Thermosetting glass fiber reinforced phenolic aldehyde composite material for injection and preparation method thereof

A technology of glass fiber and composite materials, which is applied in the field of thermosetting glass fiber reinforced phenolic composite materials for injection and its preparation, which can solve problems such as low adhesion and mechanical properties, poor anti-aging performance, and environmental pollution, and achieve comprehensive and good products High efficiency, fast curing speed, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

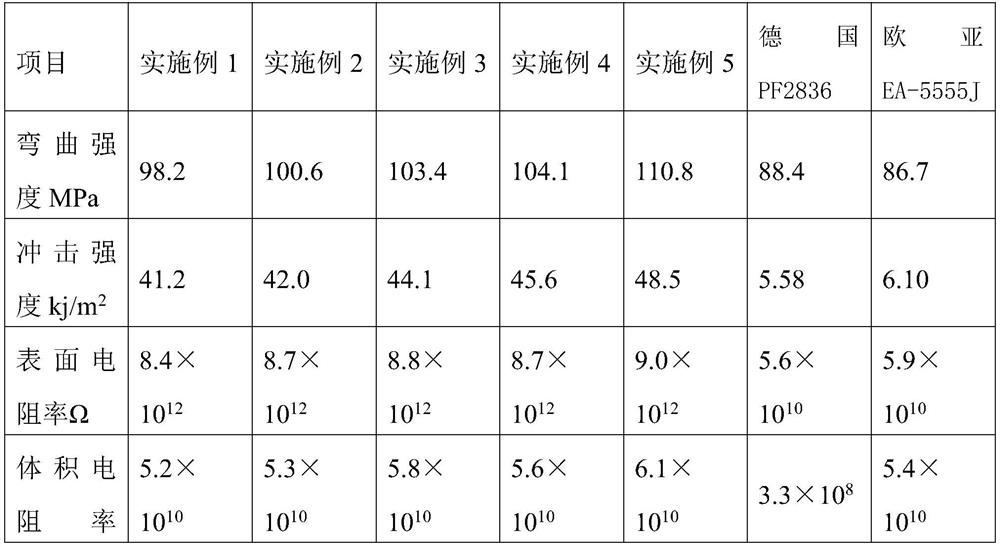

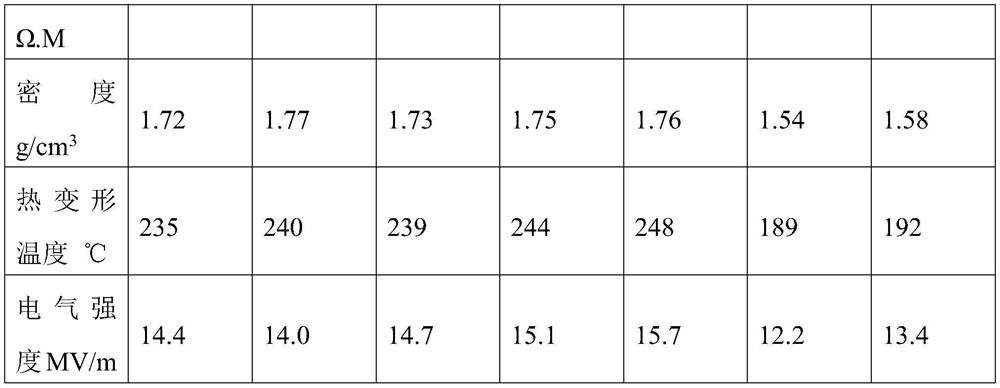

Examples

preparation example Construction

[0041] The present invention also includes the preparation method of thermosetting glass fiber reinforced phenolic composite material for injection, comprising the following steps:

[0042] (1) Mix 40-50 parts of polyvinyl acetal modified thermosetting phenolic resin, 0.5-1.5 parts of silane coupling agent, and 0.5-1.0 parts of calcium stearate, and add 4-12 parts of ultra-fine aluminum hydroxide to it, 10-20 parts of mica powder, uniformly dispersed with a high-speed disperser to obtain the first mixture;

[0043] Wherein the polyvinyl acetal modified thermosetting phenolic resin is prepared according to the following steps:

[0044] ①Put phenol and 1 / 3 of the total amount of formaldehyde into the reaction kettle, heat up to 50°C under stirring, add light magnesium oxide to it, react at 65-70°C for 1-2 hours, add the total amount of 1 / 3 formaldehyde, react at 80-90°C for 30-60 minutes, then add 1 / 3 of the total amount of formaldehyde, react at 70-80°C for 1-2 hours, add ure...

Embodiment 1

[0053] A thermosetting glass fiber reinforced phenolic composite material for injection, consisting of the following raw materials: 40kg of polyvinyl acetal modified thermosetting phenolic resin, 45kg of glass fiber, 4kg of ultrafine aluminum hydroxide, 10kg of mica powder, 1kg of zinc stearate, Silane coupling agent 0.5kg, calcium stearate 0.5kg, ethanol 5kg, zinc borate 3kg, silicon micropowder 5kg and talcum powder 3kg;

[0054] Wherein the polyvinyl acetal modified thermosetting phenolic resin is prepared according to the following steps:

[0055] ①Put 100kg of phenol and 30kg of formaldehyde into the reaction kettle, heat up to 50°C under stirring, add 40kg of light magnesium oxide to it, react at 65°C for 1 hour, add 30kg of formaldehyde, and react at 80°C for 30 minutes , then add 30kg of formaldehyde, react at 70°C for 2 hours, add 60kg of urea and react for 30 minutes, then cool to room temperature to obtain a thermosetting phenolic resin;

[0056] ② Dissolve 4kg of ...

Embodiment 2

[0058] A thermosetting glass fiber reinforced phenolic composite material for injection, consisting of the following raw materials: 50kg of polyvinyl acetal modified thermosetting phenolic resin, 55kg of glass fiber, 12kg of ultrafine aluminum hydroxide, 20kg of mica powder, 5kg of zinc stearate, Silane coupling agent 1.5kg, calcium stearate 1.0kg, ethanol 10kg, zinc borate 5kg, silicon micropowder 7kg and talcum powder 6kg;

[0059] Wherein the polyvinyl acetal modified thermosetting phenolic resin is prepared according to the following steps:

[0060] ①Put 150kg of phenol and 50kg of formaldehyde into the reaction kettle, heat up to 50°C under stirring, add 60kg of light magnesium oxide to it, react at 70°C for 2 hours, add 50kg of formaldehyde, and react at 90°C for 60 minutes , then add 50kg of formaldehyde, react at 70°C for 1 hour, add 90kg of urea and react for 20 minutes, then cool to room temperature to obtain a thermosetting phenolic resin;

[0061] ② Dissolve 10kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com