Technology for producing natural stone composite board

A production process and composite board technology, applied in the field of building decoration materials, can solve the problems of low production capacity and poor quality of natural stone composite boards, and achieve the effects of shortening the curing time, high yield and reducing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

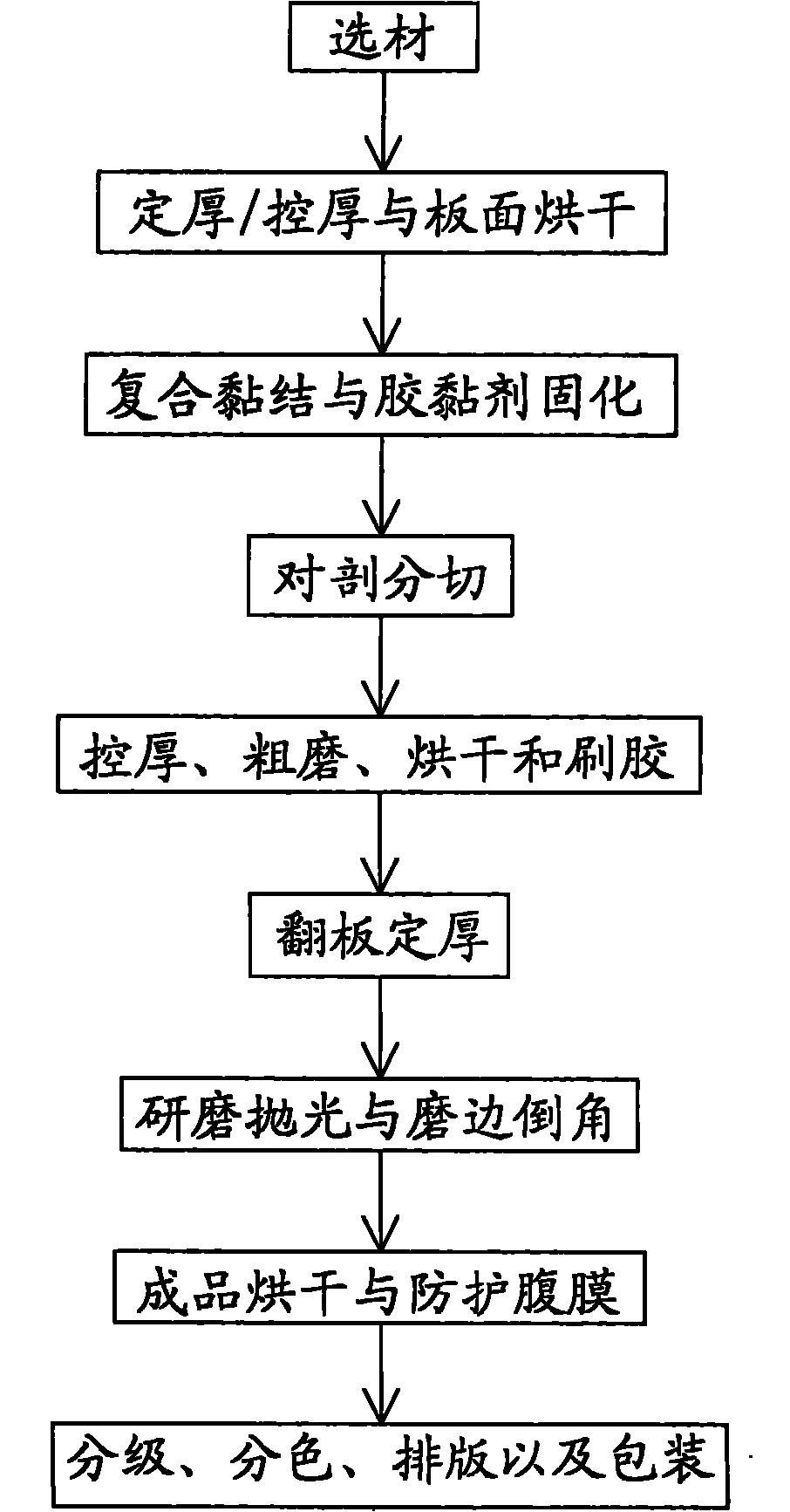

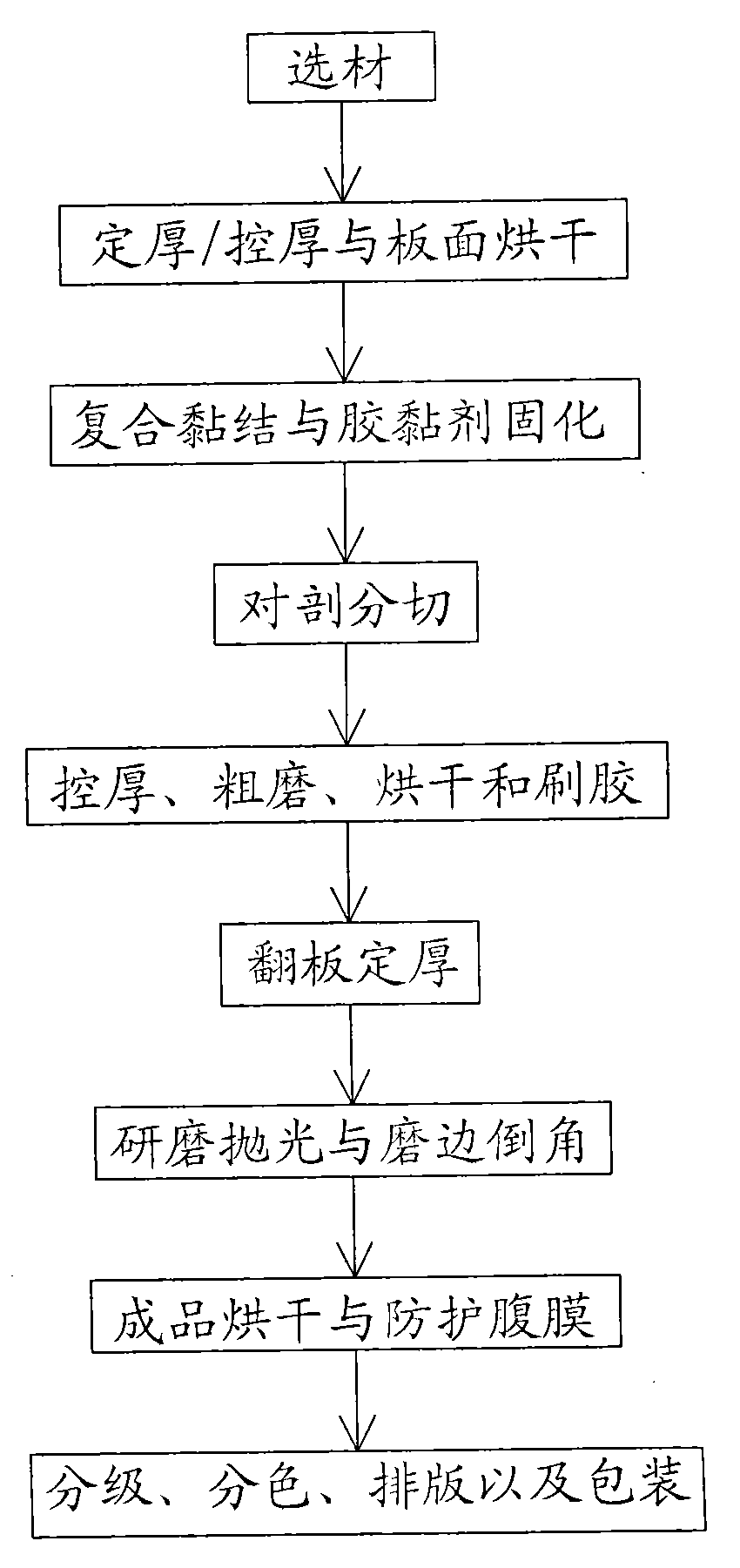

[0036] like figure 1 As shown, a schematic flow chart of a production process of a natural stone composite board related to the present invention, which is used to compound natural stone and carrier materials through an adhesive, specifically includes the following steps:

[0037] (1) Material selection 1: Select the required natural stone and process it into a plate with a specified thickness and specification; at the same time, select a carrier material and process it into a plate with a specified thickness and specification; among them, fragile products must be glued on one side With wire mesh reinforcement protection, the surface of the carrier material is also roughened by scraping and grinding to increase the bonding strength; the carrier material can be selected from tiles, glass, aluminum honeycomb pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com