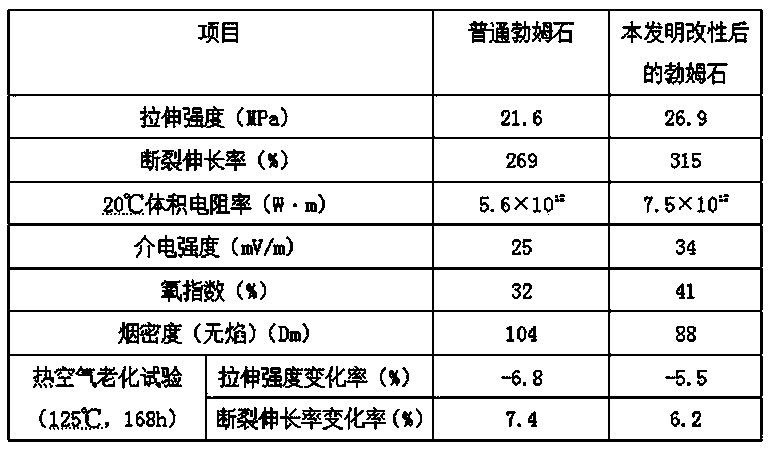

Modified boehmite for heatproof flame retardant cable materials and preparation method thereof

A flame-retardant cable and boehmite technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of unsatisfactory multi-functional fillers and low filling function of boehmite, and achieve good filling effect , low cost, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A modified boehmite for heat-resistant and flame-retardant cable materials, made of the following raw materials (kg): boehmite 100, expanded graphite powder 20, triglycidyl isocyanurate 4, nano blackstone 25, Ceramic Microbeads 13, Cresyl Butyl Phthalate 12, Tetramethylpiperidinamine 2.5, Triisopropylphenyl Phosphate 8, Magnesium 2-Hydroxybenzoate 2, P-Hydroxybenzoic Acid Hydrazide 2.5, Behenyl Acid amide 5, resorcinol monobenzoate 1, dilauryl thiodipropionate 1.5, additive 4;

[0011] The preparation method of the auxiliary agent is as follows: a, take the raw materials of the following weight (kg): dimethyl trimethylsilyl phosphonate 5, cobalt linoleate 2, phenyl o-hydroxybenzoate 6, 2,4- Dihydroxybenzophenone 1.5, waste brick powder 15, (2,4-di-tert-butylphenyl) phosphite triester 3, dibutyl maleate 10, oil shale ash 6, nano-clay 5, sorbet Tantrioleate 2.5, degreasing naphthenic acid 2, polytetramethylene glycol ether 3.5, diisononyl adipate 8; b, waste bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com