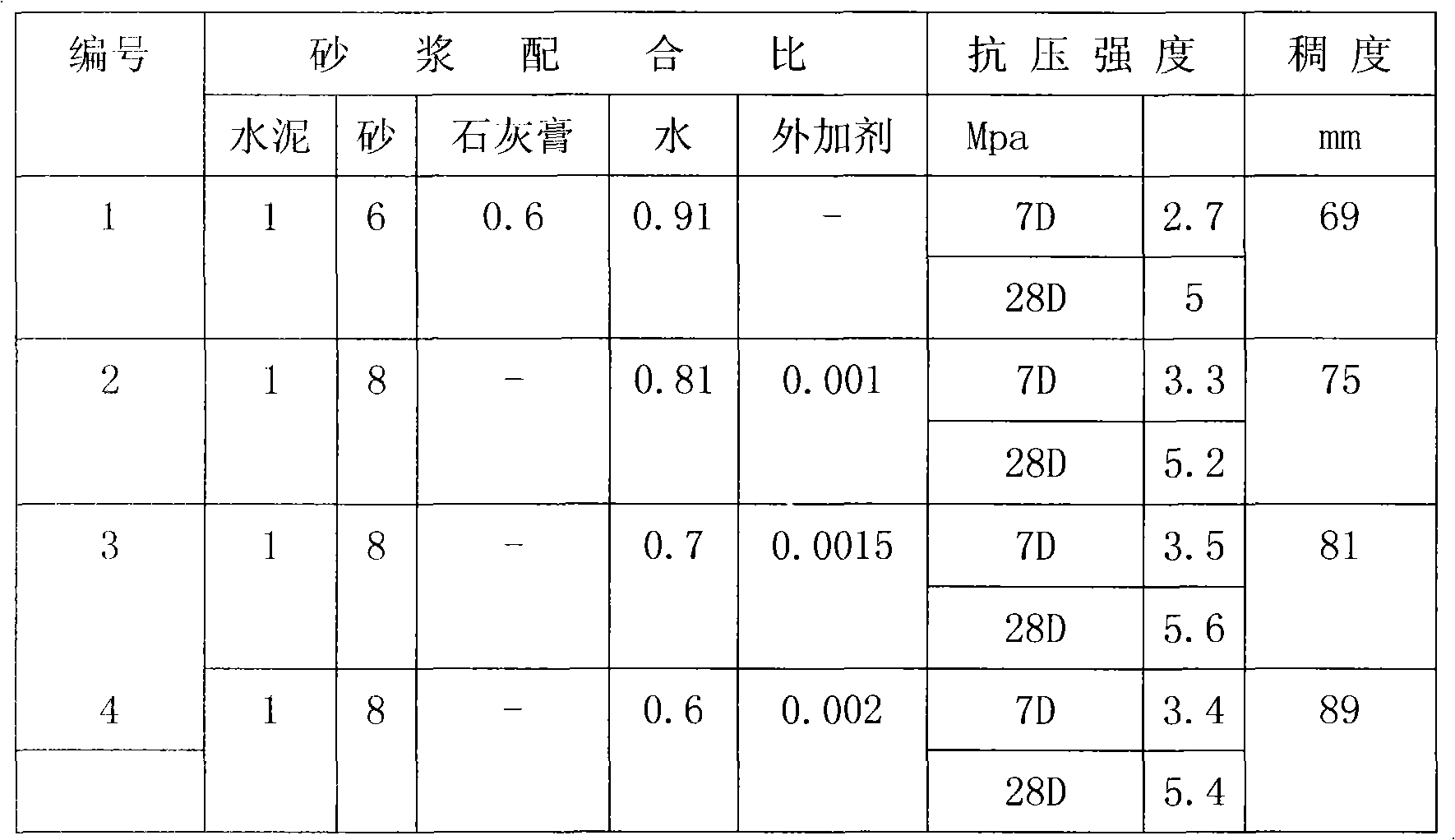

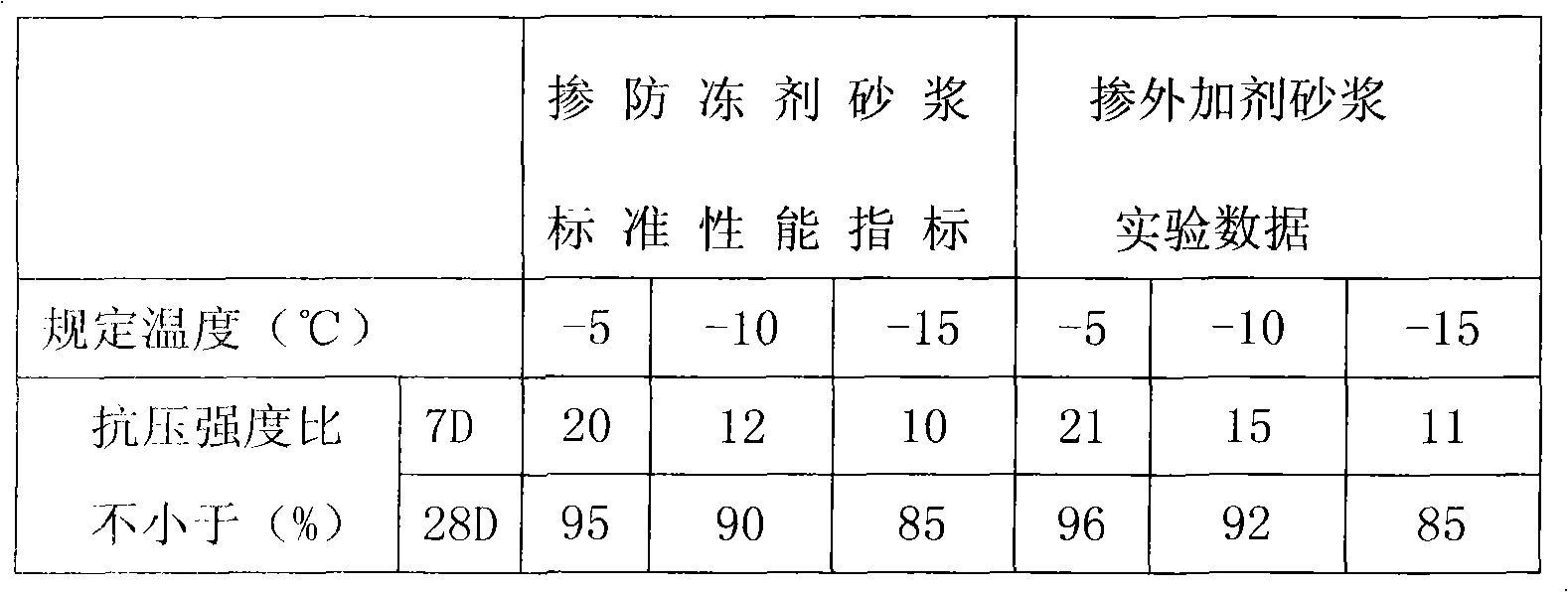

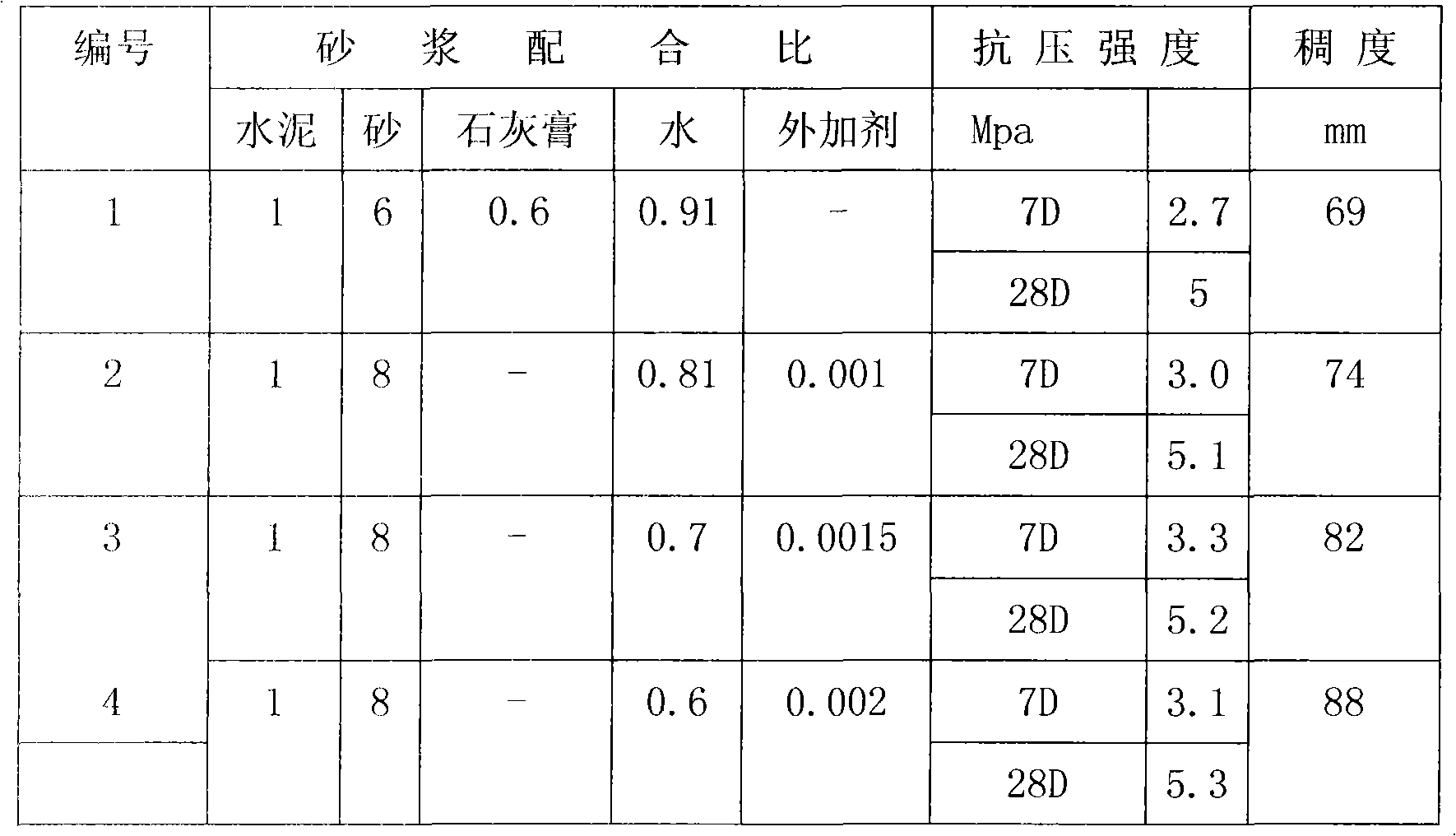

Building mortar additive and production method thereof

ActiveCN101863634AWith emulsification and foaming functionGood thickening effectPhenolSodium sulfate

The invention relates to a building mortar additive and a production method thereof. The building mortar additive is prepared by the following raw materials in parts by weight: 50-60 parts of sepiolite, 40-50 parts of calcium carbonate, 6-8 parts of lauryl sodium sulfate, 1.2-2 parts of calcium lignosulfonate, 1.6-2.5 parts of triethanolamine, 2-4 parts of dihydroxyethyl dodecylacyl, 2-3 parts of nonyl phenol polyvinyl ether, 0.2-0.4 part of tributyl phosphate (TBP) and 3-5 parts of ethylene glycol. The production method is as follows: adding the sepiolite and calcium carbonate to a stirrer, and adding the other raw materials to the stirrer for sealed stir for 13-15min to obtain a powdery product. The additive in the invention enables the mortar consistency to be in direction proportion to mortar strength, adapts to use requirements in low temperature environments, and achieves the anti-freezing purpose without adding other anti-freezing materials additionally; and when the additive is used as an additive for whitewash mortar, the mortar can be plastered on the smooth surface of concrete in no need of lime putty and other auxiliary materials, thus solving the difficult problem of cracked and hollow mortar in the process of plastering the concrete smooth surface, having the capability of replacing the lime putty in whitewash mortar completely and realizing low carbon and environment protection.

Owner:湖南省第五工程有限公司

Method for producing trees and flowers special fertilizer by using anaerobic fermentation vinegar residue

InactiveCN103159515APromote resource utilizationPromote harmlessnessBio-organic fraction processingWaste based fuelSewageWhitewash

The invention relates to a method for producing trees and flowers special fertilizer by using anaerobic fermentation vinegar residues. The method comprises the flowing steps of (1) adding whitewash at the concentration of 5% in 1000kg to adjust PH to be 6.8-7.6; (2) adding baiyibao EM stock solution which is 0.3% of the 1000kg of fresh vinegar residues and corruption agent which is 0.2% of the 1000kg of fresh vinegar residues in the mixed vinegar residues, transporting the stirred vinegar residues in a fermentation tank, and conducting anaerobic digestion at the temperature of 35 DEG C for 35 days; and (3) collecting sewage gas produced by fermentation in an air storage tank, separating surplus biogas residues and biogas slurry to obtain trees and flowers special liquid fertilizer and trees and flowers special solid fertilizer produced by using the anaerobic fermentation vinegar residues. The method effectively uses the vinegar residues to produce the trees and flowers special fertilizer, saves resources, changes waste into wealth, reduces environmental pollution, improves recycling and harmless of the vinegar residues, increases peasant income through the produced special fertilizer, simultaneously achieves high-yield and high-quality high-efficiency agriculture and has wide market prospects.

Owner:JINZHONG VOCATIONAL & TECHN COLLEGE

Tree whitewash device and using method thereof

InactiveCN110302918AIncrease distanceReduce harmLiquid surface applicatorsSpraying apparatusSprayerWorking environment

The invention discloses a tree whitewash device and a using method thereof. The device mainly comprises an arc-shaped roller brush, a distance sensor, an arc-shaped nozzle, a telescopic corner, a signal transmission line, a stretching rod, a thin pipe, a proportional valve, a thick pipe and an electric sprayer. The arc-shaped roller brush is connected with the telescopic corner through a hinge structure and deforms according to a trunk shape under the pressure effect, the telescopic corner slides in the stretching rod, the thin pipe is connected with the arc-shaped nozzle and the proportionalvalve, the thick pipe is connected with the proportional valve and the electric sprayer, and the signal transmission line is connected to the distance sensor and the proportional valve. By means of the device, the defects of the low manual whitewash efficiency, the poor safety and the like and the defects of the poor flexibility and the poor working environment adaptability of an existing whitewash device are overcome to some extent. The tree whitewash device has high working efficiency, the remarkable whitening effect, strong safety, good flexibility and low cost, and can be widely applied totree whitening work.

Owner:NORTHWEST A & F UNIV

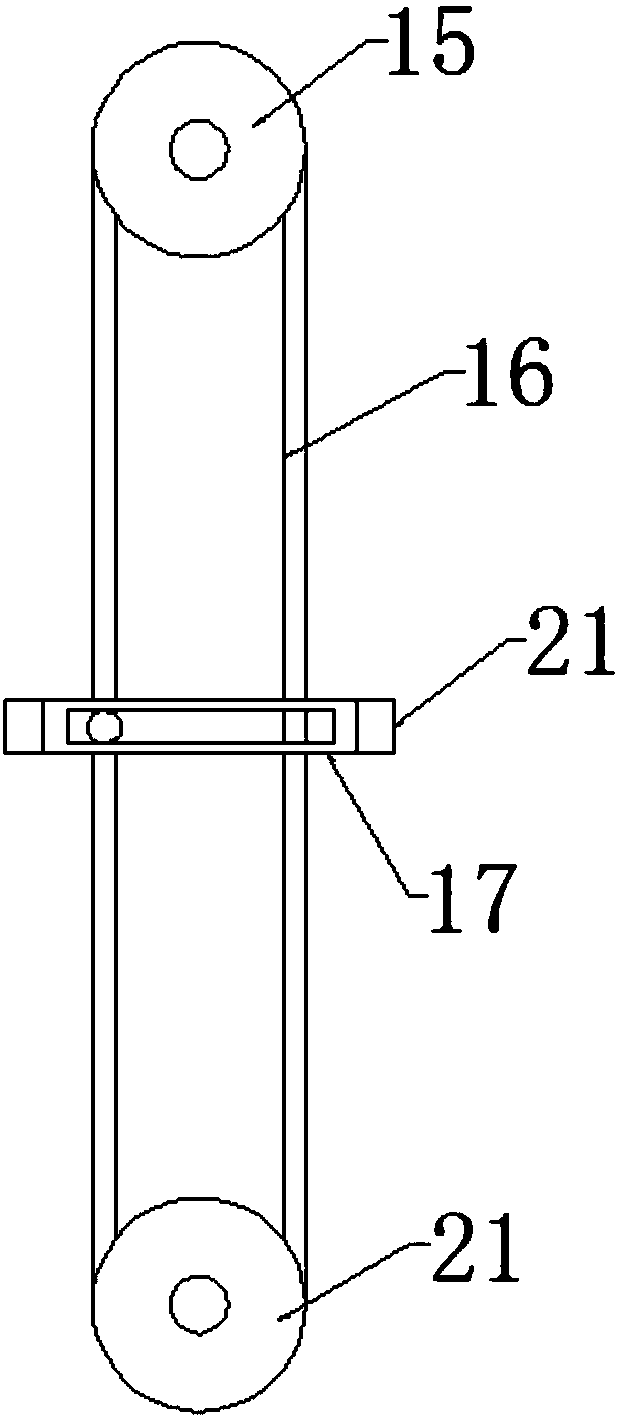

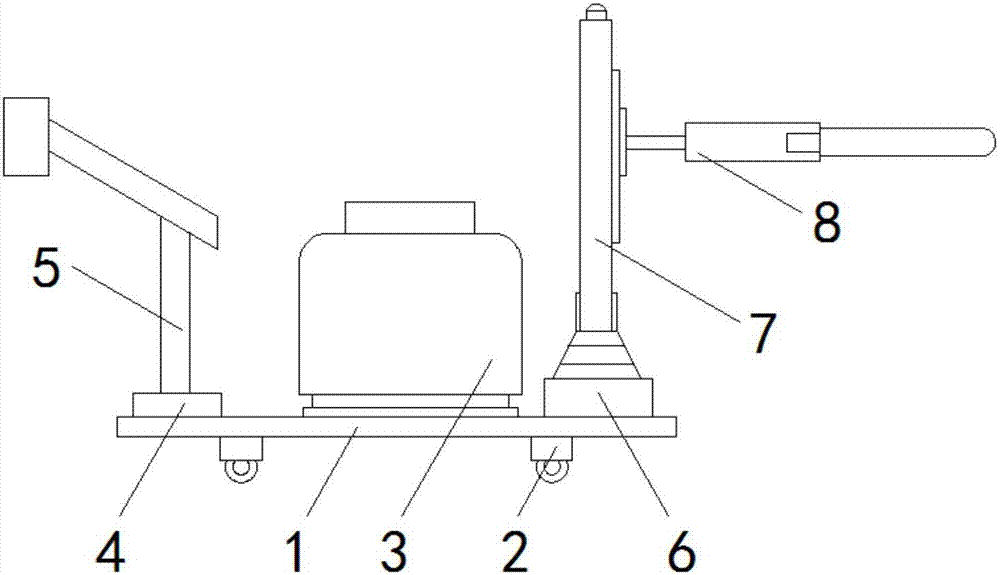

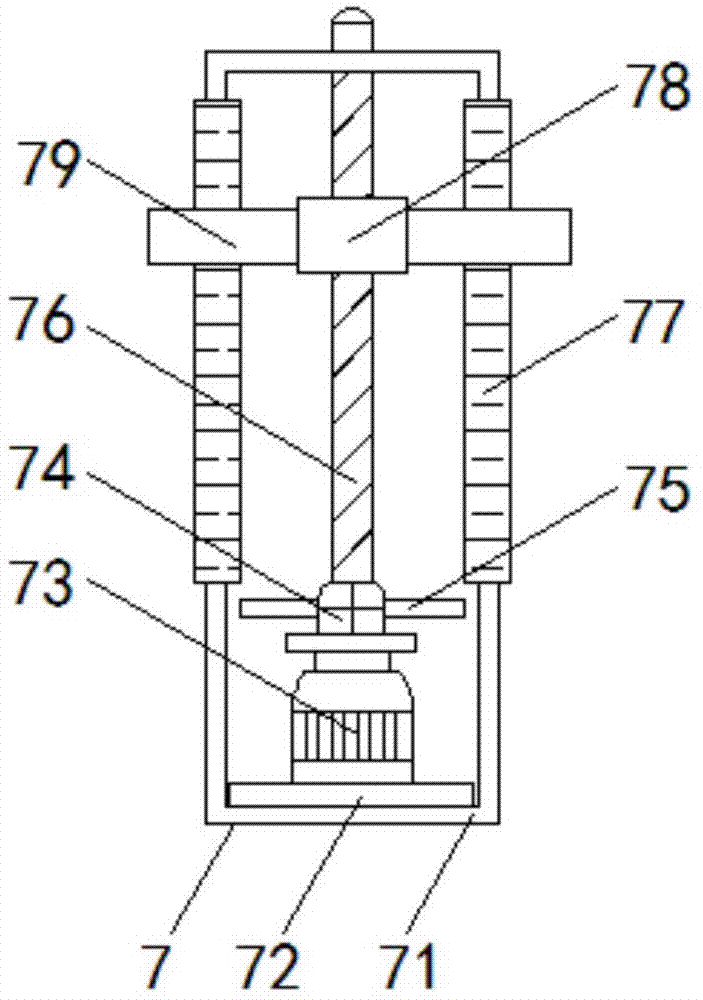

Tree trunk white painting device for gardens

InactiveCN107876247AGuaranteed neutral requirementsAppropriate distanceSpraying apparatusCouplingTree trunk

The invention relates to the technical field of gardens, and discloses a tree trunk white painting device for gardens. The tree trunk white painting device for gardens comprises a base, self-locking truckles are fixed on the bottom of the seat, a lacquered can is fixed on the top of the seat, a metal block which is located at the left side of the lacquered can is fixed on the top of the seat, anda pushing hand is fixed on the top of the metal block; a cushion block which is located at the right side of the lacquered can is fixed on the top of the seat, a lifting device is fixed on the top ofthe cushion block, and a spraying device is fixed on the right side of the lifting device; the lifting device comprises a metal frame, a fixing plate is fixed at the bottom wall of the inner side of the metal frame, and a gear motor is fixed on the top of the fixing plate; a shaft sleeve is fixed on the position of an output shaft of the gear motor by a coupling, and limiting blocks are separatelyfixed on the two sides of the shaft sleeve. Through the tree trunk whitewash device for gardens, the spraying effect is good, the labor intensity of workers is reduced, and the tree trunk white painting device for gardens is convenient for people to use.

Owner:周飞燕

Oxidized graphene-silica sol enhanced pretreating agent for wicker for wickerwork and preparation method of oxidized graphene-silica sol enhanced pretreating agent

InactiveCN105345904AGood braiding mechanical propertiesSolution to short lifeReed/straw treatmentWood impregnation detailsFiberAdditive ingredient

The invention relates to the technical field of modified treatment of wicker for wickerwork, in particular to an oxidized graphene-silica sol enhanced pretreating agent for wicker for wickerwork and a preparation method of the oxidized graphene-silica sol enhanced pretreating agent. The oxidized graphene-silica sol enhanced pretreating agent is prepared from, by weight, 0.1-0.2 part of sodium carbonate, 0.1-0.2 part of carboxymethylcellulose, 0.001-0.002 part of graphene oxide, 6-8 parts of clear whitewash, 10-20 parts of silica sol with the solid content of 20%-25%, 0.1-0.2 part of alkyl sodium sulfonate, 0.1-0.2 part of sodium chloride and 40-50 parts of water. After the pretreating agent permeates into wicker fibers through high pressure, graphene oxide, silica sol and other ingredients permeate into the fibers, then the toughness of a material is enhanced, and better heat resistance and fire resistance are achieved. The clear whitewash has the effects of helping the material to adhere to and bond with the fibers, and the utilization rate of the material is increased. A product woven from the pretreated wicker is longer in service life, bearing force is increased, and the use range is further widened.

Owner:ANHUI MEIJING ARTS & CRAFTS CO LTD

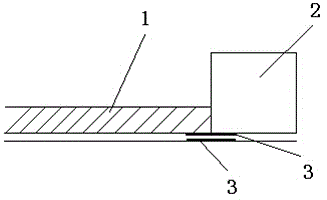

Method for whitewashing filler wall

InactiveCN104453134AReduce surface cracksAvoid secondary repair costsCovering/liningsWallsSurface layerEngineering

The invention discloses a method for whitewashing a filler wall. The method comprises the steps of providing a whitewash ash cake, conducting primary bottom layer maintenance, conducting secondary surface layer construction and conducting surface pressing and polishing. Before the primary bottom layer maintenance is conducted, a gridding cloth is laid at the combined position of the filler wall, a beam and a column, and before the surface pressing and polishing is carried out, a gridding cloth is laid on the surface of slurry at the combined position of the filler wall,the beam and the column. The method can effectively reduce surface cracks caused due to the fact that the materials on the two sides of the combined position are different, and secondary maintenance cost for crack repair is omitted.

Owner:STATE GRID CORP OF CHINA +2

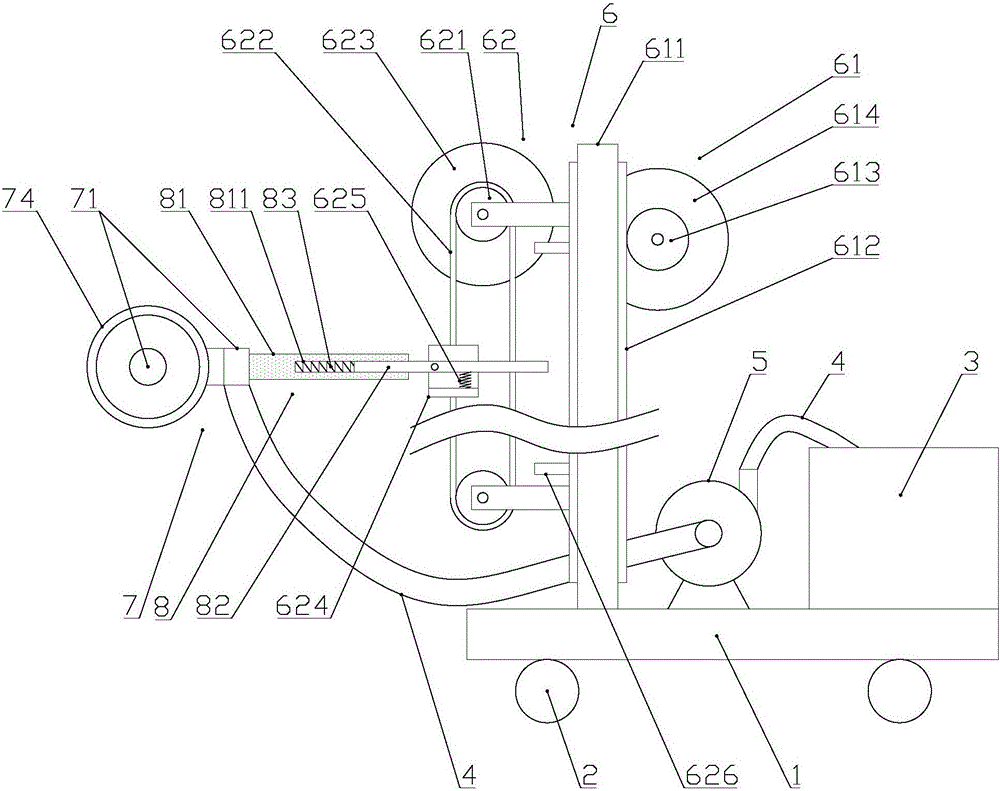

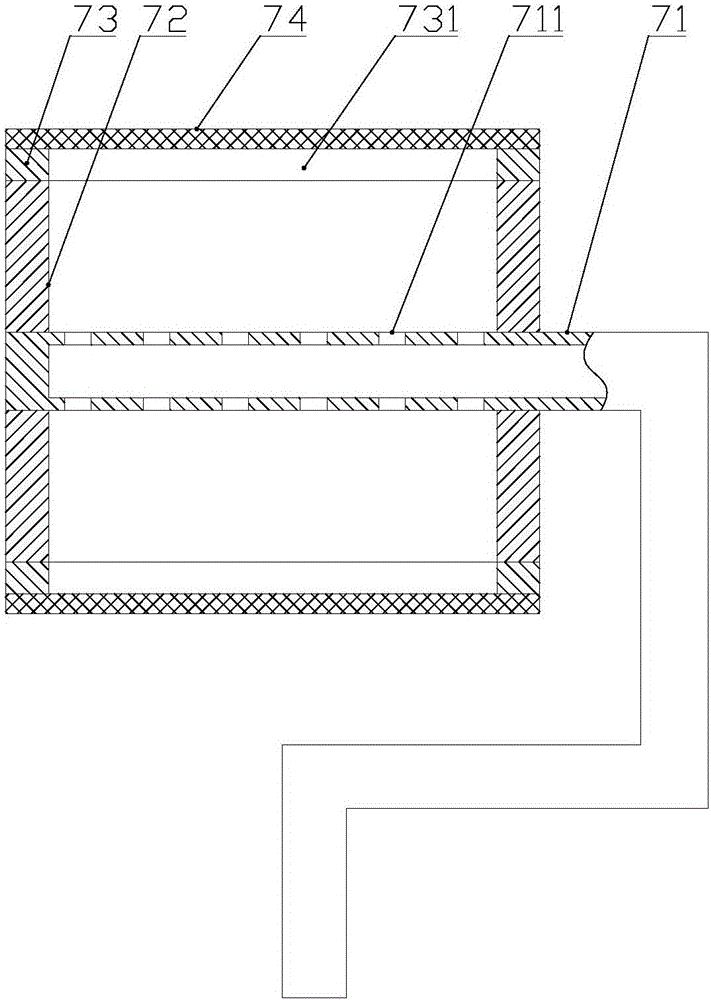

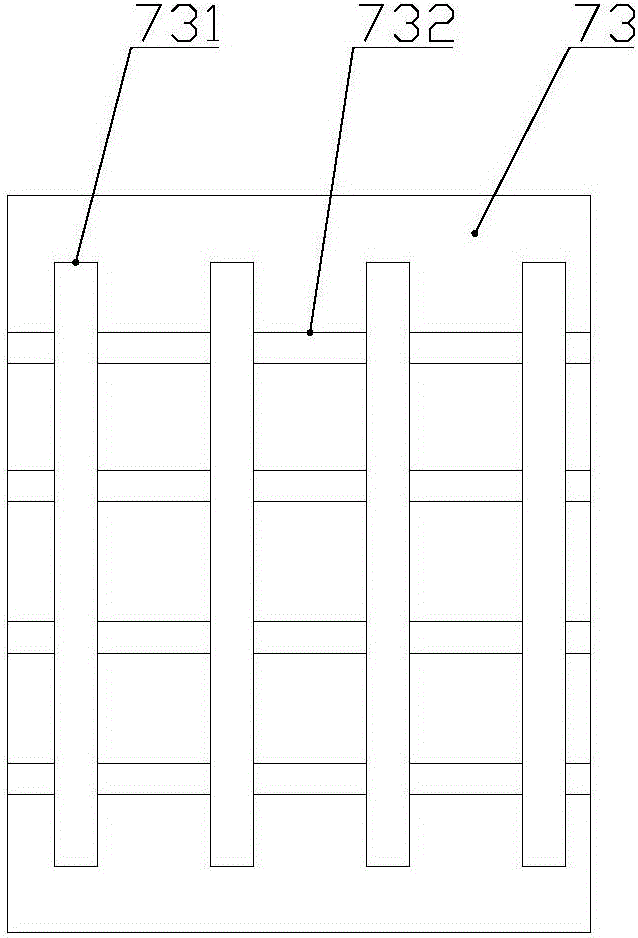

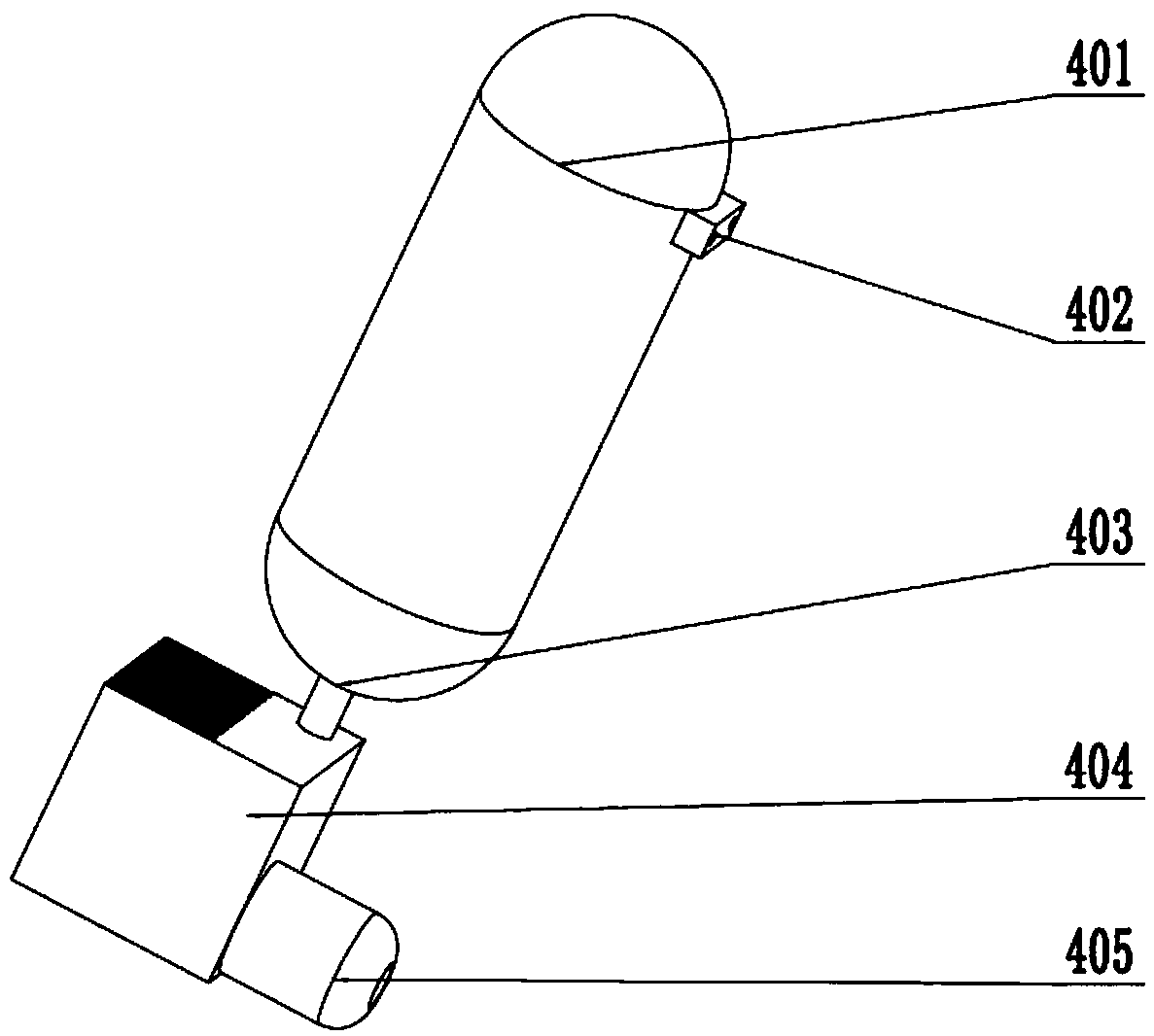

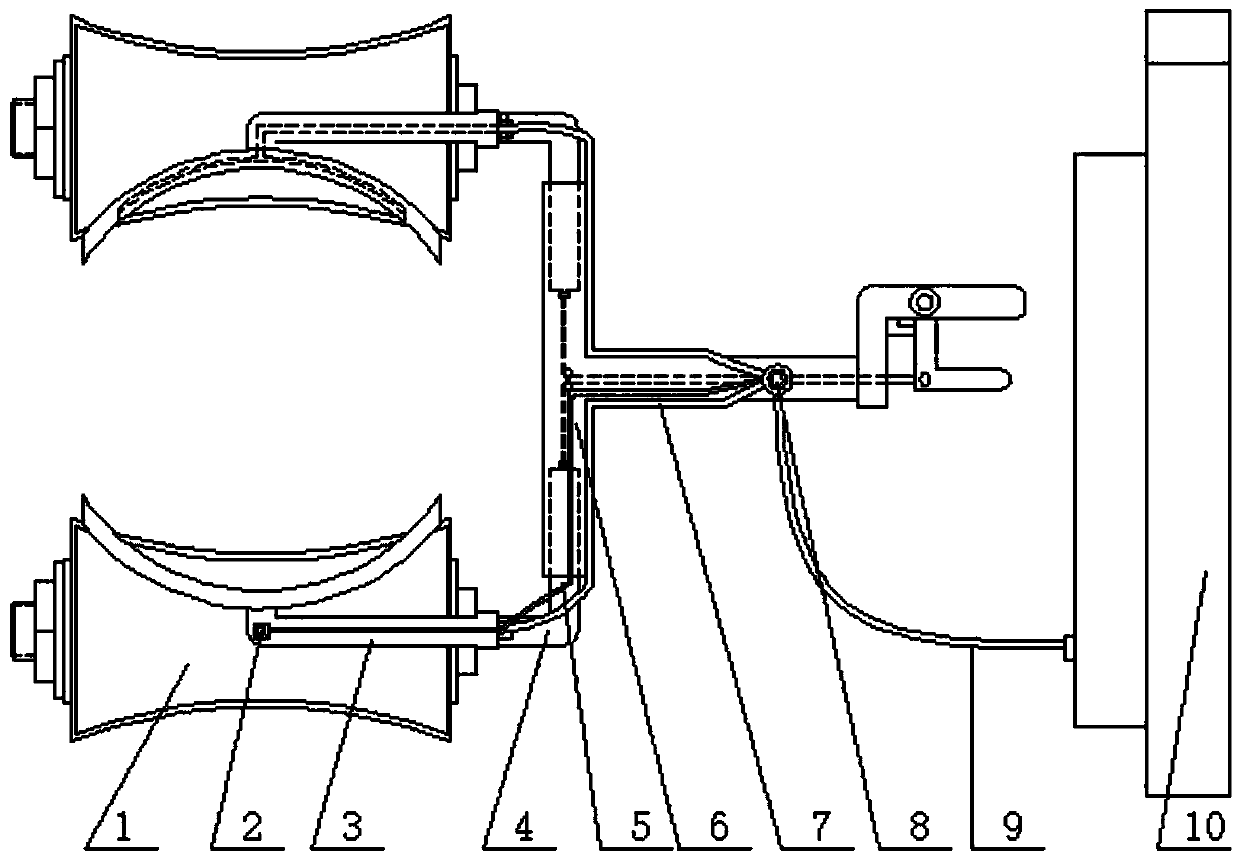

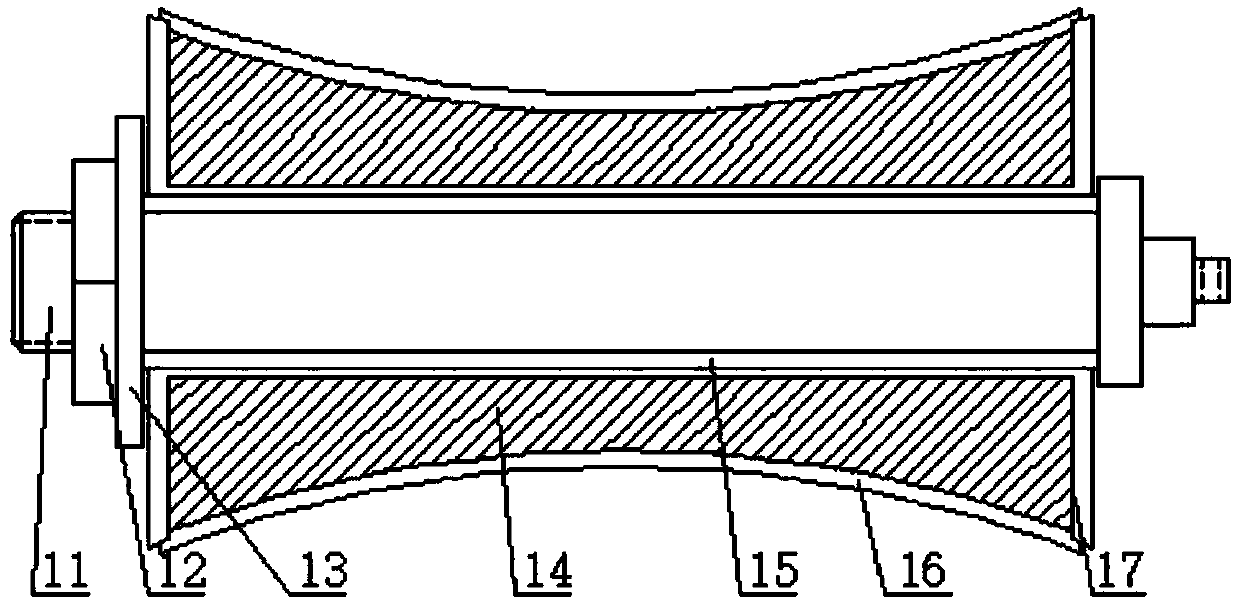

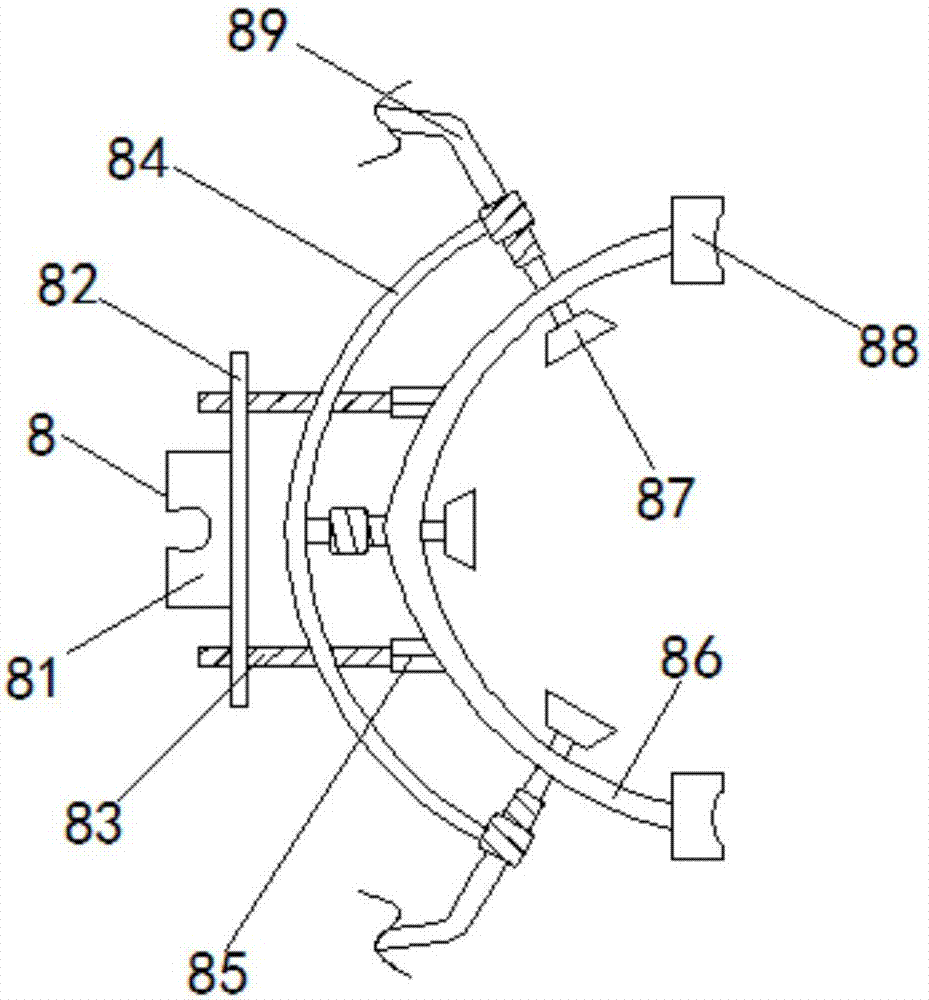

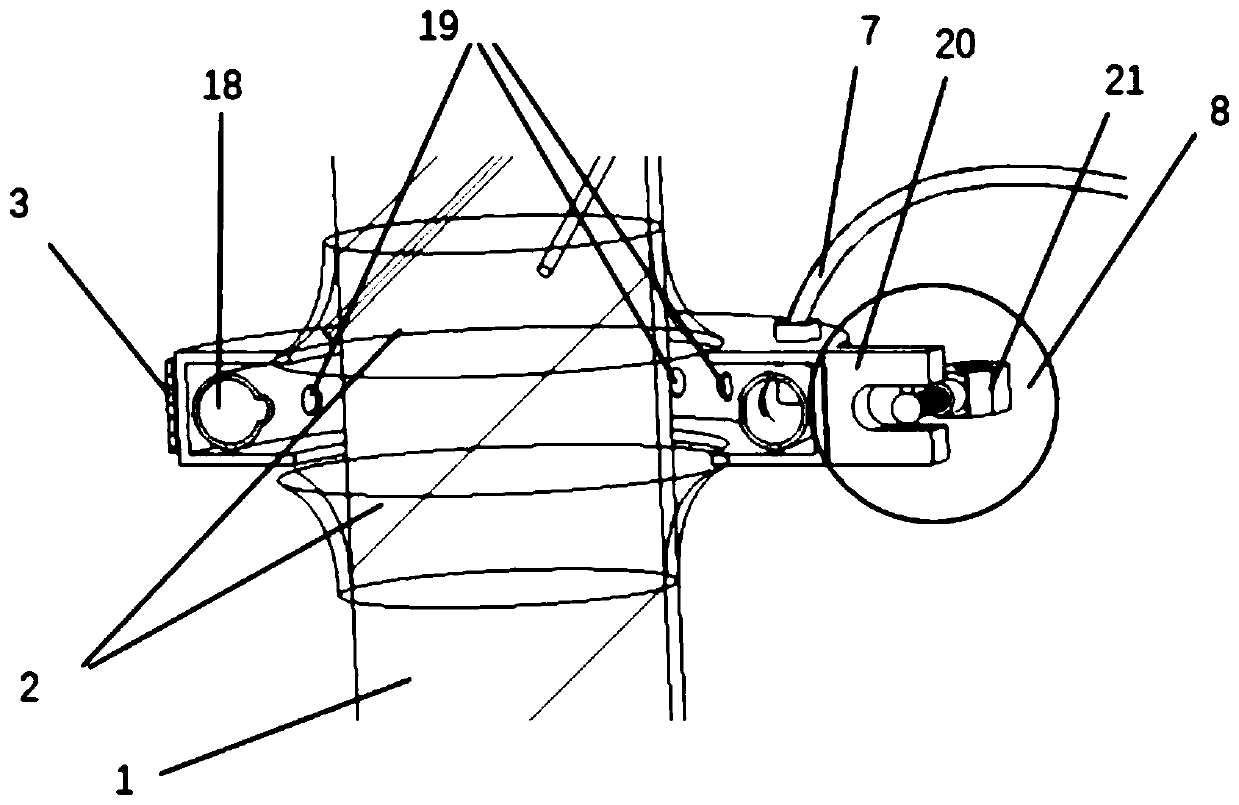

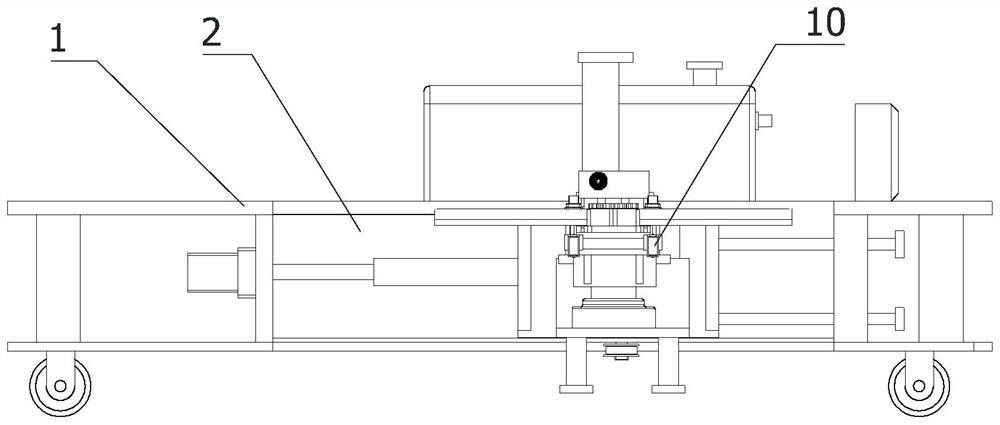

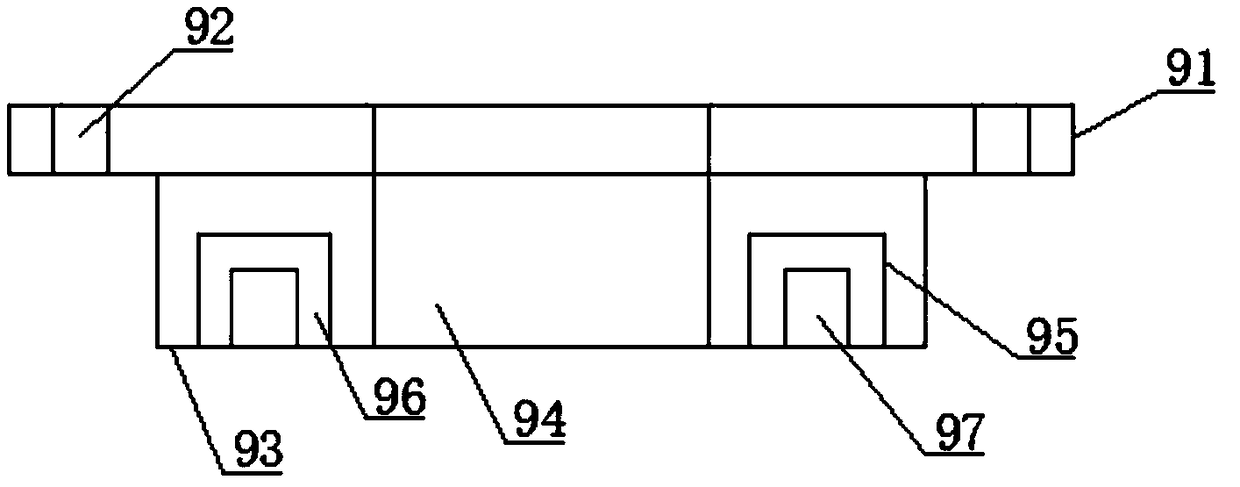

Portable tree whitewashing machine and whitewashing method

InactiveCN110538739AReduce manufacturing costEasy to installLiquid surface applicatorsLiquid spraying apparatusTerrainTree trunk

The invention belongs to the technical field of agriculture and forestry machinery and relates to a portable tree whitewashing machine and a whitewashing method. One ends of two semi-circular-ring structures of the whitewashing machine are connected through a hinge, and the other ends of the two semi-circular-ring structures are connected through a hand-operated buckle; rubber sleeves are fixed atthe upper and lower parts of the semi-circular-ring structures; the two semi-circular-ring structures form a circular ring which is fixed on a tree trunk; the rubber sleeves fit closely to the tree trunk to prevent the leakage of a whitewash during whitewashing; the upper surface of each semi-circular-ring structure is provided with a lifting hook which is fixed to the upper surface; the other end of each lifting hook is fixed at the lower end of a descent control device; and the other end of the descent control device is connected with a rope which is fixed on the tree trunk. The portable tree whitewashing machine has the advantages of low manufacturing cost, and convenient and easy mounting which is completed in only 2 steps; the use of the whitewashing machine saves time and effort, and the labor intensity is very low; and the whitewashing machine can be used in various working conditions including not only greenbelts of urban highways but also areas with complex terrains.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Mortar used for wall whitewash or tile fixing, and preparation method thereof

ActiveCN107162507AHigh bonding strengthImprove adhesionSolid waste managementPolymer scienceThermal insulation

The invention belongs to the technical field of mortar used for wall whitewash, and especially discloses a mortar used for wall whitewash or tile fixing, and a preparation method thereof. The mortar is prepared from cement, sand, and glass bead; the granularity of sand, and the glass bead are modified so as to improve the bonding strength of the mortar. The mortar is excellent in workability; no stagging is caused; the mortar is nontoxic, possesses no peculiar smell; bonding is firm; cracking or shedding is not easily caused; and thermal insulation performance is excellent.

Owner:贵州中能高新材料有限公司

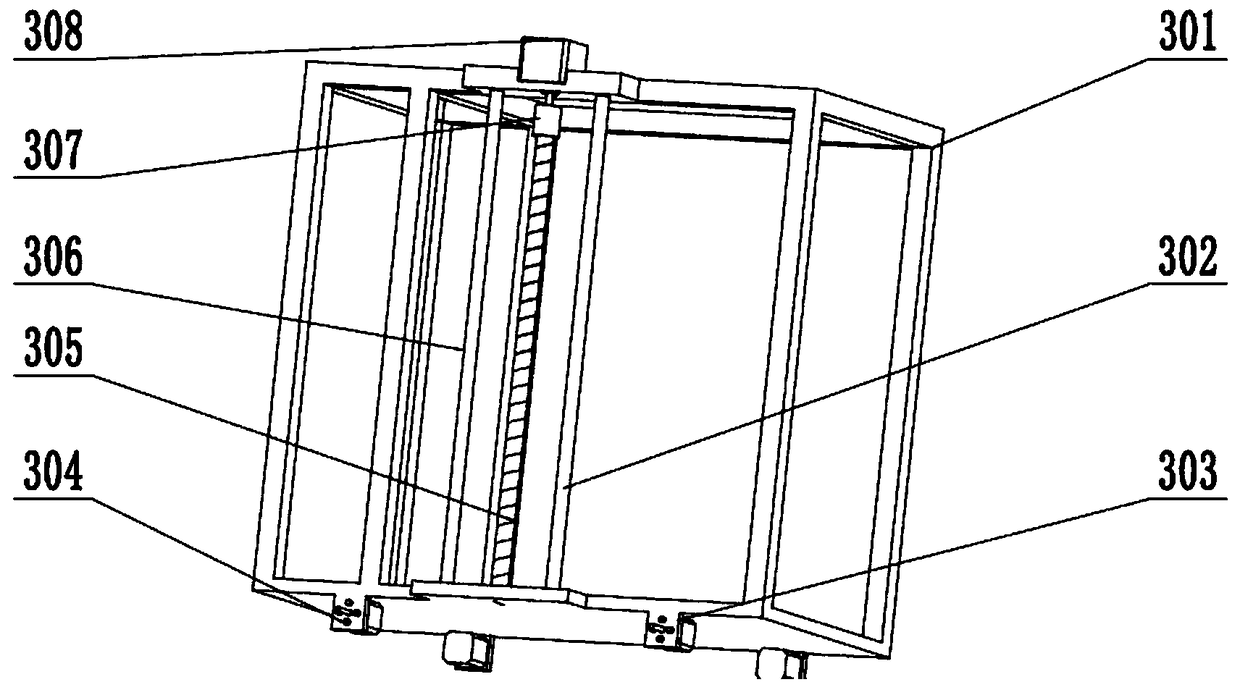

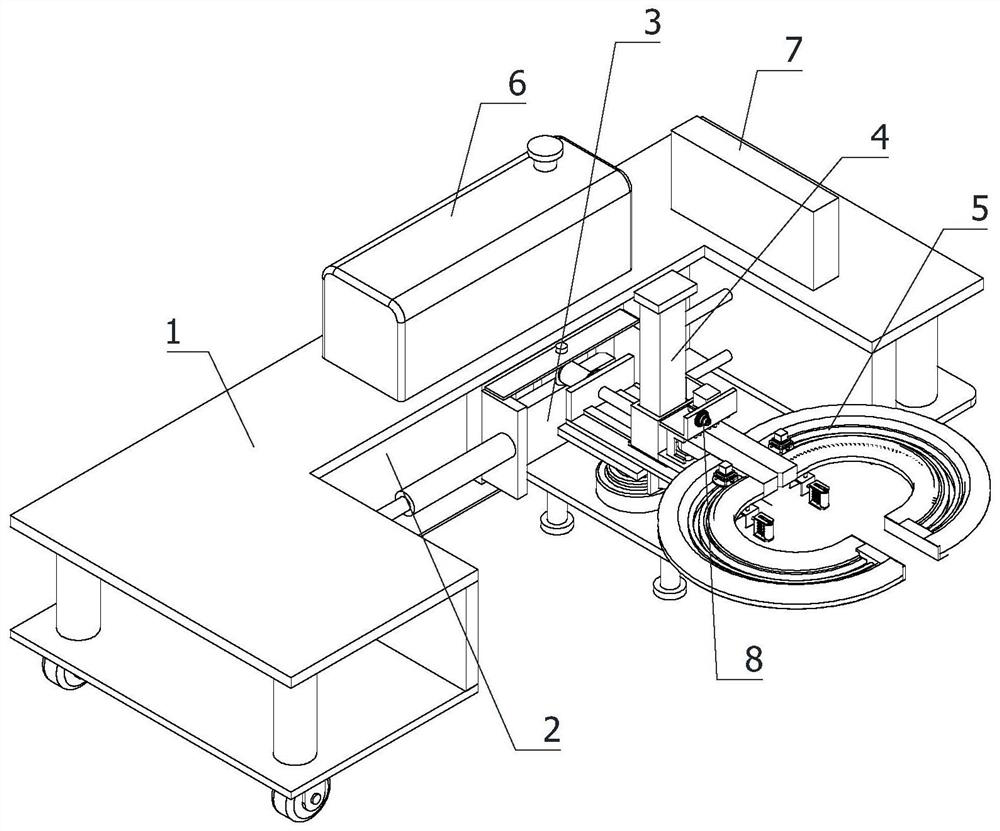

Full-automatic whitewash painting protection device for municipal greening trees in winter

ActiveCN112619978AGood coating effectImprove work efficiencyLiquid surface applicatorsCoatingsAgricultural scienceAgricultural engineering

The invention relates to the technical field of municipal administration street tree winter maintenance, in particular to a full-automatic whitewash painting protection device for municipal greening trees in winter. The protection device comprises: a vehicle body, wherein a rectangular working area is arranged on one side of the vehicle body; a main body displacement assembly, arranged on the rectangular working area of the vehicle body; a lifting assembly, vertically arranged at the output end of the main body displacement assembly; an around-tree coating assembly, arranged at the output end of the lifting assembly; a lime water spraying assembly, arranged on the vehicle body; a controller, arranged on the vehicle body; and a camera, horizontally arranged on the around-tree coating assembly. The tree around-tree coating assembly comprises: semi-ring sliding rails; a clamping mechanism; arc-shaped sliding mechanisms; first linear pushing devices; and coating devices. The protection device can automatically achieve coating protection operation on street trees, and is high in working efficiency and more stable in coating, the labor intensity of workers is reduced, and the whitewash coating effect is improved.

Owner:山东智亚德新型材料有限公司

Treating method for wicker used for manufacturing wickerwork

InactiveCN106182273AExtended use timeSimple processWood treatment detailsReed/straw treatmentMedicineGleditsia triacanthos

The invention discloses a treating method for wicker used for manufacturing wickerwork. The method comprises the following steps that (1) temperature of a deploying treating agent is controlled between 20-22 DEG C, and the deploying treating agent comprises areca-nuts, Chinese red peppers, 0.5% whitewash, Chinese honey locusts and water; (2) the wicker is placed into the deploying treating agent, and the temperature of the deploying treating agent is slowly heated from 20-22 DEG C to 58-60 DEG C in one and half hours, then cooling is conducted, and the temperature of the deploying treating agent is slowly cooled down from 58-60 DEG C to 20-22 DEG C in one and half hours; and (3) the wicker treated in the step (2) is placed in a drying box to be dried for half an hour, so that the wicker to be used is obtained. According to the treating method for the wicker used for manufacturing the wickerwork, the process is simple; the cost is low; the wicker is placed into the deploying treating agent and is subjected to slow heating, so that the flow of pesticide effect is accelerated, and the pesticide is rapidly effective in the wicker and is distributed evenly; then the deploying treating agent is subjected to slow cooling, so that the pesticide effect is fixed; the service life of the wickerwork made of the wicker is greatly prolonged, and the time of insect resistance and moth resistance can be ten years or more.

Owner:童恒

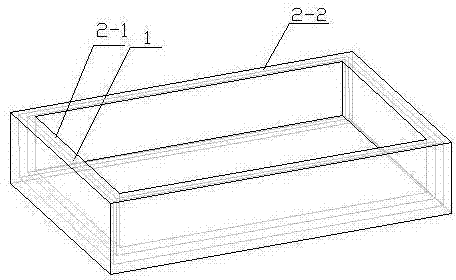

Plastic steel building template

A manufacturing method of a plastic steel building template adopts an intra-mould injection molding method to produce the plastic steel building template. The intra-mould injection molding method comprises placing a metal building template in a mould of an injection moulding machine, and utilizing plastic particles to produce the plastic steel building template by injection moulding in the injection moulding machine. Metal template portions of the produced plastic steel building template are totally covered by plastic materials, and the plastic steel building template has rigidity of a metal template and has the advantages of corrosion resistance, shock resistance and avoidance of adhesion to concrete of a nonmetal material. The plastic steel building template is lighter than a metal steel template, resistant to corrosion and free of rust, the surface of the template does not need oil coating, and the surface of the concrete cast by the plastic steel building template is smooth so that external whitewash is not needed.

Owner:王崇高

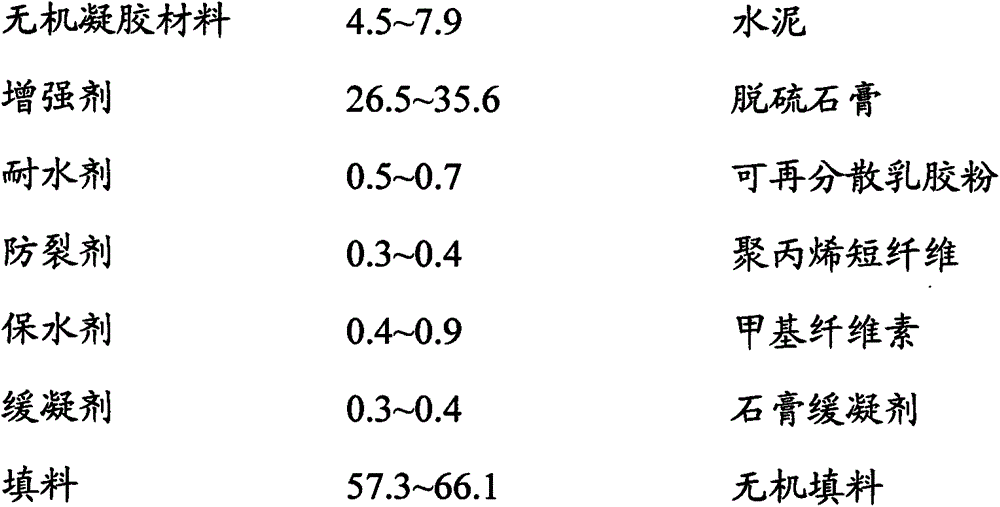

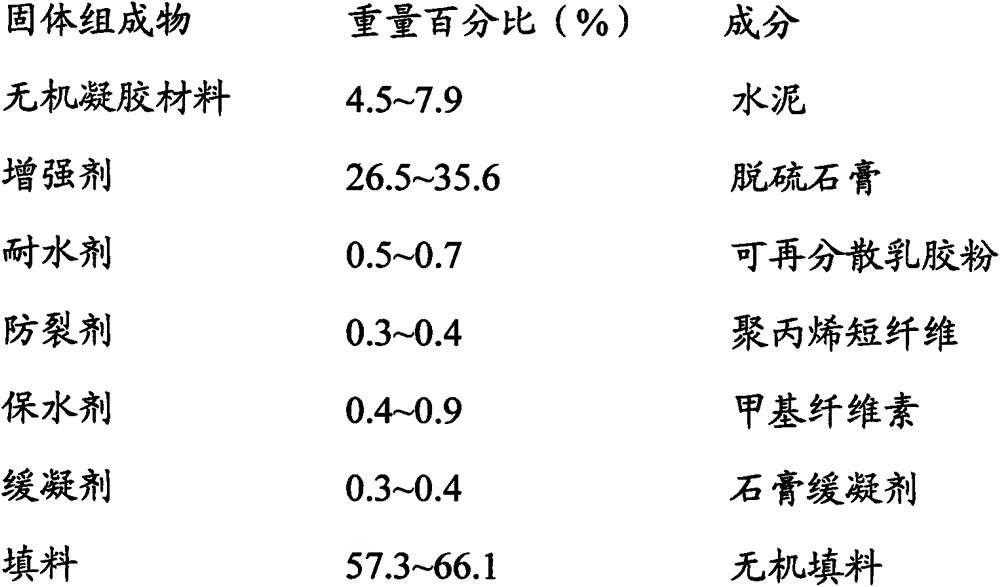

Aerating building block special-purpose whitewash mortar and preparation method thereof

The invention discloses aerating building block special-purpose whitewash mortar and a preparation method thereof. The aerating building block special-purpose whitewash mortar comprises solid components such as 4.5-7.9% by mass of an inorganic gel material, 26.5-35.6% by mass of a reinforcing agent, 0.5-0.7% by mass of a water resistant agent, 0.3-0.4% by mass of an anti-cracking agent, 0.4-0.9% by mass of a water-retaining agent, 0.3-0.4% by mass of a delayed coagulant and 57.3-66.1% by mass of a filler, and 100 parts of the solid components are added with 30-35 parts by mass of water. The prepared whitewash mortar has good water retention performances, good flexibility and a good contraction rate similar to that of the aerating building block. Through use of desulfurized gypsum, the whitewash mortar has good breathing characteristics, retractility and low relative density. Through use of polypropylene short fibers, adhesion between mortar and a wall is improved, up-down sliding and cracking of the mortar on the wall are prevented, wall stability is guaranteed well, and gridding cloth laying and guniting processes are avoided.

Owner:叶建恒

Self-sterilization food bag and preparation method thereof

InactiveCN104986419AImprove mechanical propertiesImprove antibacterial propertiesBio-packagingClimate change adaptationGlass fiberCornus officinalis

The invention discloses a self-sterilization food bag and a preparation method thereof. The method comprises following steps: 1) mixing raw materials and whitewash, and boiling the mixed materials so as to obtain paper pulp; 2) washing, bleaching and flapping the paper pulp, and finishing, drying and baking the paper so as to obtain the sterilization paper; and 3) processing the sterilization paper so as to obtain the self-sterilization food bag. The raw materials comprise bamboo, bark, linen, Chinese alpine rush, silk, glass fibers, perilla leaves, galagal rhizome, biota orientalis, pomegranate rind, loquat leaves, cirsium japonicum, radix paeoniae rubra, oriental wormwood, cornus officinalis, cassia seeds, curcuma zedoary and pyrrosia leaves. The self-sterilization food bag prepared through the preparation method has excellent mechanical strength and sterilization capability, and the self-sterilization food bag can be industrially produced in batch as the raw materials in the preparation method can be easily obtained.

Owner:TONGLING FOUNDER PLASTICS TECH

Wall repainting device for indoor decoration

InactiveCN108729629AQuick coveragePrevent overload damageBuilding constructionsButt jointEngineering

The invention discloses a wall repainting device for indoor decoration. The wall repainting device for indoor decoration comprises a main storage shell; a bottom mounting base plate is arranged on theside surface of the main storage shell; and the main storage shell and the bottom mounting base plate adopt an integrated structure. Pressure is applied to liquid painting coating by air pressure with controllability, so that the liquid coating is ejected from a high-pressure ejecting gun, the ejected mist-shaped whitewash can cover the wall surface rapidly, the labor intensity is reduced and thewhitewash efficiency is improved; furthermore, the device is provided with a control mechanism for preventing the air pressure intensity from being too high, so that the non-uniform ejecting phenomenon caused by too high injected air pressure can be effectively avoided; in addition, the device is provided with a control mechanism for preventing overload of an electromotor and can effectively prevent the phenomenon that the electromotor is overloaded and damaged caused by too high air pressure; and the device is provided with a middle clamping and inlaying mechanism, can realize butt joint effect and can guarantee that air leakage of a butt joint part is avoided, so that injection of raw materials and cleaning of the internal parts of parts are realized and the practicability is high.

Owner:郭超强

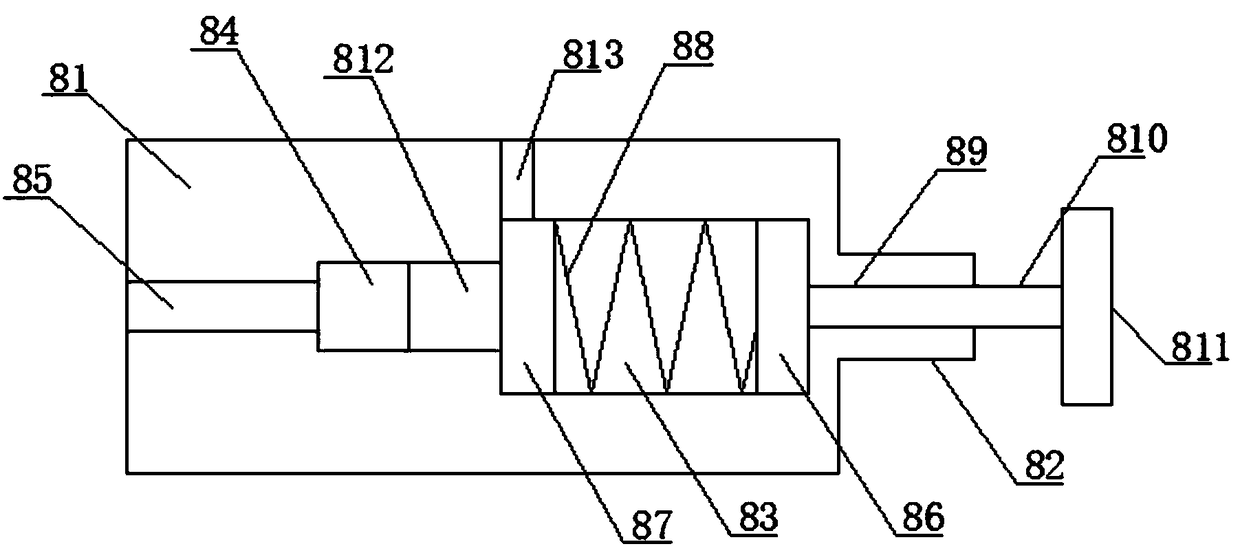

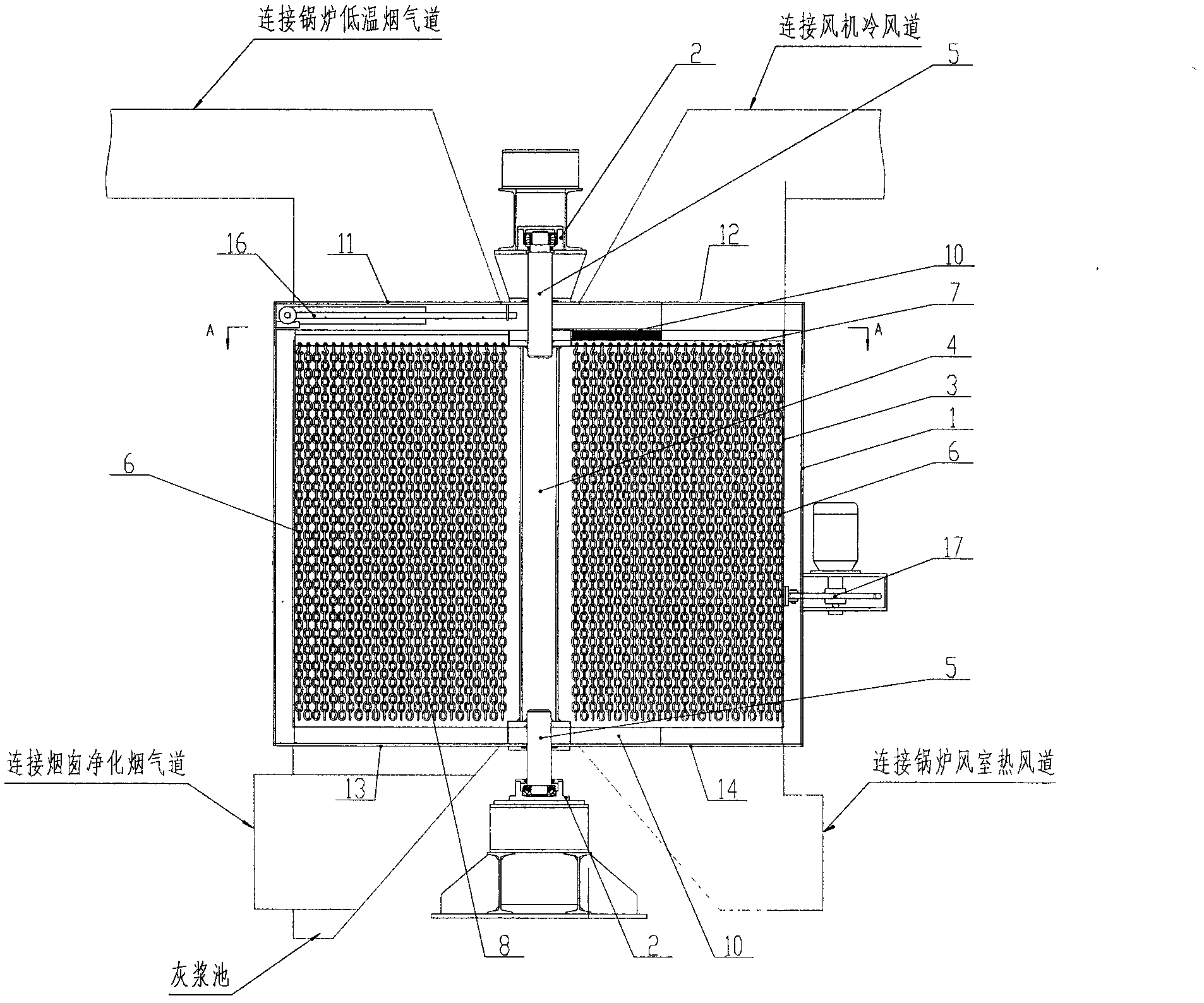

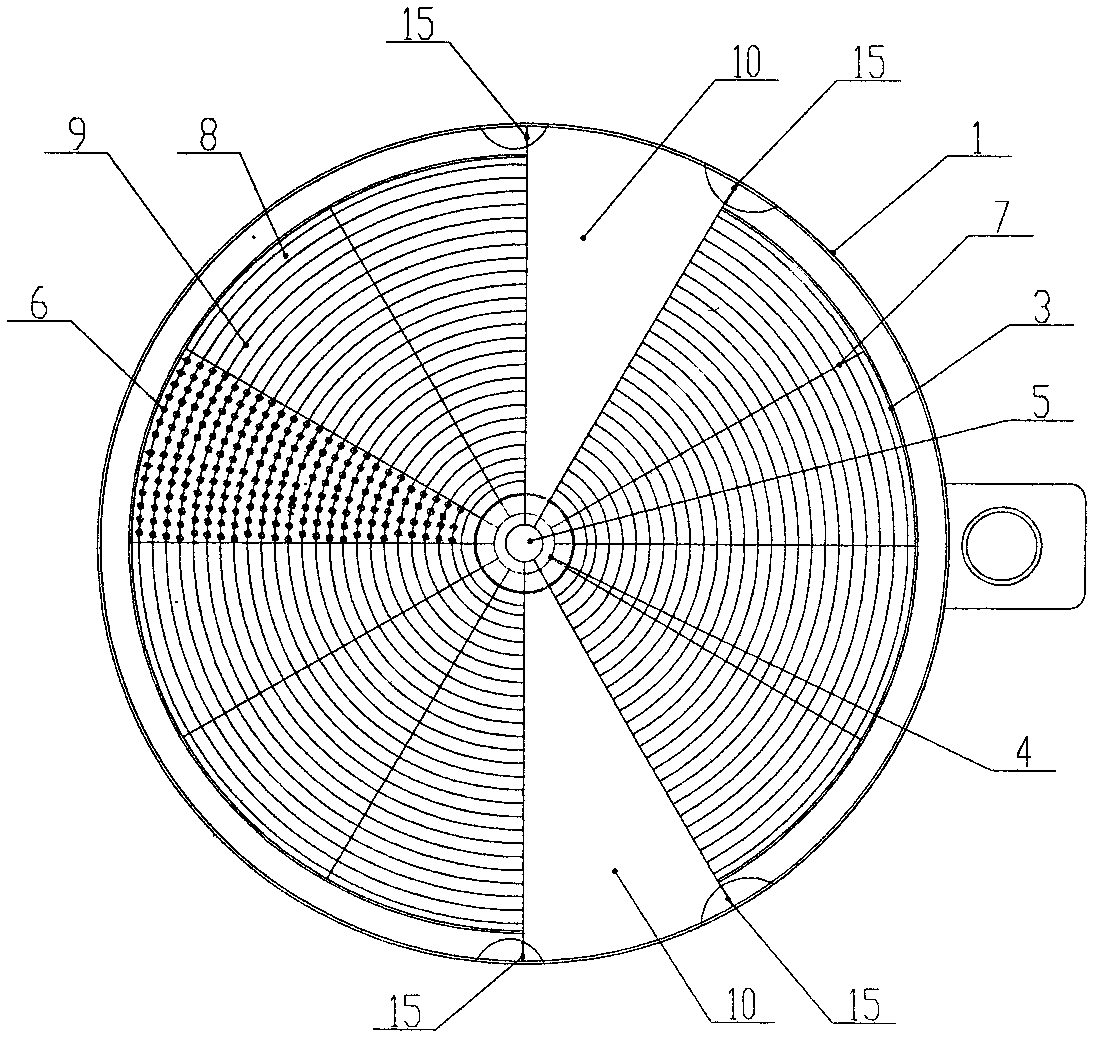

Desulfurization dust removal deep cooling exchange all-in-one machine

InactiveCN102989287AEasy to removeImprove heat transfer efficiencyDispersed particle separationHeat carrierFlue gas

The invention relates to boiler auxiliary equipment. The technical problems to be solved are that as heat exchange equipments for desulfurization, dust removal and heat recovery of exhaust fumes of boilers are separated from one another, the structure is huge and the construction cost is high, and as the heat exchange equipment is in an interval heat exchange mode and can not recycle heat of low-temperature flue gas below dewpoint, the heat exchange efficiency is low and the energy resource is wasted. According to the adopted technical scheme, a desulfurization dust removal deep cooling exchange all-in-one machine comprises a vertical fixed barrel, a vertical rotary body arranged in the vertical fixed barrel, an upper bearing pedestal, a lower bearing pedestal and a whitewash spraying device, wherein the vertical rotary body comprises a vertical rotary barrel, a vertical sleeve arranged at the center of the vertical rotary barrel, an upper rotary vertical shaft, a lower rotary vertical shaft and a heat carrier endless chain, and the vertical rotary barrel is internally provided with a number of heat carrier cavities with equal fan-shaped openings, which are spaced by vertical clapboards; and the vertical rotary barrel; and two fan-shaped sealing devices, central angles of which correspond to the central angles of the fan-shaped openings of the heat carrier cavities, are correspondingly and respectively distributed at an upper port end and a lower port end of the vertical fixed barrel.

Owner:马成果

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com