Patents

Literature

87results about How to "With smoke suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

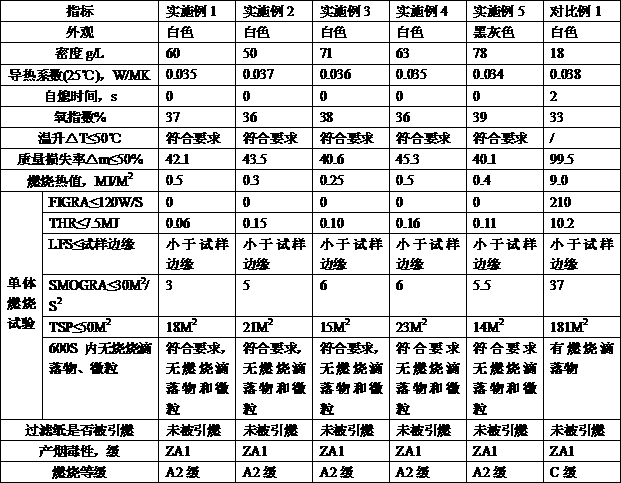

High-flame-retardance composite heat-insulating foam material and preparation method thereof

The invention relates to the technical field of polystyrene foam materials, in particular to a high-flame-retardance composite heat-insulating foam material and a preparation method thereof. The high-flame-retardance composite heat-insulating foam material comprises polystyrene foaming particles with the density of 18 to 20 g / L and a flame-retardant composite layer wrapped on the surface of the polystyrene foaming particles, wherein the flame-retardant composite layer consists of a flame-retardant binder of 5 to 50 g / L and an inorganic flame retardant of 5 to 75 g / L. Compared with the prior art, the invention optimizes the formula of the flame retardant and adopts environment-friendly, non-toxic and low-price organic and inorganic flame retardants. The prepared composite heat-insulating material has low production cost. After the product is combusted, the product has the advantages of alveolate skeleton structure, no melted drop, low smoke output quantity, no combustion dripping substance and no particle, so the flame-retardant performance and the flame-retardant grade of the product are obviously improved and the product has wide development prospect in the heat insulation field of buildings such as roofs and walls.

Owner:宁波龙利钜能新材料有限公司 +1

Halogen-free flame-retardant dicyclopentadiene material and preparation method thereof

ActiveCN101792505AImprove appearance qualityImprove mechanical propertiesPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPhosphateAluminium hydroxide

The invention discloses a halogen-free flame-retardant dicyclopentadiene material and a preparation method thereof. The material consists of polydicyclopentadiene, flame retardant, modifier and catalyst, wherein the flame retardant is silane coupling agent, titanate coupling agent, aluminium zirconate coupling agent, organic chromium coupling agent, higher fatty acid and salt thereof, phosphate, unsaturated organic acid or organic ammonium salt modified aluminium hydroxide. The preparation method prepares the flame-retardant material by using reaction injection moulding. The oxygen index of the obtained material is 22 to 26 percent, and the horizontal combustion test can reach HB level; and the bending strength is 40 to 45MPa, the bending modulus is 1,400 to 1,700MPa, the tensile strength is 34 to 37MPa, the impact strength is 26-80kJ / m<2>, and the hardness is 74 to 76 Shaw D. The material does not contain halogen flame retardant, and has high flame-retardant performance and high mechanical property.

Owner:LIMING RES INST OF CHEM IND

Nanometer grade paligorskite-flame retardant epoxide resin composite material

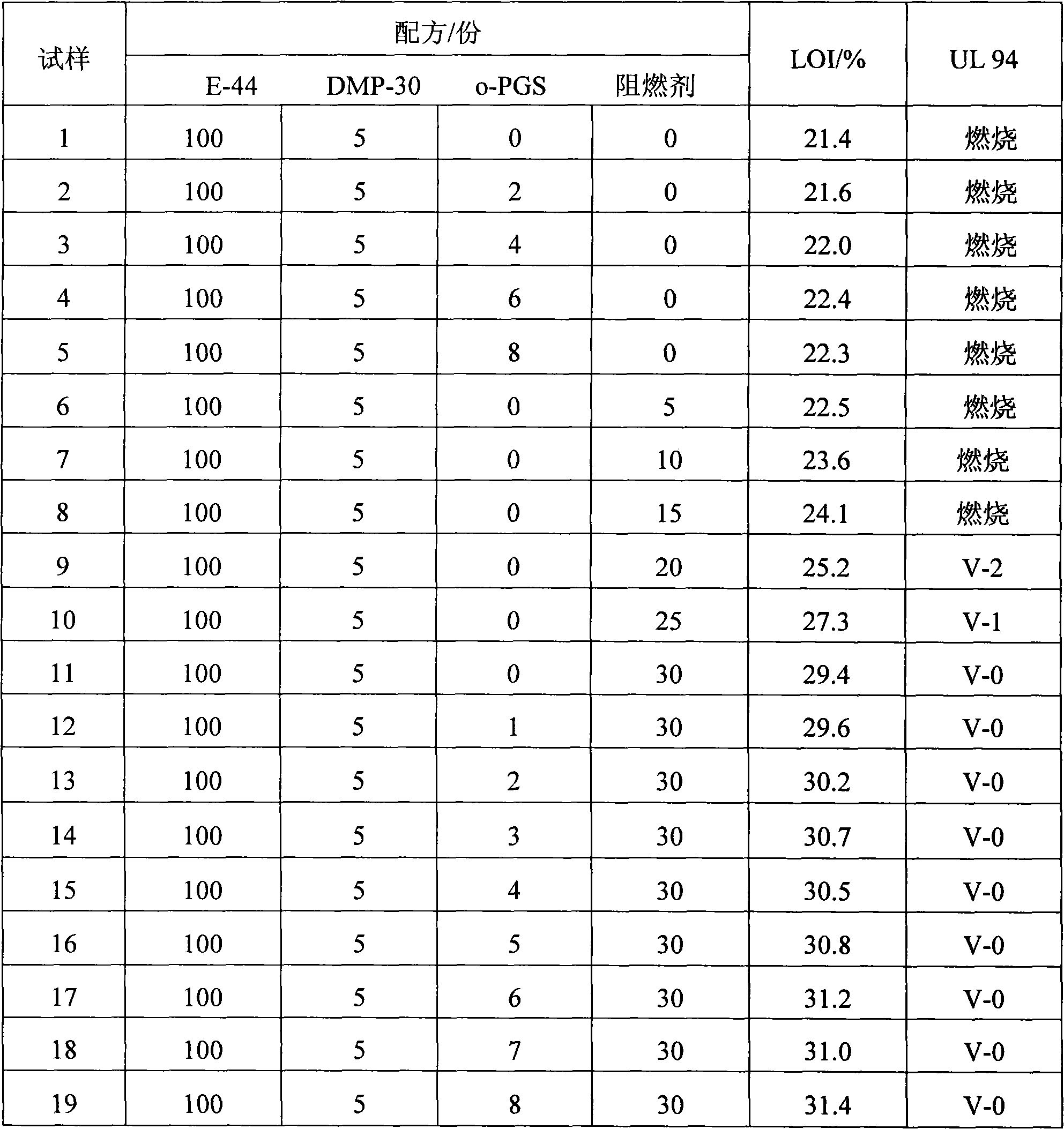

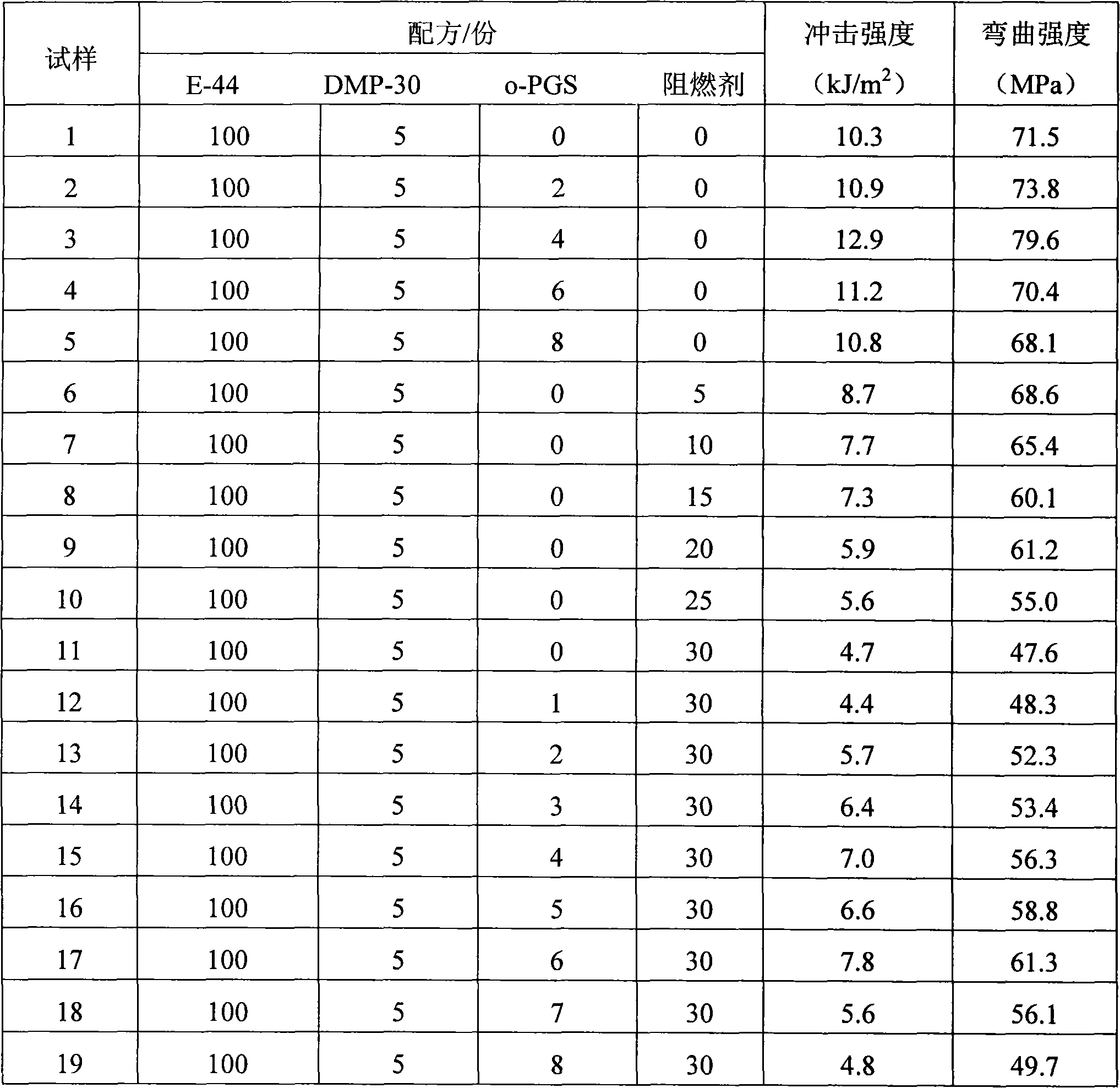

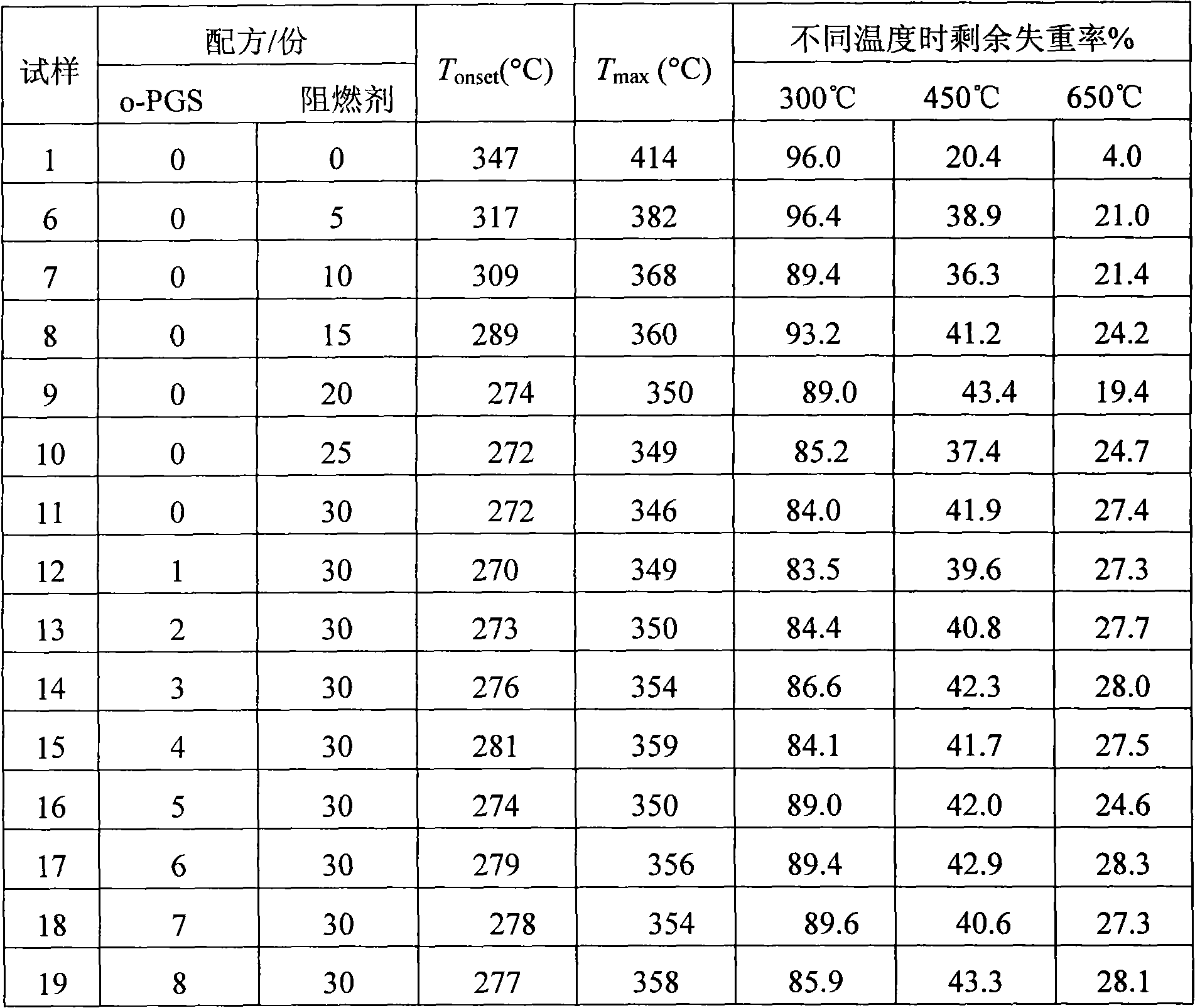

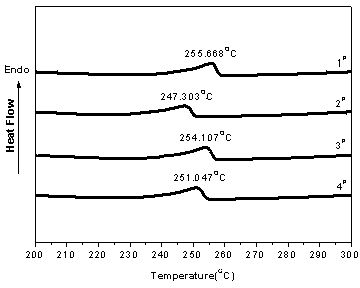

The invention provides a nano-palygorskite reinforced flame retarding epoxy resin composite material which disperses the nano-palygorskite into epoxy resin matrix by means of ultrasonic dispersion by mass ratio between 1:100 and 8:100 after surface treatment is carried out to the nano-palygorskite, then mix the obtained palygorskite epoxy resin mixture with a reactive-type flame retardant by the mass ratio between 100:5 and 100:30, and casting and curing are carried out. A plurality of P-N bond intermediates formed in the reactive-type flame retardant of the invention are phosphorylating agents better than routine phosphorus compounds, and water vapor generated from nano-palygorskite acting as a synergistic flame retardant during burning is in great favor for a phosphorous flame retardant, and the reinforcement of appropriate amount of nano-palygorskite compensates for the reduction of the mechanical property of the epoxy resin caused by adding the flame retardant to some extent, serving double effect of flame retardation and reinforcement, thus, the flame retarding epoxy resin composite material of the invention has the advantages of high oxygen index, good smoke suppression effect and excellent physical and mechanical properties.

Owner:NORTHWEST NORMAL UNIVERSITY

Expansive type dripping-resistant flame retardant and preparation method thereof

ActiveCN104262620AImprove flame retardant performanceLittle impact on mechanical propertiesFiberPolyester

The invention relates to a method for preparing an expansive type dripping-resistant flame retardant. The method is characterized by comprising the following steps: mixing phosphorus-containing copolymerization type flame retardant and dihydric alcohol, reacting under the conditions of the temperature of 70-170 DEG C and the pressure of 0.01MPa below zero to 0.096MPa below zero for 4-10 hours, thereby preparing a flame-retardant esterification fluid; and enabling the flame-retardant esterification fluid to react with diamine and ethanol under the conditions of the temperature of 60-140 DEG C and the pressure of 0.01MPa below zero to 0.096MPa below zero for 4-10 hours, adding a dripping-resistant agent and an inorganic flame retardant, thereby preparing the expansive type dripping-resistant flame retardant. The expansive type dripping-resistant flame retardant prepared by the invention has the advantages of high flame retardant efficiency, high temperature resistance, dripping resistance, smoke suppression and small influence on mechanical properties of materials, the flame retardant grade reaches the V-0 level in the UL-94 standard, and the limit oxygen index is over 32 percent. The expansive type dripping-resistant flame retardant can be used for flame-retardant nylon, polyesters and other engineering plastics, also can be applied to the field of fiber textiles and has wide market prospects.

Owner:CHENGDU TALY TECH CO LTD

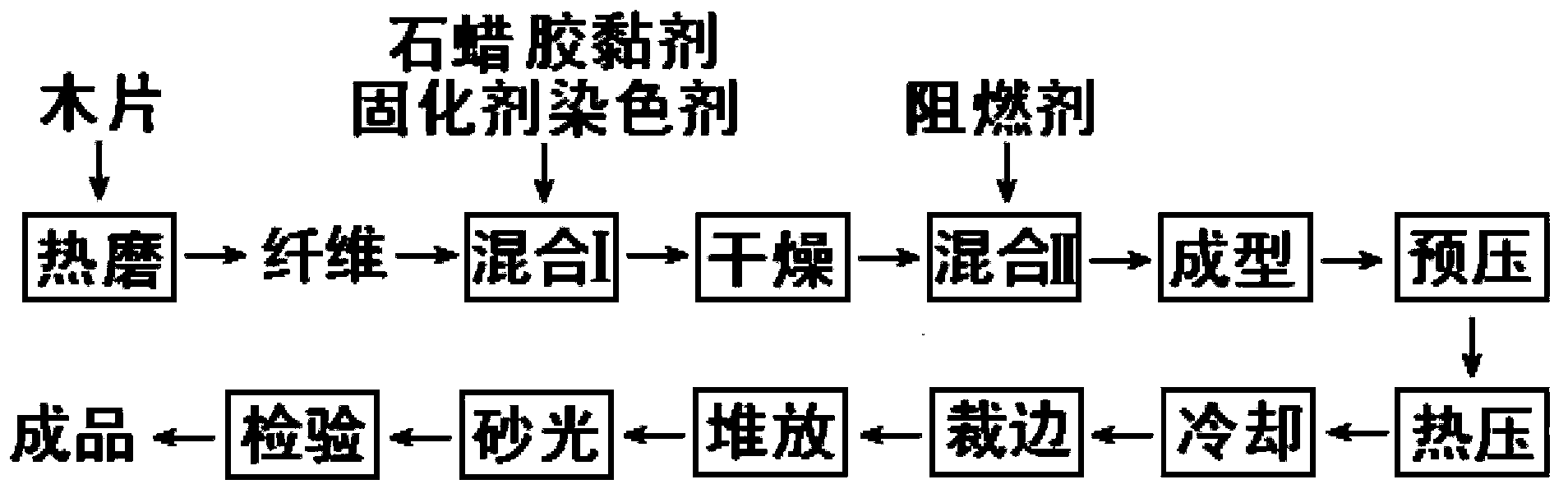

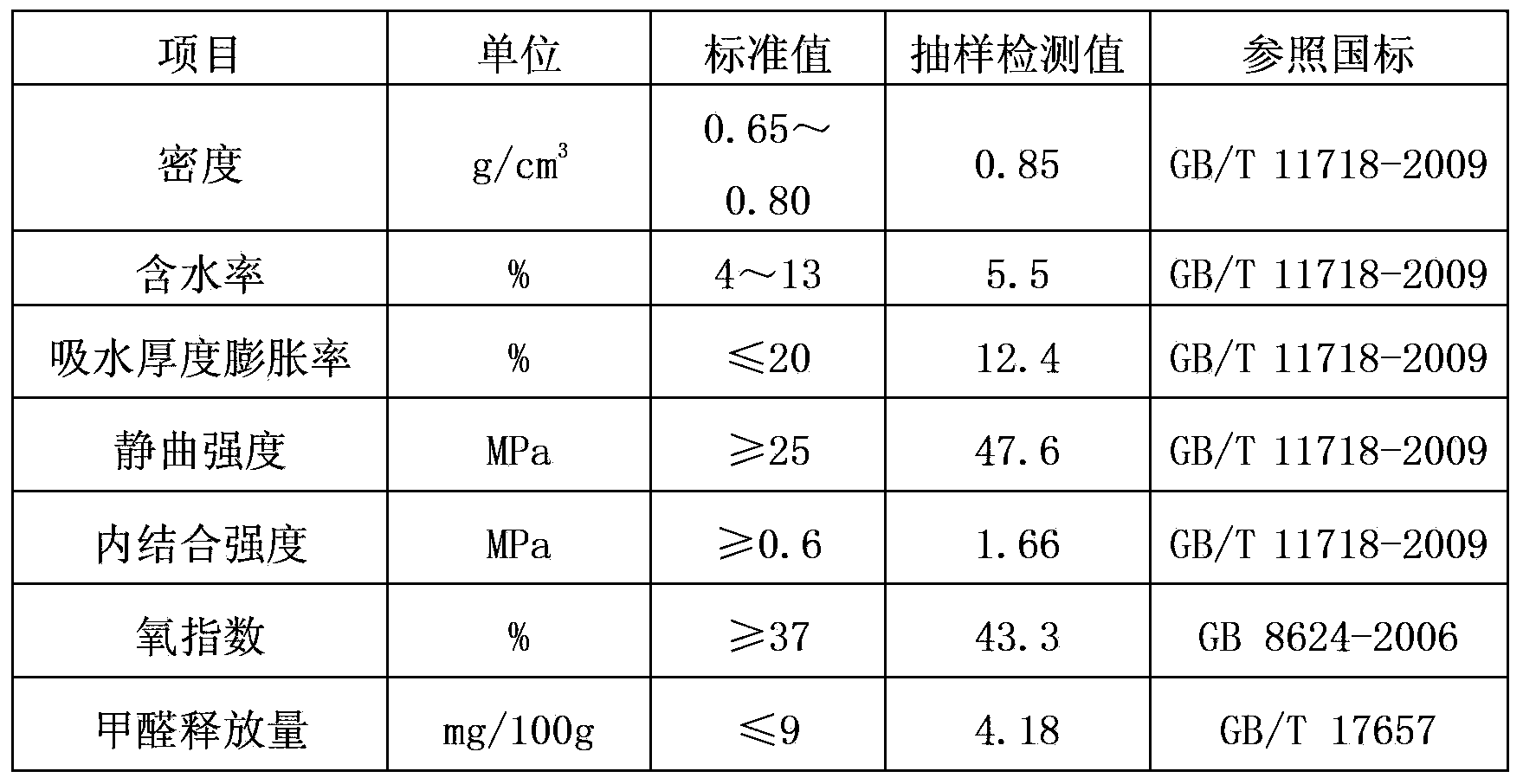

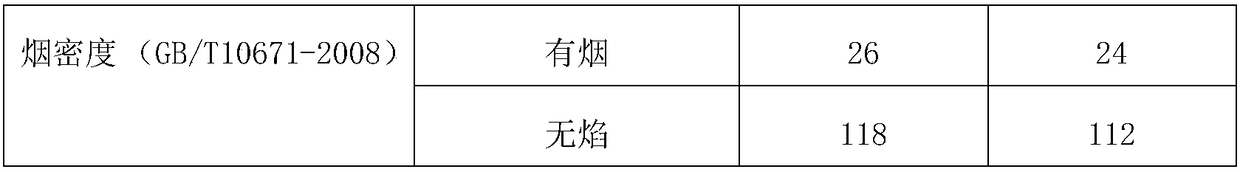

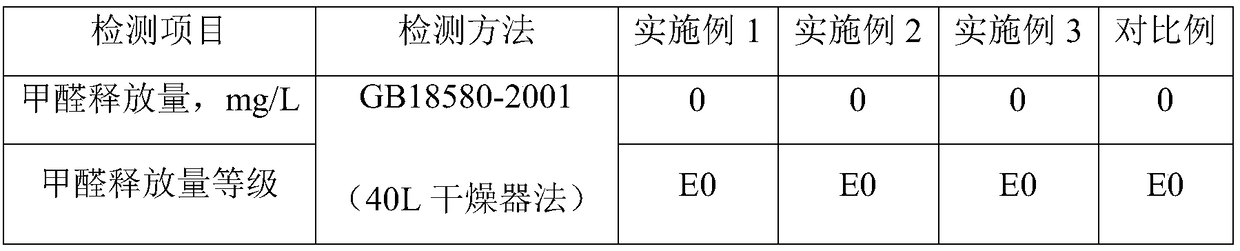

High-grade environment-friendly flame-retardant fiberboard and manufacturing method thereof

ActiveCN103406968AEasy to implementSimple production processFlat articlesDomestic articlesParaffin oilsFire retardant

The invention discloses a high-grade environment-friendly flame-retardant fiberboard and a manufacturing method thereof. Wood chips are used as raw materials and hot-ground to obtain fibers, auxiliary raw materials are added to the fibers, and the high-grade environment-friendly flame-retardant fiberboard is manufactured. Each cubic meter of the high-grade environment-friendly flame-retardant fiberboard is composed of, by weight, 580-630kg of fibers, 7-9kg of paraffin, 200-230kg of adhesive (the solid content ranges from 40% to 50%), 0.2-0.3kg of curing agent, 1.0-2.0kg of coloring agent, 38-50kg of fire retardant and appropriate water. The manufacturing method of the high-grade environment-friendly flame-retardant fiberboard comprises the working procedures of hot-grinding, mixing, drying, shaping, hot-pressing, edge cutting and sanding. Production processes are simple, technical parameters are accurate, process reliability is strong, production efficiency is high, and the high-grade environment-friendly flame-retardant fiberboard produced in the manufacturing method is good in flame retardant property, low in formaldehyde emission and excellent in physical and mechanical performance.

Owner:GUANGXI UNIV

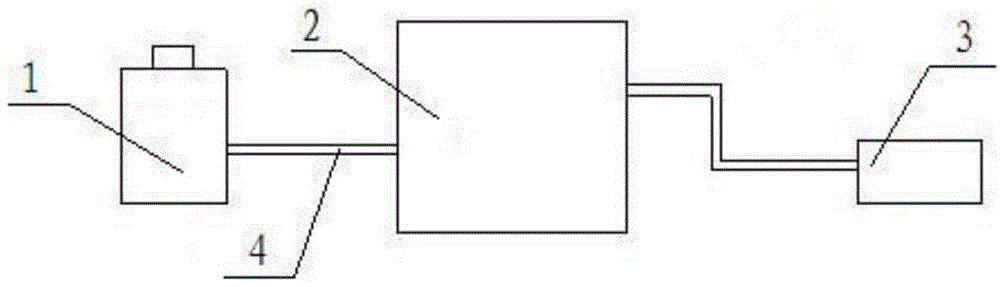

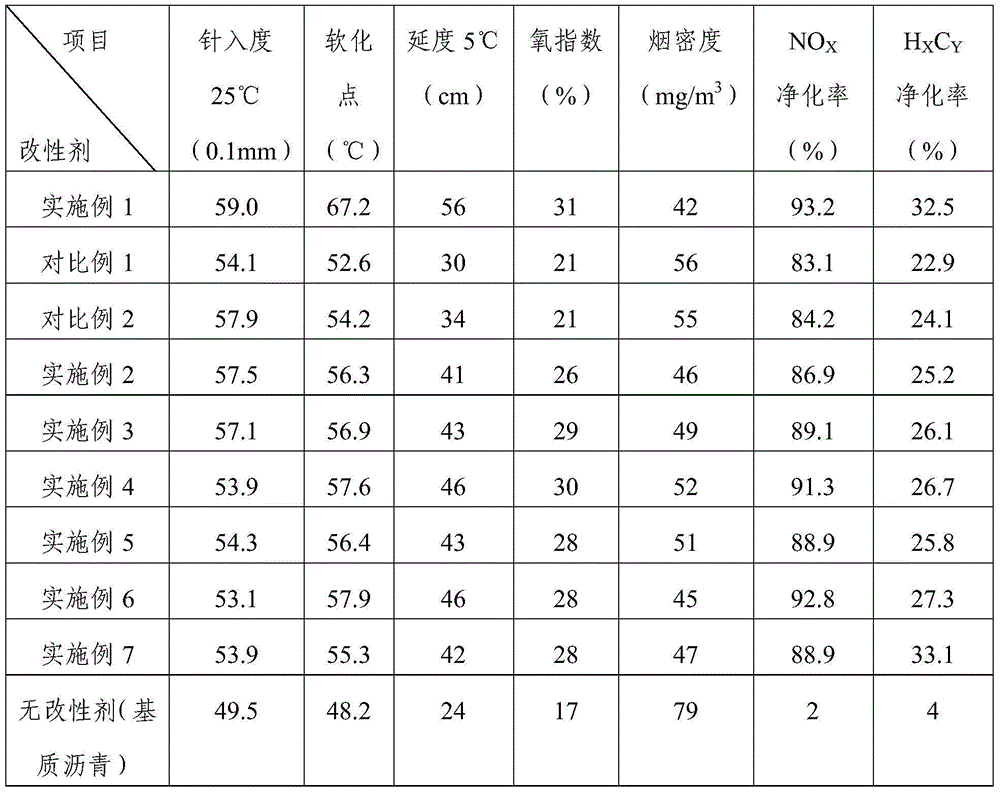

A kind of road asphalt modifier and preparation method thereof

The invention discloses a road asphalt modifier. The road asphalt modifier is prepared from the following main raw materials in parts by weight: 4-20 parts of mullite powder, 6-14 parts of cordierite powder, 1-3 parts of fatty alcohol polyoxyethylene ether and 1-4 parts of polyacrylic acid. In addition, the invention aslo discloses a preparation method of the road asphalt modifier. The preparation method comprises the following steps: step one. mixing the mullite powder and the cordierite powder, uniformly stirring so as to obtain a mixture, adding the mixture to the fatty alcohol polyoxyethylene ether diluted by absolute ethyl alcohol, and uniformly stirring so as to obtained the mixture subjected to surface treatment; and step two. adding the polyacrylic acid to the mixture subjected to surface treatment, and uniformly stirring so as to obtain the road asphalt modifier. All the components in the road asphalt modifier are non-toxic, environmentally-friendly and low in cost; the preparation technology of the modifier is simple, and the modifier has good thermal stability and is suitable for wide application.

Owner:CHANGAN UNIV

P-N expanded reaction type flame retardant and preparation method thereof

InactiveCN104072759AWith smoke suppressionEfficientGroup 5/15 element organic compoundsFiltrationEnd-group

The invention discloses a P-N expanded reaction type flame retardant p-(carboxyphenyl-amino)-(carboxyphenyl-amidoethyl) phenylphosphine oxide and a preparation method thereof. The preparation method comprises the following steps: (a) adding a p-aminobenzoic acid solution into glacial acetic acid; (b) adding triethylamine and mixed solution obtained in the step (a) into a 2-carboxethylphenyl hypophosphorous acid solution, stirring at a high speed and reacting for 2 hours, raising the temperature to 80 DEG C, reacting for 4 hours, cooling, hydrolyzing, performing suction filtration, washing and drying to obtain white powder, namely the P-N expanded reaction type flame retardant. The defects that harmful gases are generated by general flame retardants, the environment is polluted, fuming is caused and the mechanical property is influenced are overcome, the P-N expanded reaction type flame retardant has double-carboxyl end groups, effective flame retardant components are bonded to a PA66 main chain, an inherently flame retardant effect is achieved, and the flame retardant has the advantages of harmlessness, smoke inhibition, high efficiency, environmental friendliness and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

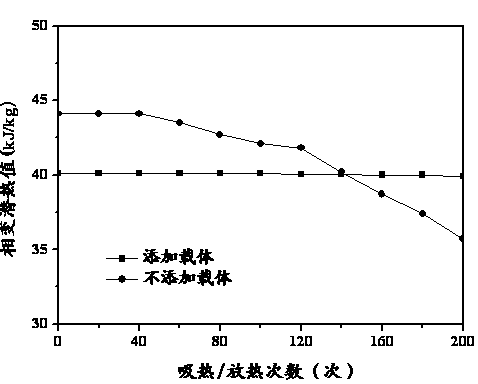

Phase-change energy storage floor tile and manufacturing method thereof

The invention discloses a phase-change energy storage floor tile and a manufacturing method thereof. According to a formula, the floor tile comprises: 50-100 parts of a phase change material, 100 parts of an inorganic flame retardant and 40-100 parts of a high polymer elastomer, wherein the phase change material consists of: 30-70 parts of cement, 30-50 parts of fly ash, 5-20 parts of gamma-alumina, and 50-100 parts of a phase change substance. The floor tile is manufactured by: first adsorbing the phase change substance into a porous substance composed of cement, fly ash and gamma-alumina in a proper portion, and then subjecting the adsorbed porous substance, the flame retardant and the high polymer elastomer to mixing. The obtained floor tile has the characteristics of high strength, good thermal shock resistance and wear resistance, difficult breackage, stable chemical properties, and strong thermal storage / refrigeration capability, and can prevent the phase change substance from seeping from the energy storage floor tile. And the phase change material has the advantages of long service life, good flame retardance and environmental performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-retardant toughening HPVC (polyvinyl with high degree of polymerization)/ABS (acrylonitrile butadiene styrene) composite material and preparation method thereof

The invention belongs to the field of engineering plastics and particularly relates to a flame-retardant toughening HPVC (polyvinyl with high degree of polymerization) / ABS (acrylonitrile butadiene styrene) composite material and a preparation method thereof. The preparation method of the flame-retardant toughening HPVC / ABS composite material comprises the following steps: putting 100 parts by mass of HPVC powder, 0.5-3.0 parts by mass of a thermal stabilizer, 0.5-5.0 parts by mass of a plasticizer, 0.2-1.0 part by mass of a lubricant, 0.2-1.0 part by mass of an antioxidant and 5-20 parts by mass of a halogen-free flame retardant into a high-speed mixer and mixing; then, pouring 40-100 parts by mass of ABS resin, 10-40 parts by mass of POE-g-MAH and 5-20 parts by mass of CPE (chlorinated polyethylene) into the mixer and performing secondary mixing to obtain HPVC / ABS mixed materials, pouring the obtained HPVC / ABS mixed materials into a hopper of a twin-screw extruder, and pelletizing after extruding to prepare flame-retardant toughening HPVC / ABS raw material particles. The finally prepared HPVC / ABS composite material has the advantages of flame resistance, smoke suppression, low cost, impact resistance, easiness in processing, and the like, and can be used for preparing various high-strength flame-retardant electrical appliance shells.

Owner:LIAONING TECHNICAL UNIVERSITY

Modified polypropylene cable protection pipe and forming process thereof

InactiveCN106633439AStrong impact resistanceImprove insulation performanceTubular articlesMasterbatchGlass fiber

The invention discloses a modified polypropylene cable protection pipe and a forming process thereof. The pipe is prepared from the following components in parts by weight: 100 parts of modified polypropylene, 1 to 5 parts of a tackifier, 0.5 to 5 parts of glass fiber, 1 to 5 parts of an anti-impact modifier, 1 to 5 parts of a nucleating agent, 0 to 10 parts of a filling matrix, 0.1 to 3 parts of an antioxidant, 0.1 to 3 parts of a light stabilizer and 2 to 8 parts of rubber. On the basis of modified polypropylene, the comprehensive performance of the modified polypropylene cable protection pipe can be improved by adding the components such as the tackifier, the glass fiber, the anti-impact modifier, the nucleating agent, the filling matrix, the antioxidant, the stabilizer, the rubber and the; particularly by the adding of the glass fiber, the performance such as the mechanical property and the corrosion resistance of the pipe are greatly improved.

Owner:青阳县绿通复合材料有限公司

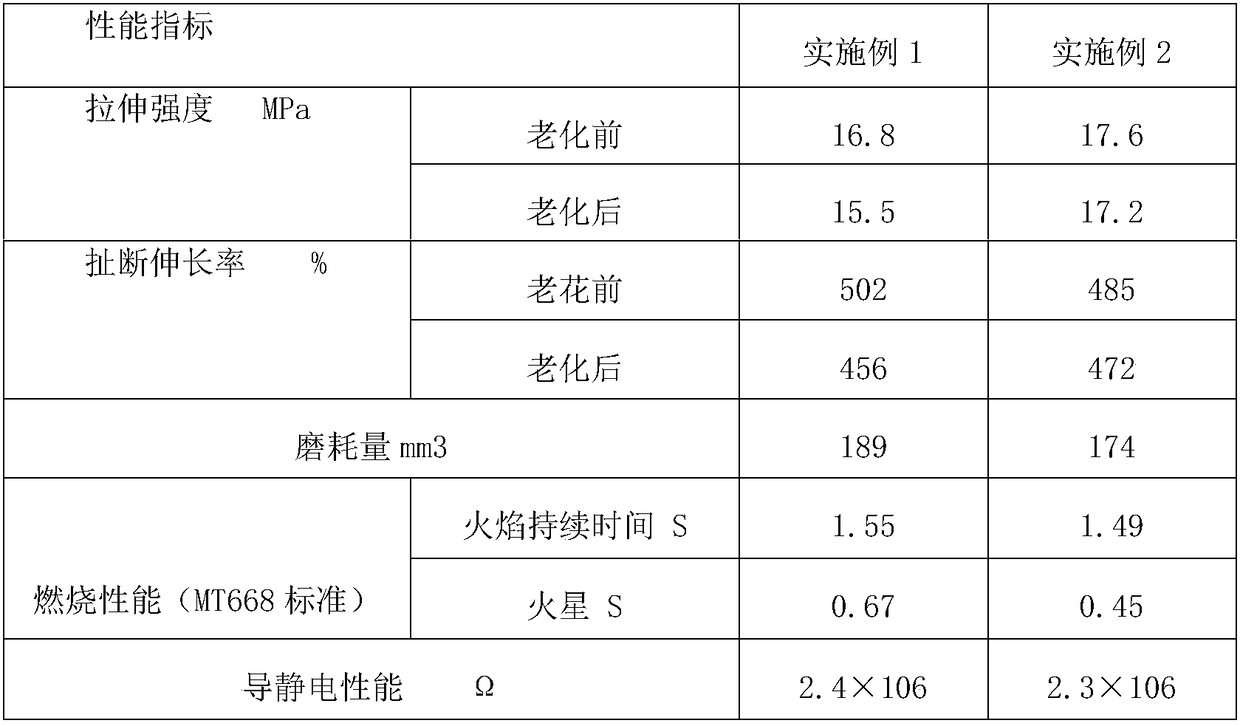

Low-smoke low-halogen flame-retardant conveyor belt covering glue for coal mine and preparation process thereof

InactiveCN108659285AHigh bromine contentImprove thermal stabilityConveyorsComposite ceramicEngineering

The invention discloses low-smoke low-halogen flame-retardant conveyor belt covering glue for a coal mine, and relates to the technical field of conveyor belt covering glue. The covering glue comprises the following chemical components: natural standard rubber, styrene-butadiene rubber SBR1502, cis-butyl BR9000 rubber, polyisobutylene PB1300, an anti-aging agent, zinc oxide, magnesium oxide, stearic acid, a flow release agent, N234 carbon black, nano-aluminum hydroxide, antimony trioxide, decabromodiphenylethane, composite ceramic powder, expanded halogen-free flame-retardant IFR, a multi-purpose synergistic halogen-free flame retardant PNA220, molybdenum salt used as a smoke suppressant, an accelerator and sulfur. The low-smoke low-halogen flame-retardant conveyor belt covering glue disclosed by the invention is used under a coal mine well to meet flame-retardant performance of the conveyor belt, has excellent wear resistance and flame retardancy, and is low in smoke amount and smoketoxicity.

Owner:江苏凯嘉橡胶科技股份有限公司

Environment-friendly flame-retardant non-adhesive fiberboard of crop straw and preparation method thereof

ActiveCN108656305AHigh bonding strengthImprove mechanical propertiesWood working apparatusDomestic articlesFiberFiberboard

The invention relates to an environment-friendly flame-retardant non-adhesive fiberboard of crop straw and a preparation method thereof. The fiberboard is prepared by the following steps that 1 ) wheat straw and sorghum straw are taken to be cut off correspondingly, and the wheat straw and the sorghum straw are soaked in water to obtain a softened material; 2 ) steam explosion is correspondingly carried out on the softened material to obtain wheat straw fiber and sorghum straw fiber; 3 ) nano calcium carbonate, nano zinc oxide are mixed with nano copper oxide, and modifying is carried out toobtain a modified additive A; nano zinc borate, the nano zinc oxide are mixed with the nano copper oxide, and modifying is carried out to obtain a modified additive B; 4 ) the wheat straw fiber and the sorghum straw fiber are mixed with the modified additive A to obtain a core layer mixture; the wheat straw fiber is mixed with the modified additive B to obtain a surface layer mixture; and 5 ) thecore layer mixture is taken as a core layer, the surface layer mixture is taken as a surface layer to be laid and pre-pressed to obtain a slab, after hot-pressing forming and post-treatment are carried out, the environment-friendly flame-retardant non-adhesive fiberboard is obtained. The fiberboard has no formaldehyde release and has good mechanical property, good anti-water, moisture-proof, anti-corrosion and antibacterial properties; and good in fireproof and flame-retardant effects, and suitable for popularization and application.

Owner:霸州市光洋人造板制造有限公司

Plantation wood modification processing method

InactiveCN104858953AImprove permeabilityGood application effectRadiation/waves wood treatmentWood treatment detailsMicrowaveHardness

The invention discloses a plantation wood modification processing method including steps of preliminary selection, drying and microwave processing; preparation of a modification agent; preparation of a modification solution; vacuum impregnation and post drying. The beneficial effect is that through use of microwave treatment, the permeability of plantation wood is improved, the modification processing effect is improved, the processed wood has flame retardant, smoke suppression, anticorrosive, moth-proofing, color distortion preventing, good erosion resistance and other advantages, and the surface hardness, wear resistance, impact strength, waterproof property and the like are significantly improved, so that the application effect and fields of the plantation wood are well improved, and the plantation wood modification processing method has the very high practical value and promotion prospects.

Owner:王玉燕

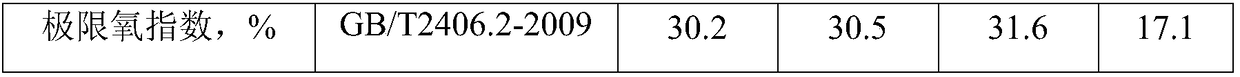

Styrene-butadiene rubber composite material for high-performance tire and preparation method thereof

InactiveCN103865133AImprove mixing uniformityImprove flame retardant performanceSpecial tyresPolymer scienceMooney viscosity

The invention discloses a styrene-butadiene rubber composite material for a high-performance tire. The styrene-butadiene rubber composite material comprises the following raw materials in parts by weight: 80-100 parts of powdered styrene-butadiene rubber, 8-13 parts of nano-loess powder, 15-20 parts of hydroxyl-terminated liquid styrene-butadiene rubber, 5-7 parts of montmorillonite, 13-20 parts of aluminum hydroxide, 18-23 parts of calcium sulfate whisker, 8-12 parts of furnace carbon black, 0.6-0.98 part of sulfur, 0.7-0.92 part of promotor, 0.23-0.5 part of 1,3-diphenylguanidine, 1-3 parts of zinc oxide, 1.5-2.4 parts of stearic acid and 2-3 parts of titanate coupling agent, wherein the content of styrene in the powdered styrene-butadiene rubber is 25-30%, and the Mooney viscosity of the powdered styrene-butadiene rubber (ML1+4, 100 DEG C) is 52-57; the content of styrene in the hydroxyl-terminated liquid styrene-butadiene rubber is 23.4-26.5%, and the viscosity of the hydroxyl-terminated liquid styrene-butadiene rubber is 14.4-16.2Pa.s. The invention also discloses a preparation method of the styrene-butadiene rubber composite material for the high-performance tire.

Owner:ANHUI SHENGDONG CHEM

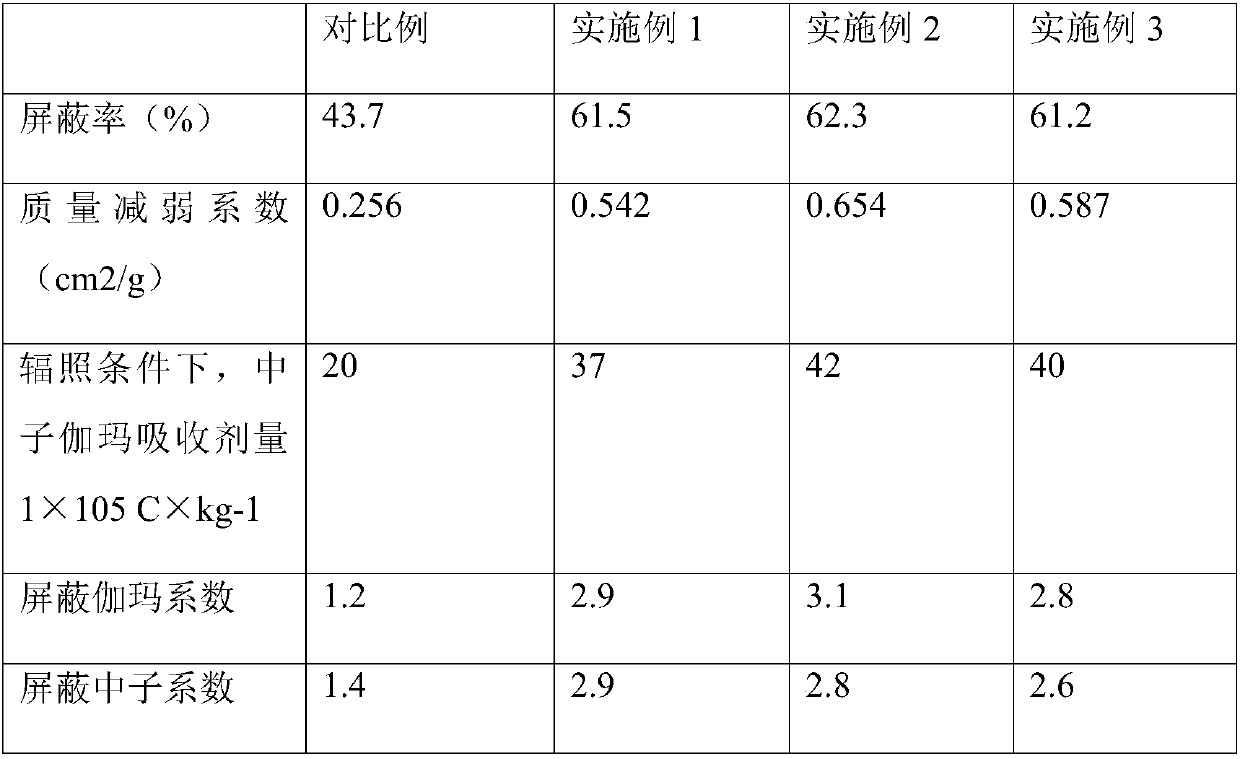

Composite particle material and radiant panel for shielding neutron gamma radiation by high strength

PendingCN107722425AImprove adhesionTotal reflectionSynthetic resin layered productsShieldingFiberColemanite

The invention discloses a composite particle material and a radiant panel for shielding neutron gamma radiation by high strength, and relates to the technical field of radiation-shielding plates. Thecomposite particle material comprises, by mass, 26-33% of high-density polyethylene, 2.2-2.7% of polyvinyl alcohol, 10-12% of lead sand, 2.9-4.0% of boron carbide powder, 1.2-1.5% of polyethylene wax,1.7-2.3% of coupling agents, 0.6-1.2% of colemanite, 1.1-1.4% of aluminum hydroxide, 1.0-1.2% of carbon fibers, 2.1-2.3% of 2, 6-butylated hydroxytoluene, 0.6-1.1% of oleamide, 0.6-0.9% of powdered aluminum and the balance samarium powder and tungsten powder.

Owner:镇江奥特氟科技有限公司

Preparation method of silica gel with high flame retardant rating

The invention discloses a preparation method of silica gel with high flame retardant rating. The silica gel with high flame retardant rating is prepared by mixing the following raw materials in parts: a raw material A: methyl vinyl silicon rubber; a raw material B: methyl vinyl silicon rubber; a raw material C: precipitated silica; a raw material D: hydroxyl silicon oil; a raw material E: dimethyl diethoxy silane; a raw material F: zinc stearate; a raw material G: stearic acid; a raw material H: methyl silicone oil; a raw material I: aluminum hydroxide; a raw material J: zinc stannate; a raw material K: vinyl trimethoxy silane; a raw material L: platinum water; a raw material M: benzotriazole; a raw material N: ferric oxide; a raw material P: magnesium oxide; and a few of raw material Q: curing agent. The silica gel raw material prepared by mixing the raw materials is excellent in flame retardant performance which can reach 5VB and 5VA of UL94 flame retardant rating.

Owner:东莞市朗晟材料科技有限公司

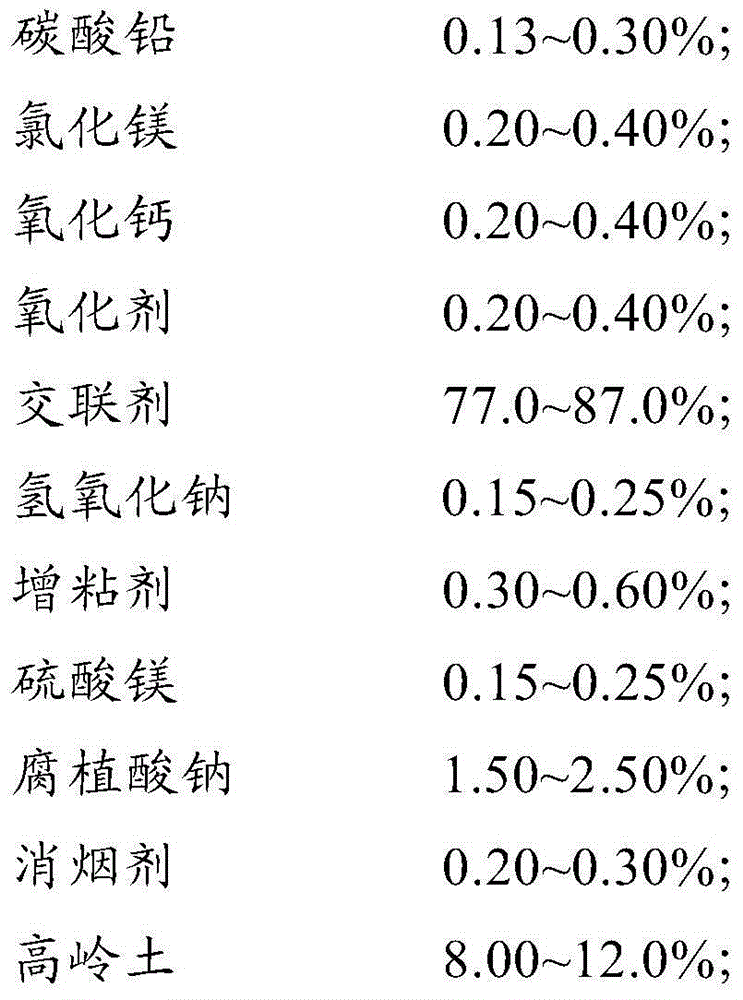

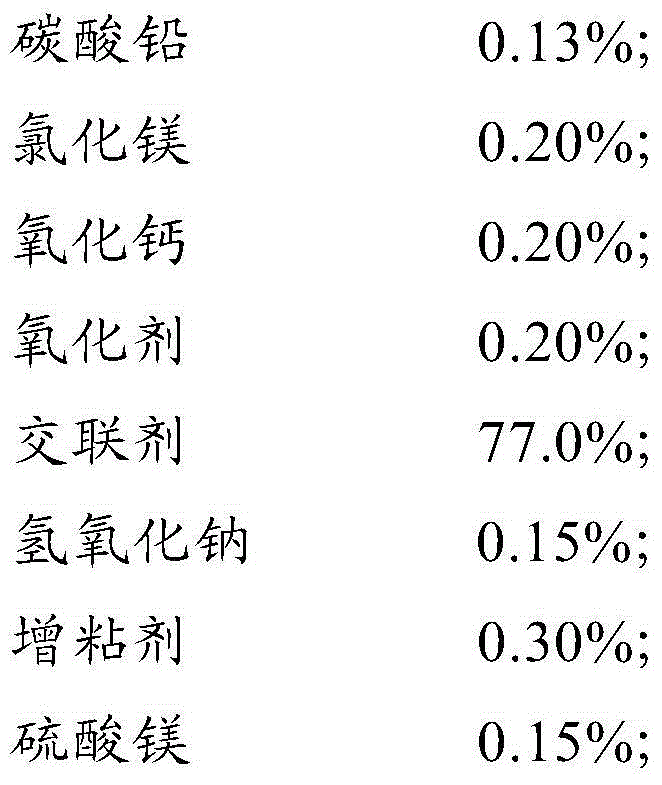

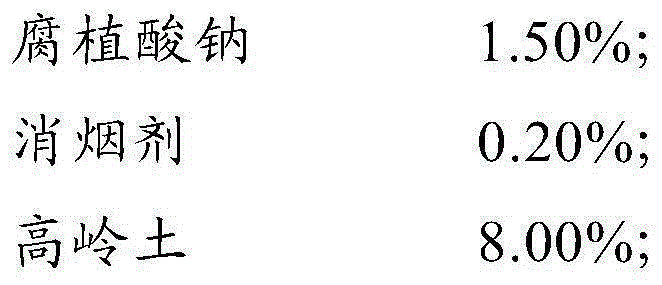

Cleaning briquette coal binder

The invention discloses a cleaning briquette coal binder. The binder comprises the following raw materials: 0.13-0.30% of lead carbonate, 0.20-0.40% of magnesium chloride, 0.20-0.40% of calcium oxide, 0.20-0.40% of an oxidizing agent, 77.0-87.0% of a crosslinking agent, 0.15%-0.25% of sodium hydroxide, 0.30-0.60% of a tackifier, 0.15%-0.25% of magnesium sulfate, 1.50-2.50% of sodium humate, 0.20-0.30% of a smoke suppressant and 8.00-12.0% of kaolin. The briquette coal binder disclosed by the invention has the effects of suppressing smoke, preventing moisture, reducing dust, fixing sulfur, inhibiting nitrogen and the like, and is developed in line with the national situation of energy conservation, emission reduction and haze treatment according to China coal energy actual application and the characteristics of the haze formation cause in recent years; the binder has prominent energy conservation and emission reduction effects and an oxidative combustion-promoting effect; and since the binder is fully burnt, the energy conservation effect is achieved.

Owner:李晓雷

Halogen-free flame retardant PC/PET alloy material and preparation method thereof

The invention discloses a halogen-free flame retardant PC / PET alloy material and a preparation method thereof. The halogen-free flame retardant PC / PET alloy material comprises, by mass, 10-40% of PC, 50-70% of PET, 5-12% of a compound halogen-free flame retardant master batch, 3-8% of a compatibilizer, 0.5-2% of a dispersant and 0.1-1% of an antioxidant. The halogen-free flame retardant PC / PET alloy material simultaneously has the respective advantages of the PC and the PET, has the high strength and heat resistance of the PC, has the chemical resistance and easy machinability of the PET, and also has excellent comprehensive properties; and the compound halogen-free flame retardant master batch has the characteristics of no halogen, flame retardation, smoke inhibition, non-toxicity, safety, high efficiency, less consumption, use convenience and the like when the compound halogen-free flame retardant master batch is used in the flame retardation modification of the halogen-free flame retardant PC / PET alloy material.

Owner:QINGDAO XINZHAN PLASTIC

Efficient environmentally-friendly fire retardant for wood impregnation, and treatment technology thereof

InactiveCN104647522AWith smoke suppressionWith smoke suppression effectWood treatment detailsPressure impregnationRetardation effectAmmonium polyphosphate

The invention discloses an efficient environmentally-friendly fire retardant for wood impregnation, and a treatment technology thereof. The efficient environmentally-friendly fire retardant for wood impregnation comprises, by mass, 10-25% of phosphoric acid, 5-10% of borax, 5-10% of boric acid, 30-45% of water-soluble ammonium polyphosphate, 5-30% of aluminum sulfate and 3-6% of ammonium molybdate. Compared with fire retardants in the prior art, the efficient environmentally-friendly fire retardant has smoke elimination and inhibition effects through the addition of ammonium molybdate, contains P, N and B fire retardation components, and has the advantages of good fire retardation effect, no halogen, low toxicity, no irritation, no corrosion, good stability in the use process, difficult degradation or loss, abundant sources of raw materials, low cost and use convenience.

Owner:高天红

Nano polyethylene composite material and preparation method thereof

The invention discloses a nano polyethylene composite material and a preparation method thereof. The nano polyethylene composite material comprises the following components in percentage by mass: 60-75% of polyethylene resin, 5-15% of nano particles, 18-25% of halogen-free flame retardant, 0.1-0.3% of surface treating agent, 0.2-1.5% of lubricant, 0.1-1% of antioxidant, and 0-0.5% of pigment. The nano polyethylene composite material disclosed by the invention has the beneficial effects that the nano particles and the polyethylene resin are blended together, and a proper amount of halogen-free flame retardant, surface treating agent and the like are added, so that the rigidity, heat resistance and stability of the material are greatly improved, and the effects of increasing the flexibility, increasing the strength and keeping relatively good strength can be achieved; moreover, the halogen-free flame retardant has smoke-suppressing, nontoxic and environment-friendly high flame retarding efficiency, and is excellent in comprehensive performance, good in processing performance and low in cost.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

Modified boehmite for heatproof flame retardant cable materials and preparation method thereof

InactiveCN104163939AAcid resistantFlame retardantPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPhosphateBenzoic acid hydrazide

The invention discloses modified boehmite for heatproof flame retardant cable materials and a preparation method thereof, and the modified boehmite is made from the following raw materials by weight: 100 parts of boehmite, 15-25 parts of expanded graphite powder, 3-6 parts of triglycidyl isocyanurate, 20-30 parts of nano black stone, 10-15 parts of ceramic beads, 10-15 parts of butyl benzyl phthalate, 2-3 parts of 4-amion-2,2,6,6-tetramentylniperidine, 5-10 parts of phenyl isopropylphenyl phosphate, 1.5-2.5 parts of 2-hydroxy magnesium benzoate, 2-3 parts of p-hydroxy benzoic acid hydrazide, 4-6 parts of behenamide, 0.5-1.5 parts of resorcinol monobenzoate, 1-2 parts of dilauryl thiodipropionate and 3-5 parts of an auxiliary. The modified boehmite has the advantages of high in acid resistant, flame retardant and smoke suppression functions, good in filling effect, free of secondary pollution after combustion, low cost, and the like, not only can improve the flame retardant properties of the cable materials, but also can improve the heat resistance, corrosion resistance, dielectric property and mechanical strength of the cable materials.

Owner:滁州市富力克斯电线电缆有限公司

PBT environment-friendly and flame-retardant material toughened and reinforced by blending elastomer and micrometer particles

The invention discloses a PBT environment-friendly and flame-retardant material toughened and reinforced by blending elastomer and micrometer particles. The PBT environment-friendly and flame-retardant material comprises components by mass: 50%-70% of PBT, 18%-25% of a halogen-free flame retardant, 5%-20% of elastormer, 5%-20% of the micrometer particles, 0.1%-0.5% of a surface treating agent, 0.2-1.5% of a lubricant, 0.1%-1% of an antioxidant and 0-0.5% of a light stabilizer. Compared with a conventional PBT material, the prepared PBT has high notch impact strength and good toughness, keeps relatively good strength, and can greatly increase rigidity, heat resistance and processability. At the same time, the used halogen-free flame retardant has the advantages of security, smoke-suppressing, no toxicity, environment protection and low cost. The PBT material has high flame-retardant property and excellent comprehensive properties, and can be used as materials for preparing electronics, electrics, automobile industries and mechanical components.

Owner:QINGDAO XINZHAN PLASTIC

Superfine magnesium hydrate polyethylene fire retardant composite material and preparation process thereof

The invention relates to a superfine magnesium hydroxide polyethylene fire resistant composite material, which consists of following compositions by weight portion: 20 to 50 portions of polyethylene matrixes, 60 to 80 portions of surface modification superfine magnesium hydroxides, 1 to 3 portions of zinc borate, 5 to 10 portions of tertiary phosphate and 0.1 to 0.5 portions of acetone, wherein, the grain diameter of the magnesium hydroxides is 15 micrometers; the surface modifier is silane coupling agent; and the mass ratio of the silane coupling agent and the superfine magnesium hydroxides is 0.5 to 1.5 percent. The superfine magnesium hydroxide polyethylene fire resistant composite material has the advantages of smoke suppression, low toxicity, halogen free without Sb2O3, friendly environment, low formulation cost and high economic benefit and social benefit.

Owner:广州市啊啦棒高分子材料有限公司

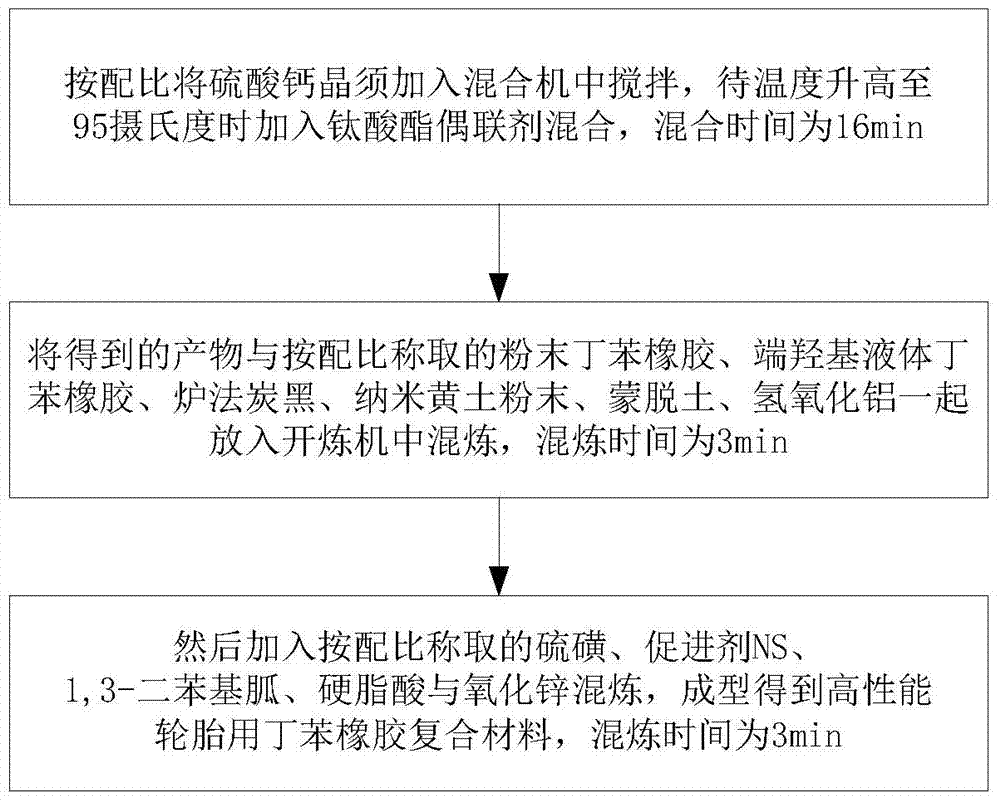

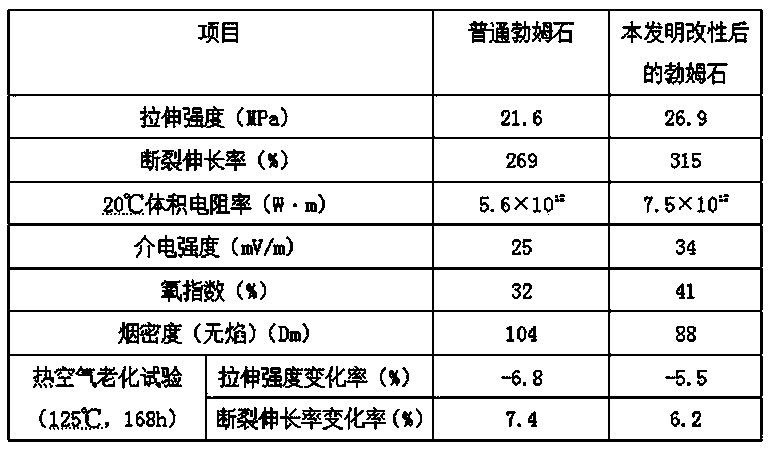

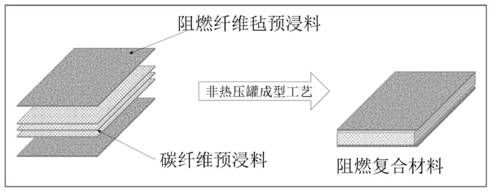

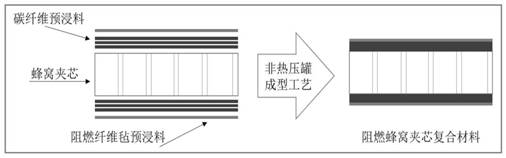

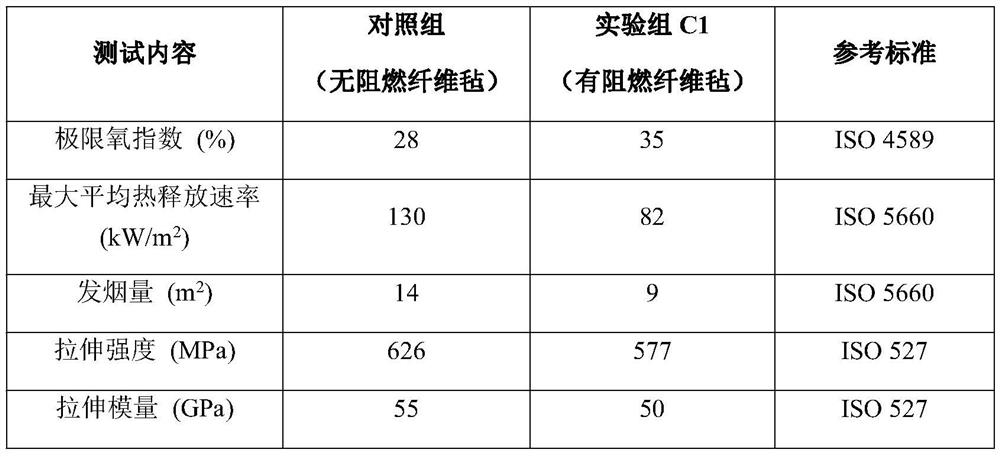

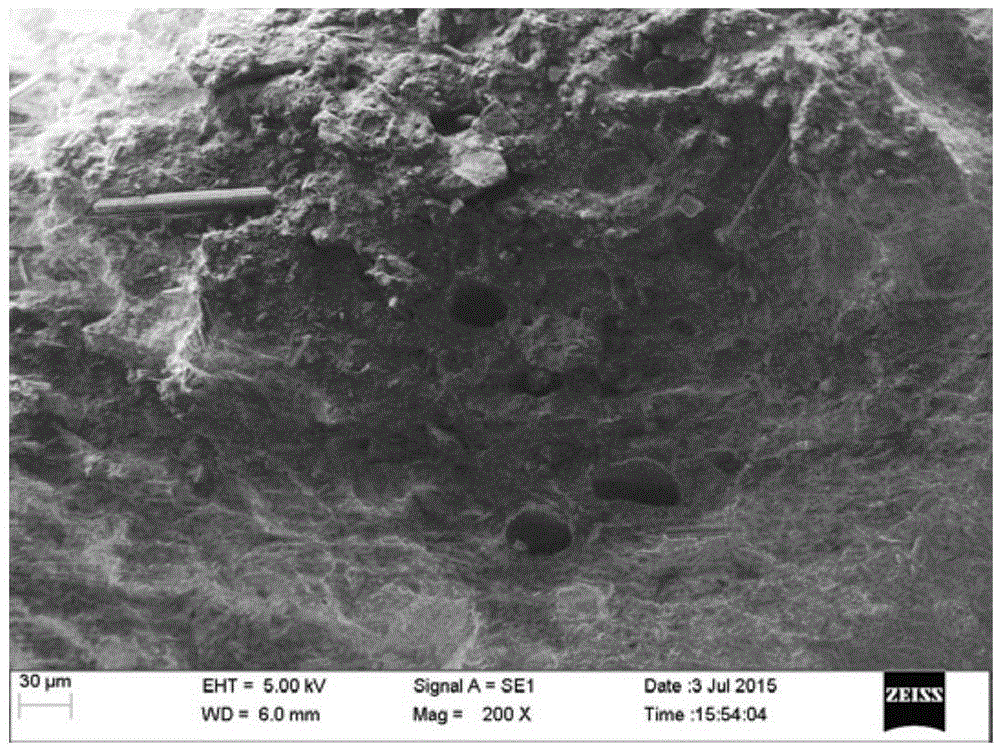

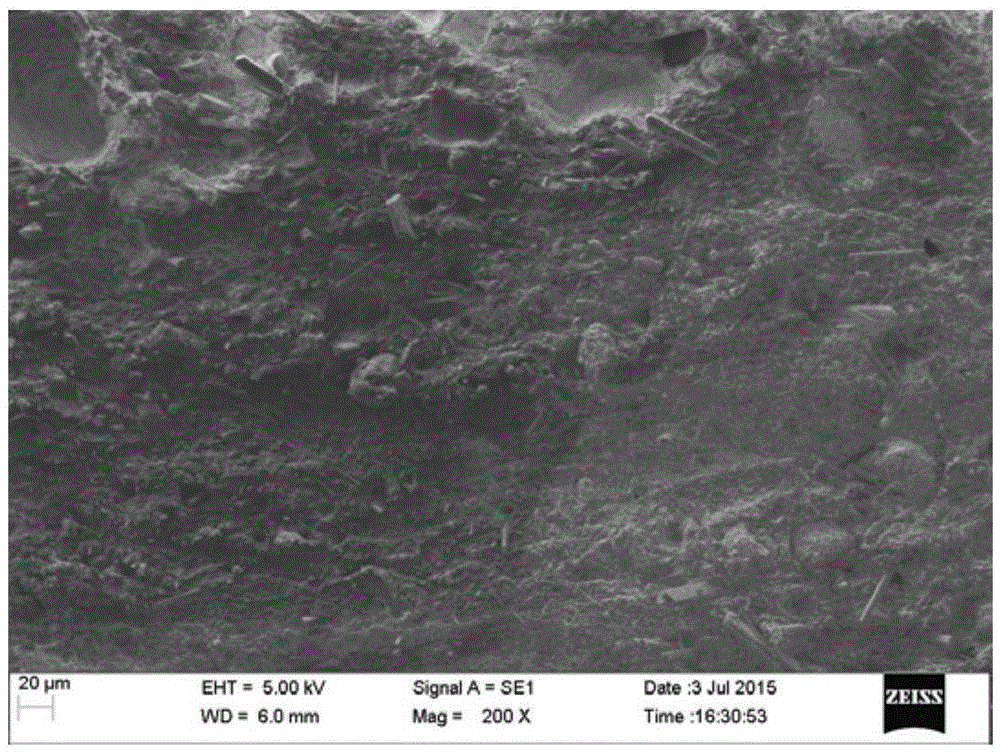

Structural flame-retardant functional composite material and preparation method thereof

ActiveCN112009038AAvoid destructionImprove flame retardant performanceSynthetic resin layered productsLaminationFiberCombustion

The invention provides a structural flame-retardant functional composite material which comprises a flame-retardant fireproof fiber felt and a composite material, and the surface of the composite material body is coated with the flame-retardant fireproof fiber felt. The invention further provides a preparation method of the structural flame-retardant functional composite material. The preparationmethod comprises the following steps: (1) preparing the flame-retardant fireproof fiber felt; (2) pre-impregnating the fiber felt; and (3) preparing the flame-retardant composite material. Compared with the prior art, a surface flame-retardant structure is adopted, the flame-retardant functional structure layer with the functions of flame retardance, heat insulation, smoke suppression and the likeis concentrated on the surface of the composite material based on the combustion behavior that the composite material expands from outside to inside after being ignited, and in the process that the composite material is on fire, the structure can be used as a fireproofing suit to isolate flame and heat outside the composite material so that the internal structure of the material is protected, andthe damage of a flame retardant to the composite material matrix is avoided.

Owner:NINGBO NOTTINGHAM NEW MATERIALS INST CO LTD +1

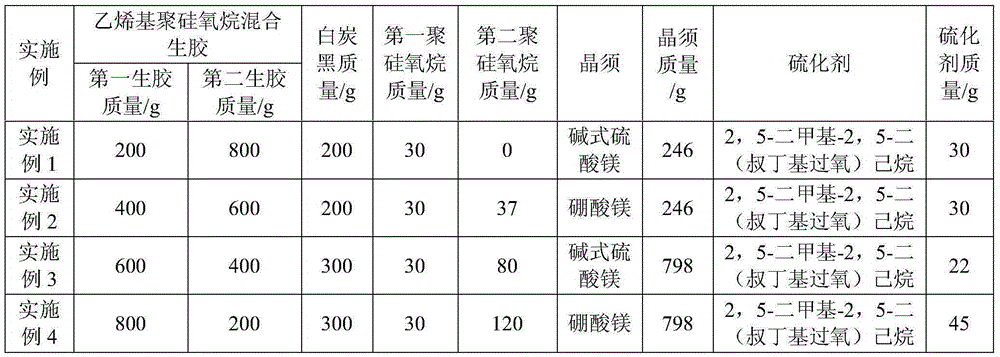

Whisker/silicone rubber composite and preparation method thereof

The invention discloses a whisker / silicone rubber composite and a preparation method thereof. The preparation method includes the steps that A, 100 parts of vinyl polysiloxane compound rubber, 20-30 parts of white carbon black and 3 parts of first polysiloxane by mass are kneaded for at least 4 h at the temperature of 30-80 DEG C, and base rubber is obtained, wherein first polysiloxane is hydroxyl-terminated polysiloxane with the average molecular weight of 610-1,110; B, the base rubber and 24-60 parts of magnesium sulfate whiskers or magnesium borate whiskers by mass are kneaded for at least 3 h at the temperature of 30-80 DEG C, and a rubber compound is obtained; C, the rubber compound and 2-5 parts of vulcanizing agent by mass are mixed on a double-roller machine, a first mixture is obtained, the first mixture is pressurized and vulcanized for 20 min-30 min in a press vulcanizer at the pressure of 9 MPa-11MPa and the temperature of 165 DEG C-175 DEG C, the pressure is kept for at least 1 h, cooling is conducted, and then the whisker / silicone rubber composite is obtained. The whisker / silicone rubber composite prepared through the preparation method is further disclosed. The whiskers serve as flame retardant of the whisker / silicone rubber composite, and the advantages of being low in toxicity, stable, capable of abating smoke and the like are achieved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

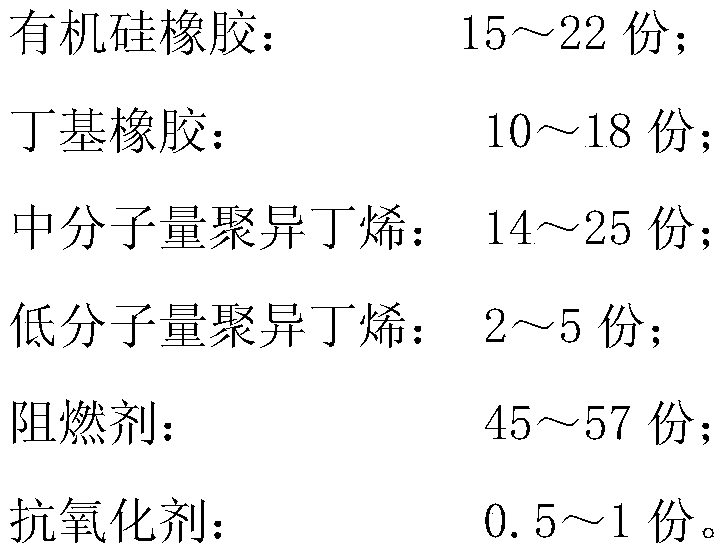

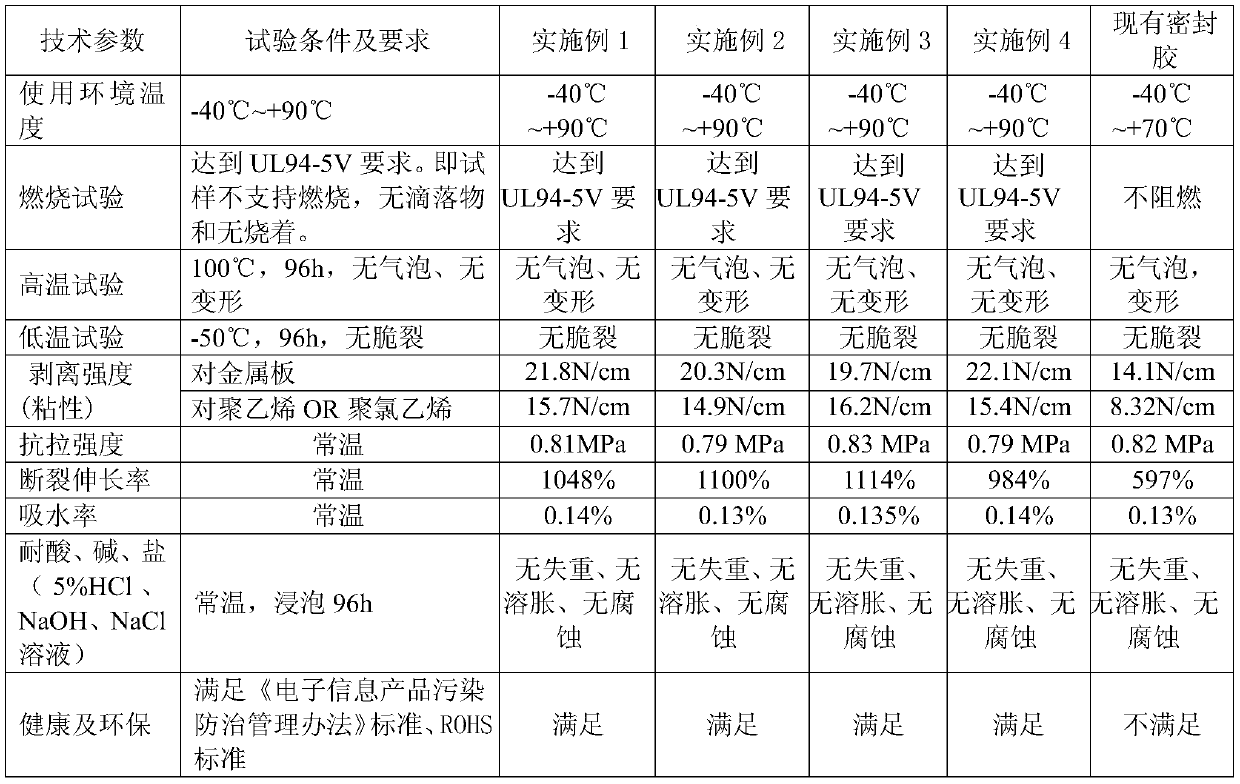

Novel environmentally-friendly cable splice closure sealant and preparation method thereof

ActiveCN109897570AWide range of applicationsGood thermal stabilityNon-macromolecular adhesive additivesSolventSalt resistance

The invention discloses a novel environmentally-friendly cable splice closure sealant and a preparation method thereof, and belongs to the technical field of preparation of sealants. The sealant comprises silicone rubber, a flame retardant, butyl rubber, medium molecular weight polyisobutylene, low molecular weight polyisobutylene and an antioxidant. The preparation method comprises the followingsteps: S1, weighing: weighing the raw materials for later use; S2, kneading: adding and kneading the raw materials; S3, blending: blending the obtained kneaded rubber compound; and S4, extruding: extruding the blended rubber compound, and cooling and cutting the extruded rubber compound to obtain the novel environmentally-friendly sealant. The sealant of the invention has excellent adhesion, flameretardancy, filling property, sealing property, water resistance, high and low temperature resistance, acid resistance, alkali resistance, salt resistance and dielectric property; preparation materials of the sealant do not contain solvents or halogens, so the sealant is environmentally friendly; and the preparation method has the characteristics of simple production process, time saving and energy saving, and is suitable for industrial large-scale production.

Owner:SICHUAN TIANYI COMHEART TELECOM

High-flame-retardant organic phosphate fire-proof plate capable of insulating heat and oxygen and suppressing smoke and preparation method thereof

InactiveCN102211344AGuaranteed decorative effectWith smoke suppressionWood working apparatusDomestic articlesToxic gasPhosphate

The invention relates to a high-flame-retardant organic phosphate wheat straw fire-proof plate capable of insulating heat and oxygen and suppressing smoke and a preparation method thereof. The high-flame-retardant organic phosphate wheat straw fire-proof plate is characterized by being prepared by the steps of: adding a high-flame-retardant organic phosphate flame retardant with high flame retardance, low smoke and no toxic gas and a silica sol binder with high binding power, serving as additive accessories, into processed wheat straws, stirring, and molding at high temperature and high pressure. The high-flame-retardant organic phosphate wheat straw fire-proof plate can achieve the purposes of uniformly insulating heat and oxygen, suppressing smoke, retarding inflaming and preventing fire. The flame-retardant and fire-proof components of the high-flame-retardant organic phosphate wheat straw fire-proof plate can not volatilize or lose, and the decoration performance of wood is maintained. The high-flame-retardant organic phosphate wheat straw fire-proof plate is a new-generation green product with the advantages of smoke suppressing capability, no toxicity, no obvious pungent odor, and better environment friendliness and safety in the performances of fire prevention and flame retardance.

Owner:刘方旭

Flame-retardant ceramic slurry for lithium battery coating diaphragm and preparation method of flame-retardant ceramic slurry

InactiveCN108847469ATo preventReduce combustion explosionCell component detailsInorganic particleHeat resistance

The invention discloses a flame-retardant ceramic slurry for a lithium battery coating diaphragm and a preparation method of the flame-retardant ceramic slurry, wherein the slurry comprises inorganicparticles, an intumescent flame retardant, a dispersing agent, a binding agent, a thickening agent and a solvent; the preparation method comprises the following steps of adding the inorganic particles, the dispersing agent, the thickening agent and the solvent into a ball mill according to the proportion to be dispersed, so as to obtain a dispersion liquid; and then adding the binding agent and the intumescent flame retardant into the dispersion liquid, and carrying out dispersing by using a dispersing machine to prepare the flame-retardant ceramic slurry. The ceramic slurry disclosed by the invention can improve the heat resistance of the diaphragm, the lithium battery can be prevented from burning and exploding in a large range, and the safety performance of the lithium battery is improved.

Owner:瑞固新能(上海)材料科技有限公司

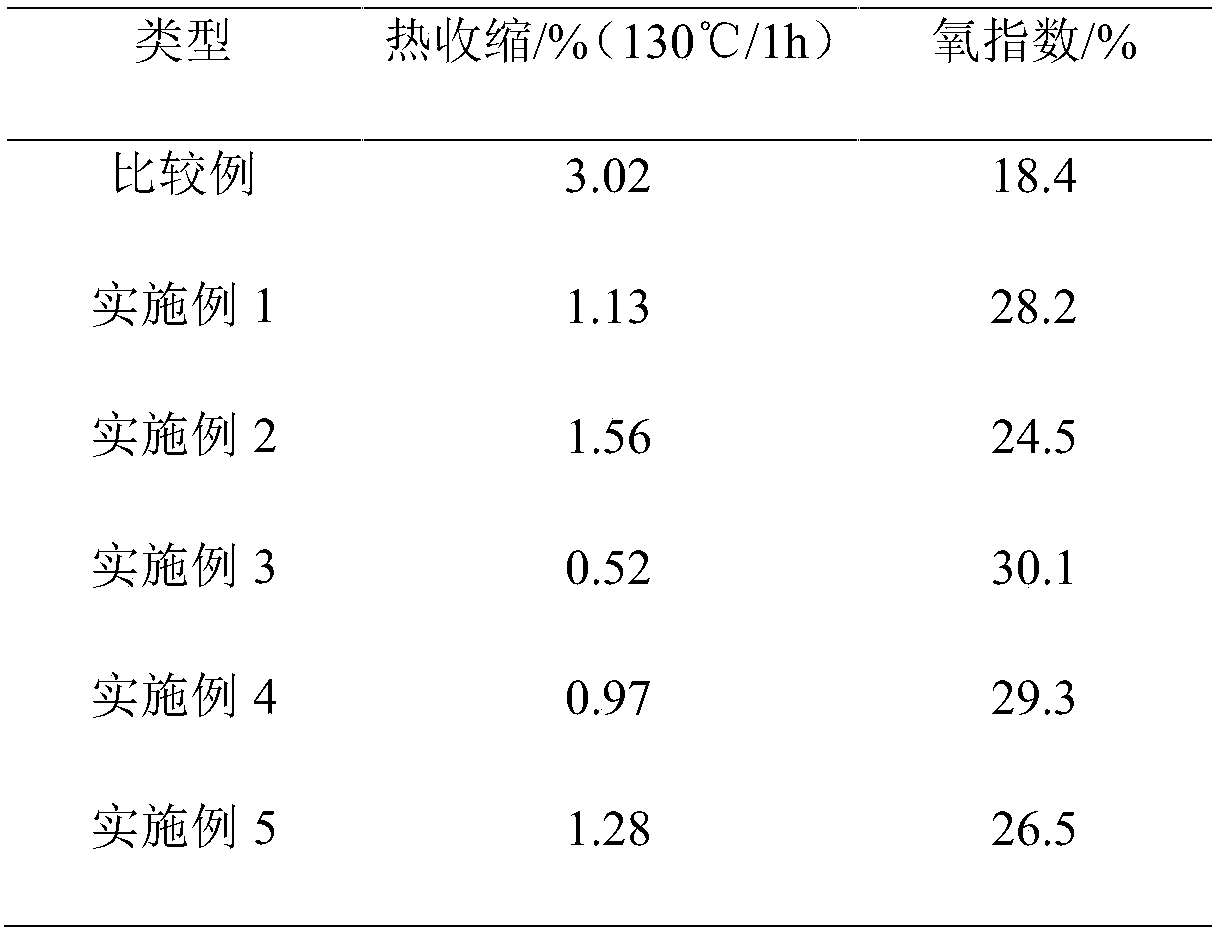

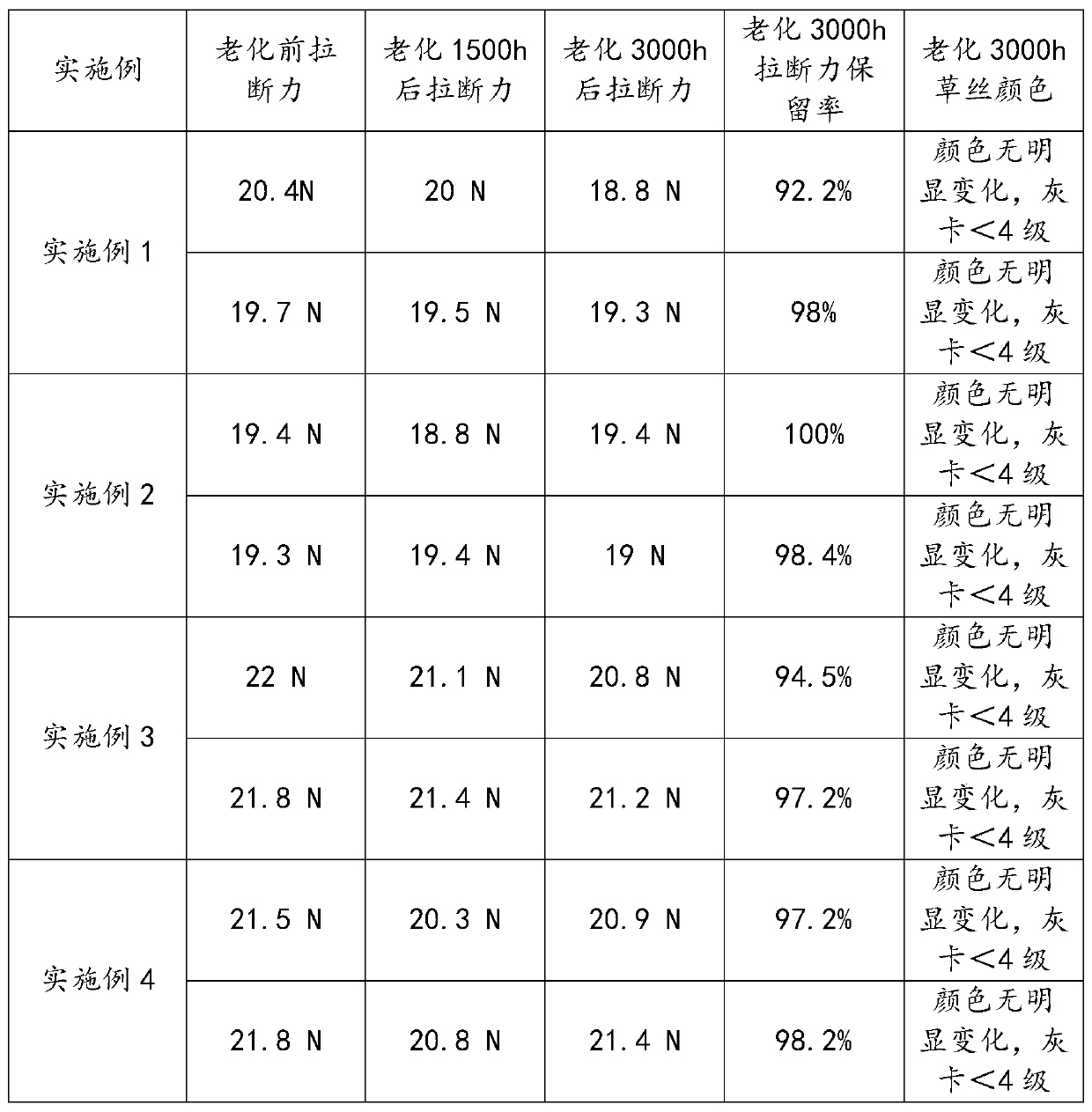

Flame-retardant composition, preparation method thereof, artificial grass yarn, artificial turf backing adhesive and artificial turf

ActiveCN109735913AWith smoke suppressionNon-corrosiveNon-macromolecular adhesive additivesFlame-proof filament manufactureYarnAdhesive

The invention relates to the technical field of an artificial turf and particularly relates to a flame-retardant composition, a preparation method thereof, an artificial grass yarn, an artificial turfbacking adhesive and an artificial turf. The flame-retardant composition contains the following components in parts by mass: 10-30 parts of a nitrogen-containing flame retardant, 40-60 parts of a bromine-containing flame retardant, 5-10 parts of a flame-retardant aid A and 1-3 parts of a flame-retardant aid B, wherein the nitrogen-containing flame retardant is melamine cyanurate, the bromine-containing flame retardant is any one of decabromodiphenyl ethane, octabromoether and ethylene ditetrabromo-o-phenylenimide, the flame-retardant aid A is antimonous oxide or sodium antimonide, and the flame-retardant aid B is 2,3-dimethyl-2,3-diphenylbutane. The flame-retardant composition has a good flame-retardant effect and is applied to the flame retardance of the artificial grass yarn so as to realize an automatic extinguishing effect away from the fire, and the artificial grass yarn has relatively good aging resistance and mechanical property.

Owner:纵横优仪(江苏)科技有限公司

Method for preparing composite wood with hydroxide

InactiveCN105034107AImprove stabilityImprove flame retardant performanceWood treatment detailsPressure impregnationHalogenMaterials science

The invention discloses a method for preparing composite wood with hydroxide. The method comprises the steps that an inflaming retarding solution is prepared, and after solid materials and liquid materials of components are mixed and stirred evenly, solids and liquid are mixed at normal temperature to obtain the inflaming retarding solution; and the mixed inflaming retarding solution is impregnated in wood, constant temperature treatment is carried out in a hydrothermal reaction kettle, and finally cooling and washing are carried out. According to the method, inflaming retarding liquid has the beneficial effects of being good in stability, non-volatile, free of generation of poisonous gas, free of halogen, environment-friendly, good in inflaming retarding effect, efficient, low in use level, low in cost and the like, and the prepared wood has the effects of retarding inflaming, restraining smoke, resisting corrosion and damage by worms and the like. The preparation method is simple in structure, and industrial production is achieved easily.

Owner:NANTONG A ZENITH DONGFANG FURNITURE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com