Aerating building block special-purpose whitewash mortar and preparation method thereof

An air-entrained block and mortar technology is applied in the field of special plastering mortar for aerated blocks and its preparation, which can solve the problems of unsatisfactory effect, insufficient hydration, long water absorption time, etc., and achieves saving in laying grid cloth, The effect of preventing slippage and cracking and reducing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

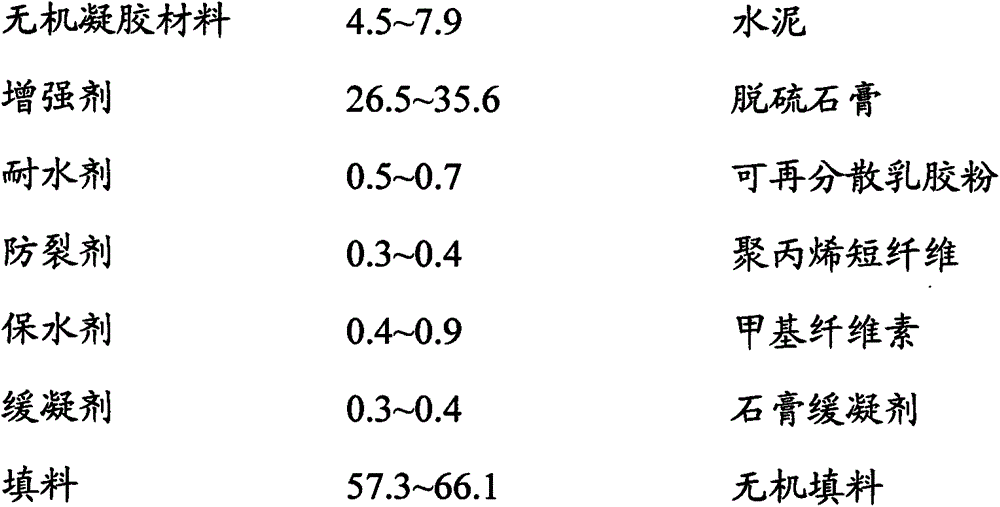

[0025] Described plastering mortar is formulated according to the following proportions:

[0026]

[0027] Add 33 parts of water to 100 parts of the solid composition.

[0028] Add the calculated amount of water into the mortar mixer, and add the calculated amount of cement, desulfurized gypsum, redispersible latex powder, polypropylene short fiber, methyl cellulose, gypsum retarder, and inorganic filler into the mortar Start stirring and mixing in the mixer, and the mixing time is 60 minutes.

Embodiment 2

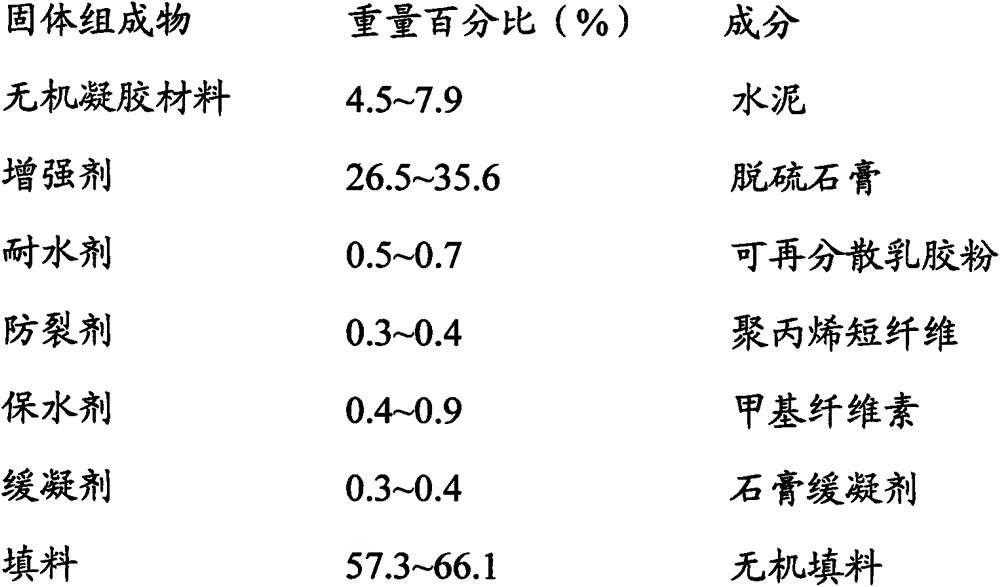

[0030] Described plastering mortar is formulated according to the following proportions:

[0031]

[0032]

[0033] Add 30 parts of water to 100 parts of the solid composition.

[0034] Add the calculated amount of water into the mortar mixer, and add the calculated amount of cement, desulfurized gypsum, redispersible latex powder, polypropylene short fiber, methyl cellulose, gypsum retarder, and inorganic filler into the mortar Start stirring and mixing in the mixer, and the mixing time is 60 minutes.

Embodiment 3

[0036] Described plastering mortar is formulated according to the following proportions:

[0037]

[0038] Add 35 parts of water to 100 parts of the solid composition.

[0039] Add the calculated amount of water into the mortar mixer, and add the calculated amount of cement, desulfurized gypsum, redispersible latex powder, polypropylene short fiber, methyl cellulose, gypsum retarder, and inorganic filler into the mortar Start stirring and mixing in the mixer, and the mixing time is 60 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com