Patents

Literature

53results about How to "No hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen purging-assisted organic exhaust gas recycling method through pressure swing adsorption of adsorbent resin

ActiveCN104107621ALarge volume adsorption capacityNo chemical reactionDispersed particle separationSolubilityCollection system

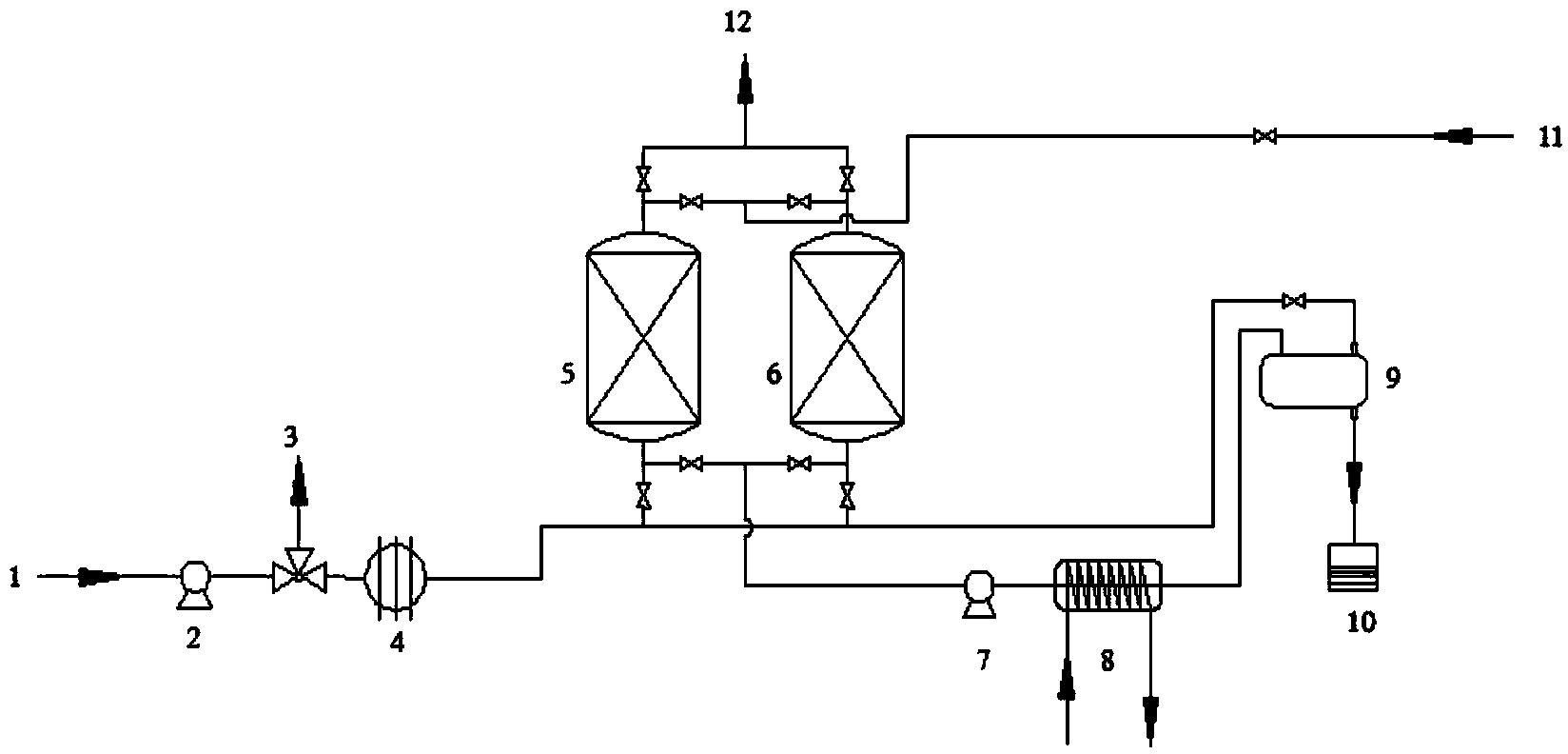

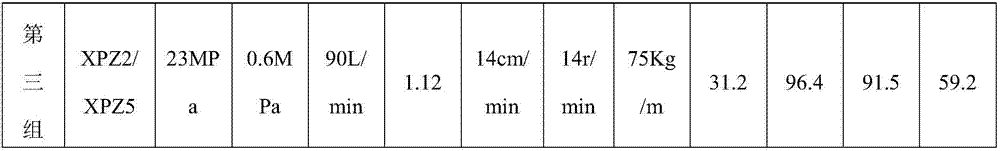

The invention discloses a nitrogen purging-assisted organic exhaust gas recycling method through the pressure swing adsorption of adsorbent resin. The organic exhaust gas recycling method comprises the following steps: (1) adsorption, namely performing adsorption when exhaust gas including volatile organic compounds (VOCs) enters an adsorber filled with the macroporous adsorption resin by a gas collection system; (2) desorption, namely vacuumizing the adsorbent resin in the adsorber and purging the adsorbent resin by using nitrogen in an auxiliary manner to desorb the adsorbed VOCs from the adsorbent resin to obtain the desorbed gas; and (3) recycling, namely condensing or absorbing the desorbed gas to recycle the VOCs. The adsorbent adopted by the method disclosed by the invention is the macroporous adsorption resin, the surface of the macroporous adsorption resin has no catalytic performance and has the characteristics of being easy to regenerate, high in mechanical strength, great in volumetric adsorption capacity and the like. A adsorption technique assisted by nitrogen purging in vacuum at normal temperature is high in adsorption efficiency and has the very excellent recycling effect on VOCs gas which can be easily oxidized and hydrolyzed or is high in solubility.

Owner:NANJING UNIV

Novel cyanide-free silver plating electroplating liquid and electroplating technology

InactiveCN105088293AImprove solderabilityExcellent discoloration resistanceSilver plateSurface-active agents

The invention provides novel cyanide-free silver plating electroplating liquid and an electroplating technology. The cyanide-free silver plating electroplating liquid comprises, by mass concentration, 1.5-4 g / L of silver nitrate, 2-50 g / L of potassium carbonate, 2-100 g / L of hydantoin, 0.1-100 g / L of potassium gluconate, 0.1-100 g / L of potassium malate, 0.1-150 g / L of citric acid, 0.1-280 g / L of hydantoin, 0.1-280 g / L of butynediol and 0.001-20 g / L of alkyl sulfonic acid surface active agent. The electroplating technology comprises the steps of pretreatment, washing, activating, washing, beforehand silver plating, silver plating, recycling, washing, adjusting treatment, washing, hot water washing (80 DEG C), washing and silver protective agent treatment. The novel silver plating technology has the main beneficial effects that firstly, the plating liquid is very stable and easy to control, the current efficiency of the plating liquid is high, and the dispersing capability and covering capability are good; secondly, a cyanide-free formula is adopted in the electroplating liquid, potential danger of cyanide is eliminated, and pollution to the environment is greatly reduced; and thirdly, the various properties of a plating layer are not lower than those of cyaniding silver plating, and a functional cyaniding silver plating technology can be thoroughly replaced.

Owner:CHONGQING LIDAO SURFACE TECH

Composite urea formaldehyde resin curing agent as well as preparation method and application thereof

InactiveCN101870773ANo hydrolysisLong application periodNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesWorking lifeResin adhesive

The invention discloses a composite urea formaldehyde resin curing agent as well as a preparation method and application thereof. The composite urea formaldehyde resin curing agent comprises the following components: catalyst, controlled release formulations, pH stabilizing agent and water. After the composite urea formaldehyde resin curing agent of the invention is directly mixed into urea formaldehyde resin adhesive with low molar ratio, the curing rate and the curing performance of the urea formaldehyde resin adhesive with low molar ratio can be effectively improved, and thereby the bonding strength thereof is improved and the formaldehyde released content thereof is obviously reduced, and the production efficiency and the product quality are improved; and moreover, the composite urea formaldehyde resin curing agent of the invention has long working life, and can meet the requirements of production operation of artificial boards.

Owner:EVERFIRST WISEFUND TECH BEIJING

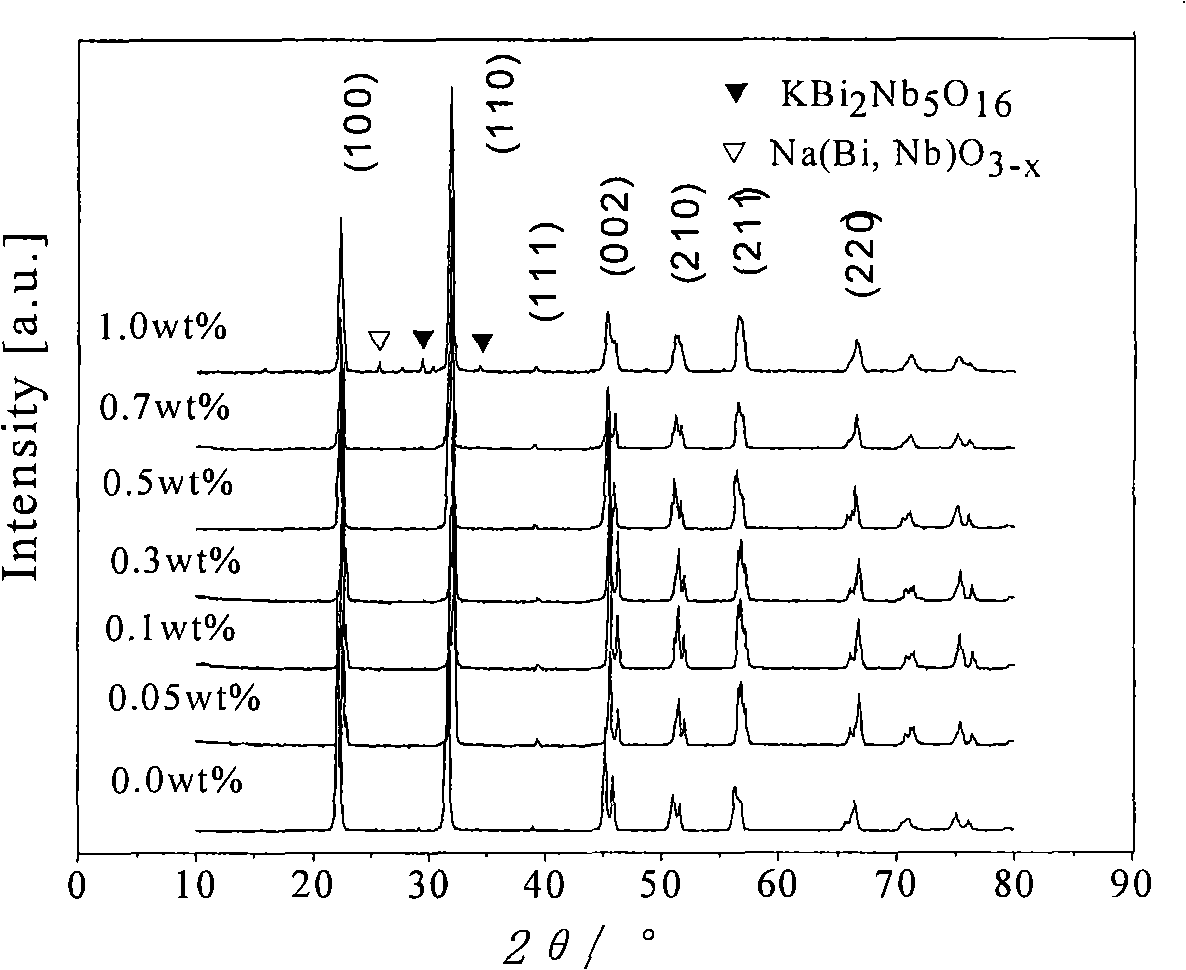

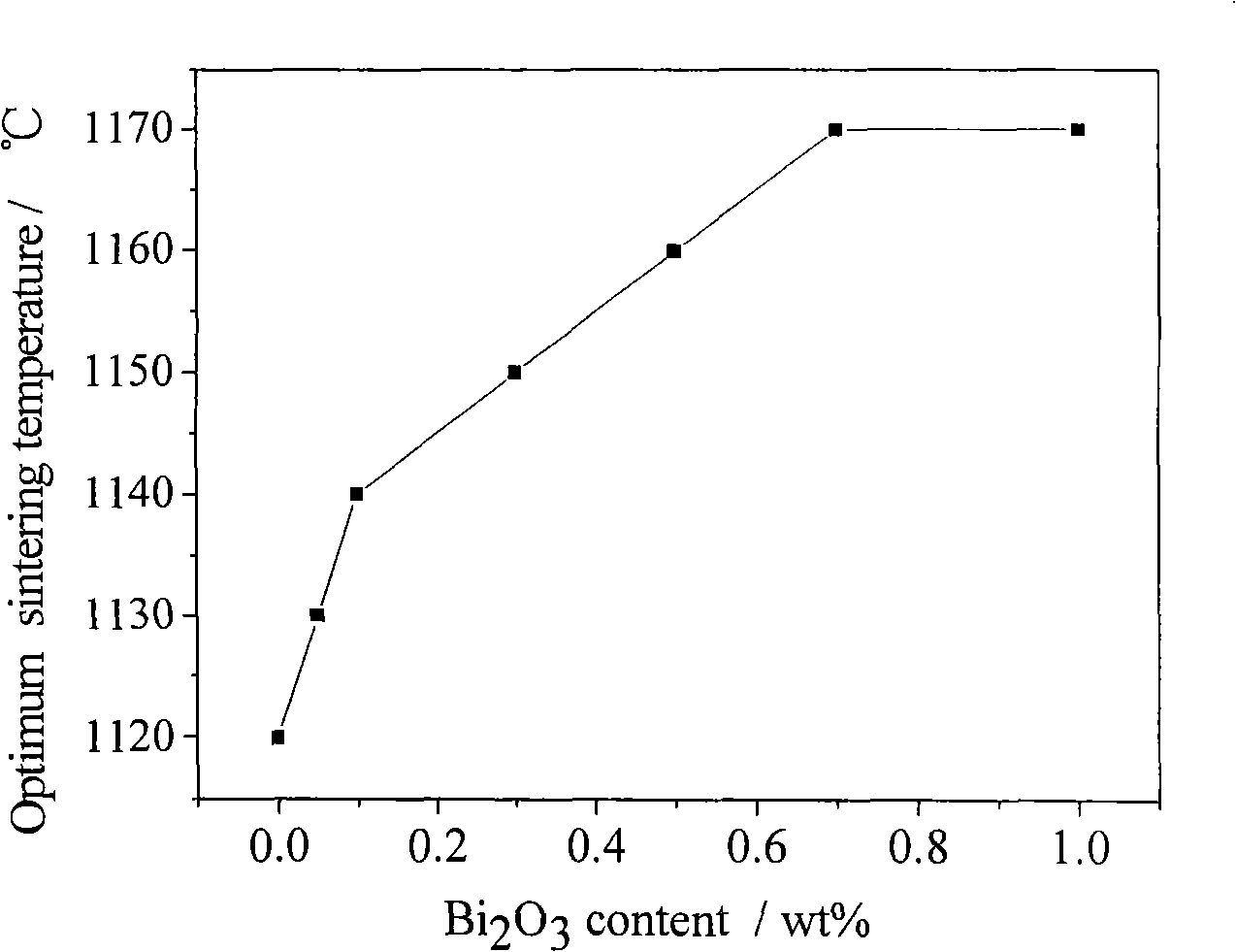

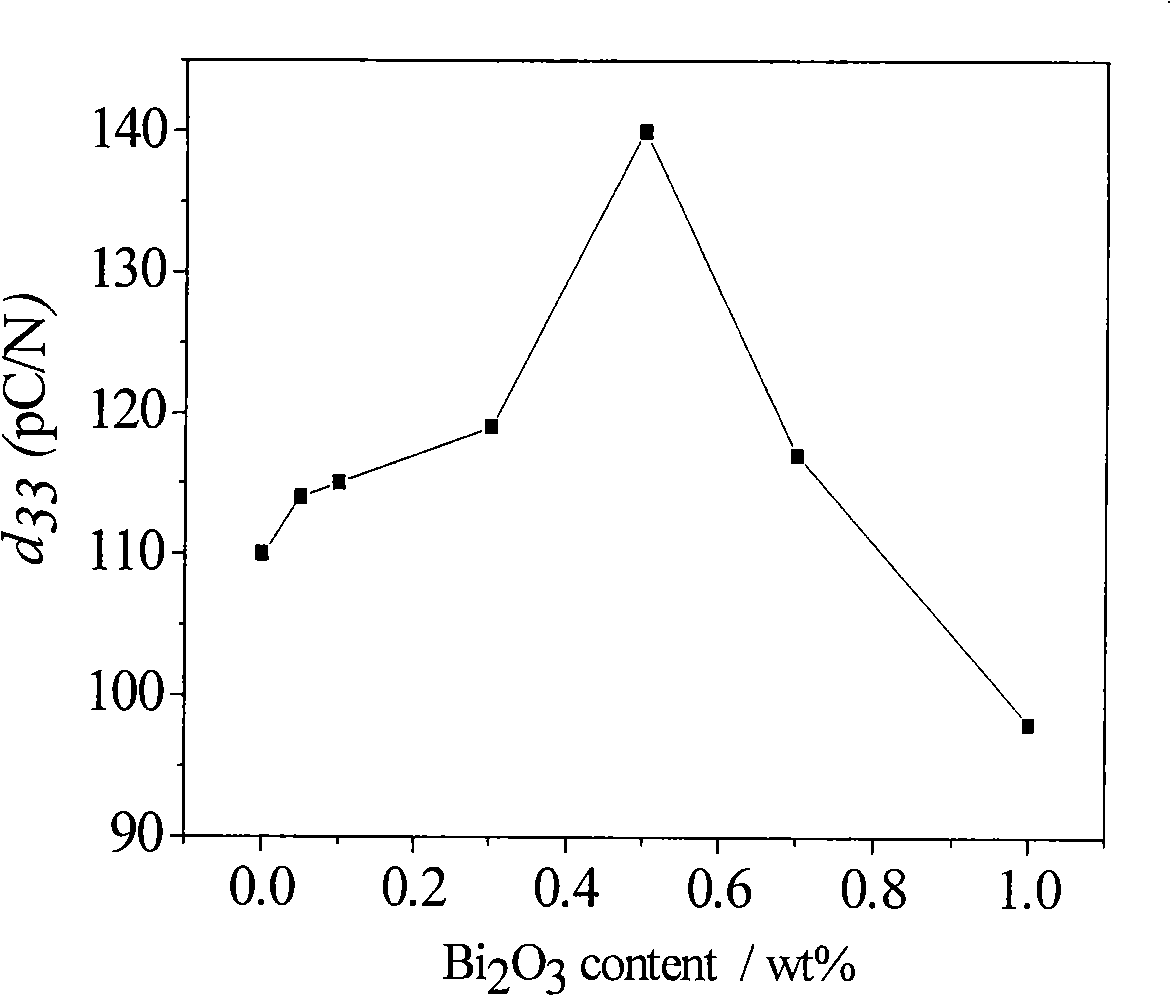

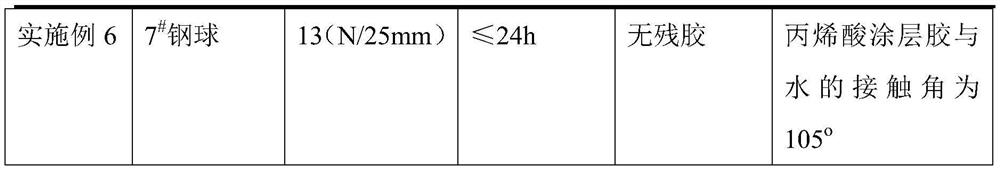

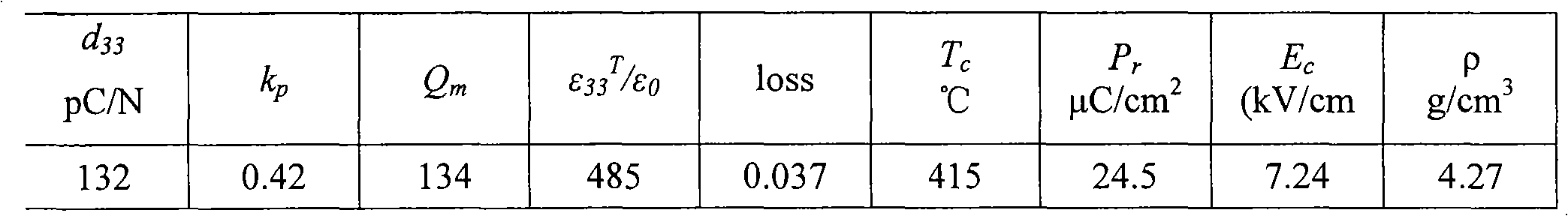

Potassium-sodium niobate-based leadless piezoelectric material and preparation thereof

InactiveCN101302106AImprove sintering propertiesHigh degree of densificationSilver electrodeDrain current

The invention discloses a piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate and a preparing method, which strengthens the ferroelectric performance of potassium-sodium niobate ceramic and further improves the piezoelectric performance. The material of the invention comprises anhydrous potassium carbonate, natrium carbonicum calcinatum, niobium pentaoxide and dibismuth trioxide, the stoichiometric proportion of the lead-free piezoelectric ceramic is (K0.5 Na0.5) Nb3 + x weight percent Bi 2O3, wherein the x is more than or equal to 0 and less than or equal to 1, the piezoelectric material for lead-free piezoelectric ceramic with potassium-sodium niobate is obtained through mixture making, drying and burnishing, granulation, molding, sintering and after polarization by a silver electrode; therefore, the densification of the ceramic is improved, polarized drain current of the ceramic is reduced, and the polarization process is carried out more easily; moreover, the piezoelectric material adopts the material from a conventional process and industry, has the characteristics of good process stability and no pollution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

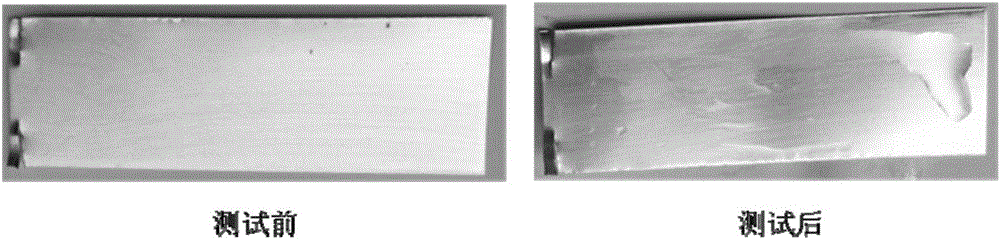

Low-pressure sandstone reservoir gas well temporary blocking workover fluid and preparation method thereof

ActiveCN104531105AStrong ability to draw waterAvoid water lock damageDrilling compositionSealing/packingFiberAlcohol

The invention relates to the technical field of oil and gas field down-hole operation, and specifically relates to a low-pressure sandstone reservoir gas well temporary blocking workover fluid and a preparation method thereof. The workover fluid is composed of the following components, according to percentages in the wellbore volume: 10-20% of an alcohol-based temporary blocking workover fluid, 0.5-1% of an oil-based spacer fluid, and 79-89.5% of a high-efficiency clay stabilizing agent. The alcohol-based temporary blocking workover fluid is composed of the materials of, by mass, 0.5-1% of a water-absorbent polymer, 1-2% of temporary blocking fiber, 0.5-1% of a fiber dispersing agent, 45-50% of water, and balance of alcohol. The high-efficiency clay stabilizing agent is composed of the materials of, by mass, 0.6-1% of a clay stabilizing agent and 99-99.4% of water. With the workover fluid provided by the invention, effective temporary blocking can be realized upon a porous sandstone reservoir; and the harm of the workover fluid upon stratum can be reduced. The workover fluid also has the characteristic of good salt tolerance. With the workover fluid, hydrate blockage is not formed. The workover fluid is safe and environment-friendly, and is convenient for construction.

Owner:PETROCHINA CO LTD

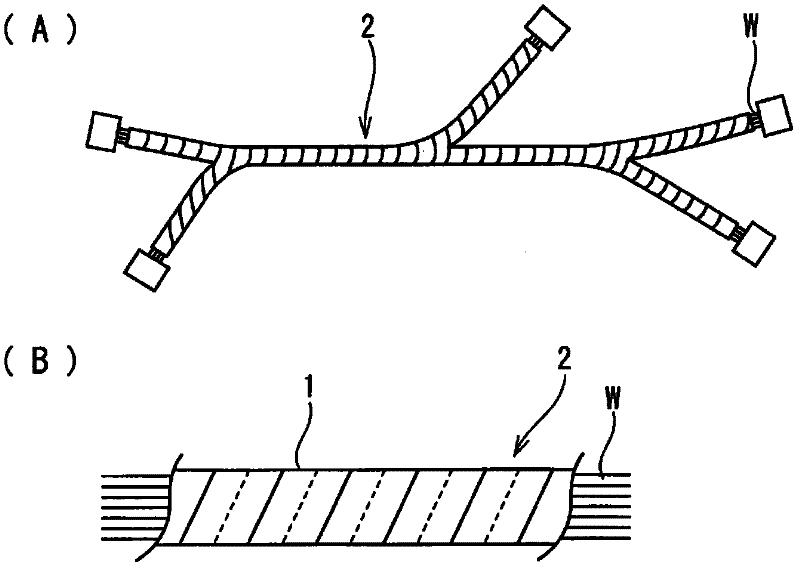

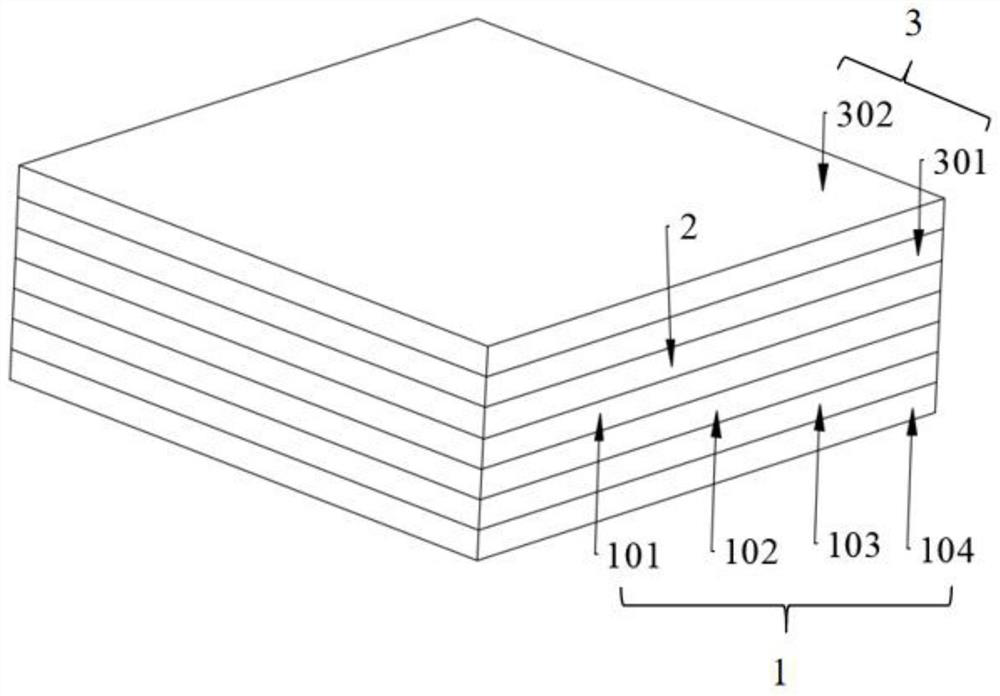

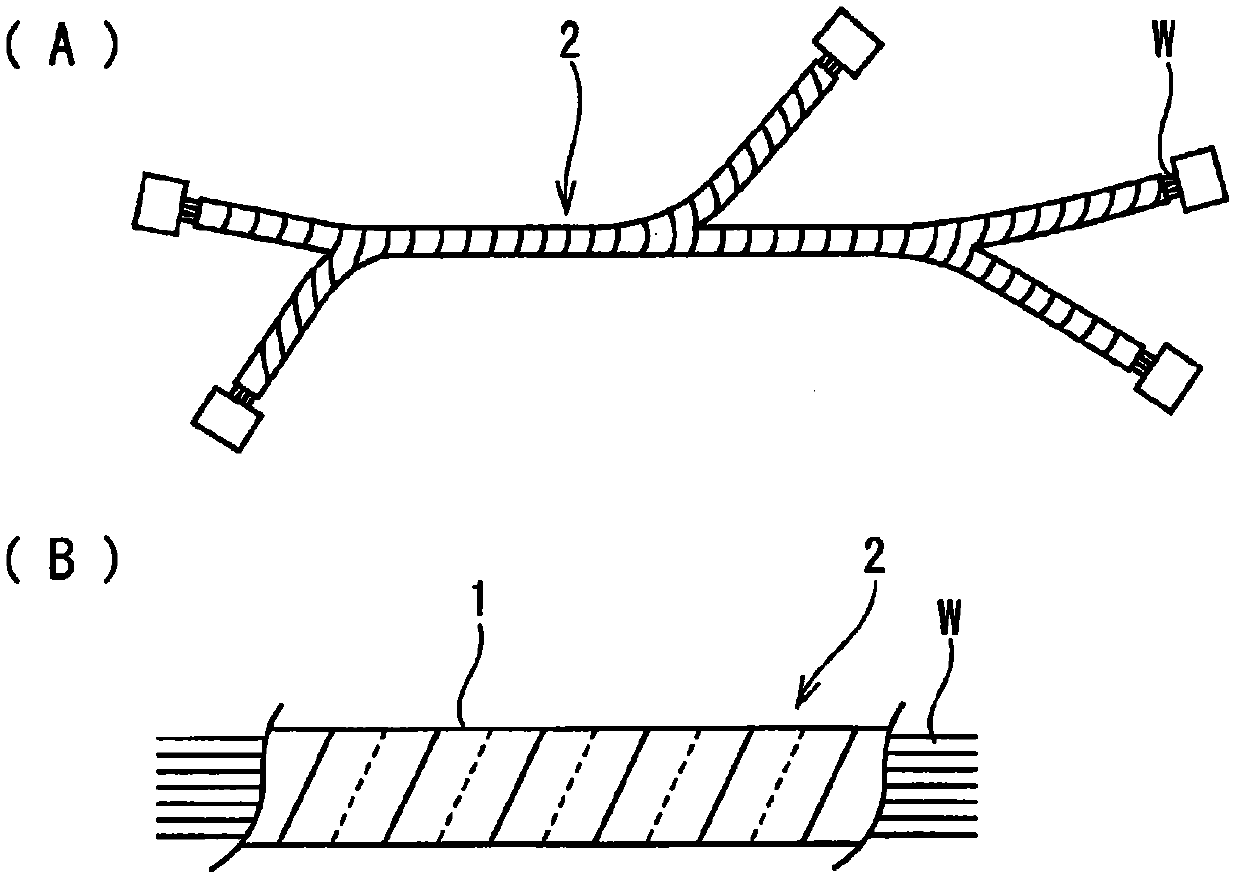

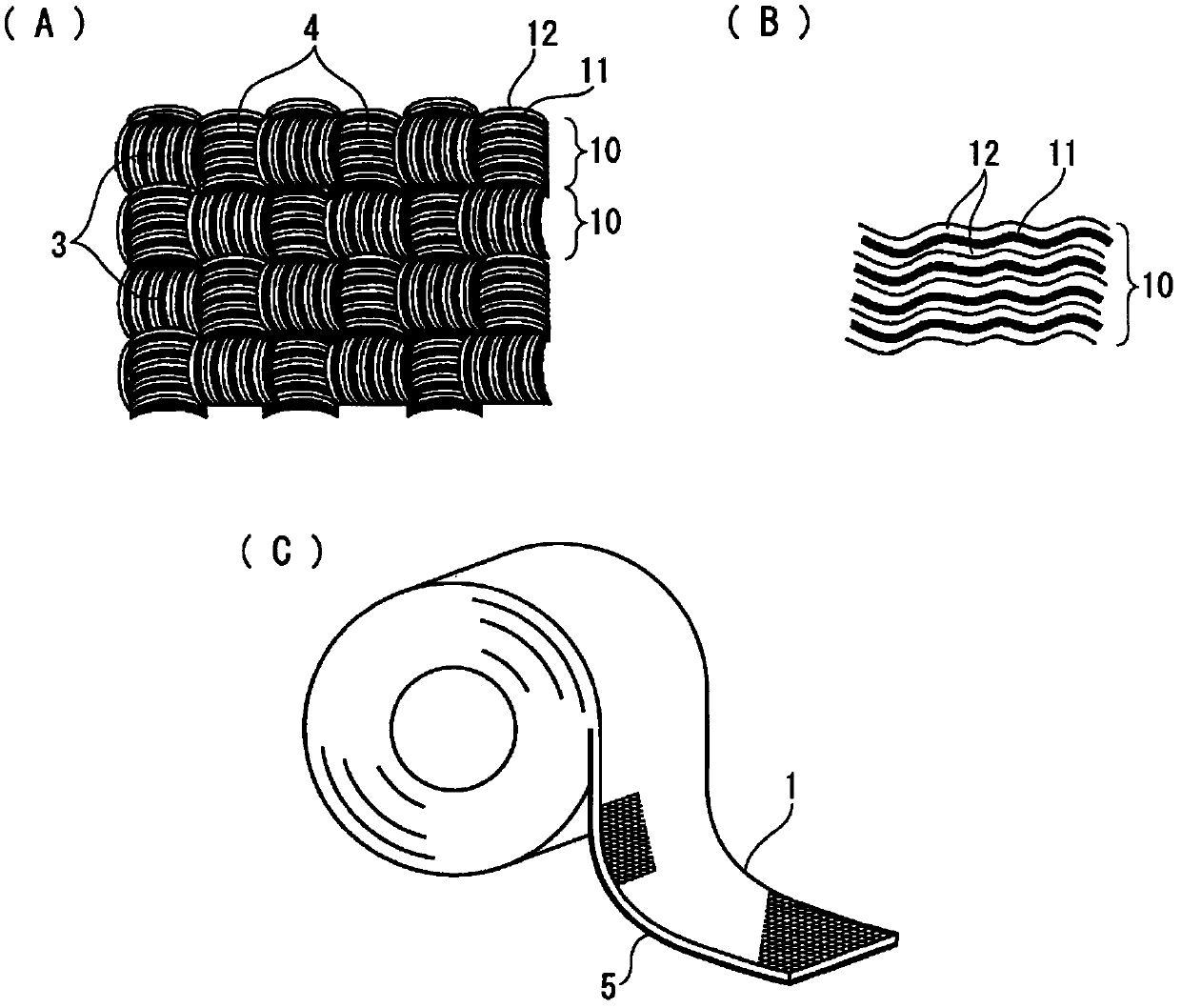

Tape for electric wire

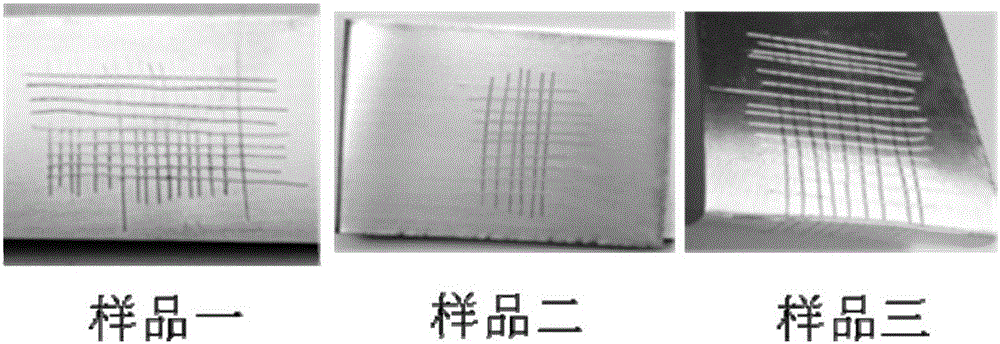

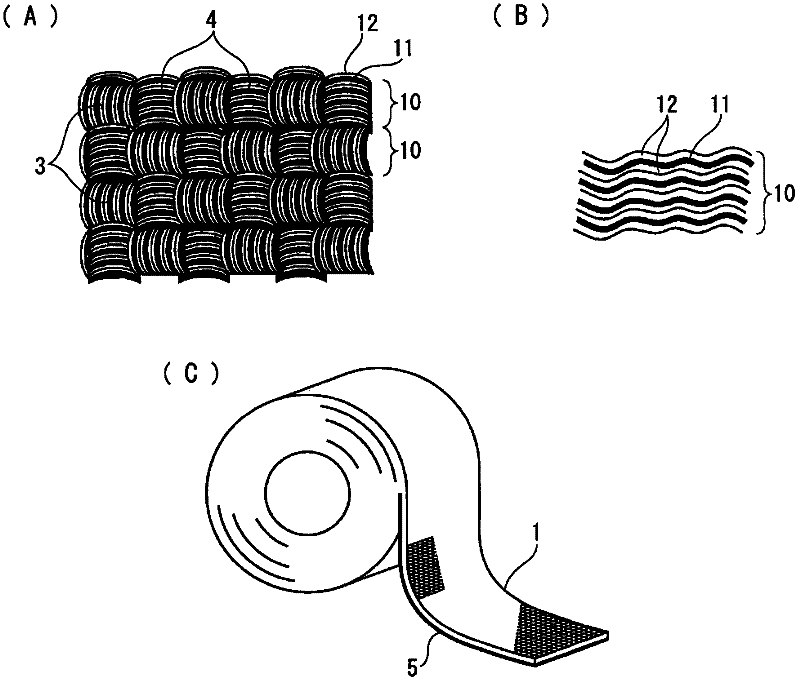

InactiveCN102197556AImprove heat resistanceIncrease flame retardancyPlastic/resin/waxes insulatorsFilm/foil adhesivesYarnPolyester

A tape which has enhanced heat resistance, flame retardancy, and wearing resistance and is suitable for use in bundling a group of electric wires which will be laid in a high-temperature environment. The tape is configured using the same yarns (10) each composed of high-function fiber filaments (11) and general-purpose fiber filaments (12), as a warp (3) and a weft (4). The high-function fiber filaments are superior to the general-purpose fiber filaments in heat resistance, flame retardancy, and wearing resistance. The high-function fiber filaments are of at least one kind selected from para-aramid fibers, polyarylate fibers, ultrahigh-molecular polyethylene fibers, glass fibers, and polyphenylene sulfide fibers. The general-purpose fiber filaments comprise at least one selected from polyesters, polyethylene, and polypropylene.

Owner:SUMITOMO WIRING SYST LTD

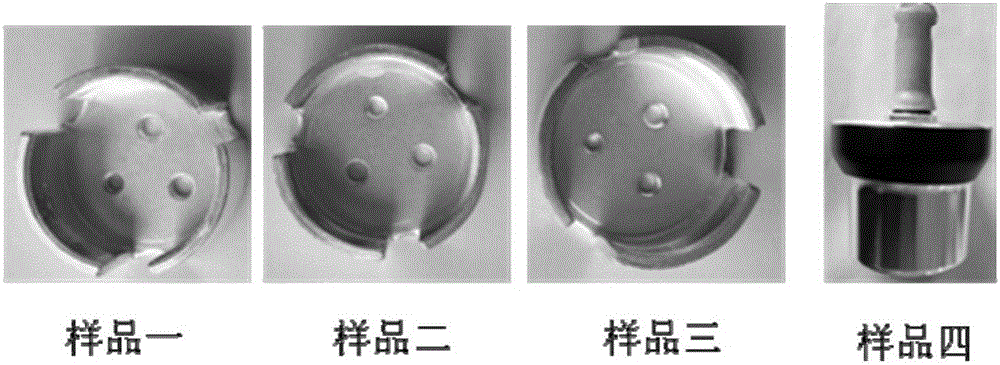

High-performance cyanide-free silver pre-plating liquid

The invention provides high-performance cyanide-free silver pre-plating liquid aiming at the problem of poor adhesion between a substrate and a plating layer in an existing cyanide-free silver plating technology. The pre-plating liquid mainly comprises silver nitrate, methylsulphonic acid, hydantoin, potassium hydroxide, potassium carbonate and nicotinic acid. A high-performance cyanide-free silver pre-plating process has the main advantages that the process is strong in operability and easy to control, the current density is 0.2-0.5 A / dm<2>, the dispersing and covering capabilities are good, and the process adapts to the pre-electroplating of complicated parts; the adhesion between the substrate and the plating layer obtained by silver pre-plating and silver plating is good, the color change resistance is good, and the conductivity and weldability are excellent; by a high-concentration complexing agent and a stabilizer, the pre-plating liquid can be stored for a long term without hydrolysis and is hardly decomposed under the electroplating process conditions. The cyanide-free silver pre-plating liquid provided by the invention can be used for copper, iron and alloy castings, also can be used for silver plating of plastic surfaces, and is widely applied to product surface finishing and the like in the fields of aviation and electronic industries.

Owner:CHONGQING LIDAO SURFACE TECH

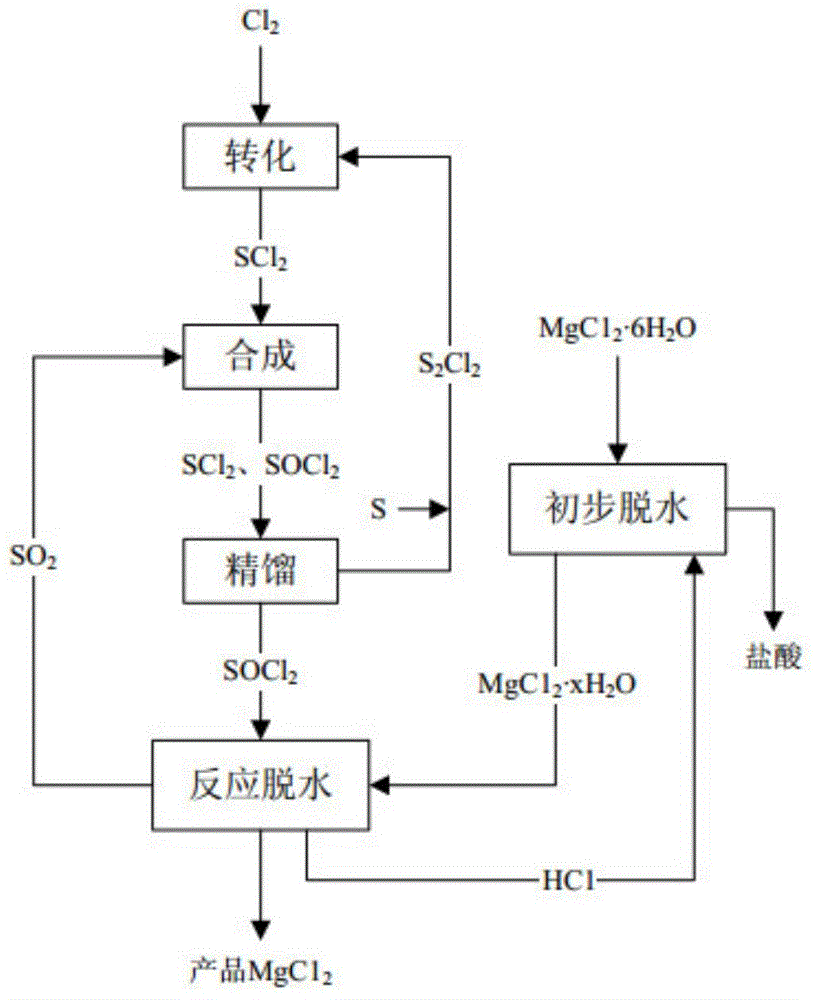

Preparation method of anhydrous magnesium chloride

ActiveCN104556156AReduce energy consumptionAvoid hydrolysisMagnesium chloridesSide reactionWater environment

The invention discloses a preparation method of anhydrous magnesium chloride. The method comprises the following steps: firstly, internally dehydrating magnesium chloride high hydrate under the protection of HCl gas, so as to obtain low hydrate, and then removing residual water through chemical reaction, so as to obtain the high-purity anhydrous magnesium chloride. The initial dehydrating temperature is low, so that the fact that the magnesium chloride is not hydrolyzed and the energy consumption is greatly reduced; a dehydrating agent adopted during the dehydrating in the chemical reaction is formed by the reaction of sulfur and chlorine, intermediate components are continuously recycled, the dehydrating in the chemical reaction ensures that the product anhydrous magnesium chloride is completely disengaged with water environment, and produced side reaction products SO2 and HCL are gases, so that the occurrence of hydrolysis reaction is thoroughly avoided. The method is wide in raw material resource and low in price, the whole technical process is good in economic benefit, and the method provided by the invention is high in operability and easy to realize industrialization.

Owner:CHINA TIANCHEN ENG +1

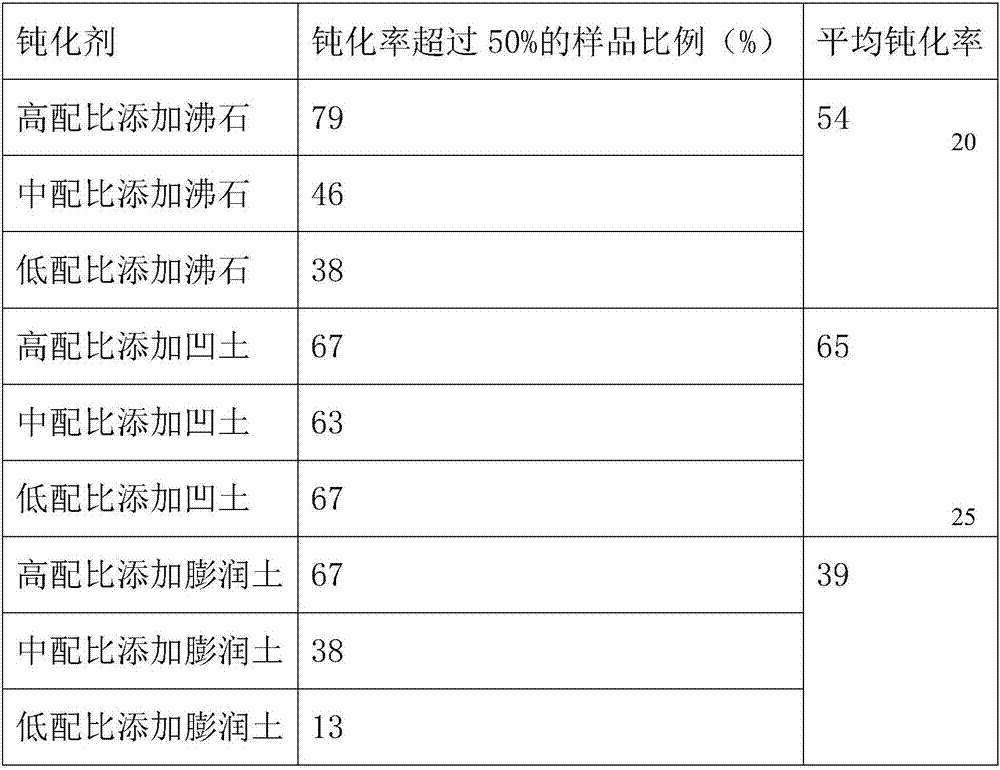

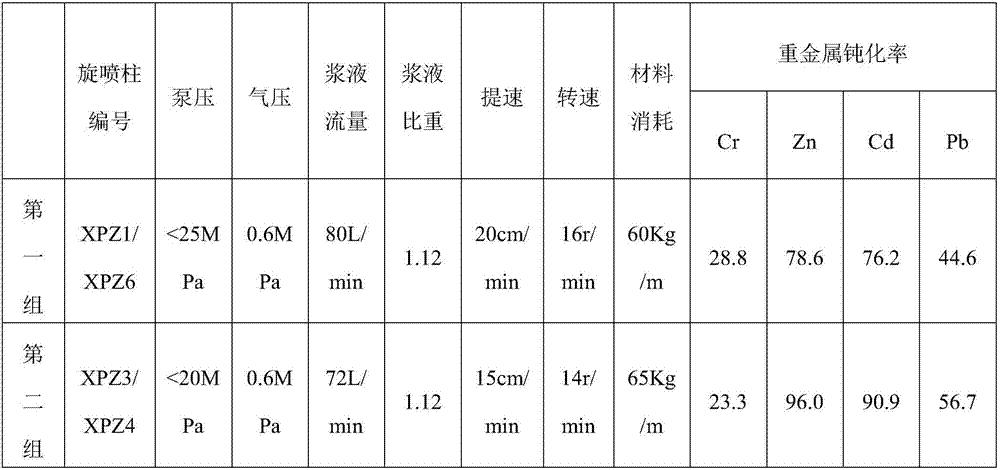

In-situ repair method of tailing sand heavy metal

InactiveCN107470346APromote migrationReduce infiltrationContaminated soil reclamationHigh pressureMaterials science

The invention discloses an in-situ repair method of tailing sand heavy metal. The in-situ repair method of the tailing sand heavy metal is characterized in that a high-pressure jet grouting process is adopted to perform the jet grouting on modified attapulgite-contained pulp into tailing sand in situ, so that the heavy metal is cured.

Owner:NAT RESERACH CENT OF GEOANALYSIS +1

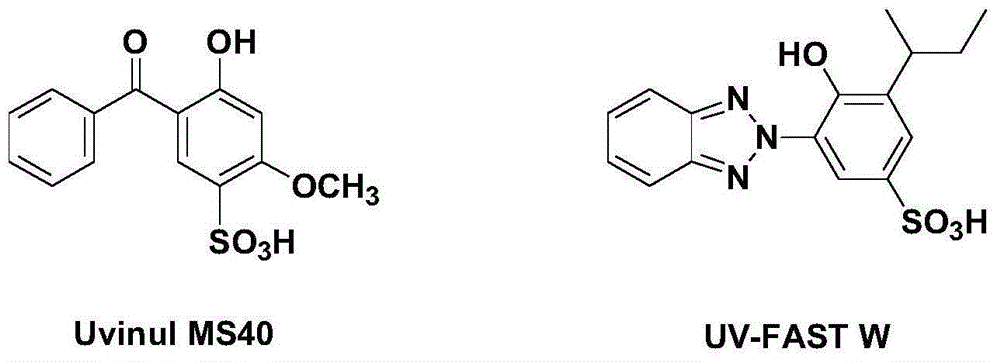

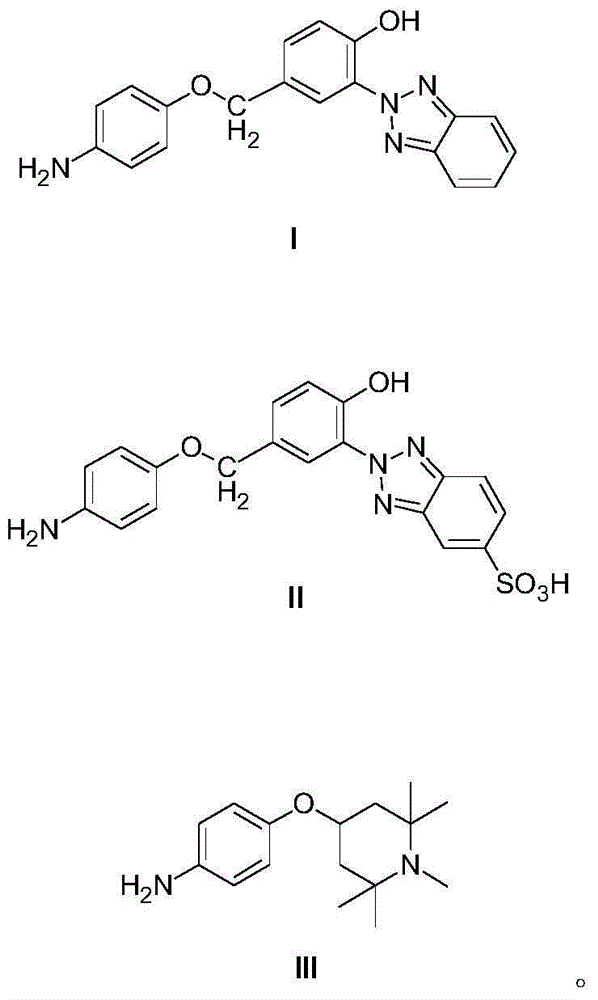

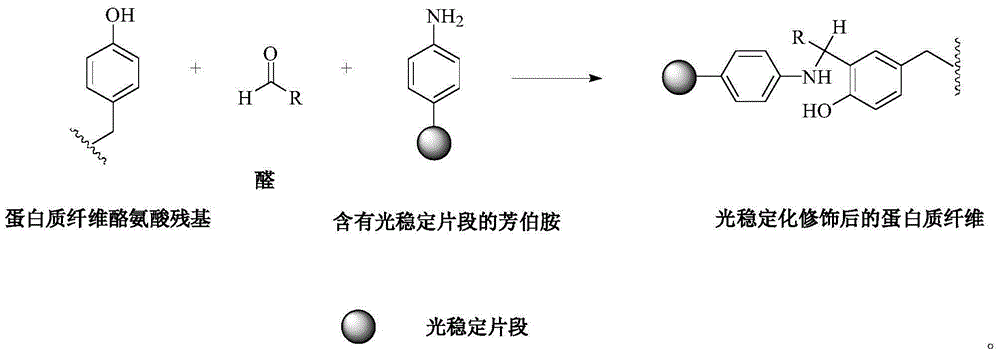

Reactive light stabilizer suitable for protein fibers and preparing method thereof

InactiveCN105040428AImprove fastness to wet treatmentReduce development costsOrganic chemistryAnimal fibresFiberChemical reaction

The invention discloses a reactive light stabilizer suitable for protein fibers. The structural formula of the reactive light stabilizer is any one of the following structural formulas (please see the specification for the structural formulas). The invention further provides a preparing method of the reactive light stabilizer. The preparing method includes the steps that halogen is introduced into light stabilizing sections of the light stabilizer through a chemical reaction, obtained compounds and p-nitrophenol generate a substitution reaction in alkali liquor with the equivalent amount, and therefore nitro-group-containing ether compounds are generated; primary arylamine compounds, with ether bonds as bridge groups, connected with the light stabilizing sections are generated through the ether compounds with a thiourea dioxide reduction method, wherein amino groups of the primary arylamine compounds are located at the para-position of ether groups. The light stabilizer and the protein fibers can be firmly combined through aldehydes materials under the mild reaction condition by means of a Mannich reaction.

Owner:ZHEJIANG SCI-TECH UNIV

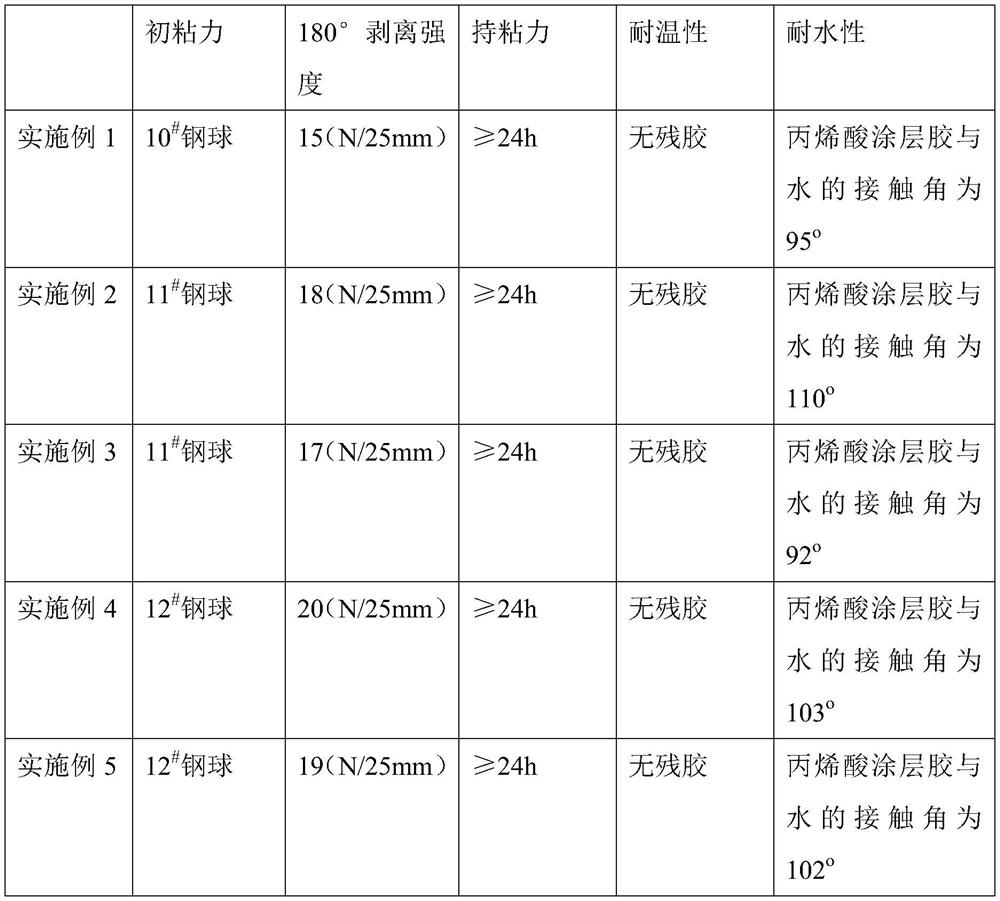

Low-temperature-resistant acrylic acid coating adhesive and preparation method and application thereof

ActiveCN111748301AHigh peel strengthImprove low temperature resistanceFilm/foil adhesivesEster polymer adhesivesSodium bicarbonatePolymer science

The invention discloses a low-temperature-resistant acrylic acid coating adhesive and a preparation method and application thereof. The low-temperature-resistant acrylic acid coating adhesive is prepared by adopting a seed semi-continuous emulsion polymerization method. The adhesive is prepared from the following raw materials in parts by weight: 20-50 parts of acrylate soft segment monomer; 1-6 parts of an acrylate hard segment monomer; 1-6 parts of a fluorine-containing monomer; 1-5 parts of an emulsifier; 0.1 to 1 part of an initiator; 0.05 to 3 parts of a silicon monomer; 0.05 to 1 part ofsodium bicarbonate; and 30 to 90 parts of deionized water, wherein the initiator is persulfate. The acrylic acid coating adhesive has good low-temperature resistance, water resistance and acid and alkali resistance, and also has relatively high peel strength and initial viscosity on a bonding surface with low surface energy.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

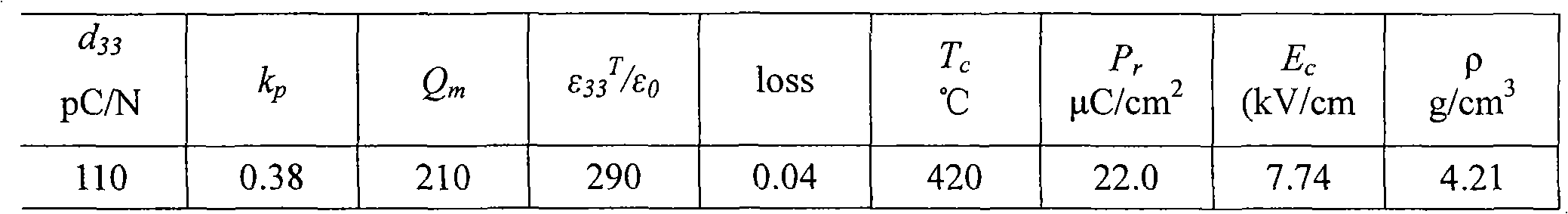

Leadless piezoelectric ceramics with bismuth ion replacing modified potassium sodium niobate base and method for preparing same

InactiveCN101311139AImprove sintering propertiesHigh degree of densificationPiezoelectric/electrostrictive/magnetostrictive devicesNiobium compoundsTrioxideSodium carbonate anhydrous

The invention relates to a modified potassium-sodium niobate based leadless piezoelectric ceramics substituted by bismuth ion and a preparation method thereof; the raw materials includes anhydrous potassium carbonate, anhydrous sodium carbonate, niobium pentaoxide and dibismuth trioxide; the stoichiometric ratio thereof is ((K0.5Na0.5)1-3xBix)NbO3(x is more than or equal to 0.0 and less than or equal to 0.05), wherein, x is more than or equal to 0.0 and less than or equal to 0.5; the bismuth ion is added to replace the ion at A position in (K0.5Na0.5)NbO3 ceramics, thus improving sintering characteristics and ferroelectric properties of potassium-sodium niobate ceramics and further enhancing piezoelectric properties thereof. During preparation, according to the principle of electrical valence equilibrium, the bismuth ion is added and K ion and Na ion are reduced at the same time, thus generating the vacancy at the A position and avoiding the formation of residual matter; therefore, the piezoelectric properties d33 and kp can reach 164pC / N and 47% respectively; moreover, the invention is characterized by broad source of the raw materials, good stability of the technique and no environment pollution.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

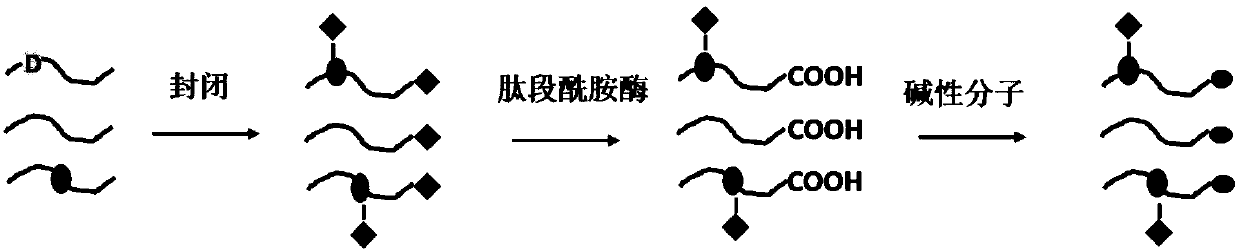

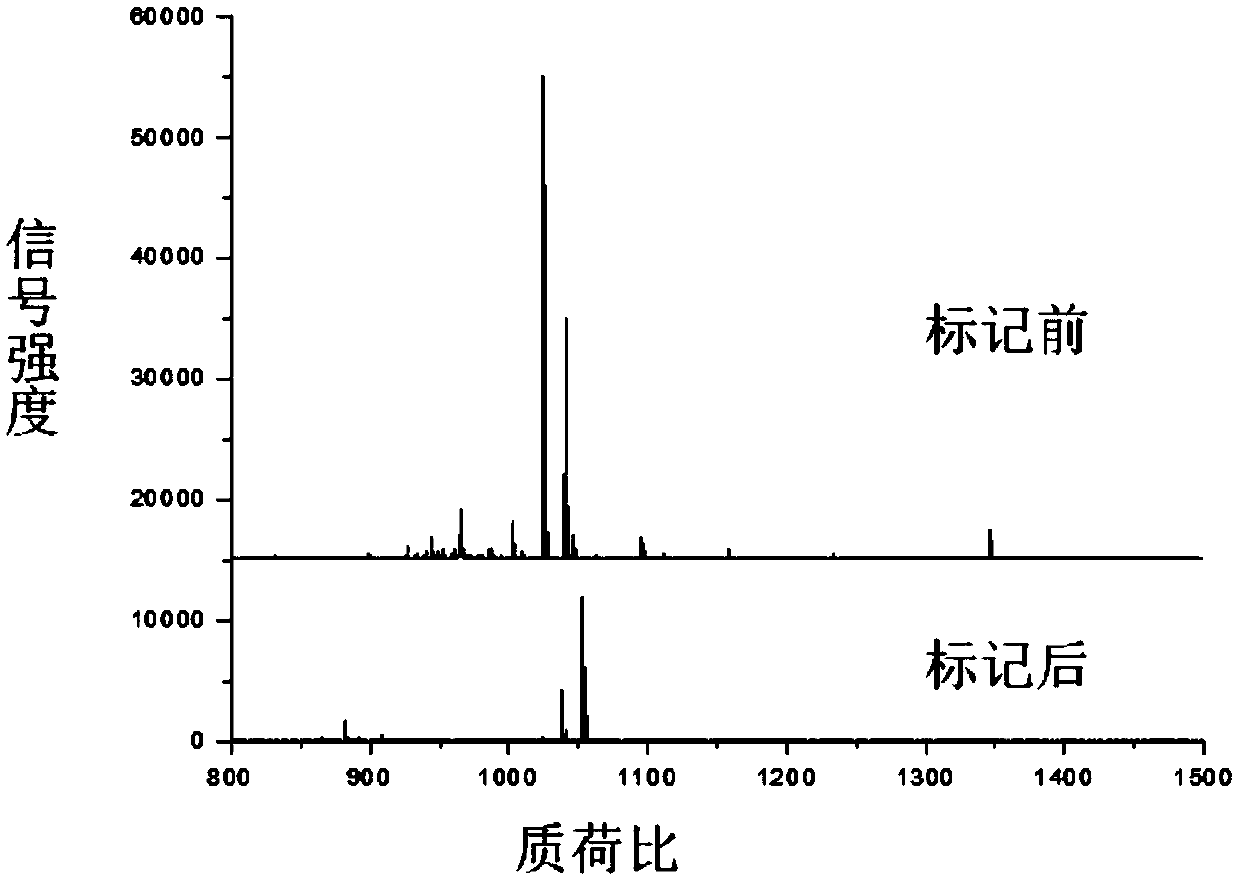

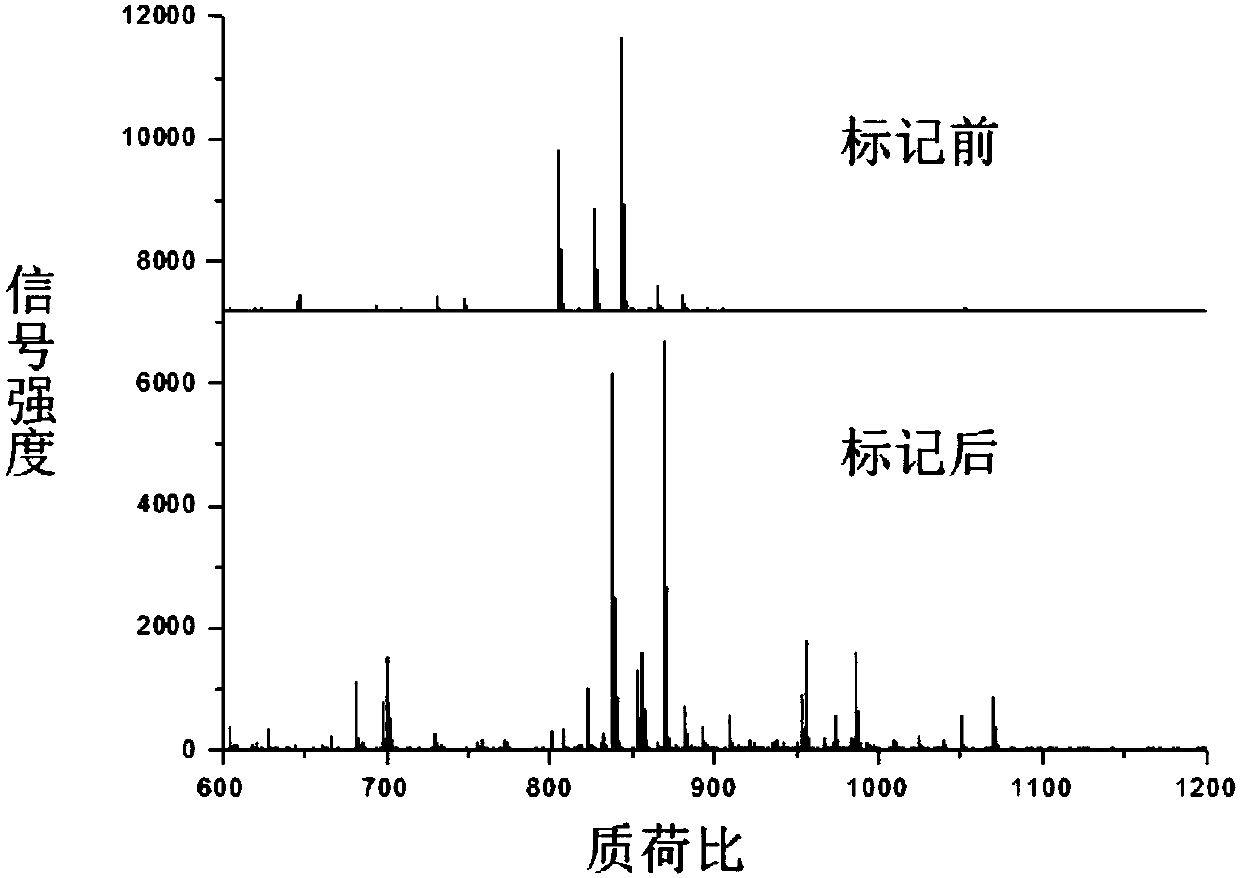

Method for improving mass spectrum fragmentation efficiency and response based on peptide fragment C-terminal chemical derivation

ActiveCN111208237AImprove reaction efficiencyNo hydrolysisComponent separationCarboxyl radicalSide chain

The invention relates to a method for improving mass spectrum fragmentation efficiency and response based on peptide fragment C-terminal chemical derivation. The method comprises three steps of reaction: firstly, sealing carboxyl at the tail end of a peptide fragment C or carboxyl at the tail end of the peptide fragment C and carboxyl of side-chain glutamic acid or aspartic acid; then, using peptide fragment amidase for specific hydrolysis and exposing carboxyl at the tail end of the peptide fragment C; and finally, carrying out chemical derivation of alkaline molecules on the exposed C-terminal carboxyl. Alkaline molecules marked at the tail end of the peptide fragment C can increase the number of y ions in the secondary mass spectrum and improve the fragmentation efficiency and responseof the peptide fragment in the mass spectrum so that the method is applied to improve the detection sensitivity of polypeptide drug peptides.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for synthesizing high-yield nandrolone

The invention relates to a method for synthesizing high-yield nandrolone. The method comprises the following synthesizing steps of: (1) etherification reaction: absolute ethyl alcohol and triethyl orthoformate are put into a reactor which is provided with an agitation device to be agitated, 19-norandrostendione, and pyridine hydrobromate and triethylamine are then put into the reactor and are agitated, freeze crystallized, sprinkled and centrifugally filtered to obtain wet etherate; (2) reduction hydrolysis reaction: in a reaction vessel, methanol is put at first to be mixed, the etherate and sodium borohydride are then put, acid is added to regulate pH, vacuum concentration is carried out, water is flushed, centrifugation is carried out to obtain a reduction hydrolysate, i.e. crude nandrolone, and the crude nandrolone is dried; and (3) crude product refining: the crude nandrolone, ethyl acetate and petroleum ether are put into a tank at one time and are heated to dissolve, cooled, centrifuged and dried, so that refined nandrolone is obtained. The method adopts a new catalyst-pyridine hydrobromate, so that a hydrolysis phenomenon cannot be caused after protection materials are added, and thus, the protection yield and quality are improved.

Owner:YICHENG GOTO PHARMA

High-yield Boldenone synthesis method

The invention relates to a high-yield Boldenone synthesis method. The method comprises the following steps of: 1, etherification reaction: adding absolute ethyl alcohol and triethyl orthoformate in a reaction kettle, stirring, adding 1.4-ADD, pyridine hydrobromide and triethylamine, freezing for crystallization, washing with absolute ethyl alcohol, and filtering in a swinging manner to get the wet etherate; 2, reduction and hydrolysis reaction: firstly, adding methyl alcohol in the reaction kettle, stirring, then, adding etherate pyridine and sodium borohydride, preserving heat for reaction, and carrying out thin layer chromatography, after the reduction reaction, regulating the temperature, regulating pH, concentrating the mixture to be in dense slurry form, adding water, cooling, centrifuging to get reduced hydrolysate, namely a Boldenone crude product, and drying; and 3, refining of crude product: adding the Boldenone crude product, methyl alcohol and water in the production kettle, heating with steam, cooling, and centrifuging. In the method, a new catalyst, namely pyridine hydrobromide, is used, thus, the yield and the quality of the product are improved. The method realizes one-step preparation of Boldenone, and in comparison with the DDQ (dihydro dicyan benzoquinone) dehydrogenation used in the past, the cost of products is saved in the synthesis method.

Owner:YICHENG GOTO PHARMA

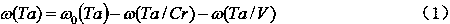

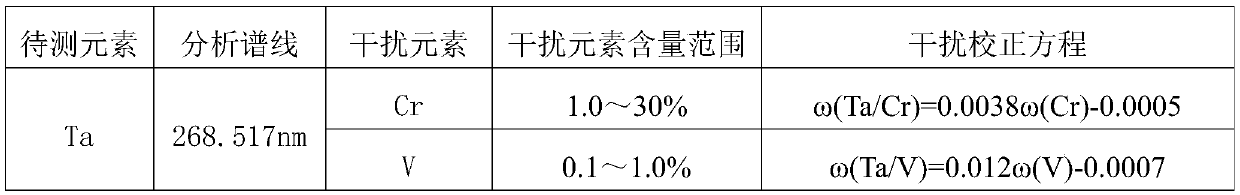

Method for determining content of tantalum element in nickel-based alloy

InactiveCN111024682AImprove test accuracyFully digestedPreparing sample for investigationAnalysis by thermal excitationOptical spectrometerInductively coupled plasma emission spectroscopy

The invention discloses a method for determining the content of a tantalum element in a nickel-based alloy. The method comprises the following steps: (1) preparing a standard Ta element standard solution; (2) establishing an interference correction model according to the actual content range of Cr, V and other elements in the nickel-based alloy; (3) measuring the Ta element standard solution on aninductively coupled plasma emission spectrometer, and drawing a standard curve; (4) accurately weighing a nickel-based alloy sample, and preparing a sample solution; and (5) determining the emissionintensity of the Ta element in the sample solution, calculating the content of the Ta element in the sample solution according to the standard curve, and correcting through an interference correctionformula to obtain the actual content of the Ta element in the nickel-based alloy. The method can accurately determine the actual content of the tantalum element in the nickel-based alloy, and has goodtest precision.

Owner:HEBEI IRON AND STEEL

Fresh brewing spilit and its preparation process

InactiveCN1597906AImprove yieldImprove decomposition abilityAlcoholic beverage preparationBrewingWhite spirit

The invention discloses a fresh made white spirit and its making method, on the basis of producing process and technique of yellow wine and Qing wine, regulating and changing the use modes and methods of raw materials, saccharifying agent and fermenting agent in the fermenting wine process, its yield high. It is a simple-process, low-cost white spirit producing process, and the made white spirit has rich nutrition, tastes pure and mild and sweet and refreshing, and has a style of white spirit in taste and the same inner quality and nutrition content as those of the yellow wine and Qing wine.

Owner:岳喜才

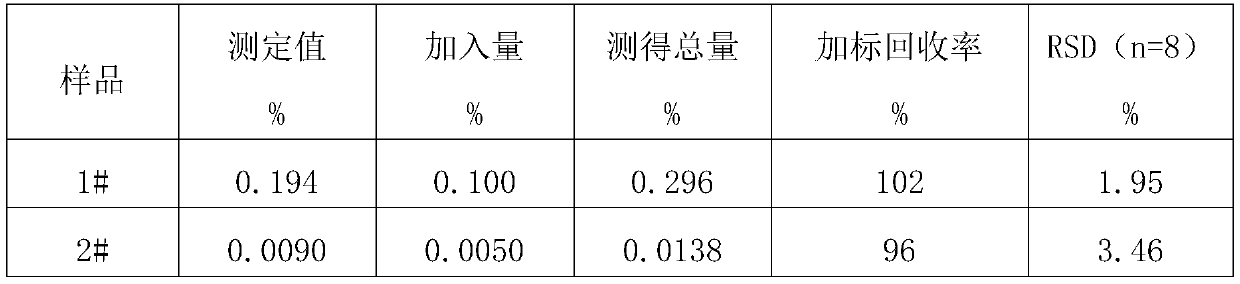

Method for preparing ruthenium nitrosyl nitrate solution

ActiveCN112142127AReduce chlorine contentMeet the use requirementsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsMetal impuritiesAqueous solution

The invention relates to a method for preparing a ruthenium nitrosyl nitrate solution, and belongs to the technical field of precious metal compound preparation. The method comprises: introducing ruthenium tetroxide gas into a nitric acid aqueous solution, and carrying out an absorption reaction to prepare a ruthenium absorption liquid; adding a reducing agent into the ruthenium absorption liquid,and reacting at 5-15 DEG C to obtain a ruthenium absorption liquid containing nitrosyl; adding a pH regulator A, regulating the pH value to 5-7, adding a pH regulator B, regulating the pH value to 8-10 to obtain a ruthenium precipitate, and repeatedly filtering and washing to remove impurities; and adding a nitric acid aqueous solution, and carrying out a reflux reaction for more than 2 hours toobtain a ruthenium nitrosyl nitrate solution; According to the invention, the ruthenium nitrosyl nitrate solution prepared by the method has the characteristics of low chlorine content, low nitric acid content, low metal impurity content, low corrosion and high stability.

Owner:中国船舶集团有限公司第七一八研究所

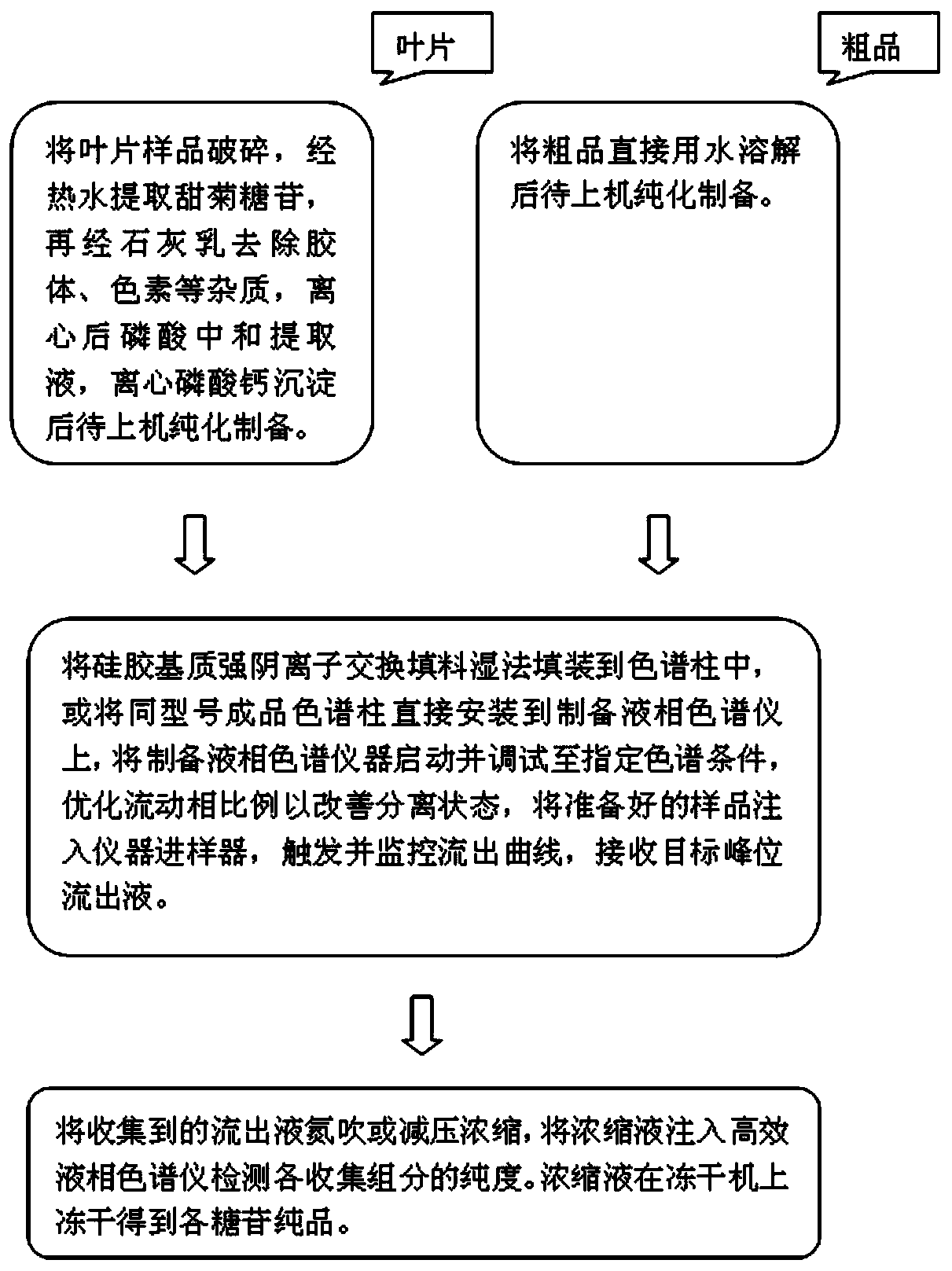

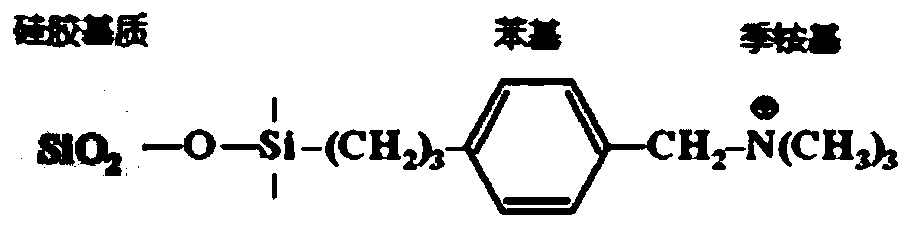

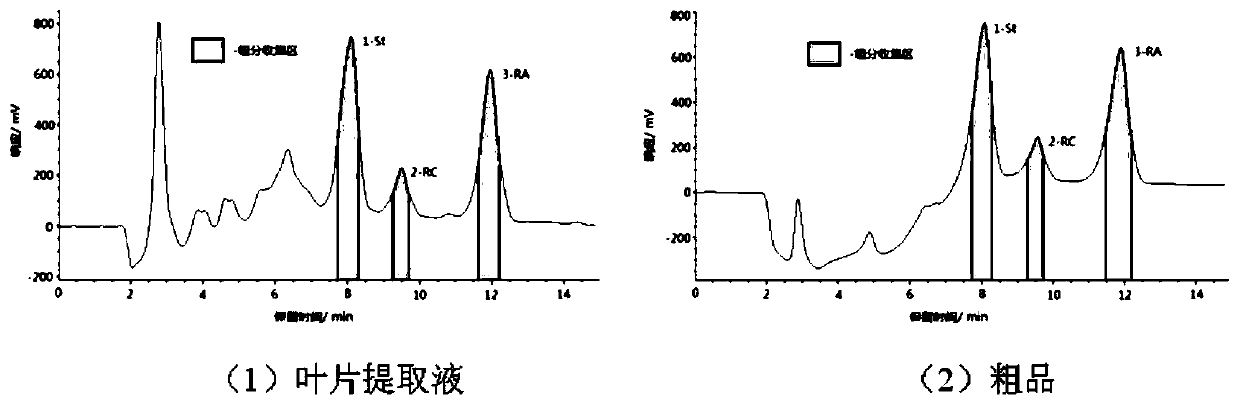

Method for separating and purifying stevioside by using silica gel substrate strong anion exchange chromatography

PendingCN109897074AExtended service lifeEasy to operateSugar derivativesSugar derivatives preparationChromatographic separationIon exchange

The invention relates to a method for separating and purifying stevioside by using silica gel substrate strong anion exchange chromatography. Stevia leaves or stevioside crude products are used as rawmaterials, HP-SAX silica gel substrate strong anion exchange chromatography filler or a homotype finished product chromatographic column is used as a separation medium, separation and purification are performed with liquid chromatography, and three steviosides including stevioside, rebaudioside C and rebaudioside A are obtained simultaneously. The invention also relates to an application of the method in preparation of the stevioside, the rebaudioside C and the rebaudioside A by separation and purification. The method is convenient and rapid, single separation can be completed within 15 min,the purity of purified products is higher than 99.0%, repeatability is good, operability is high, an organic solvent aqueous solution in any proportion and even 100% water can be used as a chromatographic separation medium to wash away impurities such as inorganic salt and pigment caused by samples on the head of the chromatographic column, the separation medium is not prone to hydrolysis or collapse in the washing process, and the separation medium has long service life and can be reused for a long time.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

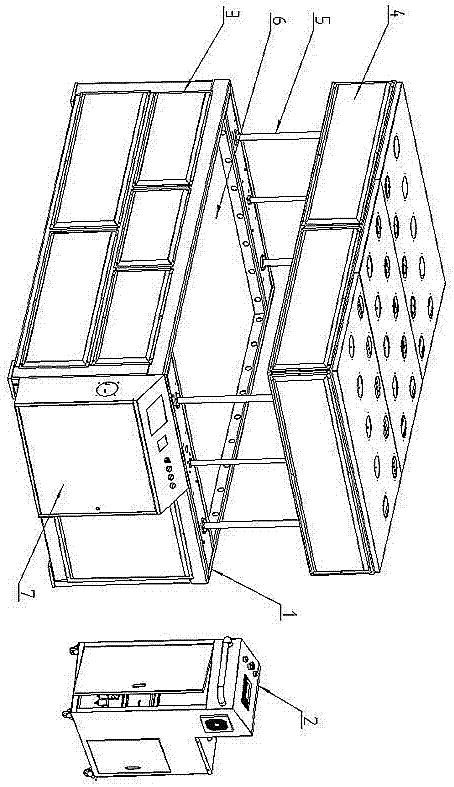

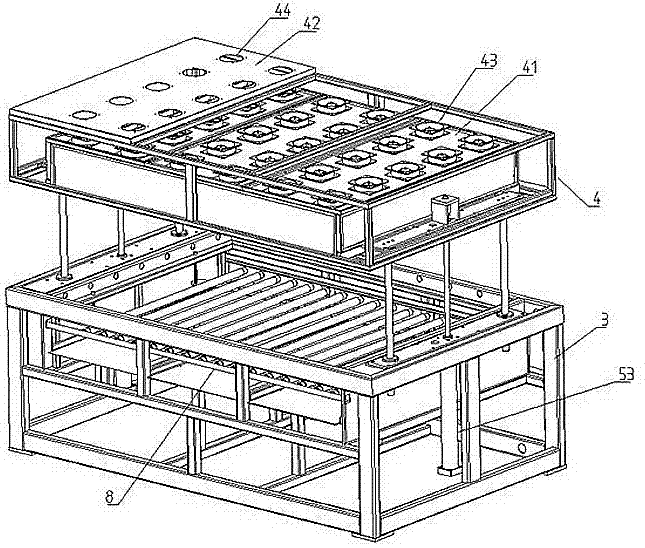

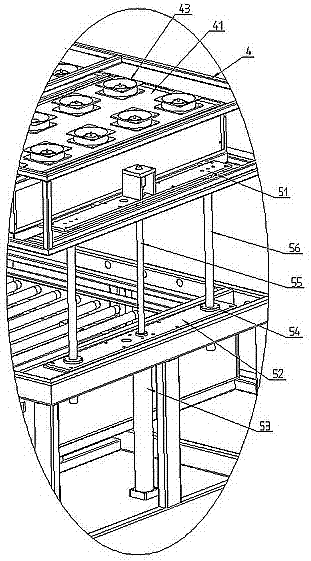

Novel solidifying machine

PendingCN107160848ABright and uniform luminous effectHigh light transmittancePrinting press partsEpoxyUltraviolet lights

A novel solidifying machine comprises a main machine seat and a main electrical cabinet. The main machine seat comprises a main lathe body and an upper frame. The two sides of the main lathe body are provided with sliding guide rod groups. The sliding guide rod groups are connected with the main lathe body and the upper frame. The main lathe body is further provided with a tempered glass platform which is horizontally fixed. The tempered glass platform is used for placement of matrixes. An ultraviolet radiator array is arranged below the temperate glass platform. The upper frame is provided with a lining top plate and an outer top plate. The lining top plate is provided with a cooling fan array. The outer top plate is provided with corresponding through holes corresponding to the cooling fans in position. An auxiliary electrical cabinet is further arranged on one side of the main lathe body. The auxiliary electrical cabinet is electrically connected with the sliding guide rod groups, the ultraviolet lamp array, the cooling fan array and the main electrical cabinet. According to the novel solidifying machine, a light source emitted by the ultraviolet radiator array is fully converted, the manufactured words are high in luminous effect and uniform in luminance, and the light transmittance and light conductivity of the manufactured words are far higher than those of traditional acrylic materials and epoxy resin materials.

Owner:广州市粤雕自动化设备有限公司

Micro-water dyeing method suitable for wool

The invention relates to a micro-water dyeing method suitable for wool. The micro-water dyeing method comprises the following steps that a, products to be dyed are prepared; b, a dedicated dyeing system is configured, specifically, reactive dyes and metered water only used for dissolving the reactive dyes are uniformly stirred, and poor solvents of the reactive dyes are added to prepare the dedicated dyeing system; c, dyeing is carried out; d, soaping is carried out; e, dehydrating is carried out; and f, drying is carried out, and dyeing products are obtained. Compared with a traditional woolreactive dyeing method, the dyeing method does not require any accelerating salt, with the help of non-aqueous media with low surface tension, the reactive dyes can be rapidly dyed to the surfaces ofwool fibers, the reactive dyes hardly hydrolyze without an alkaline agent, and the fixation rate of the reactive dyes is greatly improved. According to the micro-water dyeing method suitable for the wool, the use ratio of the reactive dyes for wool dyeing is effectively improved, the dyed wool is not required to be specifically processed, and the wet rubbing fastness meets the requirements in themarket.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD +1

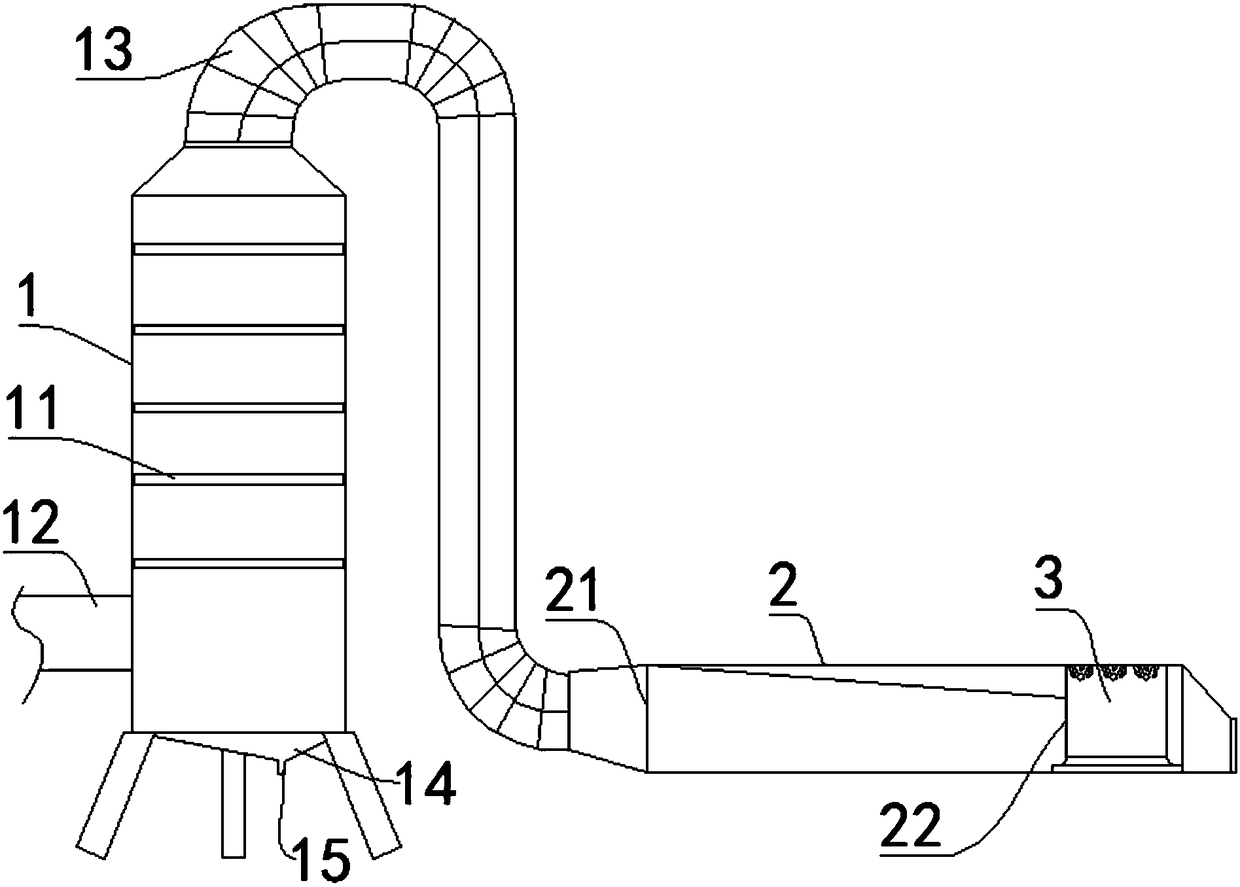

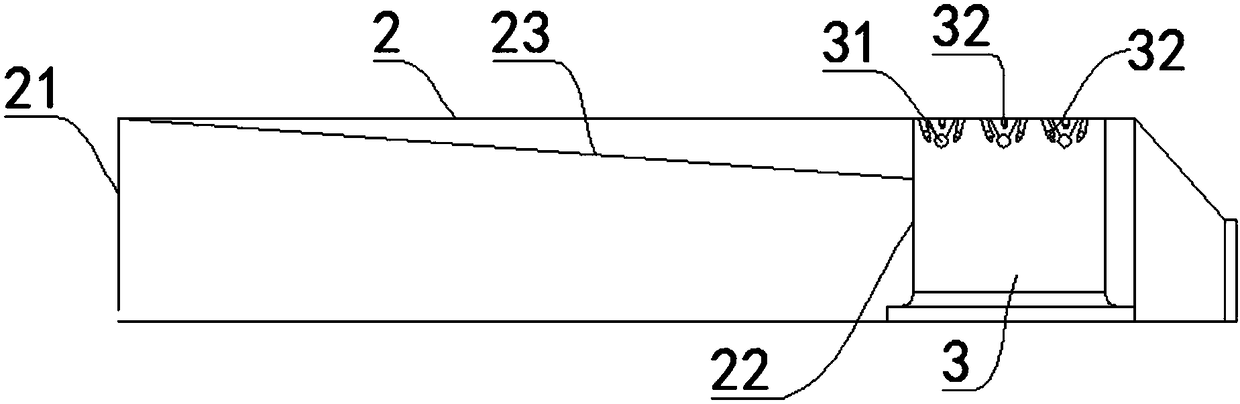

UV light-cured varnish spraying waste gas recycling equipment and technology

PendingCN108554103AIncrease profitImprove performanceCombination devicesActivated carbonEnvironmental engineering

The invention relates to the technical field of environmental protection and discloses UV light-cured varnish spraying waste gas recycling equipment and a technology. The equipment comprises a collection tower, a deflecting deceleration air-duct and a drying curing box which are successively communicated. Multiple layers of separating plates are fixedly installed inside the collection tower. An ultraviolet lamp tube is installed at the upper part inside the drying curing box. By the utilization of characteristics of varnish waste gas, the varnish waste gas successively undergoes gas-to-liquidconversion recovery, ultraviolet radiation curing, dust recovery, UV photolysis or activated carbon adsorption box adsorption, and finally the varnish spraying waste gas is discharged. The waste gas treatment is safe and environmentally friendly, and varnish waste gas is recycled and reused so as to save cost. Recycling of varnish waste gas is realized, and the equipment is safe, reliable and environmentally friendly by the curing process of the waste gas which is not completely recovered. The equipment is safe and environmentally friendly, and the technology is simple and effective.

Owner:康联君

Temporary plugging and workover fluid for gas wells in low-pressure sandstone reservoirs and its preparation method

ActiveCN104531105BStrong ability to draw waterAvoid water lock damageDrilling compositionSealing/packingFiberAlcohol

The invention belongs to the technical field of downhole operations in oil and gas fields, and in particular relates to a temporary plugging and workover fluid for gas wells in low-pressure sandstone reservoirs and a preparation method. %, oil-based spacer fluid 0.5~1%, high-efficiency clay stabilizer 79~89.5%; alcohol-based temporary plugging and workover fluid is composed of the following materials by mass: 0.5~1% water-absorbing polymer, 1~2% temporary plugging Fiber, 0.5~1% fiber dispersant, 45~50% water, and the rest are alcohol; high-efficiency clay stabilizer is composed of materials in the following mass percentages: 0.6~1% clay stabilizer and 99~99.4% water. The invention can effectively temporarily plug the porous sandstone reservoir during workover operation, reduce the damage of the workover fluid to the formation, and has the characteristics of good salt resistance, no hydrate blockage, convenient construction, safety and environmental protection.

Owner:PETROCHINA CO LTD

Treatment method for carbon-containing solid waste in aluminum electrolysis industry

PendingCN114751746AMeet the requirements of electrolysisNo hydrolysisAluminium electrolysisFluidized bed

The invention provides a method for treating carbon-containing solid waste in the aluminum electrolysis industry, which comprises the following steps: the carbon-containing solid waste is crushed and then added into a fluidized bed furnace to be roasted, boiling gas in the fluidized bed furnace is at least one of preheated air and industrial oxygen, the height of a boiling layer is 10-300cm, the temperature of the boiling layer is maintained at 500-800 DEG C, the roasting time is 0.1-10 hours, and the carbon-containing solid waste is obtained. The roasted product is electrolyte mainly containing cryolite, and the carbon content is less than or equal to 1%. According to the method, after the waste cathodes of the aluminum electrolysis cell, the aluminum electrolysis carbon residues or the electrolytes obtained through flotation of the waste cathodes and the aluminum electrolysis carbon residues are subjected to boiling oxidation roasting, products are pure electrolytes, the carbon content is reduced to 1% or below, other impurities are not added, the requirements of aluminum electrolysis can be met, and all the electrolytes are subjected to resource utilization.

Owner:ZHENGZHOU UNIV +1

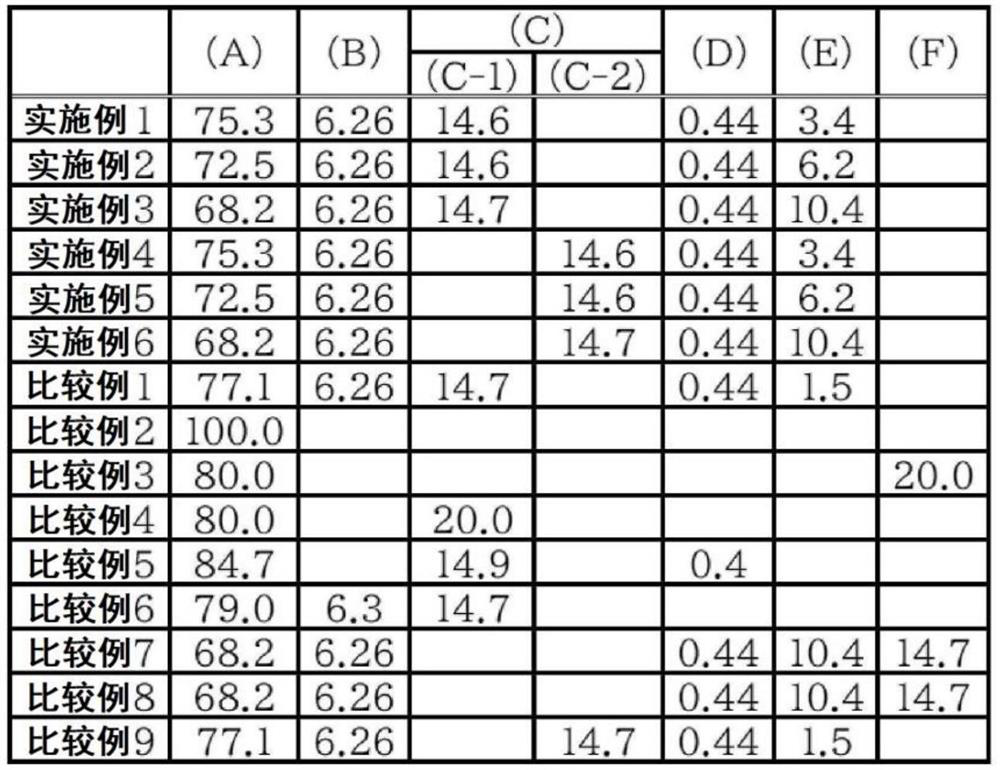

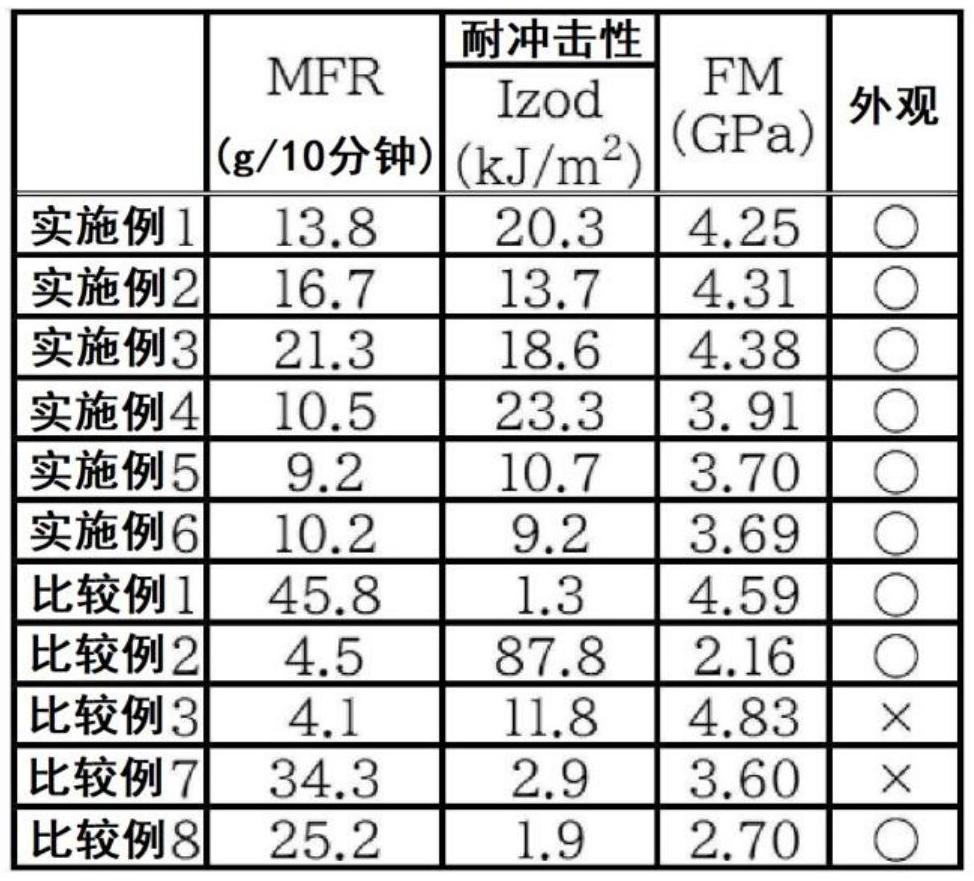

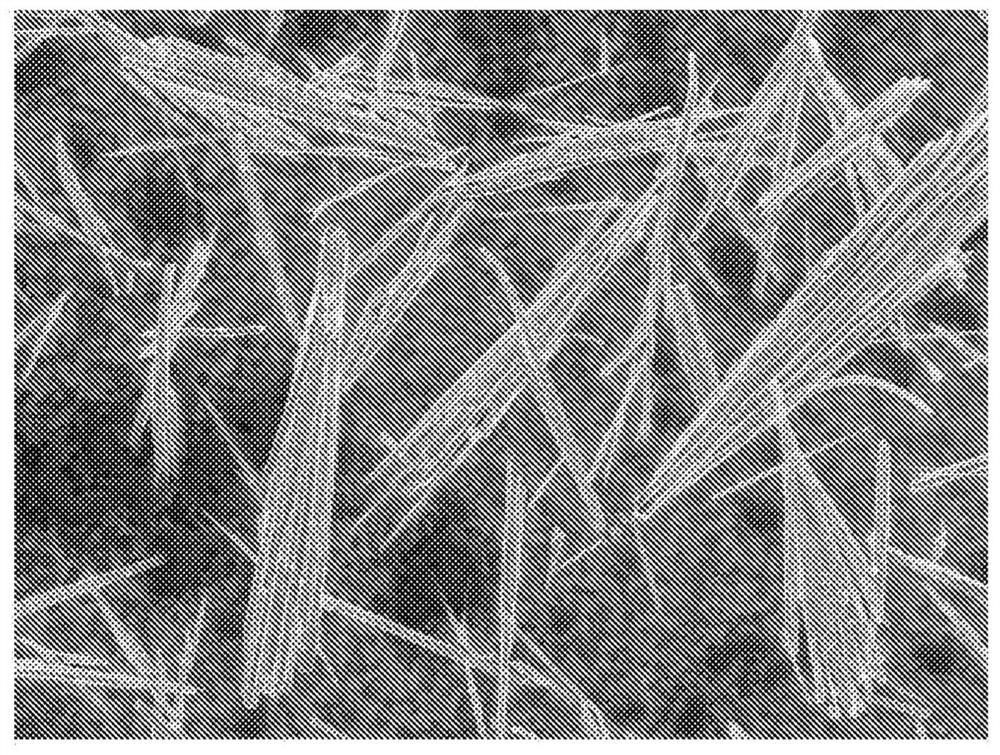

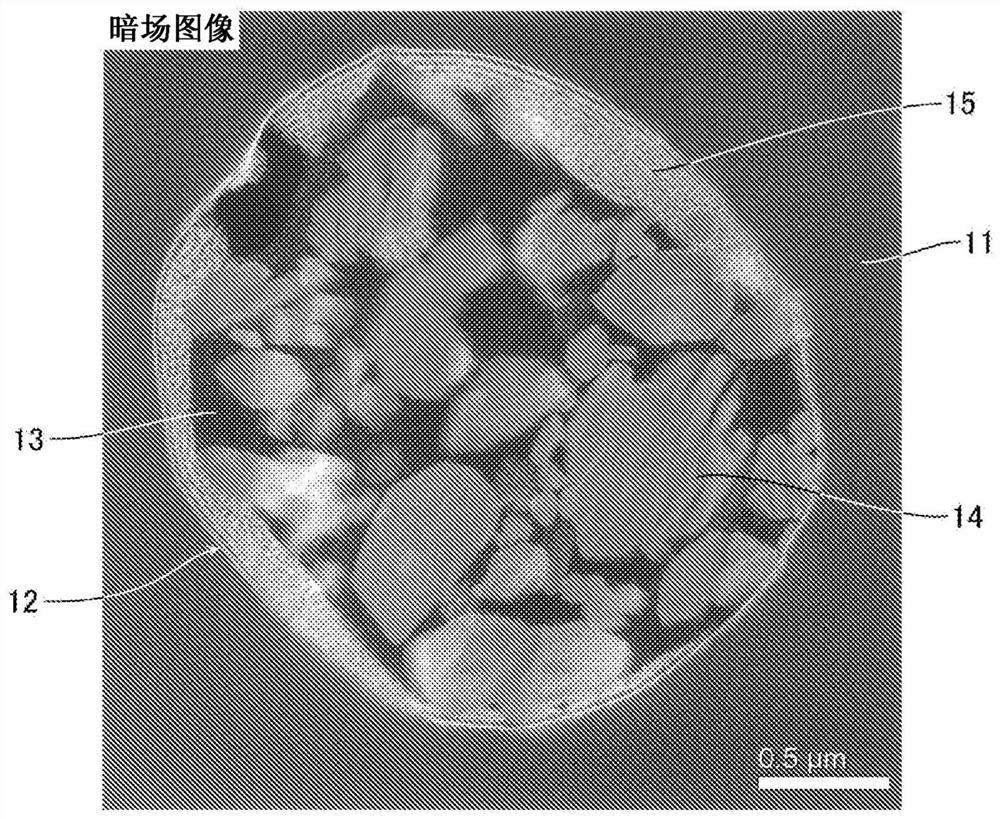

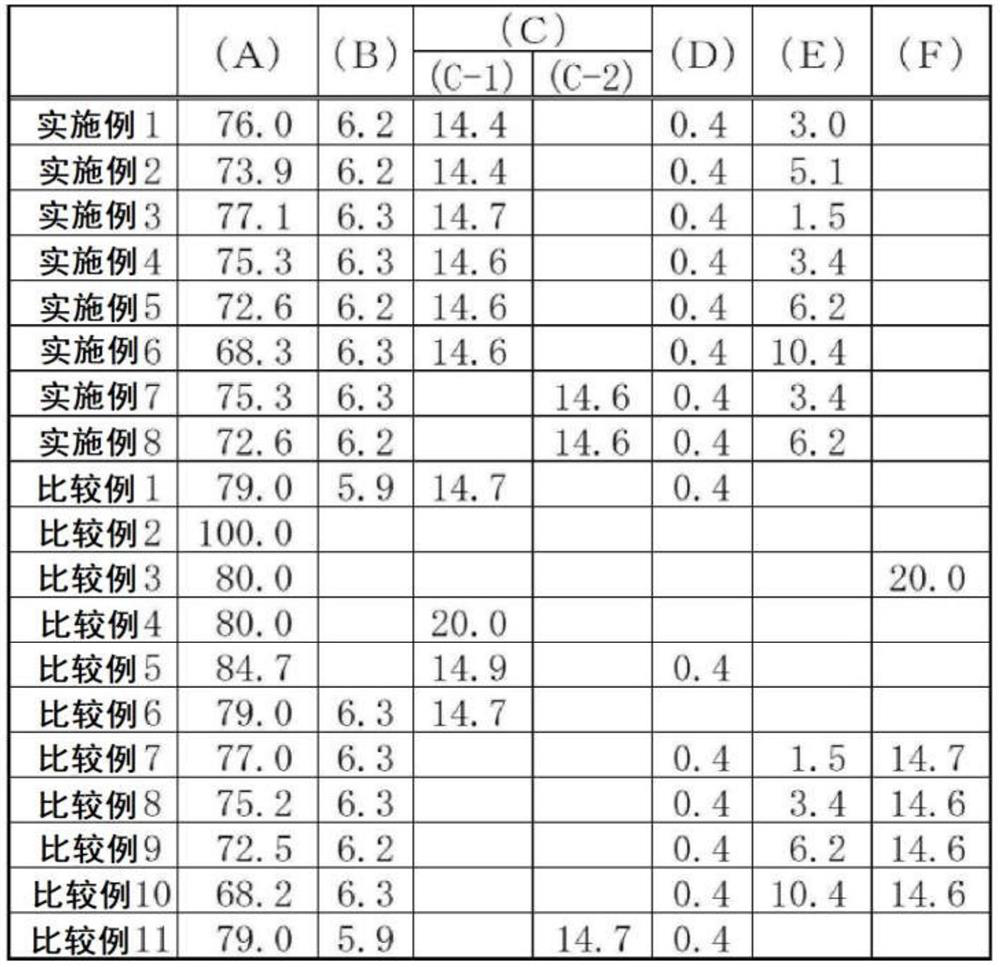

Polycarbonate resin composition, production method therefor, masterbatch pellet, and molded body

A polycarbonate resin composition characterized by including: 50%-90% by mass of a polycarbonate resin (A); 2%-30% by mass of an acrylonitrile-butadiene-styrene copolymer resin (B); 5%-40% by mass of at least one type of basic magnesium sulfate selected from a fibrous basic magnesium sulfate (C-1) and a fan-shaped basic magnesium sulfate (C-2); 0.1%-8% by mass of at least one type (D) selected from a fatty acid metal salt and a fatty acid; and 1%-20% by mass of an elastomer (E).

Owner:UBE CHEM IND CO LTD +1

Polycarbonate resin composition and method for producing same, master batch pellet, and molded article

The polycarbonate resin composition according to the present invention contains (A) 50-90 mass% of a polycarbonate resin, (B) 2.0-20 mass% of an olefin polymer, (C) 5-40 mass% of a basic magnesium sulfate selected from a fibrous basic magnesium sulfate (C-1) and a folding fan-like basic magnesium sulfate (C-2), (D) 0.1-8 mass% of at least one selected from fatty acid metal salts and fatty acids, and (E) 1-20 mass% of an elastomer.

Owner:UBE CHEM IND CO LTD +1

Infrared window anti-reflection protection structure and preparation method thereof

PendingCN112080722ASimple structureHigh process repetition rateVacuum evaporation coatingSputtering coatingCarbon filmCarbon layer

The invention relates to the technical field of optical films, in particular to an infrared window anti-reflection protection structure and a preparation method thereof. The structure comprises an anti-reflection layer, a substrate and a protection layer, wherein an anti-reflection layer is attached to one side of the substrate, and a protection layer is attached to the other side of the substrate; the anti-reflection layer sequentially comprises a first germanium layer, a first zinc sulfide layer, a second germanium layer and a second zinc sulfide layer from the substrate; and the protectionlayer sequentially comprises a germanium- arsenic-selenium layer and a diamond-like carbon layer from the substrate. The infrared window anti-reflection protection structure and the preparation methodthereof are provided, the germanium-arsenic-selenium layer serves as a unique middle layer between the diamond-like carbon layer and a substrate layer, on one hand, the optical permeability of a window is improved, and on the other hand, the stress between film layers is reduced, and the problem that a diamond-like carbon film cannot be deposited on a sulfur group material is solved.

Owner:昆明奥夫特光电技术有限公司

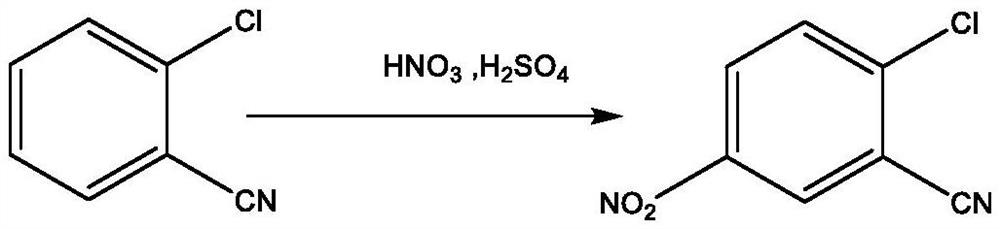

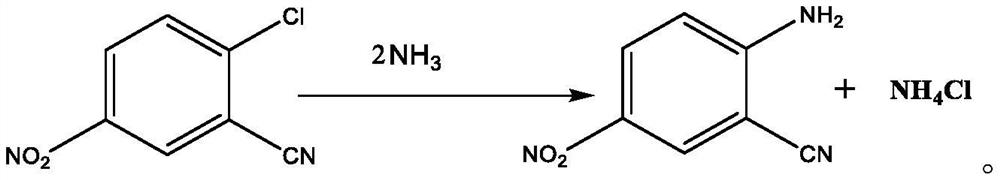

Synthesis method of 2-cyano-4-nitroaniline

PendingCN114213281ANo hydrolysisEliminate water analysisCarboxylic acid nitrile preparationOrganic compound preparationChlorobenzeneNitration

The invention provides a synthesis method of 2-cyano-4-nitroaniline. The synthesis method comprises the following steps of: synthesizing 2-cyano-4-nitroaniline; the synthesis method comprises the following steps: a nitration step: 2-chlorobenzonitrile is dissolved in an organic solvent, a nitration reaction is carried out in the presence of mixed acid, a nitration product is obtained, and the nitration product contains 2-chloro-5-nitrobenzonitrile; a mixing step: mixing the nitration product with an inorganic solvent to obtain a mixed product; a separation step: standing and layering the mixed product to obtain an organic phase; ammonia gas and / or ammonia gas are / is introduced into the organic phase, an ammonolysis reaction is carried out, an ammonolysis product is obtained, and the ammonolysis product contains the 2-cyano-4-nitroaniline. According to the synthesis method, a large amount of sulfuric acid can be saved, and the used organic solvent can be recycled after the reaction is finished. Furthermore, the synthetic method disclosed by the invention can ensure that the 2-chloro-5-nitrobenzonitrile does not carry water and the cyano group is not hydrolyzed in the ammonolysis reaction process.

Owner:ZHEJIANG RUNTU +1

Tape for electric wire

InactiveCN102197556BImprove heat resistanceIncrease flame retardancyPlastic/resin/waxes insulatorsFilm/foil adhesivesFiberPolyester

A tape which has enhanced heat resistance, flame retardancy, and wearing resistance and is suitable for use in bundling a group of electric wires which will be laid in a high-temperature environment. The tape is configured using the same yarns (10) each composed of high-function fiber filaments (11) and general-purpose fiber filaments (12), as a warp (3) and a weft (4). The high-function fiber filaments are superior to the general-purpose fiber filaments in heat resistance, flame retardancy, and wearing resistance. The high-function fiber filaments are of at least one kind selected from paraaramid fibers, polyarylate fibers, ultrahigh-molecular polyethylene fibers, glass fibers, and polyphenylene sulfide fibers. The general-purpose fiber filaments comprise at least one selected from polyesters, polyethylene, and polypropylene.

Owner:SUMITOMO WIRING SYST LTD

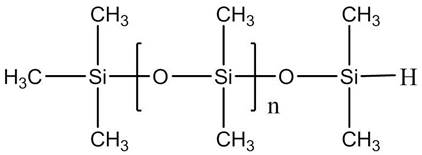

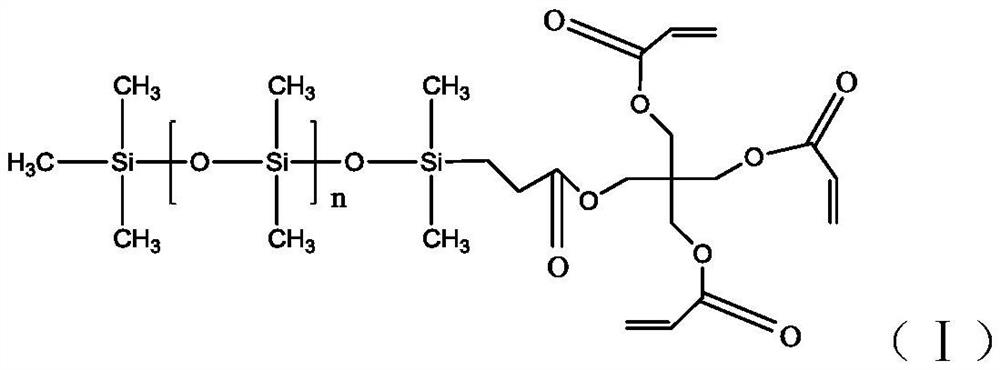

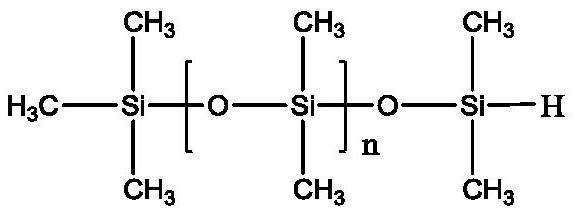

A kind of unsaturated organosilicon and preparation method, a kind of silicon-acrylic emulsion and preparation method and use thereof

ActiveCN113214485BNo hydrolysisGood scrub resistanceEmulsion paintsGraft polymer adhesivesPolymer scienceEmulsion

The invention relates to an unsaturated organosilicon and a preparation method, a silicone-acrylic emulsion, a preparation method and application thereof. The structure of the unsaturated organosilicon is shown in formula (I): the organosilicon contains multiple double bonds, and can be polymerized to form a polymer network with high crosslink density without hydrolysis. The silicone-acrylic emulsion of the present invention is prepared by including unsaturated organosilicon represented by formula (I) and acrylate monomers. The silicone-acrylic emulsion has self-covering properties, is used for building interior wall paint, and has excellent covering performance and scrub resistance.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com