Patents

Literature

181results about How to "Guaranteed decorative effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based primer-topcoat braking paint and preparation method thereof

The invention relates to a water-based primer-topcoat braking paint and a preparation method thereof. The braking paint comprises the following materials by weight percentage: 30-40 of water-based acrylic resin, 2-10 of amino resin, 1-3 of neutralizing agent, 2-5 of compound rustproofing pigment, 1-3 of tinting pigment, 10-20 of filling agent, 0.1-0.5 of defoaming agent, 0.1-0.5 of flatting agent and 25-40 of deionized water, wherein the water-based acrylic resin is a free radical polymerization resultant which comprises the following materials by weight percentage: 10-30 of monomer containing hydroxy acrylic acid, 5-20 of monomer containing carboxyl acrylic acid, 2-8 of internal crosslinking monomer, 20-40 of other acrylic acid monomer, 15-30 of phenyl ethylene monomer, 1-5 of evocating agent and 40-50 of alcohol ether latent solvent. When the paint is prepared, the dispersion and the abrading condition of the pigments and the filling agents are reasonably controlled to ensure that each component of the paint fully plays the respective function. The paint ensures the corrosion prevention effect and the decoration of a coating and realizes the combination of a primer and a topcoat.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

Putty powder used for walls in house

InactiveCN101705027AExcellent scratch coating construction performanceGuaranteed crack resistanceFilling pastesCalcium hydroxideSodium Bentonite

The invention provides putty powder used for walls in a house. The putty powder comprises the following ingredients: ground calcium carbonate, sodium-base bentonite, 1788 powder of polyving akohol, hydroxypropyl methyl cellulose and talcum powder, besides, white cement or / and calcium hydroxide powder is / are added therein as a reinforcing material, and also, sodium hexametaphosphate powder and / or tourmaline powder are / is added in the product. The putty powder has excellent scraping construction performance, long-acting mould-proof performance and excellent dense degree of the putty coating as well as the function of releasing negative ions for a long time, can effectively adsorb various harmful substances in the air and purify the air, and has excellent environment-friendly performance.

Owner:毕家新

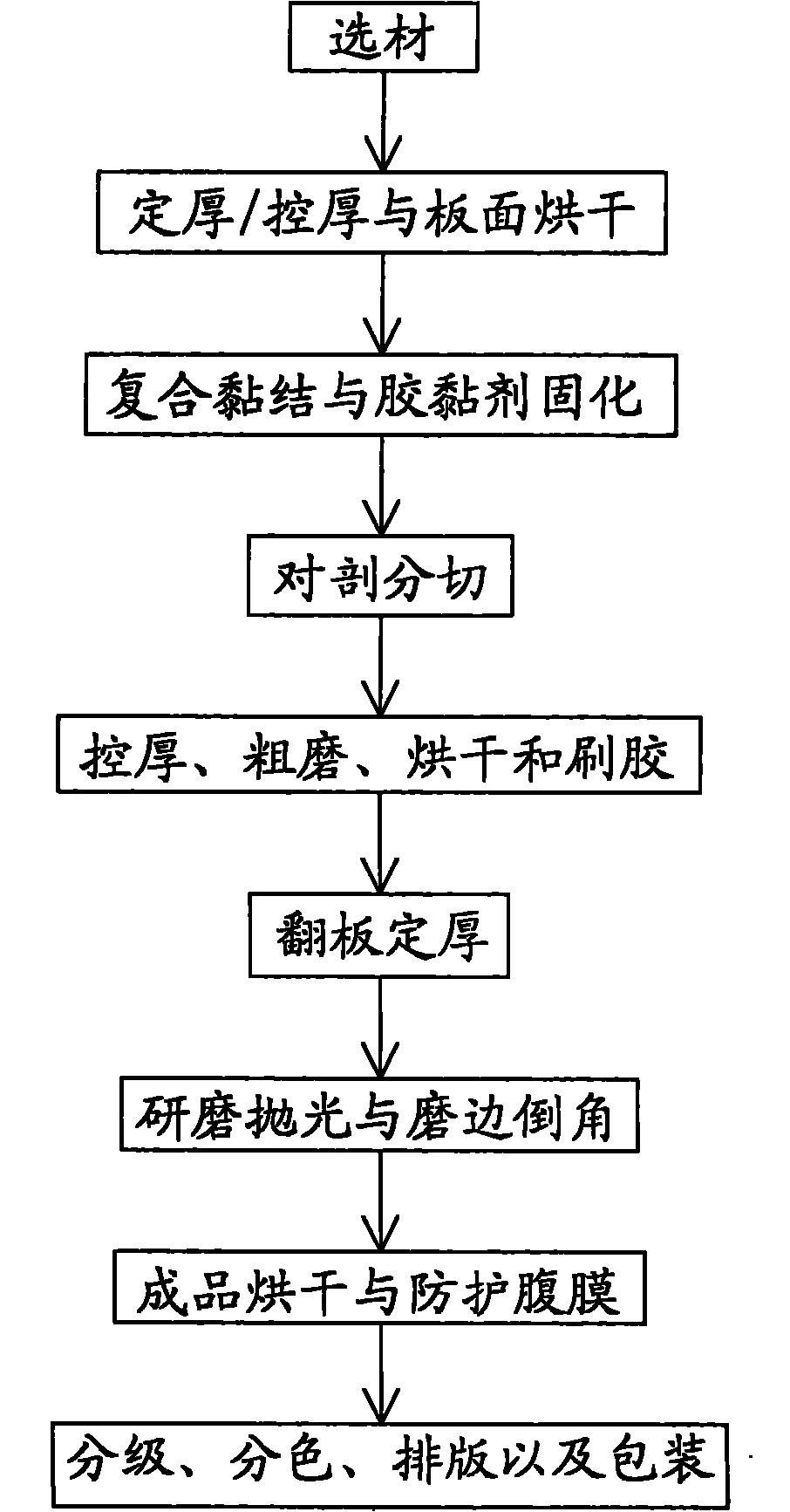

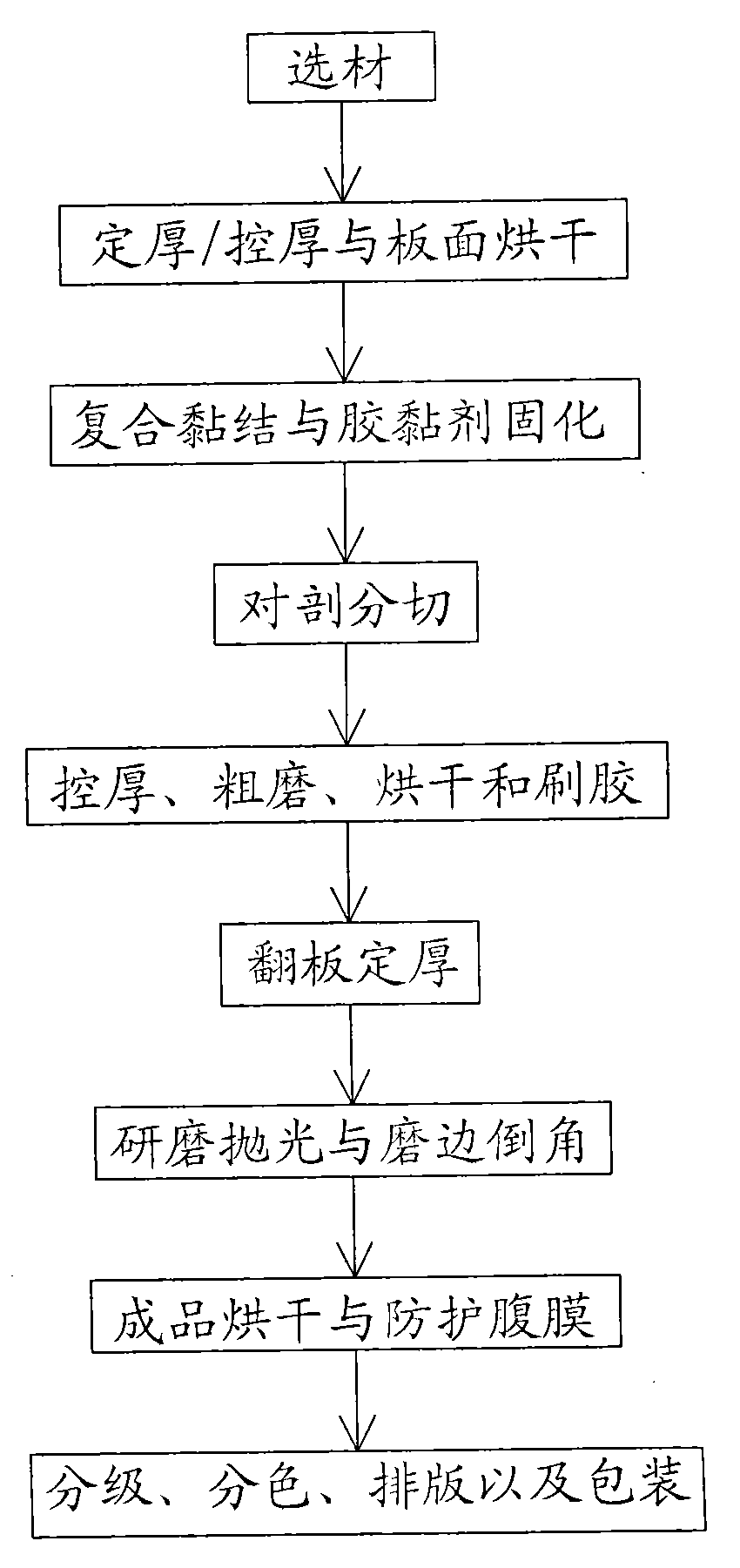

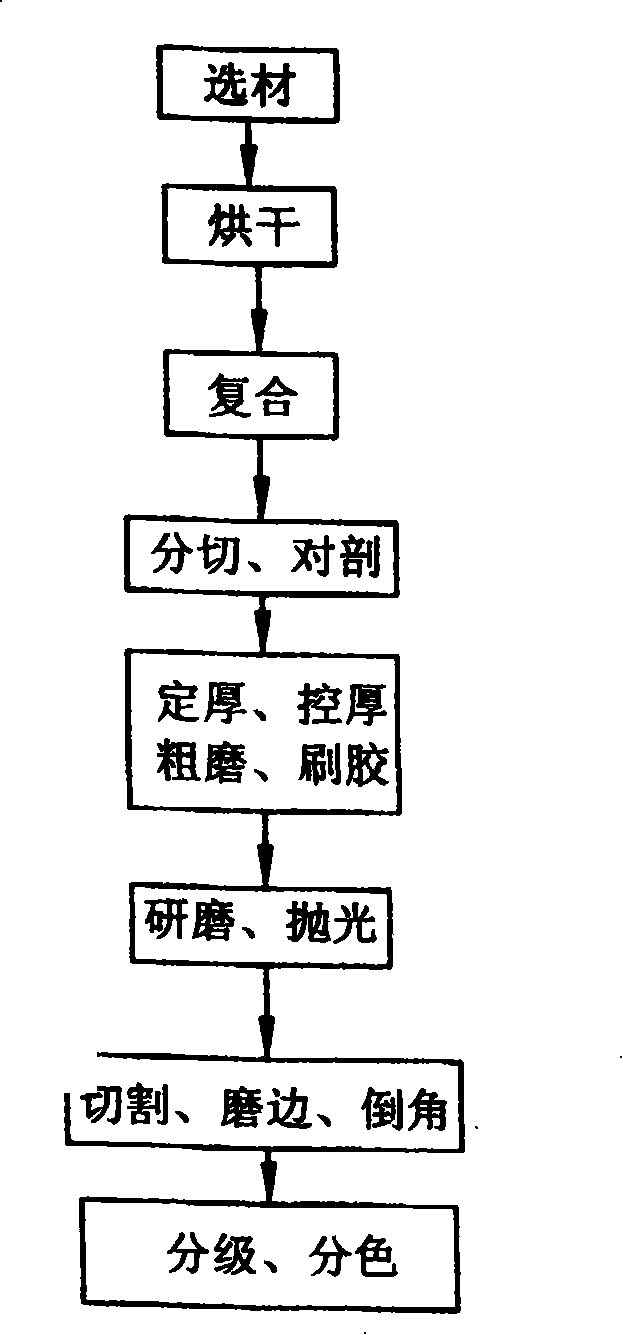

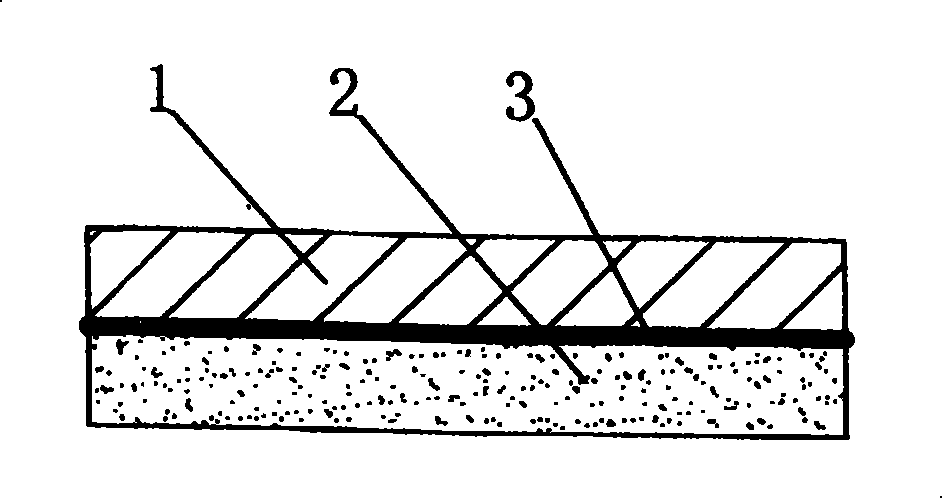

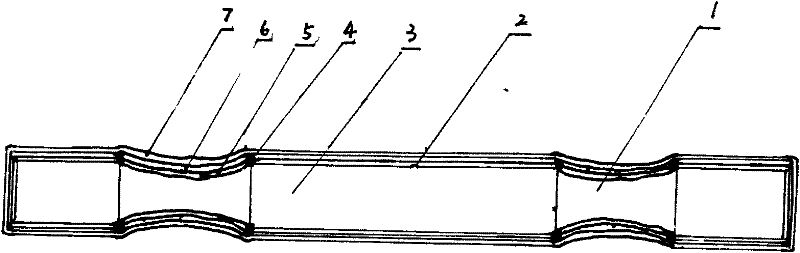

Technology for producing natural stone composite board

InactiveCN101966719AGuaranteed decorative effectHigh strengthLaminationLamination apparatusEngineeringNatural stone

The invention discloses technology for producing a natural stone composite board, which comprises the following steps of: (1) selecting materials; (2) fixing and controlling the thickness and drying a board; (3) performing composite bonding and adhesive curing; (4) halving and slitting; (5) controlling the thickness, coarsely grinding, drying and cementing; (6) turning the board and fixing the thickness; and (7) grinding and polishing and chamfering so as to form the finished product of the natural stone composite board. The natural stone composite board produced by the technology has the characteristics of high efficiency, high yield and high strength.

Owner:FUJIAN NANAN XINDONGYUAN STONE +2

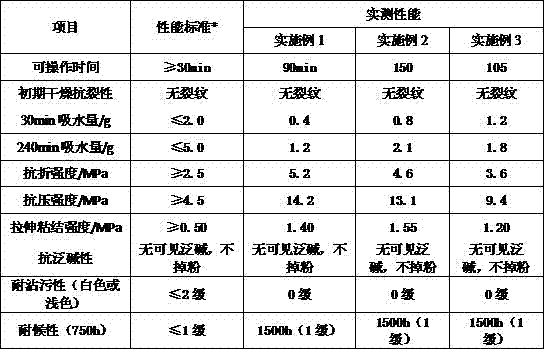

Ternary cementitious system stucco finish, and application method thereof

The invention belongs to the technical field of building material, and more specifically relates to a ternary cementitious system stucco finish, and an application method thereof. The ternary cementitious system stucco finish is composed of white Portland cement, sulphate aluminium cement, gypsum, superfine slag powder, zeolite powder, latex powder, cellulose ether, an air entraining agent, an antifoaming agent, a water repellent, a thixotropic agent, an inorganic pigment, an quartz sand. The ternary cementitious system stucco finish possesses excellent physical mechanical properties; setting time and operable time are controllable; development of early strength is rapid; strength is high; bonding strength with matrix is high; no shrinkage cracking is caused; durability is excellent; no crystalline bloom is caused; stain resistance is excellent; and decorative effect is excellent. The ternary cementitious system stucco finish is suitable for decoration engineering of building internal and external walls and building thermal-insulation decorative integrated systems; relatively mechanical strength is achieved in a relatively short term; construction efficiency is increased; performance of long-term application is excellent; and engineering quality is ensured.

Owner:TONGJI UNIV

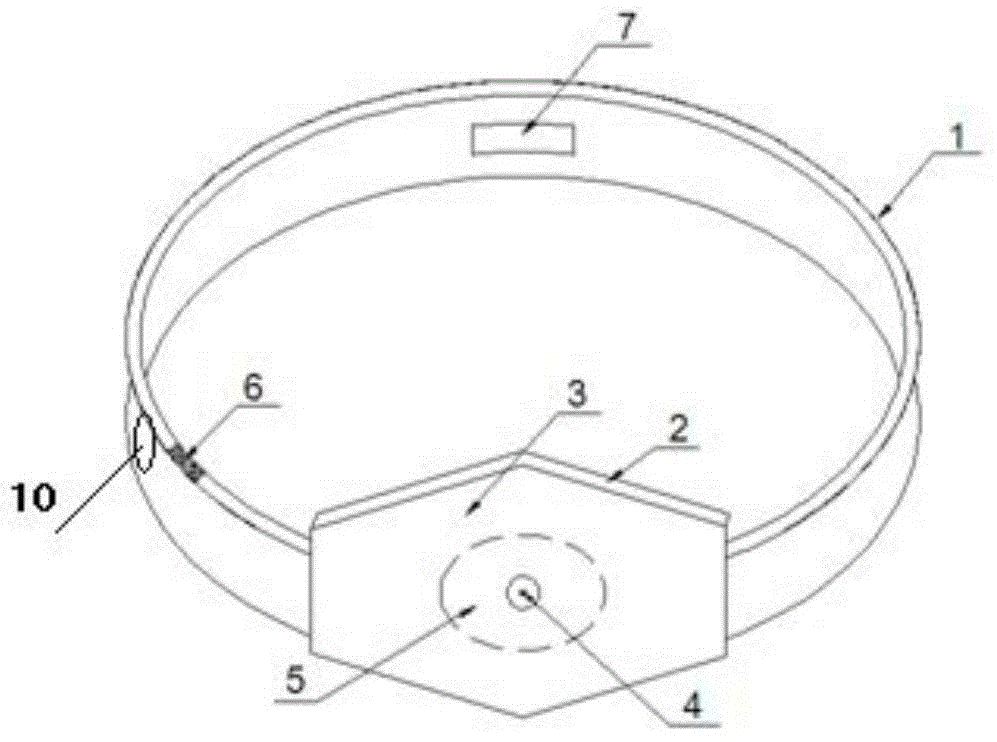

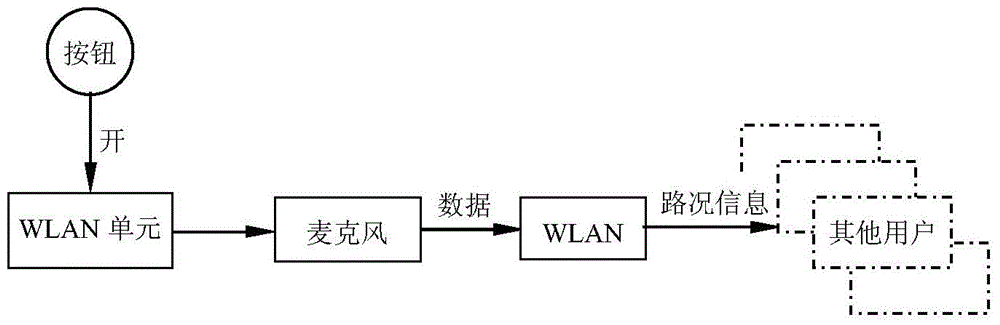

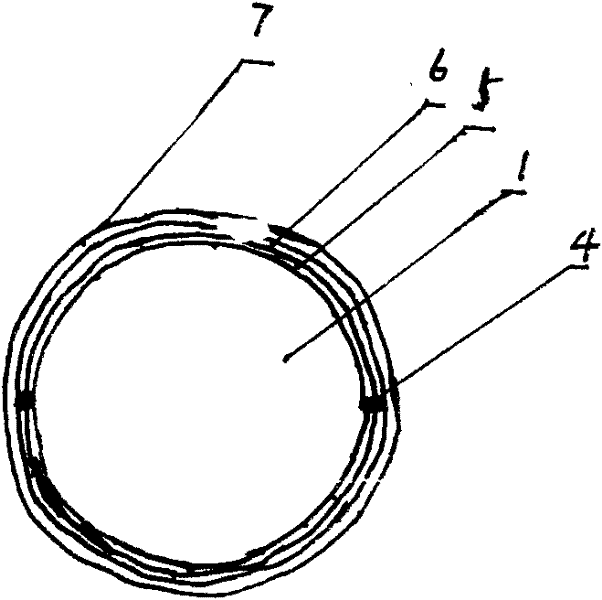

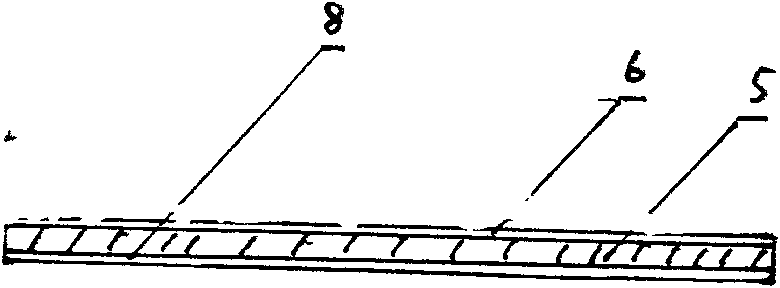

Intelligent finger ring and wearable intelligent display system

ActiveCN104157116AEasy to wearGuaranteed decorative effectTransmission systemsClosed circuit television systemsData informationDisplay device

The invention discloses an intelligent finger ring which comprises a main body part worn on a finger of a wearer, a display device which is arranged on the main body part and is used for displaying set and / or real-time received data information. The display device of the intelligent finger ring can display a decoration pattern and available information, so that the decoration property of a conventional finger ring is retained, and a display function is added on the basis of portability. The invention also discloses a wearable intelligent display system.

Owner:BOE TECH GRP CO LTD +1

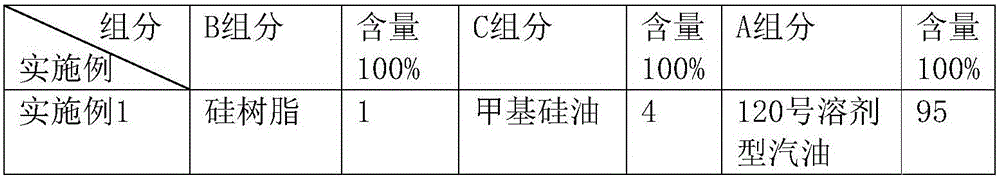

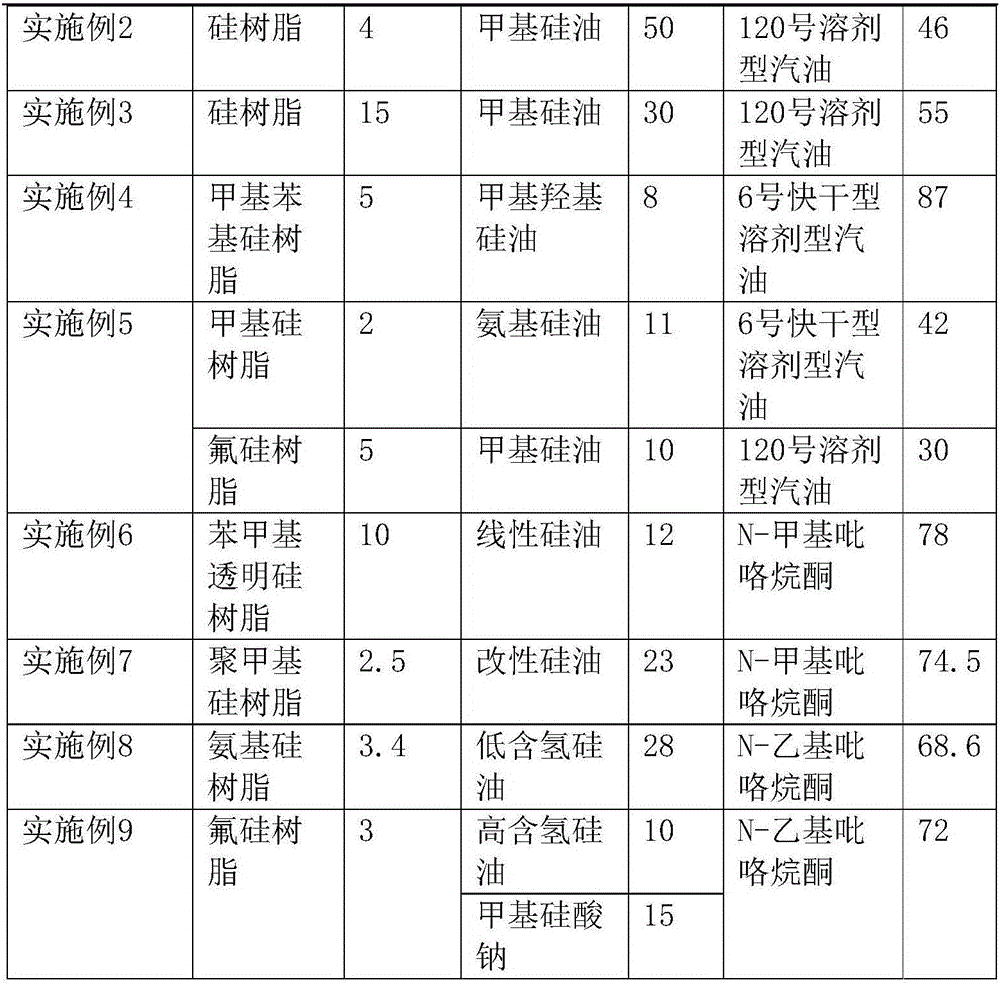

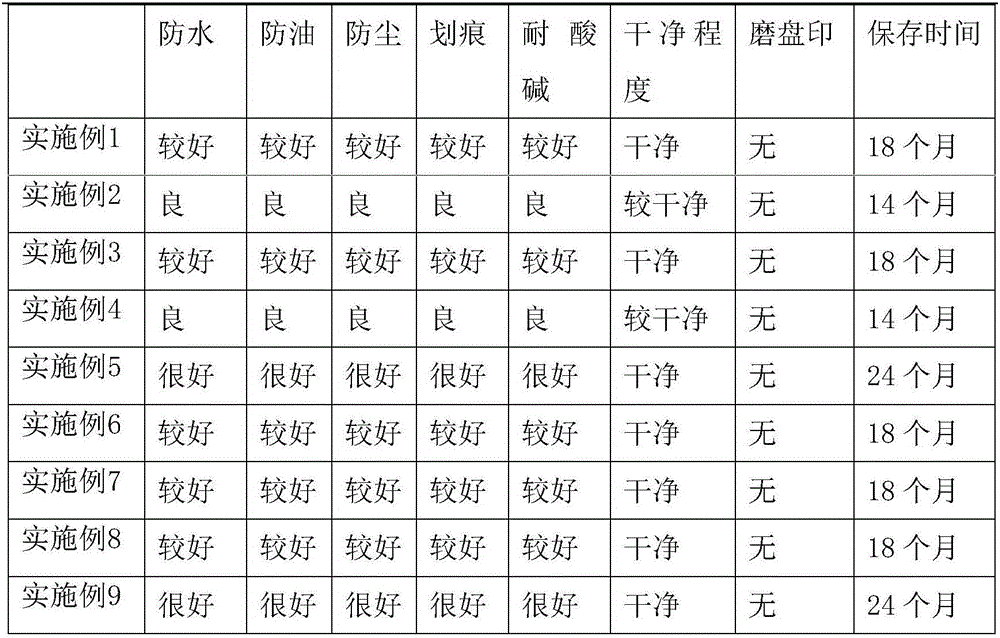

Matte brick stain-proofing agent and preparation method thereof

ActiveCN105860831AAntifoulingExtended service lifeAntifouling/underwater paintsPaints with biocidesOrganic solventBrick

The invention discloses a matte brick stain-proofing agent. The matte brick stain-proofing agent is prepared from a component A, a component B and a component C, wherein the component A is an organic solvent, the component B is silicon resin, and the component C is at least one of silicone oil and organosiloxane monomers. The invention further provides a preparation method of the matte brick stain-proofing agent. By compounding the components, the matte brick stain-proofing agent can achieve a good stain-proofing effect when used for performing stain-proofing treatment on the surfaces of matte bricks in follow-up application; besides, the matte brick stain-proofing agent has a very long shelf life and service life; moreover, the preparation technology is simple and easy to implement and can be conveniently applied to industrial production.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

Marble composite board processing technique

InactiveCN101195255AHigh strengthHigh glossStone-like material working toolsResource consumptionAdhesive

The invention relates to the field of building decoration materials, in particular to a manufacturing process of marble clad plates. The manufacturing process of marble clad plates is characterized in that the steps of the process include materials selecting, drying, compounding, dividing and cutting, bisecting, thickness defining, thickness controlling, roughly grinding, glue brushing, abrading, polishing, cutting, chamfering or edging, chamfering, grading, color separating and packing. The process has advantages of high production efficiency, short cycle and large outputs, and the multi-purpose marble clad plates manufactured by the production process has the advantages of shock resistance, countering bending, twist resistance and low costs. Furthermore, the manufactured product has the advantages of light weight, strong intensity, high yielding rate and pressure resistance, which is difficult to be broken after continuous grinding. After abrading and polishing, the marble clad plates have higher glossiness than original marbles, which has the advantages of light weight, strong intensity, high glossiness and the like. Furthermore, the marble clad plates have light weight and reduce resources consumption, thereby reducing production and construction costs, which are capable of being fixed on walls by utilizing composite adhesives. The economic benefic of the marble clad plates is increased by nearly one time of the original high-grade marbles.

Owner:杨加强

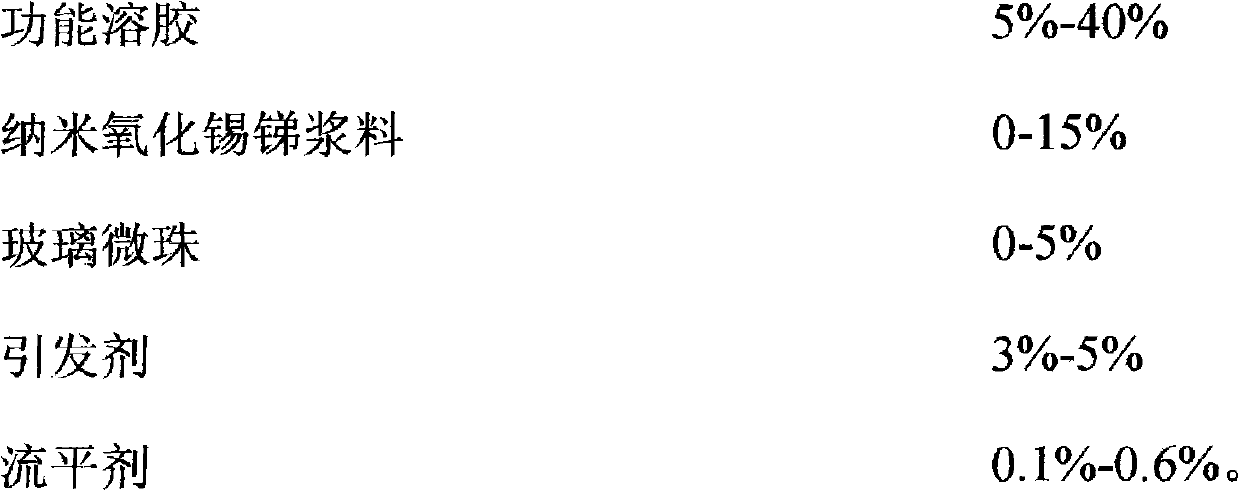

Method for preparing ultraviolet (UV) curing flame-retardant coating material and UV curing flame-retardant coating material

The invention discloses a method for preparing an ultraviolet (UV) curing flame-retardant coating material. The method comprises the following steps of: (1) preparing functional sol which is nano-sol modified by a silane coupling agent or sol generated by hydrolyzing alkoxide or the silane coupling agent; and (2) adding 20 to 70 mass percent of UV curing resin, 20 to 50 mass percent of reactive diluent, 5 to 40 mass percent of functional sol, 0 to 15 mass percent of nano antimony tin oxide slurry, 0 to 5 mass percent of glass microspheres, 3 to 5 mass percent of initiator and 0.1 to 6 mass percent of leveling agent into a dispersing kettle, and dispersing for 0.5 to 3 hours at the rotating speed of 1,000 to 2,000rpm to obtain the UV curing high-hardness wear-resistant flame-retardant coating material. The invention also discloses the UV curing flame-retardant coating material. The UV curing flame-retardant coating material can prevent heat transfer from the source, the surface temperature and internal environment temperature of the coating material are effectively reduced, and the aims of improving the working environment and reducing energy consumption are fulfilled.

Owner:上海大学浙江嘉兴新兴产业研究院

Air permeable pure polyester powdery paints

InactiveCN101157820AGuaranteed decorative effectGuaranteed protective effectPowdery paintsPolyester coatingsElectrostatic coatingPolyester resin

The invention discloses a pure polyester powder coating with permeability, pertaining to the powder coating technique field of electrostatic coating. According to weight proportion, the components of the invention are 50 to 60 percent of outdoor polyester resin, 3 to 5 percent of curing agent, 0.8 to 5 percent of flow agent, 1 to 20 percent of pigment, 0.1 to 0.8 percent of degasifying agent, other additives and excessive materials filler. The invention is produced by using the existing powder coating production technique, and the degasifying agent is one of the polyethylene waxes of APP230F, 230VF, 620F, 620VF, 620XF. The invention has the advantages of being widely applicable to powder coating treatment of devices such as castings, etc., and having smooth coating surface, and good construction performance and internal quality.

Owner:XUZHOU ZENITH COATING

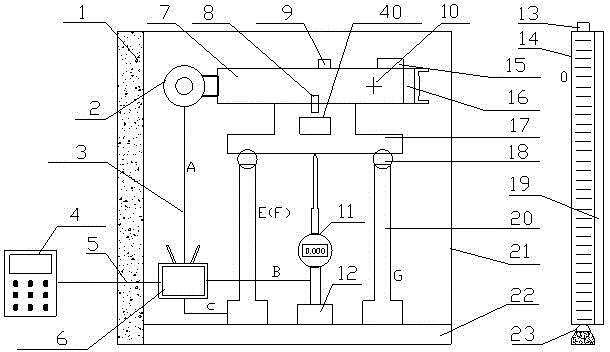

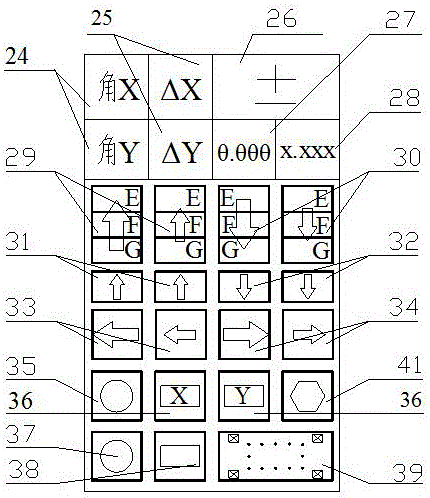

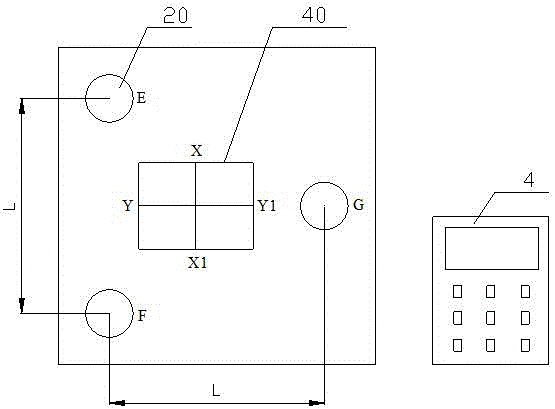

Remote multifunctional monitoring system for architectural structure and monitoring method

ActiveCN106679618ARealize remote controlImprove efficiencyAngle measurementOptical rangefindersEyepieceEngineering

The invention discloses a remote multifunctional monitoring system for an architectural structure. The remote multifunctional monitoring system comprises a fixed pile, wherein a fixedly connected horizontal rigid base is arranged on one side of the bottom of the fixed pile; a support platform is supported on the base through a servo motor; a telescope is connected onto the support platform through a rotating motor; a heat source sensor, a reticule and a laser ranger are arranged on the telescope, and a camera is arranged corresponding to an eyepiece of the telescope; a dual-axis tilt sensor is arranged on the support platform, a dial indicator contacted with the support platform is arranged at the bottom of the support platform, and the lower part of the dial indicator is arranged on a strong magnet fixed on the horizontal rigid base; a ruler is arranged corresponding to an automatic focusing lens of the telescope, a heat source is arranged at the top of the ruler, the bottom of the ruler is fixed on a reference ball, and a sensor light is further arranged on the ruler; the appliance components are all connected with a signal acquisition controller through data cables, and the signal acquisition controller is connected with a data processing terminal. The invention further discloses a monitoring adjusting method using the system.

Owner:NANJING HYDRAULIC RES INST +1

Furniture and wood door adhered with veneers on surfaces and manufacturing method thereof

InactiveCN102450875ALabor intensiveReduce production efficiencyWood working apparatusDoor leavesPulp and paper industry

The invention relates to furniture and wood door adhered with veneers on the surfaces and a manufacturing method thereof. Each of the furniture and the wood door comprises a wood inner blank, an upper veneer, a base coat and a top coat, and the well sand-ground base coats are pre-coated on the veneers before the veneers containing concave-down or convex-up or curved arc-shaped surface and other special-shaped surface members or parts are bonded with the wood inner blanks. Therefore, the problems of large labor intensity of artificial manual sand-grinding of the special-shaped surfaces, low production efficiency and series dust pollution are solved, the production efficiency of such type of the furniture and the wood doors is greatly improved and the application prospects are significant.

Owner:唐善学

Breathing epoxy polyester mixed type powder paint

InactiveCN101434808AGuaranteed decorative effectGuaranteed protective effectPowdery paintsEpoxy resin coatingsEpoxyElectrostatic coating

The invention discloses a permeable epoxy polyester mixed powder coating, belonging to the field of powder coating technique of static coating. According to the weight percentage of the compounding, the coating consists of 25-18 percent of epoxy resin, 25-42 percent of indoor polyester resin, 0.8-5 percent of leveling agent, 1-20 percent of pigment, degasifying agent, and the rest of filling materials and other normal auxiliary agents; the preparation method is carried out by the production process of the existing powder coating. The coating is characterized in that the degassifying agent is one of polyethylene wax APP230F, 230VF, 230XF, 620F, 620VF and 620XF and occupies the weight percentage of 0.1-0.8 percent compared with the total weight. The permeable epoxy powder coating has the advantages of outstanding degassifying effect, being widely used for the powder coating disposal of devices such as castings, flat and smooth surface of the coating, good construction performance and excellent internal quality.

Owner:XUZHOU ZENITH COATING

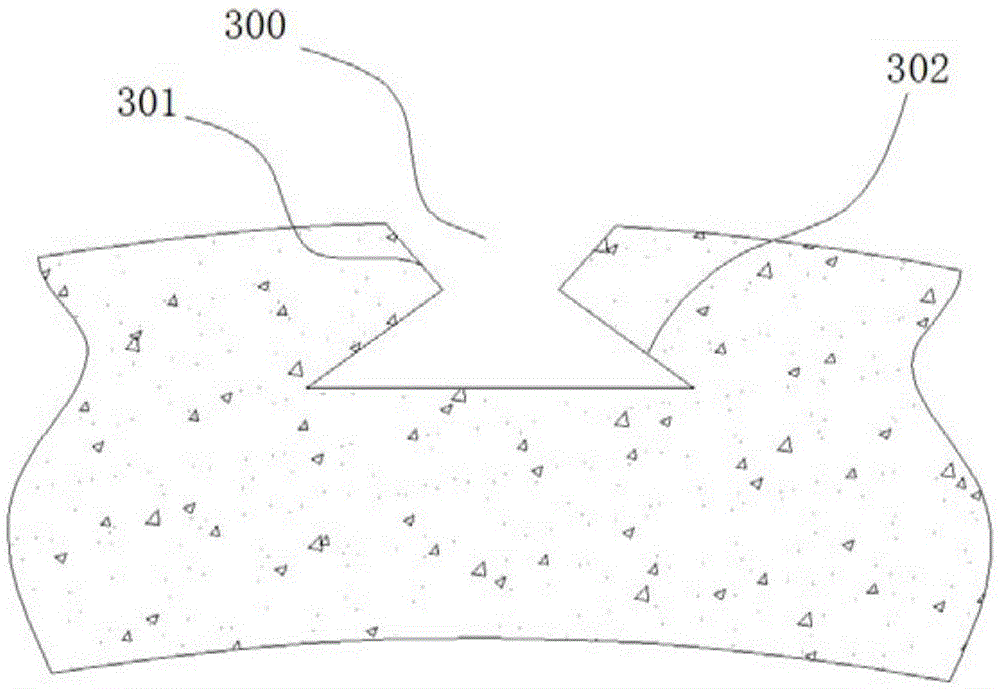

Decorating process for inlaying metal to ceramic

ActiveCN105644249AFirmly connectedGuaranteed decorative effectDecorative surface effectsGroove widthAdhesive

The invention provides a decorating process for inlaying metal to ceramic, and relates to the technical field of ceramic decoration. The decorating process for inlaying the metal to the ceramic comprises the following steps that a, a groove is formed in the surface of a ceramic product and comprises a first groove part, a second groove part is formed in the groove bottom of the first groove part, and the groove width of the groove bottom of the second groove part is larger than that of the groove bottom of the first groove part; b, the groove bottom of the second groove part is coated with an adhesive, meanwhile, a metal decoration is inlaid into the groove so that a metal decorated ceramic product can be formed by the ceramic product; and c, the surface of the metal decorated ceramic product is polished. According to the inlaying process, the metal decoration is firmly inlaid to the ceramic product under the dual action of the clamping force of the groove and the bonding force of the adhesive, and the ornamental value and collection value of the metal inlaid ceramic product are improved.

Owner:艾楚涧

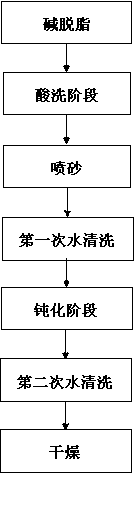

Aviation pipe stainless steel passivation technology

InactiveCN103320778ASolve the problem of poor pollutionGuaranteed decorative effectMetallic material coating processesAviationMetallurgy

The invention belongs to an aviation flight field, more specifically to an aviation pipe stainless steel passivation technology, comprising the following steps of: alkali derosination, a pickling stage; sandblast; cleaning with water for a first time; a passivation stage; cleaning with water for a second time; and drying. The aviation pipe stainless steel passivation technology provided by the invention has advantages of safety and high efficiency; solves a problem of bad fingerprint pollution resistance for the surface of stainless steel; and makes sure decorative characteristic of the surface of stainless steel.

Owner:春兴铸造(苏州工业园区)有限公司

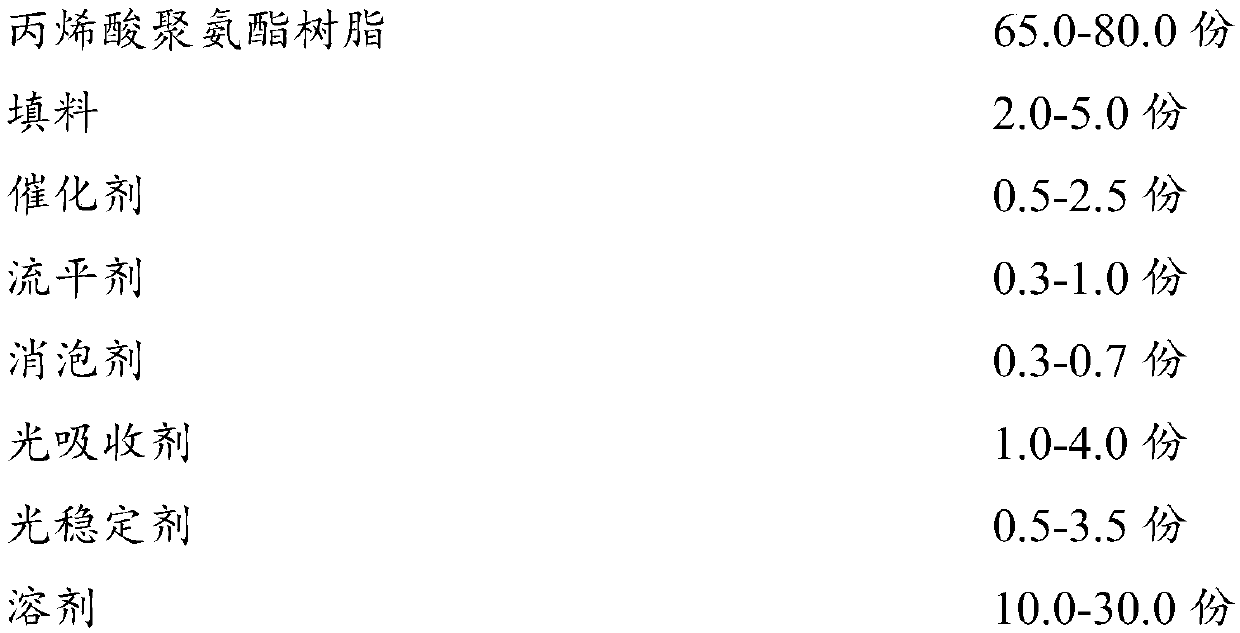

Weathering resistance enhancing coating varnish and preparation method and application thereof

InactiveCN108047924AHigh viscosityLow viscosityPolyurea/polyurethane coatingsReflecting/signal paintsWeather resistanceSolvent

The invention discloses a weathering resistance enhancing coating varnish and a preparation method and application thereof. The weathering resistance enhancing coating varnish is prepared from a mainagent and a hardener, wherein the parts by weight of the main agent and the hardener are (100:30) to (100:50). The weathering resistance enhancing coating varnish is prepared from the main agent usingpolyurethane acrylate resin along with filler, catalyst, defoaming agent, leveling agent, light absorbent, light stabilizer, solvent and other materials and then cooperating with polyisocyanate, water absorbent, solvent and the like of the hardener. The coating varnish can be applied on a matched coating layer under the condition of self-dying or medium-and-low-temperature baking, and the thickness of a varnish film applied once is 30 Mu m to 40 Mu m. The coating varnish enhances the weathering resistance of the original matched coating, solves the problem that ordinary coating varnish only has decorativeness and cannot effectively enhance the weathering resistance of coating, and in particular, plays an important role in enhancing the weathering resistance of non-flashing finishing paint.

Owner:ZHEJIANG SHUREN UNIV

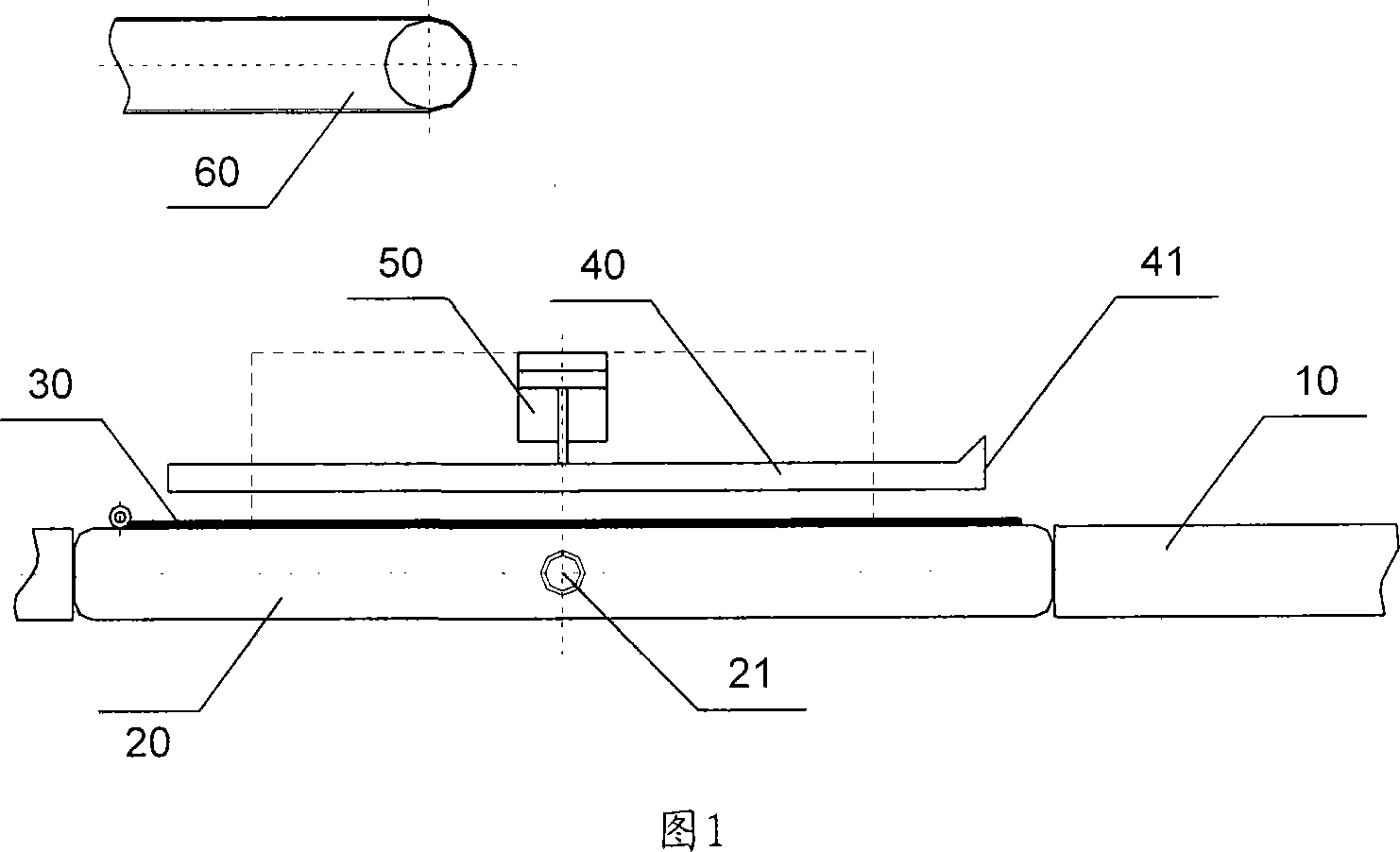

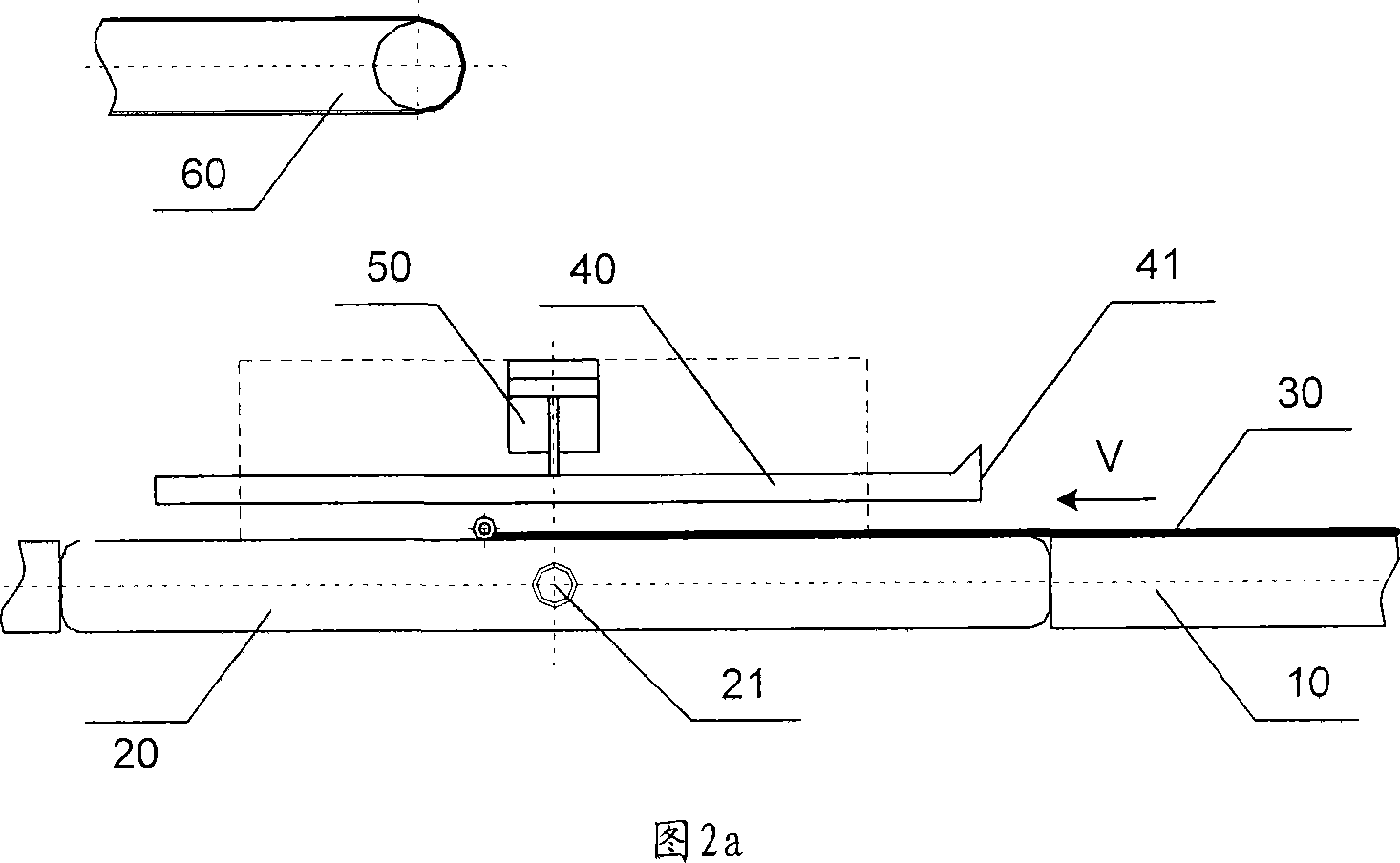

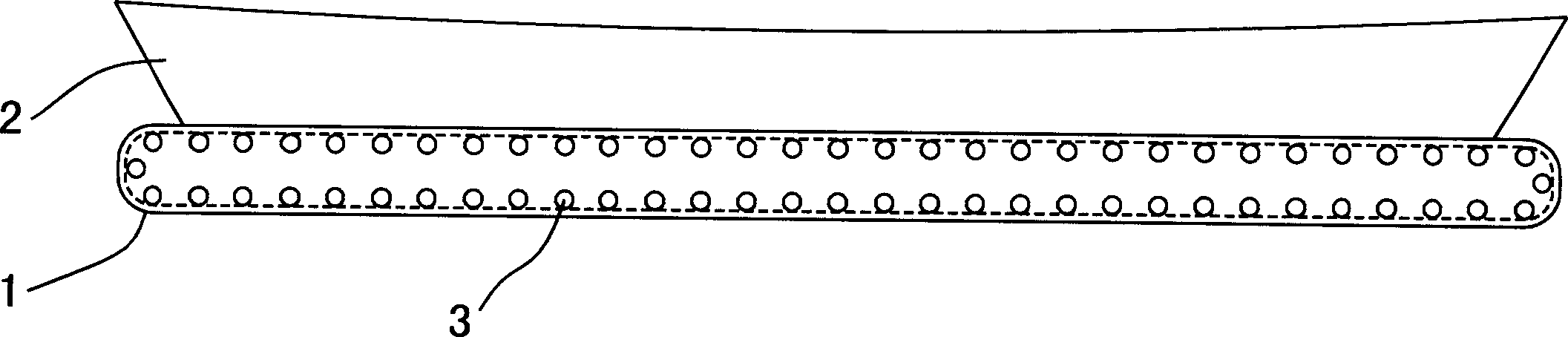

Vertical material-distributing device and material-distributing method

InactiveCN101077592AReduced splicing flatness requirementsGuaranteed decorative effectFeeding arrangmentsEngineeringClosed cavity

The present invention relates to one kind of vertical material distributing apparatus and process. The vertical material distributing apparatus includes one turnable platform capable of being turned into horizontal state or vertical state, one material box over the platform, one powder carrier with closed cavity, and one material feeder to fill the cavity with powdered material. The vertical material distributing process includes the following steps: setting the powder carrier on the turnable platform in horizontal state, forming one closed cavity with the material box and the powder carrier, turning the platform to vertical state, filling powdered material with the material feeder to the closed cavity, turning the platform reversely to horizontal state for the powdered material on the powder carrier, and feeding the powdered material with the powder carrier to the press for forming. The present invention has reasonable structure, high production efficiency and capacity of raising product quality.

Owner:KEDA INDUSTRIAL GROUP CO LTD

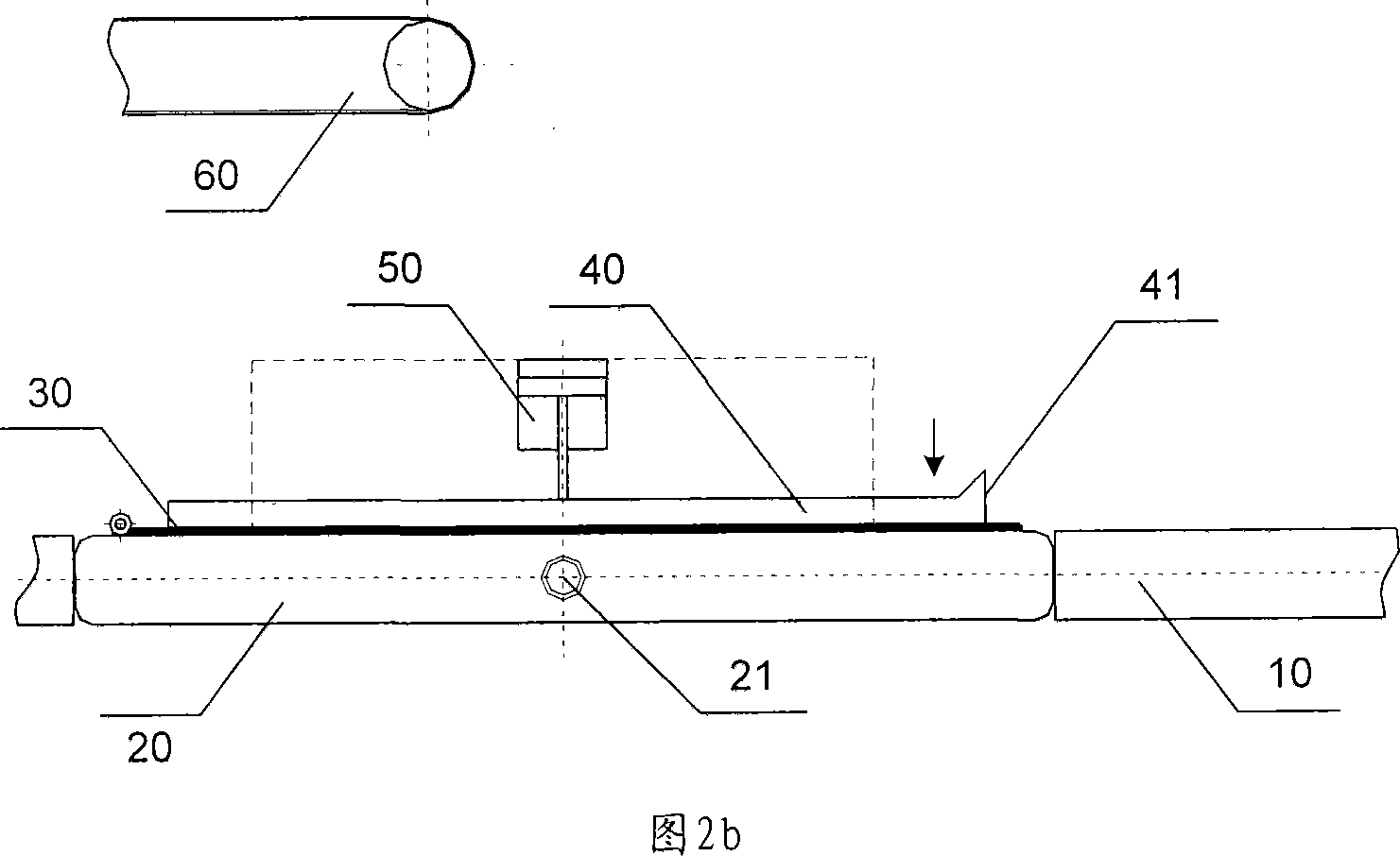

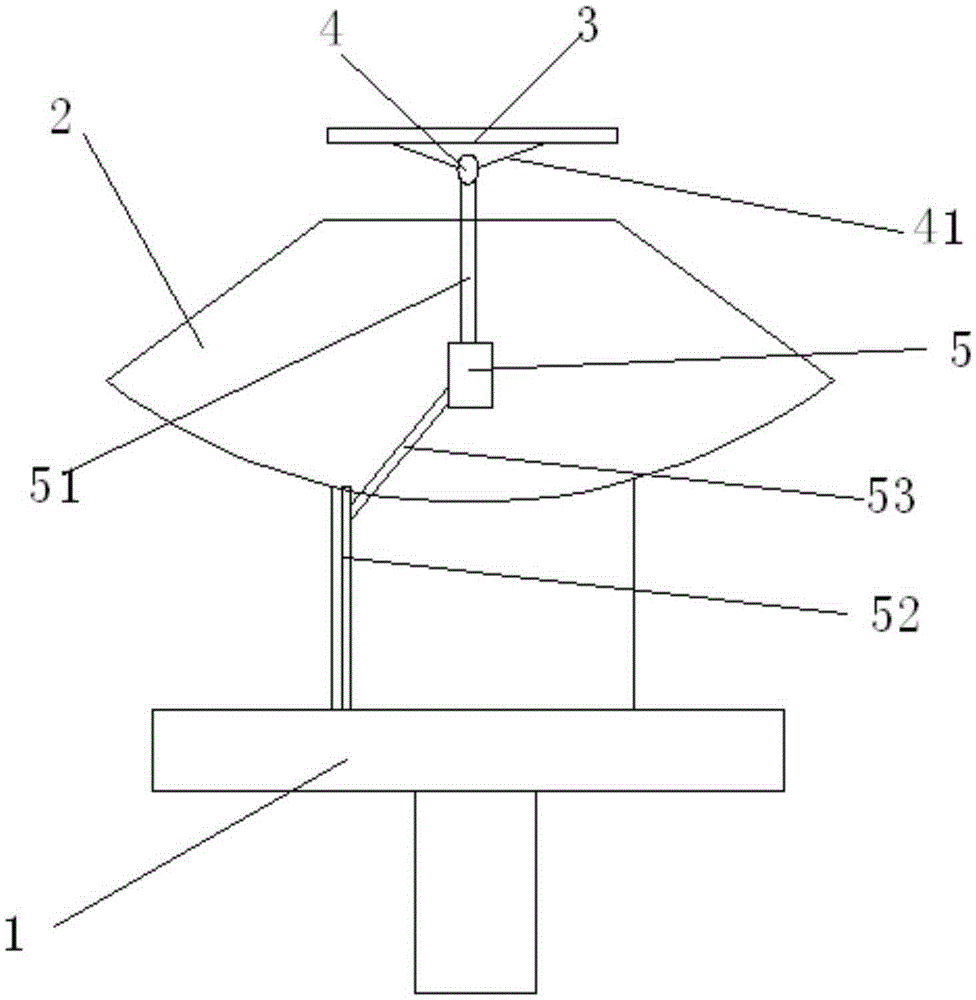

Solar lawn lamp

InactiveCN105258065AMaintain decorative effectIncrease power generationElectric circuit arrangementsCleaning using toolsLawnGenerating capacity

The invention discloses a solar lawn lamp. The solar lawn lamp comprises a lamp support (1), a lampshade (2), a solar cell panel (3), a rotating head (5), a cleaning mechanism, a control circuit and a light sensing piece (31). The light sensing piece (31) is arranged on the solar cell panel (3), and is connected with a control circuit; the control circuit controls the rotating head (5) to rotate according to the inclined angle between the solar cell panel (3) and the sun, and therefore the angle between the solar cell panel (3) and the sun is adjusted; and the cleaning mechanism comprises a rotating motor (5) and a brush (52). According to the solar lawn lamp, the angle between the solar cell panel (3) and the sun can be adjusted in real time, so that the generating capacity of the solar cell panel (3) can be maximum; and meanwhile, the inner wall of the lampshade can be cleaned, and the decoration effect is better.

Owner:JIANGSU YINJIA GROUP

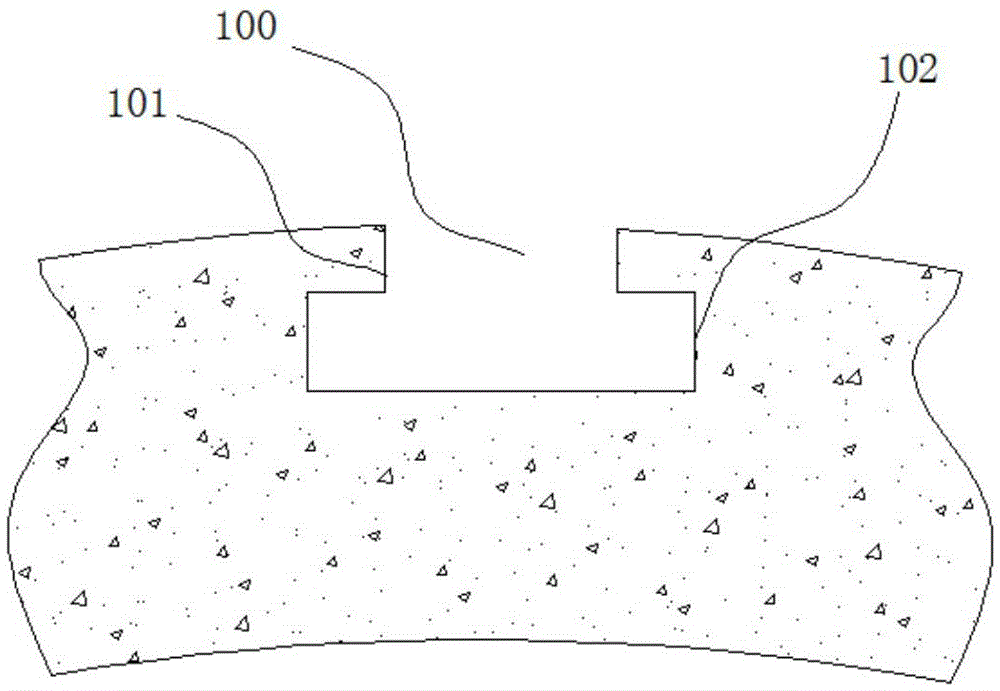

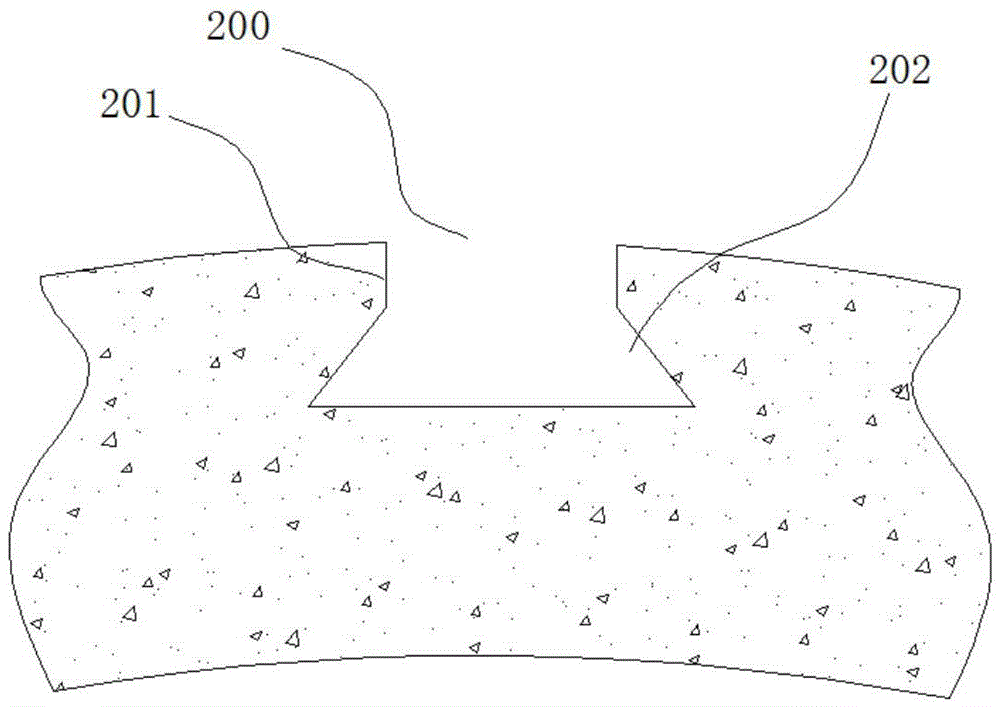

Unit curtain wall of composite bearing structure

InactiveCN104594535AReduce mechanical performance requirementsReasonable forceWallsSkin effectEngineering

A unit curtain wall of a composite bearing structure solves the problems that high-rigidity panels of an existing curtain wall of a frame supporting system do not share wind loads and consequently construction cost is high and construction energy consumption is large. The unit curtain wall comprises unit plates and connecting assemblies for assembling the unit plates and a building main body, and is technically characterized in that according to each unit plate, an inner panel, an outer panel and a frame with a port are combined through core materials and bonding layers to form an integrated structure with a skin effect; each connecting assembly comprises a plate inner embedded part, a plate connecting part, a main body structure connecting part, a sealing rubber strip and a plate insertion positioning block or a plate insertion positioning frame, and the two ends of each main body structure connecting part are fixedly connected with the corresponding plate connecting part and a building main body structure. The composite bearing structure design is adopted, the plates of the curtain wall bear force more reasonably, and the materials are utilized more sufficiently; on the basis of guaranteeing construction safety and decoration effects, the materials are further saved, the construction cost and energy consumption of the curtain wall are reduced, and diversified demands of construction effects are met.

Owner:上海易旋建筑设计咨询有限公司

Contamination resistant acrylic ester emulsion

Owner:江苏日出化工有限公司

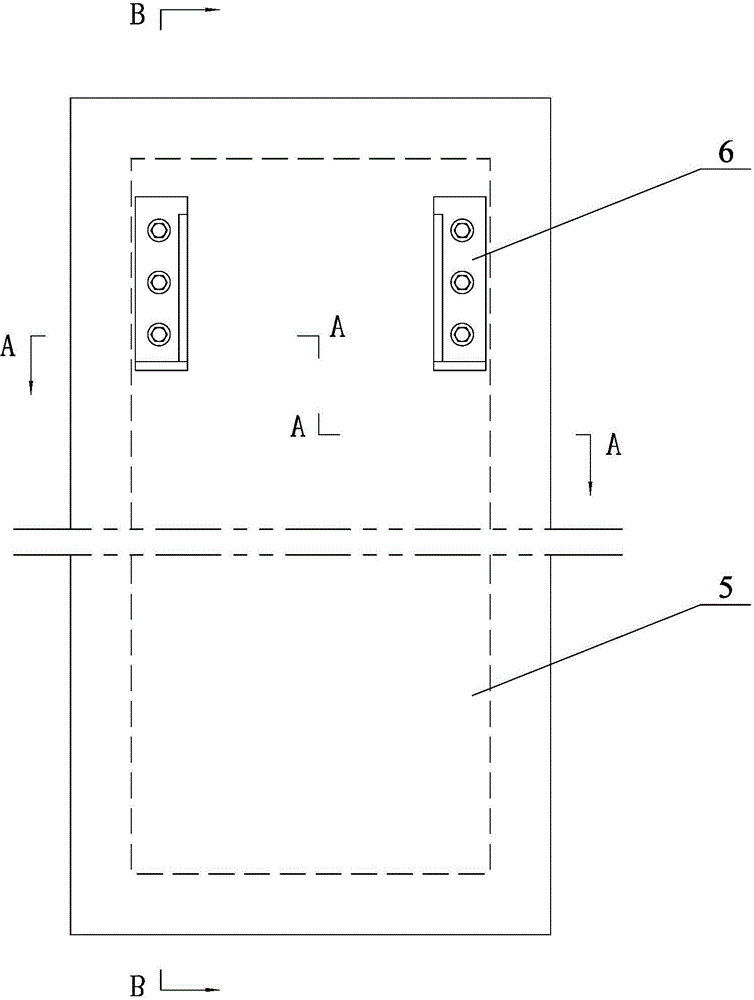

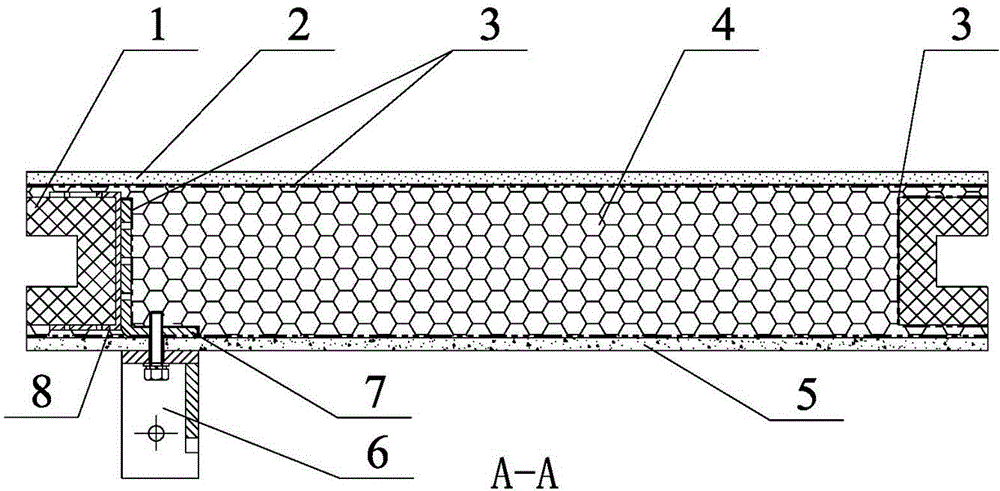

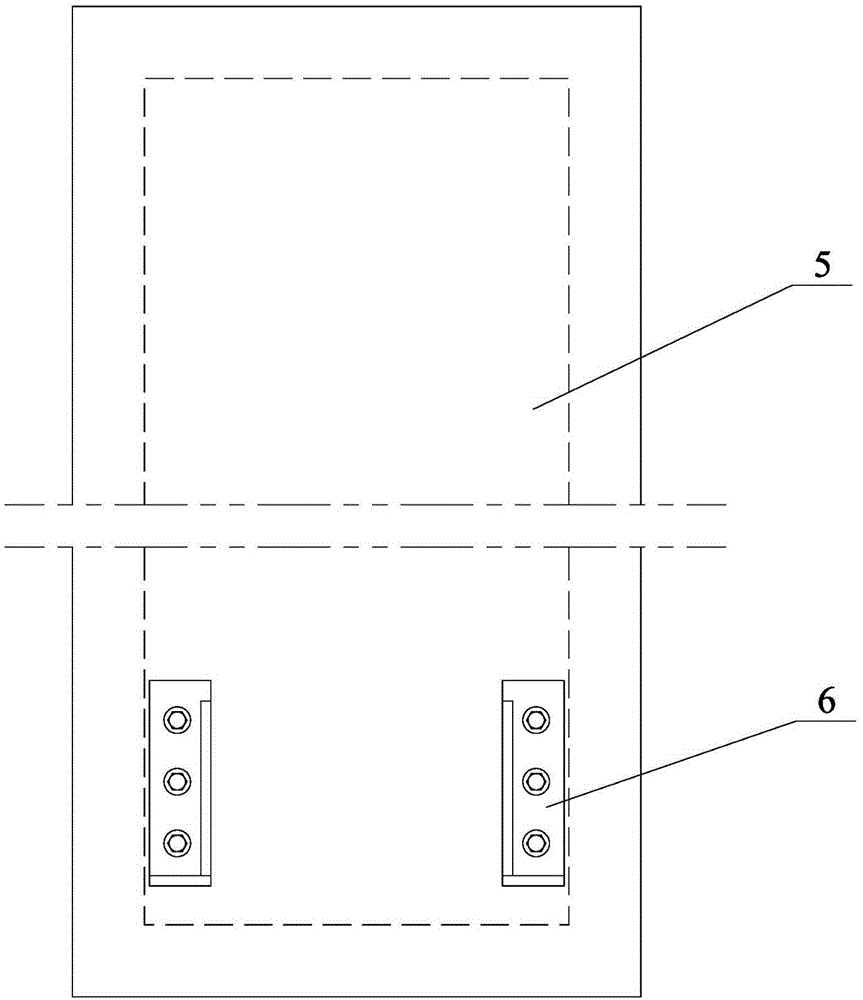

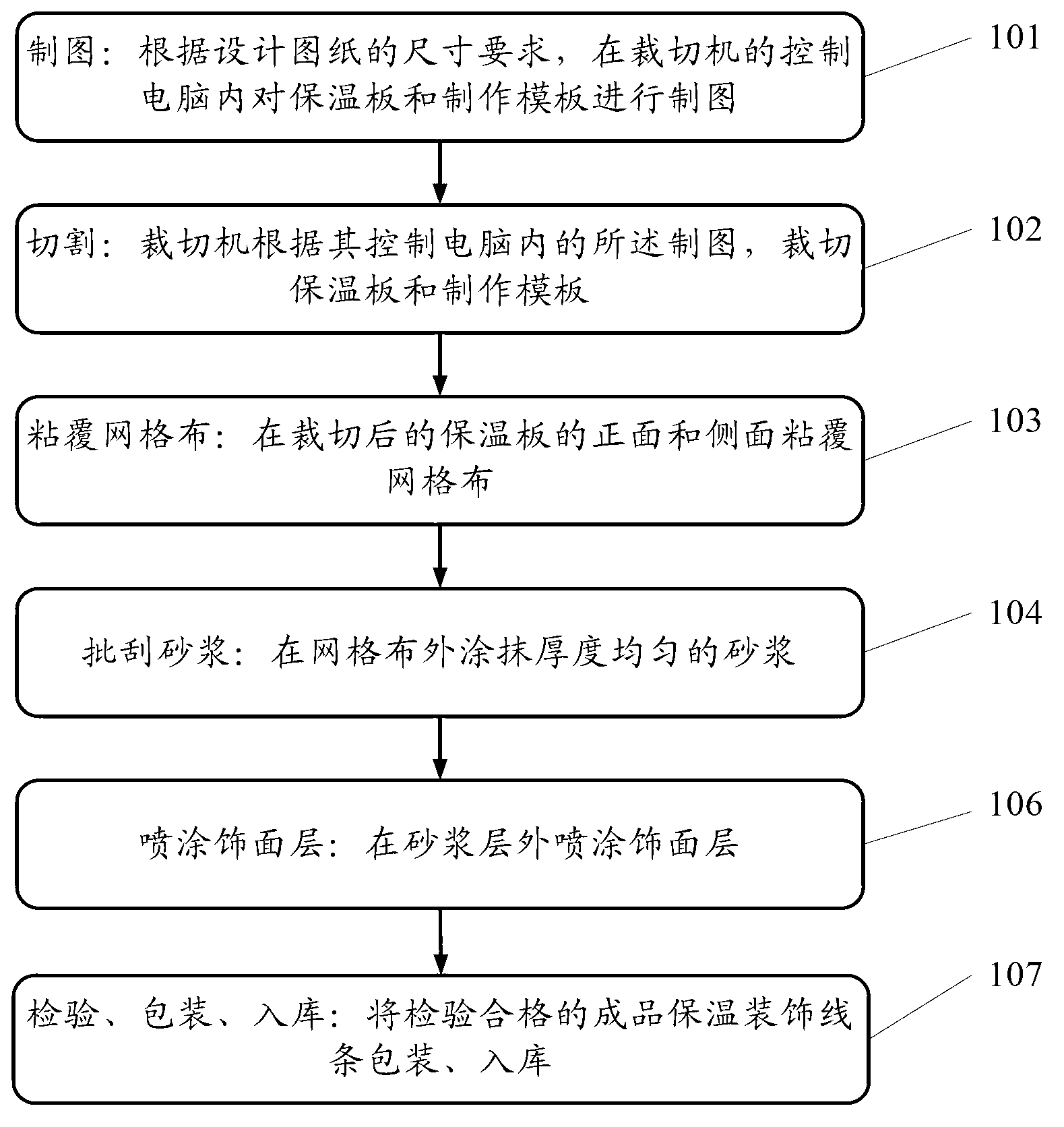

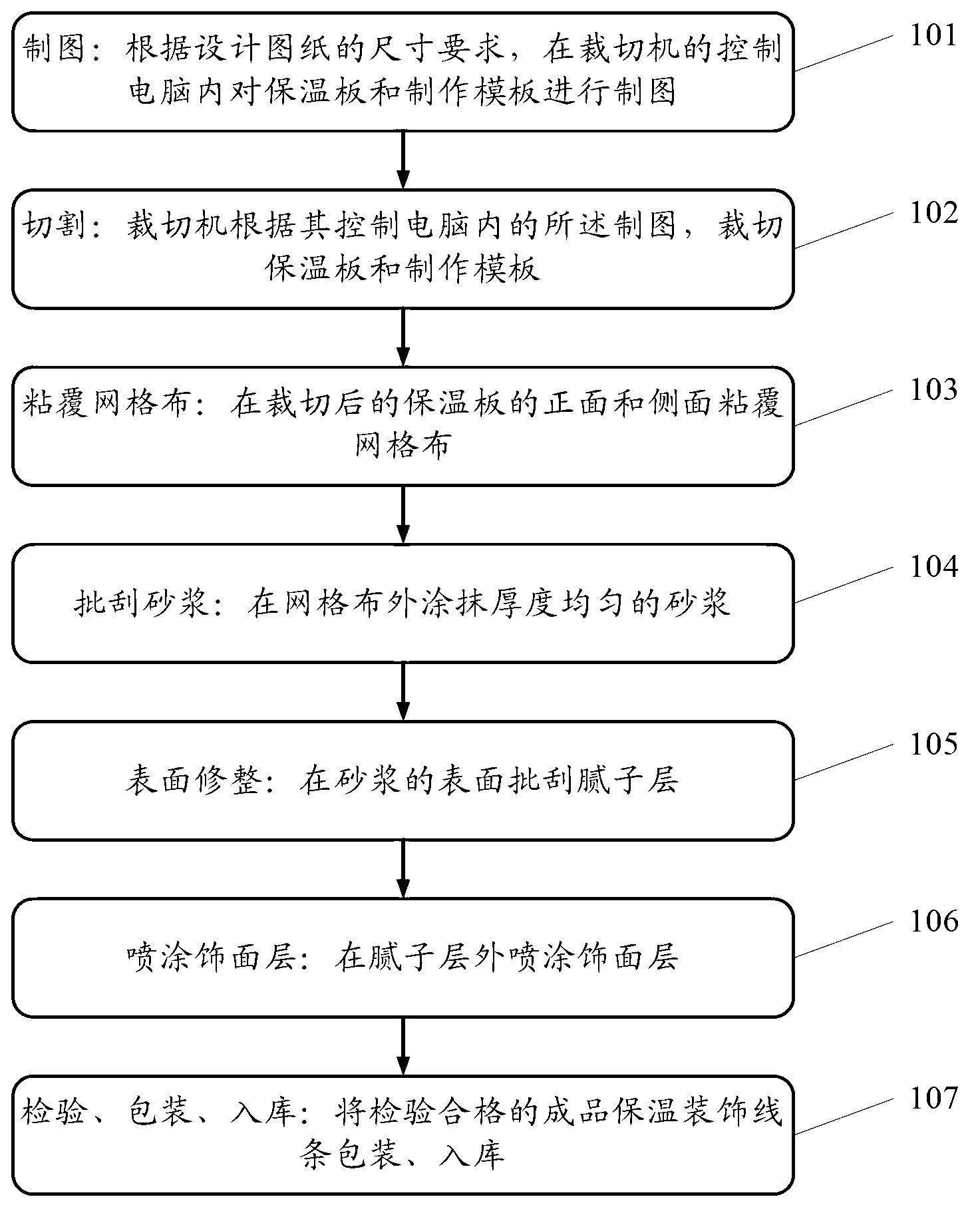

Manufacturing method of heat insulation decorative line

ActiveCN103015686AReduce weightImprove the decorative effectLamination ancillary operationsSynthetic resin layered productsPuttyTextile

The invention provides a manufacturing method of a heat insulation decorative line. The manufacturing method comprises the following steps: step 101: drawing: drawing a heat insulation plate and a manufacturing template in a control computer of a cutting machine according to the dimensional requirements of a design drawing; step 102: cutting: cutting the heat insulation plate and the manufacturing template by the cutting machine according to the drawing in the control computer; step 103: sticking and covering grid cloth: sticking and covering the grid cloth on the front surface and the side surface of the heat insulation plate after cutting; step 104: scraping mortar: smearing the mortar with uniform thickness outside the grid cloth; step 105: finishing the surface: scraping a putty layer on the surface of the mortar; step 106: spraying a finish coat: spraying the finish coat outside the mortar; and step 107: inspecting, packaging and warehousing: packaging and warehousing a finished product, namely the heat insulation decorative line, which is inspected to be qualified. According to the technical scheme provided by the invention, the manufactured heat insulation decorative line has the advantages of light weight, good decoration effect, convenience in processing and mounting and high performance-cost ratio.

Owner:ASIA CUANON TECH SHANGHAI

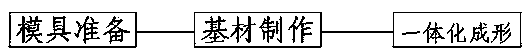

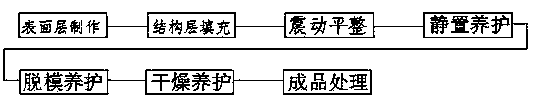

Preparation method of high-strength non-fading imitation wood plank

ActiveCN103660425AGuaranteed decorative effectOvercome longevityWater-setting substance layered productCellulosePolymer modified

The invention provides a preparation method of a high-strength non-fading imitation wood plank. The preparation method comprises a mold preparation stage, a substrate manufacturing stage and an integrally forming stage, wherein the substrate manufacturing stage comprises the steps as follows: manufacturing of a surface coloring layer substrate: cement used for manufacturing the surface coloring layer substrate is taken as a cementing material, an iron oxide pigment, an acrylic emulsion and hard calcium are combined, cement-based polymer modified color paste is prepared, and all component materials are required to be mixed and stirred uniformly into dilute paste; and manufacturing of a structure packing layer substrate: the structure packing layer takes cement as a cementing material, river sand, macadam, a superplasticizer, cellulose, an iron oxide pigment, an acrylic emulsion and hard calcium are combined, all component materials of the structure packing layer substrate are required to be mixed and stirred uniformly, and high-performance filling concrete is prepared. An imitation wood plank finished product prepared with the preparation method of the imitation wood plank is high in strength and imitation degree and good in weather resistance, the finished product cannot layer or strip, and the performance of an obtained material is excellent.

Owner:广东崀玉新材料科技股份有限公司

Repairing method for bulging and falling of finish material

InactiveCN106285037APatching is simple, fast and safeImprove repair effectBuilding repairsAdhesiveVitrified tile

The invention provides a repairing method for bulging and falling of a finish material. The method comprises the steps that (1) the finish material at the bulging portion is taken out, and the surface of an adhesion layer and the adhesion surface of the finish material are cleaned; (2) bulging and falling repairing adhesives are painted to the surface of the adhesion layer and the adhesion surface of the finish material, and the thickness of the adhesives is controlled to range from 0.1 mm to 0.2 mm; (3) the finish material is placed back to the bulging portion, a joint is arranged between the finish material and finish materials around, the finish material is leveled and compacted, and the bulging and falling repairing adhesives squeezed out of the joint are completely removed, specifically, the amount of the bulging and falling repairing adhesives per square meter is 0.3-0.4 kg; and (4) 2-3 days after natural maintenance, the joint is cleaned, the joint is filled with a flexible joint mixture so that the joint can be leveled up, the joint filling depth is not smaller than 3 mm, and natural maintenance is carried out to cure the flexible joint mixture. The repairing method is simple, rapid and safe, the repairing effect is good, design is ingenious, the original decoration effect of stone and vitreous tiles can be maintained, the maintenance cost can be greatly reduced, and the repairing method is suitable for being widely applied and popularized.

Owner:余春冠

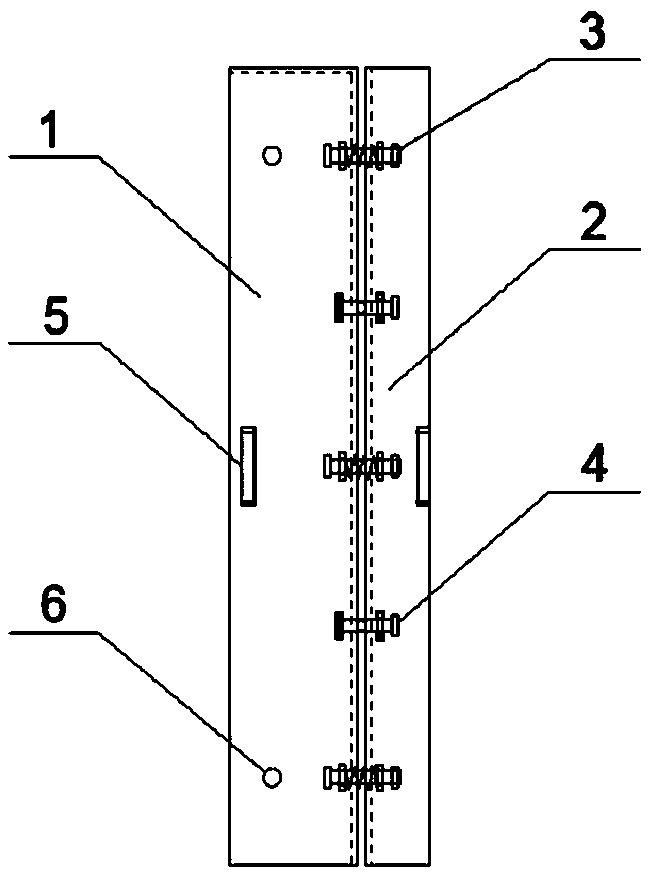

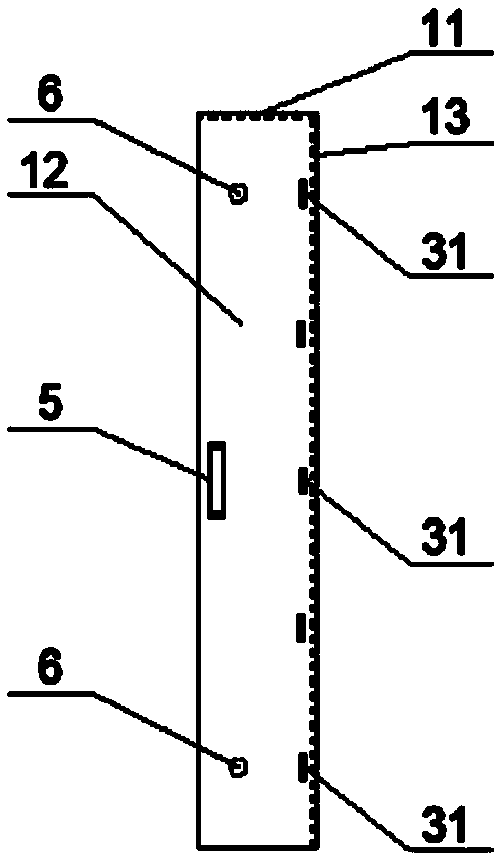

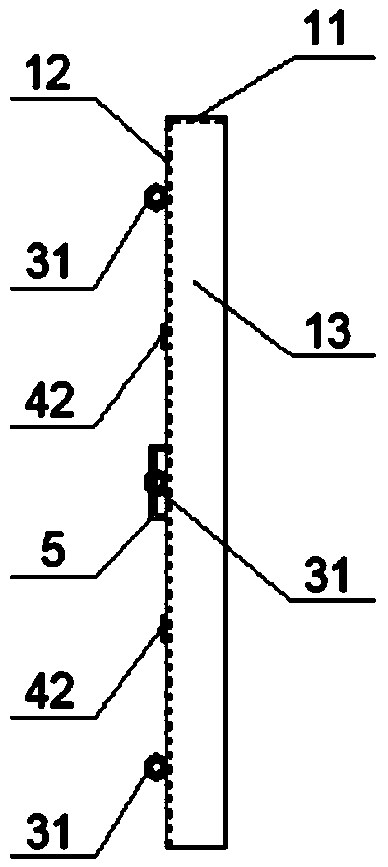

Auxiliary device for installing prefabricated outer wall board and using method thereof

PendingCN110409771AGuaranteed decorative effectGuaranteed performanceBuilding constructionsEngineeringBuilding construction

The invention provides an auxiliary device for installing a prefabricated outer wall board and a using method thereof. The auxiliary device comprises a protecting plate, a limiting plate, a movable connecting part and a limiting buckle. The protecting plate is attached to the outer side of an installed wall board in a covering manner. A protecting plate side plate and a limiting plate side plate are arranged on the same face. A protecting plate partition plate and a limiting plate partition plate are arranged in the middle back to back, and a gap is reserved between the protecting plate partition plate and the limiting plate partition plate. The movable connecting part and the limiting buckle are connected with the protecting plate side plate and the limiting plate side plate. A limiting rod of the limiting buckle is vertically fixed to a limiting clamping plate and extends into the gap between the protecting plate partition plate and the limiting plate partition plate, the width of the gap can be controlled, and the wall board can be protected. The auxiliary device is novel in structure and easy to operate, the movable connecting part and the limiting buckle can move freely, thusthe protecting plate and a cover plate can be flexibly connected in an adjustable manner, corners of the installed wall board can be protected against bumping, the size and the flatness of the vertical joint between wall boards can be controlled precisely, the installing efficiency and the installing quality are improved substantially, the auxiliary is convenient to use and popularize, and the auxiliary device is applicable to installing construction of assembly type prefabricated wall boards with concrete structures.

Owner:TIANYUAN CONSTR GROUP +1

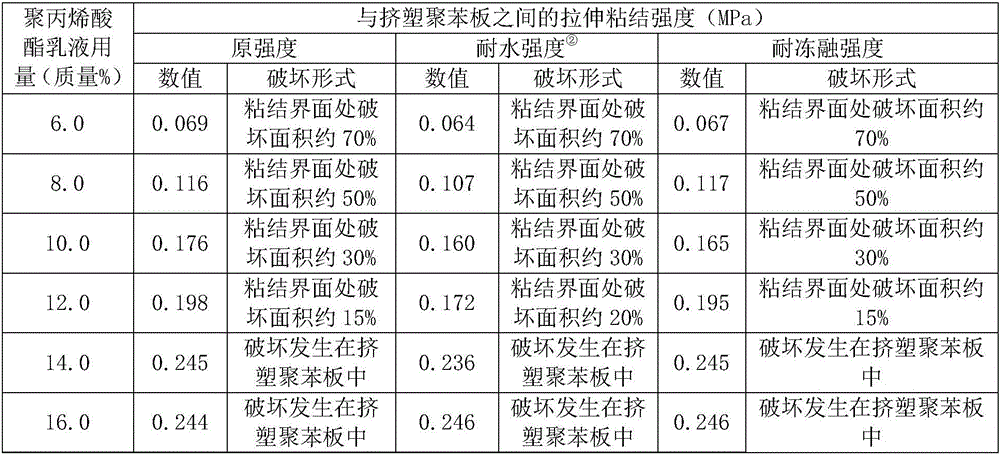

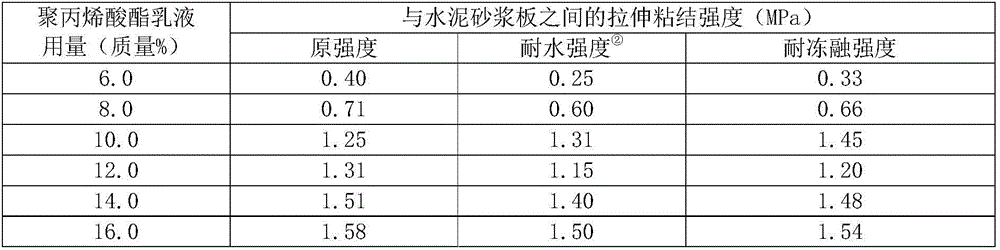

Polymer protective and decorative adhesive cement

The invention relates to polymer protective and decorative adhesive cement. The adhesive cement comprises, by mass, 6.0-12.0 parts of ester alcohol, 3.5-6.0 parts of cellulose ether, 1.5 parts of mildew inhibitor, 1.0-2.0 parts of ammonia water, 2.0-3.0 parts of dispersant, 12.0-16.0 parts of propylene glycol, 1.5 parts of a defoaming agent, 0.2-1.2 parts of wood fiber, 450.0-600.0 parts of quartz sand and 200.0-300.0 parts of silica flour and further comprises 100.0-150.0 parts of water and ylate emulsion which accounts for 14-16% the total mass of the adhesive cement, wherein the ylate emulsion is formed by blending common ylate emulsion and elastic ylate emulsion. By means of the polymer protective and decorative adhesive cement, various performance and construction problems of existing polymer-cement based or polymer latex powder type plastering adhesive cement can be effectively solved.

Owner:HUANGSHAN RUISHENG NEW MATERIAL TECH CO LTD

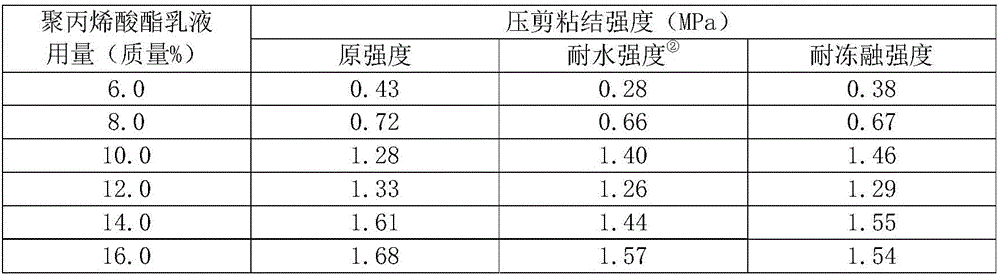

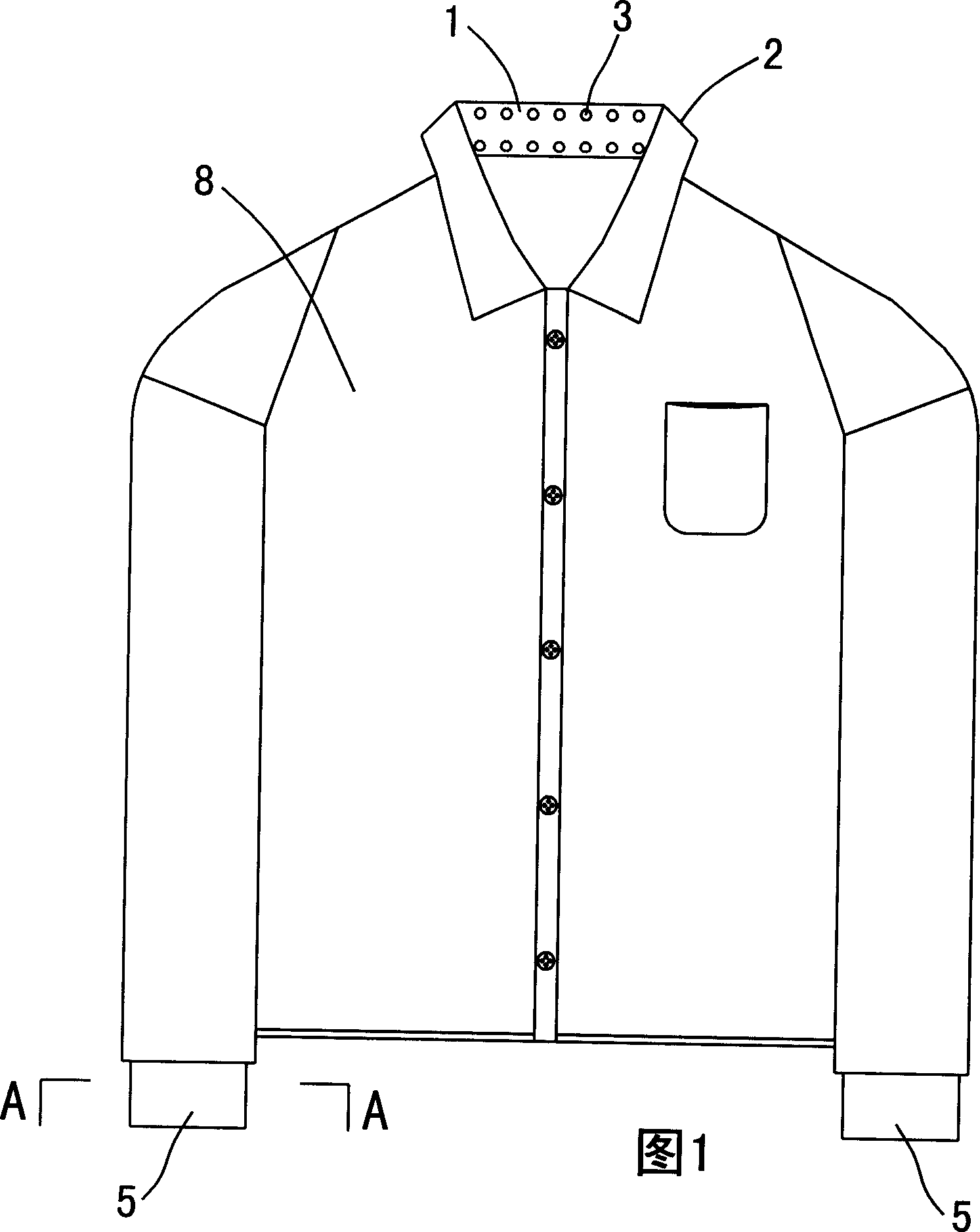

Comfortable clothes

A comfortable garment with health-care function features that the multiple semispherical, cylindrical, spherical, or elliptical beads which is made of pearl, pearl powder, or shell powder are regularly arranged on the inner surface of its collar along the neck circumference and on the inner surface of cuff along the wrist circumference.

Owner:杨宝星

High-strength colorfast faux-wooden plate material

ActiveCN103693903AGuaranteed decorative effectLarge design spaceWater-setting substance layered productCellulosePolymer modified

The invention provides a high-strength colorfast faux-wooden plate material including a surface colored layer and a structure filled layer. The surface colored layer adopts a cement-based polymer modified color paste, and the structure filled layer adopts high-performance filling concrete. The cement-based polymer modified color paste is prepared from the following components: 45 to 65 parts by weight of cement, 8 to 30 parts by weight of calcium stearate, 2 to 20 parts by weight of an iron oxide pigment, 10 to 30 parts by weight of an acrylic emulsion, and 10 to 35 parts by weight of water. The high-performance filling concrete is prepared from the following components: 15 to 35 parts by weight of cement, 15 to 35 parts by weight of river sand, 35 to 65 parts by weight of gravel, 0.3 to 1 part by weight of a high-range water reducing agent, 0.2 to 1 part by weight of cellulose, and 0.1 to 8 parts by weight of an iron oxide pigment. The faux-wooden plate material finished product is not delaminated and peeled off, has good weather resistance, high degree of simulation and more durable color, is more wear-resistant, and is easy to maintain.

Owner:广东崀玉新材料科技股份有限公司

Stainless steel passivation technology

InactiveCN106637167AGuaranteed decorative effectImprove corrosion resistanceMetallic material coating processesSurface roughnessPollution

The invention relates to a stainless steel passivation technology. The stainless steel passivation technology comprises the following steps: 1) degreasing: immersing a stainless steel workpiece in an alkaline degreasing solution for 120 min at the temperature of 50 DEG C; 2) washing by deionized water: immersing the workpiece in deionized water for 5 min; 3) sandblasting: performing sand-blast treatment on the surface of the stainless steel workpiece so that the surface roughness Ra of the processed stainless steel workpiece can reach 3.2; 4) washing by deionized water: immersing the workpiece in deionized water for immersion for 5 min; 5) passivating: adjusting the pH value of a passivating solution to 3-4, immersing the workpiece in the passivating solution at normal temperature for 20 min; 6) washing by deionized water: immersing the workpiece in the deionized water for 5 min, cleaning the passivating solution on the surface of the workpiece; and 7) drying: heating the deionized water to the temperature of more than 80 DEG C, placing the passivated workpiece, immersing the workpiece for 8 min and taking the workpiece out, and drying the workpiece in air. The above technical operation increases the corrosion resistance of the stainless steel workpiece and solves the problem of poor fingerprint pollution resistance on the surface of the stainless steel.

Owner:QINGDAO BOLIER MACHINERY EQUIP

High-flame-retardant organic phosphate fire-proof plate capable of insulating heat and oxygen and suppressing smoke and preparation method thereof

InactiveCN102211344AGuaranteed decorative effectWith smoke suppressionWood working apparatusDomestic articlesToxic gasPhosphate

The invention relates to a high-flame-retardant organic phosphate wheat straw fire-proof plate capable of insulating heat and oxygen and suppressing smoke and a preparation method thereof. The high-flame-retardant organic phosphate wheat straw fire-proof plate is characterized by being prepared by the steps of: adding a high-flame-retardant organic phosphate flame retardant with high flame retardance, low smoke and no toxic gas and a silica sol binder with high binding power, serving as additive accessories, into processed wheat straws, stirring, and molding at high temperature and high pressure. The high-flame-retardant organic phosphate wheat straw fire-proof plate can achieve the purposes of uniformly insulating heat and oxygen, suppressing smoke, retarding inflaming and preventing fire. The flame-retardant and fire-proof components of the high-flame-retardant organic phosphate wheat straw fire-proof plate can not volatilize or lose, and the decoration performance of wood is maintained. The high-flame-retardant organic phosphate wheat straw fire-proof plate is a new-generation green product with the advantages of smoke suppressing capability, no toxicity, no obvious pungent odor, and better environment friendliness and safety in the performances of fire prevention and flame retardance.

Owner:刘方旭

Water-resistant elastic outer wall paint

InactiveCN103992698AImprove mildew resistanceGuaranteed decorative effectCoatingsWater resistantDefoaming Agents

The invention discloses a water-resistant elastic outer wall paint which is prepared from the following components in parts by weight: 100 parts of styrene-acrylic emulsion, 35-40 parts of styrene emulsion, 7-9 parts of acrylic acid emulsion, 6-10 parts of hydroxyethyl cellulose, 5-8 parts of dispersant, 0.8-1.6 parts of defoaming agent, 12-16 parts of ethylene glycol, 0.5-1.5 parts of preservative, 1-2 parts of wetting agent, 40-50 parts of titanium white, 35-45 parts of light calcium carbonate, 20-24 parts of talcum powder, 33-35 parts of kaolin, 0.3-0.7 part of leveling agent and 70-76 parts of water. The outer wall paint has the advantages of excellent weather resistance, excellent water resistance, excellent resistance to chemical attack and excellent molding resistance, and can maintain the original decoration performance of the outer wall for a long time. The outer wall coating formed by the paint has favorable elastic elongation rate and overhigh outdoor durability.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

Reinforced-concrete stainless-steel tubing pillar

InactiveCN1982635AGuaranteed decorative effectGet the most out of hoop performanceStrutsPillarsReinforced concretePre stress

A reinforced concrete stainless steel pipe made by pouring prestrssed reinforced concrete in stainless steel pipe. This structure reduces the consumption of stainless steel on the premise to guarantee the stability of compression bar and integrated bearing capacity of pipe.

Owner:朱运祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com