E0 class low imbibitions routing fibreboard and production method thereof

A production method and fiberboard technology, which are applied in the field of fiberboard manufacturing, can solve the problems that the formaldehyde emission of the milling fiberboard can not reach the E0 level standard and the water resistance is low, and can solve the problem of moisture absorption deformation, improve the water resistance, and expand the application site. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

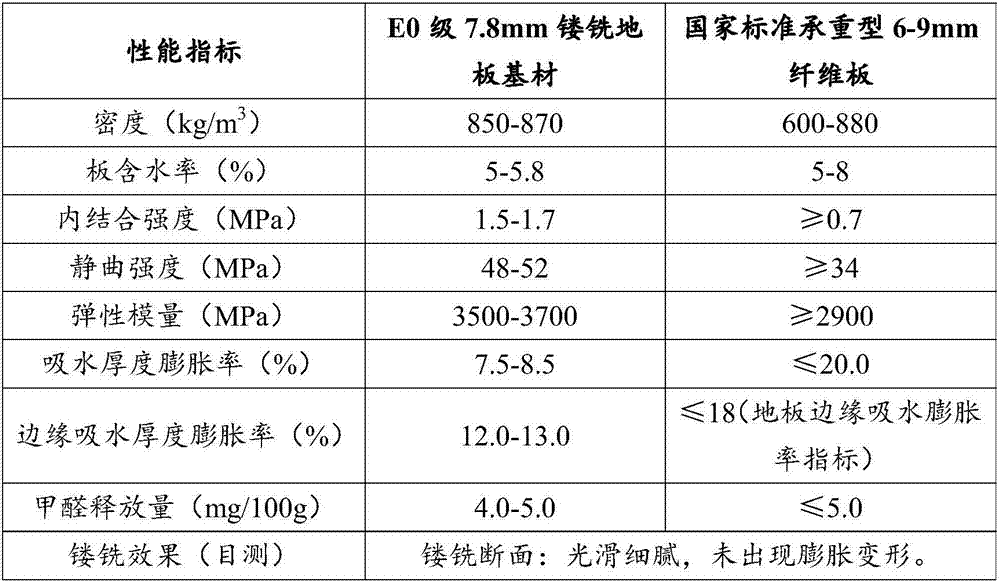

Embodiment 1

[0029] 1. The preparation method of water-resistant melamine-modified urea-formaldehyde resin

[0030] The weight ratio of melamine to the moisture-proof adhesive is 15.0%, the molar ratio of formaldehyde to the sum of urea and melamine is controlled at 0.86-0.88, the formaldehyde is added at one time, the urea is fed in three batches, and the melamine is fed in three batches. The preparation process is as follows:

[0031] A. Put formaldehyde in the reaction kettle, add caustic soda solution to adjust the pH value to 4.5-5.0, and heat up to 35°C;

[0032] B. Add melamine for the first time, raise the temperature to 50°C immediately after adding, take a sample to observe whether the melamine is completely dissolved, and measure the pH value after the melamine is completely dissolved;

[0033] C. Add urea for the first time, control the molar ratio of formaldehyde to the sum of urea and melamine at 1.8-2.0, heat up to 80-88°C, take samples to check the pH value, and react at c...

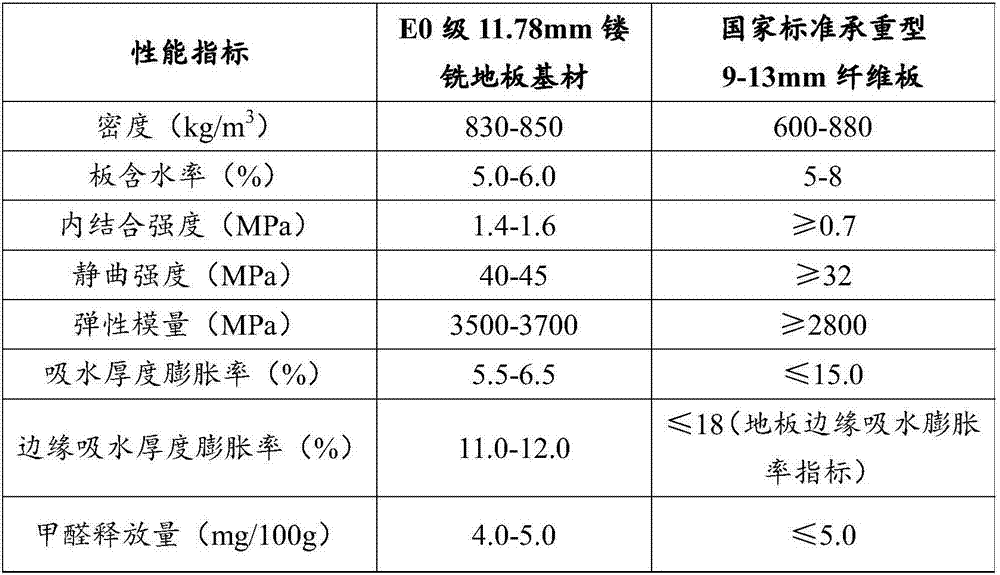

Embodiment 2

[0044] 1. The preparation method of water-resistant melamine-modified urea-formaldehyde resin

[0045] The weight ratio of melamine to the moisture-proof adhesive is 13.0%, the molar ratio of formaldehyde to the sum of urea and melamine is controlled at 0.85-0.88, the formaldehyde is added at one time, the urea is fed in three batches, and the melamine is fed in three batches. The preparation process is as follows:

[0046] A. Put formaldehyde in the reaction kettle, add caustic soda solution to adjust the pH value to 5.0-5.5, and heat up to 40°C;

[0047] B. Add melamine for the first time, raise the temperature to 50°C immediately after adding, take a sample to observe whether the melamine is completely dissolved, and measure the pH value after the melamine is completely dissolved;

[0048] C. Add urea for the first time, control the molar ratio of formaldehyde to the sum of urea and melamine at 1.9-2.0, heat up to 80-88°C, take samples to check the pH value, and react at c...

Embodiment 3

[0057] 1. The preparation method of water-resistant melamine-modified urea-formaldehyde resin

[0058] The weight ratio of melamine to the moisture-proof adhesive is 12.0%, the molar ratio of formaldehyde to the sum of urea and melamine is controlled at 0.88-0.89, the formaldehyde is added at one time, the urea is fed in three batches, and the melamine is fed in three batches. The preparation process is as follows:

[0059] A. Put formaldehyde in the reaction kettle, add caustic soda solution to adjust the pH value to 5.0-5.5, and heat up to 35°C;

[0060] B. Add melamine for the first time, raise the temperature to 50°C immediately after adding, take a sample to observe whether the melamine is completely dissolved, and measure the pH value after the melamine is completely dissolved;

[0061] C. Add urea for the first time, control the molar ratio of formaldehyde to the sum of urea and melamine at 1.8-1.9, heat up to 80-88°C, take samples to check the pH value, and react at c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com