Lignin-based filler and preparation method and application of lignin-based filler

A lignin-based, industrial alkali lignin technology, applied in the field of lignin-based fillers and its preparation, can solve the problems of unsatisfactory bonding strength of wood-based panels, poor mechanical properties of the adhesive layer, poor strength, etc., and achieve the best industrial application prospects, The effect of reducing formaldehyde emission and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] As mentioned above, Embodiment 1 of the present invention provides a method for preparing a lignin-based filler, including: hydrolyzing agricultural and forestry biomass residues; purifying industrial alkali lignin; hydrolyzing the obtained agricultural and forestry The biomass residue powder is mixed with the industrial alkali lignin powder obtained after purification treatment to obtain the lignin-based filler. Wherein, the steps of hydrolysis treatment are as follows: mixing the agricultural and forestry biomass residues with an aqueous catalyst solution, the aqueous catalyst solution being any one or several acidic solutions of sulfuric acid solution, hydrochloric acid solution or acetic acid solution; mixing the agricultural and forestry biomass residues performing hydrolysis treatment with an aqueous catalyst solution; drying and pulverizing the agricultural and forestry biomass residue after the hydrolysis treatment to obtain the agricultural and forestry biomass ...

Embodiment 5

[0067] 1. Preparation of filler

[0068] (1) After crushing corn stalks to 1cm-sized particles, mix them with sulfuric acid solution with a mass percent concentration of 0.5% at a solid-to-liquid ratio of 1:5, react at 140°C and 0.5MPa pressure for 1.5h, and then hydrolyze the The corn stover hydrolyzed solids were dried and crushed to 200 mesh.

[0069] (2) After the corncob industrial alkali lignin is dissolved in a system with pH=10.5, the pH thereof is adjusted to 2, and the obtained acid-analyzed corncob industrial alkali lignin solid is dried and crushed to 200 mesh.

[0070] (3) Fully mix 50 parts by mass of hydrolyzed corn stalk powder and 50 parts of purified corncob industrial alkali lignin powder to obtain a lignin-based natural polymer urea-formaldehyde resin filler.

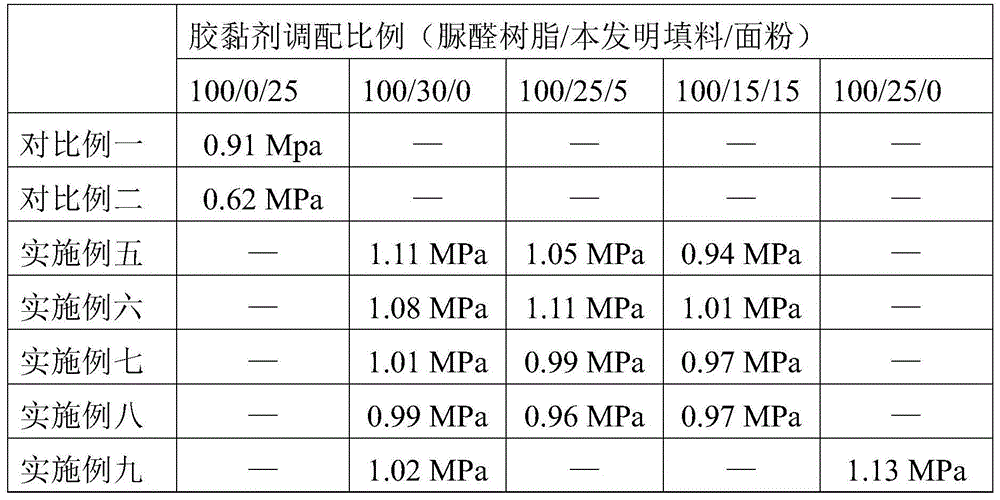

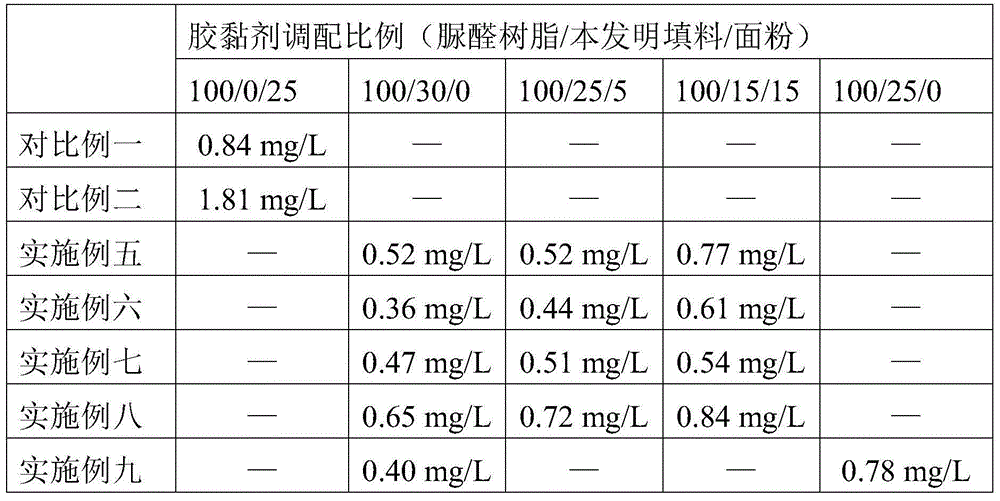

[0071] 2. Adhesive preparation and plywood preparation

[0072] Set up three glue mixing schemes: (1) mix 100 parts by mass of urea-formaldehyde resin with 30 parts of lignin-based natural polymer ...

Embodiment 6

[0074] 1. Preparation of filler

[0075] (1) Wheat straw is crushed to 2 cm in size, mixed with hydrochloric acid solution with a mass percentage concentration of 2% at a solid-to-liquid ratio of 1:10, reacted for 3 hours at 140°C and 0.7 MPa pressure, and then the hydrolyzed wheat Straw solids were dried and crushed to 350 mesh.

[0076] (2) After dissolving poplar basic kraft lignin in a system with pH=11.5, adjust its pH to 2.5, and dry and pulverize the obtained acid-analyzed poplar basic kraft lignin solid to 350 mesh.

[0077](3) Fully mix 75 parts by mass of hydrolyzed wheat straw powder and 25 parts of purified poplar alkaline sulfate lignin powder to obtain a lignin-based natural polymer urea-formaldehyde resin filler.

[0078] 2. Adhesive preparation and plywood preparation

[0079] Set up three glue mixing schemes: (1) mix 100 parts by mass of urea-formaldehyde resin with 30 parts of lignin-based natural polymer urea-formaldehyde resin filler; (2) mix 100 parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com