Patents

Literature

239results about How to "Reduce formaldehyde emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

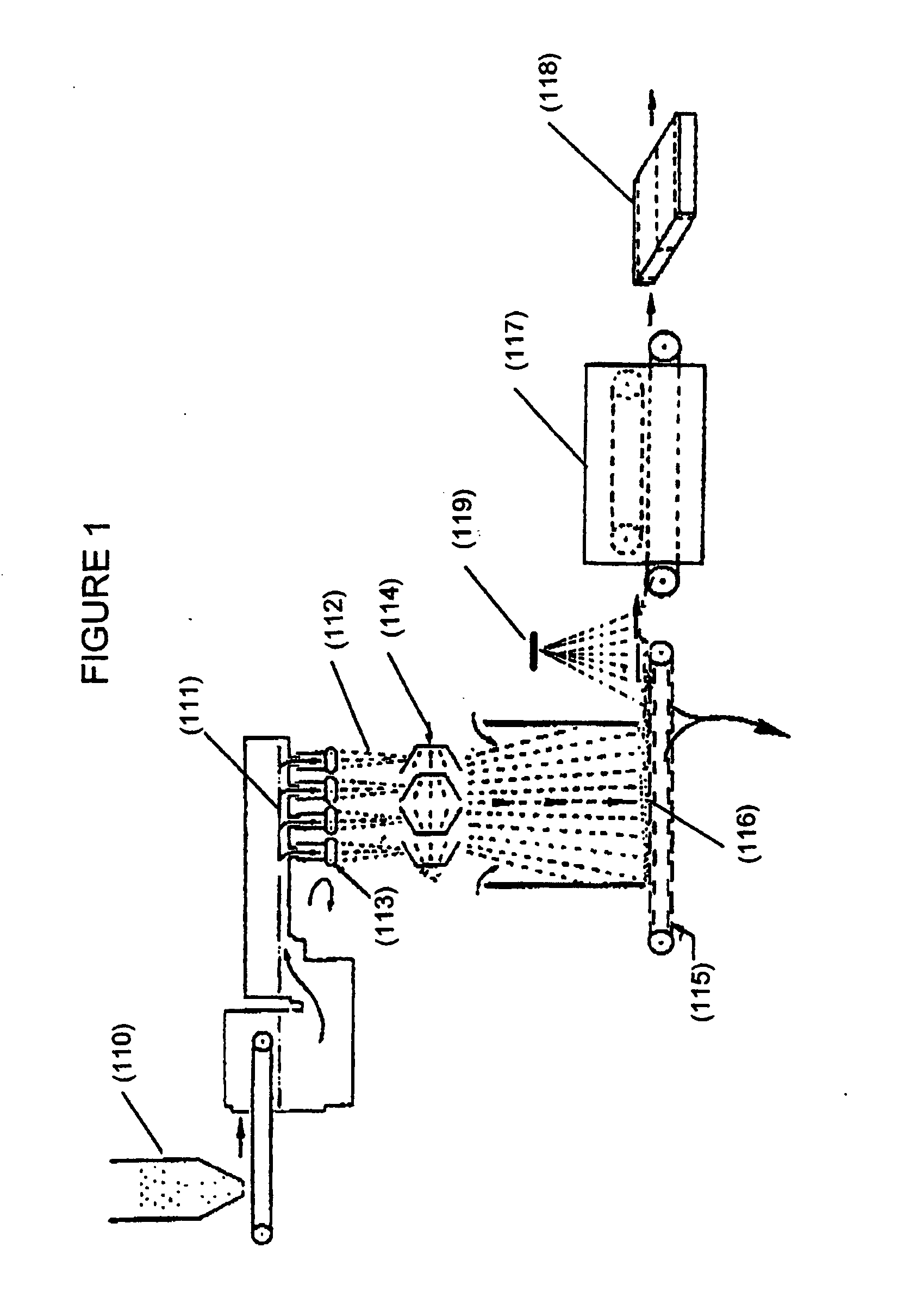

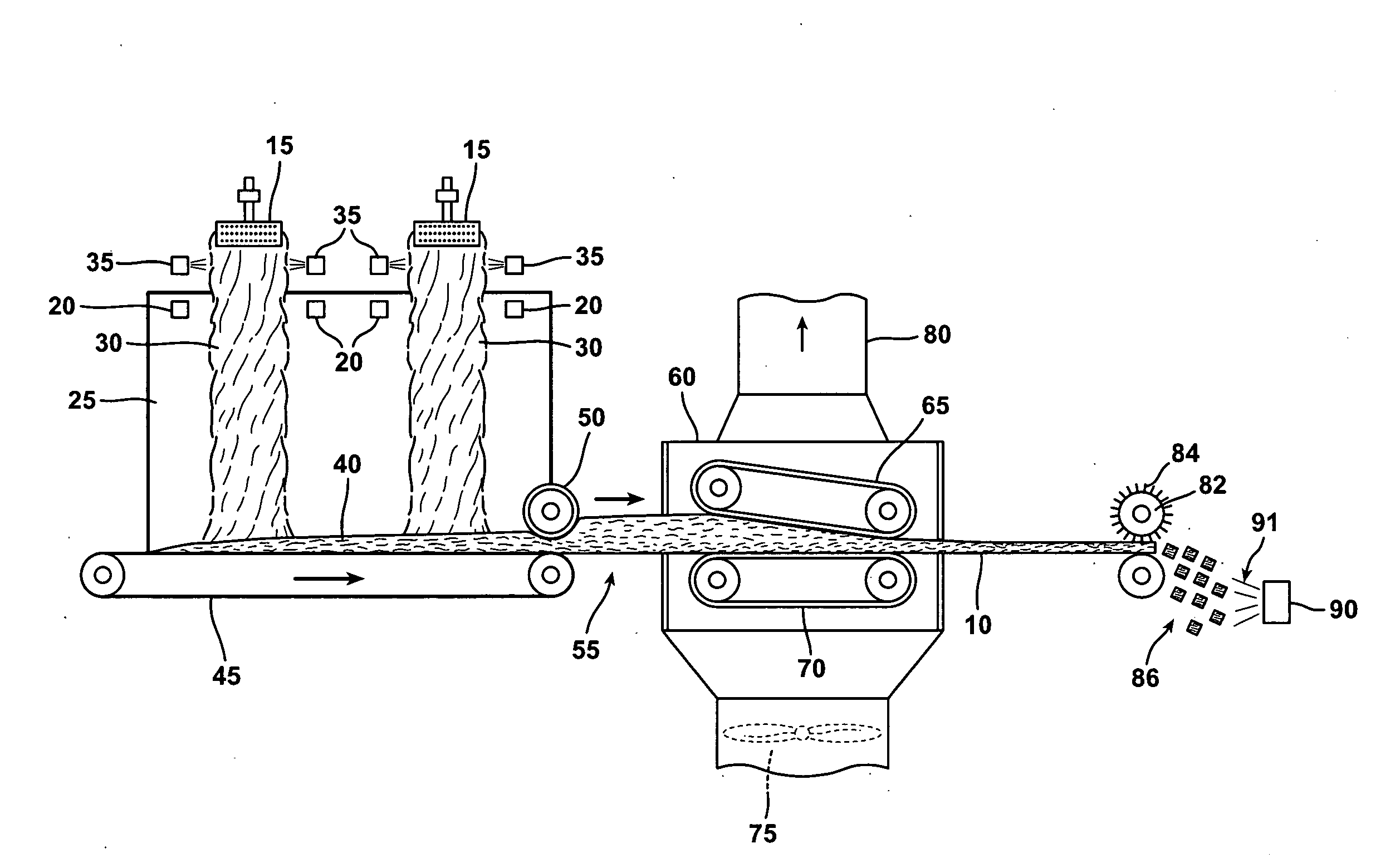

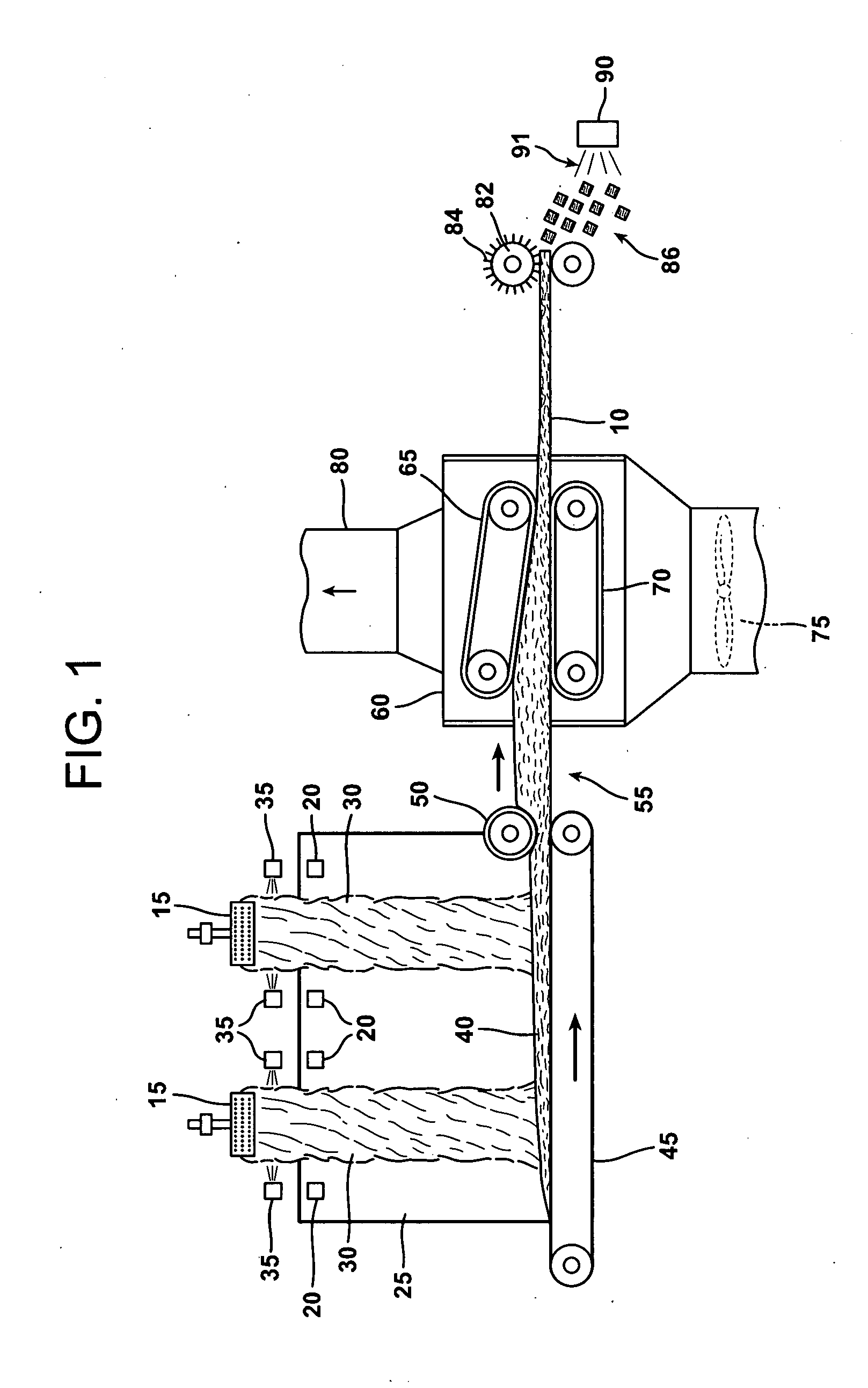

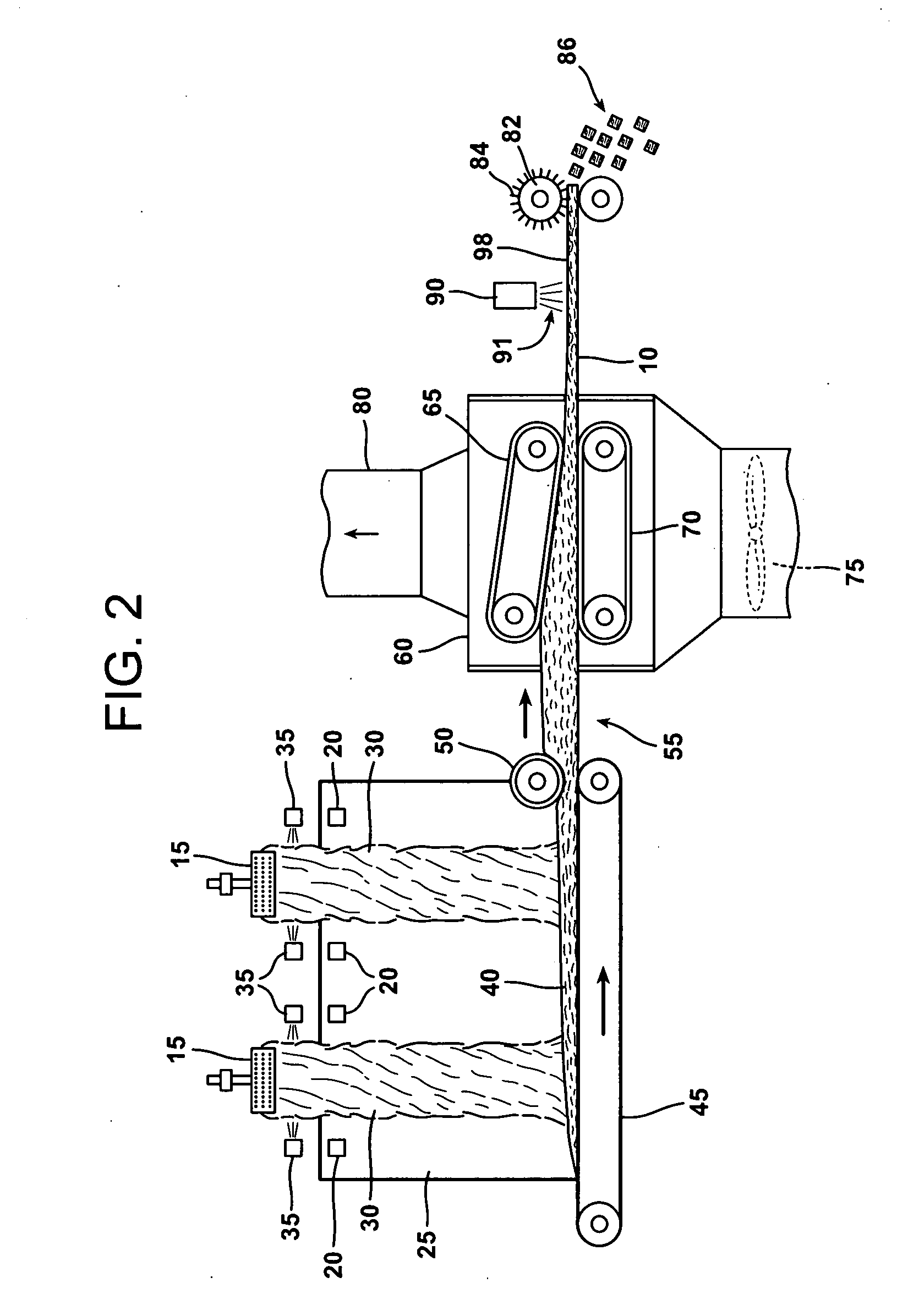

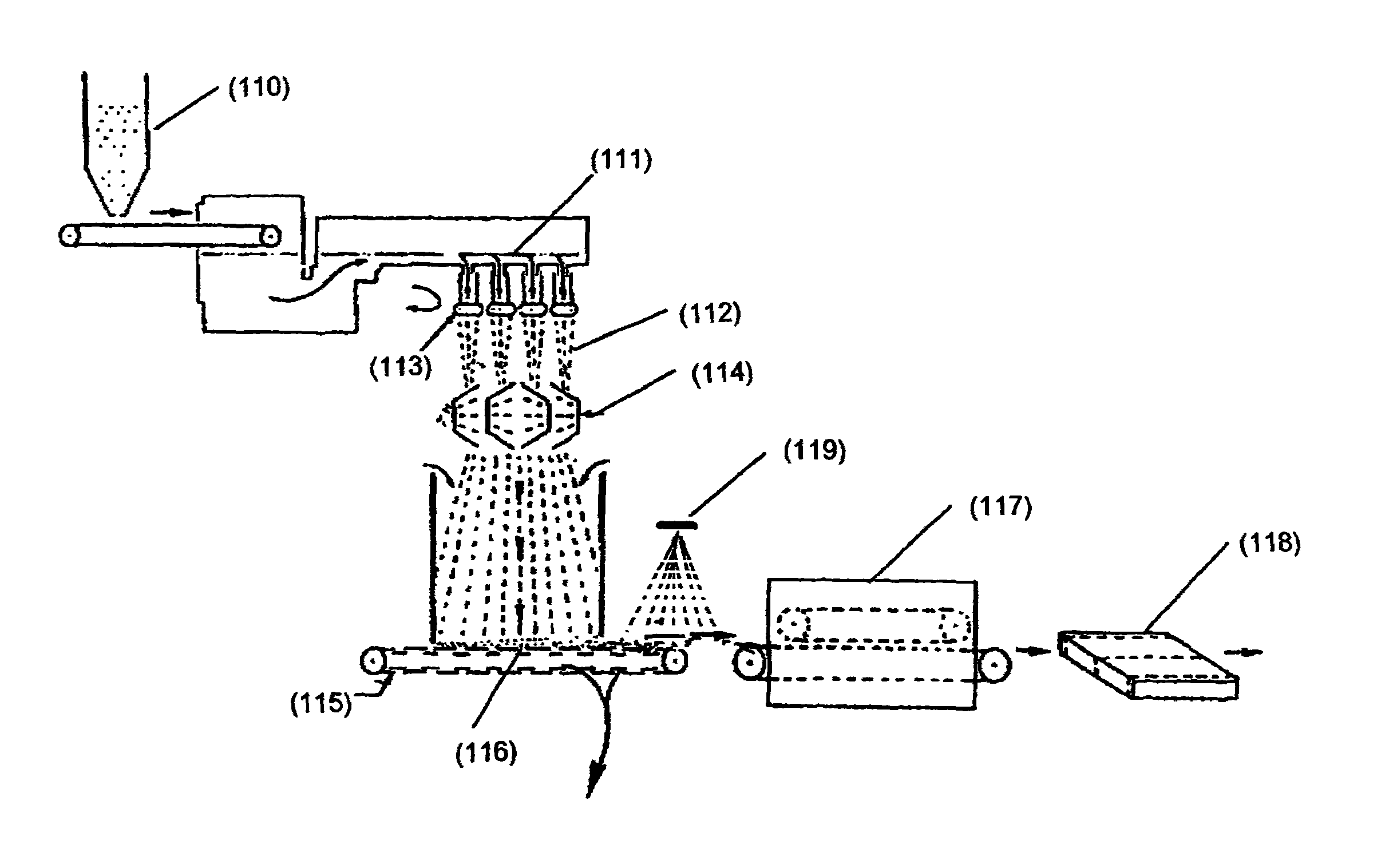

Fibrous mats having reduced formaldehyde emissions

InactiveUS20070287018A1Reduce stretchTrend downSynthetic resin layered productsLiquid/solution decomposition chemical coatingFiberGlass fiber

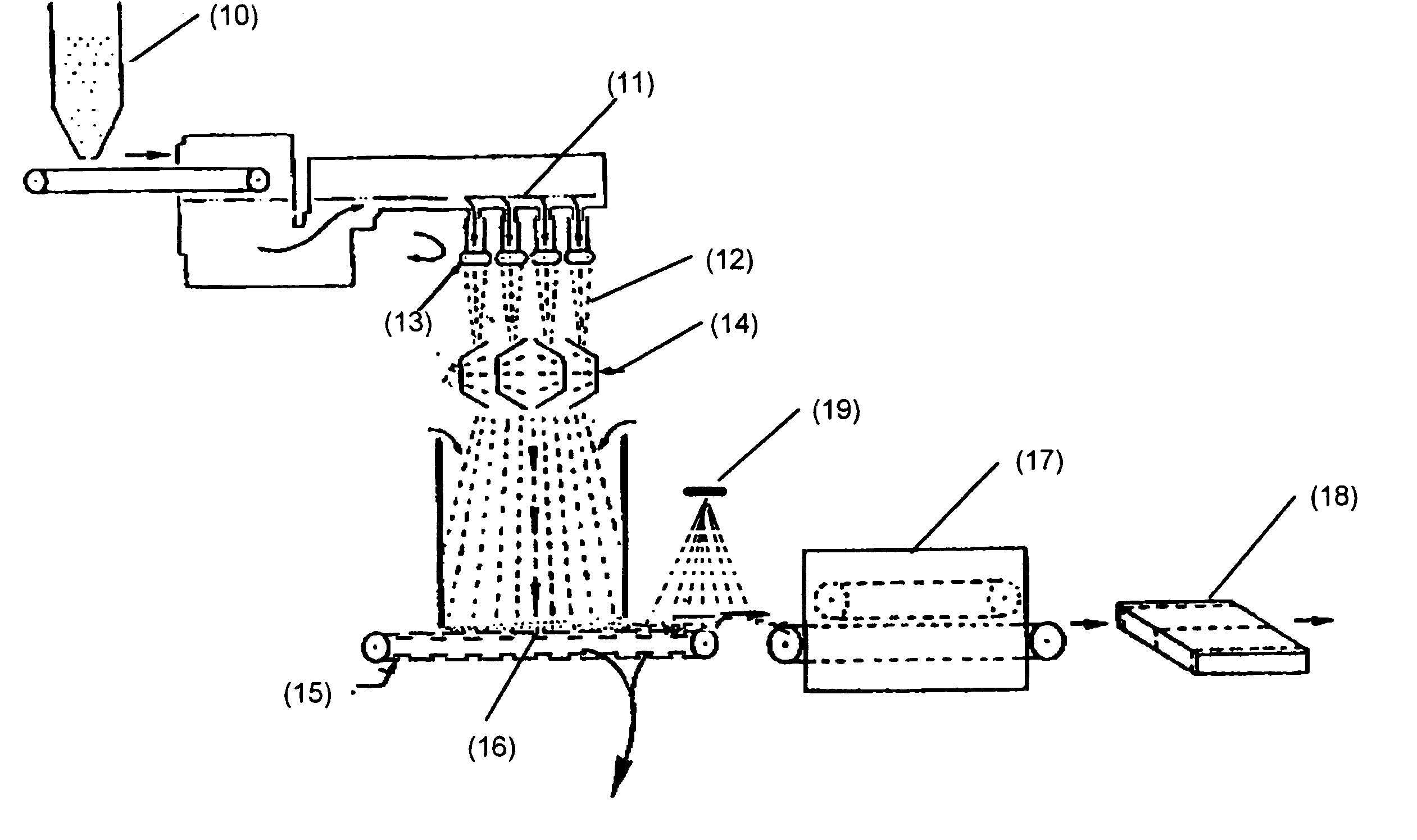

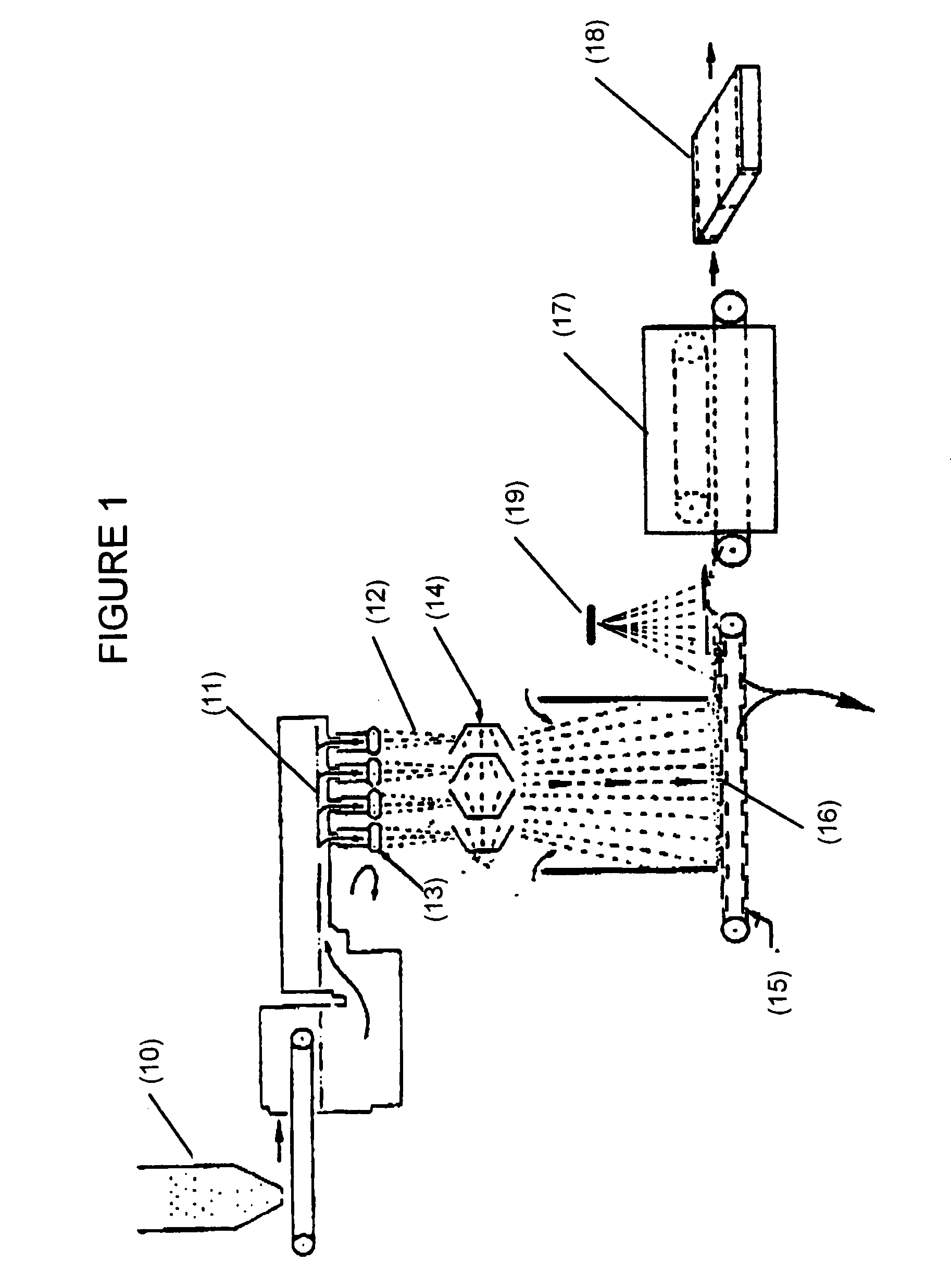

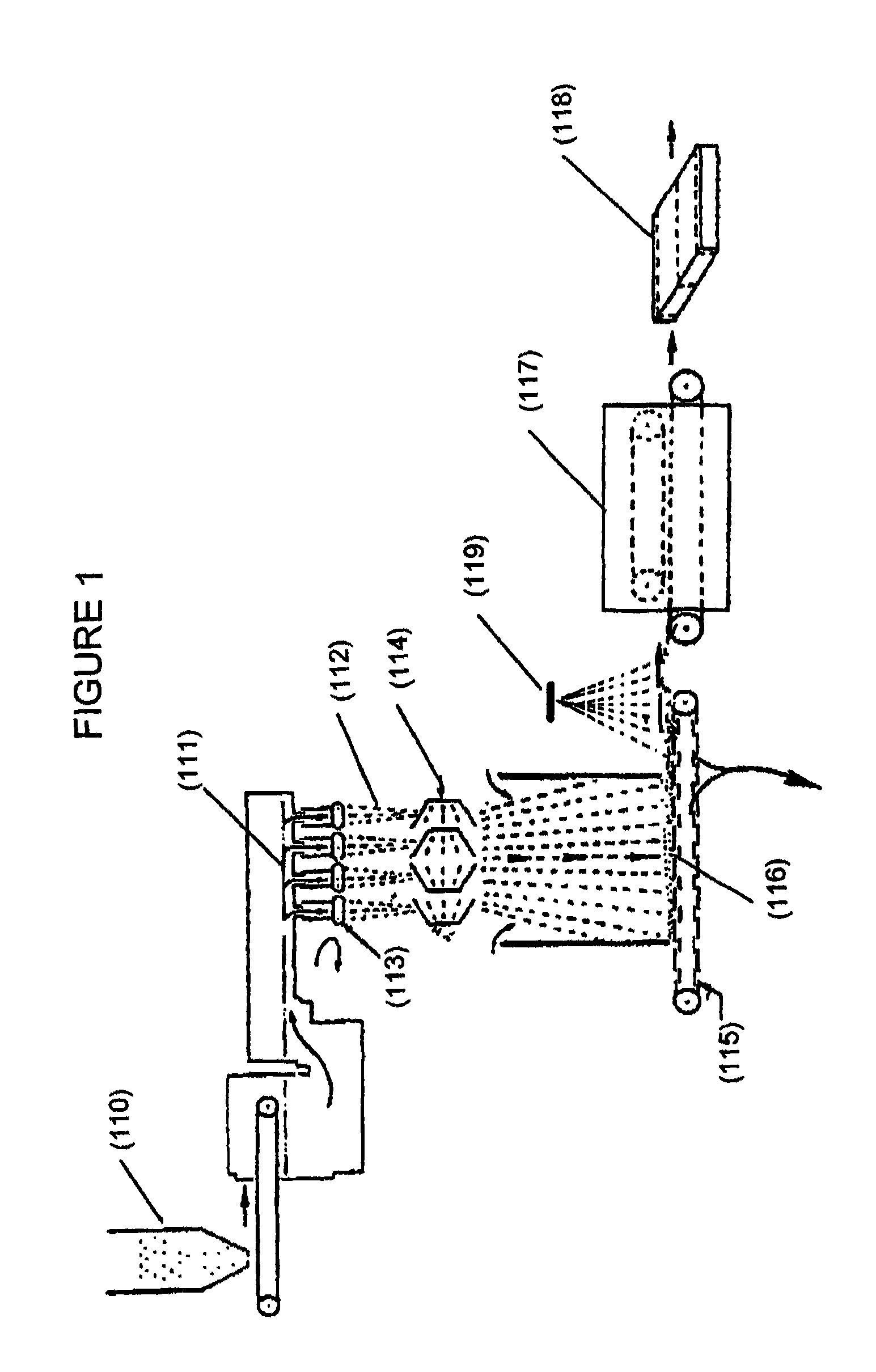

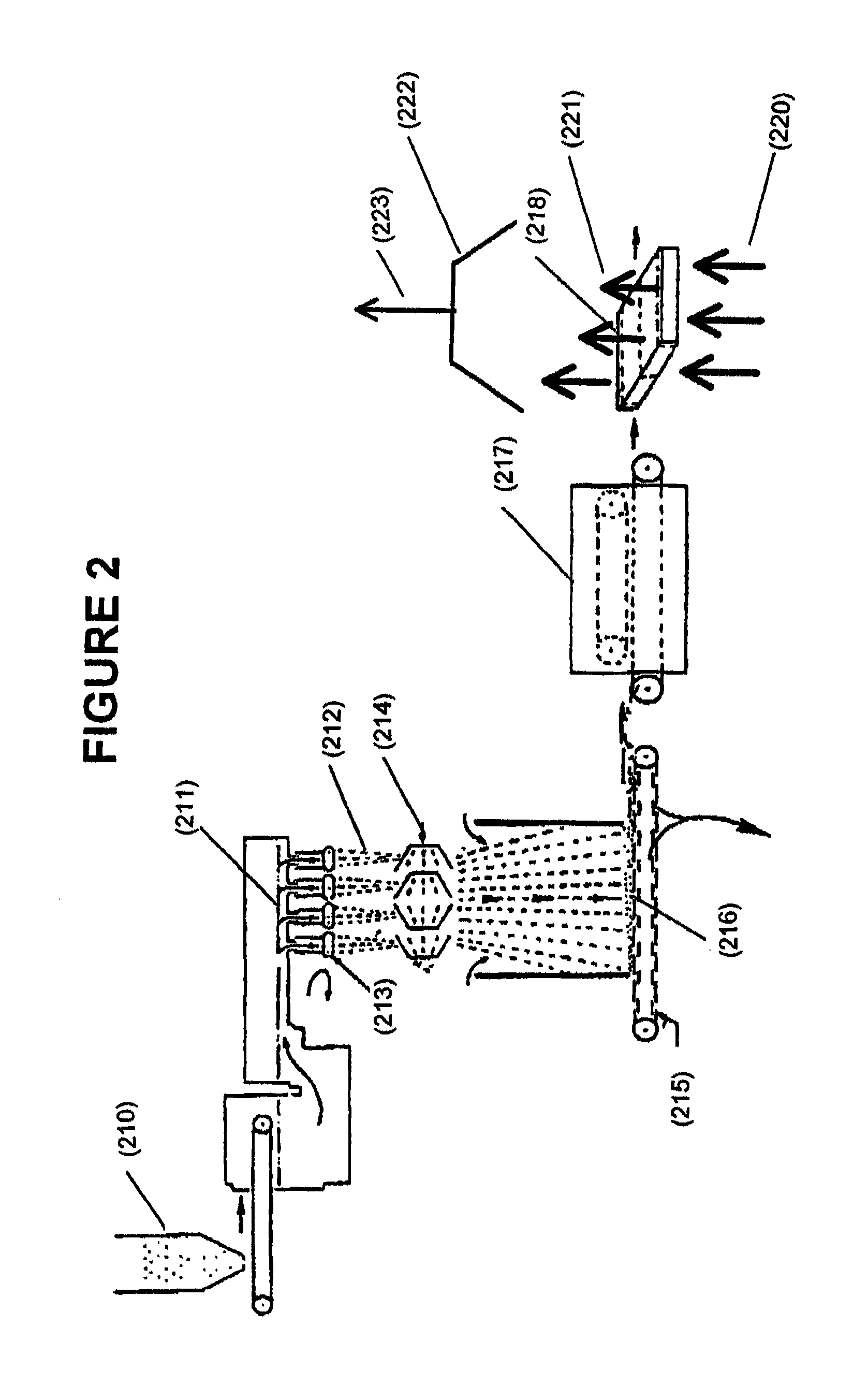

A process for making a fibrous product using a binder based on a formaldehyde-containing resin and especially for making fiberglass insulation, and to the fibrous product itself, wherein a formaldehyde scavenger is separately applied to the fibrous mat, such as by treating the fibers with an aqueous mixture consisting essentially of the formaldehyde scavenger, with the result that the fibrous product exhibits a reduced level of formaldehyde emissions.

Owner:GEORGIA PACIFIC CHEM LLC

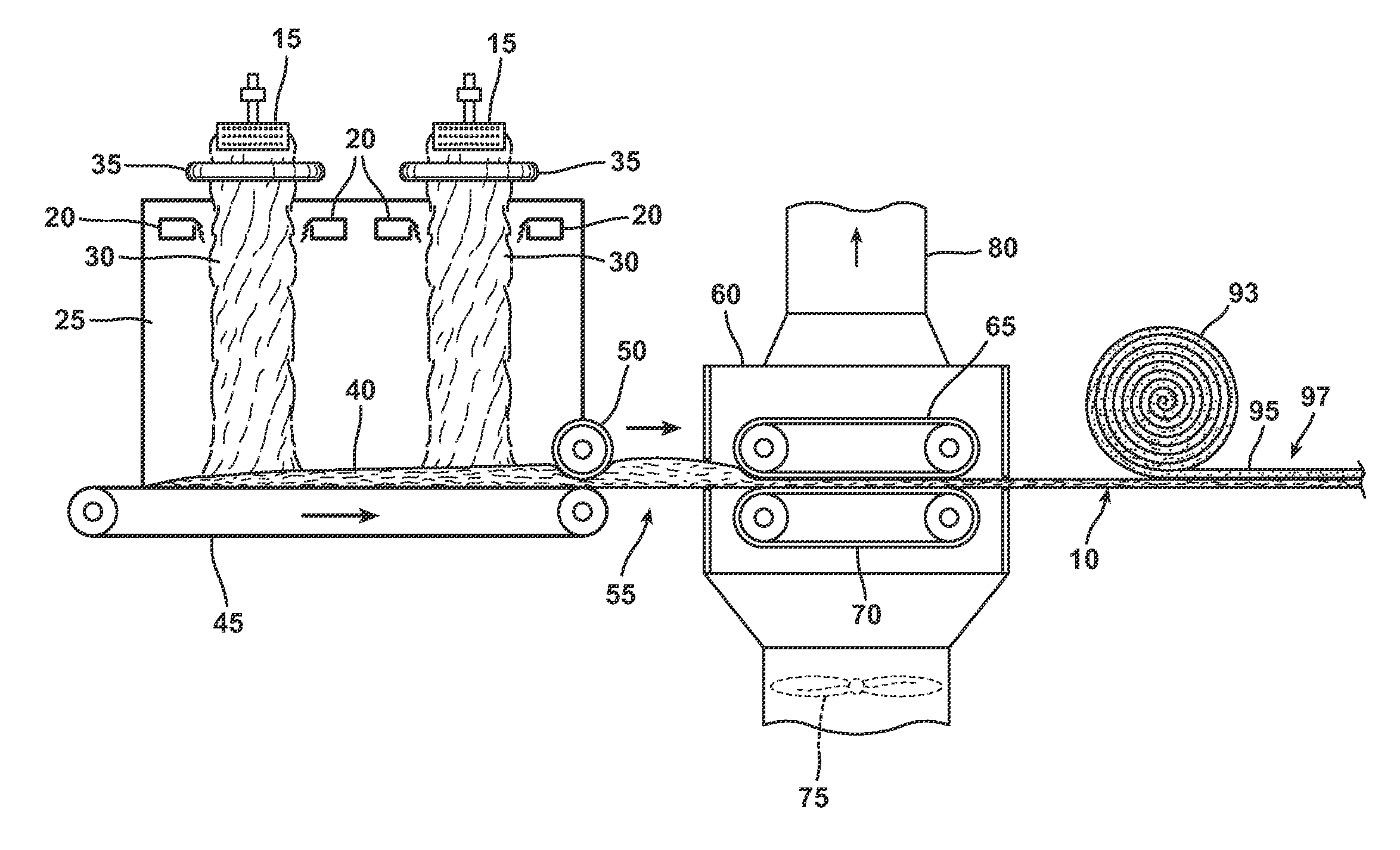

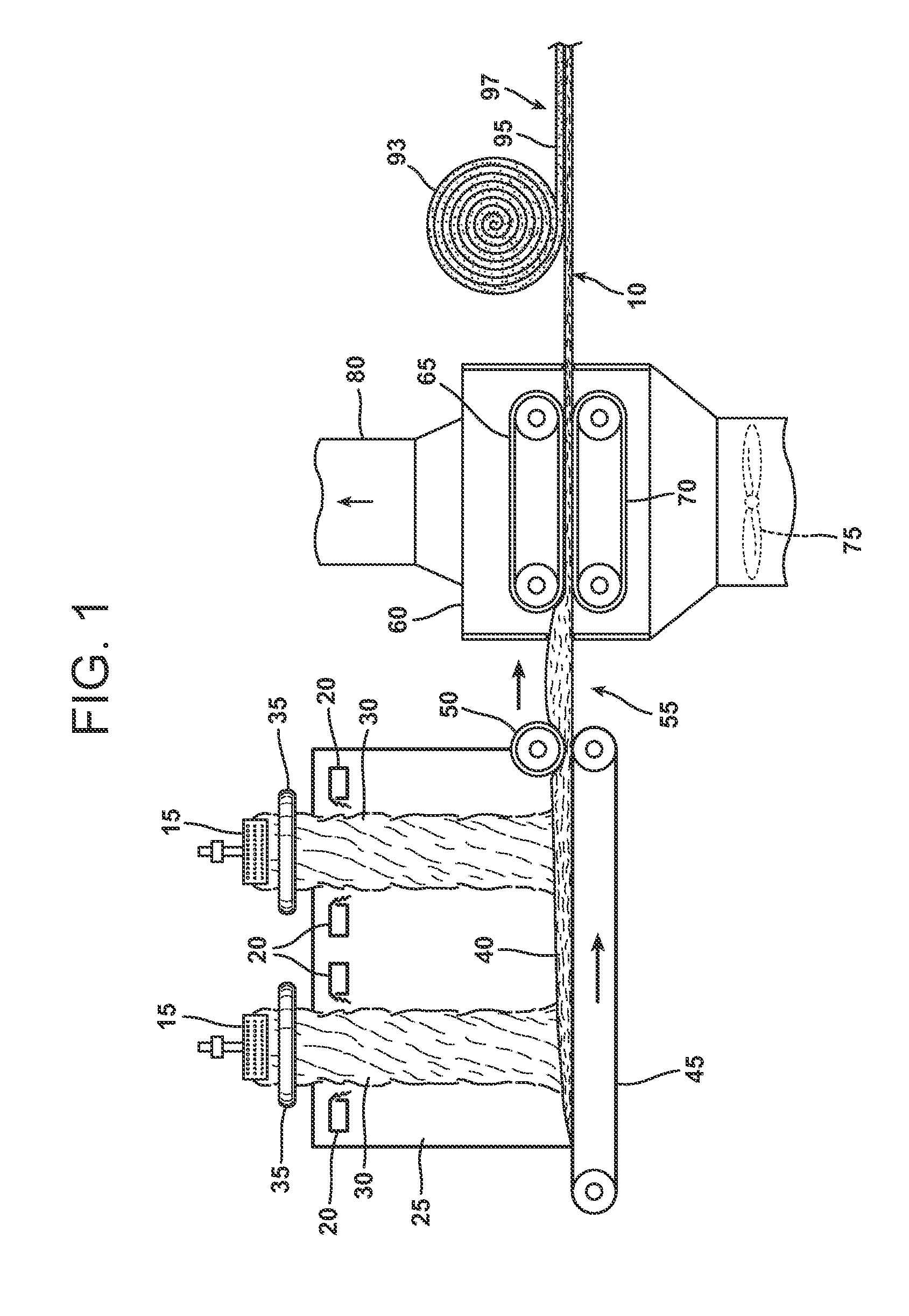

Bio-based aqueous binder for fiberglass insulation materials and non-woven mats

InactiveUS20110003522A1Reduced insulation performanceImprove worker safetyOther chemical processesProtein adhesivesGlass fiberAnimal Sources

An aqueous binder composition is provided that includes a protein-containing biomass and a pH adjuster. Optionally, a crosslinking agent and / or a moisture resistant agent may be included in the binder composition. The protein-containing biomass is natural in origin and may be derived from plant or animal sources. The pH adjuster is used to adjust the pH of the binder to a desired pH and lower the viscosity of the protein-based biomass. In addition, the pH adjuster may act as a crosslinking agent. The crosslinking agent may be any compound suitable for crosslinking the protein-containing biomass and reacting with the moisture resistant agent, when the moisture resistant agent is present in the binder. In addition, the binder has a light color after it has been cured. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

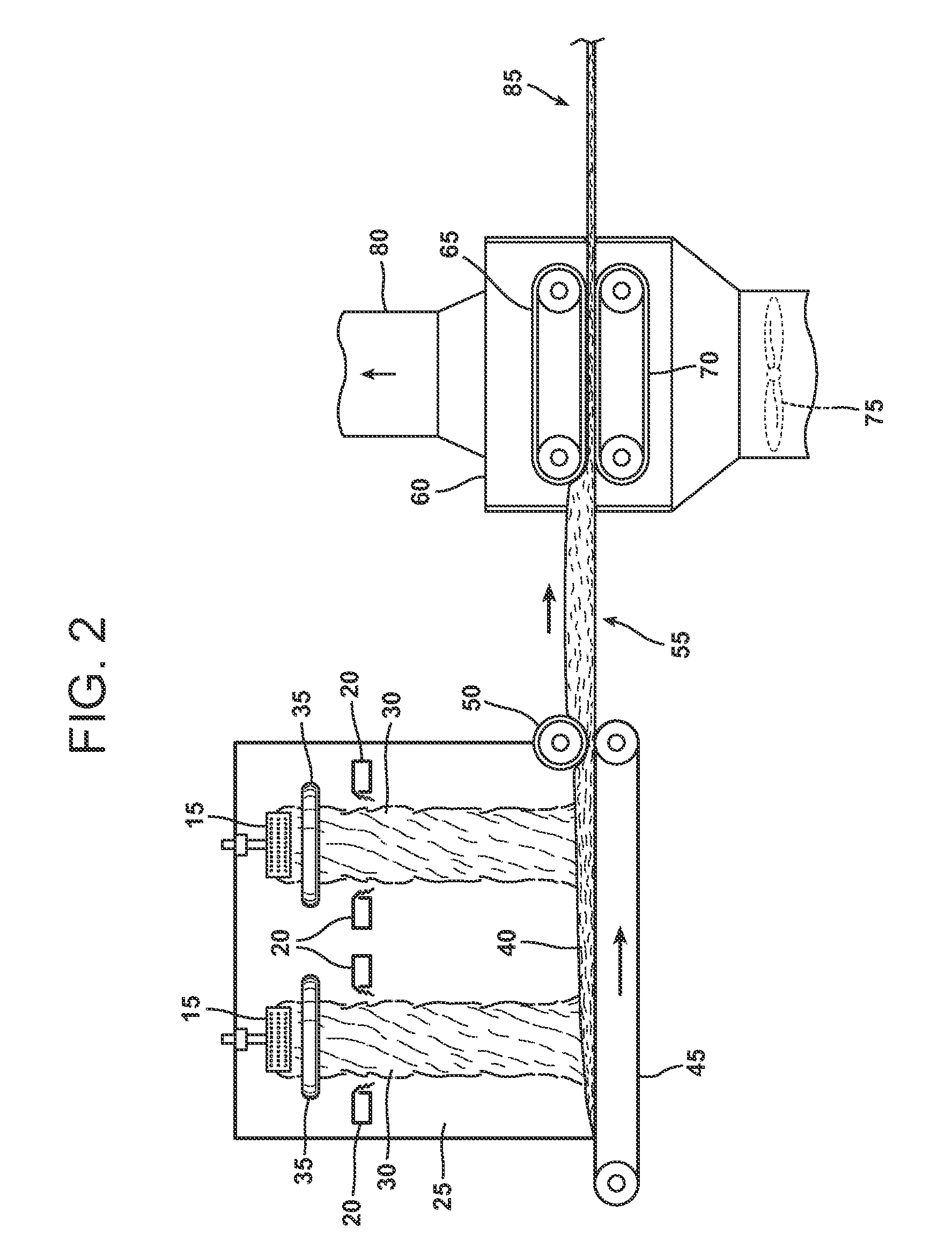

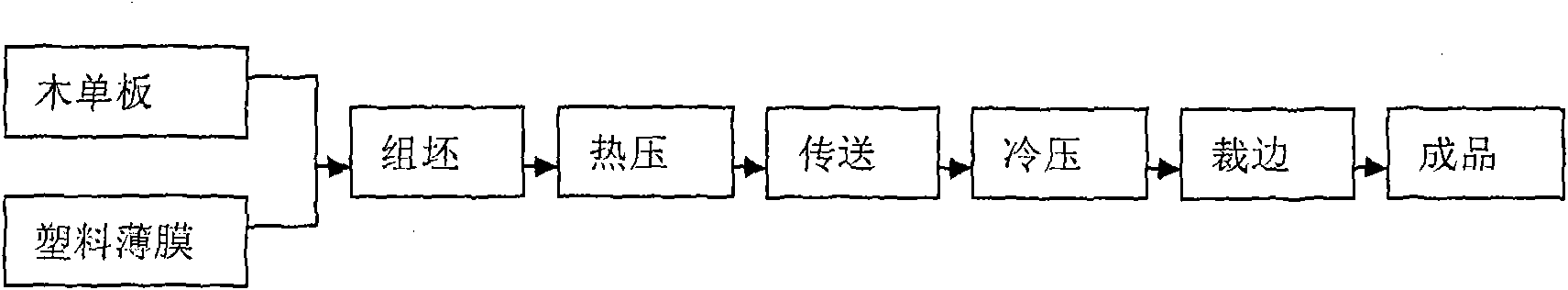

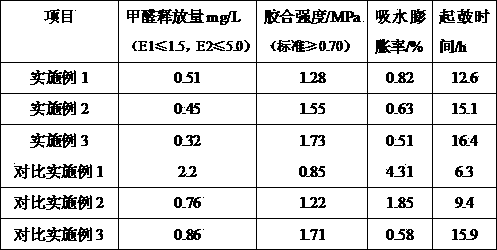

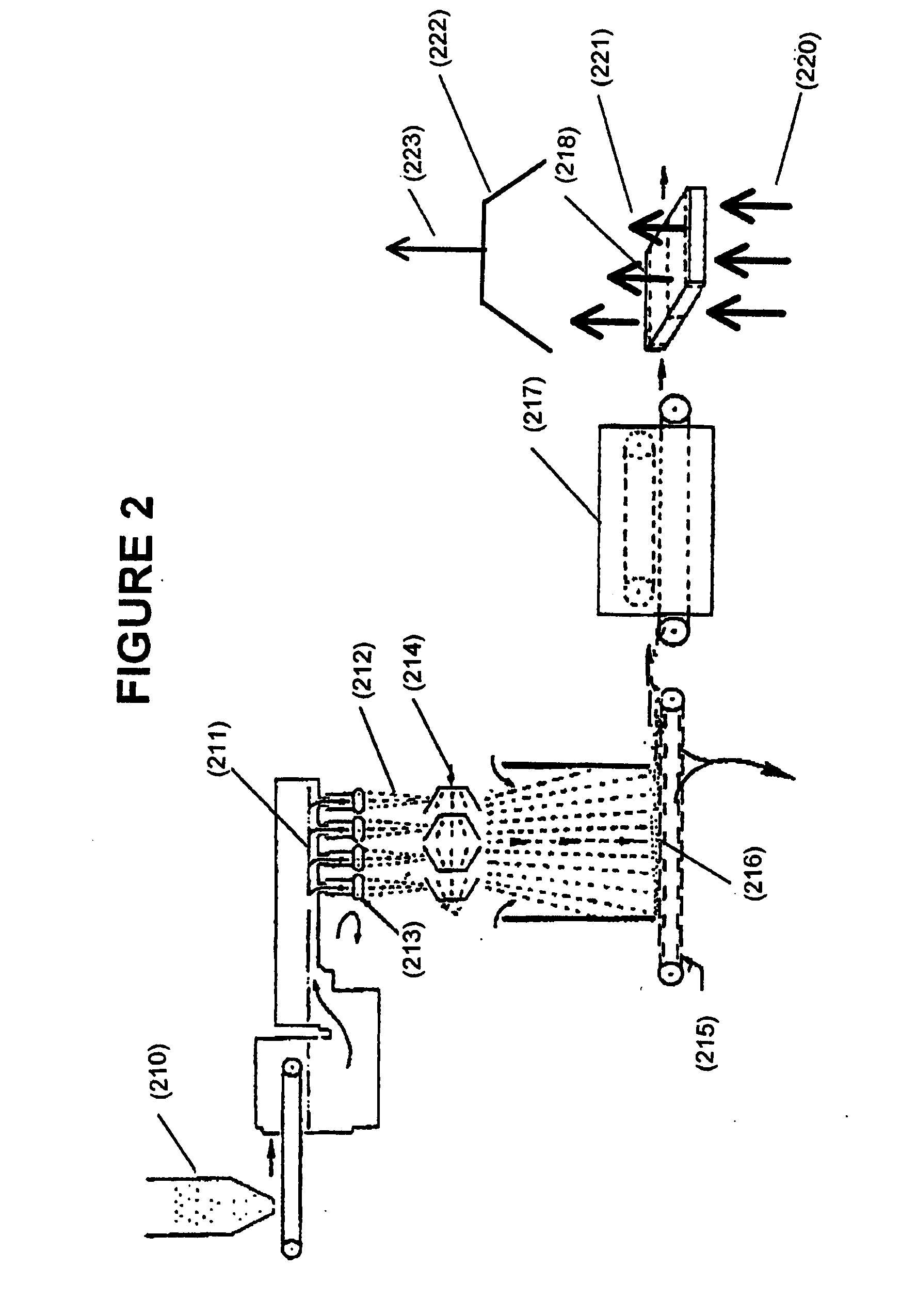

Manufacturing method of thermoplastic resin wood composite board and special equipment

InactiveCN101870127AMeet the use requirementsReasonable workmanshipPlywood pressesVeneer pressesBuilding renovationEngineering

The invention discloses a manufacturing method of thermoplastic resin wood composite board and special equipment. The bonding strength of the thermoplastic resin wood manufactured by the invention is more than 0.7 MPa, has the characteristics of low formaldehyde releasing amount and favourable waterproofness and humidity resistance, has peculiar application value and can be widely applied in the fields of building renovation, furniture, vehicles and ship decoration.

Owner:唐善学

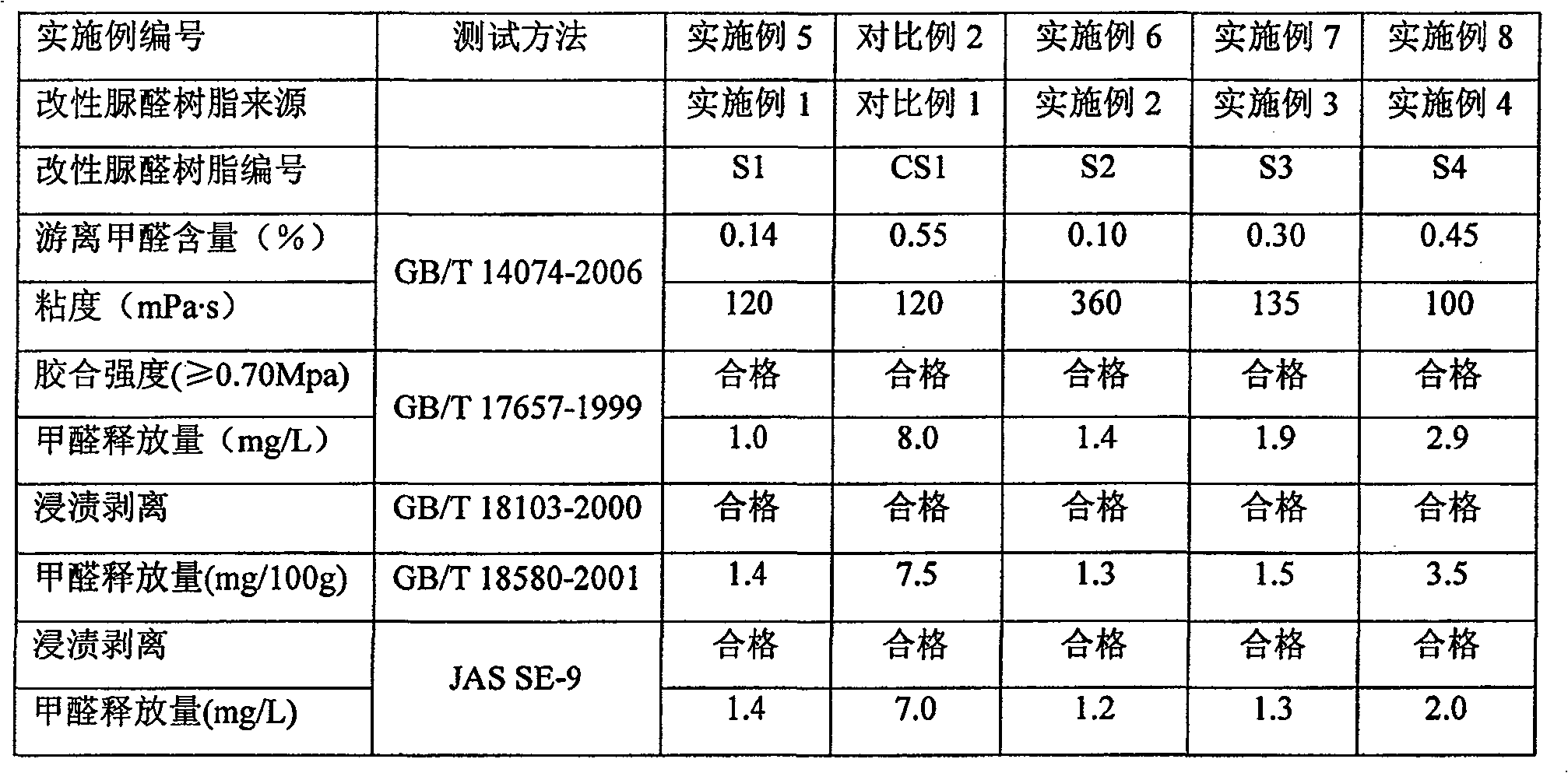

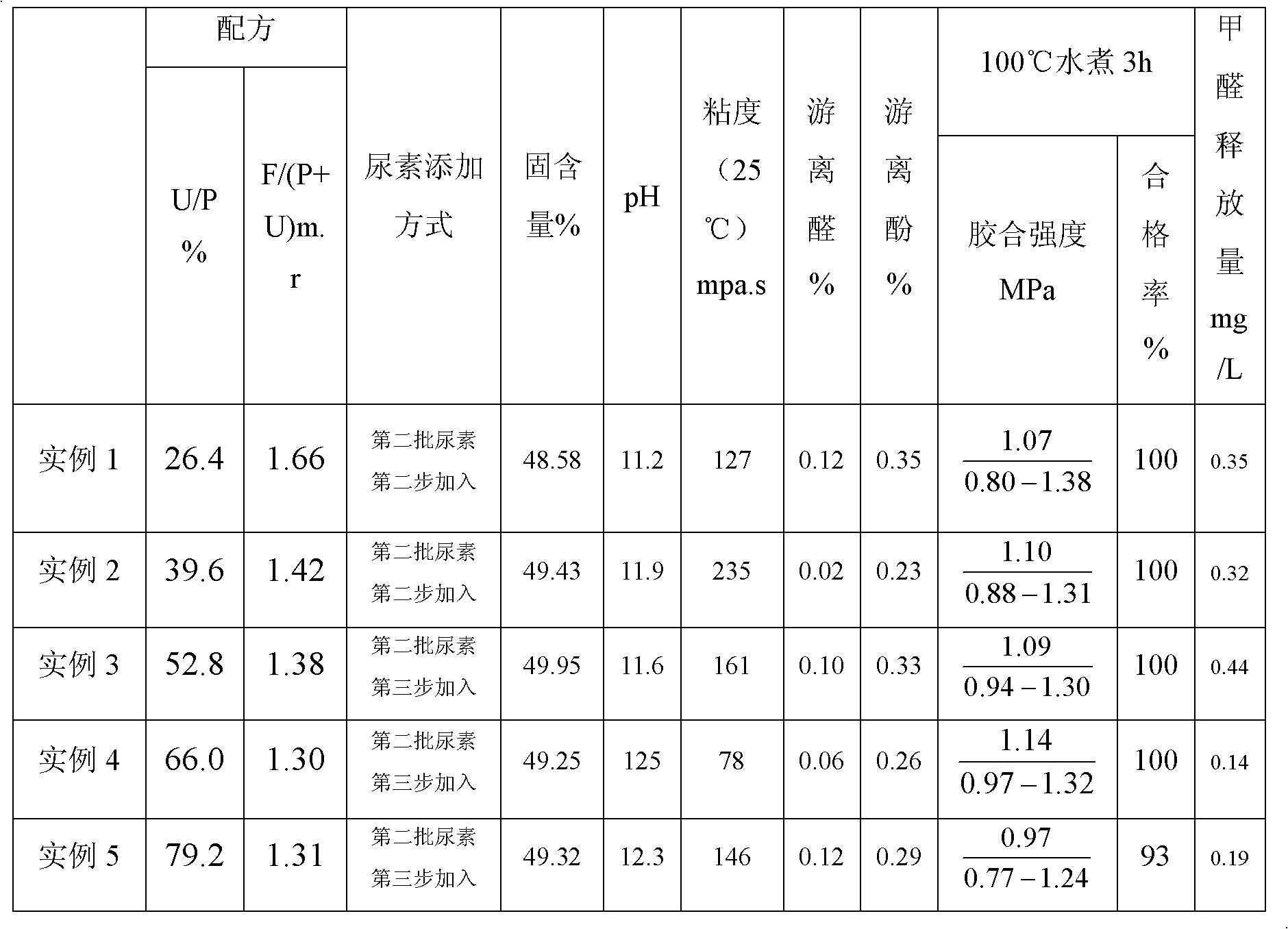

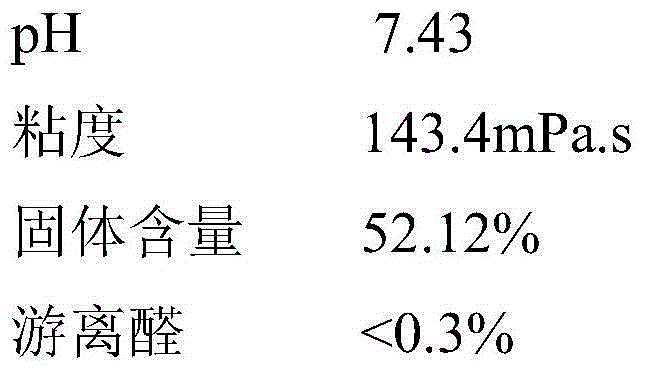

Method for preparing modified urea-formaldehyde resin

InactiveCN100572445CLow free formaldehyde contentReduce formaldehyde emissionPolymer scienceNational standard

A method for preparing a modified urea-formaldehyde resin, the method comprises mixing and contacting the product of the contact reaction between formaldehyde and urea and a urea-formaldehyde resin modifier, wherein the urea-formaldehyde resin modifier is added at least twice. The free formaldehyde content of the urea-formaldehyde resin prepared by the preparation method of the modified urea-formaldehyde resin provided by the invention is very low, so that the formaldehyde release amount of wood-based panel products can be greatly reduced when used in the wood manufacturing process. For example, the free formaldehyde content of the modified urea-formaldehyde resin prepared by the method provided by the invention can be reduced to no more than 0.20%, so that the plywood prepared by using the modified urea-formaldehyde resin can reach the E1 (≤1.5 mg / liter) regulation in the national standard . In addition, the modified urea-formaldehyde resin prepared by the method provided by the invention can not only be in liquid form, but also in powder form, and can be used under wet and outdoor conditions.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

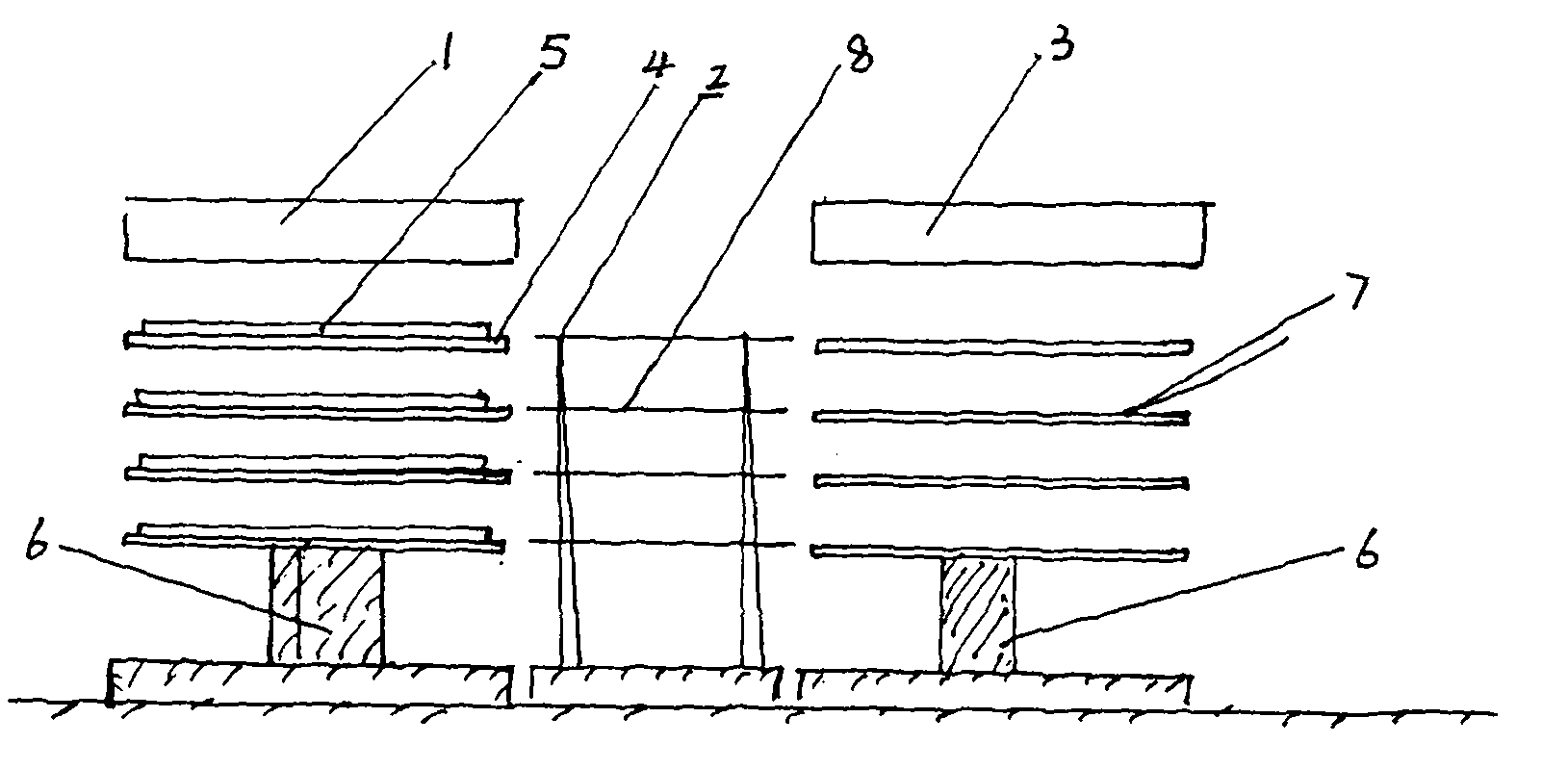

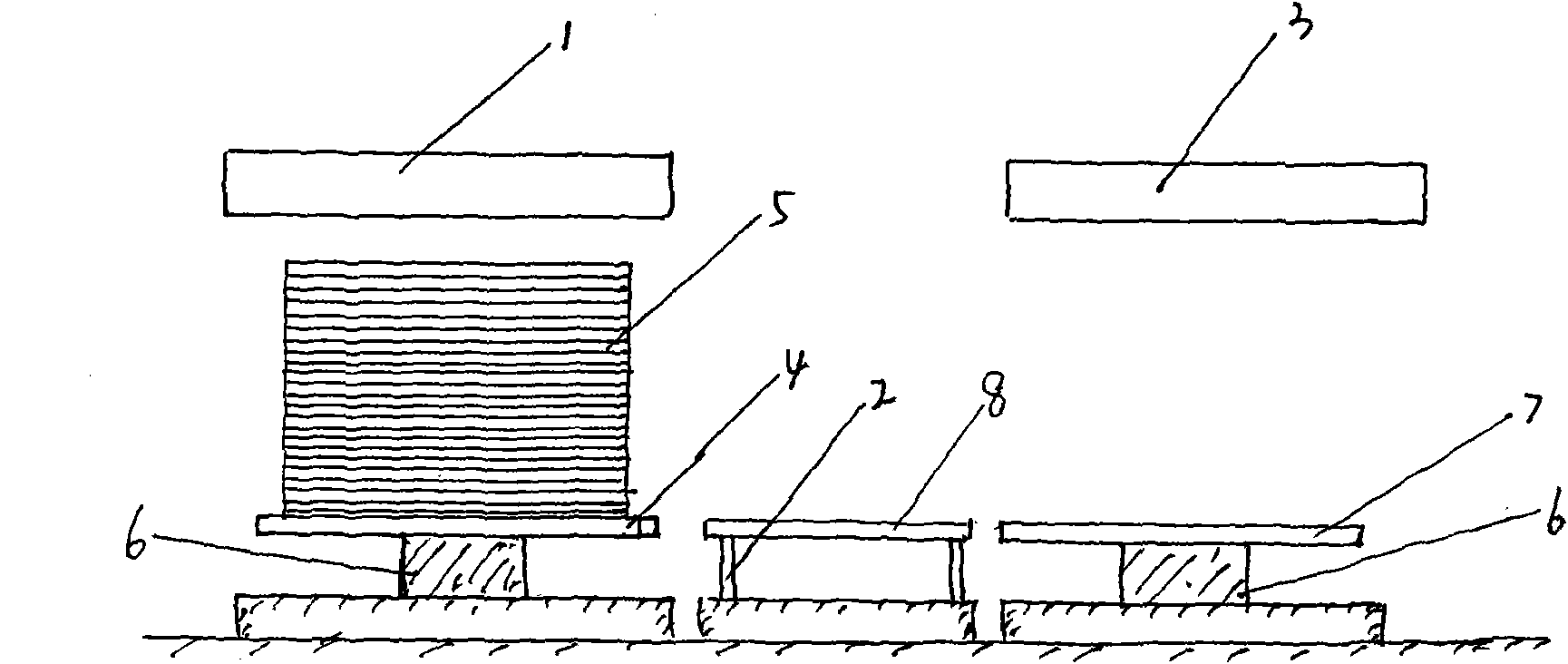

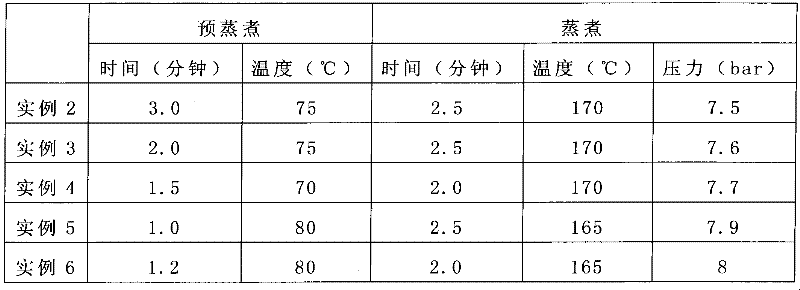

Production method for damp-proof full-eucalyptus laminated wood veneer

ActiveCN103406951AStress reliefReduce water exposurePlywood pressesVeneer pressesWood veneerAdhesive

The invention provides a production method for a damp-proof full-eucalyptus laminated wood veneer. The artificial board is formed by high-temperature pressing and pasting of a base material and melamine impregnated paper, wherein the base material is formed by bonding a plurality of layers of eucalyptus veneers through adhesives. The production method comprises the steps of veneer sorting, gluing, cold pressing, hot pressing, stacking maintenance and pasting of the melamine impregnated paper. The production method is characterized in that three times of cold pressing and hot pressing and two times of thermostatic chamber standing maintenance and cooling maintenance processes are adopted, the cold pressing is performed at the room temperature and under the pressure of 0.8-1.0MPa, the hot pressing is performed under the pressure of 1.5-2.0MPa, the first hot pressing is performed at the temperature of 120-125DEG C, the second hot pressing is performed at the temperature of 115-120DEG C, and the third hot pressing is performed at the temperature of 125-130DEG C; the thermostatic chamber standing maintenance is performed at the temperature of 80-90DEG C for 4-6h; the cooling maintenance is cooled to the room temperature from the temperature of a thermostatic chamber through natural ventilation for 3-4h.

Owner:莫明鑫

Porous fiberglass materials having reduced formaldehyde emissions

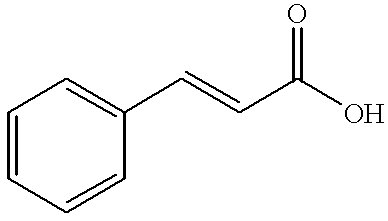

InactiveUS20080138526A1Reduce stretchReduce formaldehyde emissionPretreated surfacesBuilding constructionsGlass fiberScavenger

The present invention relates to formaldehyde scavenger treatments for porous fiberglass material having formaldehyde emitting binders thereon. The invention also relates to methods of making porous fiberglass material having reduced formaldehyde emissions.

Owner:GEORGIA PACIFIC CHEM LLC

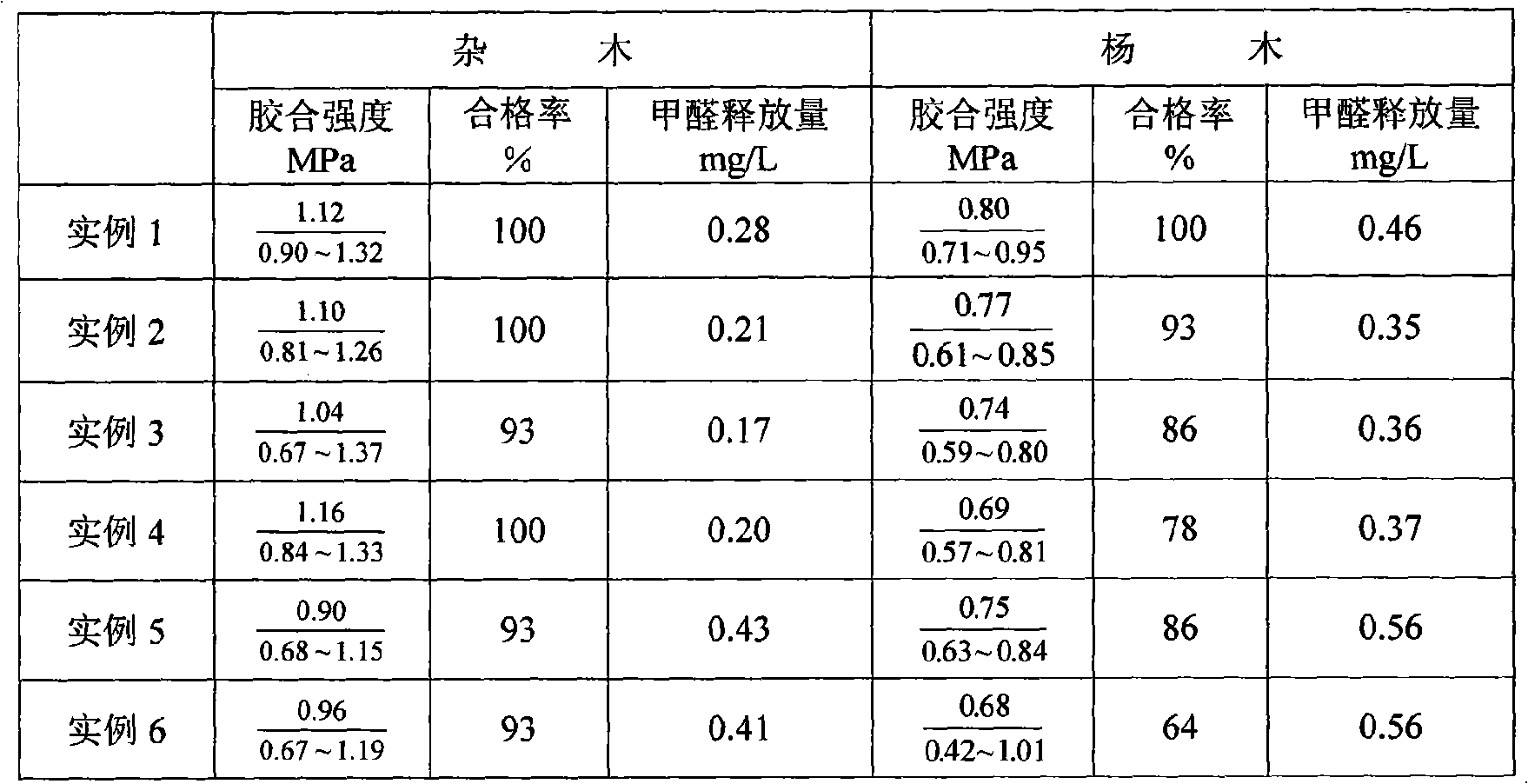

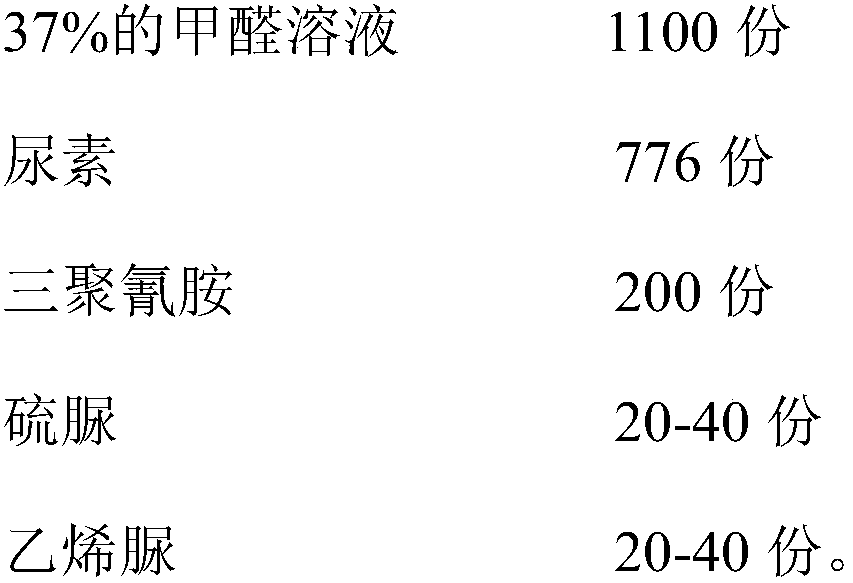

Preparation method of low-cost UMF resin adhesive used for E0-level plywood

InactiveCN101550323AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesEtherStrong acids

The invention discloses a preparation method of low-cost UMF resin adhesive used for an E0-level plywood. The preparation method of the adhesive is simple and has good reproducibility, lower cost and long storage period. For serayah plywood and poplar plywood pressed by the adhesive, the bonding strength and the formaldehyde emission thereof conform to the requirements of the E0-level plywood. The preparation method adopts the technique of a strong acid method, urea is selected for adding by four batches; melamine is added by three batches; the urea is added by batches, which can play the role of regulating the molecular weight of resin, especially the third adding of the urea not only can degrade macromolecule parts in rearranged molecules, but also can reduce the content of ether linkage therein, thus reducing the formaldehyde emission.

Owner:NANJING TECH UNIV

Ultralow-aldehyde impregnating adhesive for impregnated paper and preparation method of ultralow-aldehyde impregnating adhesive

InactiveCN108276942AReduce formaldehyde emissionImprove water resistancePolyureas/polyurethane adhesivesMacromolecular adhesive additivesEmulsionAdhesive

The invention discloses an ultralow-aldehyde impregnating adhesive for impregnated paper and a preparation method of the impregnating adhesive. The impregnating adhesive is characterized by being prepared by mixing the following components in parts by weight: 60 to 80 parts of melamine-modified ultralow-aldehyde-level urea resin, 10 to 20 parts of a modifier (1), 10 to 20 parts of a modifier (2) and 1 to 4 parts of a penetrating agent, wherein the modifier (1) is cationic polyurethane resin, and the modifier (2) is acrylate composite emulsion. The Tu-4 cup viscosity of the impregnating adhesive for the ultralow-aldehyde impregnated paper is 12.0 to 15.0 seconds, and the PH value is 6.0 to 8.5. The ultralow-aldehyde impregnating adhesive for the impregnated paper is low in formaldehyde release amount; furthermore, the impregnated paper manufactured by the impregnating adhesive is high in water resistance and high in surface performance when used for producing impregnated paper veneer aldehyde-free artificial board.

Owner:NANNING KETIAN SHUIXING TECH LTD CO

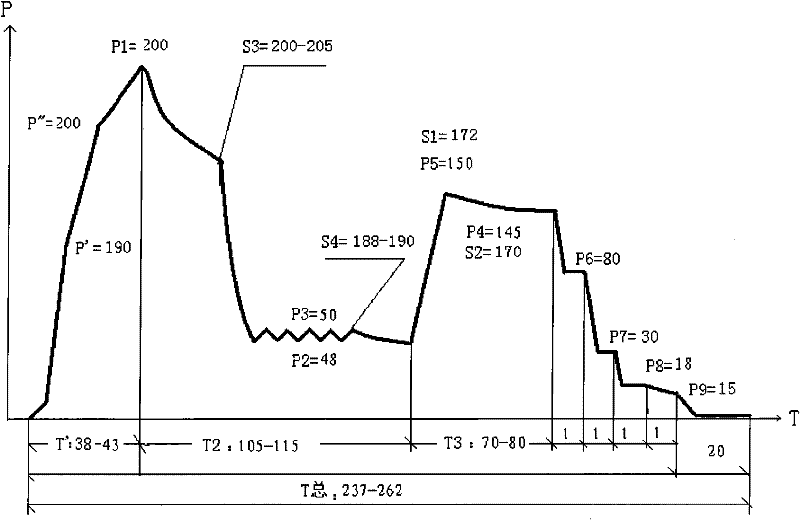

Manufacturing method of high density fiberboard for whitened type E1 grade floor substrate

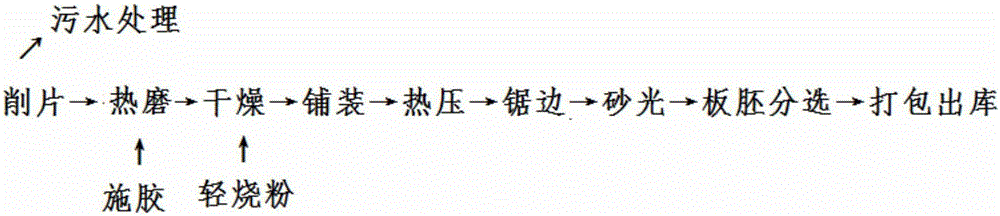

InactiveCN102407553ASmall aspect ratioReduce cellulose contentWood working apparatusFlat articlesHexamethylenetetraminePhosphoric acid

The invention relates to a manufacturing method of a high density fiberboard for a whitened type E1 grade floor substrate, which comprises the steps of wood chipping and screening, pre-stewing and stewing, defibrator process for causing fiber separation, concoction of E1 grade urea formaldehyde resin glue, curing agent preparation, the application of urea-formaldehyde glue, curing agents and paraffins, drying, paving, hot pressing, cooling and tempering, and sanding and saw cutting, and is characterized in that woods are selected from major diameter cottonwoods with diameters larger than 8cm, are evenly chipped and are then placed in an outdoor storage yard to be fermented for 5 to 15 days; in the concoction process of the E1 grade urea formaldehyde resin glue, urea is added at 5 times; and the curing agents are formed by preparing phosphoric acid accounting for 3 to 5 percent of the total content, urotropin accounting for 1 to 3 percent of the total content, triethanolamine accounting for 1 to 3 percent of the total content, and ammonium sulfate accounting for 19 to 21 percent of the total content. The obtained whitened type E1 grade floor substrate has the advantages of little surface impurity, fine and smooth fiber, white color, good visual effect, reasonable density distribution and moderate intensity, and is frequently used for producing top grade indoor laminate flooring and composite floors.

Owner:DARE TECH

Self-cleaning environment-friendly bamboo particle board and method for manufacturing same

The invention discloses a self-cleaning environment-friendly bamboo particle board. The self-cleaning environment-friendly bamboo particle board comprises, by weight, 100 parts of bamboo particles, 10-15 parts of additives, 8-10 parts of activators, 0-5 parts of adhesive, 0.5-1.0 part of waterproof agents, 0.5-10 parts of adsorbents and 0.2-0.5 part of cleaning agents. The invention further discloses a method for manufacturing the bamboo particle board. The self-cleaning environment-friendly bamboo particle board and the method have the advantages that the particle board is made of waste ethanol residues of wood fuel, the absorbents, the cleaning agents, the waterproof agents and the like, the performance of the manufactured particle board can reach national standards, usage of the traditional adhesive can be prevented or reduced, and accordingly formaldehyde emission of the particle board can be greatly reduced; indoor pollution gas can be effectively absorbed by the manufactured particle board with the adsorbents, self-cleaning effects can be realized by the aid of the cleaning agents on the surfaces of the self-cleaning environment-friendly bamboo particle board, and accordingly the self-cleaning environment-friendly bamboo particle board is suitable for building decoration.

Owner:ZHEJIANG FORESTRY UNIVERSITY

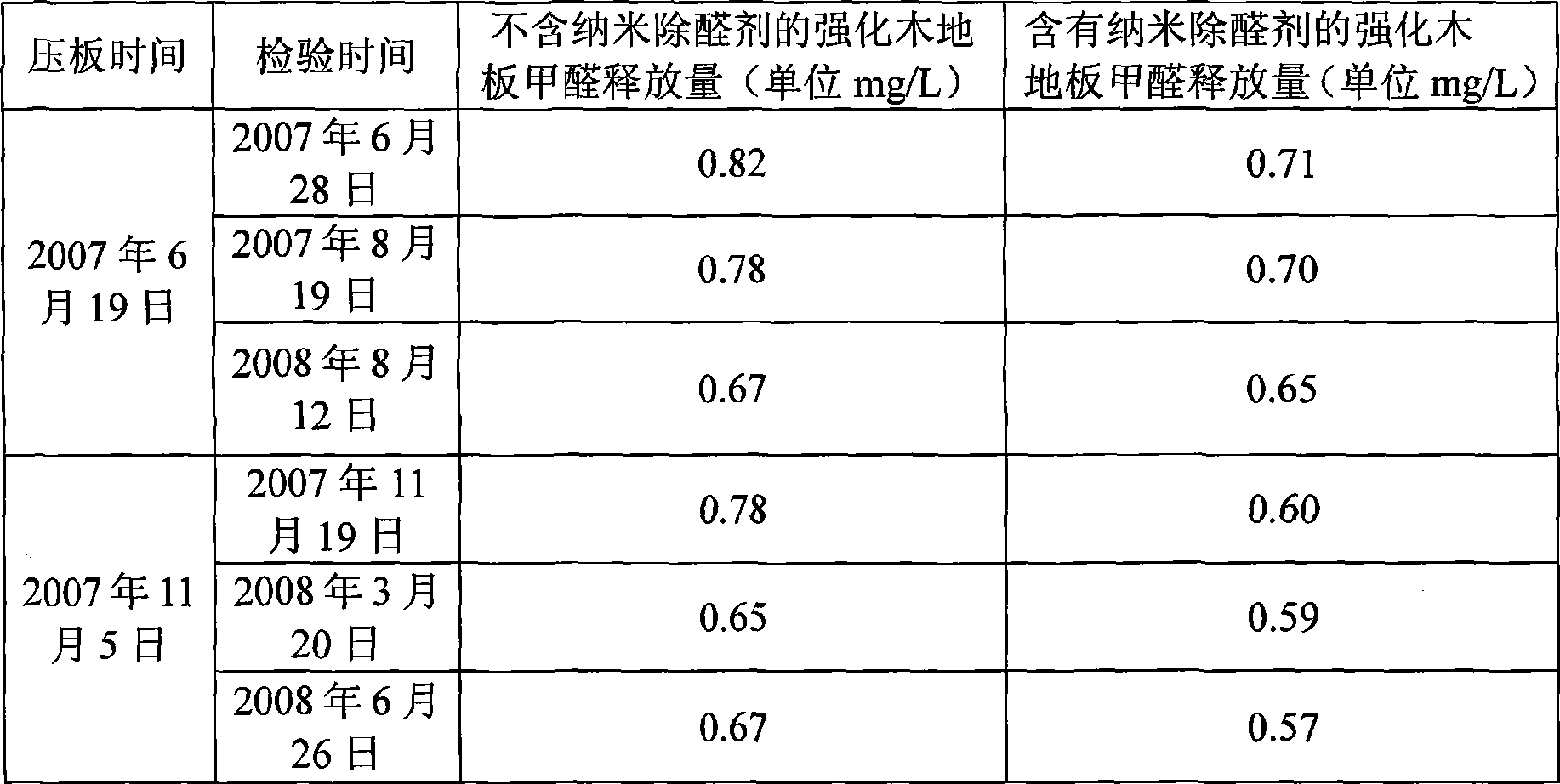

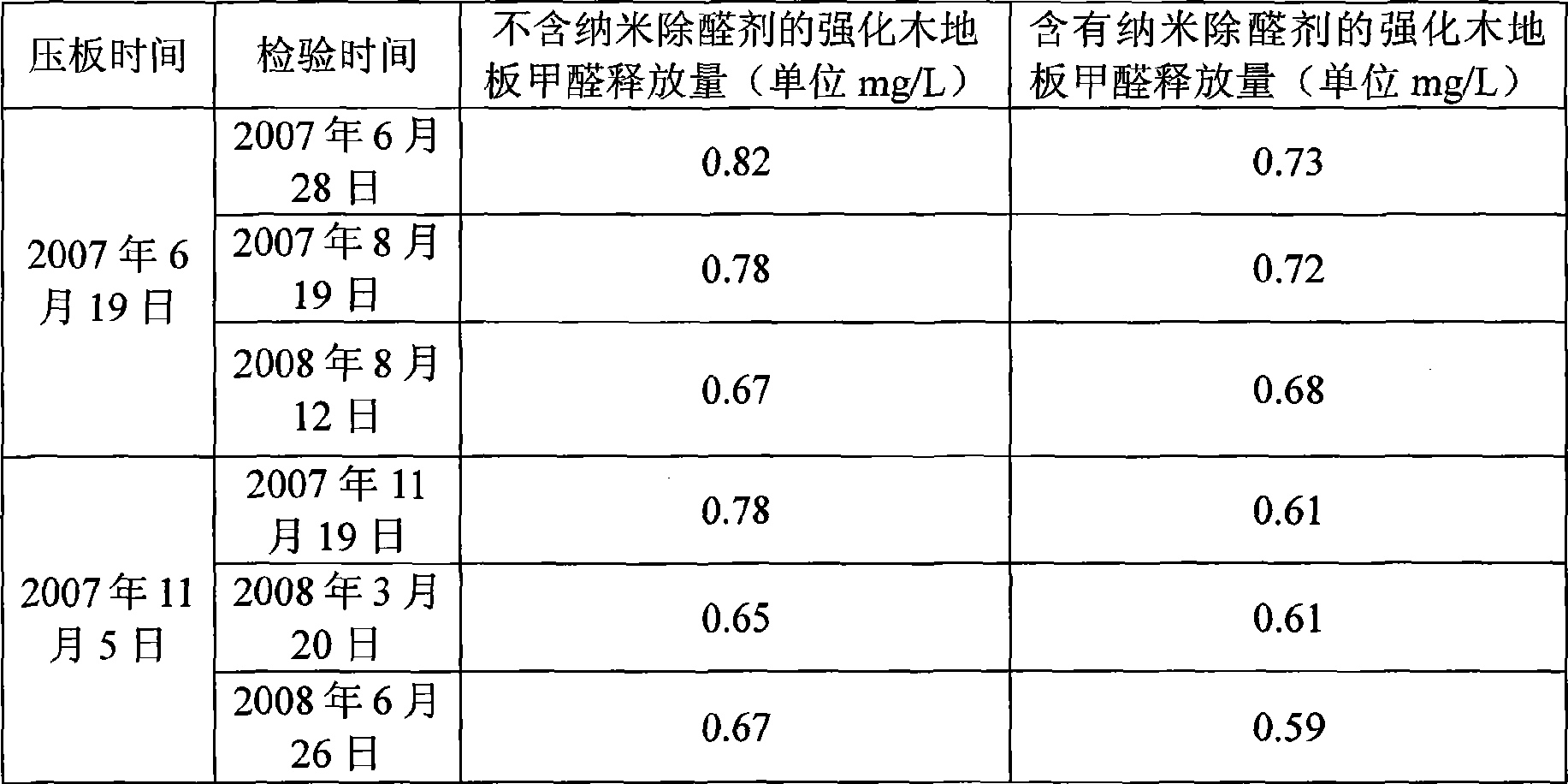

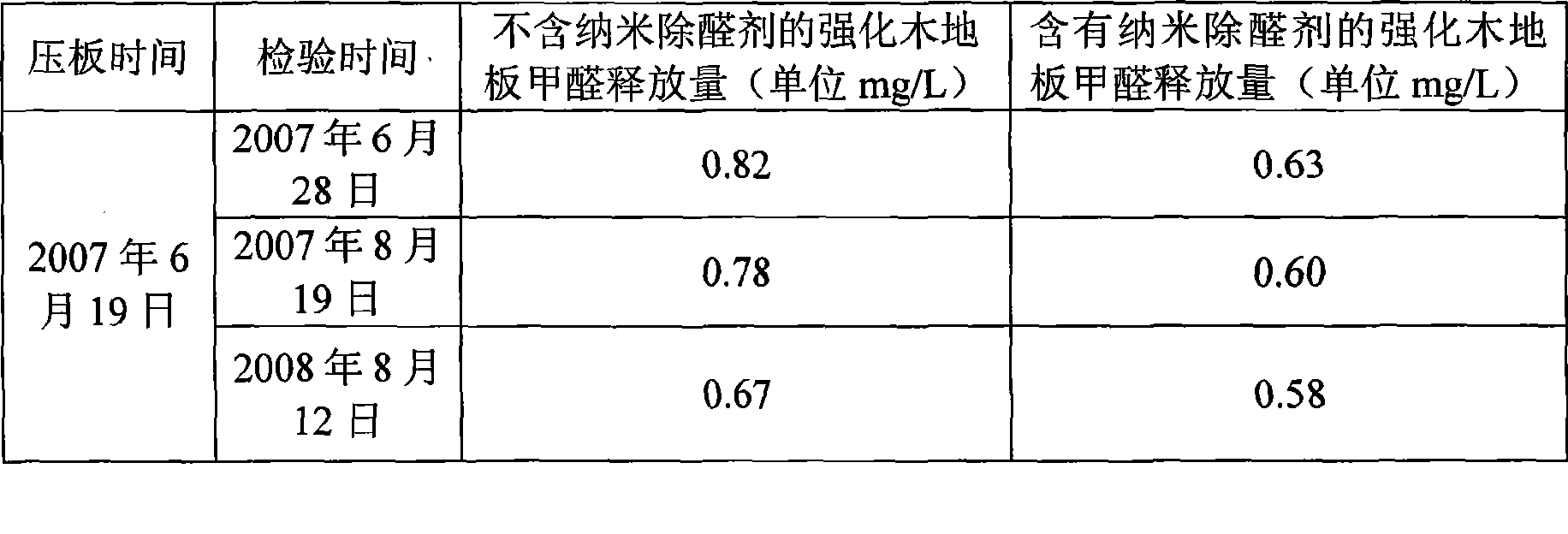

Intensified wooden floor capable of reaching EO grade standard

ActiveCN101418636AReduce formaldehyde emissionSimple processing technologyPaper/cardboard layered productsWood layered productsMedium density fiberboardPulp and paper industry

The invention discloses a laminate flooring which can reach the EO standard. The laminate flooring is formed by hot pressing dipped abrasion resistant paper, decoration paper, balance paper, and medium density fiberboard, wherein the abrasion resistant paper is made by dipping melamine resin added with nano aldehyde removing agent, the weight percent of the nano aldehyde removing agent in the composition is 1% to 20%, and the other is melamine resin. The formaldehyde releasing amount of the laminate flooring is very low and can reach EO standard, which reduces the harm of formaldehyde to the human health and achieves the purpose of environmental protection. The processing technology of the laminate flooring is simple, only need adding prepared nano aldehyde removing agent to the melamine resin for dipping abrasion resistant paper, and then processing the abrasion resistant paper, decoration paper, balance paper, and medium density fiberboard into the laminate flooring by conventional processes.

Owner:圣象实业(江苏)有限公司

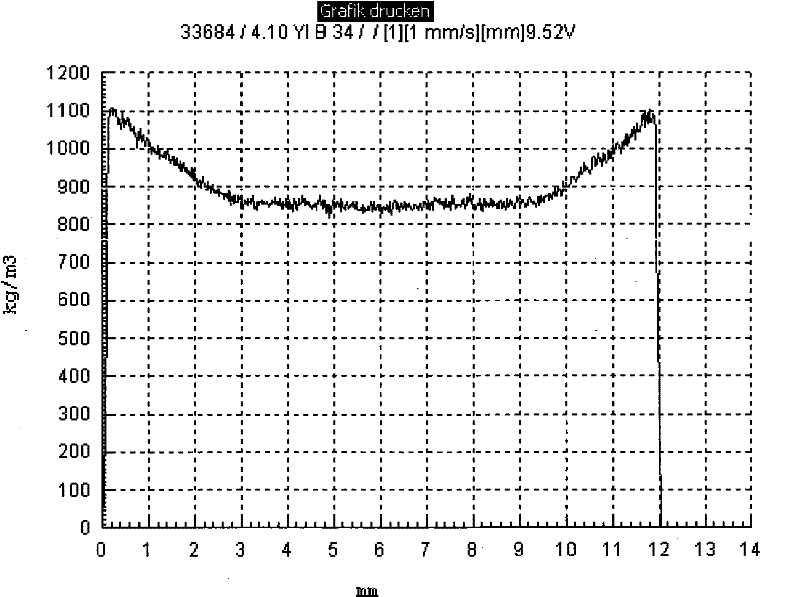

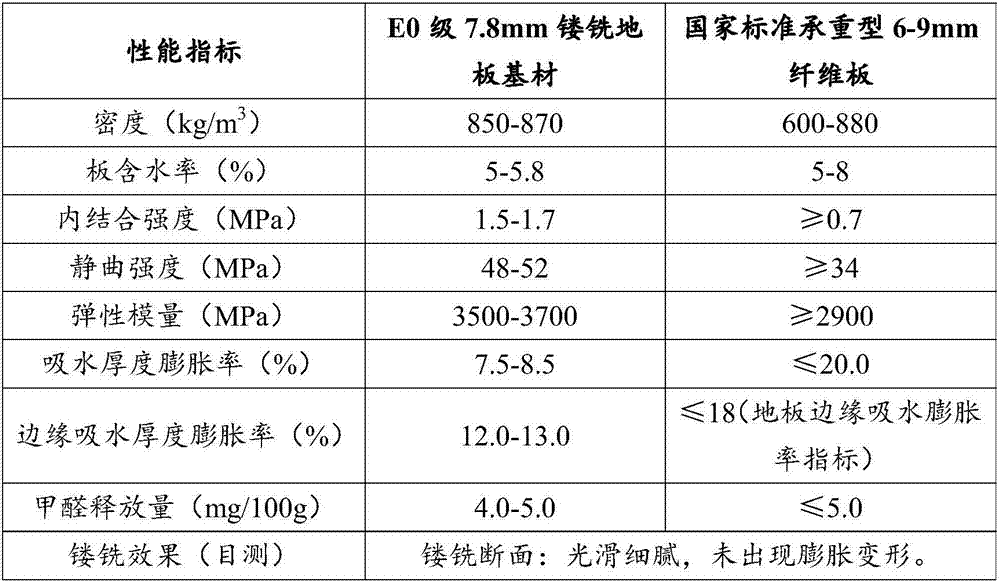

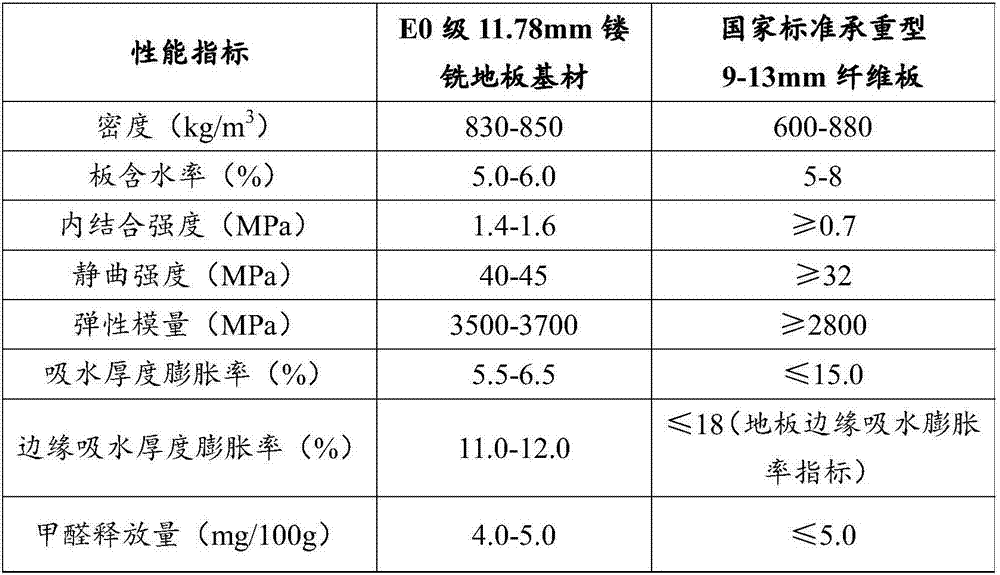

E0 class low imbibitions routing fibreboard and production method thereof

ActiveCN107030841AReduce formaldehyde emissionImprove water resistanceWood working apparatusFlat articlesWater basedAdhesive

The invention discloses an E0 class low imbibitions routing fibreboard and a production method thereof, further discloses a preparing method of water-resistant type melamine modified urea resin for producing the E0 class low imbibitions routing fibreboard, and belongs to the technical field of fibreboard manufacturing. The preparing method of the water-resistant type melamine modified urea resin includes the steps that an acid-acid-alkali-alkali synthetic process is adopted for synthesizing the water-resistant type melamine modified urea resin with the PH value being 8.5 to 9.0, the viscosity number being 16.0 S to 20.0 S and the solid content being 54.0% to 57.0% through four stages including an acid addition reaction, acid primary polycondensation, alkaline secondary polycondensation and alkaline aftertreatment. The preparing method of adhesive is improved and optimized, abrasive disc screening, hot milling and hot pressing production technological parameters of the fibreboard preparing are adjusted, the aim of reducing the formaldehyde emission of the routing fibreboard to the E0 class standard is achieved, and the problem that moisture absorption deformation is prone to occurrence in the routing machining or veneering machining (adopting the water-based type adhesive) and using process is solved.

Owner:DARE WOOD BASED PANEL GRP

Composite urea formaldehyde resin curing agent as well as preparation method and application thereof

InactiveCN101870773ANo hydrolysisLong application periodNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesWorking lifeResin adhesive

The invention discloses a composite urea formaldehyde resin curing agent as well as a preparation method and application thereof. The composite urea formaldehyde resin curing agent comprises the following components: catalyst, controlled release formulations, pH stabilizing agent and water. After the composite urea formaldehyde resin curing agent of the invention is directly mixed into urea formaldehyde resin adhesive with low molar ratio, the curing rate and the curing performance of the urea formaldehyde resin adhesive with low molar ratio can be effectively improved, and thereby the bonding strength thereof is improved and the formaldehyde released content thereof is obviously reduced, and the production efficiency and the product quality are improved; and moreover, the composite urea formaldehyde resin curing agent of the invention has long working life, and can meet the requirements of production operation of artificial boards.

Owner:EVERFIRST WISEFUND TECH BEIJING

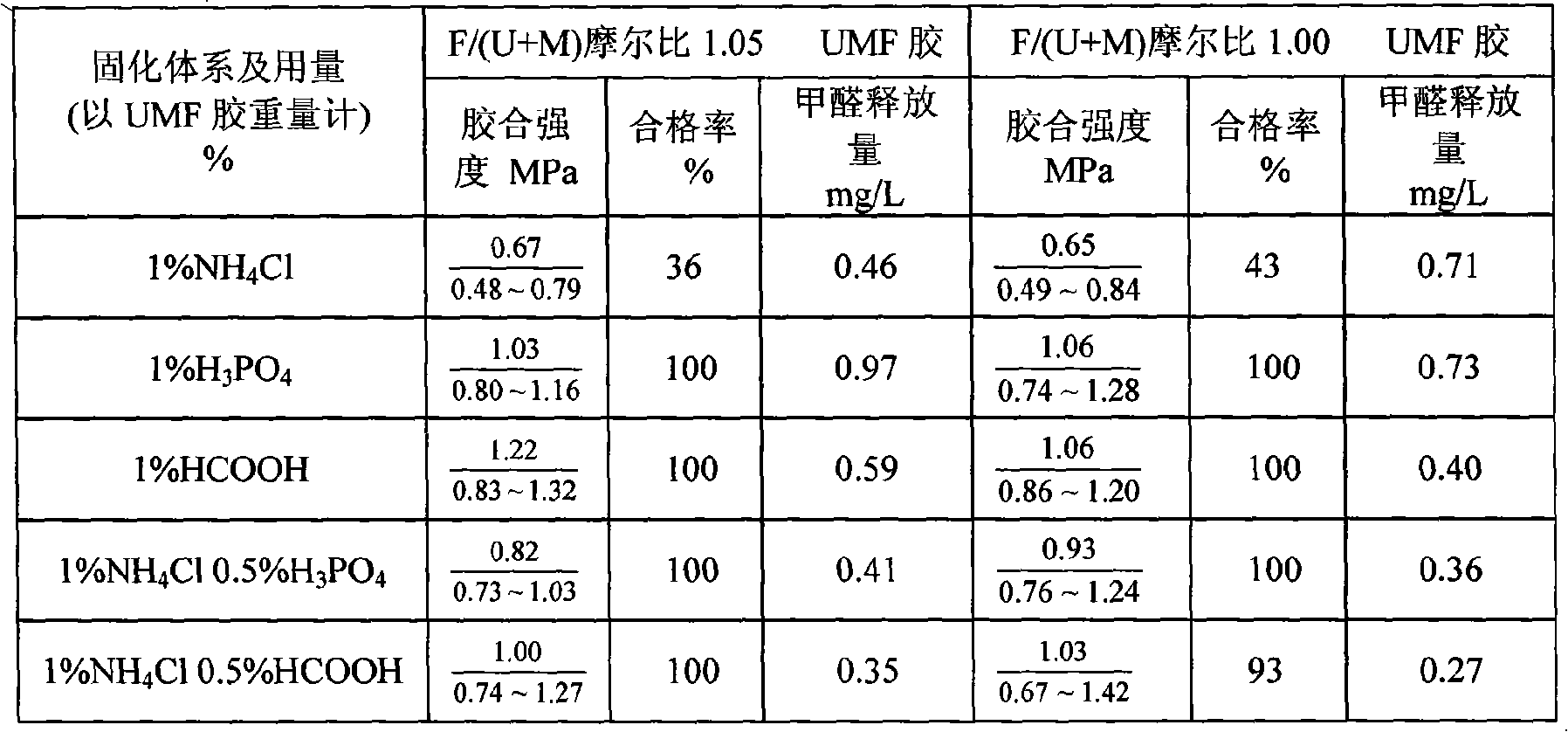

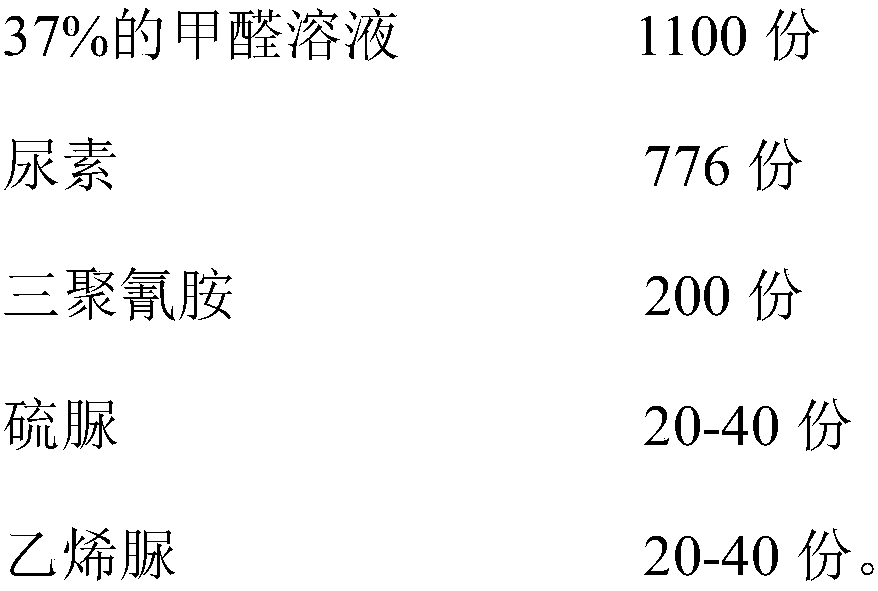

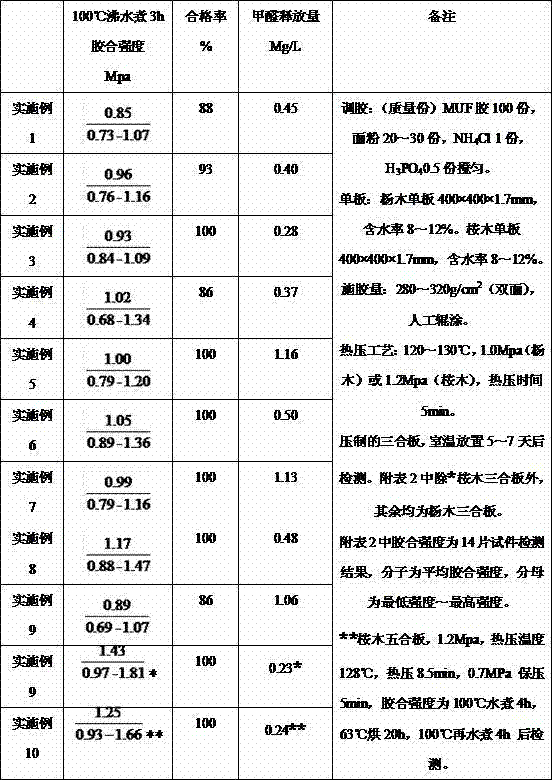

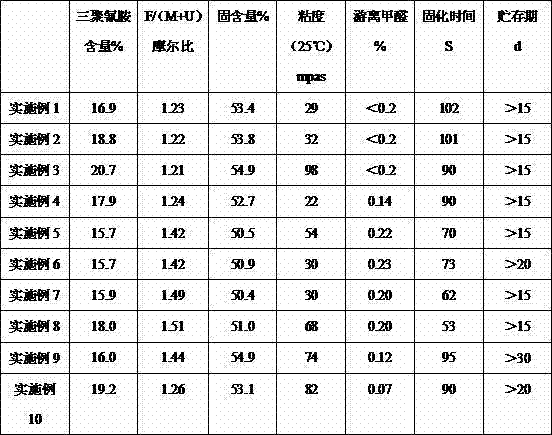

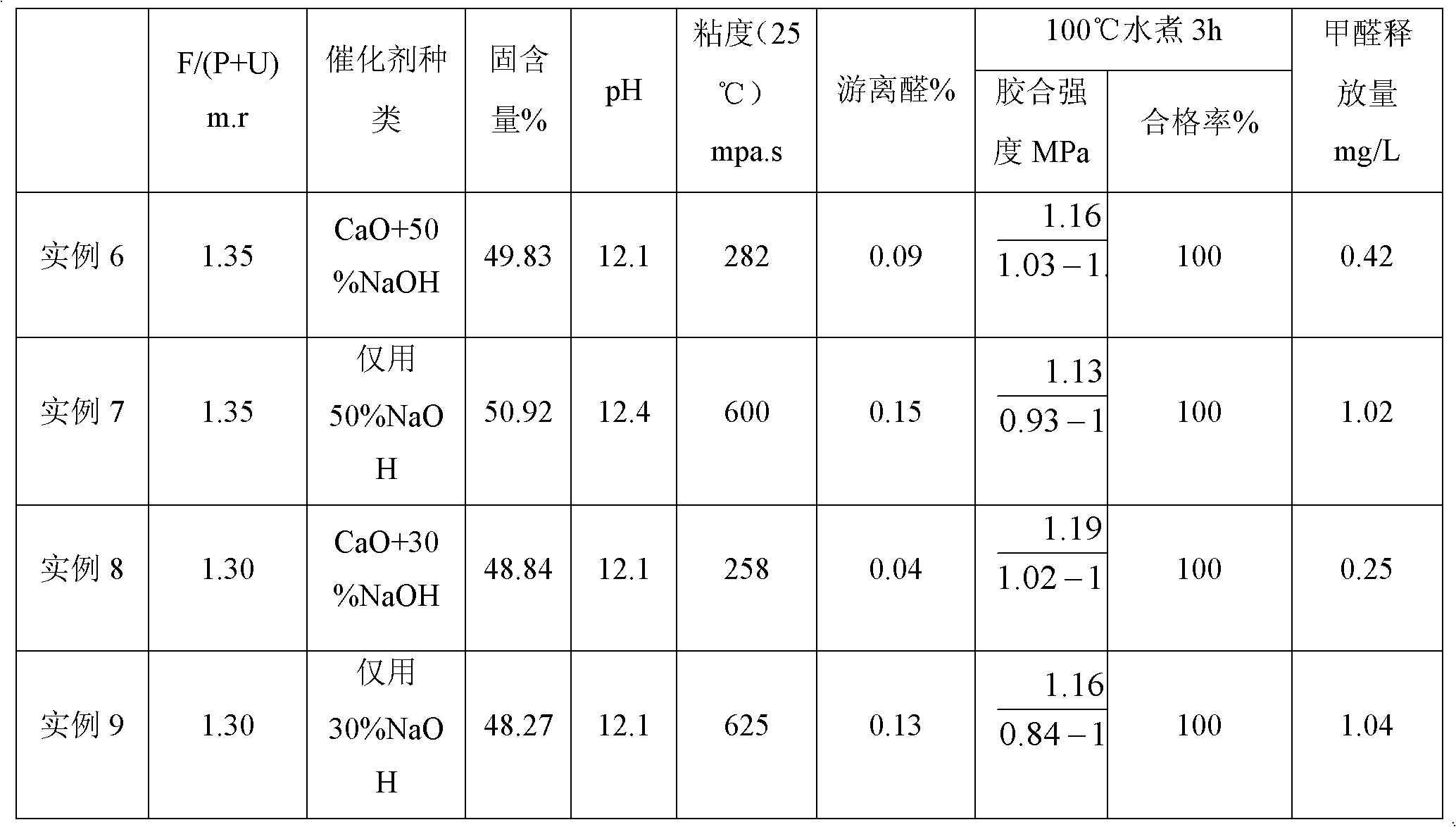

Method for preparing melamine-urea-formaldehyde resin adhesives for outdoor plywood low in formaldehyde release

InactiveCN102775571AExtended shelf lifeFast curingAldehyde/ketone condensation polymer adhesivesWood veneer joiningPolymer scienceResin adhesive

The invention discloses a method for preparing melamine-urea-formaldehyde resin adhesives for outdoor plywood low in formaldehyde release. The method includes adding formaldehyde solution, melamine and urea into a reactor, adjusting pH value to the cloud point; adding urea and melamine for reaction; adding melamine, adding urea for subsequent reaction, and cooling before discharging. According to the convention process of alkali-acid-alkali, the melamine and the urea are added by three steps, ply bond of plywood made of plying the MUF (melamine, urea and formaldehyde) resin adhesives made of 16-20% of modified melamine is accordant with the requirements of the first type of plywoods. According to difference of usage the melamine and F / (M+U) mole ratio, the formaldehyde release of the plywood is accordant with the E1 level or E0 level. The method for preparing melamine-urea-formaldehyde resin adhesives is mild in reaction, easy to control and fine in repeatability, storage life of the adhesives is longer than 15 days. The MUF resin adhesives are lacte and faster in curing and are lower in temperature and cost than those of phenol glue.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

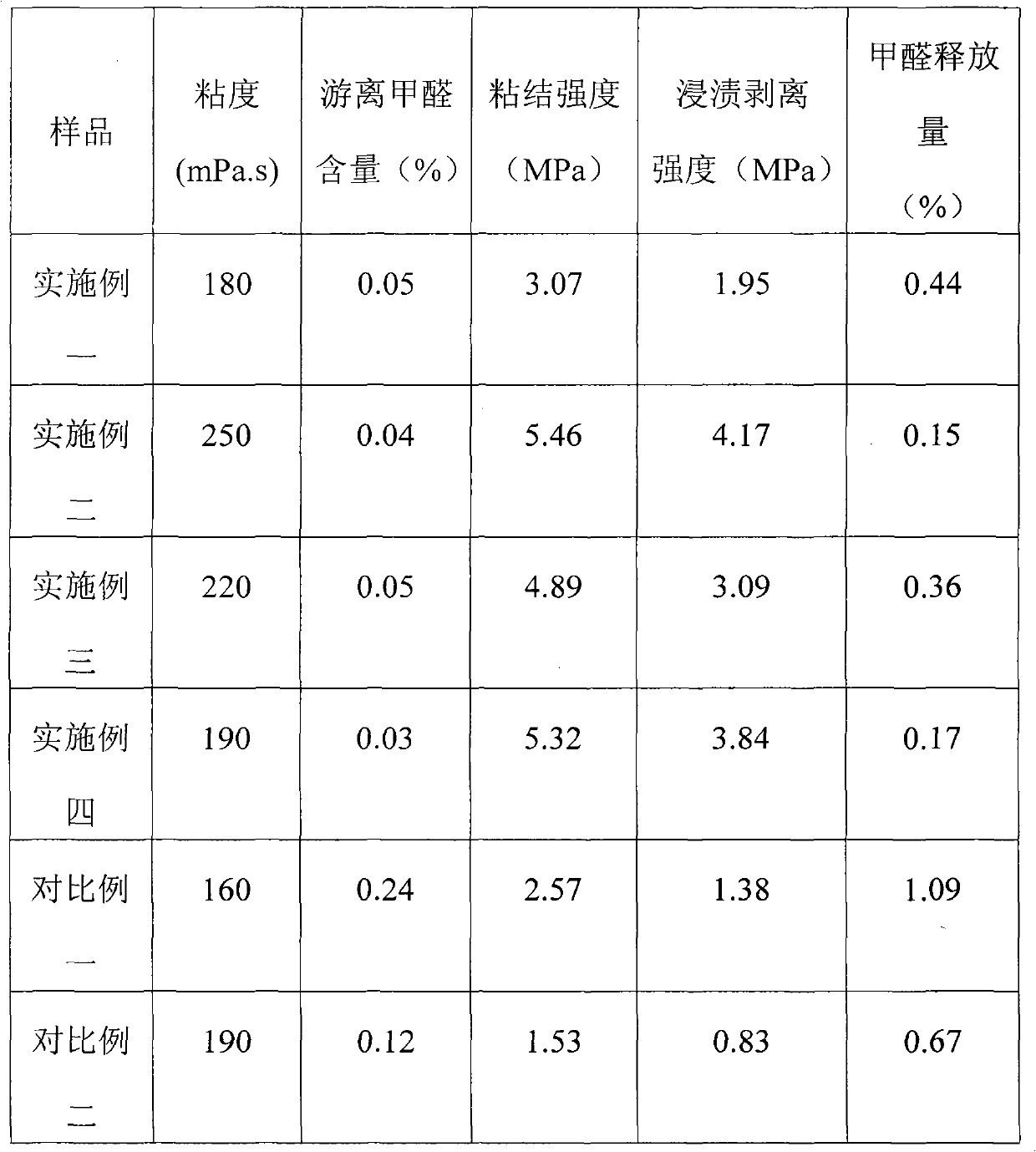

Preparation method of urea formaldehyde resin rubber powder

ActiveCN102167788AReduce formaldehyde emissionHigh bonding strengthAldehyde/ketone condensation polymer adhesivesReaction temperatureTurbidity

The invention discloses a preparation method of urea formaldehyde resin rubber powder, which comprises the following steps: firstly adding formalin with the design amount into a three-neck flask with a reflux condensation tube, regulating the pH value to 1.5-2.5, adding a first batch of urea accounting for 50-70% of the total amount into a reaction kettle, when being at the reaction temperature of 90-95 DEG C, immediately rapidly reducing the temperature to 75-80 DEG C when turbidity appears during the reaction, regulating the pH value to 8.0-9.0, adding a second batch of 10-29% urea, then regulating the pH value to 4.5-5.5, and reacting for 30-40 minutes; and further regulating the pH value to 7.0-8.0, adding a modifier, and performing the acid-base-acid-base process so as to synthesize urea formaldehyde resin prepared by the method, and the viscosity of stock solution does not change greatly in comparison with the ordinary process. After the rubber powder obtained by spray drying forms regenerated rubber with water, the free formaldehyde content is reduced, the bonding strength and the dipping and peeling strength are greatly improved, and the formaldehyde releasing amount is lower than 0.5%.

Owner:北京天维宝辰化学产品有限公司

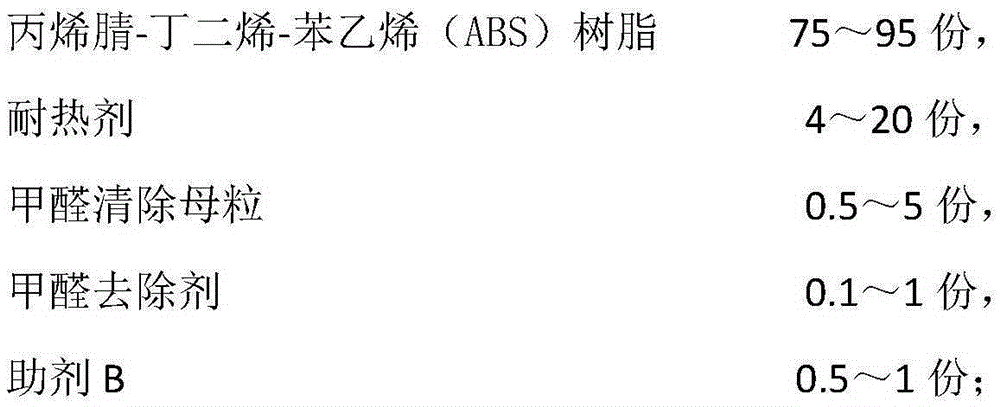

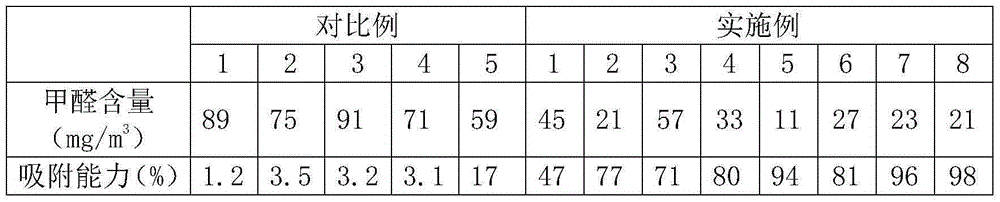

Self-formaldehyde-clearing and heat-resistant acrylonitrile butadiene styrene (ABS) material and preparation method thereof

ActiveCN105385097AReduce formaldehyde contentFormaldehyde content suppressionClearing AgentAcrylonitrile butadiene styrene

The invention discloses a self-formaldehyde-clearing and heat-resistant acrylonitrile butadiene styrene (ABS) material and a preparation method thereof. The material is prepared from, by weight, 75-95 parts of ABS resin, 4-20 parts of heat resistant agent, 0.5-5 parts of formaldehyde clearing master batches, 0.1-1 part of formaldehyde clearing agent and 0.5-1 part of other auxiliaries. During preparation, the ABS resin, the heat resistant agent and other auxiliaries are mixed and fed through a main feeding port of a twin-screw extruder; the formaldehyde clearing master batches and the formaldehyde clearing agent are fed through the rear section of the extruder, and the material can be obtained through extruding and granulating. Thanks to the method, the content of formaldehyde in granules can be reduced by 40%, the content of formaldehyde in sealed space is reduced by 50% or above, and the content of other volatile organic compounds is reduced by 10% to 20% at the same time, so that the effects of controlling emission of material formaldehyde for a long time and inhibiting the content of formaldehyde in space are achieved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Copolycondensation resin type formaldehyde catching agent and preparation method thereof

InactiveCN102675574AReduce formaldehyde emissionEasy and flexible operationAldehyde/ketone condensation polymer adhesivesUrea-formaldehydeMelamine

The invention provides a melamine-urea-formaldehyde copolycondensation resin type formaldehyde catching agent which is made of urea, melamine and formaldehyde by means of copolycondensation reaction, wherein the final molar ratio F / U of the formaldehyde to the urea is 1:2.4-4.0, the formaldehyde is added once, the urea is added twice, the reaction temperature ranges from 85 DEG C to 95 DEG C, and the reaction time is 2-3 hours. The formaldehyde catching agent can be mixed and used with various urea resin adhesives and especially applicable to urea resins prepared with low molar ratio of the formaldehyde to the urea. Strength of main adhesives of urea resins is unaffected within a certain weight addition proportional range. The melamine-urea-formaldehyde copolycondensation resin type formaldehyde catching agent has the advantages of flexibility in use, high comprehensive performances and the like and is applicable to production of various indoor artificial boards.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Urea-formaldehyde resin wood adhesive modifier and applications thereof

InactiveCN103540282AIncreased veneer strengthLow costNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSilica particlePolyethylene glycol

The invention discloses a urea-formaldehyde resin wood adhesive modifier and applications thereof. The urea-formaldehyde resin wood adhesive modifier disclosed by the invention comprises the following components in parts by weight: 1-10 parts of silica particles, 1-10 parts of light calcium carbonate, 1-10 parts of titanium dioxide particles, 0.1-0.5 part of ferric chloride, 1-5 parts of polyethylene glycol, and 0.1-0.5 part of sodium dodecyl sulfate. A urea-formaldehyde resin wood adhesive modified by the modifier is applied to the cementing processing of woods and bamboos, and the veneer strength of a finished product plate is increased by more than 10%, the cost is reduced by about 5%, and the formaldehyde release amount is reduced by more than 20%.

Owner:ZHEJIANG FORESTRY UNIVERSITY

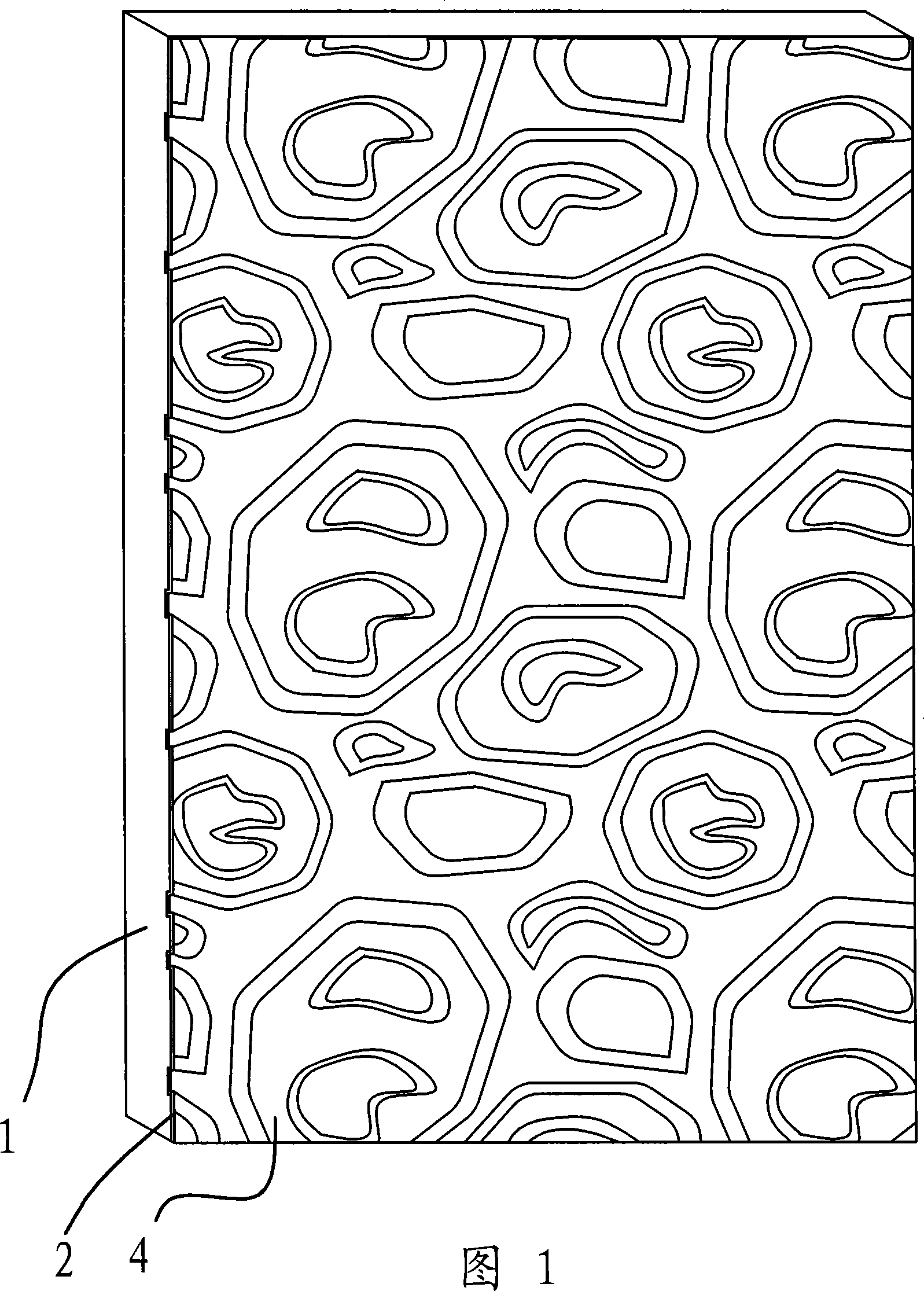

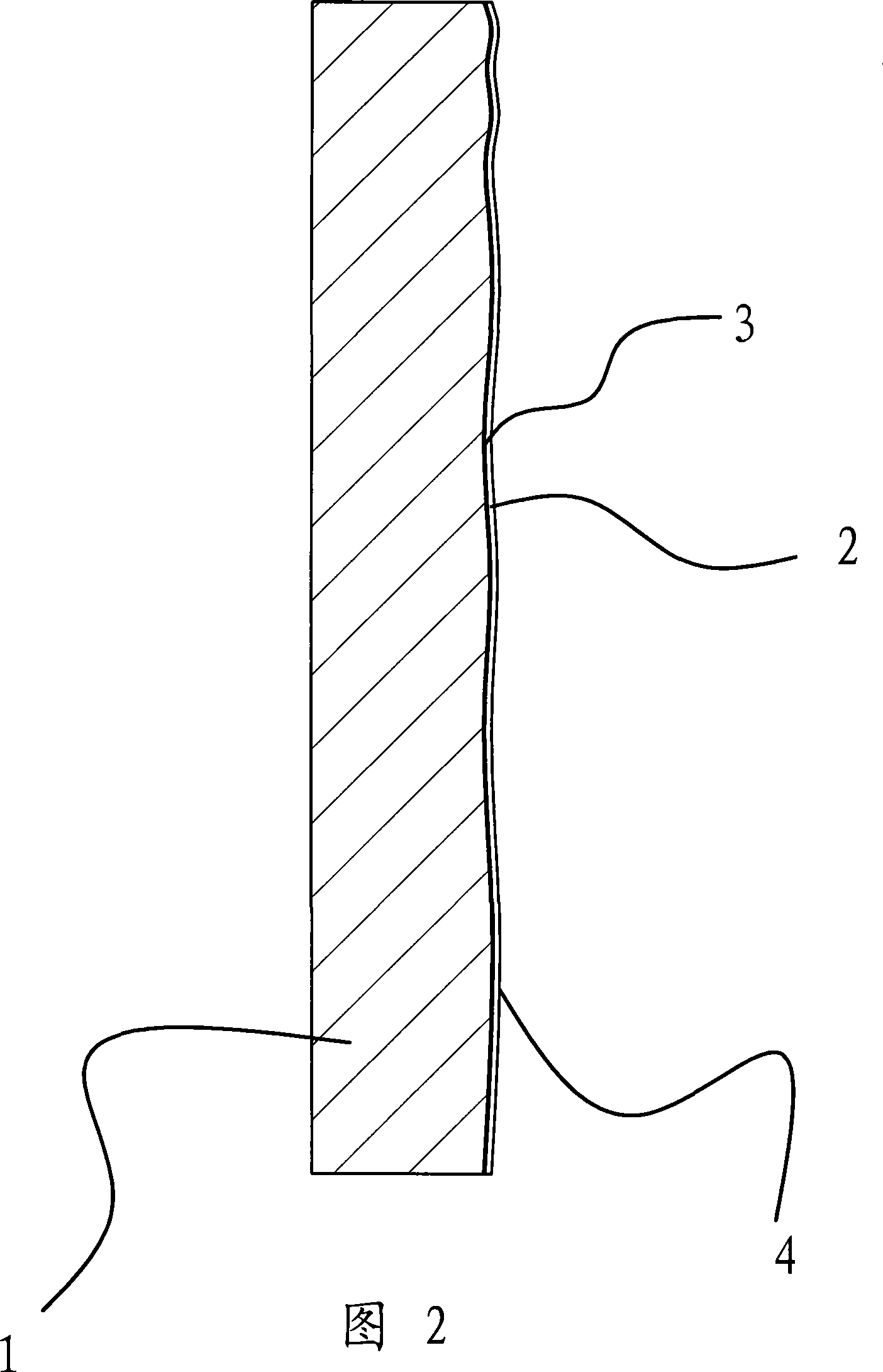

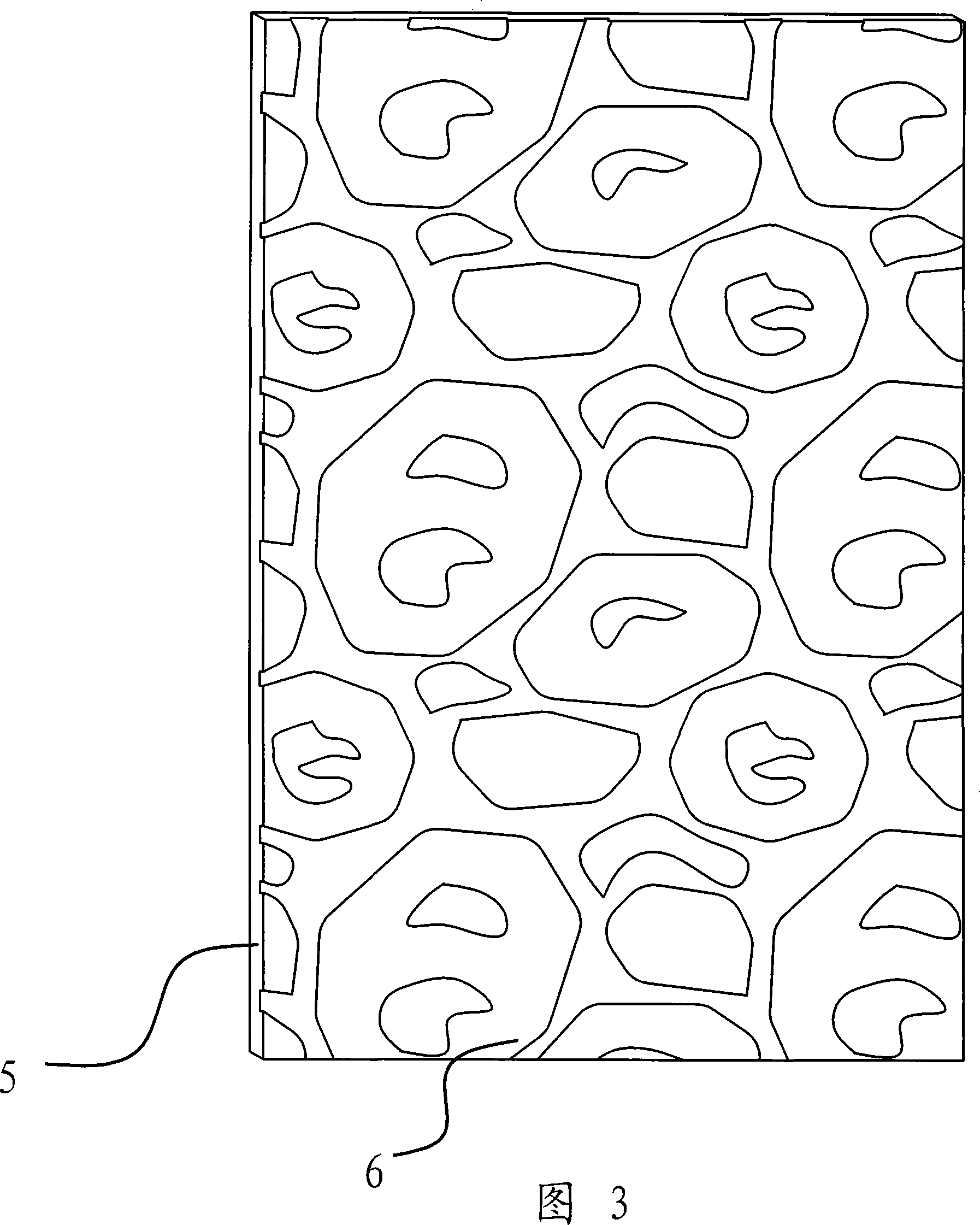

Method for manufacturing decoration sheet material with concave-convex surface

InactiveCN101195291AStrong three-dimensional senseImprove aestheticsLamination ancillary operationsLaminationCardboardEngineering

The invention provides a process for preparing decoration plates with concave-convex surfaces, which belongs to the technical field of materials. The invention resolves the problems that the surfaces of the existing sheets are not concave-convex, the exited cubic effect is not strong and the graceful property is poor. The process for preparing the decoration plates with concave-convex surfaces includes the steps of A gumming, B drying and C compressing, wherein the step of gumming comprises firstly selecting decoration sheets, then transferring the decoration sheets by a transferring machine and sinking the decoration sheets in hot-curing resin, enabling the right surfaces and back surfaces of the decoration sheets to be immerged in the hot-curing resin. The step of drying is realized by immerging the decoration sheets in a baking box to be precisely dried, wherein the drying temperature is 50 DEG C to 100 DEG C. In the step of compressing, flat distributing the precisely dried decoration sheets on a wood plate and compressing under a press through being transferred by the transferring machine at high temperature. Wood sheets produced by the process for preparing decoration plates with concave-convex surfaces has the advantages of fire resistance, moisture prevention, wear resistance, mar-proof property, high cubic effect and sound graceful property.

Owner:张纪元

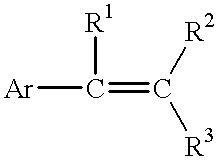

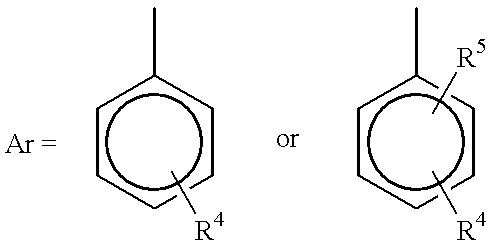

Process for reducing mono-functional and non-functional by-products during aralkylation of phenolics

Phenol aralkyistion polymers can be prepared by reaction among a phenolic monomer, at least one styrenic monomer and an aryl diolefin. A phenolic monomer can be initially aralkylated in the presence of an acid catalyst with a first portion of at least one styrenic monomer to obtain an aralkylated phenol. The aralkylated phenol thereafter can be reacted with an aryl diolefin to obtain a phenol aralkylation polymer. Optionally, (though preferably) the phenol aralkylation polymer is further aralkylated with a second portion of at least one styrenic monomer. By employing specific catalyst concentrations, reactant concentrations, reaction temperatures, and reaction times, the formation of mono-functional and non-functional by-products is substantially reduced.

Owner:GEORGIA PACIFIC CHEM LLC

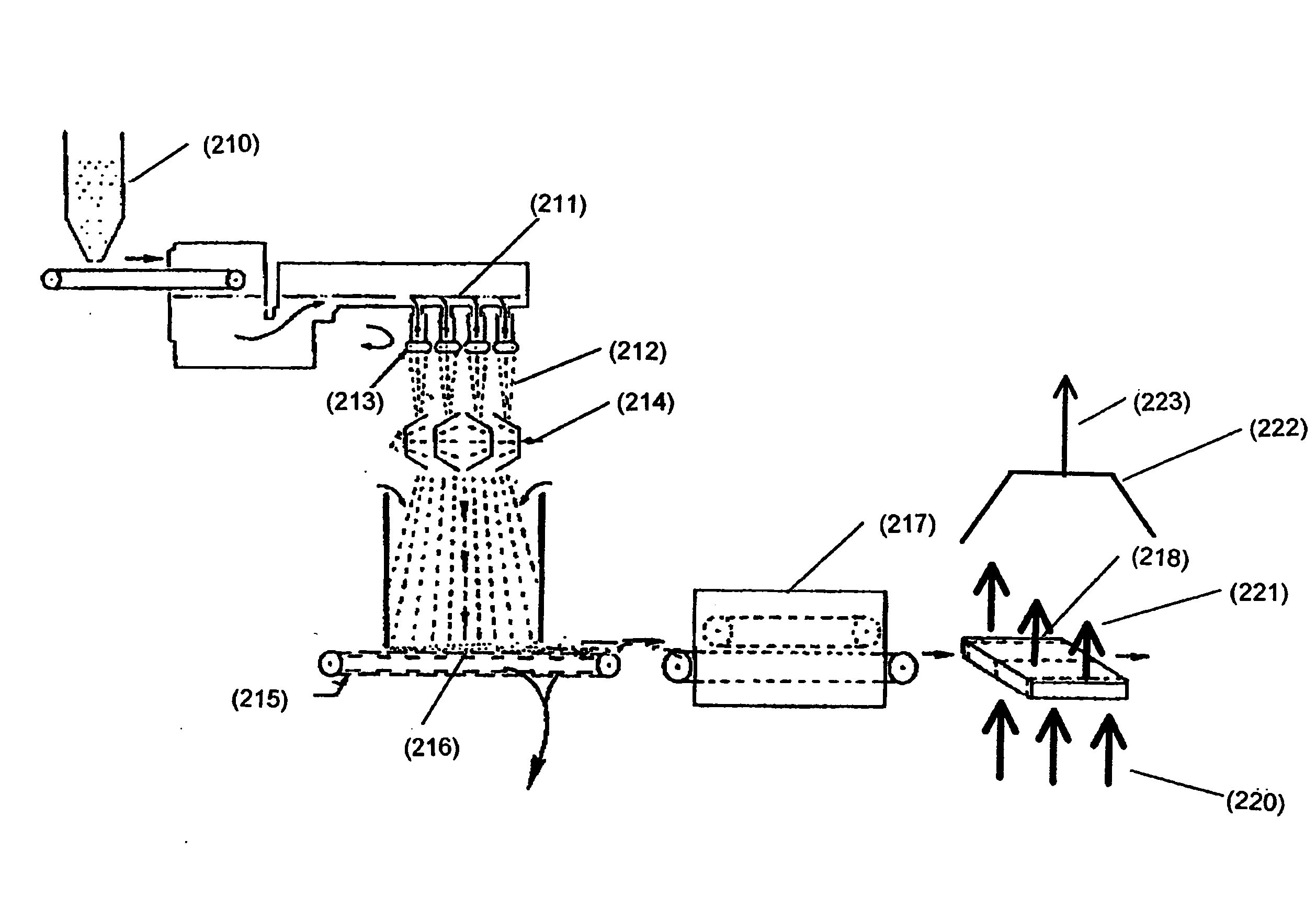

Post addition of amine-based compounds to reduce formaldehyde emmission in insulation products

InactiveUS20080248303A1Reduce formaldehyde emissionReduced insulation performancePretreated surfacesBuilding constructionsFiberScavenger

A method of reducing the emission of formaldehyde from fibrous insulation having thereon a formaldehyde-based binder is provided. In particular, an amine-based compound is added after the formaldehyde-based has been cured and prior to the insulation being processed for storage or shipment to customers. The amine-based compound may be added after binder cure and either prior to the insulation product being cut into nodules or after the insulation product has been cut into nodules. Non-limiting examples of amine-based compounds include urea, melamine and / or dicyandiamide. Once applied to the insulation product, the amine-based compound acts as a formaldehyde scavenger to reduce the emission of formaldehyde into the air. In preferred embodiments, the amine-based compound is added with an antistatic agent. The post-cure addition of urea to fibrous insulation reduces the emission of formaldehyde into the atmosphere to meet stringent GREENGUARD standards and achieve GREENGUARD certification for formaldehyde emission.

Owner:OWENS CORNING FIBERGLAS TECH INC

Polymerization reaction type formaldehyde catching agent and preparation method thereof

ActiveCN108727546AImprove water resistanceHigh bonding strengthAldehyde/ketone condensation polymer adhesivesMacromolecular adhesive additivesWater resistantStructural unit

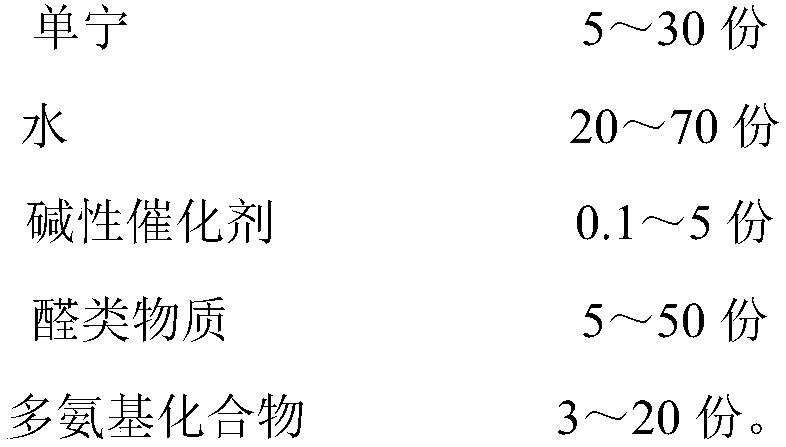

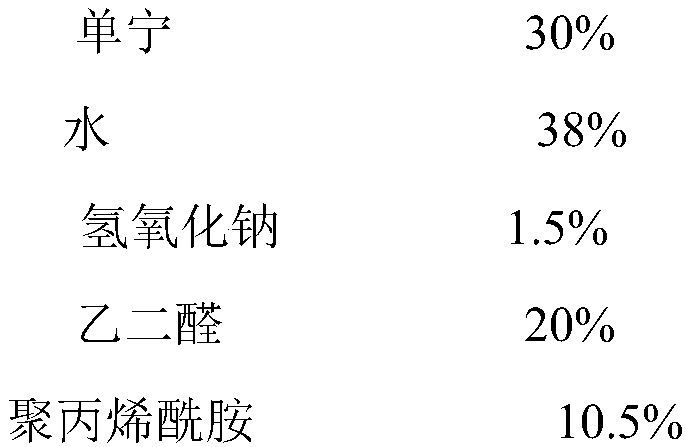

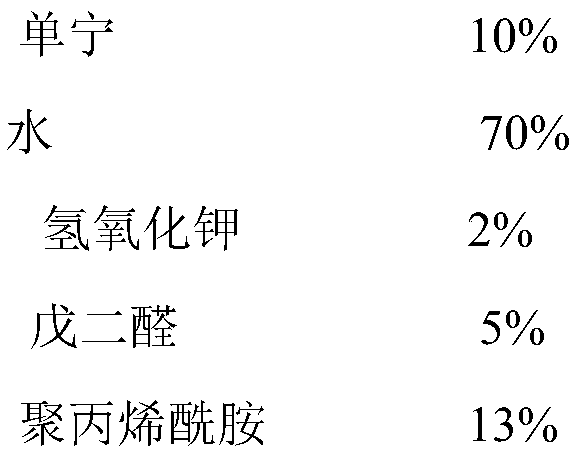

The invention discloses a polymerization reaction type formaldehyde catching agent, which is prepared from 5 to 30 parts of tannin, 20 to 70 parts of water, 0.1 to 5 parts of basic catalysts, 5 to 50parts of aldehyde substances and 3 to 20 parts of polyamino compounds. The invention also discloses a preparation method of the polymerization reaction type formaldehyde catching agent. Through addition polycondensation, water-soluble polymers using tannin water-resistant structures are main bodies and comprising a great number of amino groups and hydroxymethyls are formed; amino groups and activereaction hollow sites in the polymers can achieve the goal of capturing formaldehyde through reaction with formaldehyde; in addition, through polymerization reaction, water-resistant tannin structureunits are embedded into urea formaldehyde and modified urea formaldehyde resin; the water resistance and the bonding intensity of the urea formaldehyde and the modified urea formaldehyde resin can beimproved; the resin curing time is shortened; no adverse influence is caused on the active period of the resin. The polymerization reaction type formaldehyde catching agent can be added into the ureaformaldehyde and the modified urea formaldehyde bonding agents to reduce the free formaldehyde in the resin adhesive; the polymerization reaction type formaldehyde catching agent can be sprayed and smeared onto the surface of artificial board products to directly reduce the formaldehyde release quantity of the artificial boards.

Owner:灌南县天和胶业有限公司

Method for manufacturing environment-friendly medium density fiberboard using plant straws instead of partial wood fibers

ActiveCN106272868AReduce usageReduce formaldehyde emissionPretreatment with water/steamDigestersAdhesiveFiberboard

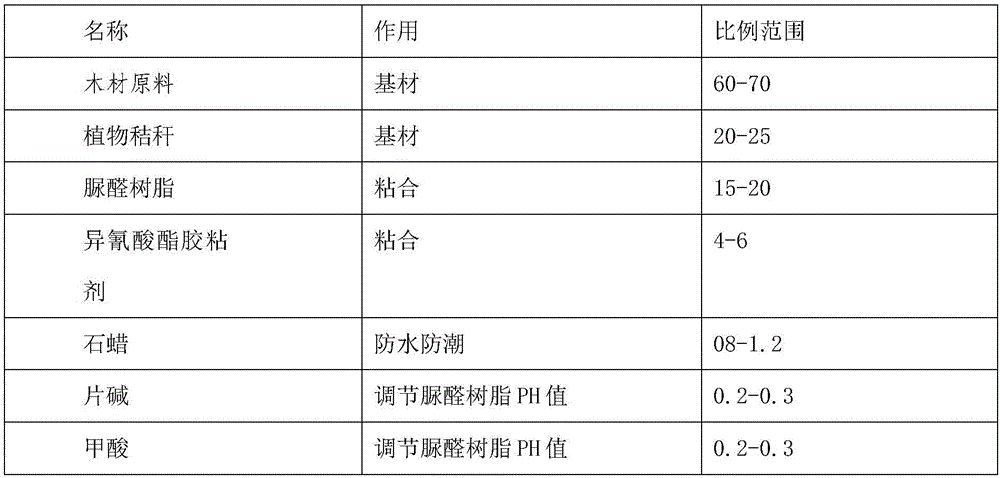

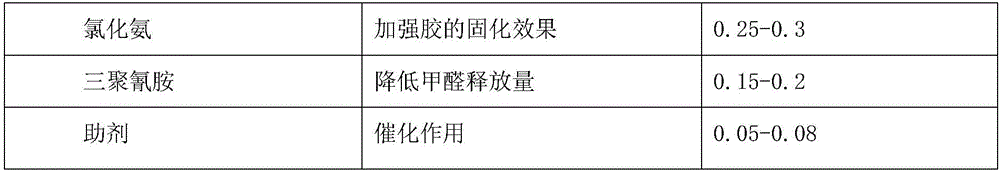

The invention discloses a method for manufacturing an environment-friendly medium density fiberboard using plant straws instead of partial wood fibers. The fiberboard is composed of the following components in parts by weight: 60-70 parts of wood materials, 20-25 parts of plant straws, 15-20 parts of urea resin, 4-6 parts of methylenediphenyl diisocyanate adhesive, 0.8-1.2 parts of paraffin, 0.2-0.3 part of caustic soda flakes, 0.2-0.3 part of formic acid, 0.25-0.3 part of ammonia chloride, and 0.15-0.2 part of melamine. The method for manufacturing an environment-friendly medium density fiberboard using plant straws instead of partial wood fibers has the following advantages: the usage amount of wood is reduced; moreover, as the methylenediphenyl diisocyanate (MDI) is a non-formaldehyde adhesive, the addition thereof results in great reduction of formaldehyde emission of the density fiberboard, improvement in the environmental protection property of the density fiberboard, and promotion of the production level and the product quality, and also promotion of technical innovation, process innovation and product innovation with respect to artificial board products.

Owner:辽宁蓝亿实业有限公司

Low formaldehyde resin adhesive for decorative impregnating paper and preparation method thereof

ActiveCN103045140ALow molar ratioGuaranteed physical index requirementsNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesive cementPolymer science

The invention discloses a low formaldehyde resin adhesive for decorative impregnating paper and a preparation method thereof, wherein the resin adhesive contains: 60% by weight of 37% formaldehyde, 40% by weight of 98% urea, and 1.0-1.5% by weight of composite auxiliary agents which contains 0.2-0.3% by weight of curing agent, 0.5-0.8% by weight of cross-linking agent, and 0.3-0.4% by weight of reinforcing agent. The resin adhesive has the characteristics of low free formaldehyde content and high water resistance, and enhances the internal bonding force of the resin adhesive while reduces the mol ratio, which reduces the free formaldehyde releasing amount of the impregnating paper in the impregnating paper production process, and makes sure the each physical index demand of the decorative plate in the secondary hot pressing process.

Owner:GUANGDONG T&H NEW MATERIALS CO LTD

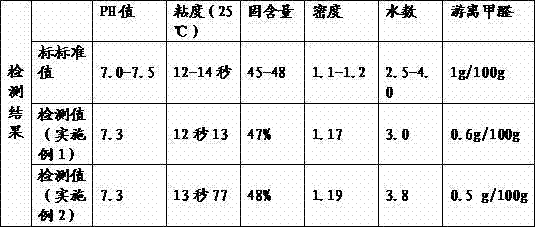

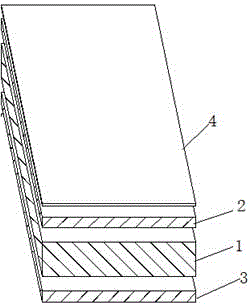

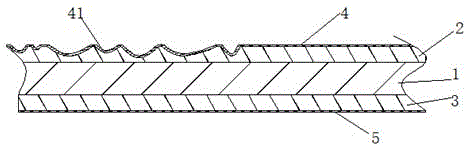

High-structural-strength three-dimensional solid wood composite board and forming method thereof

The invention discloses a high-structural-strength three-dimensional solid wood composite board which comprises a hard base layer and further comprises a first capacity layer group, a second capacity layer group and a surface layer, wherein the first capacity layer group and the second capacity layer group are arranged on the two sides of the base layer, wherein each of the first capacity layer group and the second capacity layer group is provided with at least one flexible capacity layer; the surface layer is arranged on the surface of the first capacity layer; a decoration groove is formed in the surface layer; and the bottom of the decoration groove is embedded into the first capacity layer group. The hard base layer can provide enough mechanical strength for the whole board and support the capacity layers and the surface layer in the board, so as to prevent the board from deforming in the process of making the decoration groove under high pressure. The solid wood composite board provided by the invention has a brand-new structure different from that of a conventional board, has the characteristics of stereoscopic vision, high mechanical strength and long service life, further has the advantages of low formaldehyde release amount and environment friendliness in use and can be widely applied to the fields of home decoration, artwork processing, commercial place decoration and municipal construction.

Owner:SHENZHEN SONGBOYU TIMBERING

Production method for environment-friendly type middle-density board glue

InactiveCN101063028ASimple manufacturing processImprove performanceAldehyde/ketone condensation polymer adhesivesVolumetric Mass DensityMelamine

The invention discloses a preparing method of environment-friendly type density plate glue, which comprises the following steps: changing mole ratio of traditional urea-formaldehyde resin formaldehyde and aquacare; adding melamine into urea-formaldehyde resin; proceeding polycondensation; changing twice throwing aquacare to third throwing aquacare; allocating formaldehyde, caustic soda, aquacare, melamine, ammonia and PVA; checking the end product. This craft possesses simple craft and stable property, which increases the total quality to another stage.

Owner:SHANDONG HEYOU GROUP

Preparation method of phenol-urea-formaldehyde resin adhesive for E0-grade outdoor plywood

InactiveCN102140156ALow in free phenolsIncrease dosageAldehyde/ketone condensation polymer adhesivesWood veneer joiningChemistryAlkali hydroxide

The invention discloses a preparation method of a phenol-urea-formaldehyde resin adhesive for E0-grade outdoor plywood. The preparation method comprises the following steps: step 1, mixing phenol, a formaldehyde solution and urea, adding a catalyst, and rising the temperature for reaction; step 2, adding the formaldehyde solution and urea which can also be added in the step 3 again, adding an alkali metal hydroxide solution for reaction; step 3, continuing to add the formaldehyde solution and the alkali metal hydroxide solution, if the urea is not added in the former step, adding the urea forreaction at the moment; and step 4, adding the urea and the alkali metal hydroxide solution for reaction until the viscosity is 1.5-2.0 seconds measured by a gardner-holdt tube reverse bubble measurement method, and then discharging. The adhesive-making process is mild in reaction and is easy to control, repeatability is good, and the storage life of the adhesive is more than 30 days. The strength of the plywood made of the adhesive meets the E0-grade requirement of I type plywood.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method of reducing the formaldehyde emission of a mineral fiber product, and mineral fiber product with reduced formaldehyde emission

InactiveUS20130295813A1Reduce formaldehyde emissionOrganic detergent compounding agentsConfectioneryFiberPhenol

A method of reducing the formaldehyde emission of a mineral fibre product bonded with a urea-modified phenol-formaldehyde resol resin-type binder comprises the step of adding dextrose to the binder composition during and / or after preparation of the binder composition but before curing of the binder composition applied to the mineral fibres.

Owner:ROCKWOOL INT AS

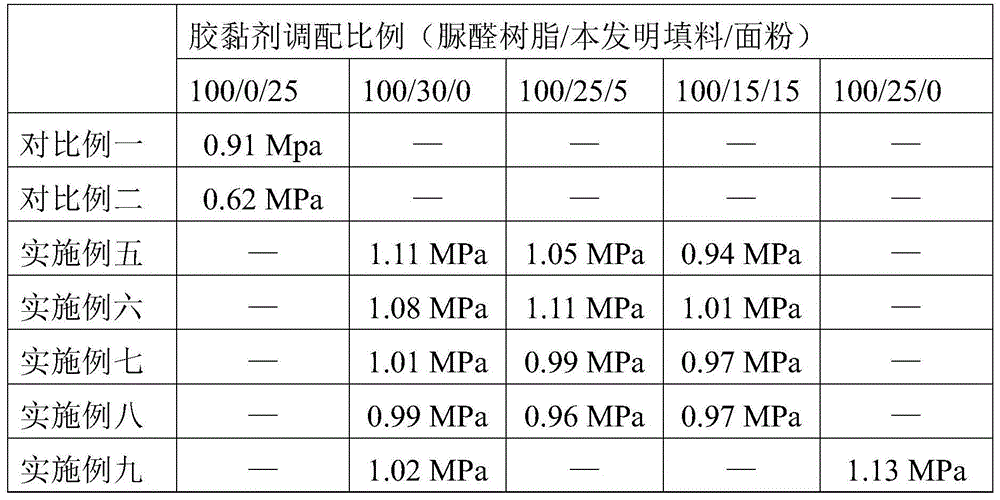

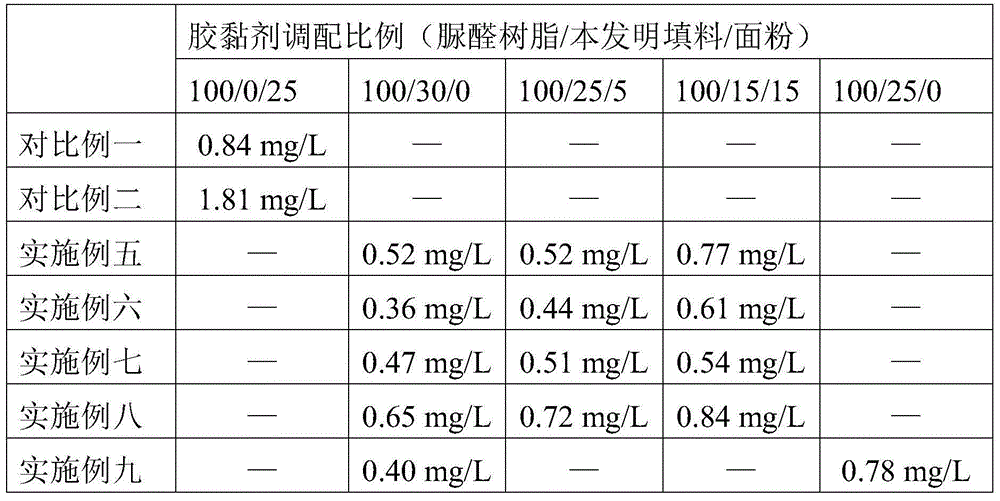

Lignin-based filler and preparation method and application of lignin-based filler

ActiveCN104312480AReduce formaldehyde emissionEasy to prepareMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesResin adhesiveBiomass

The invention discloses lignin-based filler and a preparation method and application of the lignin-based filler, relates to the field of chemical engineering, and aims to obtain urea-formaldehyde resin adhesive filler having a low cost of production and ideal using effects and being capable of completely replacing flour. The technical scheme is mainly adopted as follows: an agriculture and forestry biomass residue is subjected to hydrolysis treatment to obtain agriculture and forestry biomass residue powder; industrial alkali lignin is subjected to purification treatment to obtain purified industrial alkali lignin powder; the agriculture and forestry biomass residue powder and the industrial alkali lignin powder are mixed to obtain the lignin-based filler. The lignin-based filler disclosed by the invention is mainly used as a urea-formaldehyde resin adhesive additive.

Owner:BEIJING FORESTRY UNIVERSITY

Porous fiberglass materials having reduced formaldehyde emissions

InactiveUS8173219B2Reduce stretchReduce formaldehyde emissionPretreated surfacesBuilding constructionsGlass fiberScavenger

The present invention relates to formaldehyde scavenger treatments for porous fiberglass material having formaldehyde emitting binders thereon. The invention also relates to methods of making porous fiberglass material having reduced formaldehyde emissions.

Owner:GEORGIA PACIFIC CHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com