Furniture and wood door adhered with veneers on surfaces and manufacturing method thereof

A manufacturing method and veneer technology, applied in the field of wooden doors and wooden furniture, can solve the problems of sanding dust and paint pollution, low production efficiency, large labor consumption, etc., and achieve low production efficiency, high production efficiency and long delivery time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

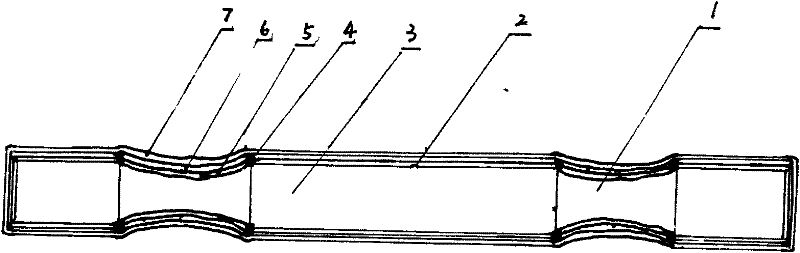

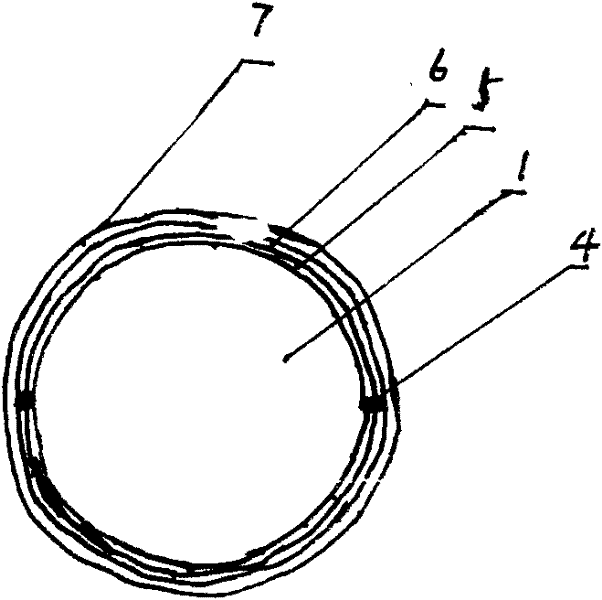

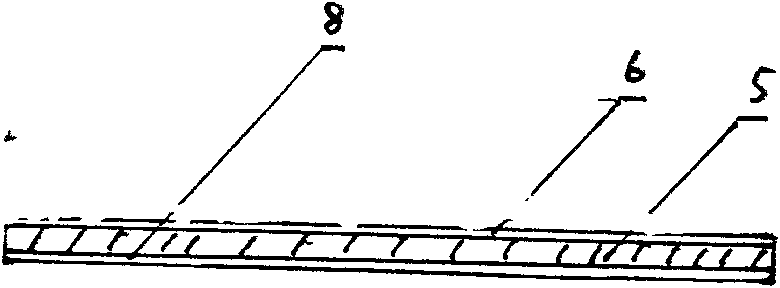

[0025] Embodiment 1: A wooden door with veneer, which is composed of planar parts, components and special-shaped surfaces such as parts, components or components containing concave or convex or curved arc-shaped surfaces, and contains a wooden inner blank, on which veneer is bonded , with primer and topcoat on the veneer. Before the veneer is bonded to the special-shaped parts, components or parts, it is pre-coated with primer and sanded. Since the veneer is flat, it can be painted and polished quickly by machinery, such as UV paint and its production line. PU paint or PE paint or NC paint can also be used. In this way, compared with manual grinding, the production efficiency is increased by 5-50 times, or even higher. Since the problem of painting and sanding of special-shaped surfaces is solved, the plane parts and components of the same wooden door can also be painted and sanded by mechanization, such as UV paint and its production line, and PU paint or PE paint or NC pain...

Embodiment 2

[0028] Embodiment 2: other is identical with embodiment 1, but is the furniture that sticks veneer.

Embodiment 3

[0029] Embodiment 3, others are the same as Embodiment 1 or 2, but the coating adopts American antique coating, when multiple primers on the veneer and when priming the plane parts and components, and when repairing the veneer joints, and when topcoating Corresponding antique measures are adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com