Preparation method of phenol-urea-formaldehyde resin adhesive for E0-grade outdoor plywood

An outdoor, plywood technology, applied in adhesives, manufacturing tools, adhesive types, etc., to solve problems such as dark color, high cost of phenolic resin, and short shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

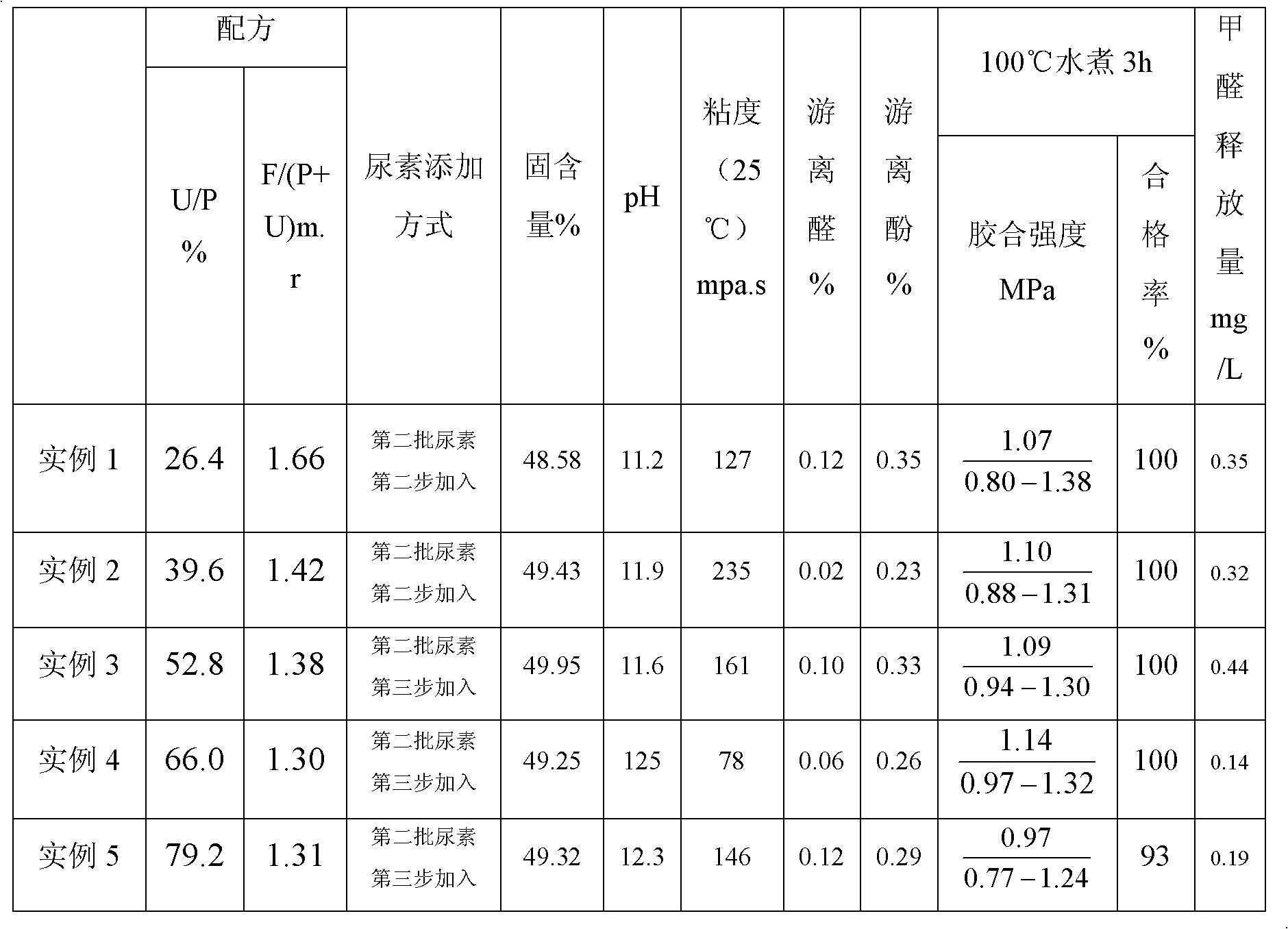

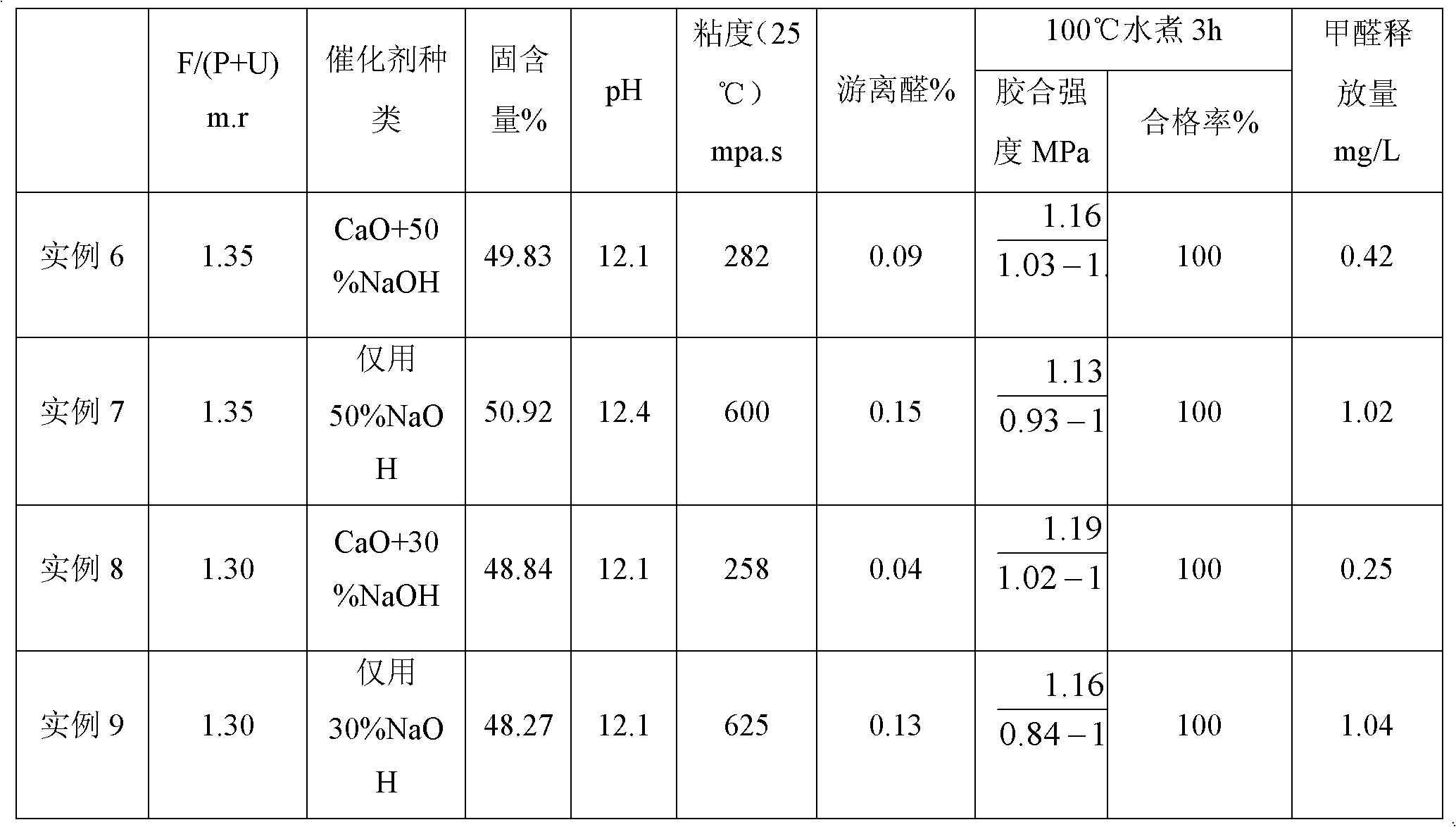

Examples

Embodiment 1

[0029] Step 1: Add 136.4g of phenol, 110g of the first batch of formaldehyde solution with a mass concentration of 36.5%, 9g of the first batch of urea, 15g of water and 0.3g of CaO into a 500ml four-necked flask, and heat up to 90°C for 50min. Wherein the molar ratio of formaldehyde / phenol is 0.84~0.99, and the molar ratio of formaldehyde / (phenol+urea) is 0.64~0.85;

[0030] The second step: adding again mass concentration is 36.5% formaldehyde solution 100g, urea 9g, gradually adding mass concentration is 50% NaOH solution 14g, the mol ratio of formaldehyde / phenol in the control system is 1.68~2.28, formaldehyde / (phenol+ urea) with a molar ratio of 1.46 to 1.68, and reacted at 90° C. for 70 minutes.

[0031] The third step: adding 70g of formaldehyde solution with a mass concentration of 36.5%, gradually adding 14g of NaOH solution with a mass concentration of 50%, the molar ratio of formaldehyde / phenol in the control system is 2.30~3.00, the molar ratio of formaldehyde / (pheno...

Embodiment 2

[0035] Step 1: Add 136.4g of phenol, 118g of the first batch of formaldehyde solution with a mass concentration of 36.5%, 15g of the first batch of urea, 15g of water and 0.3g of CaO into a 500ml four-neck flask, and heat up to 90°C for 50min.

[0036] The second step: add the second batch of 116g of formaldehyde solution with a mass concentration of 36.5%, the second batch of urea 15g, gradually add the first batch of 14g of NaOH solution with a mass concentration of 50%, and react at 90°C for 70min.

[0037] Step 3: add the third batch of 40 g of formaldehyde solution with a mass concentration of 36.5%, gradually add the second batch of 14 g of NaOH solution with a mass concentration of 50%, and react at 85-90° C. for 60 minutes.

[0038] Step 4: add the third batch of urea 24g, the third batch of 50% NaOH solution 40g, react at 80°C for 15min, the viscosity is 1.6s according to the Grizzard tube pouring test method, and cool and discharge.

[0039] Test its physical and che...

Embodiment 3

[0041] Step 1: Add 95.4g of phenol, 80g of the first batch of formaldehyde solution with a mass concentration of 36.5%, 18g of the first batch of urea, 11g of water and 0.3g of CaO into a 500ml four-necked flask, and heat up to 90°C for 50min.

[0042] The second step: add the second batch of 90 g of formaldehyde solution with a mass concentration of 36.5%, gradually add the first batch of 10 g of NaOH solution with a mass concentration of 50%, and react at 90° C. for 70 minutes.

[0043] Step 3: add the third batch of 40g of formaldehyde solution with a mass concentration of 36.5%, the second batch of urea 18g, gradually add the second batch of 10g of NaOH solution with a mass concentration of 50%, and react at 90°C for 60min.

[0044] Step 4: Add the third batch of urea 14.4g, the third batch of 50% NaOH solution 28g, react at 80°C for 10min, the viscosity is 1.8s according to the Grizzard tube inversion method, and cool and discharge.

[0045] Test its physical and chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com