Halide-containing brake material and preparation method and application thereof

A braking material and halide technology, applied in chemical instruments and methods, applications, other household appliances, etc., can solve the problems of low hardness and low melting point of aluminum alloy, and achieve high bonding strength, good heat resistance, wear and tear. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0053] Embodiment 3 Automobile brake pad

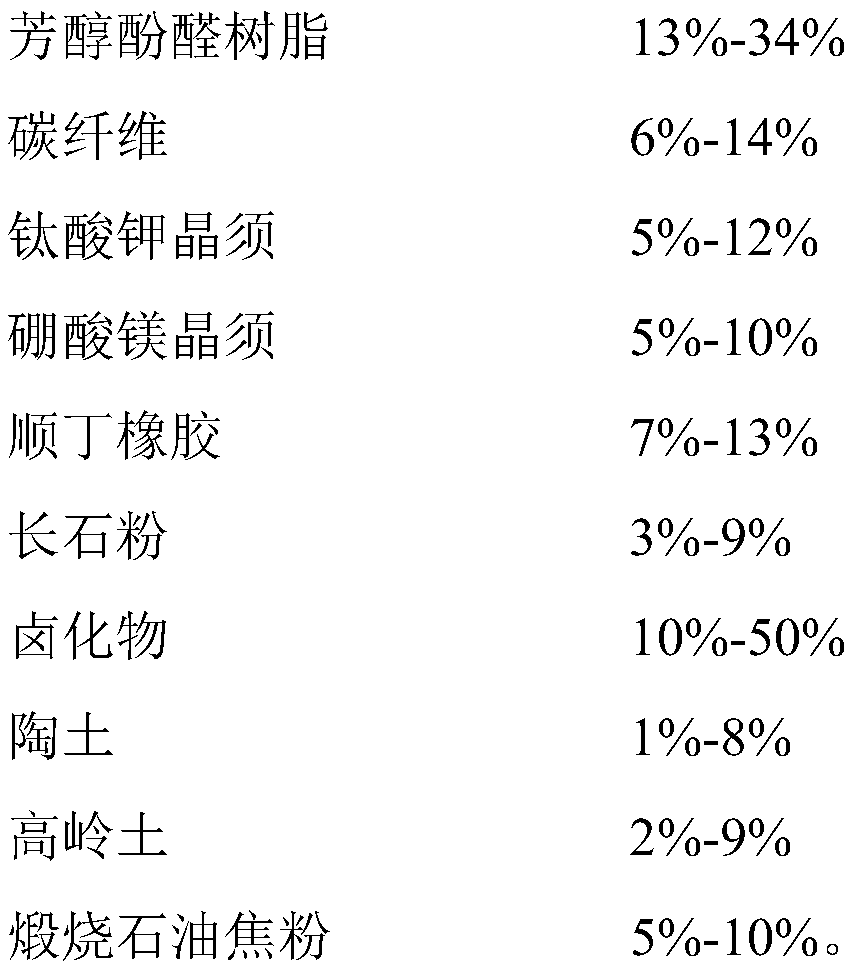

[0054] A brake material containing halogen compounds, comprising the following components and weight percentages:

[0055]

[0056] The present embodiment provides the method that brake material containing halide is used for making automobile brake pad, comprises the following steps:

[0057] (1) Add aromatic alcohol phenolic resin, butadiene rubber, feldspar powder, clay, kaolin, calcined petroleum coke powder and halides to the mixer in proportion and mix for 22 minutes, then add carbon fiber, potassium titanate whiskers and The magnesium borate whiskers were mixed and stirred for 16 minutes until uniform to obtain the halide-containing brake material;

[0058] (2) Place the steel back and the halide-containing braking material in a mold with a mold temperature of 150°C, a molding pressure of 20MPa, and a holding pressure of 15 minutes;

[0059] (3) After demolding, put it into an oven to heat and cure, the heating temperature ...

Embodiment 4

[0062] Embodiment 4 Automobile brake pad

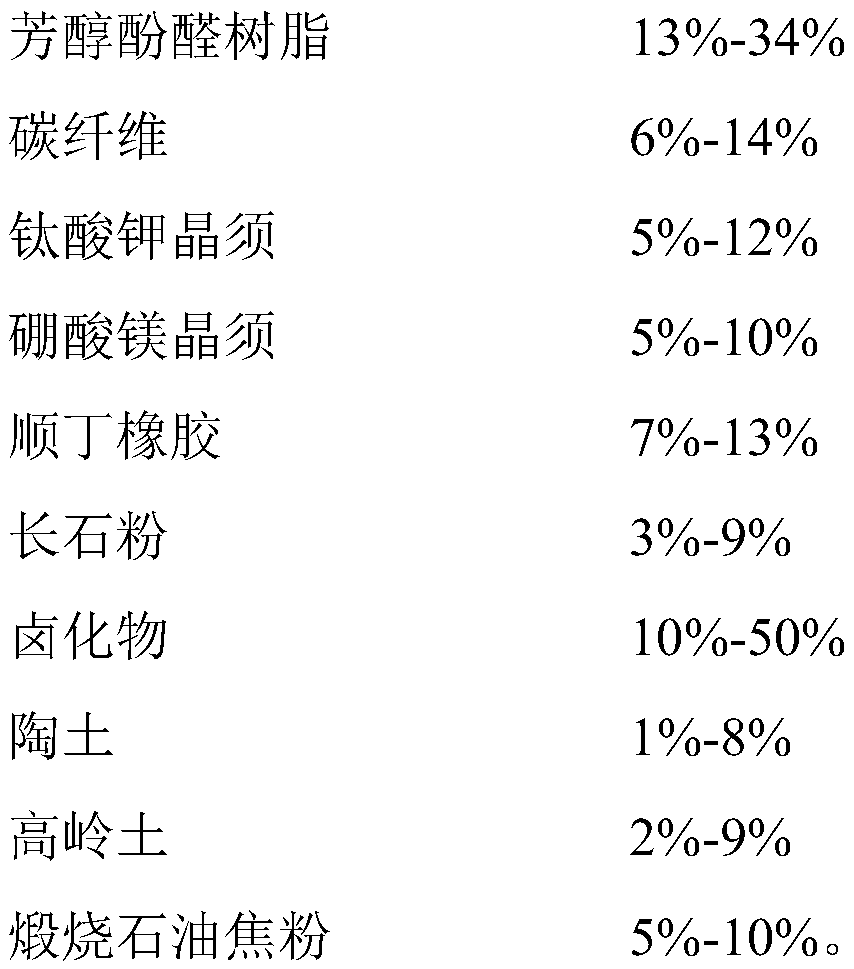

[0063] A brake material containing halogen compounds, comprising the following components and weight percentages:

[0064]

[0065]

[0066] The present embodiment provides the method that brake material containing halide is used for making automobile brake pad, comprises the following steps:

[0067] (1) Add aromatic alcohol phenolic resin, butadiene rubber, feldspar powder, clay, kaolin, calcined petroleum coke powder and halides to the mixer in proportion and mix for 25 minutes, then add carbon fiber, potassium titanate whiskers and The magnesium borate whiskers were mixed and stirred for 18 minutes until uniform to obtain the halide-containing brake material;

[0068] (2) Place the steel back and the halide-containing braking material in a mold with a mold temperature of 150° C., a molding pressure of 18 MPa, and a holding pressure of 13 minutes;

[0069] (3) After demolding, put it into an oven to heat and cure, the heati...

Embodiment 5

[0079] Embodiment 5 Rail Transit Brake

[0080] A brake material containing halogen compounds, comprising the following components and weight percentages:

[0081]

[0082]

[0083] This embodiment provides a method for making a brake pad containing halides, comprising the following steps:

[0084] (1) Add aromatic alcohol phenolic resin, butadiene rubber, feldspar powder, clay, kaolin, calcined petroleum coke powder and halides to the mixer in proportion and mix for 20 minutes, then add carbon fiber, potassium titanate whiskers and The magnesium borate whiskers were mixed and stirred for 12 minutes until uniform to obtain the halide-containing brake material;

[0085] (2) Put the steel back and the halide-containing braking material in the mold, the mold temperature is 170°C, the molding pressure is 30MPa, deflate 8 times within 5 minutes, and then hold the pressure for 20 minutes;

[0086] (3) After demolding, put it into an oven to heat and cure, the heating tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com