High-grade environment-friendly flame-retardant fiberboard and manufacturing method thereof

A flame retardant fiber and environmental protection technology, applied in the field of advanced environmental protection flame retardant fiberboard and its manufacturing, can solve the problems of increasing the drying moisture content of the fiber, low effective utilization rate of flame retardants, inconvenient storage and transportation, etc., and achieve flame retardant products. The effect of good performance, high production efficiency and superior physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

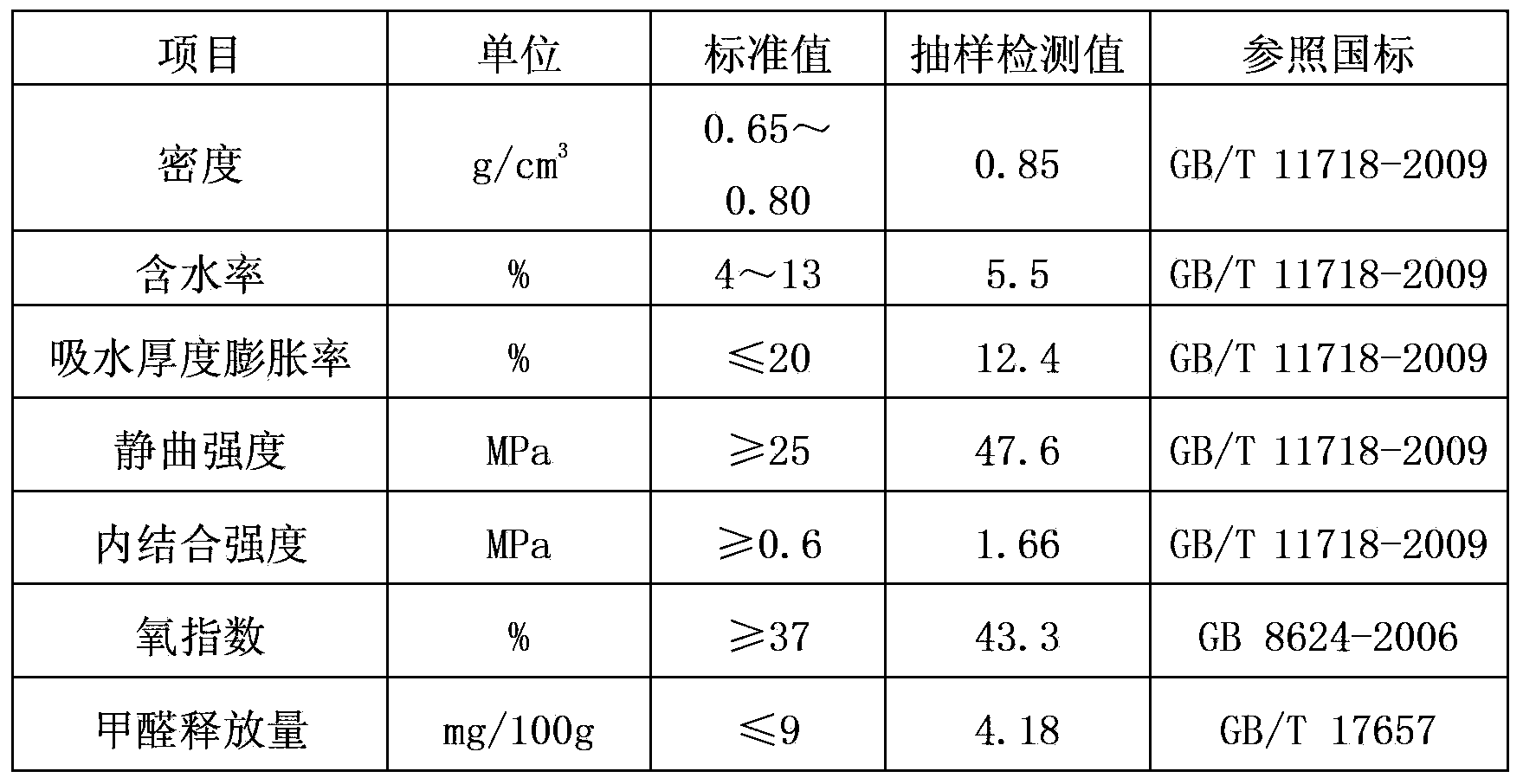

[0030] A high-grade environmentally friendly flame-retardant fiberboard, using wood chips as raw materials, heat-milled to obtain fibers, and adding auxiliary materials to manufacture high-grade environmentally friendly flame-retardant fiberboards, per 1m 3 The composition and weight of the finished fiberboard are: 610kg of fiber, 8kg of paraffin, 210kg of adhesive, 0.21kg of curing agent, 1.6kg of dyeing agent, 43kg of flame retardant and an appropriate amount of water; wherein, the flame retardant is a mixture of PNBMoMgZnAl; The adhesive uses E1 grade environmental protection urea-formaldehyde resin; the curing agent uses ammonium sulfate curing agent; the coloring agent uses fuchsia liquid industrial coloring agent. These materials are purchased directly from the market.

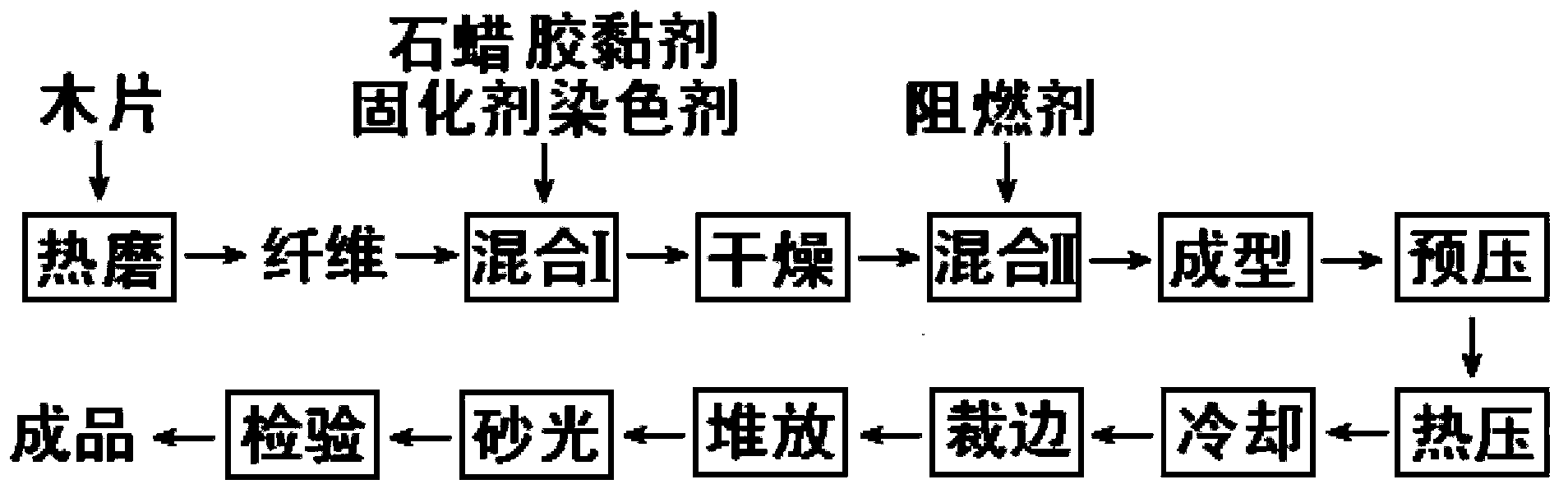

[0031] The manufacturing method of the above-mentioned high-grade environmentally friendly flame-retardant fiberboard mainly includes the processes of heat grinding, mixing, drying, forming, hot pressing...

Embodiment 2

[0042] A high-grade environmentally friendly flame-retardant fiberboard, using wood chips as raw materials, heat-milled to obtain fibers, and adding auxiliary materials to manufacture high-grade environmentally friendly flame-retardant fiberboards, per 1m 3 The composition and weight of the finished fiberboard are: 625kg of fiber, 7kg of paraffin, 200kg of adhesive, 0.2kg of curing agent, 1.6kg of dyeing agent, 43kg of flame retardant and an appropriate amount of water; wherein, the flame retardant is a mixture of PNBMoMgZnAl; The adhesive uses E1 grade environmental protection urea-formaldehyde resin; the curing agent uses ammonium sulfate curing agent; the coloring agent uses fuchsia liquid industrial coloring agent. These materials are purchased directly from the market.

[0043] The manufacturing method of the above-mentioned high-grade environmentally friendly flame-retardant fiberboard mainly includes the processes of heat grinding, mixing, drying, forming, hot pressing,...

Embodiment 3

[0054] A high-grade environmentally friendly flame-retardant fiberboard, using wood chips as raw materials, heat-milled to obtain fibers, and adding auxiliary materials to manufacture high-grade environmentally friendly flame-retardant fiberboards, per 1m 3 The composition and weight of the finished fiberboard are: 590kg of fiber, 9kg of paraffin, 230kg of adhesive, 0.26kg of curing agent, 2.0kg of dyeing agent, 50kg of flame retardant and an appropriate amount of water; wherein, the flame retardant is a mixture of PNBMoMgZnAl; The adhesive uses E1 grade environmental protection urea-formaldehyde resin; the curing agent uses ammonium sulfate curing agent; the coloring agent uses fuchsia liquid industrial coloring agent. These materials are purchased directly from the market.

[0055] The manufacturing method of the above-mentioned high-grade environmentally friendly flame-retardant fiberboard mainly includes the processes of heat grinding, mixing, drying, forming, hot pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com